Cut Costs with Paper Cutting Machine China: The Ultimate Guide (2025)

Introduction: Navigating the Global Market for paper cutting machine china

In today’s fast-paced global market, sourcing a reliable paper cutting machine from China presents a unique set of challenges for international B2B buyers. Whether you are a manufacturer in Africa, a distributor in South America, or a print shop owner in Europe, understanding the nuances of this complex supply chain is crucial. This comprehensive guide dives deep into the various types of paper cutting machines available, their specific applications, and the key factors to consider when selecting a supplier.

As an international buyer, you will face hurdles such as language barriers, varying quality standards, and differing regulations across regions. This guide aims to empower you with the knowledge to navigate these complexities effectively. You will learn how to evaluate suppliers, understand pricing structures, and identify the best machines that align with your operational needs.

Additionally, we will explore the latest trends in the paper cutting industry, helping you stay ahead of your competitors. With insights tailored to the unique contexts of buyers from Africa, South America, the Middle East, and Europe, this guide serves as a valuable resource for making informed purchasing decisions. By the end, you will be equipped with actionable insights that enhance your sourcing strategy and ultimately contribute to the success of your business.

Understanding paper cutting machine china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Guillotine Paper Cutters | Manual or electric operation, precision cutting | Print shops, schools, offices | Pros: High accuracy; Cons: Requires skilled operation. |

| Rotary Paper Cutters | Circular blade, suitable for cutting multiple sheets | Design studios, craft shops | Pros: Versatile; Cons: Limited cutting thickness. |

| Laser Cutting Machines | Uses laser technology for intricate designs | Manufacturing, custom projects | Pros: High precision; Cons: Higher initial investment. |

| Die Cutting Machines | Uses metal dies for specific shapes and designs | Packaging, labels, textile industry | Pros: Efficient for bulk production; Cons: Setup time can be lengthy. |

| Industrial Paper Cutters | Heavy-duty, high-speed operation for large volumes | Large print houses, manufacturing | Pros: Fast and robust; Cons: Requires significant floor space. |

What Are the Key Characteristics of Guillotine Paper Cutters?

Guillotine paper cutters are known for their manual or electric operation and precision cutting capabilities. They are ideal for applications in print shops, schools, and offices where accuracy is paramount. Buyers should consider the skill level required for operation, as improper use can lead to safety hazards and wasted materials. The ability to cut through multiple sheets at once is a significant advantage, making it a staple in environments that require high-volume cutting.

How Do Rotary Paper Cutters Differ from Other Types?

Rotary paper cutters feature a circular blade that allows for smooth and consistent cutting, making them suitable for design studios and craft shops. Their versatility enables them to handle various materials, including paper, cardstock, and even fabric. However, buyers should note the limitations in cutting thickness, as these machines are best suited for thinner materials. The ease of use makes them a popular choice for businesses that require frequent, varied cuts.

Why Choose Laser Cutting Machines for Precision Work?

Laser cutting machines utilize advanced laser technology to achieve intricate designs and high precision. These machines are particularly beneficial for manufacturing and custom projects where detail is essential. While the initial investment can be higher than other types, the long-term benefits of precision and the ability to cut a wide range of materials often justify the cost. Buyers should consider the operational costs and maintenance requirements when evaluating this option.

What Are the Advantages of Die Cutting Machines?

Die cutting machines are designed to create specific shapes and designs using metal dies. This type of machine is widely used in industries such as packaging, labels, and textiles. One of the primary advantages is efficiency in bulk production, as they can quickly create large quantities of the same shape. However, buyers should be aware of the setup time required to create custom dies, which can be a drawback for businesses needing quick turnaround times.

What Makes Industrial Paper Cutters Essential for Large Operations?

Industrial paper cutters are heavy-duty machines built for high-speed operation and large volumes of cutting. They are essential for large print houses and manufacturing facilities that require rapid processing of materials. While they offer speed and robustness, prospective buyers should consider the substantial floor space required for installation and operation. Additionally, the investment in these machines can be significant, so it’s crucial to evaluate long-term production needs.

