Top Custom Gear Manufacturers You Should Know

Are you tired of settling for mediocre custom gear that just doesn’t meet your expectations? You’re not alone! Finding the right manufacturer can be a daunting task, but it’s crucial for bringing your vision to life. Imagine collaborating with a top-notch factory that not only understands your needs but also delivers high-quality products on time. The right partner can elevate your brand and ensure your gear stands out in a crowded market.

In this article, we’re diving into the top 30 custom gear manufacturers that can turn your ideas into reality. Ready to discover the best suppliers out there? Let’s get started!

Top 17 Custom Gear Manufacturer Manufacturers

Precision Gears – Custom Gear Manufacturing Solutions

Domain: precisiongears.com

Registered: 1998 ( 27 years )

Introduction: Precision Gears, Inc. specializes in manufacturing high-quality custom gears, including worms, worm gears, spur gears, helical gears, internal and external splines, keyway and broaching services, and sprockets.

Gearmotions – Custom Gear Manufacturing Services

Domain: gearmotions.com

Registered: 1997 ( 28 years )

Introduction: Custom gear manufacturing services specializing in various types of gears including spur, helical, bevel, worm, and pump gears.

Hmcgears – High-Performance Gear Manufacturing

Domain: hmcgears.com

Registered: 1997 ( 28 years )

Introduction: HMC manufactures high-quality gears and components using alloy-enhanced forgings, providing longer life and superior performance.

Geartec – Custom Gear Manufacturing Services

Domain: geartec.com

Registered: 1996 ( 29 years )

Introduction: Custom gear manufacturing services including gear cutting, machining, gearbox repair, and emergency services.

Croix Gear – Custom Gear Manufacturing Solutions

Domain: croixgear.com

Registered: 2010 ( 15 years )

Introduction: Croix Gear offers extensive custom gear manufacturing capabilities, specializing in spiral bevel gears but also producing a variety of gear types including hypoid, Zerol, straight bevel, spur, helical, worm wheels, and splines.

Aagearinc – Custom Gear Manufacturing Solutions

Domain: aagearinc.com

Registered: 2006 ( 19 years )

Introduction: Custom gear manufacturing services including design, reverse engineering, tooling creation, and prototype manufacturing.

Amgear – Custom Precision Gears & Machining Services

Domain: amgear.com

Registered: 1997 ( 28 years )

Introduction: Custom precision gears and related machining services.

Dopplergear – Custom Gear Manufacturing Solutions

Cage Gear – Custom Gear Manufacturing Solutions

Domain: cagegear.com

Registered: 2005 ( 20 years )

Introduction: Cage Gear is a custom gear manufacturer that produces gears from 2.00″ up to 180.00″ in diameter, including various types of gears such as spur, helical, bevel, and worm gears.

KHK Gears – Custom Gear Manufacturing Solutions

Domain: khkgears.net

Registered: 2015 ( 10 years )

Introduction: Custom gears are manufactured according to specific user specifications, including variations in teeth, bore size, keyway, face width, helix angle, and more. KHK Quick-Mod Gears are modified standard gears to meet specific user requirements.

Churonco – Gear Repair and Custom Manufacturing Solutions

Domain: churonco.com

Registered: 2009 ( 16 years )

Introduction: Churon Company is a full-service gear machine shop that offers repair and rebuilding of gears, pinions, gearboxes, pumps, blowers, and airlocks. They also manufacture new and custom-cut pinions.

Fg Machine – Precision Gear Cutting and Machining Solutions

Domain: fg-machine.com

Registered: 2021 ( 4 years )

Introduction: Federal Gear and Machine offers gear cutting, precision machining, keyway cutting, reverse engineering, and gear box design and repair services.

Ptggear – Custom Gear Manufacturing & Repair Services

Domain: ptggear.com

Registered: 2020 ( 5 years )

Introduction: Custom gear manufacturing and gearbox repair services, including reverse engineering and design using CMM and SolidWorks 3D modeling software.

HM Manufacturing – Custom Gear Solutions

Domain: hmmanufacturing.com

Registered: 2002 ( 23 years )

Introduction: HM Manufacturing is a manufacturer of custom gears including helical gears, spur gears, chain sprockets, internal gears, and pawl & ratchet gears, produced to meet specific customer requirements.

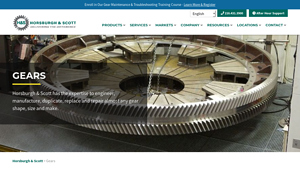

Horsburgh & Scott – Custom Gear Manufacturing Solutions

Domain: horsburgh-scott.com

Registered: 1996 ( 29 years )

Introduction: Horsburgh & Scott specializes in custom gear manufacturing, including gears, gearboxes, premium gearboxes, Dominion gearboxes, OEM spare parts, and gear couplings.

