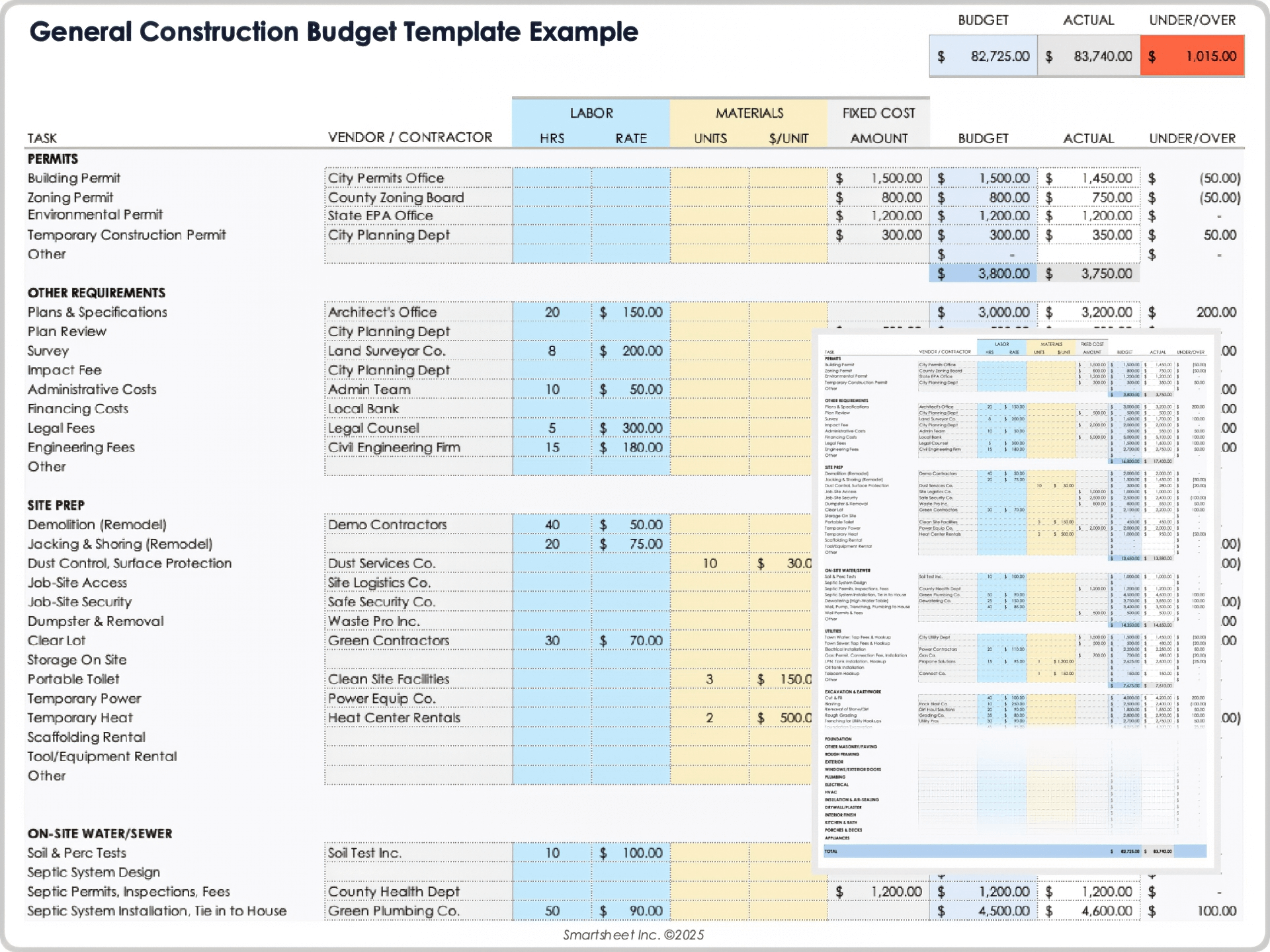

Best Cutting Speed Calculator: Top 5 Tools Compared

Finding the Best Cutting Speed Calculator: An Introduction

When it comes to machining, determining the appropriate cutting speed is crucial for achieving optimal performance and efficiency. However, with numerous tools available online, finding a reliable cutting speed calculator can be a daunting task. Many users are overwhelmed by the variety of options, each promising different features and levels of accuracy. The challenge lies not just in locating a tool that provides the necessary calculations, but also in ensuring that the results are accurate and applicable to specific machining scenarios.

This article aims to streamline the process of selecting a cutting speed calculator by reviewing and ranking the best tools available online. Our goal is to save you time and effort, providing you with a curated list of options that meet diverse needs in the machining industry. Whether you are a seasoned machinist or a hobbyist, having access to the right calculator can enhance your workflow and improve the quality of your work.

