Cut Costs with Carbide Inserts from China: The Ultimate Guide (2025)

Introduction: Navigating the Global Market for carbide inserts china

In today’s competitive manufacturing landscape, sourcing high-quality carbide inserts from China can present significant challenges for international B2B buyers. The rapid evolution of global supply chains, coupled with fluctuating market demands, necessitates a strategic approach to procurement. This guide on carbide inserts from China delves into essential aspects such as types, applications, supplier vetting processes, and cost considerations. By understanding these critical factors, businesses from Africa, South America, the Middle East, and Europe—particularly in regions like Indonesia and Saudi Arabia—can make informed purchasing decisions that enhance operational efficiency and product quality.

Navigating the global market for carbide inserts requires not only knowledge of the product itself but also an awareness of the broader economic and logistical context. This comprehensive guide aims to empower B2B buyers by offering insights into selecting the right types of carbide inserts for specific applications, understanding the nuances of supplier relationships, and evaluating pricing structures. Additionally, we will provide practical tips for mitigating risks associated with international sourcing, ensuring that your investments yield maximum returns.

By leveraging the information in this guide, international buyers can enhance their competitive edge, streamline their supply chain operations, and ultimately drive growth in their respective industries. Prepare to navigate the complexities of the global market with confidence and clarity.

Understanding carbide inserts china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Carbide Turning Inserts | High wear resistance, sharp edges, various shapes | Lathe machining, finishing operations | Pros: Excellent surface finish; Cons: Higher cost than HSS. |

| Carbide Milling Inserts | Designed for high-speed applications, various geometries | Face milling, slotting, contouring | Pros: Versatile; Cons: May require specific tooling. |

| Carbide Boring Inserts | Specialized for internal machining, precision cutting | Boring holes, internal features | Pros: High precision; Cons: Limited to specific applications. |

| Carbide Grooving Inserts | Unique shapes for creating grooves, notches | Grooving, parting off operations | Pros: Efficient for narrow cuts; Cons: Fragile for heavy-duty tasks. |

| Carbide Insert Grades | Different compositions for various hardness levels | General machining, specialized applications | Pros: Tailored for specific materials; Cons: Complexity in selection. |

What Are Carbide Turning Inserts and When Should They Be Used?

Carbide turning inserts are designed for lathe machining and finishing operations. Their high wear resistance and sharp edges enable them to produce excellent surface finishes, making them ideal for precision components in industries such as automotive and aerospace. When purchasing, B2B buyers should consider the insert geometry and cutting parameters, as these can significantly impact machining efficiency and tool life.

How Do Carbide Milling Inserts Enhance Machining Processes?

Carbide milling inserts are crucial for high-speed applications and come in various geometries to suit different milling tasks. They are commonly used in face milling, slotting, and contouring operations. Buyers should evaluate the versatility of these inserts and ensure that they are compatible with their existing tooling systems. The ability to handle a wide range of materials is a key advantage, but the potential need for specific tooling can be a drawback.

Why Are Carbide Boring Inserts Essential for Precision Work?

Carbide boring inserts are specialized for internal machining tasks, providing high precision for boring holes and internal features. Their design allows for exceptional accuracy, making them suitable for applications in industries requiring tight tolerances. Buyers should focus on the insert’s compatibility with their boring tools and the specific internal dimensions they need to machine. While they offer precision, their use is limited to specific applications, which can restrict their versatility.

What Applications Benefit from Carbide Grooving Inserts?

Carbide grooving inserts are uniquely shaped to create grooves and notches in workpieces. They excel in grooving and parting-off operations, making them efficient for narrow cuts in materials like steel and aluminum. However, their fragility can be a concern for heavy-duty tasks. B2B buyers should assess the intended application and ensure that the insert’s design aligns with the required cutting depth and width, as this will influence machining performance.

How Do Carbide Insert Grades Affect Material Selection?

Carbide insert grades vary in composition, offering different hardness levels tailored for specific materials and applications. This variation allows B2B buyers to select inserts based on the material being machined—be it steel, cast iron, or non-ferrous metals. While this customization can enhance machining efficiency and tool life, the complexity in selecting the right grade can be challenging. Buyers should invest time in understanding the material properties and the corresponding insert grades to optimize their machining processes effectively.

Related Video: MGMN Carbide inserts manufacturer in China

Key Industrial Applications of carbide inserts china

| Industry/Sector | Specific Application of carbide inserts china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Precision machining of engine components | Enhanced durability and precision, reducing rework costs | Quality certifications, supplier reliability, and lead times |

| Aerospace | Cutting tools for turbine manufacturing | Improved cutting efficiency and safety | Compliance with international standards, material traceability |

| Oil & Gas | Drilling and milling operations | Increased productivity and reduced downtime | Performance specifications, local regulations, and logistics |

| Metalworking | Tooling for CNC machining | Higher material removal rates and extended tool life | Tool geometry, coating options, and customization abilities |

| Construction | Fabrication of heavy machinery parts | Cost-effective manufacturing with high wear resistance | Bulk purchasing options, delivery timelines, and payment terms |

How Are Carbide Inserts Used in Automotive Manufacturing?

