Cut Costs & Improve Quality: Steel Pipe China Guide (2025)

Introduction: Navigating the Global Market for steel pipe china

Navigating the global market for steel pipes sourced from China presents unique challenges for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. The complexity of procurement, fluctuating prices, and the need for compliance with local regulations can often deter companies from making informed decisions. This guide aims to demystify the process of sourcing steel pipes from China by providing a comprehensive overview of the various types available, their applications across industries, and strategic insights into supplier vetting.

In addition to exploring the different grades and specifications of steel pipes, we will delve into crucial factors such as cost analysis, shipping logistics, and quality assurance practices. Buyers will also learn how to effectively evaluate potential suppliers, ensuring that they align with both product standards and ethical practices. By equipping international B2B buyers with actionable insights and clear strategies, this guide empowers them to make informed purchasing decisions that enhance their operational efficiency and competitive edge.

Whether you are a seasoned buyer or new to the steel pipe market, understanding the intricacies of sourcing from China can significantly impact your project outcomes. This guide will serve as a valuable resource in navigating these complexities, helping you to secure the best quality products at competitive prices while mitigating risks associated with international procurement.

Understanding steel pipe china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Seamless Steel Pipe | Manufactured without a seam, offering higher strength and reliability. | Oil and gas, construction, automotive | Pros: High pressure tolerance, corrosion resistance. Cons: Higher cost, limited sizes. |

| Welded Steel Pipe | Created by welding steel plates together, available in various sizes. | Water supply, structural applications | Pros: Cost-effective, versatile. Cons: Less strength compared to seamless, potential weld defects. |

| Galvanized Steel Pipe | Coated with zinc to prevent corrosion, typically used in outdoor applications. | Plumbing, HVAC, agricultural systems | Pros: Corrosion resistance, extended lifespan. Cons: Limited temperature range, potential for zinc flaking. |

| Carbon Steel Pipe | Contains carbon as the primary alloying element, known for strength and durability. | Construction, manufacturing, energy sectors | Pros: High tensile strength, cost-efficient. Cons: Prone to corrosion without protective coating. |

| Alloy Steel Pipe | Made from a combination of steel and other elements, enhancing specific properties. | Aerospace, automotive, high-pressure applications | Pros: Enhanced mechanical properties, tailored for specific applications. Cons: Higher cost, may require special handling. |

What Are the Characteristics of Seamless Steel Pipes?

Seamless steel pipes are produced from a solid round steel billet, which is heated and pushed or pulled over a form until it is shaped into a pipe. This manufacturing process eliminates any welded seams, providing a consistent and uniform structure. Seamless pipes are particularly suited for high-pressure applications, making them ideal for the oil and gas industry, as well as construction projects that require reliable materials. When purchasing seamless pipes, buyers should consider factors such as diameter, wall thickness, and the specific pressure ratings necessary for their applications.

How Do Welded Steel Pipes Differ from Other Types?

Welded steel pipes are created by rolling steel plates into a cylindrical shape and then welding the edges together. This method allows for a wide range of sizes and shapes, making welded pipes versatile for various uses, including water supply and structural applications. While they are generally more affordable than seamless pipes, buyers should be cautious about potential weld defects that could compromise integrity. Key considerations include the quality of the weld, the intended application, and compliance with industry standards.

Why Choose Galvanized Steel Pipes for Outdoor Applications?

Galvanized steel pipes are coated with a layer of zinc to provide excellent corrosion resistance, making them suitable for outdoor installations where exposure to moisture is common. These pipes are often used in plumbing, HVAC systems, and agricultural applications. The zinc coating not only protects the steel but also extends the lifespan of the pipe. Buyers should evaluate the pipe’s temperature tolerance and ensure that the coating is intact to prevent issues like zinc flaking.

What Are the Benefits of Using Carbon Steel Pipes?

Carbon steel pipes are known for their strength and durability, making them a popular choice across various industries, including construction and manufacturing. With carbon as the primary alloying element, these pipes offer high tensile strength and cost efficiency. However, they can be prone to corrosion if not properly coated or maintained. When sourcing carbon steel pipes, buyers should consider the need for protective coatings and the specific mechanical properties required for their applications.

How Are Alloy Steel Pipes Tailored for Specific Applications?

Alloy steel pipes are composed of steel combined with various alloying elements, such as chromium, nickel, or molybdenum, which enhance specific properties like strength, toughness, and resistance to wear. These pipes are commonly used in demanding environments, such as aerospace and high-pressure applications. While they offer superior performance, the cost is typically higher than that of standard steel pipes. B2B buyers should assess the specific requirements of their projects and consider the long-term benefits of investing in alloy steel pipes.

