Cut Costs with Clothing Labels Custom: The Ultimate Guide (2025)

Introduction: Navigating the Global Market for clothing labels custom

Navigating the global market for custom clothing labels presents a unique set of challenges for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. As businesses strive to enhance brand identity and consumer trust, sourcing high-quality clothing labels becomes a critical component of their supply chain. This guide offers an in-depth exploration of the various types of custom clothing labels, their applications across different sectors, and essential insights into supplier vetting processes.

By understanding the nuances of materials, design options, and compliance with international standards, B2B buyers can make informed decisions that align with their branding and operational needs. We will also delve into cost considerations, helping buyers to weigh quality against price effectively. Our comprehensive approach empowers businesses to identify reliable suppliers and negotiate favorable terms, ensuring that they secure clothing labels that not only meet regulatory requirements but also resonate with their target markets.

This guide is tailored for international B2B buyers looking to enhance their sourcing strategies in the custom clothing label sector. It serves as a valuable resource for understanding market dynamics, ultimately fostering more strategic purchasing decisions that lead to successful brand positioning and consumer engagement.

Understanding clothing labels custom Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Woven Labels | Durable, high-quality fabric; can be customized in color and size. | Apparel, accessories, and home textiles. | Pros: Long-lasting, professional appearance. Cons: Higher cost compared to printed labels. |

| Printed Labels | Cost-effective; available in various materials like satin or cotton. | Fast fashion, promotional items, and low-budget clothing lines. | Pros: Affordable, quick to produce. Cons: May fade or wear out faster than woven labels. |

| Hang Tags | Often used for branding; can include pricing, care instructions, and product details. | Retail clothing, accessories, and shoes. | Pros: Excellent for marketing, versatile designs. Cons: Can be easily lost or discarded by consumers. |

| Care Labels | Essential for compliance; includes care instructions and fabric content. | All clothing manufacturers. | Pros: Necessary for consumer safety, legal requirements. Cons: Limited design options. |

| Custom Size Labels | Tailored to specific measurements; important for fit and sizing. | Tailored clothing and bespoke fashion lines. | Pros: Enhances customer satisfaction, reduces returns. Cons: Requires accurate sizing information upfront. |

What are the characteristics of Woven Labels and when should B2B buyers use them?

Woven labels are crafted from durable fabric materials, making them ideal for high-end apparel and accessories. They can be customized in various colors and sizes, providing a professional touch to products. B2B buyers should consider woven labels for products where longevity and aesthetic quality are paramount, such as luxury fashion brands or home textiles. However, the higher production costs should be weighed against the perceived value added to the brand.

How do Printed Labels differ from other types and in what scenarios are they most suitable?

Printed labels are made from materials like satin or cotton and are recognized for their cost-effectiveness. They are ideal for fast fashion brands or promotional items where budget constraints are significant. B2B buyers should opt for printed labels when seeking quick production times and lower costs, but they should be aware of the potential for fading over time, especially in high-wash environments.

What role do Hang Tags play in B2B clothing applications?

Hang tags serve as an essential marketing tool, providing not only pricing but also care instructions and product details. They are commonly used in retail environments for clothing, accessories, and shoes. B2B buyers should leverage hang tags to enhance brand visibility and communicate essential information to consumers. However, their effectiveness can be diminished if not designed carefully, as they can easily be lost or discarded.

Why are Care Labels critical for B2B buyers in the clothing industry?

Care labels are vital for compliance with legal standards, as they include necessary care instructions and fabric content information. All clothing manufacturers must incorporate care labels to ensure consumer safety and adherence to regulations. B2B buyers should prioritize care labels in their sourcing to avoid legal issues, even though they may offer limited design flexibility compared to other label types.

How do Custom Size Labels enhance the B2B purchasing experience?

Custom size labels are tailored to specific measurements, making them particularly valuable in bespoke clothing and tailored fashion lines. They enhance customer satisfaction by ensuring a better fit, which can lead to reduced return rates. B2B buyers should consider custom size labels when dealing with tailored products, but they must ensure accurate sizing information is provided at the outset to avoid complications during production.