Related Video: UTHQA4 Automatic A4 A3 Copy Paper Cutting and Sheeting Machine with Mechanical Delivery Unit

Key Industrial Applications of paper cutting machine china

| Industry/Sector | Specific Application of paper cutting machine china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Packaging and Printing | Cutting paper for packaging materials and labels | Increases efficiency in production and reduces waste | Machine durability, speed, and accuracy specifications |

| Education and Stationery | Producing notebooks, textbooks, and educational materials | Enhances product quality and reduces manual labor | Versatility for different paper sizes and thicknesses |

| Advertising and Marketing | Creating promotional materials, brochures, and flyers | Improves marketing effectiveness through high-quality prints | Customization options and after-sales support |

| Textile and Fashion Industries | Cutting paper patterns for garment production | Streamlines design processes and reduces errors | Compatibility with various paper types and thicknesses |

| Construction and Architecture | Producing architectural blueprints and plans | Ensures precision in project specifications | Ability to handle large-format paper and precision cutting |

How is a Paper Cutting Machine Used in the Packaging and Printing Industry?

In the packaging and printing sector, paper cutting machines from China are essential for producing various packaging materials and labels. These machines enhance production efficiency by automating the cutting process, significantly reducing waste and labor costs. For international buyers, particularly from regions like Africa and South America, it is crucial to consider the machine’s durability and its ability to handle high-speed operations without compromising quality, which is vital for meeting market demands.

What Role Does a Paper Cutting Machine Play in Education and Stationery?

In the education and stationery industry, paper cutting machines are used to manufacture notebooks, textbooks, and other educational materials. By automating the cutting process, these machines enhance product quality and reduce manual labor, allowing companies to focus on design and distribution. Buyers from Europe and the Middle East should prioritize machines that can accommodate various paper sizes and thicknesses to cater to diverse educational needs.

How Do Paper Cutting Machines Benefit Advertising and Marketing Firms?

Advertising and marketing firms utilize paper cutting machines to produce high-quality promotional materials, brochures, and flyers. The precision and speed of these machines enable businesses to create visually appealing marketing materials that effectively communicate their brand message. For B2B buyers in regions like South America, customization options and robust after-sales support are critical factors to consider when sourcing these machines.

In What Ways are Paper Cutting Machines Essential for Textile and Fashion Industries?

In the textile and fashion industries, paper cutting machines are vital for cutting patterns used in garment production. These machines streamline the design process, reducing errors that can occur with manual cutting. International buyers, particularly from Africa and Europe, should focus on sourcing machines that can handle various paper types and thicknesses to meet the specific demands of fabric pattern cutting.

How Do Paper Cutting Machines Support Construction and Architecture?

In the construction and architecture sectors, paper cutting machines are used to produce architectural blueprints and plans. The precision cutting ensures that project specifications are accurate, which is essential for successful project execution. Buyers from the Middle East and Europe should look for machines that can handle large-format paper and provide precision cutting capabilities to meet their architectural needs effectively.

Related Video: How to operate guillotine machine/ paper cutting machine

3 Common User Pain Points for ‘paper cutting machine china’ & Their Solutions

Scenario 1: Navigating Quality Concerns with Chinese Paper Cutting Machines

The Problem: One of the foremost challenges B2B buyers encounter when sourcing paper cutting machines from China is ensuring product quality. Many suppliers may offer competitive prices, but there is often a lack of transparency regarding the materials used, production processes, and quality assurance measures. This uncertainty can lead to significant risks, including receiving machines that do not meet operational standards or result in high maintenance costs, ultimately affecting production timelines and profitability.

The Solution: To mitigate quality concerns, B2B buyers should adopt a comprehensive supplier evaluation process. Begin by requesting samples and detailed specifications of the paper cutting machines to assess their build quality and performance. Engaging in direct communication with manufacturers can provide insight into their production techniques and quality control practices. Furthermore, consider visiting factories in China or hiring third-party inspection services to verify that the machines meet international standards. Leveraging platforms like Alibaba or Global Sources, where suppliers are rated based on past performance, can also help in selecting reputable manufacturers. Establishing a clear contract that includes warranties and return policies can safeguard your investment against potential quality issues.

Scenario 2: Understanding Shipping and Import Regulations for Paper Cutting Machines

The Problem: For international B2B buyers, navigating the complex shipping and import regulations when purchasing paper cutting machines from China can be overwhelming. Different countries have varying import duties, taxes, and compliance requirements, which can lead to unexpected delays and additional costs if not properly understood and managed.

The Solution: To avoid shipping pitfalls, it’s essential to conduct thorough research on your country’s import regulations concerning industrial machinery. Collaborate with a logistics partner who specializes in international shipping and understands the nuances of customs regulations for machinery. They can assist you in preparing the necessary documentation, such as commercial invoices and certificates of origin, which can expedite customs clearance. Additionally, buyers should factor in all associated costs, including freight, insurance, and customs duties, into the total purchase price to ensure budget accuracy. Staying informed about trade agreements between your country and China can also provide opportunities for reduced tariffs and streamlined shipping processes.