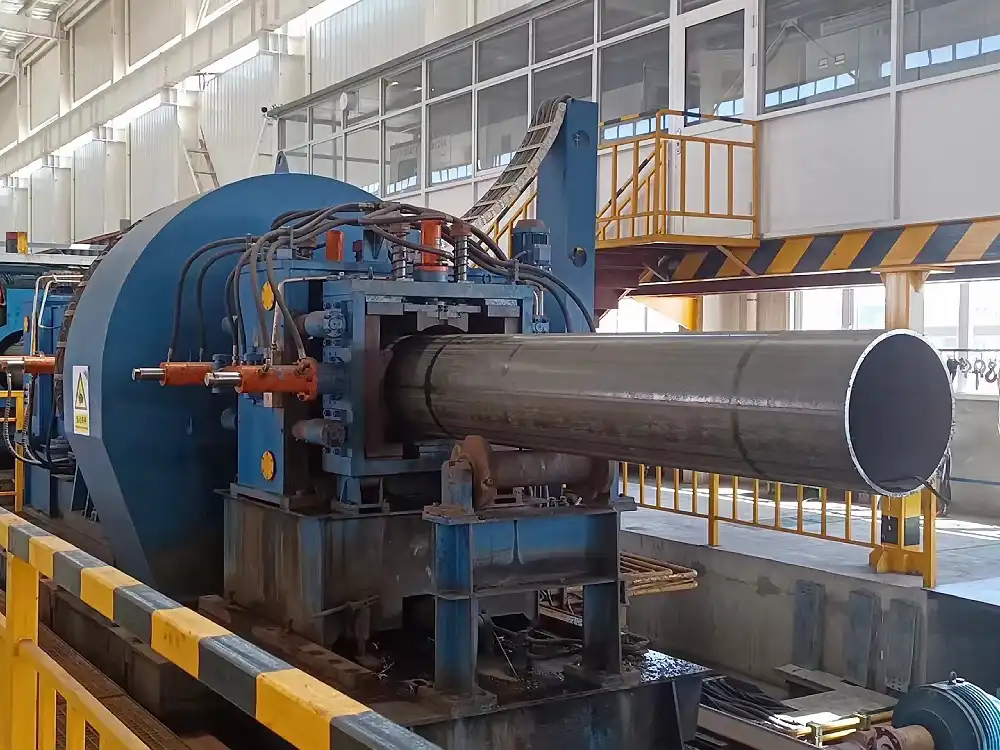

Related Video: Seamless steel pipe manufacturing

Key Industrial Applications of steel pipe china

| Industry/Sector | Specific Application of Steel Pipe China | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil and Gas | Transportation of Oil and Gas | Ensures safe and efficient transport of resources | Compliance with international standards, durability, and corrosion resistance |

| Construction | Structural Frameworks | Provides strength and support for buildings | Quality certification, load-bearing capacity, and local regulations |

| Water Supply and Treatment | Pipeline Systems | Reliable delivery of clean water | Material specifications, resistance to pressure, and local sourcing options |

| Automotive Manufacturing | Exhaust and Fuel Lines | Enhances vehicle performance and emissions control | Precision engineering, lightweight materials, and compliance with automotive standards |

| Agriculture | Irrigation Systems | Efficient water management for crop production | Resistance to wear, chemical compatibility, and adaptability to local climates |

How is Steel Pipe China Used in the Oil and Gas Industry?

In the oil and gas sector, steel pipes from China are primarily used for the transportation of crude oil, natural gas, and other petroleum products. These pipes must withstand high pressures and corrosive environments, which is critical for ensuring the safety and efficiency of resource transport. International buyers, particularly from regions like Africa and the Middle East, should consider sourcing pipes that meet international standards for pressure ratings and corrosion resistance to mitigate risks and ensure operational reliability.

What Role Does Steel Pipe China Play in Construction?

Steel pipes are integral to structural frameworks in construction, providing essential support for buildings and infrastructure. They are utilized in beams, columns, and other load-bearing components. Buyers in Europe and South America must ensure that sourced steel pipes comply with local building codes and standards, focusing on factors such as load-bearing capacity and quality certifications. This guarantees safety and durability in construction projects, which is vital for long-term investment.

How Does Steel Pipe China Enhance Water Supply and Treatment Systems?

In water supply and treatment applications, steel pipes are crucial for establishing reliable pipeline systems that deliver clean water to communities. These pipes must be designed to resist corrosion and withstand varying pressure levels. For international buyers, particularly from developing regions in Africa, it is essential to consider the material specifications and resistance to wear when sourcing pipes. This ensures the longevity and functionality of water distribution systems, ultimately contributing to public health.

A stock image related to steel pipe china.

What is the Importance of Steel Pipe China in Automotive Manufacturing?

A stock image related to steel pipe china.

In the automotive industry, steel pipes are used in the fabrication of exhaust and fuel lines, playing a significant role in vehicle performance and emissions control. These components require precise engineering and adherence to automotive standards for safety and efficiency. Buyers from Europe, known for strict automotive regulations, should prioritize sourcing lightweight yet durable steel pipes that meet these standards, enhancing vehicle performance while complying with environmental regulations.

How is Steel Pipe China Used in Agriculture?

In agriculture, steel pipes are utilized in irrigation systems to manage water efficiently for crop production. These pipes must be resistant to wear and compatible with various chemicals used in farming. Buyers in regions like South America, where agriculture is a primary industry, should focus on sourcing pipes that can withstand local climate conditions and provide long-term reliability. This ensures effective water management and supports sustainable agricultural practices.