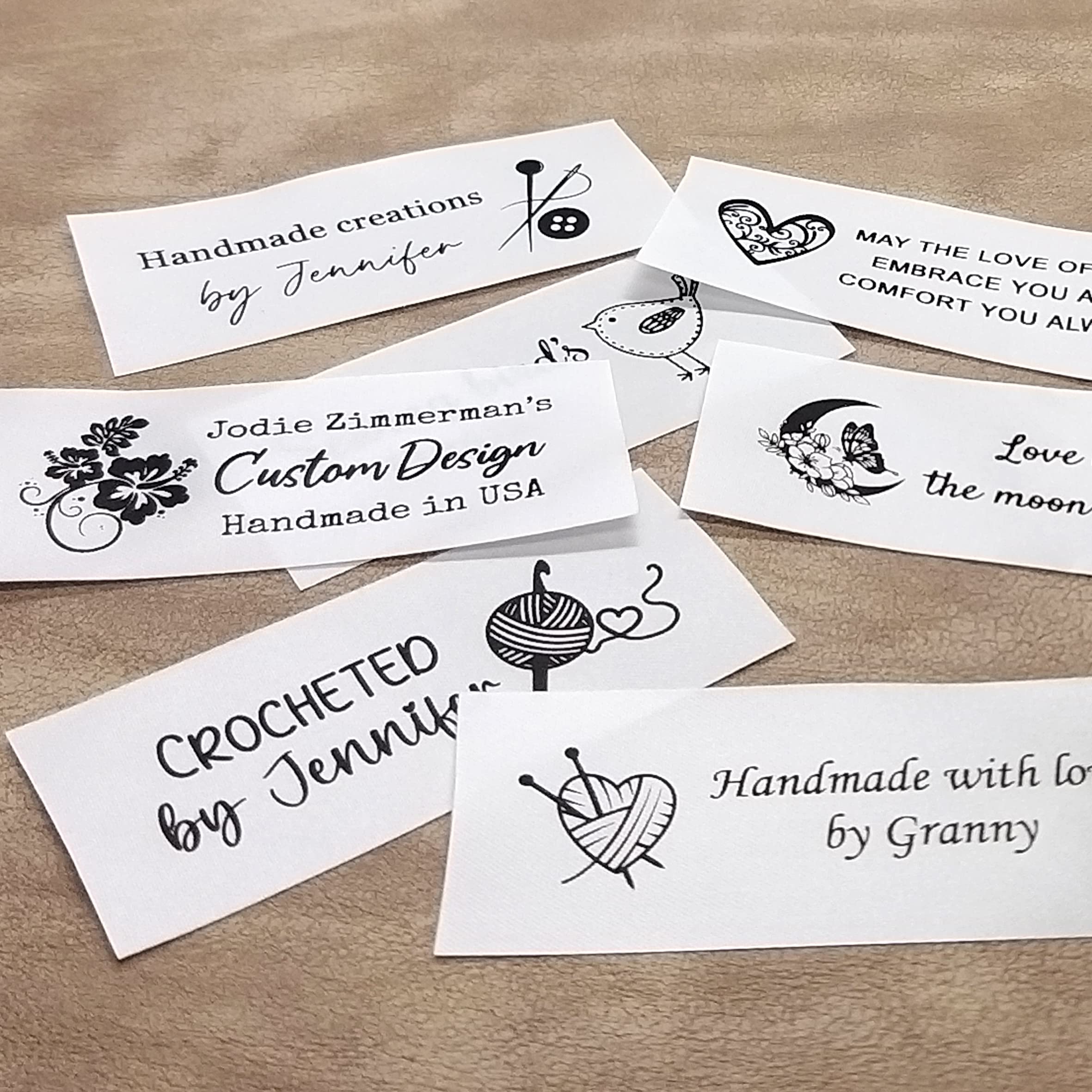

Related Video: YOUR MAKERS MARK – How and why make your own custom clothing labels to sew in the clothes you make!

Key Industrial Applications of clothing labels custom

| Industry/Sector | Specific Application of clothing labels custom | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion Retail | Custom branding labels for garments and accessories | Enhances brand identity and customer recognition | Quality of materials, printing durability, and design flexibility |

| Textile Manufacturing | Care and content labels for fabrics and finished products | Ensures compliance with regulations and consumer safety | Compliance with local labeling laws and material specifications |

| Sportswear | Performance labels indicating material technology and care instructions | Informs consumers about product features and maintenance | Material performance standards and brand alignment |

| Children’s Apparel | Safety labels detailing age recommendations and safety warnings | Builds trust with parents and meets legal requirements | Compliance with safety regulations and material safety certifications |

| Hospitality & Uniforms | Custom labels for staff uniforms and linens | Reinforces brand image and enhances professionalism | Customization options and durability against frequent washing |

How Are Custom Clothing Labels Used in the Fashion Retail Sector?

In the fashion retail sector, custom clothing labels are crucial for establishing brand identity. These labels often feature logos, care instructions, and sizing information. They help consumers recognize and trust a brand, thereby increasing customer loyalty. For international buyers, especially from diverse markets like Africa and South America, it is essential to ensure that these labels comply with local regulations regarding textile labeling. Buyers should consider the quality of materials used, as well as the durability of the printing, to withstand wear and washing.

What Role Do Custom Clothing Labels Play in Textile Manufacturing?

In textile manufacturing, custom clothing labels serve as care and content labels that provide vital information about the fabric and finished products. They ensure compliance with international regulations, guiding consumers on proper care and handling. This is especially relevant for B2B buyers in regions like the Middle East and Europe, where stringent labeling laws exist. Buyers must prioritize sourcing labels that meet these legal requirements while also considering the specific material specifications relevant to their products.

A stock image related to clothing labels custom.

How Do Custom Labels Enhance Performance in Sportswear?

Custom clothing labels in the sportswear industry often highlight advanced material technologies and care instructions, informing consumers about product features such as moisture-wicking or UV protection. This information not only enhances the consumer’s experience but also strengthens brand loyalty by providing transparency. For buyers, understanding the material performance standards and ensuring brand alignment in label design are key considerations when sourcing these labels.

Why Are Safety Labels Important in Children’s Apparel?

In the children’s apparel sector, custom labels that include safety warnings and age recommendations are essential for building trust with parents. These labels ensure compliance with safety regulations, which is a significant concern in markets such as Europe, where safety standards are rigorously enforced. Buyers must focus on sourcing labels that meet these legal requirements while also ensuring that the materials used are safe for children, thereby minimizing risk and enhancing brand reputation.

How Do Custom Labels Benefit Hospitality and Uniforms?

In the hospitality and uniforms sector, custom labels are used to identify staff uniforms and linens, reinforcing brand image and professionalism. These labels can include care instructions and branding elements, which help maintain a cohesive appearance. For B2B buyers in this sector, customization options and the durability of labels are critical sourcing considerations, particularly since uniforms are often subjected to frequent washing and wear. Ensuring that labels can withstand these conditions while maintaining their appearance is crucial for long-term value.