Scenario 3: Adapting to Diverse Production Needs with Versatile Machines

The Problem: Different industries have varying requirements when it comes to paper cutting machines, leading to a common frustration among B2B buyers: the inability to find a machine that can adapt to their specific production needs. For instance, a company that produces both large-format prints and small, intricate designs may struggle to find a single machine that can efficiently handle both tasks.

The Solution: To address the need for versatility, buyers should focus on sourcing paper cutting machines that offer customizable features and attachments. Research models that come equipped with interchangeable blades and settings to accommodate various paper sizes and cutting styles. It’s also beneficial to consult with suppliers about machine configurations that can be tailored to meet unique production demands. If possible, request demonstrations or trials to evaluate the machine’s performance across different tasks before finalizing your purchase. Additionally, consider investing in machines with advanced technological features, such as programmable settings and automation capabilities, which can enhance efficiency and adaptability in production environments. Engaging in discussions with suppliers about future scalability options can ensure that your investment remains relevant as production needs evolve.

Strategic Material Selection Guide for paper cutting machine china

When selecting materials for paper cutting machines sourced from China, international B2B buyers must consider several factors that directly influence the performance, durability, and cost-effectiveness of the machines. Here, we analyze four common materials used in the manufacturing of these machines: steel, aluminum, plastic composites, and rubber.

What Are the Key Properties of Steel in Paper Cutting Machines?

Steel is a prevalent material in the construction of paper cutting machines due to its strength and durability. Key properties include high tensile strength, excellent wear resistance, and the ability to withstand high temperatures and pressures. Steel’s corrosion resistance can vary depending on the type used; stainless steel, for instance, offers superior resistance to rust and chemical exposure.

Pros & Cons: The primary advantage of steel is its durability, which translates to a longer lifespan for the machine. However, steel can be heavier and more expensive compared to other materials, which may increase shipping costs. Additionally, the manufacturing complexity can be higher due to the need for specialized cutting and welding techniques.

Impact on Application: Steel is particularly suitable for heavy-duty applications, such as cutting thick paper or cardboard. Its robustness ensures consistent performance under high stress.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local quality standards, such as ASTM or DIN, to guarantee that the steel used meets their operational requirements.

How Does Aluminum Benefit Paper Cutting Machines?

Aluminum is often chosen for its lightweight nature and resistance to corrosion. Key properties include a favorable strength-to-weight ratio and good thermal conductivity, which can be beneficial for heat dissipation during operation.

Pros & Cons: The main advantage of aluminum is its lightweight, making it easier to handle and transport. However, it is generally less durable than steel and may not withstand heavy-duty applications as effectively. The cost of aluminum is typically moderate, but it can be higher than that of some plastic composites.

Impact on Application: Aluminum is ideal for applications requiring precision and speed, such as high-volume paper cutting tasks. Its resistance to corrosion makes it suitable for environments with high humidity or exposure to moisture.

Considerations for International Buyers: Buyers in Europe and the Middle East should look for aluminum that meets specific standards, such as JIS or EN, to ensure quality and performance.

What Role Do Plastic Composites Play in Paper Cutting Machines?

Plastic composites are increasingly used in paper cutting machines due to their versatility and resistance to corrosion. Key properties include lightweight, durability, and resistance to chemicals.

Pros & Cons: The primary advantage of plastic composites is their low weight and resistance to corrosion, making them suitable for various environments. However, they may not be as strong as metal options, which could limit their use in heavy-duty applications. The manufacturing process is generally simpler and less costly than metals.

Impact on Application: Plastic composites are well-suited for applications involving lighter materials, such as thin paper or film, where precision is crucial.

Considerations for International Buyers: Buyers should ensure that the plastic composites used comply with relevant safety and environmental regulations in their regions, particularly in Europe, where standards are stringent.

How Does Rubber Enhance Performance in Paper Cutting Machines?

Rubber is commonly used in components such as rollers and pads in paper cutting machines. Key properties include excellent grip, flexibility, and shock absorption.

Pros & Cons: The main advantage of rubber is its ability to provide a non-slip surface, enhancing the machine’s performance. However, rubber can degrade over time, especially when exposed to certain chemicals or extreme temperatures. The cost is generally low, making it an economical choice for various applications.

