Cut Costs: The Ultimate Guide to iPhone Charger China (2025)

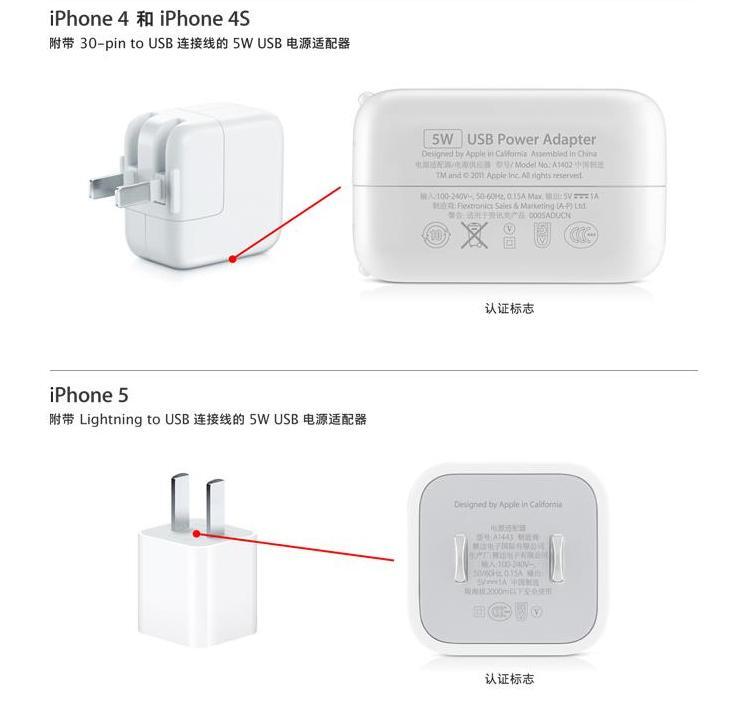

Introduction: Navigating the Global Market for iphone charger china

In today’s fast-paced digital landscape, sourcing high-quality iPhone chargers from China presents a unique challenge for international B2B buyers. With the vast array of suppliers and products available, making informed decisions is crucial to ensuring reliability, compliance, and cost-effectiveness. This comprehensive guide delves into the nuances of the Chinese market for iPhone chargers, covering essential aspects such as product types, applications, supplier vetting processes, and pricing strategies. By equipping buyers from Africa, South America, the Middle East, and Europe—particularly in regions like the UAE and Indonesia—with actionable insights, we aim to empower them in navigating this complex marketplace.

The global demand for mobile accessories continues to rise, and understanding how to effectively source iPhone chargers from China can significantly enhance your business operations. This guide not only addresses the key challenges faced by B2B buyers, such as quality assurance and compliance with international standards, but also highlights the importance of establishing strong supplier relationships. Whether you are a startup looking to enter the market or an established company seeking to optimize your supply chain, our insights will help you make strategic purchasing decisions that align with your business goals. Prepare to unlock the potential of the global market for iPhone chargers as we explore the essential elements of successful sourcing from China.

Understanding iphone charger china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard USB Charger | Basic design, usually 5V/1A output | Retail, bulk distribution | Pros: Cost-effective, widely available. Cons: Slower charging speeds. |

| Fast Charge Adapter | Supports higher voltage (up to 20W) | Electronics retailers, online sales | Pros: Faster charging, compatible with newer iPhones. Cons: Higher cost. |

| Wireless Charger | No cable needed, uses Qi technology | Modern tech retailers, gift shops | Pros: Convenience, reduces wear on charging ports. Cons: Slower than wired options. |

| Multi-port Charger | Multiple USB ports, often with various outputs | Corporate offices, shared spaces | Pros: Efficient for charging multiple devices. Cons: Bulkier design, may require more power. |

| Car Charger | Designed for use in vehicles, often with dual ports | Automotive accessories, travel retailers | Pros: Portable, convenient for on-the-go charging. Cons: Limited to vehicle use. |

What are the Characteristics of Standard USB Chargers?

Standard USB chargers are the most basic type of iPhone charger, typically providing a 5V/1A output. They are widely used in retail environments and bulk distribution channels due to their affordability and universal compatibility with many devices. B2B buyers should consider the volume of units needed, as purchasing in bulk can lead to significant cost savings. However, these chargers may not meet the charging speed requirements for newer iPhone models, which could be a drawback for businesses that prioritize efficiency.

Why Choose Fast Charge Adapters for Your Business?

Fast charge adapters are designed to deliver higher voltage outputs, often up to 20W, allowing for rapid charging of compatible devices. This type is particularly suitable for electronics retailers and online sales platforms, as they appeal to consumers looking for efficiency. B2B buyers should evaluate the compatibility of these chargers with their product offerings and consider their pricing strategy, as fast charge adapters typically come at a premium. While they provide significant advantages in charging speed, the higher cost may deter budget-conscious buyers.

What are the Advantages of Wireless Chargers?