In the automotive sector, carbide inserts from China are primarily employed in the precision machining of engine components. These inserts are designed to withstand the high stresses involved in machining hard metals, thus ensuring precise dimensions and surface finishes. For international buyers, particularly those in Africa and South America, sourcing carbide inserts that meet specific quality certifications is crucial to minimize production delays and ensure product reliability. Additionally, understanding the supplier’s production capabilities and lead times is essential to maintain a smooth supply chain.

What Role Do Carbide Inserts Play in Aerospace Applications?

In the aerospace industry, carbide inserts are critical for cutting tools used in turbine manufacturing. These inserts facilitate efficient material removal while maintaining high safety standards, which is paramount in this sector. Buyers from the Middle East and Europe should prioritize suppliers who can provide detailed documentation on compliance with international aerospace standards. Material traceability and quality assurance processes are also vital considerations to ensure that the inserts perform reliably under extreme conditions.

How Are Carbide Inserts Essential in Oil & Gas Operations?

Carbide inserts are extensively used in drilling and milling operations within the oil and gas industry. Their ability to withstand abrasive materials significantly enhances productivity while minimizing equipment downtime. B2B buyers from regions like Saudi Arabia and South America must focus on the performance specifications of these inserts, ensuring they are suited for the specific geological conditions encountered in their operations. Furthermore, understanding local regulations regarding material usage can streamline the procurement process.

Why Are Carbide Inserts Important for Metalworking?

In metalworking, carbide inserts are employed in CNC machining processes to achieve higher material removal rates and extended tool life. This leads to significant cost savings and improved efficiency for manufacturers. International buyers should consider the geometry and coating options of the carbide inserts, as these factors can greatly influence performance. Customization capabilities from suppliers can also enhance the fit for specific applications, making it essential to communicate requirements clearly.

How Do Carbide Inserts Benefit the Construction Sector?

In the construction industry, carbide inserts are crucial for the fabrication of heavy machinery parts. Their high wear resistance makes them ideal for demanding environments, allowing for cost-effective manufacturing. For buyers in Europe and Africa, exploring bulk purchasing options can lead to better pricing and more favorable payment terms. Additionally, ensuring timely delivery from suppliers is vital to avoid project delays, highlighting the importance of strong supplier relationships.

Related Video: How carbide inserts are made by Sandvik Coromant

3 Common User Pain Points for ‘carbide inserts china’ & Their Solutions

Scenario 1: Sourcing Quality Carbide Inserts from China

The Problem: B2B buyers often struggle with sourcing high-quality carbide inserts from China due to the overwhelming number of suppliers available. Many buyers report receiving substandard products that do not meet their specifications, leading to operational delays and increased costs. This issue is particularly prevalent for companies in Africa and South America, where reliable supplier relationships are crucial but harder to establish. Furthermore, language barriers and varying quality standards can complicate communication, making it difficult to ensure product quality and consistency.

The Solution: To mitigate these challenges, buyers should implement a robust supplier vetting process. Start by researching potential suppliers through platforms like Alibaba or Global Sources, paying close attention to supplier ratings and reviews. Request samples before placing bulk orders to evaluate the quality firsthand. Additionally, consider engaging third-party quality assurance services that can inspect products before shipment. Establishing clear specifications and expectations in your communications can also prevent misunderstandings and ensure that you receive products that meet your standards. Building long-term relationships with reputable suppliers can lead to better pricing and reliability over time.

Scenario 2: Understanding Carbide Insert Specifications and Grades

The Problem: Many international buyers, especially from the Middle East and Europe, face difficulties in understanding the various specifications and grades of carbide inserts available in the market. This lack of knowledge can lead to the selection of the wrong inserts for specific applications, resulting in poor machining performance, increased wear, and ultimately, higher operational costs. Buyers may also find it challenging to navigate the technical jargon and standards used in different regions, complicating their purchasing decisions.

The Solution: To address this issue, buyers should invest time in educating themselves about the different grades and specifications of carbide inserts. Engage with suppliers to obtain detailed product catalogs and technical data sheets that explain the properties and applications of each insert type. Utilize online resources, such as industry webinars and training sessions, to enhance your understanding of tooling materials. Collaborating with experienced machinists or engineers within your organization can also provide insights into which inserts are best suited for specific tasks. When in doubt, don’t hesitate to ask suppliers for recommendations based on your unique operational requirements.

Scenario 3: Managing Lead Times and Delivery Challenges

The Problem: A frequent concern among B2B buyers dealing with carbide inserts from China is the unpredictability of lead times and delivery schedules. Factors such as shipping delays, customs clearance issues, and production backlogs can significantly affect supply chain efficiency, particularly for companies in regions like Africa and South America where logistics infrastructure may be less developed. This unpredictability can lead to production downtime and missed deadlines, adversely impacting business operations.

The Solution: To better manage lead times, buyers should establish clear timelines with suppliers at the outset of negotiations. Incorporate buffer periods into your project schedules to account for potential delays. Utilize freight forwarders who specialize in international shipping to facilitate smoother logistics processes and customs clearance. Regular communication with suppliers regarding production status can also help you anticipate delays and adjust your plans accordingly. Additionally, consider diversifying your supplier base by identifying multiple sources for carbide inserts to avoid reliance on a single supplier, thereby minimizing risk in your supply chain.