Ideal Gearworks – Precision Gear Manufacturing Solutions

Domain: idealgearworks.com

Registered: 2003 ( 22 years )

Introduction: Ideal Gear offers precision gear manufacturing, including custom-designed gears, reverse engineering, gearbox refurbishment, and emergency repair services.

Mooregear – Custom Gears and Gear Racks

Domain: mooregear.com

Registered: 1999 ( 26 years )

Introduction: Moore Gear & Manufacturing® offers custom and standard gear racks and gears, including hobbed spur gears, worms, helical gears, internal shaped gears, segment gears, ring gears, pinion shafts, stem pinions, bevel gears, miter gears, splines, and sprockets.

Category Information

A custom gear manufacturer specializes in designing and producing gears tailored to specific requirements of various industries. This category encompasses a wide range of gear types, including spur gears, bevel gears, worm gears, and helical gears, each serving unique functions in mechanical systems. Custom gear manufacturers utilize advanced technologies such as CNC machining, 3D printing, and precision engineering to create components that meet precise specifications regarding size, material, and performance.

The significance of custom gear manufacturing lies in its ability to provide solutions for unique challenges faced by businesses in sectors such as automotive, aerospace, robotics, and industrial machinery. By offering bespoke gear solutions, manufacturers can enhance efficiency, improve performance, and extend the lifespan of machinery. Custom gears enable companies to optimize their operations, making them a critical component in the development of innovative technologies and competitive products.

Application Information

Custom gear manufacturers serve a wide range of industries, providing tailored solutions for specific mechanical needs. One primary application area is the automotive industry, where custom gears are crucial for transmission systems, differential assemblies, and powertrain components, enhancing performance and efficiency in vehicles. Another significant sector is aerospace, where precision-engineered gears are vital for aircraft systems, including landing gear, flight control mechanisms, and engine components. Custom gears ensure reliability and safety in high-stakes environments.

Additionally, the industrial machinery sector frequently utilizes custom gear solutions for conveyor systems, robotics, and heavy machinery, allowing for optimized operations and improved productivity. Lastly, the renewable energy sector employs custom gears in wind turbines and solar tracking systems, where they help convert and manage energy efficiently. Overall, custom gear manufacturing plays a pivotal role in enhancing functionality and efficiency across various industries.

Production Process Information

The production process for custom gear manufacturing involves several key stages that ensure the final product meets specific requirements. First, the process begins with design and engineering, where customers provide specifications, and engineers create detailed drawings or 3D models of the gear. This stage is crucial for determining the gear’s size, shape, and functionality.

Next is the material selection, where manufacturers choose the appropriate materials based on the gear’s intended use, such as metals for strength or plastics for lighter applications. Once the design and materials are finalized, the manufacturing stage begins, which may involve techniques like machining, molding, or additive manufacturing to create the gear. Finally, the process concludes with quality control and testing, ensuring that each gear meets the required standards for performance and durability.

This thorough approach guarantees that custom gears perform reliably in their intended applications.

Related Video

Frequently Asked Questions (FAQs)

What should I consider when choosing a custom gear manufacturer?

When selecting a custom gear manufacturer, consider factors such as their experience in your specific industry, the range of materials they work with, and their production capabilities. It’s also important to look at their quality control processes and certifications. Don’t forget to check their reputation by reading reviews or asking for references. Finally, assess their communication style and responsiveness, as a good partnership relies on clear and open dialogue.

How can I find reliable custom gear manufacturers?

You can start by searching online directories, trade shows, and industry associations that list manufacturers. Websites like ThomasNet or Maker’s Row can be helpful. Networking within industry forums or groups on social media platforms can also lead you to reputable manufacturers. Additionally, consider reaching out to local business chambers or export organizations that might have recommendations.

What is the typical lead time for custom gear manufacturing?

Lead times can vary widely depending on the complexity of the gear, the manufacturer’s workload, and the materials used. Generally, you can expect lead times to range from a few weeks to several months. It’s best to discuss your specific needs with potential manufacturers upfront and ask for an estimated timeline, so you can plan your project accordingly.

How can I ensure the quality of the custom gears produced?

To ensure quality, ask potential manufacturers about their quality control procedures and any certifications they hold, such as ISO standards. Request samples of their previous work to assess their craftsmanship. Additionally, consider establishing a clear set of specifications and tolerances for your gears, and discuss the possibility of regular inspections during the production process to catch any issues early.

What are the costs associated with custom gear manufacturing?

Costs can vary based on several factors, including the complexity of the design, the materials used, the volume of production, and the manufacturer’s pricing structure. It’s a good idea to get quotes from multiple manufacturers to compare prices. Remember to consider not just the upfront costs but also the long-term value, such as durability and performance, which can affect your overall budget.