Related Video: WHAT LABELS TO GET?? How to pick the right type of custom clothing label to personalize your sewing!

3 Common User Pain Points for ‘clothing labels custom’ & Their Solutions

Scenario 1: Difficulty with Label Durability and Quality

The Problem: One of the most pressing challenges for B2B buyers in the clothing industry is ensuring that custom clothing labels can withstand the rigors of manufacturing and consumer use. Labels that fade, fray, or peel off can lead to poor brand representation and customer dissatisfaction. Buyers often find themselves struggling with suppliers who promise high-quality labels but fail to deliver on durability, particularly in diverse climates like those found in Africa or South America where humidity and temperature fluctuations can affect label longevity.

The Solution: To mitigate issues related to label durability, B2B buyers should prioritize sourcing from manufacturers that specialize in high-performance materials. When discussing custom clothing labels, specify the type of fabric and printing techniques that align with your product’s requirements. For instance, using polyester labels with UV-resistant inks can significantly enhance durability. Buyers should also request samples and conduct stress tests to ensure labels can withstand washing, drying, and wear. Establishing a long-term relationship with reliable suppliers who have proven track records in quality control is crucial. Regular audits and feedback mechanisms can also help maintain high standards.

Scenario 2: Navigating Compliance with Regional Regulations

The Problem: Compliance with local regulations regarding labeling can be a daunting task for B2B buyers, especially those operating in multiple regions like Europe, the Middle East, and Africa. Each region has its own set of rules regarding the information that must be included on clothing labels, such as care instructions, fiber content, and country of origin. Failure to comply can lead to fines, product recalls, and damage to brand reputation.

The Solution: To navigate these complexities, buyers should invest time in understanding the specific labeling regulations for each target market. This can involve consulting with legal experts or using compliance software that tracks local laws. Buyers should also collaborate closely with their suppliers to ensure that all necessary information is included in the label design. Implementing a standardized checklist for compliance during the design phase can streamline the process. Additionally, providing training for staff involved in the labeling process can ensure everyone is aware of the requirements and can contribute to compliance efforts.

Scenario 3: Balancing Customization with Cost-Effectiveness

The Problem: B2B buyers often face the challenge of balancing the desire for unique, custom clothing labels with the need to keep costs down. Customization, such as unique designs or materials, can significantly increase production costs, making it difficult for buyers to maintain competitive pricing. This is especially crucial in markets where margins are tight, such as in South America and Africa, where price sensitivity is high among consumers.

The Solution: To strike the right balance between customization and cost, buyers should adopt a strategic approach to label design. Start by defining the essential elements of customization that truly add value to the product, such as brand identity or sustainability features. Next, consider bulk ordering to reduce costs per unit and negotiate with suppliers for better pricing on larger quantities. Utilizing technology, such as digital printing, can also offer more cost-effective solutions for smaller runs of custom labels. Finally, analyze the entire supply chain to identify areas where efficiencies can be gained, such as reducing lead times or optimizing shipping methods, ultimately lowering overall costs while still achieving the desired level of customization.

Strategic Material Selection Guide for clothing labels custom

When selecting materials for custom clothing labels, international B2B buyers must consider various factors that influence product performance, durability, and compliance with regional standards. Here, we analyze four common materials used for clothing labels, providing insights tailored for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Woven Labels?

Woven Labels are crafted from threads that are woven together, resulting in a durable and high-quality finish.

- Key Properties: Woven labels are known for their excellent durability and resistance to fraying. They can withstand high temperatures during washing and ironing, making them suitable for various garment types.

- Pros & Cons: The main advantage of woven labels is their longevity and ability to maintain clarity in designs over time. However, they can be more expensive to produce than other types of labels, which may be a consideration for budget-conscious buyers.

- Impact on Application: Woven labels are particularly compatible with fabrics that undergo frequent washing, such as denim and cotton.

- Considerations for International Buyers: Compliance with international textile labeling standards (such as ASTM and ISO) is crucial. Buyers in regions like Europe may prefer woven labels due to their premium feel and durability.

How Do Printed Labels Compare in Terms of Performance?

Printed Labels utilize ink to create designs on a variety of substrates, including satin, cotton, and polyester.

- Key Properties: These labels can be produced quickly and are available in vibrant colors and intricate designs. However, they may not be as durable as woven labels, especially when exposed to harsh washing conditions.

- Pros & Cons: The key advantage of printed labels is their cost-effectiveness and the ability to produce them in small quantities. Conversely, they may fade or degrade over time, especially if exposed to sunlight or frequent washing.

- Impact on Application: Printed labels are suitable for light garments and items that do not require heavy-duty washing.

- Considerations for International Buyers: Buyers should be aware of the ink used; some inks may not comply with regulations in certain regions, such as the EU’s REACH regulations regarding hazardous substances.

What Are the Benefits of Heat Transfer Labels?

Heat Transfer Labels are applied to garments using heat and pressure, allowing for detailed designs without the bulk of traditional labels.

- Key Properties: These labels are lightweight and can be applied to various fabric types. They offer flexibility in design and are resistant to fading.

- Pros & Cons: Heat transfer labels are easy to apply and can be produced quickly. However, they may not be as durable as woven labels, particularly in high-friction areas.

- Impact on Application: Ideal for activewear and sports apparel, heat transfer labels can withstand movement and moisture.