Strategic Material Selection Guide for carbide inserts china

When selecting carbide inserts from China, understanding the material composition is crucial for optimizing performance and ensuring compatibility with specific applications. Below, we analyze several common materials used in the production of carbide inserts, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Tungsten Carbide Inserts?

Tungsten carbide is one of the most widely used materials for carbide inserts due to its exceptional hardness and wear resistance. It can withstand high temperatures, typically up to 1,000°C, and offers excellent performance under high-pressure conditions. Additionally, tungsten carbide exhibits good corrosion resistance, making it suitable for various machining applications.

Pros & Cons: The durability of tungsten carbide inserts is a significant advantage, allowing for longer tool life and reduced downtime. However, they can be more expensive than other materials, and their brittleness may lead to chipping under excessive impact. The manufacturing complexity can also increase costs and lead times.

Impact on Application: Tungsten carbide inserts are particularly effective in machining hard metals and alloys, making them ideal for industries like aerospace and automotive. Buyers should ensure compliance with international standards such as ASTM and DIN, particularly when sourcing from China.

How Does Cermet Compare as a Material for Inserts?

Cermet, a composite of ceramic and metallic materials, is another option for carbide inserts. Cermet inserts are known for their high-temperature resistance and lower thermal expansion, which helps maintain dimensional stability during machining.

Pros & Cons: The key advantage of cermet inserts is their ability to provide a superior finish on workpieces due to their fine grain structure. However, they are generally less durable than tungsten carbide and can wear out faster in heavy-duty applications. Their cost is typically medium, making them a balance between performance and affordability.

Impact on Application: Cermet inserts are best suited for finishing operations on softer materials, such as aluminum and brass. International buyers should consider the specific machining requirements and ensure that the suppliers adhere to relevant quality standards.

What Are the Benefits of Using Coated Carbide Inserts?

Coated carbide inserts, often made from tungsten carbide and coated with materials like titanium nitride (TiN) or titanium carbonitride (TiCN), enhance the performance of the base material. The coatings improve hardness and reduce friction, allowing for higher cutting speeds and better wear resistance.

Pros & Cons: The primary advantage of coated inserts is their ability to extend tool life and improve machining efficiency. However, the coating can add to the overall cost, and improper handling may lead to damage. The complexity of the coating process may also affect lead times.

Impact on Application: Coated carbide inserts are versatile and can be used across various materials, including steel, cast iron, and some non-ferrous metals. Buyers from regions like the Middle East and Europe should ensure that the coatings meet their specific operational needs and comply with local regulations.

Why Consider High-Speed Steel Inserts?

High-speed steel (HSS) inserts are less common than carbide options but are still relevant for specific applications. HSS can operate effectively at high speeds and temperatures, making it suitable for drilling and milling operations.

Pros & Cons: The main advantage of HSS inserts is their lower cost compared to carbide options, making them an economical choice for less demanding applications. However, they lack the hardness and wear resistance of carbide, which may limit their use in high-performance settings.

Impact on Application: HSS inserts are often used in lower-speed machining operations and are compatible with softer materials. Buyers should evaluate their application requirements and consider the trade-offs between cost and performance.

Summary Table of Material Selection for Carbide Inserts

| Material | Typical Use Case for carbide inserts china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Tungsten Carbide | Machining hard metals and alloys | Exceptional hardness and durability | Higher cost and brittleness | High |

| Cermet | Finishing operations on softer materials | Superior surface finish | Less durable than tungsten carbide | Medium |

| Coated Carbide | Versatile applications across various materials | Extended tool life and efficiency | Higher cost and potential for damage | Medium to High |

| High-Speed Steel (HSS) | Lower-speed machining operations | Economical for less demanding tasks | Lacks hardness and wear resistance | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling informed decisions when sourcing carbide inserts from China. Understanding these materials’ properties and implications will help optimize performance and ensure compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for carbide inserts china

What Are the Key Stages in the Manufacturing Process of Carbide Inserts in China?

The manufacturing of carbide inserts in China involves several critical stages that ensure the final product meets industry standards and customer expectations. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The primary material used for carbide inserts is tungsten carbide, often mixed with cobalt. The first step involves sourcing high-quality raw materials from reputable suppliers. The quality of these materials directly impacts the performance and durability of the inserts. After sourcing, the materials are crushed and milled to achieve the desired particle size, which is crucial for the later stages.

-

Forming: Once the materials are prepared, they undergo a process called powder metallurgy. This involves pressing the tungsten carbide powder into specific shapes using high-pressure molds. The pressing process is often followed by a sintering phase, where the molded inserts are heated in a controlled atmosphere furnace. This step enhances the hardness and strength of the inserts, making them suitable for various machining applications.

-

Assembly: For certain types of carbide inserts that require additional components, such as inserts with chip breakers or special coatings, an assembly stage follows. This may involve attaching various features to the basic insert to improve its performance.

-

Finishing: The final stage involves precision machining to achieve the required dimensions and surface finish. Techniques such as grinding or honing are used to refine the edges and surfaces of the inserts. This stage ensures that the inserts meet stringent tolerances and quality specifications required by end-users.

