Boost Profits: The Ultimate Toy Custom Sourcing Guide (2025)

Introduction: Navigating the Global Market for toy custom

In an increasingly competitive landscape, sourcing custom toys that resonate with diverse markets poses a significant challenge for international B2B buyers. Navigating the global market for toy custom solutions requires a deep understanding of regional preferences, safety regulations, and manufacturing capabilities. This guide aims to provide comprehensive insights into various types of custom toys, their applications, and essential supplier vetting processes. By addressing critical factors such as cost analysis and quality assurance, we empower buyers from Africa, South America, the Middle East, and Europe to make informed purchasing decisions that align with their business goals.

Understanding the complexities of the toy custom market is essential for success. Buyers must consider not only the aesthetic appeal and functionality of toys but also compliance with international safety standards and cultural relevance. This guide covers a wide array of topics, including the latest trends in sustainable materials, innovative designs, and the impact of digital technologies on custom toy production.

By leveraging the information presented, B2B buyers will be better equipped to identify reliable suppliers, negotiate favorable terms, and ultimately enhance their product offerings. Whether you are a startup looking to penetrate the toy market or an established player seeking to diversify your portfolio, this guide serves as your roadmap to navigating the intricacies of the custom toy industry effectively.

Understanding toy custom Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Plush Toys | Soft, cuddly, often made from synthetic fibers | Gift shops, children’s stores | Pros: High demand, easy to customize; Cons: Higher shipping costs due to size. |

| Educational Toys | Designed to promote learning and development | Schools, educational institutions | Pros: Growing market, promotes brand loyalty; Cons: Requires adherence to educational standards. |

| Action Figures | Detailed character replicas, often collectible | Toy retailers, online marketplaces | Pros: Strong collector market; Cons: Requires licensing for branded figures. |

| Eco-Friendly Toys | Made from sustainable materials | Eco-conscious retailers, specialty shops | Pros: Appeals to environmentally aware consumers; Cons: Higher production costs. |

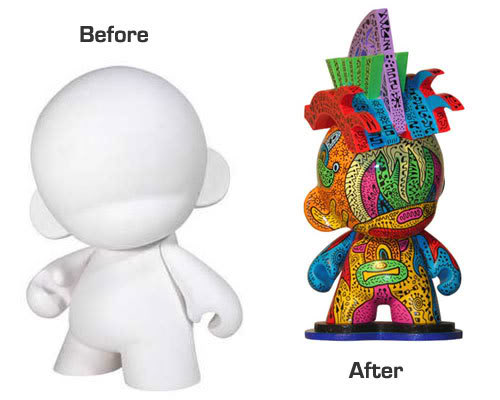

| Customizable Toys | Allows user interaction and personalization | Online retailers, craft stores | Pros: Engages consumers, fosters creativity; Cons: Complexity in production and inventory management. |

What Are the Characteristics of Plush Toys in Customization?

Plush toys are characterized by their soft texture and cuddly design, often appealing to children and collectors alike. In the B2B sector, these toys are primarily used in gift shops and children’s stores. Buyers should consider the material quality, safety standards, and customization options available, such as embroidery or unique designs. While plush toys have high demand and can be easily customized, their larger size can lead to increased shipping costs, which may affect pricing strategies.

How Do Educational Toys Differ in Customization Options?

Educational toys are specifically designed to enhance learning and cognitive development, making them an attractive option for schools and educational institutions. They often come with custom branding opportunities, which can help reinforce educational themes. When purchasing, B2B buyers should evaluate the educational value, compliance with safety regulations, and the potential for customization. Although the market for educational toys is growing, it requires adherence to specific educational standards, which may complicate the customization process.

A stock image related to toy custom.

What Should Buyers Know About Action Figures in the Custom Market?

Action figures are detailed replicas of characters from various media, appealing to both children and adult collectors. They are commonly sold through toy retailers and online marketplaces, making them a versatile product for B2B buyers. Key purchasing considerations include licensing agreements for branded figures, production costs, and the potential for limited-edition releases that can drive demand. While the collector market is robust, the need for licensing can complicate the customization process and increase costs.

Why Are Eco-Friendly Toys Gaining Popularity Among B2B Buyers?

Eco-friendly toys are made from sustainable materials and designed to minimize environmental impact. They are increasingly popular among eco-conscious retailers and specialty shops. Buyers should assess the sourcing of materials, certifications for sustainability, and the potential for customization that aligns with eco-friendly messaging. Although eco-friendly toys appeal to a growing segment of consumers, they often come with higher production costs, which can affect profit margins.

What Are the Benefits and Challenges of Customizable Toys for B2B Buyers?

A stock image related to toy custom.

Customizable toys allow for user interaction and personalization, fostering creativity among consumers. This type of toy is ideal for online retailers and craft stores, where buyers can leverage customization as a unique selling proposition. When considering these toys, B2B buyers should evaluate the complexity of production processes, inventory management challenges, and the ability to meet consumer demand for personalization. While customizable toys can engage consumers and enhance brand loyalty, they require careful planning and execution to manage production and fulfillment effectively.