- Considerations for International Buyers: Compliance with local regulations regarding adhesives and inks is essential. Buyers from regions like South America should ensure that the materials used are suitable for the climate and washing conditions.

Why Choose Synthetic Labels for Custom Clothing?

Synthetic Labels, often made from materials like polyester or nylon, offer a range of benefits for clothing manufacturers.

- Key Properties: These labels are resistant to moisture, chemicals, and UV light, making them suitable for outdoor apparel.

- Pros & Cons: The main advantage is their durability and resistance to environmental factors. However, they can feel less premium compared to woven labels, which may affect brand perception.

- Impact on Application: Synthetic labels are ideal for garments that will be exposed to harsh conditions, such as workwear or outdoor clothing.

- Considerations for International Buyers: Buyers should ensure that synthetic materials meet local environmental regulations, particularly in Europe, where sustainability is increasingly prioritized.

Summary Table of Material Selection for Clothing Labels

| Material | Typical Use Case for clothing labels custom | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Woven Labels | High-end garments, frequent washing | Excellent durability | Higher production costs | High |

| Printed Labels | Light garments, small batches | Cost-effective, vibrant designs | Less durable, prone to fading | Low |

| Heat Transfer Labels | Activewear, sports apparel | Lightweight, flexible designs | Less durable in high-friction areas | Medium |

| Synthetic Labels | Outdoor apparel, workwear | Resistant to moisture and UV light | Less premium feel | Medium |

This strategic analysis serves as a guide for international B2B buyers, ensuring informed decisions when selecting materials for custom clothing labels that align with their market needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for clothing labels custom

What Are the Key Stages in the Manufacturing Process of Custom Clothing Labels?

The manufacturing process for custom clothing labels involves several key stages that ensure quality and consistency. Understanding these stages can help B2B buyers from regions like Africa, South America, the Middle East, and Europe make informed decisions when sourcing their labels.

1. Material Preparation: What Materials Are Used for Clothing Labels?

The first stage is material preparation, which involves selecting the right fabric for the labels. Common materials include:

- Woven Fabric: Known for durability and a premium look, ideal for high-end brands.

- Printed Fabric: Typically made from cotton or polyester, suitable for budget-conscious brands.

- Satin and Tyvek: Offer a softer touch and are often used for special garments.

Buyers should consider the end use of the clothing labels and the desired aesthetic when choosing materials. In addition, they should inquire about the sourcing of materials to ensure ethical practices, especially in regions sensitive to sustainability.

2. How Are Clothing Labels Formed?

The forming stage involves several techniques to create the label design, including:

- Weaving: Utilizes looms to weave the design directly into the fabric, producing a high-quality and durable label.

- Printing: Involves screen printing or digital printing, where the design is printed onto the label material. This is a cost-effective method for complex designs but may not be as durable as woven labels.

- Heat Transfer: A method where the design is printed on a special transfer paper and then applied to the label material using heat. This technique is great for intricate designs and allows for vibrant colors.

Buyers should evaluate the techniques used by suppliers to ensure they align with their branding and quality expectations.

3. What Does the Assembly Process Entail?

After forming, the labels go through the assembly stage, where they are cut, sewn, or finished according to specifications. This may include:

- Cutting: Labels are cut to size, ensuring uniformity across batches.

- Sewing: Some labels require sewing onto garments, which necessitates additional quality checks to ensure durability.

- Finishing: This includes adding features such as tags, barcodes, or care instructions, which enhances the label’s functionality.

It is essential for buyers to communicate their specific assembly requirements to suppliers to ensure alignment with their production processes.

4. How Is Quality Assurance Implemented in Clothing Label Manufacturing?

Quality assurance (QA) is critical in the manufacturing process to ensure that the labels meet both international and industry-specific standards. Here are some common practices:

- International Standards: Suppliers often adhere to ISO 9001, which focuses on quality management systems. This certification indicates that the supplier has a structured approach to quality assurance.

- Industry-Specific Standards: Depending on the market, suppliers may also follow standards such as CE marking for safety or API standards for specific applications.

What Are the Key Quality Control Checkpoints in Clothing Label Production?

Quality control (QC) is integral to maintaining standards throughout the production process. Typical QC checkpoints include:

1. Incoming Quality Control (IQC)

This initial checkpoint involves inspecting raw materials upon arrival. Buyers should verify that the materials meet specified quality criteria before production begins. This can include checking for color consistency, fabric integrity, and any defects.

2. In-Process Quality Control (IPQC)

During production, ongoing checks are conducted to ensure that the manufacturing process adheres to quality standards. This may involve:

- Monitoring the weaving or printing process to catch any deviations early.

- Conducting random sampling of labels to assess consistency and quality.

Establishing a routine for IPQC can help prevent costly errors later in the process.

3. Final Quality Control (FQC)

Once production is complete, the final quality control checks are performed. This involves inspecting finished labels for:

- Accuracy in design and specifications.

- Durability tests to ensure labels can withstand washing and wear.

- Packaging checks to confirm labels are shipped in proper condition.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, especially from diverse markets like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is crucial. Here are some strategies:

1. Conduct Supplier Audits

Regular audits allow buyers to assess the supplier’s manufacturing processes and quality control measures firsthand. This can help identify any weaknesses in their production practices.

2. Request Quality Assurance Documentation

Buyers should ask for documentation that outlines the supplier’s quality assurance processes, including inspection reports and certifications. This can provide insights into their commitment to quality.