What Quality Assurance Measures Are Commonly Implemented for Carbide Inserts?

Quality assurance (QA) is an integral part of the manufacturing process for carbide inserts. Chinese manufacturers typically adhere to both international and industry-specific standards to ensure product reliability and safety.

-

International Standards Compliance: Many manufacturers comply with ISO 9001, a globally recognized quality management standard. This certification ensures that the manufacturing processes are consistent and that the products meet customer and regulatory requirements. Additionally, compliance with industry-specific standards such as CE (Conformité Européenne) and API (American Petroleum Institute) is crucial, especially for products intended for specific markets.

-

Quality Control Checkpoints: Effective quality control is maintained through various checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help identify defects early, minimizing waste and rework.

– Final Quality Control (FQC): Finished products undergo a thorough inspection to ensure they meet all specifications before being shipped. -

Common Testing Methods: Various testing methods are employed to assess the quality of carbide inserts. These include:

– Hardness Testing: To determine the hardness of the inserts, ensuring they meet the required specifications.

– Microstructure Analysis: This checks the distribution and quality of the carbide grains within the inserts, which is crucial for performance.

– Dimensional Inspection: Using precision measuring tools to ensure that the inserts meet the exact specifications outlined in the design.

How Can B2B Buyers Verify Supplier Quality Control in China?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers in China is essential to ensure product reliability and compliance with local regulations.

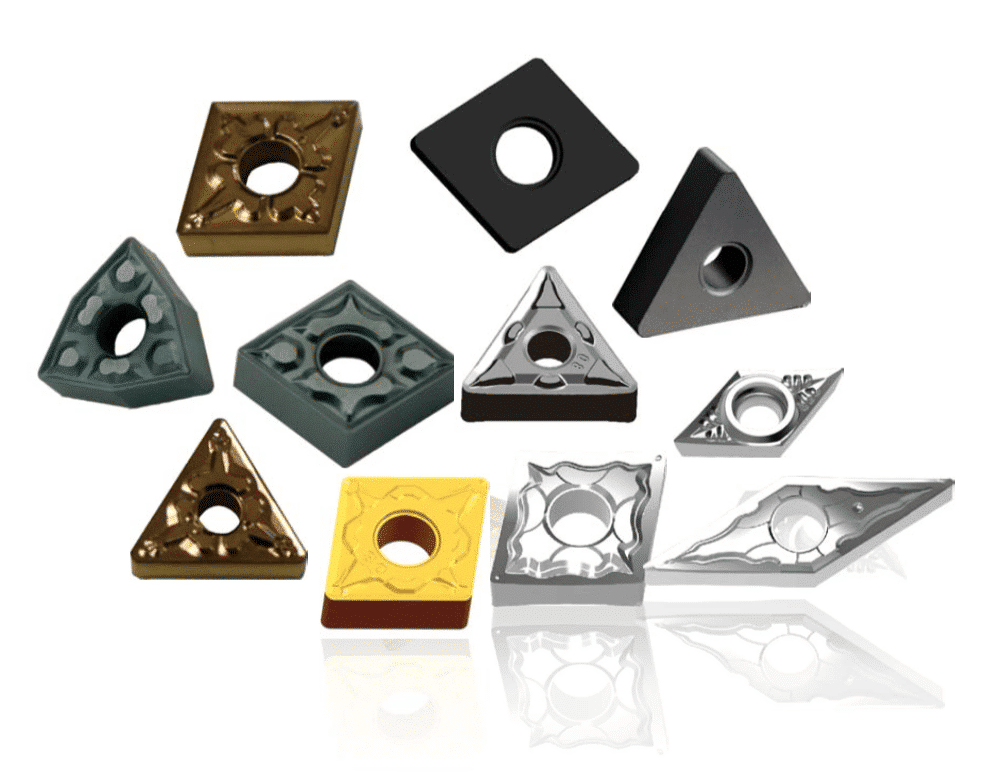

A stock image related to carbide inserts china.

-

Conducting Audits: One of the most effective ways to assess a supplier’s quality control is to conduct a factory audit. This process allows buyers to evaluate the manufacturing environment, processes, and adherence to quality standards firsthand. During an audit, buyers can review quality control documentation and observe testing procedures.

-

Requesting Quality Reports: Buyers should ask suppliers for detailed quality assurance reports. These reports should outline the results of various tests conducted on the carbide inserts, including hardness tests, dimensional checks, and compliance with relevant standards. A well-documented QA process enhances transparency and builds trust.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These services can conduct inspections at various stages of production and provide detailed reports on compliance with international standards.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

When sourcing carbide inserts from China, international buyers must be aware of certain nuances regarding quality control and certification. Understanding these can help mitigate risks and ensure product quality.

-

Local Regulations and Compliance: Each region may have specific regulations governing the importation of industrial products. Buyers from Africa, South America, the Middle East, and Europe should familiarize themselves with their local regulations regarding carbide inserts. Ensuring that the supplier complies with these regulations can prevent costly delays and fines.