Impact on Application: Rubber components are critical for ensuring smooth operation and preventing slippage during the cutting process, especially in high-speed machines.

Considerations for International Buyers: Buyers should be aware of the quality of rubber materials used, as substandard rubber can lead to premature wear and increased maintenance costs.

Summary Table of Material Selection for Paper Cutting Machines

| Material | Typical Use Case for paper cutting machine china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty cutting applications | Exceptional durability | Heavier and more expensive | High |

| Aluminum | High-speed, precision cutting | Lightweight and corrosion-resistant | Less durable than steel | Medium |

| Plastic Composites | Light paper and film cutting | Low weight and chemical resistance | Limited strength for heavy-duty use | Low |

| Rubber | Rollers and pads in cutting machines | Excellent grip and shock absorption | Degrades over time | Low |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, enabling them to make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for paper cutting machine china

What Are the Main Stages of Manufacturing a Paper Cutting Machine in China?

The manufacturing process of a paper cutting machine in China is a multi-stage operation that emphasizes precision and efficiency. Understanding this process can help international B2B buyers ensure they are sourcing high-quality equipment. The key stages include:

-

Material Preparation: The first step involves selecting the right raw materials, such as high-grade steel for the machine’s frame and high-performance cutting blades. Suppliers often source materials locally to reduce costs and ensure timely availability. It’s essential for buyers to inquire about the material specifications and certifications, as these directly affect the machine’s durability and cutting performance.

-

Forming: This stage involves shaping the raw materials into the desired components using techniques such as stamping, laser cutting, and CNC machining. CNC (Computer Numerical Control) machining is particularly important for achieving high precision in the parts that will affect the machine’s cutting accuracy. Buyers should look for manufacturers that use advanced forming technologies, as this can significantly enhance the quality of the final product.

-

Assembly: Once the components are formed, they are assembled into the final machine. This process includes installing the cutting mechanism, electrical components, and safety features. Skilled technicians perform the assembly to ensure that all parts fit correctly and function together seamlessly. B2B buyers should ask about the assembly workforce’s expertise and whether they follow strict assembly protocols.

-

Finishing: The finishing stage includes surface treatment, painting, and quality checks. Surface treatments like powder coating or anodizing enhance corrosion resistance and aesthetic appeal. Quality checks at this stage ensure that the machine meets both functional and visual standards. Buyers should verify that the manufacturer has a dedicated finishing process to maintain the quality of the product.

How Is Quality Assurance Implemented in the Manufacturing of Paper Cutting Machines?

Quality assurance (QA) is a critical aspect of the manufacturing process for paper cutting machines. It ensures that the products meet international and industry-specific standards. Here are the key elements of QA:

-

International Standards: Many manufacturers adhere to ISO 9001, a widely recognized standard for quality management systems. Compliance with ISO 9001 indicates that the manufacturer has a systematic approach to managing quality across all stages of production. Additionally, certifications like CE mark for European markets and API standards for equipment safety are important for ensuring that the machines meet regional regulations.

-

Quality Control Checkpoints: Effective QA involves multiple checkpoints throughout the manufacturing process, including:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon delivery to ensure they meet specified standards.

– In-Process Quality Control (IPQC): This includes monitoring the manufacturing process to detect defects as they occur, which helps to prevent costly errors.

– Final Quality Control (FQC): After assembly, the finished machines undergo rigorous testing to ensure they operate correctly and safely before shipment. -

Common Testing Methods: Manufacturers typically employ various testing methods, including functional tests, load tests, and safety inspections. These tests assess the machine’s performance under real-world conditions, ensuring that it meets the buyer’s specifications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying the quality control practices of suppliers is crucial to ensuring that they receive reliable products. Here are some actionable strategies:

-

Conducting Audits: Buyers should consider conducting on-site audits of potential suppliers. This allows them to evaluate the manufacturing processes, quality control systems, and working conditions directly. It also provides an opportunity to discuss quality standards and practices with the management team.

-

Requesting Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including inspection reports and compliance certifications. Buyers should request these documents to assess the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturing process and product quality. These inspectors can verify that the products meet specified standards and can also help to identify any potential issues before shipment.

What Are the QC and Certification Nuances for International Buyers?

Navigating the quality control and certification landscape can be complex for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. Here are some nuances to consider:

-

Regional Compliance: Different regions have varying compliance requirements. For example, while CE marking is essential for European markets, other regions may have different certifications. Buyers should familiarize themselves with local regulations to ensure compliance and avoid any legal issues.