Related Video: Explore the production processes of square steel pipe from steel sheet and round pipe

3 Common User Pain Points for ‘steel pipe china’ & Their Solutions

Scenario 1: Navigating Quality Control Challenges in Steel Pipe Sourcing

The Problem: One of the most pressing challenges faced by international B2B buyers, especially from regions like Africa and South America, is the inconsistency in quality when sourcing steel pipes from China. With numerous manufacturers and varying standards, a buyer may receive products that do not meet the required specifications, leading to project delays, increased costs, and potential safety hazards. This situation is particularly concerning in industries like construction and oil and gas, where the integrity of steel pipes is critical.

The Solution: To effectively navigate these quality control challenges, buyers should establish a robust sourcing strategy. Begin by conducting thorough due diligence on potential suppliers. This includes reviewing their certifications, production processes, and past customer feedback. Utilizing third-party inspection services can also ensure that the products meet international quality standards before shipment. Additionally, establishing a clear set of specifications and performance standards in the purchase agreement can mitigate risks. Finally, consider forming strategic partnerships with trusted local agents who understand the Chinese market and can facilitate better communication and oversight.

Scenario 2: Overcoming Shipping and Logistics Delays

The Problem: International B2B buyers often encounter significant delays in shipping and logistics when sourcing steel pipes from China. These delays can be caused by factors such as port congestion, customs clearance issues, and inadequate shipping documentation. For companies operating on tight timelines, such delays can lead to missed deadlines, increased project costs, and strained relationships with end clients.

The Solution: To minimize shipping and logistics delays, buyers should engage in proactive logistics planning. This involves selecting reputable freight forwarders with experience in handling industrial materials and a strong track record in timely deliveries. Moreover, it is crucial to maintain open communication with suppliers regarding shipping timelines and potential delays. Utilizing technology, such as shipment tracking systems, can provide real-time updates on the status of orders. Furthermore, buyers should familiarize themselves with customs regulations in both China and their destination country, ensuring all necessary documentation is prepared and compliant to avoid unnecessary holdups.

Scenario 3: Addressing Cost Fluctuations in Steel Pipe Procurement

The Problem: Fluctuating prices of steel pipes can create budgetary constraints for B2B buyers, particularly in markets in the Middle East and Europe where pricing volatility is common. Buyers often find themselves facing unexpected cost increases due to rising raw material prices or shifts in demand, making it difficult to maintain profitability on projects that have fixed budgets.

The Solution: To effectively manage cost fluctuations, buyers should consider implementing a strategic procurement approach. This includes establishing long-term contracts with suppliers that lock in prices for a specified period, thereby providing price stability. Additionally, diversifying the supplier base can create competitive pricing pressure and reduce dependency on a single source. Buyers should also closely monitor market trends and engage in forward buying when prices are favorable. Utilizing financial instruments such as hedging can further protect against price volatility. Lastly, maintaining a flexible budget that accounts for potential price changes can help companies adapt without jeopardizing project viability.

Strategic Material Selection Guide for steel pipe china

What Are the Key Properties of Common Materials Used in Steel Pipe Manufacturing in China?

When selecting materials for steel pipes, international B2B buyers must consider various factors such as temperature and pressure ratings, corrosion resistance, and compatibility with specific media. Here’s a detailed analysis of four common materials used in steel pipe manufacturing in China.

1. Carbon Steel

Key Properties:

Carbon steel is known for its high strength and durability, making it suitable for high-pressure applications. It typically has a temperature rating of up to 400°C and can withstand significant pressure.

Pros & Cons:

The advantages of carbon steel include its cost-effectiveness and widespread availability. However, it is susceptible to corrosion, which can limit its lifespan in certain environments, particularly those involving moisture or aggressive chemicals.

Impact on Application:

Carbon steel is ideal for transporting water, oil, and gas. However, its vulnerability to corrosion means it may not be suitable for applications involving acidic or saline environments.

Considerations for International Buyers:

Buyers from regions like Africa and the Middle East should be aware of local regulations regarding corrosion resistance. Compliance with standards such as ASTM A106 or ASTM A53 is crucial for ensuring product reliability.

2. Stainless Steel

Key Properties:

Stainless steel offers excellent corrosion resistance and can handle temperatures up to 800°C. It is particularly effective in environments where moisture or corrosive substances are present.

Pros & Cons:

The primary advantage of stainless steel is its longevity and low maintenance requirements. However, it comes at a higher cost than carbon steel, which may be a limiting factor for budget-conscious projects.

Impact on Application:

Stainless steel is commonly used in food processing, pharmaceuticals, and chemical industries due to its hygienic properties. Its resistance to corrosion makes it suitable for transporting aggressive media.

Considerations for International Buyers:

European buyers, particularly in Spain, may prefer stainless steel due to stringent hygiene regulations. Compliance with standards like ASTM A312 or EN 10216 is essential for market acceptance.

3. Alloy Steel

Key Properties:

Alloy steel is engineered to enhance specific properties such as strength, toughness, and wear resistance. It can perform well at high temperatures and pressures, often exceeding 500°C.

Pros & Cons:

The key advantage of alloy steel is its ability to withstand extreme conditions, making it suitable for specialized applications. However, the manufacturing complexity can lead to higher costs.

Impact on Application:

Alloy steel is often used in high-stress environments, such as power plants and chemical processing facilities. Its enhanced properties allow it to transport more aggressive media safely.