3. Engage Third-Party Inspection Services

Third-party inspection firms can conduct independent assessments of the supplier’s processes and products. This adds an extra layer of assurance, especially for buyers who may not have the resources to conduct their own audits.

What Testing Methods Are Commonly Used in Quality Control for Clothing Labels?

Common testing methods used in quality control for clothing labels include:

- Colorfastness Testing: Ensures that colors remain vibrant after washing.

- Tensile Strength Testing: Measures how much force a label can withstand before breaking.

- Adhesion Testing: Checks how well labels adhere to fabrics, particularly for heat transfer labels.

By understanding these testing methods, B2B buyers can ask informed questions and set expectations when selecting suppliers.

Conclusion: Navigating the Manufacturing and Quality Assurance Landscape

For B2B buyers in the clothing label industry, understanding the manufacturing processes and quality assurance measures is essential for making informed sourcing decisions. By focusing on material selection, production techniques, and stringent quality control measures, buyers can ensure that they receive high-quality labels that meet their brand standards. Moreover, engaging in regular audits, requesting documentation, and utilizing third-party inspections can further enhance confidence in supplier quality.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘clothing labels custom’

In the competitive landscape of the clothing industry, custom clothing labels play a pivotal role in branding and product identification. This guide serves as a comprehensive checklist for B2B buyers from Africa, South America, the Middle East, and Europe seeking to procure custom clothing labels. By following these steps, you can ensure a seamless sourcing process, leading to high-quality labels that align with your brand’s identity.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to clearly outline your technical specifications. This includes the material, size, color, printing method, and any special features (e.g., care instructions, barcodes). Defining these parameters will help you communicate your needs effectively to potential suppliers, ensuring that the labels meet your requirements.

- Material Considerations: Choose from options like woven, printed, or heat-transfer labels based on your clothing type and branding needs.

- Size and Shape: Ensure that the label size fits well within the clothing design without compromising aesthetics.

Step 2: Research and Shortlist Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in custom clothing labels. Use online marketplaces, industry directories, and trade shows to compile a list of manufacturers.

- Supplier Reputation: Look for suppliers with positive reviews and a history of successful projects in your region.

- Product Range: Ensure they offer a variety of label types and customization options to fit your specific needs.

Step 3: Request Samples for Quality Assessment

Once you have shortlisted potential suppliers, request samples of their work. This step is crucial for evaluating the quality of the materials and the accuracy of the printing.

- Quality Checks: Inspect the samples for durability, color accuracy, and overall finish.

- Compliance with Standards: Ensure that the labels meet any industry-specific regulations, especially if selling in regions with strict labeling laws.

Step 4: Verify Supplier Certifications and Compliance

Before finalizing a supplier, verify their certifications and compliance with international standards. This is especially important for buyers in Europe and North America, where regulations can be stringent.

- ISO Certifications: Check for certifications that demonstrate adherence to quality management standards.

- Sustainability Practices: If relevant, inquire about eco-friendly materials and ethical manufacturing practices.

Step 5: Negotiate Terms and Pricing

Once you have selected a supplier, initiate discussions on pricing and terms. Be clear about your budget and the quantity you require, as these factors can significantly influence pricing.

- Bulk Discounts: Ask about pricing tiers based on order volume, as larger orders often qualify for discounts.

- Payment Terms: Clarify payment terms and methods to avoid misunderstandings later on.

Step 6: Establish a Clear Communication Channel

Set up a reliable communication channel with your chosen supplier. This will facilitate smooth interactions throughout the order process, from design to delivery.

- Regular Updates: Schedule regular check-ins to discuss progress, address any concerns, and ensure timelines are being met.

- Cultural Sensitivity: Be aware of cultural differences in communication styles, especially when dealing with suppliers from diverse regions.

Step 7: Review and Finalize the Order

Before placing the final order, review all details to ensure everything aligns with your specifications. This includes double-checking designs, quantities, and delivery timelines.

- Approval Samples: Consider requesting a final approval sample before full production begins to confirm that everything meets your expectations.

- Logistics Planning: Coordinate shipping and delivery timelines to align with your product launch schedules.

By following this step-by-step checklist, B2B buyers can effectively navigate the complexities of sourcing custom clothing labels, ensuring a successful partnership with suppliers and a high-quality product that enhances their brand identity.

Comprehensive Cost and Pricing Analysis for clothing labels custom Sourcing

What Are the Key Cost Components in Custom Clothing Labels Sourcing?

When sourcing custom clothing labels, understanding the cost structure is essential for B2B buyers. The main components include:

-

Materials: The type of fabric or raw materials used significantly impacts the overall cost. High-quality materials such as organic cotton or recycled polyester may have a higher initial price but can enhance brand value and appeal to eco-conscious consumers.

-

Labor: Labor costs vary by region and depend on the skill level required for label production. Countries with lower labor costs may offer a more economical option, but this can affect quality and turnaround times.

-

Manufacturing Overhead: This encompasses all indirect costs related to production, including utilities, rent, and administrative expenses. Efficient management of overhead can lead to lower pricing for buyers.

-

Tooling: Initial tooling costs can be significant, especially for custom designs or specific printing techniques. These costs are usually amortized over larger production runs, so higher order volumes can reduce the per-unit cost.

-

Quality Control (QC): Implementing QC measures is crucial to ensure that labels meet specifications. This may involve additional costs for inspection and testing, but it helps prevent costly errors and returns.