-

Certification Validity: Not all certifications are equal. Buyers should verify the validity of certifications provided by suppliers. This can include checking the issuing authority and ensuring that the certifications are current. Some suppliers may present outdated or irrelevant certifications, which can lead to compliance issues.

-

Cultural and Communication Barriers: Language differences and cultural nuances can affect the clarity of quality assurance practices. Buyers should establish clear communication channels and consider hiring local representatives or consultants familiar with the Chinese manufacturing landscape to facilitate smoother interactions.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing carbide inserts from China, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘carbide inserts china’

In the competitive landscape of B2B sourcing, procuring carbide inserts from China requires careful planning and execution. This practical sourcing guide provides a step-by-step checklist to help international buyers, particularly from Africa, South America, the Middle East, and Europe, navigate the complexities of sourcing effectively and efficiently.

Step 1: Define Your Technical Specifications

Clearly outlining the technical specifications of the carbide inserts you need is crucial for successful sourcing. This includes parameters such as material grade, coating type, and dimensions. A well-defined specification will not only help you communicate effectively with potential suppliers but also ensure that you receive products that meet your operational requirements.

- Material Grade: Specify the type of carbide needed (e.g., tungsten carbide) to ensure durability.

- Coating Type: Determine if a specific coating (like TiN or TiAlN) is required for your application.

Step 2: Conduct Market Research on Suppliers

Before reaching out to suppliers, conduct thorough market research to identify potential manufacturers of carbide inserts in China. Understanding the landscape of suppliers will allow you to compare their offerings and capabilities.

- Identify Key Players: Look for suppliers with a strong presence in the carbide insert market.

- Review Online Marketplaces: Platforms like Alibaba or Made-in-China can provide insights into various suppliers and their products.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; instead, consider visiting their production facilities if possible.

- Check Certifications: Ensure suppliers have relevant quality certifications like ISO 9001.

- Assess Production Capacity: Confirm that the supplier can meet your volume requirements.

Step 4: Request Samples for Testing

Always request samples before placing a bulk order. Testing samples allows you to evaluate the quality and performance of the carbide inserts in your specific applications.

- Quality Assurance: Use samples to assess hardness, wear resistance, and overall performance.

- Application Fit: Test the inserts in your machinery to ensure compatibility.

Step 5: Negotiate Pricing and Terms

Once you have shortlisted suppliers and evaluated their samples, initiate negotiations on pricing and terms. This step is vital for securing a favorable deal that aligns with your budget and operational needs.

- Volume Discounts: Inquire about pricing tiers based on order quantities.

- Payment Terms: Discuss payment options to ensure financial flexibility.

Step 6: Understand Import Regulations and Duties

Before finalizing your purchase, familiarize yourself with the import regulations and duties applicable to your country. This knowledge will help you avoid unexpected costs and ensure compliance with local laws.

- Tariffs and Duties: Research any applicable tariffs on imported carbide inserts.

- Documentation Requirements: Ensure you have all necessary paperwork, such as invoices and certificates of origin.

Step 7: Establish a Logistics Plan

Finally, create a logistics plan to manage shipping and delivery. Consider factors such as shipping methods, lead times, and customs clearance procedures to ensure smooth delivery of your carbide inserts.

- Shipping Options: Evaluate air freight versus sea freight based on urgency and cost.

- Customs Brokers: Consider hiring a customs broker to navigate the complexities of import regulations.

By following this comprehensive checklist, international B2B buyers can streamline their sourcing process for carbide inserts from China, ensuring they make informed decisions that contribute to their operational efficiency and profitability.

Comprehensive Cost and Pricing Analysis for carbide inserts china Sourcing

What Are the Key Cost Components in Sourcing Carbide Inserts from China?

Understanding the cost structure is critical for international B2B buyers sourcing carbide inserts from China. The primary cost components include:

- Materials: The quality of tungsten carbide and cobalt used directly affects the price. Higher-grade materials improve performance but come at a premium.

- Labor: Labor costs in China are generally lower than in Europe or North America, but skill levels can vary. Ensure that the workforce is adequately trained to meet your quality standards.

- Manufacturing Overhead: This includes utilities, rent, and administrative costs. Efficient manufacturing practices can reduce these expenses, impacting the final price.

- Tooling: Initial tooling costs for custom carbide inserts can be significant. Understanding the tooling requirements upfront helps in negotiating better prices.

- Quality Control (QC): Investing in rigorous QC processes is essential, as it ensures that the inserts meet international standards. However, this adds to the overall cost.

- Logistics: Shipping costs can vary significantly based on the destination and shipping method. Buyers should consider both freight costs and potential tariffs.

- Margin: Supplier margins can vary based on market dynamics and competition. It’s essential to compare multiple suppliers to understand typical margins.

How Do Price Influencers Affect Carbide Insert Sourcing Costs?

Several factors influence the pricing of carbide inserts that buyers must consider:

- Volume/MOQ (Minimum Order Quantity): Larger orders typically result in lower per-unit costs. Negotiating for favorable terms on MOQs can lead to substantial savings.

- Specifications and Customization: Customized inserts tailored to specific applications may incur additional costs. Clearly defining your requirements can help manage these expenses.