Considerations for International Buyers:

Buyers from South America should consider the availability of alloy steel grades that meet local standards, such as ASTM A335. Understanding the specific requirements for high-stress applications is critical.

4. PVC Coated Steel

Key Properties:

PVC coated steel pipes provide additional corrosion protection and can handle temperatures up to 60°C. The coating enhances the pipe’s resistance to chemicals and environmental factors.

Pros & Cons:

The main advantage of PVC coated steel is its affordability and ease of installation. However, the coating can be susceptible to damage, which may compromise its protective qualities.

Impact on Application:

These pipes are often used in underground applications or environments where chemical exposure is a concern. They are suitable for transporting water and other non-aggressive media.

Considerations for International Buyers:

Buyers in regions like Africa should assess the local climate and potential for physical damage to the coating. Compliance with standards such as ASTM F1043 is vital for ensuring durability.

Summary Table of Material Selection for Steel Pipe China

| Material | Typical Use Case for steel pipe china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Water, oil, and gas transportation | Cost-effective and widely available | Susceptible to corrosion | Low |

| Stainless Steel | Food processing, pharmaceuticals, chemical transport | Excellent corrosion resistance | Higher cost compared to carbon steel | High |

| Alloy Steel | Power plants, chemical processing | High strength and toughness | Manufacturing complexity increases cost | Medium |

| PVC Coated Steel | Underground applications, chemical exposure | Affordable and easy to install | Coating can be damaged | Low |

This comprehensive analysis provides international B2B buyers with the insights needed to make informed decisions regarding material selection for steel pipes sourced from China. Understanding the properties, advantages, limitations, and compliance requirements will ensure that the chosen materials meet both performance and regulatory standards in their respective markets.

In-depth Look: Manufacturing Processes and Quality Assurance for steel pipe china

What Are the Main Stages of the Steel Pipe Manufacturing Process in China?

The manufacturing of steel pipes in China involves several critical stages, each contributing to the overall quality and performance of the final product. Understanding these stages can help international B2B buyers make informed decisions when sourcing steel pipes.

-

Material Preparation

The process begins with the selection of raw materials, typically steel billets or slabs. The quality of these materials is paramount, as it directly influences the integrity of the finished pipes. Suppliers often utilize advanced technologies for material inspection, such as spectrometers to analyze chemical compositions, ensuring compliance with international standards. -

Forming

Once the material is prepared, it undergoes forming processes. Depending on the desired pipe specifications, techniques such as hot rolling, cold drawing, or extrusion are employed. Hot rolling is common for larger diameter pipes, while cold drawing is preferred for smaller sizes and tighter tolerances. These methods not only shape the steel but also refine its mechanical properties through deformation. -

Assembly

In the assembly stage, the formed pipes may be joined or further processed to create specific configurations. This can include welding or flanging, depending on the application requirements. Advanced welding techniques, such as submerged arc welding (SAW) or gas tungsten arc welding (GTAW), are often utilized to ensure robust and leak-proof joints. -

Finishing

The finishing stage involves various processes such as heat treatment, surface treatment, and coating. Heat treatment enhances the strength and ductility of the pipes, while surface treatments like galvanization or painting provide corrosion resistance. Quality assurance checks are critical during this stage to ensure that all specifications are met.

How Does Quality Assurance Work in Steel Pipe Manufacturing?

Quality assurance (QA) is an essential aspect of the manufacturing process, particularly for international B2B transactions. Buyers from regions such as Africa, South America, the Middle East, and Europe should be familiar with the relevant standards and practices.

-

International Standards

Manufacturers often adhere to international quality standards like ISO 9001, which ensures consistent quality management systems. In addition, industry-specific certifications such as CE (Conformité Européenne) for Europe and API (American Petroleum Institute) for oil and gas applications are crucial for ensuring product reliability and compliance with regional regulations. -

Quality Control Checkpoints

Quality control (QC) checkpoints are integrated throughout the manufacturing process, typically categorized into three main areas:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Continuous monitoring during manufacturing processes helps identify defects early. Techniques include visual inspections and measurement checks.

– Final Quality Control (FQC): Before shipment, finished products undergo comprehensive testing, including pressure tests, dimensional checks, and surface quality assessments. -

Common Testing Methods

Testing methods play a critical role in quality assurance. Common techniques include:

– Hydrostatic Testing: To verify the strength and leak-tightness of pipes.

– Ultrasonic Testing: To detect internal flaws or inconsistencies in the material.

– Radiographic Testing: Utilized for weld integrity assessment, particularly in critical applications.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial for ensuring product reliability. Here are some strategies:

-

Conducting Audits

Regular audits of suppliers’ facilities can provide valuable insights into their manufacturing processes and quality assurance practices. Buyers should look for compliance with international standards and assess the effectiveness of QC checkpoints. -

Requesting Quality Reports

Suppliers should provide detailed quality reports that outline their testing methods, results, and certifications. These documents should include data from IQC, IPQC, and FQC stages, demonstrating adherence to quality standards. -

Engaging Third-Party Inspectors

Utilizing third-party inspection services can offer an unbiased assessment of the supplier’s quality control processes. These inspectors can conduct on-site evaluations and product testing to ensure compliance with specified standards.

What Are the Quality Control and Certification Nuances for International Buyers?