-

Logistics: Shipping and handling costs must be factored in, especially for international shipments. Understanding Incoterms can help buyers negotiate better terms and manage logistics expenses effectively.

-

Margin: Suppliers will include a margin on top of their costs. Understanding the typical markup in the industry can aid in negotiations.

How Do Pricing Influencers Impact Custom Clothing Labels?

Several factors influence the pricing of custom clothing labels, including:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often offer better pricing for larger orders. Understanding the MOQ can help buyers plan their inventory and budget more effectively.

-

Specifications and Customization: The complexity of the design, the number of colors used, and any special finishes will affect the price. Buyers should clearly communicate their requirements to avoid unexpected costs.

-

Materials Used: As mentioned earlier, the choice of materials plays a crucial role in pricing. Premium materials will lead to higher costs but can justify a higher retail price.

-

Quality and Certifications: Labels that meet specific quality standards or certifications (e.g., OEKO-TEX) may have higher prices but can enhance brand reputation and customer trust.

-

Supplier Factors: Supplier reputation, production capacity, and reliability can impact pricing. Established suppliers with a proven track record may charge more but can provide better quality and service.

-

Incoterms: Understanding shipping terms is crucial for cost management. DDP (Delivered Duty Paid) may include additional costs, while FOB (Free on Board) places more responsibility on the buyer.

What Tips Can Help International B2B Buyers Negotiate Better Prices?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency:

-

Negotiate Terms: Engage in negotiations regarding payment terms, lead times, and shipping costs. Flexibility can lead to better deals.

-

Evaluate Total Cost of Ownership (TCO): Consider all associated costs, including shipping, duties, and potential returns. A lower upfront cost may not always translate to better value.

-

Understand Pricing Nuances: Be aware that suppliers may have different pricing strategies based on regional market conditions. Buyers should conduct market research to ensure they are getting a competitive price.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing and terms as trust develops over time.

-

Consider Local Suppliers: Exploring local suppliers can reduce shipping costs and lead times, making it easier to manage inventory.

Conclusion

While sourcing custom clothing labels, B2B buyers must analyze the comprehensive cost structure and pricing influences carefully. By understanding these elements and employing strategic negotiation tactics, businesses can optimize their sourcing process, ensuring quality products at competitive prices. Always keep in mind that prices can vary widely based on numerous factors, so continuous market research is essential for maintaining a competitive edge.

Alternatives Analysis: Comparing clothing labels custom With Other Solutions

In the competitive landscape of clothing manufacturing, selecting the right solution for labels is crucial. While custom clothing labels offer unique branding opportunities, there are several viable alternatives that can fulfill similar needs. This section provides a comprehensive comparison of custom clothing labels against alternative labeling solutions, helping international B2B buyers make informed decisions.

| Comparison Aspect | Clothing Labels Custom | Digital Printing Labels | Hang Tags |

|---|---|---|---|

| Performance | High durability, tailored design | Moderate durability, high print quality | High visibility, versatile uses |

| Cost | Higher initial investment | Lower initial investment, variable costs | Moderate cost, bulk discounts available |

| Ease of Implementation | Requires design input and setup | Quick setup, minimal design input | Easy to produce, can be pre-printed |

| Maintenance | Low maintenance, long-lasting | Moderate maintenance, can fade over time | Low maintenance, easily replaceable |

| Best Use Case | High-end brands needing custom designs | Short runs or quick turnarounds | Promotional items or branding |

What are the Advantages and Disadvantages of Digital Printing Labels?

Digital printing labels are an excellent alternative for businesses needing flexibility and quick turnaround times. They are particularly beneficial for small batch runs, allowing brands to produce high-quality labels without the need for extensive setup. The cost-effectiveness of digital printing is appealing for businesses that frequently change designs or require labels in smaller quantities. However, the durability of these labels may not match that of custom woven labels, as they can fade or deteriorate over time, especially if exposed to harsh conditions.

How Do Hang Tags Compare to Custom Clothing Labels?

Hang tags serve as another alternative to custom clothing labels, offering a unique way to communicate brand identity and product information. They are often used in retail environments, providing a visually appealing way to display essential details about a product. Hang tags can be produced quickly and are relatively inexpensive, especially when ordered in bulk. However, they may not offer the same level of permanence as custom labels, which are directly sewn into garments. Additionally, hang tags can be easily removed, which may not provide the same branding presence as a custom label.

Conclusion: Which Label Solution is Right for Your Business?

Choosing the right labeling solution depends on various factors, including budget, branding goals, and production needs. For businesses seeking high durability and a unique branding identity, custom clothing labels remain the top choice despite their higher initial costs. In contrast, digital printing labels are ideal for companies needing flexibility and quick production times. Hang tags can be an effective solution for promotional strategies or temporary branding. International B2B buyers should carefully assess their specific needs, considering factors such as target market, product type, and overall marketing strategy, to select the most suitable labeling solution.

Essential Technical Properties and Trade Terminology for clothing labels custom

What Are the Essential Technical Properties of Custom Clothing Labels?

When sourcing custom clothing labels, understanding the technical specifications is crucial for ensuring product quality and compliance with industry standards. Here are some key properties to consider:

1. Material Grade: What Should You Choose for Durability?

The material of clothing labels can significantly impact their durability and aesthetic appeal. Common materials include polyester, cotton, and nylon, each offering different levels of durability, softness, and environmental resistance. For instance, polyester labels are often favored for their resistance to fading and fraying, making them suitable for high-wear garments. Choosing the right material is essential for aligning with your brand’s quality standards and consumer expectations.