- Material Quality and Certifications: Inserts with specific certifications (e.g., ISO) may be more expensive but can lead to better performance and longer lifespan, ultimately reducing the Total Cost of Ownership (TCO).

- Supplier Factors: Reputation and reliability of the supplier can affect pricing. Established suppliers may charge more, but they often deliver superior quality and service.

- Incoterms: Understanding Incoterms (e.g., FOB, CIF) is vital for calculating total landed costs. The choice of Incoterm can significantly influence shipping costs and responsibilities.

What Are the Best Buyer Tips for Cost-Efficiency in Carbide Insert Procurement?

To maximize value and minimize costs when sourcing carbide inserts from China, consider the following strategies:

- Negotiate Effectively: Use your understanding of cost components and market conditions to negotiate better terms. Leverage relationships and volume commitments for discounts.

- Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with performance, durability, and potential downtime. High-quality inserts may lead to lower operational costs over time.

- Conduct Market Research: Stay informed about market trends and pricing fluctuations. Understanding the competitive landscape can empower you during negotiations.

- Quality Assurance: Invest in third-party inspections or audits to ensure that the products meet your standards. This upfront cost can prevent larger losses due to poor quality.

- Consider Local Regulations: Be aware of import duties and regulations in your home country. These can significantly affect your overall costs and should be factored into your budget.

Conclusion: What Should International Buyers Keep in Mind?

While sourcing carbide inserts from China presents opportunities for cost savings, buyers must navigate a complex landscape of pricing components and influencers. By understanding these elements and employing effective negotiation and procurement strategies, international B2B buyers from regions like Africa, South America, the Middle East, and Europe can optimize their sourcing decisions. Always remember that prices are indicative and subject to change based on market conditions, so staying adaptable and informed is crucial.

Alternatives Analysis: Comparing carbide inserts china With Other Solutions

When considering the procurement of cutting tools, particularly for machining applications, international B2B buyers often evaluate a range of options. Understanding the alternatives to carbide inserts from China can lead to more informed purchasing decisions, ensuring the right fit for diverse operational needs. Below, we explore comparisons between carbide inserts from China and two viable alternatives: ceramic inserts and high-speed steel (HSS) tools.

| Comparison Aspect | Carbide Inserts China | Ceramic Inserts | High-Speed Steel (HSS) Tools |

|---|---|---|---|

| Performance | High durability and wear resistance; suitable for a wide range of materials. | Excellent for high-speed operations; maintains hardness at elevated temperatures. | Good performance for softer materials; less durable than carbide or ceramic. |

| Cost | Generally lower cost due to manufacturing scale in China. | Higher initial investment but potentially lower total cost in high-speed applications. | Lower upfront cost but may require more frequent replacements. |

| Ease of Implementation | Easy to integrate into existing systems; wide compatibility with various machines. | May require specific machine adjustments for optimal use. | Straightforward to use but limited by material type and cutting conditions. |

| Maintenance | Low maintenance; requires periodic checks for wear. | Moderate maintenance; needs careful handling to avoid chipping. | Higher maintenance due to wear and tear; regular sharpening needed. |

| Best Use Case | Versatile; ideal for a range of industries including automotive, aerospace, and general manufacturing. | Best for high-speed machining and hard materials like ceramics and composites. | Suitable for low-speed machining and softer metals, great for prototyping. |

What Are the Pros and Cons of Using Ceramic Inserts?

Ceramic inserts offer distinct advantages, particularly in high-speed machining environments. Their ability to withstand elevated temperatures without losing hardness makes them suitable for applications involving tough materials. However, they can be brittle and may chip if not handled properly. This fragility can limit their usability in certain operations, particularly where vibration or shock is present. Buyers must weigh the benefits of longer tool life and performance against the potential for increased downtime due to tool failure.

How Does High-Speed Steel (HSS) Compare?

High-speed steel tools have been a staple in machining for decades, known for their versatility and ease of sharpening. They are cost-effective for softer materials and can be ground to various shapes, making them ideal for custom applications. However, they do not perform as well as carbide or ceramic inserts in high-speed or high-heat conditions. The need for more frequent replacements and maintenance can lead to higher long-term costs. Buyers should consider their specific machining environment and production volumes when evaluating HSS tools.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Choosing the right cutting tool solution requires a comprehensive understanding of your operational needs, including material types, machining speeds, and production volumes. For high-volume production and hard materials, carbide inserts from China may provide the best balance of cost and performance. In contrast, for specialized high-speed applications, ceramic inserts may yield better results despite a higher initial investment. HSS tools remain a viable option for softer materials and prototyping, particularly for businesses looking to minimize upfront costs. Ultimately, buyers should assess their specific requirements, potential return on investment, and long-term operational goals to select the most suitable cutting tool solution.

Essential Technical Properties and Trade Terminology for carbide inserts china

What Are the Key Technical Properties of Carbide Inserts?

When sourcing carbide inserts from China, understanding the essential technical properties is crucial for making informed purchasing decisions. Here are some critical specifications that B2B buyers should consider:

-

Material Grade

– Definition: The material grade refers to the composition and hardness of the carbide used in the inserts. Common grades include carbide grades such as K10, K20, and K30.