Understanding the nuances of quality control and certification is essential for B2B buyers engaging with suppliers in China. Here are key considerations:

-

Regional Compliance Requirements

Different regions have varying regulatory requirements. For instance, buyers in Europe must ensure that products meet CE marking standards, which signify compliance with health, safety, and environmental protection regulations. Similarly, buyers in the Middle East may require compliance with local standards such as GSO (Gulf Standards Organization). -

Documentation and Traceability

Buyers should ensure that suppliers maintain comprehensive documentation regarding material traceability and quality control measures. This includes certificates of compliance, test reports, and details about the manufacturing process. Proper documentation is vital for warranty claims and product recalls. -

Supplier Relationships

Establishing strong relationships with suppliers can facilitate better communication regarding quality control processes. Buyers should engage in regular discussions about quality expectations and any concerns that arise during production.

Conclusion

For international B2B buyers sourcing steel pipes from China, understanding the manufacturing processes and quality assurance protocols is vital. By familiarizing themselves with the key stages of production, relevant quality standards, and effective verification methods, buyers can ensure they are making informed purchasing decisions. This knowledge not only helps in securing high-quality products but also builds trust and reliability in supplier relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘steel pipe china’

Introduction

Navigating the procurement of steel pipes from China can be a complex process, especially for international B2B buyers from regions like Africa, South America, the Middle East, and Europe. This guide provides a practical checklist to streamline your sourcing efforts, ensuring you make informed decisions that align with your project’s requirements and standards.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring that the steel pipes meet your project’s requirements. Consider factors such as material grade, dimensions, and applicable standards.

- Material Grade: Identify the specific steel grade necessary for your application (e.g., ASTM A53, API 5L).

- Dimensions: Specify the diameter, wall thickness, and length needed for optimal performance in your project.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to compile a list of potential suppliers in China. Utilize online platforms, trade shows, and industry directories to identify reputable manufacturers.

- Online Platforms: Use sites like Alibaba, Made-in-China, or Global Sources to find suppliers with positive reviews and ratings.

- Industry Directories: Refer to industry-specific directories to discover manufacturers that specialize in steel pipes.

Step 3: ✅ Verify Supplier Certifications

Before proceeding, ensure that your selected suppliers possess the necessary certifications. This step is vital for compliance with international standards and quality assurance.

- ISO Certifications: Look for ISO 9001 certification, which indicates a commitment to quality management.

- Product Certifications: Verify if the supplier has specific product certifications, such as API or CE marking, relevant to your market.

Step 4: Request Detailed Quotes

Once you’ve narrowed down your suppliers, request detailed quotes that outline pricing, payment terms, and delivery timelines. This transparency is essential for effective budgeting and planning.

- Pricing Structure: Ensure the quote includes all potential costs, such as shipping and customs duties.

- Payment Terms: Clarify payment options (e.g., advance payment, letter of credit) to avoid misunderstandings later.

Step 5: Evaluate Supplier Experience and Reputation

Assess the experience and reputation of potential suppliers by checking their track record in the industry. This evaluation helps mitigate risks associated with quality and reliability.

- Client References: Ask for references from previous clients, particularly those in similar industries or regions.

- Case Studies: Review case studies or project histories to gauge their capabilities and past performance.

Step 6: Conduct Site Visits or Virtual Tours

If feasible, conduct site visits to the manufacturing facilities of your shortlisted suppliers. If travel is not possible, request virtual tours to gain insights into their operations.

- Quality Control Processes: Observe their quality control measures and production capabilities.

- Working Conditions: Evaluate the working environment and labor practices to ensure compliance with ethical standards.

Step 7: Finalize Contracts and Agreements

Once you have selected a supplier, finalize contracts that detail all agreed-upon terms, including delivery schedules, warranties, and dispute resolution processes.

- Legal Review: Consider having a legal expert review the contract to ensure all terms are clear and enforceable.

- Contingency Plans: Include clauses that address potential delays or quality issues to protect your interests.

By following this step-by-step checklist, international B2B buyers can effectively navigate the sourcing process for steel pipes from China, ensuring they secure quality products that meet their specific needs.

Comprehensive Cost and Pricing Analysis for steel pipe china Sourcing

What are the Key Cost Components in Sourcing Steel Pipes from China?

When sourcing steel pipes from China, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The type of steel used significantly impacts the overall cost. Common materials include carbon steel, stainless steel, and alloy steel, each varying in price based on market demand and availability. Buyers should specify the desired grade and type to receive accurate quotes.

-

Labor: Labor costs in China are generally lower than in Europe or North America, which can lead to cost savings. However, fluctuations in labor costs due to wage increases or labor shortages can affect pricing.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, equipment maintenance, and administrative costs. Efficient manufacturers often have lower overheads, which can translate into competitive pricing.

-

Tooling: Custom tooling for specific pipe specifications can be a significant upfront cost. Buyers should consider whether they need custom tooling or if standard options will suffice, as this can affect both initial investment and lead times.

-

Quality Control (QC): Implementing rigorous quality control measures ensures the steel pipes meet international standards. While this adds to the cost, it is essential for avoiding issues related to compliance and product failure.