Wireless chargers leverage Qi technology, allowing users to charge their devices without the need for cables. This type of charger is gaining popularity in modern tech retail and gift shops, appealing to consumers seeking convenience and a sleek design. B2B buyers should assess the market demand for wireless charging solutions, as they can enhance the customer experience. However, it’s important to note that wireless chargers generally offer slower charging speeds compared to wired options, which may affect customer satisfaction.

How Do Multi-port Chargers Benefit Businesses?

Multi-port chargers come equipped with several USB ports, allowing multiple devices to charge simultaneously. They are ideal for corporate offices and shared spaces where multiple employees may need to charge their devices at once. B2B buyers should consider the power requirements of these chargers, as they are often larger and may require more electrical capacity. While they provide a practical solution for high-traffic areas, their bulkier design could pose logistical challenges in terms of placement and organization.

When Should You Consider Car Chargers?

Car chargers are specifically designed for use in vehicles, often featuring dual ports for charging multiple devices on the go. They are suitable for automotive accessory suppliers and travel retailers, catering to consumers who prioritize convenience during commutes or road trips. B2B buyers should consider the demand for portable charging solutions in their target markets. However, these chargers are limited to vehicle use, which may restrict their appeal compared to more versatile charging options.

Related Video: Best MFi iPhone Charging Cables | Apple Certified Cables | What is MFi?

Key Industrial Applications of iphone charger china

| Industry/Sector | Specific Application of iPhone Charger China | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Consumer Electronics Retail | Bundling with Smartphones | Enhances customer satisfaction and brand loyalty | Quality assurance, certification, and price competitiveness |

| Hospitality and Travel | Charging Stations in Hotels and Airports | Improves guest experience and increases foot traffic | Durability, fast charging capabilities, and compliance |

| Education and Training | Charging Solutions for Tablets and Laptops | Supports learning environments and reduces downtime | Compatibility with multiple devices and safety standards |

| Telecommunications | Accessories for Mobile Device Retail | Increases sales of complementary products | Stock availability, variety of models, and supplier reliability |

| E-commerce and Online Retail | Direct Sales to Consumers | Expands market reach and enhances customer convenience | Logistics, shipping options, and product return policies |

How are iPhone Chargers Used in Consumer Electronics Retail?

In the consumer electronics retail sector, iPhone chargers sourced from China are often bundled with smartphones and other devices. This strategy not only enhances the overall customer experience but also fosters brand loyalty. Retailers benefit from increased sales and customer satisfaction by providing high-quality, reliable chargers that meet user expectations. International buyers should prioritize suppliers who offer certified products and can ensure quality assurance, as these factors are critical in maintaining brand reputation.

What is the Role of iPhone Chargers in Hospitality and Travel?

In the hospitality and travel industry, iPhone chargers are essential for creating charging stations in hotels and airports. These stations cater to the needs of guests, allowing them to recharge their devices while they wait or relax. This service significantly improves the guest experience and can lead to increased foot traffic and longer stays. Buyers in this sector must consider the durability and fast charging capabilities of the chargers, as well as compliance with local safety regulations to avoid liability issues.

How Do iPhone Chargers Support Education and Training?

In educational settings, iPhone chargers play a vital role in supporting tablets and laptops used in classrooms. They ensure that devices remain charged and ready for use, which is crucial for maintaining a productive learning environment. Reducing downtime caused by uncharged devices enhances the learning experience. B2B buyers in education should look for suppliers that provide chargers compatible with various devices and adhere to safety standards, ensuring that they meet the diverse needs of students and educators.

Why are iPhone Chargers Important in Telecommunications?

For telecommunications companies, iPhone chargers serve as essential accessories that complement mobile devices. Retailers can increase their sales by offering a range of chargers alongside smartphones, making it convenient for customers to purchase everything they need in one place. Key considerations for sourcing include stock availability and the variety of models offered, as well as the reliability of the supplier. Ensuring that chargers are compatible with multiple devices can also enhance customer satisfaction and drive sales.

A stock image related to iphone charger china.

What Benefits Do E-commerce Businesses Gain from iPhone Chargers?

In the e-commerce sector, selling iPhone chargers directly to consumers can significantly expand market reach. Offering a variety of chargers provides customers with convenience and can improve overall satisfaction. Businesses must consider logistics and shipping options when sourcing chargers from China, as timely delivery is crucial for maintaining customer trust. Additionally, clear product return policies can enhance customer confidence in purchasing, ultimately leading to increased sales and customer loyalty.

Related Video: Wireless Charger | Theory & Homemade Circuit

3 Common User Pain Points for ‘iphone charger china’ & Their Solutions

Scenario 1: Quality Assurance Challenges in Sourcing iPhone Chargers from China

The Problem: One of the most significant challenges faced by international B2B buyers, especially in regions like Africa and South America, is ensuring the quality of iPhone chargers sourced from China. Many suppliers may offer low prices, but this often comes at the expense of product quality. Buyers frequently encounter issues with chargers that do not meet safety standards, leading to device damage or, worse, safety hazards. This can result in costly returns, a tarnished reputation, and ultimately a loss of customer trust.