-

Cultural Differences: Understanding cultural attitudes toward quality and business practices can enhance communication with suppliers. For instance, in some cultures, direct feedback may be viewed differently than in others. Building a rapport can facilitate more effective discussions regarding quality expectations.

-

Documentation and Traceability: Buyers should ensure that suppliers maintain thorough documentation of their quality control processes, including traceability of materials used in production. This is particularly important for industries where compliance with safety standards is critical.

Conclusion

For international B2B buyers, understanding the manufacturing processes and quality assurance protocols for paper cutting machines in China is essential for making informed purchasing decisions. By focusing on material preparation, forming, assembly, finishing, and rigorous quality control measures, buyers can ensure they are sourcing high-quality machines that meet their specific needs. Engaging in audits, requesting quality reports, and understanding regional compliance nuances further empower buyers to navigate the complexities of international sourcing effectively.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘paper cutting machine china’

When sourcing a paper cutting machine from China, it’s essential to approach the process methodically to ensure you make a well-informed decision. This guide provides a step-by-step checklist that will help international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, navigate the complexities of procurement.

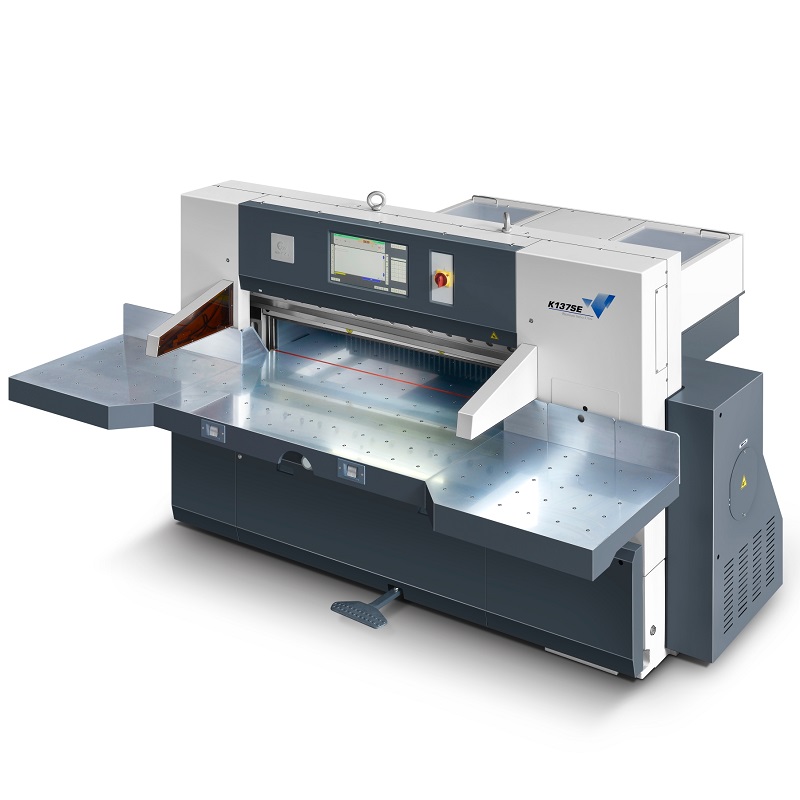

A stock image related to paper cutting machine china.

Step 1: Define Your Technical Specifications

Begin by determining the technical specifications needed for your paper cutting machine. This includes the cutting capacity, dimensions, and the materials it can handle. Precise specifications help narrow down potential suppliers and ensure you select a machine that meets your operational needs.

- Consider the type of paper: Will you be cutting standard sheets, or do you need to accommodate thicker materials?

- Evaluate automation needs: Do you require manual, semi-automatic, or fully automatic machines?

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers in China. Utilize platforms such as Alibaba, Made-in-China, or global trade shows to find manufacturers specializing in paper cutting machines.

- Check for company longevity: Look for suppliers with a proven track record of successful transactions.

- Read reviews and ratings: Customer feedback can provide insights into product quality and service reliability.

Step 3: Verify Supplier Certifications

Before proceeding with any supplier, it’s crucial to confirm their certifications. This not only ensures compliance with international standards but also enhances your purchasing confidence.

- Look for ISO certifications: These indicate adherence to quality management systems.

- Inquire about CE or UL certifications: These demonstrate that the machine meets safety and performance standards applicable in your region.

Step 4: Request Product Samples

Always request samples of the machines you are considering. This step allows you to assess the quality and functionality of the product firsthand, ensuring it meets your specifications.