-

Logistics: Shipping costs can vary widely based on the Incoterms used, the distance to the destination, and whether sea or air freight is chosen. Logistics should be a key consideration, as it can significantly influence the total cost.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the market average for margins in the steel pipe industry can help buyers negotiate better deals.

How Do Price Influencers Affect Steel Pipe Costs from China?

Several factors can influence the pricing of steel pipes sourced from China:

-

Volume and Minimum Order Quantity (MOQ): Larger orders generally lead to lower per-unit costs due to economies of scale. Buyers should assess their needs against supplier MOQs to optimize pricing.

-

Specifications and Customization: Unique specifications or custom designs may incur additional costs for tooling and production. Buyers should weigh the benefits of customization against the potential price increase.

-

Material Quality and Certifications: Higher-quality materials and certifications (like ISO or ASTM compliance) often come at a premium. Buyers should determine the necessary quality standards for their applications.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more but provide better service and quality assurance.

-

Incoterms: The chosen Incoterms (e.g., FOB, CIF) can affect total costs. Buyers should understand their responsibilities under different terms to avoid unexpected expenses.

What Tips Can Help International B2B Buyers Negotiate Better Prices?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, the following tips can enhance negotiation outcomes:

-

Conduct Market Research: Understanding the average prices for steel pipes in the market can provide a solid foundation for negotiations. Utilize local industry reports and online resources.

-

Leverage Relationships: Building long-term relationships with suppliers can lead to better pricing and service. Regular communication can also help in negotiating terms that are favorable for both parties.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also long-term factors like durability, maintenance, and logistics when evaluating costs. A slightly higher upfront cost may lead to lower overall expenses.

-

Negotiate Payment Terms: Flexible payment options can ease cash flow constraints. Discussing payment terms can provide leverage in negotiations.

-

Consider Alternative Suppliers: Having multiple suppliers in consideration can increase competition and provide leverage during negotiations. This can lead to better pricing and terms.

Disclaimer on Indicative Prices

It is essential to note that prices for steel pipes can fluctuate based on market conditions, material costs, and supplier pricing strategies. Therefore, the figures presented in this analysis are indicative and should not be considered fixed. Buyers are encouraged to obtain multiple quotes and conduct thorough due diligence before making purchasing decisions.

Alternatives Analysis: Comparing steel pipe china With Other Solutions

Understanding Alternatives to Steel Pipe China for B2B Buyers

When considering procurement options for steel pipes, international B2B buyers must evaluate various alternatives that can fulfill similar functional requirements. This analysis focuses on comparing ‘Steel Pipe China’ with other viable solutions, particularly for buyers in regions such as Africa, South America, the Middle East, and Europe. The aim is to provide actionable insights that can guide decision-making.

Comparison Table of Steel Pipe China and Alternatives

| Comparison Aspect | Steel Pipe China | Carbon Steel Pipe | PVC Pipe |

|---|---|---|---|

| Performance | High strength and durability | Excellent tensile strength | Good for low-pressure systems |

| Cost | Competitive pricing | Moderate to high cost | Low cost |

| Ease of Implementation | Requires specialized equipment | Straightforward installation | Easy to handle and install |

| Maintenance | Low maintenance | Moderate maintenance | Low maintenance |

| Best Use Case | Industrial applications, construction | Oil and gas, structural applications | Water supply, drainage systems |

In-Depth Analysis of Alternatives

What are the Benefits and Drawbacks of Carbon Steel Pipe?

Carbon steel pipes are an alternative often used in high-pressure applications. Their excellent tensile strength makes them suitable for oil and gas transport, as well as structural applications. However, carbon steel pipes can be more expensive than steel pipes sourced from China, particularly due to fluctuating material costs. They also require more maintenance due to susceptibility to corrosion, which may lead to higher long-term costs. Buyers should consider the specific requirements of their projects, especially in harsh environments, to determine if the durability justifies the investment.

How Does PVC Pipe Compare to Steel Pipe China?

PVC pipes represent a low-cost alternative primarily used for water supply and drainage systems. They are lightweight, making them easy to handle and install, which can reduce labor costs. The maintenance requirements for PVC are minimal, and they resist corrosion effectively. However, PVC pipes are not suitable for high-pressure applications, limiting their use cases compared to steel pipes. Buyers in regions with extensive plumbing infrastructure might find PVC to be a practical choice, while those needing robust solutions for heavy-duty applications may lean toward steel options.

How to Choose the Right Solution for Your Needs

Selecting the right pipe solution involves assessing specific project requirements, budget constraints, and application environments. Buyers should weigh the pros and cons of each alternative against their unique needs. For instance, if the project involves high-pressure environments or requires structural integrity, steel pipe options—be it from China or elsewhere—may be the most suitable. Conversely, for lower-pressure systems or budget-sensitive projects, PVC could provide a viable solution. Ultimately, understanding the trade-offs between performance, cost, and maintenance will empower buyers to make informed decisions that align with their operational objectives.

Essential Technical Properties and Trade Terminology for steel pipe china

What Are the Key Technical Properties of Steel Pipes from China?

When evaluating steel pipes from China, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications:

1. Material Grade

Material grade refers to the type of steel used in the production of pipes, which significantly impacts their strength, durability, and suitability for various applications. Common grades include ASTM A53, ASTM A106, and API 5L. For B2B buyers, selecting the appropriate material grade ensures the pipe can withstand specific environmental conditions, pressures, and temperatures relevant to their projects.