The Solution: To mitigate these quality assurance challenges, B2B buyers should implement a rigorous supplier vetting process. This includes requesting samples and conducting thorough quality checks before placing bulk orders. Utilizing third-party inspection services can also provide an unbiased assessment of the products. Additionally, establishing clear quality standards and contractual agreements with suppliers will ensure accountability. Buyers should prioritize suppliers that have certifications like ISO or relevant safety compliance marks. Regular communication and feedback can further enhance quality assurance throughout the sourcing process.

Scenario 2: Navigating Cultural and Communication Barriers in Supplier Relations

The Problem: Cultural and language differences can pose significant barriers for B2B buyers when negotiating with Chinese suppliers. Misunderstandings can arise during discussions about product specifications, pricing, and delivery timelines. This often leads to frustration and can jeopardize the relationship between the buyer and supplier, affecting order fulfillment and overall satisfaction.

The Solution: To overcome these challenges, B2B buyers should invest in cultural training or hire local intermediaries who understand both the Chinese market and the buyer’s needs. Using professional translation services during negotiations can also minimize misunderstandings. Establishing clear and concise communication through visual aids, such as diagrams or product prototypes, can help bridge any gaps. Regular updates and check-ins during the production process will foster a collaborative atmosphere and enhance mutual understanding, ensuring smoother transactions.

Scenario 3: Managing Supply Chain Risks and Delays

The Problem: Supply chain disruptions, such as shipping delays or unexpected tariffs, are prevalent in international sourcing, particularly for buyers in the Middle East and Europe. These disruptions can lead to stock shortages, affecting the buyer’s ability to meet customer demands and maintain market competitiveness. The volatility of global trade can leave buyers feeling vulnerable and uncertain about their supply chains.

The Solution: To effectively manage supply chain risks, B2B buyers should diversify their supplier base rather than relying on a single source. This strategy not only mitigates risks associated with individual suppliers but also provides leverage in negotiations. Implementing an effective supply chain management software can aid in tracking shipments, predicting delays, and maintaining optimal inventory levels. Buyers should also stay informed about geopolitical developments and trade regulations that may affect their sourcing strategy. Establishing strong relationships with logistics providers can further enhance supply chain resilience, ensuring timely delivery and service continuity.

By addressing these common pain points with actionable solutions, international B2B buyers can navigate the complexities of sourcing iPhone chargers from China more effectively, ultimately leading to better business outcomes.

Strategic Material Selection Guide for iphone charger china

When selecting materials for manufacturing iPhone chargers in China, international B2B buyers must consider various factors such as performance, compliance with standards, and cost-effectiveness. Below is an analysis of four common materials used in the production of iPhone chargers, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of PVC in iPhone Charger Manufacturing?

Polyvinyl Chloride (PVC) is one of the most widely used materials for the insulation of electrical cables, including iPhone chargers.

- Key Properties: PVC has excellent electrical insulation properties, good flexibility, and can withstand a temperature range of -10°C to 70°C. It is also resistant to corrosion and has a low flammability rating.

- Pros & Cons: The durability of PVC is high, making it suitable for everyday use. However, the manufacturing complexity can be moderate due to the need for additives to enhance its properties. The cost is relatively low, making it an attractive option for mass production.

- Impact on Application: PVC is compatible with various media, including water and oils, but may not be suitable for high-temperature applications.

- Considerations for International B2B Buyers: Buyers should ensure that PVC used complies with international standards such as RoHS and REACH, particularly in Europe, where regulations are stringent.

How Does TPE Compare as a Material for iPhone Chargers?

Thermoplastic Elastomer (TPE) is another material gaining popularity in the production of iPhone chargers.

- Key Properties: TPE offers excellent elasticity, flexibility, and resistance to UV light and ozone. It can operate effectively within a temperature range of -40°C to 120°C.

- Pros & Cons: TPE is durable and provides a soft-touch feel, enhancing user experience. However, it is generally more expensive than PVC and can complicate the manufacturing process due to its properties.

- Impact on Application: TPE’s compatibility with various media makes it suitable for outdoor applications where exposure to elements is a concern.

- Considerations for International B2B Buyers: Buyers from regions like the Middle East and Africa should consider the higher cost of TPE against its benefits, especially in markets sensitive to price.

What Are the Advantages of Using Silicone in iPhone Charger Production?

Silicone is increasingly favored for its superior properties in high-performance applications.

- Key Properties: Silicone can withstand extreme temperatures, ranging from -55°C to 300°C, and offers excellent electrical insulation and chemical resistance.

- Pros & Cons: The durability and flexibility of silicone make it ideal for long-lasting products. However, it is one of the most expensive materials, which may not be feasible for budget-conscious manufacturers.