Criteria for Ranking

To provide a comprehensive overview, we evaluated each calculator based on several key criteria:

-

Accuracy: We assessed how reliably each tool calculates cutting speed, feed rates, and other important metrics, ensuring that the results can be trusted for real-world applications.

-

Ease of Use: User interface and experience are paramount; we focused on calculators that are intuitive and straightforward, allowing users to perform calculations quickly without unnecessary complexity.

-

Features: Additional functionalities, such as the ability to save calculations, access material databases, or receive tool recommendations, were also considered to enhance user experience.

By the end of this article, you will have a better understanding of the top cutting speed calculators, empowering you to make informed decisions for your machining projects.

Our Criteria: How We Selected the Top Tools

Key Criteria for Selecting Cutting Speed Calculators

When evaluating the best cutting speed calculators, we considered several essential factors to ensure that users can find a tool that meets their specific needs effectively. Below are the key criteria used in our selection process:

-

Accuracy and Reliability

– The primary purpose of a cutting speed calculator is to provide precise calculations that users can trust. We looked for tools that are based on established formulas and verified methodologies. Tools that offer theoretical values accompanied by disclaimers about variability in real-world applications were prioritized. -

Ease of Use

– A user-friendly interface is crucial for a positive experience, especially for those who may not be highly experienced in machining. We considered calculators that feature intuitive layouts, clear instructions, and straightforward input fields. Tools that minimize the number of steps to obtain results are particularly valuable. -

Key Features

– Effective cutting speed calculators should offer a variety of inputs to cater to different machining scenarios. We focused on tools that allow users to enter:- Tool diameter (in both metric and imperial units)

- Number of teeth on the cutting tool

- Desired cutting speed (SFM or IPM)

- Chip load or feed rate per tooth

- Material type for more tailored recommendations

- Additional functionalities, such as converting between metric and imperial units, were also taken into account.

-

Cost (Free vs. Paid)

– The cost of using a calculator can significantly influence user choice. We evaluated both free and paid options, considering what features are available at no cost versus those that require a subscription or one-time payment. Tools that offer a robust free version while providing premium features for advanced users were given special attention. -

Adaptability for Various Machining Operations

– Different machining operations—such as milling, turning, and drilling—require different parameters for optimal cutting speeds. We selected tools that provide the flexibility to switch between these operations easily, allowing users to perform a variety of calculations without needing multiple tools. -

Support and Resources

– Access to additional resources such as FAQs, customer support, and instructional content can enhance the user experience. We considered calculators that provide users with helpful information, tips, and troubleshooting guides to assist them in getting the most from the tool. -

User Reviews and Reputation

– Finally, we took into account user feedback and the overall reputation of each tool within the machining community. Tools that consistently received positive reviews for performance, reliability, and customer service were favored in our selection process.

By applying these criteria, we aimed to identify cutting speed calculators that cater to a broad audience, from hobbyists to professional machinists, ensuring they can make informed decisions for their machining tasks.

The Best Cutting Speed Calculators of 2025

1. Speeds and Feeds Calculator – Kennametal

The Speeds and Feeds Calculator from Kennametal is a valuable tool designed to optimize machining processes by accurately calculating spindle speed (RPM) and feed rates. Users can input parameters such as surface feet per minute and tool diameter to determine the appropriate RPM, while also factoring in chip load and the number of teeth for precise feed rate calculations. This tool enhances efficiency and productivity in manufacturing operations.

- Website: kennametal.com

- Established: Approx. 30 years (domain registered in 1995)

2. Milling Speed and Feed Calculator

The Milling Speed and Feed Calculator by CustomPartNet is a free online tool designed to help users calculate the optimal spindle speed (RPM) and feed rate (IPM) based on specific cutting conditions. This user-friendly calculator streamlines the milling process by providing precise parameters necessary for efficient machining, ensuring improved productivity and accuracy in various milling applications.

- Website: custompartnet.com

- Established: Approx. 19 years (domain registered in 2006)

3. Which website has the best speed and feed calculator? : r/Machinists

The FSWizard Speed and Feed Calculator is a highly recommended tool among machinists for its versatility and accessibility. Available as a free web app and mobile applications for both iOS and Android, this calculator simplifies the process of determining optimal cutting speeds and feeds for various machining operations. Its user-friendly interface and comprehensive options make it a valuable resource for both professionals and hobbyists in the machining industry.

- Website: reddit.com

- Established: Approx. 20 years (domain registered in 2005)

4. Speeds & Feeds

The Speeds & Feeds calculator from LittleMachineShop.com is a valuable tool designed for machinists to optimize their machining processes. It allows users to select units of measure (inches or millimeters) and input parameters such as cutting speed (ranging from 100 to 300 fpm) and end mill diameter. The calculator then provides the necessary spindle speed in RPM, facilitating more efficient and precise machining operations.