2. Wall Thickness

Wall thickness is a critical specification that affects the pipe’s pressure rating and overall structural integrity. It is measured in millimeters or inches and often categorized as Schedule (e.g., Schedule 40, Schedule 80). Buyers must consider wall thickness to ensure compliance with safety standards and to meet the operational requirements of their specific applications.

3. Diameter

The diameter of a steel pipe, both nominal and actual, plays a vital role in determining flow capacity and fitting compatibility. For instance, larger diameters can accommodate higher volumes of fluids, which is essential in industries such as oil and gas, construction, and manufacturing. Accurate diameter specifications help buyers avoid issues related to installation and operational efficiency.

4. Tolerance

Tolerance refers to the allowable variation in dimensions during manufacturing. It is critical for ensuring that pipes fit correctly with other components in a system. Tight tolerances can enhance performance and reduce the risk of leaks or failures. For B2B buyers, understanding tolerance levels is essential for quality assurance and meeting project specifications.

5. Coating and Corrosion Resistance

Coating materials and corrosion resistance properties are essential for the longevity of steel pipes, especially in harsh environments. Common coatings include galvanized, epoxy, and polyethylene. Buyers should assess the environmental conditions where the pipes will be installed to select the appropriate coating that provides optimal protection against corrosion.

What Are Common Trade Terms Related to Steel Pipe Procurement?

In addition to technical properties, familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are some common trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces components or products that are used in another company’s end product. In the context of steel pipes, an OEM may manufacture pipes that are integrated into larger systems, such as machinery or construction frameworks. Understanding OEM relationships can help buyers ensure quality and compatibility in their supply chain.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. It is crucial for B2B buyers to know the MOQ, as it can affect inventory management and cost efficiency. Suppliers often set MOQs to ensure that production costs are met, and buyers should negotiate these terms to align with their project needs.

3. RFQ (Request for Quotation)

An RFQ is a document sent by a buyer to suppliers requesting a price quote for specific goods or services. In the steel pipe industry, an RFQ outlines the required specifications, quantities, and delivery timelines. Submitting a detailed RFQ can lead to more accurate quotes and better pricing from suppliers.

4. Incoterms

Incoterms (International Commercial Terms) are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for B2B buyers to understand shipping costs, risks, and insurance responsibilities.

5. Lead Time

Lead time is the period between placing an order and receiving the goods. It can vary significantly based on the supplier’s location, production capacity, and shipping method. Buyers should consider lead times when planning projects to ensure timely delivery and avoid delays in construction or manufacturing.

Understanding these technical properties and trade terms can empower international B2B buyers from Africa, South America, the Middle East, and Europe to make informed decisions when sourcing steel pipes from China.

Navigating Market Dynamics and Sourcing Trends in the steel pipe china Sector

What Are the Current Market Dynamics and Key Trends in the Steel Pipe Sector in China?

The steel pipe industry in China is currently influenced by several global drivers that shape market dynamics for international B2B buyers. Key among these is the ongoing demand from infrastructure projects in emerging economies across Africa, South America, and the Middle East. These regions are investing heavily in construction, energy, and transportation sectors, leading to a surge in demand for durable steel pipes.

Emerging B2B technologies are transforming sourcing strategies. The rise of digital platforms facilitates real-time communication and transactions between suppliers and buyers, enhancing transparency and efficiency. Additionally, the adoption of artificial intelligence and machine learning in supply chain management is streamlining operations and reducing costs. For instance, predictive analytics can help buyers anticipate market fluctuations, ensuring they secure favorable pricing and availability.

International buyers should also note the increasing focus on quality and certification standards. The Chinese steel pipe market is evolving, with manufacturers striving to meet international quality benchmarks. As a result, buyers are urged to conduct thorough due diligence and verify compliance with standards such as ISO 9001 or API certifications, which can significantly impact procurement decisions.

How Can Sustainability and Ethical Sourcing Impact B2B Buyers in the Steel Pipe Sector?

Sustainability has become a cornerstone of modern sourcing strategies, particularly in the steel pipe sector. The environmental impact of steel production, including carbon emissions and resource depletion, is prompting buyers to seek suppliers committed to sustainable practices. International buyers from regions like Europe, which have stringent environmental regulations, are particularly sensitive to these issues.

Ethical supply chains are increasingly essential, as businesses recognize their role in promoting responsible sourcing. Buyers are encouraged to engage with suppliers who demonstrate transparency in their sourcing processes and adhere to ethical labor practices. Certifications such as the ResponsibleSteel certification can serve as indicators of a supplier’s commitment to sustainable and ethical practices.

Moreover, the demand for ‘green’ materials is on the rise. Manufacturers are exploring innovative solutions, such as using recycled steel and adopting energy-efficient production methods. Buyers should prioritize suppliers that can provide eco-friendly materials, as this not only aligns with global sustainability goals but can also enhance their brand reputation and marketability.

What Is the Brief Evolution of the Steel Pipe Industry in China?