- Impact on Application: Silicone’s high-temperature resistance makes it suitable for chargers used in high-performance environments or regions with extreme weather conditions.

- Considerations for International B2B Buyers: Buyers should verify compliance with ASTM and other relevant standards, particularly in Europe, where quality assurance is critical.

Why Is Polycarbonate a Good Choice for Charger Connectors?

Polycarbonate (PC) is often used for the housings and connectors of iPhone chargers.

- Key Properties: Polycarbonate offers high impact resistance, transparency, and a temperature tolerance of up to 120°C.

- Pros & Cons: Its durability makes it ideal for connectors that experience frequent handling. However, it can be more expensive than other plastics and may require specific manufacturing processes.

- Impact on Application: Polycarbonate is compatible with a wide range of environments and provides a robust solution for connectors that need to endure wear and tear.

- Considerations for International B2B Buyers: Compliance with safety standards like UL and IEC is essential, especially for buyers in Europe and the Middle East, where product safety is paramount.

Summary Table of Material Selection for iPhone Charger Manufacturing

| Material | Typical Use Case for iPhone Charger China | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Insulation for cables | Cost-effective and durable | Moderate manufacturing complexity | Low |

| TPE | Flexible outer casing | Excellent elasticity and feel | Higher cost and manufacturing complexity | Medium |

| Silicone | High-performance applications | Extreme temperature resistance | High cost | High |

| Polycarbonate | Housings and connectors | High impact resistance | More expensive and specific processes | Medium |

This guide provides a comprehensive overview of material selection for iPhone chargers manufactured in China, offering actionable insights for international B2B buyers. By understanding the properties and implications of each material, buyers can make informed decisions that align with their operational needs and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for iphone charger china

What Are the Key Stages of Manufacturing iPhone Chargers in China?

When sourcing iPhone chargers from China, understanding the manufacturing process is crucial for B2B buyers. The production typically involves several key stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step involves sourcing high-quality raw materials, such as copper wire, plastics, and silicon. Suppliers often conduct rigorous inspections of incoming materials to ensure they meet specified standards. B2B buyers should inquire about the suppliers’ material certifications and traceability.

-

Forming: In this stage, materials are shaped into components. Techniques such as injection molding for plastic parts and stamping for metal components are commonly used. Advanced machinery and molds are employed to ensure precision and reduce waste. Buyers should ask about the technology used and the potential for customization.

-

Assembly: This phase involves the integration of various components into the final product. Automated assembly lines are prevalent, but manual assembly may be used for intricate parts. Quality control is crucial during this stage to ensure that every charger functions correctly. B2B buyers should verify the assembly processes and the workforce’s training and expertise.

-

Finishing: The last stage includes testing, packaging, and labeling. Chargers undergo thorough testing for safety and performance, ensuring they meet international standards. Buyers should review the packaging standards and branding options available.

How Is Quality Assurance Implemented in iPhone Charger Manufacturing?

Quality assurance (QA) is vital in the manufacturing of iPhone chargers, as it ensures that products meet both safety and performance standards.

-

International Standards: Manufacturers often comply with international quality standards, such as ISO 9001, which outlines criteria for a quality management system. Additional certifications like CE mark (for compliance with European health, safety, and environmental protection standards) and RoHS (Restriction of Hazardous Substances) are also essential for chargers. B2B buyers from Europe, Africa, and the Middle East should ensure that their suppliers are certified and compliant with these standards.

-

Quality Control Checkpoints: Quality control is structured around several critical checkpoints:

– Incoming Quality Control (IQC): At this stage, raw materials are inspected before production begins.

– In-Process Quality Control (IPQC): This involves monitoring the manufacturing process to detect any defects early.

– Final Quality Control (FQC): After assembly, the finished products undergo comprehensive testing to ensure they meet the required specifications. -

Common Testing Methods: Various testing methods are employed, including:

– Electrical Testing: Ensuring the charger meets voltage and current specifications.

– Safety Testing: Checking for short circuits and overheating.

– Environmental Testing: Assessing the charger’s durability under different conditions, such as temperature and humidity.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, verifying the quality control practices of suppliers is essential to ensure product reliability and compliance.

-

Supplier Audits: Conducting regular audits of potential suppliers allows buyers to assess the manufacturing processes and quality control measures firsthand. This can include reviewing documentation, observing production lines, and interviewing quality assurance staff.

-

Quality Reports: Requesting detailed quality assurance reports can provide insights into the supplier’s quality management practices. These reports should include information on defect rates, testing outcomes, and corrective actions taken for any issues encountered.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturing processes and product quality. This is particularly important for buyers from regions like Africa and South America, where establishing local supplier relationships may pose challenges.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various quality control nuances when sourcing iPhone chargers from China.

-

Cultural Differences: Understanding cultural differences in business practices is crucial. Communication styles, expectations regarding quality, and negotiation tactics can vary widely. B2B buyers should invest time in building relationships with suppliers to facilitate smoother transactions.