Key Industrial Applications of toy custom

| Industry/Sector | Specific Application of Toy Custom | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Education | Custom Educational Toys for Early Learning | Enhances learning experiences, promotes engagement | Compliance with educational standards, safety certifications |

| Marketing and Promotions | Branded Promotional Toys for Corporate Events | Increases brand visibility, customer engagement | Customization options, lead times, material quality |

| Healthcare | Therapeutic Toys for Child Patients | Aids in emotional healing, reduces anxiety | Safety and hygiene standards, age-appropriate design |

| Retail and E-commerce | Personalized Toys for Retail Outlets | Differentiates product offerings, attracts customers | Inventory management, production scalability, shipping costs |

| Events and Entertainment | Custom Toys for Themed Events and Festivals | Creates memorable experiences, enhances brand loyalty | Design flexibility, turnaround time, licensing issues |

How Can Custom Educational Toys Enhance Learning Experiences?

Custom educational toys are increasingly utilized in schools and childcare centers to foster interactive learning. These toys can be tailored to align with specific educational curricula, addressing various learning styles. For B2B buyers in the education sector, ensuring compliance with local educational standards and safety regulations is crucial. Suppliers should provide certifications to guarantee that products are safe for children. Additionally, buyers should consider the durability of materials, as educational toys often undergo rigorous use in classroom settings.

What Are the Benefits of Using Branded Promotional Toys in Marketing?

In the marketing realm, custom toys serve as effective promotional tools during corporate events and trade shows. By incorporating branding into toys, businesses can significantly enhance their visibility and create memorable interactions with potential clients. For buyers in South America and the Middle East, it is essential to assess customization options and production lead times, especially when planning for large-scale events. Moreover, understanding the target audience’s preferences can help ensure that the promotional toys resonate well and lead to increased brand loyalty.

How Do Therapeutic Toys Support Child Patients in Healthcare?

In healthcare settings, particularly pediatric wards, custom therapeutic toys play a vital role in aiding emotional healing for young patients. These toys can be designed to provide comfort, distraction, and engagement during treatment processes. B2B buyers in the healthcare sector must prioritize safety and hygiene standards, ensuring that all toys are made from non-toxic materials and can withstand regular cleaning. Furthermore, age-appropriate designs are critical to cater to the diverse needs of young patients, making it essential for suppliers to have experience in pediatric-focused product development.

Why Are Personalized Toys Important for Retail Outlets?

In the retail and e-commerce sector, personalized toys are becoming a popular choice for businesses looking to differentiate their product offerings. Customization allows retailers to cater to specific customer preferences, enhancing the shopping experience and driving sales. For international buyers, especially in Europe, considerations around inventory management and production scalability are essential. Suppliers should be able to offer flexible production options to meet varying demand levels while maintaining cost efficiency.

How Can Custom Toys Enhance Experiences at Themed Events?

Custom toys are increasingly used in themed events and festivals to create unique experiences for attendees. By integrating toys that reflect the event’s theme, businesses can enhance brand loyalty and create lasting memories for participants. Buyers in the events sector should focus on design flexibility and turnaround time when sourcing these products. Additionally, understanding licensing issues related to popular themes or characters is vital to avoid potential legal complications and ensure successful product launches.

3 Common User Pain Points for ‘toy custom’ & Their Solutions

Scenario 1: Navigating Regulatory Compliance in Toy Customization

The Problem:

B2B buyers often face significant challenges in ensuring that their custom toys meet the diverse regulatory standards across various international markets. For instance, a buyer in Europe may struggle with stringent safety regulations like EN71, while a buyer in South America might be concerned about compliance with local consumer protection laws. The complexity increases when considering the variances in material safety, labeling requirements, and age restrictions, leading to potential delays in product launches and costly recalls.

The Solution:

To effectively navigate these regulatory waters, B2B buyers should engage with compliance experts or consultants who specialize in toy regulations in their target markets. Before initiating the toy custom process, conduct thorough research on the specific regulations applicable to your product in each region. Utilize resources like the International Council of Toy Industries (ICTI) and ASTM International to stay informed. Furthermore, working closely with manufacturers who have experience in compliance can streamline the process. Request detailed documentation on material safety data sheets (MSDS) and ensure that prototypes are tested against the necessary standards before mass production. This proactive approach will mitigate risks and enhance trust with your consumers.

Scenario 2: Managing Quality Control in Custom Toy Production

The Problem:

Quality control is a significant pain point for B2B buyers, especially when dealing with overseas manufacturers. A buyer from the Middle East may find that the toys produced do not meet their quality expectations, leading to customer dissatisfaction and financial losses. Issues like inconsistent product quality, incorrect specifications, and manufacturing defects can arise when there is a lack of clear communication and oversight during the production process.

The Solution:

To ensure high-quality outcomes in custom toy production, establish a robust quality assurance (QA) protocol that includes regular inspections at various production stages. This can involve hiring third-party QA inspectors or establishing a dedicated in-house team that can monitor production processes closely. It’s also essential to draft a comprehensive product specification sheet that details every aspect of the toy, from materials used to design elements. Implementing a feedback loop with the manufacturer will allow for quick adjustments and improvements. Additionally, consider starting with small batch orders to test quality before scaling up to larger orders.

Scenario 3: Overcoming Cultural Sensitivity in Toy Customization

The Problem:

B2B buyers from diverse regions may encounter cultural sensitivity issues when customizing toys for different markets. For example, a buyer in Africa may wish to introduce toys that reflect local traditions and values but may inadvertently choose designs or themes that are culturally inappropriate or offensive. This oversight can lead to backlash from consumers and damage the brand’s reputation.