The steel pipe industry in China has undergone significant evolution over the past few decades. Initially focused on meeting domestic demand during rapid industrialization in the late 20th century, China has transformed into a global leader in steel production and exports. The integration of advanced manufacturing technologies and stringent quality controls has positioned Chinese steel pipes as competitive in international markets.

As international trade expanded, Chinese manufacturers adapted to meet global standards and customer expectations. This shift has been facilitated by government initiatives aimed at promoting export quality and technological advancement. Today, China’s steel pipe sector stands as a vital player in the global supply chain, offering a diverse range of products that cater to various industries, including oil and gas, construction, and automotive.

Frequently Asked Questions (FAQs) for B2B Buyers of steel pipe china

-

How do I ensure the quality of steel pipes sourced from China?

To ensure the quality of steel pipes sourced from China, first, verify the supplier’s certifications, such as ISO 9001 or ASTM standards. Request samples to assess the product quality and check for compliance with your specifications. Additionally, consider conducting third-party inspections or audits at the supplier’s facility to evaluate their manufacturing processes and quality control measures. Engaging a reliable local agent or sourcing professional can also help facilitate this process. -

What are the common payment terms for international purchases of steel pipes?

Typical payment terms for international purchases of steel pipes include a combination of advance payment and letter of credit (LC). Many suppliers may require a 30% deposit upfront, with the balance due upon shipping or before the release of shipping documents. It’s crucial to negotiate terms that protect both parties, ensuring that you receive the quality and quantity agreed upon. Always confirm the payment methods accepted by the supplier and consider using escrow services for added security. -

What are the minimum order quantities (MOQs) for steel pipes from Chinese suppliers?

Minimum order quantities (MOQs) for steel pipes can vary significantly depending on the supplier and the type of pipe. Generally, MOQs range from 1 ton to 10 tons or more. It’s advisable to discuss your specific needs with potential suppliers to see if they can accommodate smaller orders or mixed shipments. Many suppliers may offer flexibility for first-time buyers or long-term partnerships, so don’t hesitate to negotiate. -

How can I verify the legitimacy of a steel pipe supplier in China?

To verify the legitimacy of a steel pipe supplier in China, start by checking their business license and registration information through platforms like Alibaba or Made-in-China. Look for customer reviews and ratings on their profiles. Conduct a background check by requesting references from previous clients and visiting their production facilities if possible. Using third-party verification services can also provide assurance of their legitimacy and operational capabilities. -

What customization options are available for steel pipes sourced from China?

Many Chinese suppliers offer a variety of customization options for steel pipes, including different sizes, lengths, thicknesses, and coatings. Some suppliers may also provide specialized treatments, such as galvanization or anti-corrosion finishes. Discuss your specific requirements with the supplier early in the negotiation process to ensure they can meet your needs. Be prepared to provide detailed specifications to facilitate accurate quotes and production. -

What logistics considerations should I keep in mind when importing steel pipes from China?

When importing steel pipes from China, consider logistics aspects such as shipping methods (sea freight is common for bulk shipments), delivery timelines, and customs clearance processes. Collaborate with a freight forwarder experienced in handling steel imports to navigate potential challenges. Ensure you are aware of any import duties, taxes, and regulations in your country to avoid unexpected costs. Proper documentation, including bills of lading and certificates of origin, is crucial for smooth customs clearance. -

How do I handle disputes with Chinese steel pipe suppliers?

Handling disputes with Chinese steel pipe suppliers requires a clear approach. Start by reviewing the contract terms and conditions to understand your rights and obligations. Communicate your concerns directly with the supplier to seek a resolution amicably. If necessary, involve a mediator or legal professional familiar with international trade laws. Document all communications and agreements, as this can provide crucial evidence if the dispute escalates to arbitration or legal proceedings. -

What are the risks associated with sourcing steel pipes from China?

Sourcing steel pipes from China involves several risks, including quality control issues, communication barriers, and potential delays in shipping. Currency fluctuations can also affect pricing. To mitigate these risks, conduct thorough research on suppliers, establish clear contracts, and maintain open lines of communication throughout the transaction. Utilizing third-party quality assurance services can help ensure that products meet your specifications before they are shipped.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for steel pipe china

What Are the Key Takeaways for International B2B Buyers in Steel Pipe Sourcing?

In summary, effective strategic sourcing in the steel pipe industry can significantly enhance supply chain efficiency, cost management, and product quality. International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, should prioritize establishing strong relationships with reliable suppliers in China. Leveraging China’s advanced manufacturing capabilities and competitive pricing structures can lead to significant cost savings and improved product availability.

How Can Buyers Prepare for Future Steel Pipe Procurement?

As the global market continues to evolve, it’s crucial for buyers to stay informed about industry trends, regulatory changes, and technological advancements. Engaging in market research and establishing clear communication channels with suppliers will empower buyers to make informed decisions and mitigate risks effectively.

What’s Next for B2B Buyers in the Steel Pipe Market?

Looking ahead, the demand for high-quality steel pipes is expected to rise, driven by infrastructure development and industrial expansion. International buyers should proactively explore partnerships with Chinese manufacturers to capitalize on this growth. By fostering strategic sourcing practices, buyers can enhance their competitive edge and ensure sustainable business success in the steel pipe market. Don’t miss out on the opportunities that lie ahead—take the next step in your sourcing strategy today!