-

Regulatory Compliance: Different regions have varying regulations regarding electronic products. Buyers from Europe must ensure compliance with EU directives, while those in the Middle East may need to adhere to local standards. It’s essential to discuss these requirements with suppliers early in the negotiation process.

-

Supply Chain Transparency: Buyers should prioritize suppliers who provide transparency in their supply chain practices. This includes clear documentation of sourcing materials, production processes, and certifications. A transparent supply chain minimizes risks associated with quality and compliance issues.

Conclusion: Ensuring Quality and Reliability in iPhone Charger Sourcing

In summary, B2B buyers looking to source iPhone chargers from China should have a comprehensive understanding of the manufacturing processes and quality assurance practices. By focusing on the key stages of production, verifying quality control measures, and being aware of international standards and nuances, buyers can make informed decisions that lead to successful partnerships with suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘iphone charger china’

Introduction

Sourcing iPhone chargers from China can be a lucrative opportunity for international B2B buyers, especially those from Africa, South America, the Middle East, and Europe. This guide provides a step-by-step checklist to streamline the procurement process, ensuring you find reliable suppliers and high-quality products at competitive prices.

Step 1: Define Your Technical Specifications

Clearly outline the specifications for the iPhone chargers you need. This includes voltage, current ratings, compatibility with various iPhone models, and safety certifications (like CE, FCC, or UL). Defining these parameters upfront helps you communicate your requirements effectively to potential suppliers and reduces the risk of receiving substandard products.

Step 2: Conduct Market Research

Investigate the current market landscape for iPhone chargers in China. Look into trends, pricing, and the availability of different charger types (e.g., wired vs. wireless). Understanding market dynamics will help you negotiate better prices and identify reliable suppliers who can meet your demand.

Step 3: ✅ Verify Supplier Certifications

Before engaging with suppliers, ensure they have the necessary certifications for exporting electronic products. Key certifications to look for include ISO 9001 for quality management systems and specific product safety certifications relevant to your target market. This step is crucial for ensuring that the products meet international safety and quality standards.

Step 4: Request Samples

Always request samples before placing a bulk order. This allows you to assess the quality, performance, and compatibility of the chargers with your specifications. Evaluate the samples thoroughly, checking for durability, charging speed, and any potential defects.

Step 5: Evaluate Potential Suppliers

Conduct a thorough evaluation of potential suppliers. Request detailed company profiles, including their production capacity, quality control processes, and previous client references. Look for suppliers with a proven track record in the electronics sector and positive feedback from buyers in similar markets.

Step 6: Negotiate Terms and Pricing

Once you have shortlisted potential suppliers, begin negotiations on pricing, payment terms, and delivery timelines. Be clear about your budget and any bulk order discounts you expect. Effective negotiation can significantly impact your overall procurement costs.

Step 7: Establish a Quality Assurance Process

Implement a quality assurance process to monitor product quality during manufacturing and before shipment. This may include third-party inspections or setting up specific quality benchmarks that suppliers must meet. A robust QA process helps mitigate risks related to product defects and ensures compliance with your specifications.

A stock image related to iphone charger china.

By following this checklist, B2B buyers can navigate the complexities of sourcing iPhone chargers from China more efficiently, leading to successful procurement outcomes and long-term supplier relationships.

Comprehensive Cost and Pricing Analysis for iphone charger china Sourcing

What Are the Key Cost Components for Sourcing iPhone Chargers from China?

When sourcing iPhone chargers from China, understanding the comprehensive cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The cost of raw materials, such as copper for wiring and plastics for casing, significantly impacts the overall pricing. Prices can fluctuate based on global supply chain conditions and market demand.

-

Labor: Labor costs in China are generally lower than in many Western countries. However, it’s essential to consider the skill level required for the production of high-quality chargers, as this can vary across different manufacturers.

-

Manufacturing Overhead: This includes utilities, equipment maintenance, and factory rental costs. Efficient factories often have lower overhead costs, which can be a deciding factor in pricing.

-

Tooling: Initial costs for molds and tools can be substantial, especially for customized charger designs. Understanding the tooling costs is vital for calculating the total investment needed for a specific order.

-

Quality Control (QC): Implementing stringent QC measures ensures the chargers meet required safety and performance standards. The investment in QC can influence the final price, but it is essential for maintaining brand reputation.

-

Logistics: Transportation costs, including shipping fees and insurance, must be factored into the overall cost. Incoterms will define who bears these costs, impacting the total price you pay.

-

Margin: Manufacturers typically add a profit margin to cover their risks and operational costs. This can vary based on the supplier’s reputation and the volume of the order.

How Do Price Influencers Affect the Cost of iPhone Chargers?

Several factors can influence the pricing of iPhone chargers sourced from China:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to lower unit prices due to economies of scale. Understanding a supplier’s MOQ can help in negotiating better pricing.