The Solution:

To overcome cultural sensitivity challenges, conduct extensive market research to understand the cultural nuances and preferences of your target audience. Engage local designers or cultural consultants who can provide insights into what resonates with the community. Organizing focus groups or surveys can also offer valuable feedback on design concepts. It’s crucial to adopt an inclusive approach by involving local stakeholders throughout the customization process. This not only aids in creating culturally relevant toys but also fosters goodwill and strengthens brand loyalty within the community.

Strategic Material Selection Guide for toy custom

When selecting materials for custom toys, international B2B buyers must consider various factors, including safety, durability, cost, and compliance with regional standards. Here, we analyze four common materials used in toy manufacturing, providing insights tailored for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Plastic in Toy Customization?

Plastic is one of the most widely used materials in toy manufacturing due to its versatility and cost-effectiveness. Common types of plastic include ABS (Acrylonitrile Butadiene Styrene) and PVC (Polyvinyl Chloride).

Key Properties:

– Temperature Resistance: Plastics can withstand a range of temperatures but may deform under extreme heat.

– Corrosion Resistance: Generally resistant to moisture and chemicals, making them suitable for various environments.

Pros & Cons:

– Durability: Plastics are durable and can withstand rough handling, making them suitable for children’s toys.

– Cost: Typically low-cost, which is advantageous for large-scale production.

– Manufacturing Complexity: Injection molding allows for intricate designs, but recycling can be challenging.

– End-Product Suitability: Not all plastics are food-safe, which limits their use in toys designed for infants.

Impact on Application:

Plastics are compatible with most media, but it is crucial to ensure that the specific type used meets safety standards, particularly for toys intended for young children.

Considerations for International Buyers:

Compliance with standards such as ASTM F963 (USA) and EN71 (Europe) is essential. Buyers should also be aware of the growing demand for eco-friendly plastics in regions like Europe and South America.

How Does Wood Compare as a Material for Custom Toys?

Wood is a traditional material that has seen a resurgence in the toy industry, particularly in eco-conscious markets.

Key Properties:

– Strength: Wood offers excellent structural integrity and can handle significant stress without breaking.

– Natural Resistance: Some woods have natural resistance to moisture and pests.

Pros & Cons:

– Durability: High durability when properly treated, but can be susceptible to warping and cracking.

– Cost: Generally higher than plastic, which may affect profit margins.

– Manufacturing Complexity: Requires more labor-intensive processes, such as sanding and finishing.

– End-Product Suitability: Ideal for educational toys and items that promote tactile interaction.

Impact on Application:

Wood is compatible with various finishes, but it’s essential to use non-toxic paints and varnishes to meet safety standards.

Considerations for International Buyers:

Buyers should ensure compliance with regulations like EN71 and ASTM standards. Additionally, sourcing sustainably harvested wood is becoming increasingly important, especially in Europe.

What Are the Benefits and Limitations of Metal in Toy Manufacturing?

Metal, particularly zinc and aluminum alloys, is used in toys that require durability and a premium feel.

Key Properties:

– Temperature Resistance: Metals can withstand high temperatures, making them suitable for outdoor toys.

– Corrosion Resistance: While some metals are prone to rust, others, like aluminum, are highly resistant.

Pros & Cons:

– Durability: Extremely durable and can withstand significant wear and tear.

– Cost: Higher manufacturing costs due to material and processing requirements.

– Manufacturing Complexity: Requires specialized equipment for shaping and finishing.

– End-Product Suitability: Ideal for toys that need to endure rough handling, such as outdoor or construction-themed toys.

Impact on Application:

Metal toys may require additional coatings to ensure safety and compliance with regulations.

Considerations for International Buyers:

It is crucial to adhere to safety standards, particularly regarding sharp edges and small parts. Buyers should also consider the impact of tariffs and shipping costs when sourcing metal toys.

How Does Fabric Play a Role in Custom Toy Production?

Fabric is often used in plush toys and educational items, offering a soft texture that appeals to younger audiences.

Key Properties:

– Flexibility: Fabric can be easily shaped and sewn into various designs.

– Breathability: Natural fibers allow air circulation, which can be beneficial for certain applications.

Pros & Cons:

– Durability: While generally durable, fabrics can wear out over time, especially with frequent washing.

– Cost: Fabric can be cost-effective, but quality varies significantly.

– Manufacturing Complexity: Requires sewing and finishing, which can increase labor costs.

– End-Product Suitability: Ideal for soft toys and educational items but may not be suitable for all toy types.

Impact on Application:

Fabric toys often require careful consideration of washing and cleaning methods to maintain safety and hygiene.

Considerations for International Buyers:

Compliance with safety standards is essential, particularly regarding flammability and the use of non-toxic dyes. Buyers should also consider the sourcing of organic or recycled fabrics as a selling point.