- Evaluate the sample’s performance: Test the machine with the types of paper you plan to use.

- Check for ease of use: Ensure that the machine is user-friendly and fits well within your operational workflow.

Step 5: Understand Payment and Shipping Terms

Clarify payment and shipping terms before finalizing any agreements. Understanding these elements can prevent costly misunderstandings later on.

- Discuss payment methods: Explore secure options such as letters of credit or escrow services to protect your investment.

- Review shipping logistics: Determine who will handle shipping and customs clearance, and ensure you understand the associated costs.

Step 6: Negotiate Pricing and Warranty Options

Negotiation is a critical component of any B2B purchase. Engage in discussions about pricing, payment terms, and warranty options to secure the best deal.

- Ask for bulk discounts: If you plan to order multiple machines, inquire about volume pricing.

- Clarify warranty terms: A strong warranty can save you from unexpected repair costs and downtime.

Step 7: Finalize the Contract

Once you have verified all details and are satisfied with the terms, finalize the contract. Ensure it includes all agreed-upon specifications, payment terms, and delivery timelines.

- Review legal implications: Consult with a legal expert familiar with international trade to ensure compliance with local regulations.

- Include clear dispute resolution procedures: This can provide peace of mind in case any issues arise during the transaction.

By following this checklist, B2B buyers can navigate the sourcing process more effectively, ensuring they procure a paper cutting machine that meets their needs while minimizing risks associated with international trade.

Comprehensive Cost and Pricing Analysis for paper cutting machine china Sourcing

When sourcing paper cutting machines from China, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. This analysis breaks down the key cost components and pricing influencers that impact your purchasing decisions.

What Are the Key Cost Components for Paper Cutting Machines?

-

Materials: The primary cost driver is the raw materials used in manufacturing paper cutting machines. Common materials include steel, aluminum, and various electronic components. The quality of these materials directly affects the durability and performance of the machine, which can influence your long-term investment.

-

Labor Costs: Labor is a significant factor, especially in regions where manufacturing is labor-intensive. Chinese manufacturers often benefit from lower labor costs compared to their Western counterparts. However, labor costs can vary based on the complexity of the machine and the skill level required.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help minimize these overhead costs, allowing suppliers to offer competitive pricing.

-

Tooling Costs: Customization may necessitate specialized tooling, which can add to the initial cost. If you require specific features or designs, it’s essential to factor these tooling costs into your overall budget.

-

Quality Control (QC): Ensuring quality through rigorous testing and inspection can incur additional costs. However, investing in QC can prevent costly defects and returns, ultimately saving money in the long run.

-

Logistics: Shipping and handling costs are critical components, especially for international buyers. Factors such as distance, shipping methods, and Incoterms will significantly impact the overall logistics cost.

-

Margin: Suppliers typically add a profit margin to their costs, which can vary widely based on market demand, competition, and the perceived value of the machine. Understanding the supplier’s pricing strategy can provide insights into negotiating better terms.

How Do Price Influencers Affect Sourcing Decisions?

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk can often lead to significant discounts. Be sure to negotiate MOQs with your supplier to maximize cost savings.

-

Specifications and Customization: Custom features or specifications can increase costs. Clearly define your requirements upfront to avoid unexpected expenses later in the process.

-

Material Quality and Certifications: Machines that meet international quality standards or certifications (e.g., ISO, CE) may come at a premium but can offer greater reliability and performance, enhancing your Total Cost of Ownership (TCO).

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established manufacturers with a track record of quality may charge higher prices but can provide better support and warranty options.

-

Incoterms: Understanding Incoterms is vital for determining who bears the risk and cost at various stages of transportation. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can influence your overall cost structure.

What Negotiation Tips Can Help International Buyers?

- Do Your Research: Understand the market rates for paper cutting machines and gather quotes from multiple suppliers to leverage competitive pricing.

- Build Relationships: Establishing a good rapport with suppliers can lead to better pricing and terms over time.

- Consider Total Cost of Ownership: Evaluate not just the purchase price but also maintenance, operational costs, and potential resale value when making your decision.

- Be Clear on Specifications: Clearly communicate your requirements to avoid misunderstandings that could lead to increased costs later.

What Should Buyers Keep in Mind Regarding Pricing Nuances?

International buyers should be aware that pricing can fluctuate based on geopolitical factors, currency exchange rates, and changes in trade policies. Always include a disclaimer regarding indicative prices, as costs can vary significantly based on the specifics of the order and market conditions.