-

Specifications and Customization: Customized chargers, such as those with unique branding or specific technical requirements, can increase costs. Clear specifications can help avoid unnecessary expenses.

-

Materials and Quality Certifications: Chargers made with higher-quality materials or those that meet specific international standards (like CE, FCC, or RoHS) may command a higher price. Buyers should assess the value of these certifications against their market needs.

-

Supplier Factors: The reputation and reliability of the supplier can also affect pricing. Established suppliers with a track record of quality and timely delivery may charge more but reduce overall risk.

-

Incoterms: The agreed-upon Incoterms can significantly impact the final cost. For instance, DDP (Delivered Duty Paid) may include additional fees that could affect your budgeting.

What Buyer Tips Can Help with Cost-Efficiency in iPhone Charger Sourcing?

To maximize cost-efficiency when sourcing iPhone chargers from China, consider the following actionable tips:

-

Negotiate Wisely: Always engage in negotiations with suppliers. Understanding the cost structure can provide leverage. Aim for a balance between price and quality to ensure sustainable sourcing.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider shipping, duties, and potential warranty claims. A lower upfront cost may lead to higher overall expenses if quality issues arise.

-

Explore Multiple Suppliers: Comparing quotes from various suppliers can provide insights into market rates and help identify the best offers. Be wary of prices that seem too low, as they might indicate compromised quality.

-

Stay Informed on Market Trends: Keep abreast of trends in raw material prices, labor costs, and international shipping rates. This information can aid in timing your orders to achieve the best pricing.

-

Understand Pricing Nuances for Your Region: International buyers from Africa, South America, the Middle East, and Europe should be aware of region-specific factors, such as import tariffs and regulations, which can influence overall costs.

Disclaimer on Indicative Prices

Prices for iPhone chargers sourced from China can vary widely based on market conditions, order specifications, and supplier negotiations. Always conduct thorough research and due diligence when estimating costs to ensure accurate budgeting and financial planning.

Alternatives Analysis: Comparing iphone charger china With Other Solutions

Understanding the Importance of Alternative Solutions in Charger Procurement

In the rapidly evolving technology landscape, international B2B buyers must assess various charging solutions to meet their operational needs effectively. While the iPhone charger manufactured in China is a popular choice due to its compatibility and cost-effectiveness, it is essential to explore alternative charging technologies that may offer distinct advantages. This analysis will compare the iPhone charger from China with two viable alternatives: the USB-C charger and the wireless charging solution.

Comparison Table: Key Aspects of Charging Solutions

| Comparison Aspect | Iphone Charger China | USB-C Charger | Wireless Charging Solution |

|---|---|---|---|

| Performance | High compatibility with Apple devices | Versatile, supports multiple devices | Convenient but slower charging speeds |

| Cost | Generally low cost | Moderate cost | Higher initial investment |

| Ease of Implementation | Simple and widely available | Requires compatible devices | Installation may be complex |

| Maintenance | Low maintenance | Low maintenance | Potential for wear on coils |

| Best Use Case | Ideal for Apple users | Suitable for mixed-device environments | Best for mobility and convenience |

Detailed Breakdown of Each Alternative

What are the Advantages and Disadvantages of the USB-C Charger?

The USB-C charger is becoming increasingly popular due to its versatility. It supports a wide range of devices beyond Apple products, making it an excellent choice for businesses with diverse technology ecosystems. The moderate cost associated with USB-C chargers makes them accessible, although they may not always be as affordable as the iPhone charger from China. The ease of implementation is relatively high, provided that devices are USB-C compatible. However, businesses must consider that not all devices support this technology, which could lead to additional costs for adapters.

How Does Wireless Charging Compare to Traditional Chargers?

Wireless charging solutions offer unparalleled convenience, especially in environments where multiple users need to charge devices without the hassle of cables. While they tend to have a higher initial investment, the potential for a more organized workspace can justify this cost. However, wireless chargers may have slower charging speeds compared to traditional chargers, which could be a disadvantage for time-sensitive operations. Maintenance is generally low, but wear and tear on charging coils could lead to performance issues over time. This solution is best suited for businesses prioritizing mobility and ease of use.

How Should B2B Buyers Choose the Right Charging Solution?

When selecting a charging solution, B2B buyers must align their choice with their specific operational requirements. If the primary user base consists of Apple device owners, the iPhone charger from China may be the most cost-effective and straightforward option. However, for organizations with a diverse range of devices, investing in USB-C chargers could enhance compatibility and streamline operations. Wireless charging solutions are ideal for dynamic environments where mobility and convenience are paramount, although buyers should weigh the trade-offs in charging speed and installation complexity. By thoroughly evaluating these aspects, international B2B buyers can make informed decisions that support their business objectives and enhance productivity.

Essential Technical Properties and Trade Terminology for iphone charger china

What Are the Key Technical Properties of iPhone Chargers from China?