Summary Table of Material Selection for Toy Customization

| Material | Typical Use Case for Toy Custom | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Action figures, building blocks | Versatile and cost-effective | Not all types are food-safe | Low |

| Wood | Educational toys, puzzles | Eco-friendly and durable | Higher cost and labor-intensive | Med |

| Metal | Outdoor toys, collectible items | Extremely durable | Higher manufacturing costs | High |

| Fabric | Plush toys, soft educational items | Soft and appealing | Can wear out over time | Med |

This guide aims to equip international B2B buyers with the necessary insights to make informed decisions regarding material selection for custom toys, ensuring compliance, safety, and market relevance.

In-depth Look: Manufacturing Processes and Quality Assurance for toy custom

What Are the Main Stages of the Toy Custom Manufacturing Process?

Manufacturing custom toys involves a series of carefully orchestrated stages that ensure both creativity and compliance with safety standards. The primary stages in toy manufacturing include material preparation, forming, assembly, and finishing.

-

Material Preparation

The first step in the manufacturing process is selecting and preparing the materials. Common materials for toy production include plastics, wood, and textiles. B2B buyers should ensure that suppliers source materials that meet international safety standards, such as those specified by ASTM and EN71. The preparation phase may involve cutting, molding, or treating materials to enhance durability and safety. -

Forming

Forming is the process where raw materials are shaped into toy components. Techniques like injection molding, blow molding, and CNC machining are prevalent. Injection molding is particularly favored for its efficiency in producing complex shapes with high precision. Buyers should inquire about the forming techniques used by potential suppliers and their ability to accommodate custom designs. -

Assembly

After forming, the individual components are assembled into finished toys. This stage may require manual labor or automated assembly lines, depending on the complexity of the toy design. Effective assembly processes are critical, as they directly impact the final product’s quality and safety. B2B buyers should request details on assembly techniques and the level of automation used, as this can affect lead times and pricing. -

Finishing

The finishing stage involves adding final touches such as painting, printing, or applying decals. This is where branding elements are integrated, making it essential for suppliers to use non-toxic paints and finishes. Buyers should verify that their suppliers follow best practices for finishing to ensure compliance with safety standards and to achieve the desired aesthetic appeal.

How Is Quality Control Implemented in Toy Manufacturing?

Quality control (QC) is a critical component of toy manufacturing, ensuring that products meet safety, performance, and aesthetic standards. International B2B buyers must familiarize themselves with key QC processes and standards to ensure they partner with reliable suppliers.

-

What Are the Relevant International Standards for Toy Safety?

Compliance with international safety standards is vital in the toy industry. Key standards include ISO 9001 for quality management systems and EN71, which is specific to toy safety in Europe. Additionally, the American Society for Testing and Materials (ASTM) has established guidelines for toy safety in the United States. Buyers should ensure that their suppliers are certified and compliant with these standards, as non-compliance can lead to costly recalls and damage to brand reputation. -

What Are the QC Checkpoints in Toy Manufacturing?

Quality control typically involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This checkpoint occurs when materials arrive at the factory. Suppliers should inspect raw materials for defects and ensure they meet specified standards.

-

In-Process Quality Control (IPQC): During manufacturing, quality checks are performed to monitor the production process. This includes inspecting molded components and verifying assembly accuracy.

-

Final Quality Control (FQC): Once toys are assembled, a final inspection occurs before packaging. This step includes testing for functionality, safety, and aesthetic quality.

- Which Testing Methods Are Commonly Used in Toy Quality Control?

Various testing methods are employed to ensure toys meet safety and performance criteria. Common tests include:

- Mechanical Testing: Evaluates the durability and strength of toys, ensuring they can withstand normal use.

- Chemical Testing: Assesses the presence of harmful substances, such as lead or phthalates, in materials.

- Flammability Testing: Determines the toy’s resistance to catching fire, a crucial aspect of safety standards.

B2B buyers should request documentation of testing results and certifications from suppliers to verify compliance with safety regulations.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that potential suppliers maintain high-quality standards, international B2B buyers can implement several verification strategies.

-

Conducting Supplier Audits

Regular audits are an effective way to assess a supplier’s manufacturing processes and quality control systems. Buyers should develop a checklist that includes compliance with international standards, testing protocols, and manufacturing capabilities. On-site audits offer insights into the supplier’s operations and help build trust. -

Reviewing Quality Control Reports

Suppliers should provide detailed quality control reports that outline their processes and testing outcomes. Buyers should look for transparency in these reports, including any non-conformance issues and how they were addressed. Consistent reporting indicates a supplier’s commitment to quality. -

Engaging Third-Party Inspection Services

Utilizing third-party inspection services can add an additional layer of assurance. These independent organizations can perform random inspections during different manufacturing stages to verify compliance with quality standards. This step is particularly valuable for buyers unfamiliar with local manufacturing practices or language barriers.

What Are the Quality Control Nuances for International B2B Buyers?

Navigating quality control in the international toy manufacturing landscape presents unique challenges for B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe.

-

Understanding Local Regulations

Different countries have varying regulations governing toy safety. Buyers must familiarize themselves with local laws in both their home country and the supplier’s country. This knowledge is crucial to avoid legal issues and ensure that imported toys comply with local safety standards. -

Cultural and Communication Considerations

Effective communication with suppliers is essential for maintaining quality control. Language barriers and cultural differences can lead to misunderstandings regarding quality expectations. Buyers should establish clear communication channels and consider hiring local representatives if necessary. -

Building Long-Term Relationships with Suppliers

Establishing strong, long-term relationships with suppliers can enhance quality control efforts. Buyers who invest in their supplier partnerships often benefit from better collaboration, improved transparency, and a more thorough understanding of each other’s quality assurance processes.