- Website: littlemachineshop.com

How to Get the Most Accurate Results

Double-Check Your Inputs

One of the most crucial steps in obtaining accurate results from cutting speed calculators is to ensure that all inputs are correct. Before hitting the calculate button, take a moment to review each parameter you’ve entered. Common inputs include tool diameter, material type, number of teeth on the cutter, and desired feed rate. Even a small error, such as an incorrect unit of measurement (inches versus millimeters), can lead to significant discrepancies in your results.

Understand the Underlying Assumptions

Every cutting speed calculator operates based on certain assumptions and theoretical values. It’s essential to familiarize yourself with these assumptions as they can affect the accuracy of the output. For example, some calculators may not account for specific material properties or cutting conditions such as tool wear, coolant usage, or machine stability. Knowing these limitations can help you interpret results more effectively and adjust your settings accordingly.

Use Multiple Tools for Comparison

To ensure the accuracy of your calculations, consider using multiple cutting speed calculators. Different tools may have unique algorithms or data sources that can lead to varying results. By comparing outputs from different calculators, you can identify any significant discrepancies and make more informed decisions. This practice not only provides a safety net against potential errors but also enhances your understanding of the cutting parameters.

Stay Updated on Material Properties

The properties of the materials you are working with can significantly influence cutting speed and feed rates. Ensure you have the latest information on the specific materials you are machining, including their hardness, alloy composition, and any relevant machining recommendations from manufacturers. Many calculators allow you to input the material type, which can directly affect the calculations for cutting speed and feed rate.

Consult Manufacturer Guidelines

If you are using specific tools or machinery, refer to the manufacturer’s guidelines for recommended speeds and feeds. These guidelines often provide insights based on extensive testing and real-world applications, which can be invaluable for achieving optimal results. Integrating this information into your calculations can help you fine-tune your parameters for better performance and tool longevity.

Experiment and Adjust

Finally, don’t hesitate to experiment with different parameters in your calculations. While calculators provide a good starting point, real-world machining can be unpredictable. Factors such as machine condition, tooling setup, and specific job requirements may necessitate adjustments. By being willing to tweak your settings based on practical experience, you can achieve the most accurate and efficient results for your cutting operations.

By following these guidelines, you’ll maximize the effectiveness of cutting speed calculators and enhance the precision of your machining processes.

Frequently Asked Questions (FAQs)

1. What is a cutting speed calculator?

A cutting speed calculator is an online tool designed to help machinists and engineers determine the optimal spindle speed (RPM) and feed rate (IPM) for various machining operations, such as milling, turning, and drilling. By inputting parameters like tool diameter, material type, and cutting conditions, users can receive calculated values that enhance machining efficiency and precision.

2. How do I use a cutting speed calculator?

To use a cutting speed calculator, follow these general steps:

1. Select the type of machining operation (e.g., milling, turning).

2. Enter the tool diameter, material type, and other relevant parameters such as the number of cutting edges and desired feed per tooth.

3. Submit the information to calculate the spindle speed (RPM) and feed rate (IPM).

4. Review the results and adjust your machine settings accordingly for optimal performance.

3. What factors affect cutting speed calculations?

Several factors influence cutting speed calculations, including:

– Material Type: Different materials (e.g., aluminum, stainless steel) have varying hardness and machinability, affecting the cutting speed.

– Tool Material: The type of cutting tool (high-speed steel, carbide, etc.) impacts its durability and performance under different speeds.

– Machine Type: The capabilities of the CNC machine or manual lathe can limit the maximum RPM and feed rates.

– Cooling and Lubrication: Using coolant can allow for higher speeds and feeds by reducing heat and wear on the cutting tool.

4. Can I trust the results from a cutting speed calculator?

While cutting speed calculators provide useful estimates based on theoretical values and industry standards, actual results may vary due to specific machining conditions. Factors such as tool wear, machine condition, and environmental conditions can all influence the final outcome. It is advisable to start with the calculated values and make adjustments based on real-time observations during machining.

5. Are there any recommended cutting speed calculators?

Yes, several reputable cutting speed calculators are available online, including:

– Kennametal Speeds and Feeds Calculator: Offers detailed calculations for various machining operations and materials.

– CustomPartNet Milling Speed and Feed Calculator: User-friendly interface for milling operations, providing cut time estimates as well.

– LittleMachineShop Speeds & Feeds Calculator: A versatile tool that accommodates various materials and operations.

– HSMAdvisor and FSWizard: These applications provide comprehensive features for both desktop and mobile users, catering to a wide range of machining needs.

Each tool has its unique features, so you may want to try a few to find the one that best fits your specific requirements.

Important Disclaimer

⚠️ Important Disclaimer

The information and reviews in this guide are for educational purposes only and are based on publicly available information. We are not affiliated with any of the tools mentioned. Features and pricing may change. Always conduct your own research before choosing a tool for your needs.