2. Printing Technique: Which Method Ensures Longevity?

The method used to print information on clothing labels affects both visibility and longevity. Common techniques include screen printing, digital printing, and heat transfer. Screen printing is known for its durability, while digital printing offers high-resolution designs. Understanding these techniques helps you decide which best fits your needs, especially regarding the label’s end-use, whether for fashion-forward designs or functional applications.

3. Tolerance Levels: Why Are They Important?

Tolerance refers to the allowable variations in dimensions and properties of the labels. For instance, the width of a label might need to be within ±1mm of the specified size. Tight tolerances are critical in ensuring labels fit perfectly into garment seams and maintain the professional appearance of your products. This attention to detail can significantly impact production efficiency and the final product’s quality.

4. Label Size and Shape: How Do They Affect Branding?

Custom clothing labels can come in various sizes and shapes, which can influence brand recognition and consumer perception. Standard sizes are often easier to integrate into clothing designs, but unique shapes can help differentiate your brand in a competitive market. It’s essential to consider how the size and shape of your labels will interact with the overall design of your garments and how they will be perceived by consumers.

5. Adhesive Properties: What Should You Consider?

For labels that require adhesive backing, understanding the adhesive properties is vital. Different adhesives offer varying levels of stickiness and durability under different conditions, such as washing or dry cleaning. Selecting the right adhesive ensures that labels remain securely attached throughout the garment’s lifecycle, maintaining your brand’s reputation for quality.

Which Trade Terminology Is Essential for Custom Clothing Labels?

Familiarity with industry jargon can streamline communication and negotiations with suppliers. Here are some common terms you should know:

1. OEM (Original Equipment Manufacturer): What Does It Mean for Your Sourcing?

OEM refers to companies that produce products or components that are sold under another brand’s name. In the context of clothing labels, working with an OEM can offer flexibility in design and production, allowing for tailored solutions that meet specific branding requirements.

2. MOQ (Minimum Order Quantity): How Does It Impact Your Orders?

MOQ is the smallest number of units a supplier is willing to produce or sell. Understanding MOQ is crucial for budgeting and inventory management, especially for smaller businesses or startups that may not have the capacity to order large quantities.

3. RFQ (Request for Quotation): Why Is It Necessary?

An RFQ is a formal document sent to suppliers to request pricing and terms for specific products or services. This process helps buyers compare offers and make informed decisions, ensuring they get the best value for their investment in custom clothing labels.

4. Incoterms: How Do They Affect Your Shipping Costs?

Incoterms, short for International Commercial Terms, define the responsibilities of buyers and sellers in the shipping process. Familiarity with these terms helps you understand who is responsible for shipping costs, insurance, and risk during transportation, which is critical for managing total landed costs.

5. Lead Time: What Should You Expect?

A stock image related to clothing labels custom.

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is essential for planning production schedules and meeting market demands, especially in fast-paced fashion environments.

By mastering these technical properties and trade terminologies, B2B buyers can make informed decisions that align with their business goals and enhance their product offerings in the global market.

Navigating Market Dynamics and Sourcing Trends in the clothing labels custom Sector

What Are the Current Market Dynamics and Key Trends in Custom Clothing Labels?

The custom clothing labels market is experiencing significant growth, driven by globalization, e-commerce expansion, and changing consumer preferences. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must stay attuned to several key trends. Firstly, the demand for personalized and unique branding has surged, with businesses recognizing the importance of distinct labels to enhance brand identity. This trend is particularly pronounced in countries like Argentina and South Africa, where local artisans and small businesses are gaining traction through bespoke clothing lines.

Moreover, technological advancements such as digital printing and automated production processes are transforming sourcing strategies. These innovations allow for shorter lead times and lower minimum order quantities, making it easier for small and medium enterprises to enter the market. Additionally, the rise of e-commerce platforms has made it increasingly important for B2B buyers to partner with suppliers who can offer quick turnarounds and scalable solutions.

Another noteworthy dynamic is the increasing focus on supply chain transparency. Buyers are becoming more discerning, seeking suppliers who can provide detailed information about their production processes and sourcing materials. This trend is particularly relevant for international buyers who are navigating complex trade regulations and ethical concerns.

How Is Sustainability and Ethical Sourcing Impacting the Custom Clothing Labels Market?

Sustainability is no longer just a buzzword; it has become a critical factor in the decision-making processes of B2B buyers in the clothing labels sector. The environmental impact of textile production is significant, with conventional practices often leading to waste and pollution. As a result, there is a growing emphasis on ethical sourcing and the use of sustainable materials. International buyers from regions like Europe, where environmental regulations are stringent, are particularly interested in suppliers who can demonstrate compliance with green certifications.

To meet these demands, many suppliers are transitioning to organic materials, recycled fabrics, and low-impact dyes. Certifications such as GOTS (Global Organic Textile Standard) and OEKO-TEX® are becoming essential for businesses aiming to showcase their commitment to sustainability. Moreover, companies that prioritize ethical supply chains not only contribute to environmental conservation but also enhance their brand reputation among increasingly eco-conscious consumers.

For international B2B buyers, this shift presents both challenges and opportunities. While sourcing sustainable materials may initially involve higher costs, the long-term benefits include increased customer loyalty and potential access to new markets that prioritize sustainability.

What Is the Brief Evolution of the Custom Clothing Labels Sector?