– Importance: Selecting the right material grade is essential for achieving optimal performance in machining applications. It affects wear resistance, toughness, and the overall lifespan of the insert. -

Tolerance

– Definition: Tolerance specifies the allowable deviation in dimensions of the carbide inserts from the specified measurements.

– Importance: Accurate tolerances are critical for ensuring compatibility with tooling systems and achieving precise machining results. Poor tolerance can lead to increased wear or failure during operation. -

Coating Type

– Definition: Coatings like TiN (Titanium Nitride) or TiAlN (Titanium Aluminum Nitride) are applied to enhance the performance of carbide inserts.

– Importance: The right coating can significantly improve heat resistance and reduce friction, leading to longer tool life and better surface finish on the workpiece. -

Insert Geometry

– Definition: This refers to the shape and design of the insert, including factors like cutting edge angle and chip breaker design.

– Importance: Different geometries are suited for various machining operations (e.g., turning, milling). Understanding geometry helps in selecting the right insert for specific applications, maximizing efficiency and productivity. -

Grain Size

– Definition: Grain size indicates the size of the carbide particles within the insert, which can be fine or coarse.

– Importance: Finer grains typically result in higher toughness and wear resistance, while coarser grains may provide higher hardness. The choice depends on the machining conditions and materials being processed.

What Are the Common Trade Terms for Sourcing Carbide Inserts?

Familiarity with industry jargon can facilitate smoother transactions and better communication with suppliers. Here are several essential trade terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM refers to a company that manufactures products that are then marketed by another company under its brand.

– Importance: Understanding OEM relationships can help buyers ensure they are sourcing from reputable manufacturers who adhere to quality standards. -

MOQ (Minimum Order Quantity)

– Definition: MOQ is the smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ is vital for budgeting and inventory management. It can affect the overall cost structure and cash flow for international buyers. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document used to solicit price offers from suppliers for specific quantities of products.

– Importance: Submitting an RFQ is an effective way for buyers to gather price comparisons and assess supplier capabilities before making a purchase decision. -

Incoterms (International Commercial Terms)

– Definition: Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce, which clarify the responsibilities of buyers and sellers in international transactions.

– Importance: Understanding Incoterms helps buyers comprehend shipping responsibilities, cost allocations, and risk management, which are crucial for international trade. -

Lead Time

– Definition: Lead time refers to the time taken from placing an order to receiving the goods.

– Importance: Knowing the lead time is essential for planning production schedules and inventory levels, especially in just-in-time manufacturing environments.

By grasping these technical properties and trade terms, international B2B buyers can navigate the complexities of sourcing carbide inserts from China more effectively, ensuring they make informed decisions that align with their operational needs.

Navigating Market Dynamics and Sourcing Trends in the carbide inserts china Sector

What Are the Current Market Dynamics and Key Trends in the Carbide Inserts Sector from China?

The global market for carbide inserts, particularly from China, is experiencing significant growth driven by various factors. Increased industrialization across Africa, South America, the Middle East, and Europe has heightened demand for high-performance tooling solutions. This demand is further fueled by advancements in manufacturing technologies, which prioritize precision and efficiency. Emerging trends include the integration of smart manufacturing technologies such as IoT and AI, enhancing operational efficiencies and reducing costs.

Moreover, international B2B buyers are increasingly seeking suppliers that offer customized solutions tailored to specific industry needs. This trend is particularly evident in sectors such as automotive, aerospace, and construction, where precise machining processes are critical. Another noteworthy trend is the rise of e-commerce platforms facilitating direct sourcing from Chinese manufacturers, allowing buyers to compare products and prices more efficiently.

Understanding these dynamics is crucial for international buyers, as they navigate a competitive landscape where adaptability and technological integration can lead to significant advantages.

How Is Sustainability Impacting Sourcing Decisions in the Carbide Inserts Industry?

Sustainability is becoming an essential consideration for B2B buyers in the carbide inserts market. The environmental impact of manufacturing processes, particularly in regions like China, has drawn scrutiny. International buyers are increasingly prioritizing suppliers that adhere to sustainable practices and offer ‘green’ certifications. These certifications often indicate compliance with international environmental standards, assuring buyers of responsible sourcing.

Ethical supply chains are also gaining traction, as companies recognize the importance of transparency in sourcing materials. Buyers from Africa, South America, the Middle East, and Europe are now more inclined to partner with manufacturers who demonstrate a commitment to ethical labor practices and sustainable resource management.

Moreover, the use of recycled materials in the production of carbide inserts is becoming a key factor in purchasing decisions. Buyers are encouraged to seek out suppliers who incorporate sustainable practices, as this not only reduces environmental impact but can also enhance brand reputation and customer loyalty.

How Has the Carbide Inserts Market Evolved Over Time?

The carbide inserts market has undergone substantial evolution since its inception in the early 20th century. Originally developed for cutting tools, the application of carbide inserts has expanded dramatically across various industries. The Chinese market has played a pivotal role in this evolution, becoming a global leader in production due to advancements in manufacturing technology and cost-effective labor.