When sourcing iPhone chargers from China, it is vital to understand several technical properties that can significantly impact product quality, compliance, and overall performance. Here are some critical specifications to consider:

-

Material Grade

– Definition: This refers to the type of materials used in manufacturing the charger, including plastics, metals, and internal components like wires and circuit boards.

– Importance: High-grade materials ensure durability, safety, and compliance with international standards. Buyers should look for certifications like RoHS (Restriction of Hazardous Substances) to ensure materials are safe and environmentally friendly. -

Output Voltage and Current Rating

– Definition: This specification indicates the voltage and current that the charger can deliver, typically measured in volts (V) and amperes (A).

– Importance: Understanding these ratings is essential for compatibility with various devices. An output of 5V/1A is standard for basic chargers, while fast chargers may offer higher ratings. Ensuring compatibility can prevent device damage and improve customer satisfaction. -

Charging Speed (Fast Charging Capability)

– Definition: This property measures how quickly a charger can power a device, often indicated by technologies like Quick Charge or Power Delivery.

– Importance: Fast charging is a key selling point for consumers. B2B buyers should prioritize chargers that support these technologies to meet market demands and enhance user experience. -

Safety Certifications

– Definition: These are standards that indicate a product has been tested for safety and compliance, including UL, CE, and FCC certifications.

– Importance: Safety certifications are crucial for market acceptance and legal compliance. Buyers should ensure that their suppliers provide these certifications to avoid potential liabilities and ensure product safety. -

Tolerances

– Definition: Tolerances refer to the allowable variations in the dimensions and performance specifications of the charger components.

– Importance: Tight tolerances can indicate higher quality and reliability. In B2B transactions, understanding tolerances can help buyers assess the manufacturing capabilities of suppliers and negotiate quality assurance terms effectively.

What Are Common Trade Terms Used in Sourcing iPhone Chargers?

Navigating the landscape of international trade can be challenging, especially when dealing with technical products like chargers. Familiarizing yourself with common trade terminology can streamline the sourcing process:

-

OEM (Original Equipment Manufacturer)

– Definition: This term refers to companies that manufacture products based on the designs and specifications provided by another company.

– Importance: Knowing whether a supplier operates as an OEM can help buyers secure customized products that meet specific requirements, enhancing brand differentiation. -

MOQ (Minimum Order Quantity)

– Definition: MOQ is the smallest quantity of a product that a supplier is willing to sell.

– Importance: Understanding MOQ is crucial for budget management. Buyers should negotiate MOQs that align with their sales forecasts to avoid excess inventory or stock shortages. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document sent to suppliers requesting pricing and terms for specific products.

– Importance: Utilizing RFQs can help buyers compare costs and terms across multiple suppliers, enabling informed purchasing decisions and potential cost savings. -

Incoterms (International Commercial Terms)

– Definition: These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions.

– Importance: Familiarity with Incoterms (e.g., FOB, CIF) helps buyers understand shipping costs, risk responsibilities, and delivery terms, ensuring clarity in contracts and negotiations. -

Lead Time

– Definition: This term refers to the amount of time it takes from placing an order to receiving the product.

– Importance: Understanding lead times is essential for inventory planning and customer fulfillment. Buyers should clarify lead times with suppliers to align with their operational needs.

By grasping these technical properties and trade terminologies, international B2B buyers can make informed decisions when sourcing iPhone chargers from China, ultimately enhancing their product offerings and market competitiveness.

Navigating Market Dynamics and Sourcing Trends in the iphone charger china Sector

What Are the Current Market Dynamics in the iPhone Charger China Sector?

The iPhone charger sector in China is experiencing rapid transformation driven by several global factors. Increasing smartphone penetration and the growing demand for fast-charging technology are key drivers propelling market growth. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of the shift towards higher-quality, certified products. Emerging trends include the adoption of USB-C charging standards, which align with global regulatory changes and consumer preferences for universal compatibility.

Moreover, the trend towards smart technology integration in charging devices, such as chargers that can communicate with devices for optimized charging, is gaining traction. Buyers should look for suppliers who are not only responsive to these trends but are also capable of innovating in design and functionality. The competitive landscape is intensifying, with both established manufacturers and new entrants vying for market share. Therefore, conducting thorough supplier evaluations based on technology capabilities, compliance with international standards, and production scalability is crucial for B2B buyers.

How Important Is Sustainability and Ethical Sourcing in the iPhone Charger Sector?

Sustainability and ethical sourcing have become pivotal in the iPhone charger market, as consumers and businesses alike are increasingly prioritizing environmental responsibility. The production of electronic accessories, including chargers, has significant environmental impacts, from resource extraction to manufacturing processes. Buyers from international markets should emphasize sourcing from manufacturers that adhere to sustainable practices and possess relevant certifications, such as ISO 14001 for environmental management.