In conclusion, B2B buyers in the toy industry must be proactive in understanding manufacturing processes and quality control measures. By prioritizing compliance with international standards, conducting thorough supplier evaluations, and fostering strong partnerships, buyers can ensure they receive high-quality, safe products tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘toy custom’

Introduction

In today’s competitive market, sourcing custom toys requires a strategic approach that emphasizes quality, compliance, and supplier reliability. This checklist is designed to guide international B2B buyers from Africa, South America, the Middle East, and Europe through the essential steps needed to procure custom toys effectively. By following this step-by-step guide, you can streamline your sourcing process and ensure you select the right partners to meet your business needs.

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is fundamental to the sourcing process. This includes dimensions, materials, safety standards, and any unique features your custom toys must have. Providing detailed specifications helps suppliers understand your requirements and reduces the risk of miscommunication.

- Consider safety regulations relevant to your target market, such as ASTM or EN71 standards.

- Specify materials to ensure they align with your brand values, such as eco-friendliness or durability.

Step 2: Conduct Market Research on Suppliers

Before engaging with suppliers, comprehensive market research is essential. Identify potential suppliers who specialize in custom toy manufacturing and have a strong reputation in the industry. This step will help you create a shortlist of credible suppliers to approach.

- Utilize online platforms like Alibaba, Global Sources, or trade fairs to find reputable suppliers.

- Look for reviews and testimonials from other B2B buyers to gauge supplier reliability and quality.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; engage in direct communication to assess their capabilities and responsiveness.

- Ask for samples of previous work to evaluate their quality and craftsmanship.

- Inquire about production capacity to ensure they can meet your order volumes.

Step 4: Verify Supplier Certifications

Supplier certifications are a critical indicator of compliance with industry standards and regulations. Verify that your potential suppliers hold relevant certifications, such as ISO 9001 for quality management or specific safety certifications for toys.

- Request documentation to confirm their certifications and ensure they are up-to-date.

- Check for compliance with international safety standards that apply to your market.

Step 5: Negotiate Terms and Conditions

Once you have identified a suitable supplier, engaging in negotiations is key to establishing a mutually beneficial partnership. Discuss pricing, payment terms, lead times, and other conditions to ensure clarity and avoid future disputes.

- Be clear about your budget and expected timelines to set realistic expectations.

- Consider establishing a trial order to assess performance before committing to larger orders.

Step 6: Establish a Quality Control Process

Implementing a quality control process is vital for ensuring the final products meet your standards. Define the quality assurance measures you expect from your supplier and establish regular check-ins throughout the production process.

- Specify inspection criteria and methods to monitor quality at various production stages.

- Consider third-party quality inspections to provide an unbiased assessment of product quality.

Step 7: Plan for Logistics and Delivery

Effective logistics planning is crucial to ensure timely delivery of your custom toys. Discuss shipping options, lead times, and potential customs challenges with your supplier to avoid delays.

- Understand your supplier’s shipping capabilities and whether they offer freight services.

- Prepare for customs regulations in your target market to ensure smooth importation.

By following these steps, international B2B buyers can navigate the complexities of sourcing custom toys, ensuring they select reliable suppliers that meet their specific needs and standards.

Comprehensive Cost and Pricing Analysis for toy custom Sourcing

What Are the Key Cost Components in Toy Custom Sourcing?

When engaging in toy custom sourcing, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality, non-toxic materials often come at a premium but may be necessary for compliance with safety regulations in different markets.

-

Labor: Labor costs vary widely across regions. Countries with lower labor costs, such as certain parts of Asia, may offer competitive pricing, but this can also affect quality and lead times.

-

Manufacturing Overhead: This includes expenses related to factory maintenance, utilities, and administrative costs. Understanding the overhead can provide insights into the pricing strategies of suppliers.

-

Tooling: Custom toys often require unique molds and tooling, which can be a significant upfront cost. Buyers should consider this as a long-term investment, especially for large production runs.

-

Quality Control (QC): Implementing stringent QC measures is essential for ensuring product quality. While this incurs additional costs, it can prevent costly recalls and damage to brand reputation.

-

Logistics: Shipping costs, including freight and insurance, can vary based on the shipping method and distance. Buyers should evaluate the most cost-effective logistics solutions that meet their delivery timelines.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the average margins within the industry can help buyers negotiate better deals.

How Do Price Influencers Affect Toy Custom Sourcing?

Several factors influence pricing in toy custom sourcing:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to reduced per-unit costs due to economies of scale. Buyers should consider negotiating MOQs that align with their sales forecasts.

-

Specifications and Customization: Highly customized toys will generally cost more. Buyers need to clearly define their specifications to avoid unexpected costs during production.

-

Materials and Quality Certifications: The quality of materials and certifications required for safety compliance can impact pricing. Buyers from different regions may face varying regulatory requirements, influencing material choices and costs.

-

Supplier Factors: Supplier reputation, experience, and location can affect pricing. Establishing relationships with reliable suppliers can lead to better pricing and terms.