In the past two decades, the focus has shifted from merely producing durable tools to developing high-performance, precision-engineered inserts that cater to specific machining requirements. This shift has been driven by the increasing complexity of manufacturing processes and the need for efficiency.

As technology continues to advance, the carbide inserts sector is expected to further evolve, with innovations such as coated inserts and advanced geometries leading the way. For international buyers, understanding this historical context is vital for making informed sourcing decisions and anticipating future trends in the market.

Frequently Asked Questions (FAQs) for B2B Buyers of carbide inserts china

-

How do I choose the right carbide inserts for my manufacturing needs?

Selecting the right carbide inserts begins with understanding the materials you will be machining and the specific applications. Consider factors such as the type of metal, the hardness, and the desired finish. It’s also essential to evaluate the insert geometry, coating options, and chip removal strategies. Engaging with suppliers who offer technical support can provide insights into the best inserts for your unique needs. Additionally, requesting samples for testing can help ensure compatibility with your machinery and operational requirements. -

What are the common customization options for carbide inserts from Chinese suppliers?

Many Chinese manufacturers offer customization options for carbide inserts, including tailored geometries, sizes, and coatings. You can discuss specific requirements with suppliers to develop inserts that meet your operational specifications. Some manufacturers may also provide custom packaging or branding services. Before committing, ensure that the supplier has a clear process for customization and can provide prototypes for evaluation. This approach can enhance the effectiveness of the inserts in your production line. -

What should I know about the minimum order quantities (MOQs) for carbide inserts?

Minimum order quantities for carbide inserts can vary significantly among suppliers. Typically, Chinese manufacturers set MOQs based on production costs and inventory management. Buyers should clarify MOQs upfront to avoid unexpected costs. If your needs are smaller, consider negotiating with suppliers or exploring manufacturers that specialize in lower MOQs. Additionally, purchasing in bulk can often lead to reduced unit costs, making it a viable strategy for larger enterprises. -

What payment terms are commonly offered by Chinese suppliers for carbide inserts?

Payment terms can vary widely, but common practices include a deposit (usually 30-50%) upfront with the balance due upon shipment or delivery. Some suppliers may offer flexible terms based on your order size and relationship history. It’s advisable to establish clear payment conditions in your contract to avoid disputes. Utilizing secure payment methods such as Letter of Credit (L/C) can provide additional protection for international transactions, especially when dealing with new suppliers. -

How can I ensure quality assurance (QA) for carbide inserts sourced from China?

To ensure quality assurance, first, verify that your supplier adheres to international quality standards, such as ISO 9001. Request detailed quality control processes and test reports for the carbide inserts before shipment. Additionally, consider conducting on-site inspections or using third-party inspection services to assess product quality. Establishing a robust communication channel with your supplier can also facilitate ongoing quality monitoring and address any concerns promptly. -

What logistics considerations should I keep in mind when importing carbide inserts from China?

When importing carbide inserts, consider shipping methods, lead times, and customs regulations in your country. Air freight is faster but more expensive, while sea freight is cost-effective for bulk orders. Ensure that your supplier provides accurate shipping documentation to facilitate customs clearance. Additionally, familiarize yourself with tariffs and duties applicable to your imports to avoid unexpected costs. Working with a freight forwarder can streamline the logistics process and help navigate any challenges. -

How do I vet suppliers of carbide inserts in China effectively?

Vetting suppliers involves several steps: researching their reputation, checking for certifications, and reviewing customer feedback. Utilize platforms like Alibaba or Global Sources to find verified manufacturers. Request references and conduct interviews to gauge their responsiveness and reliability. If possible, visit the factory to observe operations and quality control practices. Building a long-term relationship with a trustworthy supplier can lead to better terms and improved product quality. -

What are the key trends in carbide insert manufacturing that B2B buyers should be aware of?

Current trends in carbide insert manufacturing include advancements in coating technologies, such as PVD and CVD, which enhance wear resistance and performance. Additionally, there is a growing emphasis on sustainability, with manufacturers looking to reduce waste and optimize materials. Buyers should also be aware of the increasing demand for customized solutions, as industries evolve and require more specialized tooling. Keeping abreast of these trends can help B2B buyers make informed purchasing decisions and stay competitive in their markets.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for carbide inserts china

In navigating the complexities of sourcing carbide inserts from China, international B2B buyers must prioritize strategic sourcing practices to maximize value and minimize risks. Understanding the unique dynamics of the Chinese market—including supplier reliability, quality control, and compliance with international standards—is essential. Buyers from Africa, South America, the Middle East, and Europe can leverage these insights to build robust supply chains that enhance operational efficiency.

What are the key takeaways for successful sourcing of carbide inserts from China? First, establishing strong relationships with trusted suppliers can lead to better pricing and consistent product quality. Second, conducting thorough market research and due diligence will help identify the best partners who align with your business needs. Finally, staying informed about industry trends and technological advancements will empower buyers to make proactive sourcing decisions.

Looking ahead, the demand for high-quality carbide inserts is expected to grow, driven by advancements in manufacturing technology and increased global competition. As you consider your sourcing strategy, remember that a well-planned approach can significantly impact your operational success. Engage with reputable suppliers and invest in long-term partnerships to ensure you remain competitive in your respective markets.