Furthermore, the demand for ‘green’ materials is on the rise. Buyers should consider suppliers who utilize recyclable materials and eco-friendly manufacturing processes. This not only helps in reducing carbon footprints but also positions businesses favorably in the eyes of consumers who are increasingly making purchasing decisions based on environmental impact. Engaging with suppliers who demonstrate transparency in their supply chains and compliance with ethical labor practices is essential for fostering long-term partnerships and enhancing brand reputation.

What Is the Evolution of the iPhone Charger Market in China?

The evolution of the iPhone charger market in China can be traced back to the early days of smartphone adoption. Initially, the focus was primarily on basic charging capabilities. However, as smartphones became central to daily life, the demand for advanced charging solutions surged. This evolution saw the introduction of faster charging technologies and the shift from traditional USB to USB-C connectors, driven by Apple and other manufacturers aiming for standardization.

Today, the market is characterized by innovation, with features such as wireless charging and smart technology integration becoming mainstream. This historical context is essential for B2B buyers as it highlights the importance of staying abreast of technological advancements and understanding the competitive landscape. Buyers should leverage this knowledge to make informed decisions when selecting suppliers and products that align with current market demands and future trends.

Frequently Asked Questions (FAQs) for B2B Buyers of iphone charger china

-

How do I verify the quality of iPhone chargers sourced from China?

To ensure the quality of iPhone chargers from Chinese suppliers, request samples before placing a bulk order. Check for certifications such as CE, FCC, and RoHS to confirm compliance with international standards. Additionally, consider hiring a third-party inspection service to conduct quality checks before shipping. Establishing a quality assurance agreement with your supplier can also help in maintaining consistent product standards. -

What is the minimum order quantity (MOQ) for iPhone chargers from China?

MOQs can vary significantly depending on the manufacturer and the type of charger. Typically, Chinese suppliers may set MOQs ranging from 100 to 1,000 units. For customized designs, the MOQ might be higher. It is advisable to communicate your needs clearly with potential suppliers to negotiate favorable terms, especially if you are a smaller business looking to enter the market. -

What payment terms should I consider when purchasing iPhone chargers from China?

Common payment terms include a 30% deposit upfront and a 70% balance before shipment. Some suppliers may offer letters of credit or escrow services for added security. It is essential to understand the payment options available and choose one that minimizes risk while ensuring a smooth transaction process. Always use secure payment methods to protect your investment. -

How can I customize my iPhone chargers sourced from China?

Customizing iPhone chargers typically involves selecting specific colors, designs, and branding elements. Discuss your requirements with potential suppliers to understand their capabilities and design processes. Most manufacturers will require a minimum order quantity for custom designs. Be prepared to provide design files and specifications to facilitate the customization process. -

What logistics considerations should I be aware of when importing iPhone chargers from China?

When importing from China, consider shipping methods such as air freight for speed or sea freight for cost-effectiveness. Understand the customs regulations and tariffs applicable in your country to avoid unexpected charges. Collaborating with a reliable freight forwarder can help streamline the logistics process, ensuring timely delivery and compliance with local laws. -

How do I choose the right supplier for iPhone chargers in China?

To select the right supplier, conduct thorough research, including checking online reviews and ratings on platforms like Alibaba or Global Sources. Request references from previous clients and assess their responsiveness and communication skills. Visiting the factory, if possible, can provide valuable insights into their production capabilities and quality control processes. -

What are the common certifications required for iPhone chargers in international markets?

Most international markets require certifications such as CE (Europe), FCC (USA), and RoHS compliance to ensure safety and environmental standards. Before placing an order, verify that the supplier can provide these certifications. This not only enhances product credibility but also helps in avoiding legal issues during customs clearance. -

What should I do if I encounter issues with my iPhone charger order?

If you face issues such as defective products or delays, promptly communicate with your supplier to seek a resolution. Document all communications and keep records of agreements. If the problem persists, consider involving a dispute resolution service or an international trade attorney to protect your interests. Understanding your rights and the terms of your contract is crucial for resolving disputes effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for iphone charger china

In the competitive landscape of global electronics, strategic sourcing for iPhone chargers from China presents substantial opportunities for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. Leveraging China’s robust manufacturing capabilities can lead to cost savings and access to innovative technology, which is crucial for maintaining a competitive edge. Buyers must prioritize supplier reliability, compliance with international standards, and the capacity for scalability to meet fluctuating demands.

What are the key takeaways for successful sourcing of iPhone chargers from China? First, it’s essential to conduct thorough market research to identify reputable suppliers with a proven track record. Establishing strong relationships with manufacturers can lead to better pricing and more favorable terms. Additionally, understanding the regulatory landscape and import/export requirements will facilitate smoother transactions and mitigate risks.

Looking ahead, the demand for high-quality, affordable charging solutions will only grow. International buyers should remain proactive in exploring partnerships with Chinese suppliers, adapting to emerging technologies, and aligning with sustainability practices. By doing so, businesses can position themselves to capitalize on the evolving market trends and ensure long-term success in the global arena.