-

Incoterms: The choice of Incoterms affects responsibility for shipping costs and risks. Understanding these terms can help buyers make more informed decisions regarding total costs.

What Are the Best Negotiation Tips for International B2B Buyers?

For B2B buyers, particularly from Africa, South America, the Middle East, and Europe, effective negotiation is key to achieving favorable pricing:

-

Research Market Prices: Understanding the average market prices for similar products can provide leverage during negotiations. Utilize industry reports and networking to gather data.

-

Establish Long-term Relationships: Building strong relationships with suppliers can lead to better pricing, especially for recurring orders. Trust and loyalty can often translate into cost savings.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. Factor in costs related to logistics, quality control, and potential returns to gain a comprehensive understanding of total expenses.

-

Be Open to Alternative Solutions: Flexibility in design and materials can lead to cost savings. Discussing alternative options with suppliers may reveal more economical choices without sacrificing quality.

Why Is It Important to Understand Pricing Nuances for Different Regions?

Understanding the pricing nuances for international markets is essential for effective sourcing. Buyers from Africa, South America, the Middle East, and Europe may encounter different regulatory environments, currency fluctuations, and cultural expectations that impact pricing strategies.

For instance, buyers from the Middle East may prioritize luxury features, while European buyers might focus on sustainability. Tailoring sourcing strategies to these regional preferences can enhance competitiveness and market penetration.

Disclaimer on Indicative Prices

It’s important to note that pricing in the toy custom sourcing industry is highly variable and subject to change based on market conditions, exchange rates, and specific project requirements. Buyers should seek updated quotes from suppliers to ensure accurate budgeting and planning.

Alternatives Analysis: Comparing toy custom With Other Solutions

Understanding the Importance of Alternatives in Toy Customization

In the dynamic landscape of the toy industry, international B2B buyers must consider various options for product customization. While ‘toy custom’ presents a unique solution for tailored toy designs, it’s essential to evaluate its effectiveness against alternative methods and technologies. This analysis will focus on two viable alternatives: 3D Printing and Off-the-Shelf Customizable Toys. Each option presents its own strengths and weaknesses, making it crucial for buyers to assess which solution aligns best with their business objectives.

Comparison Table of Toy Custom and Alternative Solutions

| Comparison Aspect | Toy Custom | 3D Printing | Off-the-Shelf Customizable Toys |

|---|---|---|---|

| Performance | High-quality, unique designs | High precision, rapid prototyping | Limited design variations |

| Cost | Moderate to high | Initial setup costs can be high, but low per unit | Generally lower but variable |

| Ease of Implementation | Requires skilled labor | Requires technical expertise | Easy, minimal setup required |

| Maintenance | Medium; depends on production | Low; equipment maintenance needed | Low; minimal upkeep |

| Best Use Case | Unique market demands | Prototyping and small batches | Mass-market appeal with customization options |

What are the Pros and Cons of 3D Printing in Toy Customization?

3D printing stands out as a revolutionary technology in the toy industry, particularly for producing prototypes and small batches. The primary advantage of 3D printing is its ability to create highly detailed and intricate designs at a relatively low cost per unit, especially when producing small quantities. This method allows for quick adjustments to designs, making it ideal for businesses looking to test new concepts rapidly. However, the initial investment in 3D printing technology can be significant, and it requires skilled operators who understand the intricacies of the machines and software involved. Additionally, while 3D printing offers customization, it may not always match the quality of mass-produced toys in terms of finish and durability.

How Do Off-the-Shelf Customizable Toys Compare?

Off-the-shelf customizable toys provide a more straightforward solution for businesses seeking quick and cost-effective options. These products typically come with predefined designs that can be modified to a certain extent, allowing for some level of personalization. The key advantage here is the low entry cost and ease of implementation—businesses can quickly integrate these solutions into their offerings without the need for specialized skills or equipment. However, the limitations in design variations may restrict creativity, making it less suitable for brands aiming to differentiate themselves in a crowded market. Moreover, as these toys are mass-produced, they may not cater to niche market demands as effectively as toy custom solutions.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the right solution for toy customization hinges on understanding the specific needs of your business and target market. If your focus is on unique, high-quality designs and you have the resources to manage production, ‘toy custom’ might be the best fit. Conversely, if you’re looking to prototype quickly or produce smaller quantities, 3D printing could offer the flexibility and speed you need. On the other hand, for businesses operating in a more price-sensitive segment, off-the-shelf customizable toys could provide an attractive balance of cost and ease of use. Ultimately, the decision should be driven by an analysis of your budget, design requirements, and the level of customization needed to meet consumer expectations.

Essential Technical Properties and Trade Terminology for toy custom

What Are the Key Technical Properties for Toy Customization?