By understanding these cost components and pricing influencers, B2B buyers can make informed decisions when sourcing paper cutting machines from China, ensuring they achieve the best value for their investment.

Alternatives Analysis: Comparing paper cutting machine china With Other Solutions

When considering investments in paper cutting solutions, it’s essential to explore various alternatives to ensure that your choice aligns with your operational needs and budget constraints. Each alternative offers distinct advantages and drawbacks, and understanding these can help international B2B buyers make informed decisions.

| Comparison Aspect | Paper Cutting Machine China | Laser Cutting Technology | Manual Paper Cutting Tools |

|---|---|---|---|

| Performance | High-speed cutting, precise angles for various paper sizes | Extremely precise cuts, can handle intricate designs | Generally slower, reliant on operator skill |

| Cost | Moderate initial investment; affordable maintenance | High initial investment; costly repairs | Very low initial cost; no ongoing expenses |

| Ease of Implementation | Requires setup and training; user-friendly interfaces available | Requires specialized training; complex setup | Very easy to use; no training required |

| Maintenance | Regular maintenance needed; parts easily sourced | High maintenance costs; parts may be expensive | Minimal maintenance; durable and long-lasting |

| Best Use Case | Mass production, commercial printing, bulk cutting | Custom designs, intricate patterns, and small batch production | Small businesses, occasional use, or home offices |

What Are the Advantages and Disadvantages of Laser Cutting Technology?

Laser cutting technology provides exceptional precision and versatility, making it suitable for intricate designs and custom projects. It can cut through a variety of materials beyond just paper, including plastics and wood, which enhances its utility. However, the high initial investment and maintenance costs can be prohibitive for smaller businesses. Additionally, the need for specialized training to operate laser cutters can be a barrier for some users, especially in regions with limited access to technical education.

How Do Manual Paper Cutting Tools Compare in Functionality?

Manual paper cutting tools, such as guillotines or rotary cutters, are the most cost-effective option, making them ideal for small businesses or individuals with limited budgets. They require no electricity and have minimal maintenance needs, ensuring low operational costs. However, their performance is heavily reliant on the operator’s skill and can be time-consuming for large volumes of cutting. Manual tools are best suited for occasional use or small projects where precision is less critical.

Conclusion: How to Choose the Right Paper Cutting Solution for Your Business Needs?

Selecting the appropriate paper cutting solution depends on your specific operational requirements, budget, and production volume. If your business involves high-volume production and requires precision, investing in a paper cutting machine from China or laser cutting technology might be the best choice. On the other hand, if your needs are more modest or infrequent, manual cutting tools could suffice. Consider your long-term goals, the complexity of your projects, and the available resources to make the most informed decision.

Essential Technical Properties and Trade Terminology for paper cutting machine china

What Are the Key Technical Properties of Paper Cutting Machines from China?

When considering the purchase of a paper cutting machine from China, it is essential to understand specific technical properties that can significantly impact performance, efficiency, and overall cost-effectiveness. Here are some critical specifications to consider:

1. Material Grade

The material grade of a paper cutting machine affects its durability and performance. High-grade steel is often used for blades and frames, providing strength and resistance to wear. A robust material grade ensures longevity, which is crucial for B2B buyers looking to minimize downtime and maintenance costs.

2. Cutting Tolerance

Cutting tolerance refers to the precision with which the machine can cut paper. Typically measured in millimeters, tighter tolerances result in cleaner cuts and less waste. For industries requiring high-quality outputs, such as printing or packaging, understanding cutting tolerances can help in selecting a machine that meets specific production standards.

3. Speed and Capacity

The speed of operation (usually measured in cuts per minute) and the maximum capacity (size and thickness of paper) are vital metrics for efficiency. B2B buyers should evaluate their production requirements against these specifications. A machine that operates at higher speeds can significantly enhance productivity, especially in high-volume environments.

4. Automation Features

Many modern paper cutting machines come equipped with automation features, such as programmable settings and digital displays. These enhancements can streamline operations, reduce manual intervention, and lower the likelihood of human error. For businesses looking to scale production, automation capabilities are a critical consideration.

5. Energy Efficiency

Energy-efficient machines consume less power, leading to reduced operational costs. B2B buyers should inquire about energy ratings and consider machines that incorporate advanced technology to optimize energy use. This is particularly important for companies focused on sustainability and reducing their carbon footprint.