The evolution of the custom clothing labels sector has been shaped by various economic, technological, and social factors. Initially, the market was dominated by traditional manufacturing processes that required large production runs and minimal customization. However, the advent of digital printing technology in the late 20th century revolutionized the industry by enabling smaller batches and personalized designs at a fraction of the cost.

In recent years, the rise of fast fashion has further accelerated the demand for custom labels, as brands seek to differentiate themselves in a crowded marketplace. Additionally, the increasing importance of branding and identity in consumer purchases has led to a greater focus on the design and quality of clothing labels. As sustainability and ethical sourcing continue to gain traction, the market is expected to evolve further, with more suppliers adopting innovative practices to meet the changing demands of international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of clothing labels custom

-

How do I ensure the quality of custom clothing labels when sourcing internationally?

To guarantee high-quality custom clothing labels, start by conducting thorough research on potential suppliers. Look for manufacturers with certifications, such as ISO 9001, that indicate adherence to quality management standards. Request samples of their previous work to assess material quality and printing precision. Additionally, consider visiting the factory if possible, or use third-party inspection services to conduct quality checks before shipment. Establishing a clear quality assurance protocol with the supplier is also crucial to avoid discrepancies. -

What are the minimum order quantities (MOQs) for custom clothing labels?

Minimum order quantities for custom clothing labels can vary significantly based on the supplier and the complexity of the design. Typically, MOQs range from 100 to 1,000 labels. Some manufacturers may offer lower MOQs for simpler designs or stock labels, while custom, intricate designs usually require higher MOQs. Always discuss MOQs upfront to ensure they align with your production needs and budget. Consider negotiating MOQs if you are looking to establish a long-term partnership. -

What payment terms should I expect when sourcing custom clothing labels?

Payment terms for custom clothing labels can differ among suppliers, but common practices include a 30% deposit upon order confirmation and the remaining 70% before shipment. Some suppliers may offer letters of credit or payment upon delivery as alternatives. It’s essential to clarify payment terms during negotiations to avoid misunderstandings. Additionally, consider the implications of currency exchange rates and transaction fees when dealing with international suppliers. -

How can I customize clothing labels to reflect my brand identity effectively?

To customize clothing labels that truly represent your brand, begin by defining your brand’s visual identity, including colors, fonts, and logos. Collaborate closely with the supplier to choose materials that align with your brand ethos—such as eco-friendly fabrics for sustainability-focused brands. Discuss label size and placement options that enhance brand visibility. Finally, consider adding unique features like QR codes or care instructions that provide added value to the customer and reinforce your brand message. -

What logistics considerations should I keep in mind when importing custom clothing labels?

When importing custom clothing labels, consider shipping options, lead times, and customs regulations. Choose a reliable freight forwarder to manage shipping logistics, and ensure you understand the import duties applicable to your country. Be aware of potential delays due to customs clearance, especially when dealing with international suppliers. It’s also advisable to track shipments closely and maintain communication with the supplier to address any issues promptly. -

How do I vet suppliers for custom clothing labels effectively?

Vetting suppliers for custom clothing labels involves several steps. First, check their business licenses and certifications to confirm legitimacy. Look for reviews and testimonials from previous clients to gauge reliability and quality. Request samples to assess the quality of their labels and verify their production capacity. Additionally, engage in direct communication to evaluate their responsiveness and willingness to accommodate your specific needs. Establishing a trial order can also help in assessing their capabilities. -

What are common materials used for custom clothing labels, and how do I choose the right one?

Common materials for custom clothing labels include woven, printed, and heat transfer labels. Woven labels are durable and offer a premium feel, making them ideal for high-end garments. Printed labels can be more cost-effective and suitable for larger quantities. Heat transfer labels provide a smooth finish but may not be as long-lasting. When choosing a material, consider the garment type, the label’s purpose (branding vs. care instructions), and your budget. Discuss options with your supplier to find the best fit. -

What are the best practices for designing custom clothing labels?

When designing custom clothing labels, prioritize clarity and legibility. Use fonts that are easy to read, and ensure that essential information—such as care instructions and brand name—is prominently displayed. Keep the design aligned with your overall brand aesthetics while ensuring it complies with industry regulations. Consider the label size and placement, as they should not detract from the garment’s appeal. Finally, solicit feedback from stakeholders or target customers to refine your label design before finalizing it with the manufacturer.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for clothing labels custom

Why is Strategic Sourcing Essential for Custom Clothing Labels?

In the ever-evolving global marketplace, the strategic sourcing of custom clothing labels is paramount for international B2B buyers. By prioritizing quality, cost-efficiency, and supplier reliability, businesses can enhance their brand identity while maintaining competitive pricing. Buyers from regions such as Africa, South America, the Middle East, and Europe must leverage local expertise and global resources to optimize their supply chains.

What Key Insights Should B2B Buyers Consider?

Understanding the nuances of materials, production techniques, and compliance regulations is crucial. Engaging with suppliers who share your commitment to sustainability and ethical practices can foster long-term partnerships. Additionally, utilizing digital tools for inventory management and order tracking will streamline operations and improve responsiveness to market demands.

How Can International Buyers Prepare for Future Trends?

As consumer preferences shift towards personalization and sustainability, B2B buyers should stay ahead by embracing innovative label solutions that reflect these values. Investing in technology and fostering collaboration with suppliers will position your business for future success.

In conclusion, the strategic sourcing of custom clothing labels is not just a procurement function; it’s a vital component of your brand’s growth strategy. Take action now by assessing your sourcing strategies and exploring new partnerships that align with your vision for the future.