When engaging in toy customization, understanding the technical properties is crucial for ensuring product quality and compliance with safety standards. Here are some essential specifications to consider:

-

Material Grade

– The type of material used in toy manufacturing significantly affects durability, safety, and compliance with international standards. Common materials include plastic (ABS, PVC), wood, and fabric. For B2B buyers, selecting the right material grade ensures that the toys meet safety regulations in their target markets, such as EN71 in Europe or ASTM F963 in the USA. -

Tolerance

– Tolerance refers to the allowable deviation from a specified dimension or measurement. In toy customization, maintaining strict tolerances is vital for ensuring that parts fit together correctly and function as intended. For example, if a toy has moving parts, precise tolerances prevent malfunction and enhance user experience. Buyers should discuss tolerance levels with manufacturers to ensure product reliability. -

Finish Type

– The finish of a toy can influence both aesthetics and safety. Options include matte, glossy, or textured surfaces, which can impact a toy’s appeal and tactile experience. Additionally, finishes must comply with safety standards to prevent issues such as lead poisoning from paint. Buyers should clarify the desired finish with suppliers to align with branding and safety requirements. -

Weight Limit

– Understanding the weight limit of toys is critical, especially for larger or more complex designs. This specification affects shipping costs, material choices, and even the target age group for the toy. For instance, a toy designed for younger children should be lightweight to prevent injury. Buyers must ensure that suppliers can meet weight requirements without compromising durability. -

Color Fastness

– Color fastness refers to how well a color retains its original appearance when exposed to various conditions such as light, washing, or abrasion. This property is particularly important for toys, as fading can affect their marketability. B2B buyers should inquire about color fastness tests conducted by manufacturers to ensure that the toys maintain their visual appeal over time.

What Are Common Trade Terms in the Toy Customization Industry?

Familiarizing yourself with industry jargon can greatly enhance communication with manufacturers and suppliers. Here are some common trade terms you should know:

-

OEM (Original Equipment Manufacturer)

– OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the toy industry, this often involves customization of existing products. Understanding OEM relationships can help buyers negotiate better terms and ensure quality control. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest order quantity that a supplier is willing to process. This term is crucial for B2B buyers as it can impact inventory management and cost efficiency. Understanding the MOQ can help buyers assess whether a supplier’s offerings align with their business needs. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting a quote for specific products or services. It typically includes details such as specifications, quantities, and delivery timelines. B2B buyers should prepare detailed RFQs to receive accurate quotes, allowing for better decision-making. -

Incoterms (International Commercial Terms)

– Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping costs and risk management. Familiarity with these terms helps buyers understand who is responsible for transportation, insurance, and duties, which can affect overall costs and logistics planning. -

Lead Time

– Lead time is the amount of time it takes from placing an order to receiving it. This term is vital for B2B buyers to ensure that they can meet market demand without delays. Clear communication with suppliers about lead times can help in planning inventory and managing customer expectations. -

Prototyping

– Prototyping involves creating a preliminary model of a toy before mass production. This process allows buyers to test design concepts and functionality. Engaging in prototyping can help mitigate risks and ensure that the final product meets the desired specifications and quality standards.

Understanding these technical properties and trade terms equips B2B buyers with the knowledge needed to make informed purchasing decisions in the toy customization market. By leveraging this information, businesses can enhance their product offerings and optimize their supply chain processes.

Navigating Market Dynamics and Sourcing Trends in the toy custom Sector

What Are the Current Market Dynamics and Key Trends in the Toy Custom Sector?

The toy custom sector is experiencing significant shifts driven by various global factors. One of the primary drivers is the increasing demand for personalized and customized toys, particularly in emerging markets across Africa, South America, the Middle East, and Europe. As consumer preferences evolve towards unique and tailored products, B2B buyers must adapt their sourcing strategies to meet this demand. Additionally, technological advancements in manufacturing, such as 3D printing and automation, are making it easier and more cost-effective for companies to produce customized toys at scale.

Another key trend is the rise of e-commerce and digital platforms, which are revolutionizing how B2B transactions occur. International buyers can now leverage online marketplaces to connect with manufacturers offering custom toy solutions. This digital shift not only streamlines the procurement process but also enhances transparency and allows for better price comparisons. As a result, buyers can make more informed decisions, ensuring they source high-quality products that align with their brand values.

Furthermore, sustainability is becoming a focal point in sourcing decisions. With increasing scrutiny on environmental impacts, buyers are now prioritizing suppliers that adhere to sustainable practices and utilize eco-friendly materials. Understanding these market dynamics will enable B2B buyers to navigate the complexities of sourcing in the toy custom sector effectively.

How Can Sustainability and Ethical Sourcing Impact B2B Toy Custom Transactions?

Sustainability and ethical sourcing are no longer optional considerations; they are essential components of B2B transactions in the toy custom sector. The environmental impact of toy production—ranging from plastic waste to carbon emissions—has prompted buyers to seek suppliers who prioritize eco-friendly practices. This shift is particularly important for international buyers from regions like Africa and South America, where environmental regulations may be less stringent but consumer awareness is rapidly increasing.

Buyers should look for suppliers that hold certifications such as ISO 14001 for environmental management or those that use recycled materials in their products. These certifications not only demonstrate a commitment to sustainability but also enhance brand reputation in a market increasingly driven by conscious consumerism. Furthermore, the use of sustainable materials—such as bamboo, organic cotton, and biodegradable plastics—can provide a competitive edge in attracting eco-conscious customers.

Incorporating ethical sourcing practices also means ensuring fair labor conditions and transparent supply chains. Buyers should conduct due diligence to verify that their suppliers comply with labor laws and provide safe working environments. This commitment to ethical sourcing not only aligns with global trends but also builds trust and loyalty among consumers who value corporate social responsibility.

How Has the Toy Custom Sector Evolved Over Time?

The evolution of the toy custom sector can be traced back to the traditional toy manufacturing processes that dominated the market for decades. Historically, toys were mass-produced with little regard for individual preferences, leading to a one-size-fits-all approach. However, the late 20th century marked a significant turning point as technological advancements began to influence manufacturing capabilities.

The introduction of computer-aided design (CAD) and later, 3D printing technologies, allowed for greater customization possibilities. This evolution has been further accelerated by the rise of the internet and digital commerce, which have democratized access to manufacturing resources. Today, B2B buyers can easily connect with manufacturers who specialize in custom toys, paving the way for a diverse range of products that cater to specific market needs. The ongoing trend toward personalization and sustainability continues to shape the future of the toy custom sector, making it a dynamic area for international buyers to explore.

Frequently Asked Questions (FAQs) for B2B Buyers of toy custom

-

How do I solve issues related to minimum order quantities (MOQ) when sourcing custom toys?

To address MOQ challenges, start by clearly communicating your needs to potential suppliers. Some manufacturers may offer flexibility, especially if you can demonstrate a commitment to future orders. Consider collaborating with other buyers to meet the MOQ or explore suppliers who specialize in smaller batches. Additionally, research manufacturers in regions known for accommodating smaller orders, such as Southeast Asia or Eastern Europe, where production costs may be lower, allowing for more competitive pricing on smaller quantities. -

What is the best way to vet suppliers for custom toy manufacturing?

Begin by assessing suppliers’ credentials, including certifications like ISO and compliance with safety standards relevant to your target market. Request samples of their previous work to evaluate quality. Conduct background checks and seek references from other clients, particularly those in your region. Additionally, consider visiting the manufacturing facility if possible, as this can provide invaluable insights into their production capabilities and practices. -

How can I ensure the quality of custom toys during production?

Implement a comprehensive quality assurance (QA) plan that includes regular inspections at different production stages. Establish clear quality benchmarks and communicate these with your supplier. Utilize third-party QA services to conduct independent inspections and audits, ensuring adherence to safety and quality standards. Additionally, maintain open communication with your supplier throughout the production process to address any issues promptly. -

What payment terms should I negotiate when sourcing custom toys?

Negotiate payment terms that protect your interests while ensuring supplier commitment. Common practices include a deposit upfront (usually 30-50%), with the balance payable upon completion or delivery. Consider using secure payment methods like letters of credit for larger orders, as these provide additional security. Be transparent about your budget constraints and explore options for staggered payments based on production milestones to foster trust and cooperation. -

What are the key logistics considerations for importing custom toys?

When importing custom toys, consider shipping methods, customs regulations, and potential tariffs. Research logistics providers that specialize in international shipping to ensure timely and cost-effective delivery. Understand the import duties and taxes applicable in your region to avoid unexpected costs. Develop a solid logistics plan that includes tracking and insurance to mitigate risks during transit. -

How can I effectively communicate my design specifications to suppliers?

Utilize detailed design documentation, including CAD drawings, prototypes, and material samples, to communicate your specifications clearly. Consider creating a comprehensive project brief that outlines your expectations, timelines, and quality standards. Using visual aids and examples can bridge language barriers and help ensure your vision is accurately interpreted. Regular follow-ups and open channels for feedback during the design phase can further enhance communication. -

What are the best practices for customizing toys to meet local market preferences?

Conduct thorough market research to understand local trends, preferences, and cultural sensitivities in your target regions. Engage with local distributors or retailers to gain insights into consumer behavior. Customize your products based on feedback, incorporating popular colors, themes, or characters that resonate with your audience. Testing prototypes with focus groups in your target market can also provide valuable insights and improve product acceptance. -

How do I navigate compliance with international toy safety regulations?

Familiarize yourself with the safety standards and regulations relevant to your target markets, such as ASTM, EN71, and CPSIA. Ensure that your suppliers are compliant and can provide necessary documentation and testing results. Collaborate with certified laboratories to conduct safety tests on your products before launch. Staying updated on regulatory changes in different regions is crucial for maintaining compliance and avoiding costly recalls or fines.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for toy custom

What Are the Key Takeaways for Strategic Sourcing in Toy Customization?

In today’s competitive landscape, strategic sourcing is essential for B2B buyers in the toy industry, particularly those operating in Africa, South America, the Middle East, and Europe. Prioritizing partnerships with reliable manufacturers can lead to significant cost savings and enhanced product quality. Leveraging technology to streamline procurement processes and ensure transparent communication can further optimize sourcing strategies.

How Can B2B Buyers Enhance Their Sourcing Strategies?

Buyers should focus on building long-term relationships with suppliers who understand local market dynamics and can adapt to changing consumer preferences. Investing in sustainable practices and ethical sourcing not only enhances brand reputation but also aligns with global consumer trends favoring environmentally friendly products.

What Does the Future Hold for Toy Customization?

Looking ahead, the demand for customized toys is expected to grow, driven by increasing consumer demand for personalized products. B2B buyers must remain agile, continuously adapting their sourcing strategies to embrace innovation and respond to market shifts. By prioritizing strategic sourcing, international buyers can position themselves for success in an evolving marketplace.

Engage with trusted suppliers today to explore the limitless possibilities in toy customization and secure your competitive edge for tomorrow.