6. Safety Features

Safety is paramount in any industrial machinery. Look for features such as emergency stop buttons, safety shields, and automatic shut-off mechanisms. Understanding the safety specifications of a machine can protect employees and reduce liability for businesses.

What Trade Terminology Should B2B Buyers Understand When Sourcing Paper Cutting Machines?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are essential trade terms relevant to purchasing paper cutting machines:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding whether a machine is sourced from an OEM can affect quality assurance and warranty provisions. This is crucial for B2B buyers who prioritize reliability.

2. MOQ (Minimum Order Quantity)

MOQ denotes the minimum quantity of units a supplier is willing to sell. This term is particularly relevant for B2B buyers looking to negotiate pricing and inventory management. Understanding MOQ can help companies avoid excess inventory and optimize cash flow.

3. RFQ (Request for Quotation)

An RFQ is a standard business process in which a buyer requests pricing and terms from suppliers. By issuing an RFQ, B2B buyers can compare offers, leading to informed purchasing decisions. Crafting a clear RFQ can streamline communication and ensure that all necessary specifications are covered.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with these terms helps B2B buyers understand their obligations and rights in the purchasing process, which is crucial when sourcing from international suppliers like those in China.

5. Lead Time

Lead time refers to the time between placing an order and receiving the product. Understanding lead times is essential for B2B buyers to plan their production schedules effectively. A shorter lead time can enhance responsiveness to market demands.

6. Warranty and After-Sales Support

Warranty terms outline the manufacturer’s responsibility for repairs or replacements. Understanding warranty conditions and the availability of after-sales support is vital for B2B buyers to ensure long-term operational continuity and to mitigate risks associated with equipment failure.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing paper cutting machines from China, ensuring that they select equipment that meets their operational needs and strategic goals.

Navigating Market Dynamics and Sourcing Trends in the paper cutting machine china Sector

What Are the Current Market Dynamics and Key Trends in the Paper Cutting Machine Sector?

The global paper cutting machine market is currently experiencing significant transformation, driven by technological advancements and changing consumer preferences. One of the key trends is the increasing demand for automated and semi-automated paper cutting machines, which enhance productivity and reduce operational costs. This shift is especially relevant for international B2B buyers in Africa, South America, the Middle East, and Europe, where efficient production processes are crucial for maintaining competitiveness in diverse markets.

Additionally, the rise of e-commerce and digital printing is reshaping sourcing strategies. Businesses are increasingly looking for suppliers who can offer customized solutions and quick turnaround times. This trend has been particularly pronounced in South America, where local manufacturers are adapting to meet the specific needs of digital printing operations. Buyers from regions like Africa and the Middle East should prioritize suppliers with a robust supply chain capable of rapid response to fluctuations in demand.

Another significant factor influencing the market is the growing emphasis on sustainability. International buyers are now more inclined to collaborate with manufacturers who demonstrate a commitment to environmentally friendly practices, from production to packaging. This trend is not only about compliance but also about enhancing brand value and customer loyalty in a market that increasingly values corporate responsibility.

How Important Is Sustainability and Ethical Sourcing in the Paper Cutting Machine Sector?

Sustainability is becoming a critical criterion for B2B buyers in the paper cutting machine market. The environmental impact of manufacturing processes can no longer be overlooked, as businesses face pressure from consumers and regulatory bodies to adopt greener practices. This includes reducing waste, minimizing energy consumption, and using sustainable materials in production.

Ethical sourcing is also essential for establishing a responsible supply chain. Buyers should seek manufacturers that prioritize transparency and fair labor practices. Certifications such as ISO 14001 (Environmental Management) and FSC (Forest Stewardship Council) are indicators of a company’s commitment to sustainability and ethical practices. By choosing suppliers with these certifications, international buyers can ensure they are sourcing from companies that align with their values and contribute positively to the environment.

Moreover, integrating sustainable practices can result in cost savings in the long run. For instance, energy-efficient machines reduce operational costs, while using recycled materials can lower raw material expenses. Buyers from Europe, the Middle East, and Africa should not only focus on the initial investment but also consider the long-term benefits of partnering with eco-conscious manufacturers.

What Has Been the Evolution of the Paper Cutting Machine Sector?

The paper cutting machine sector has evolved significantly over the past few decades. Initially, the market was dominated by manual cutting tools that required significant human labor and expertise. However, the introduction of electric and automated machines revolutionized the industry, allowing for greater precision and efficiency.

In the early 2000s, advancements in digital technology led to the development of computer-controlled cutting systems, which further enhanced the capabilities of paper cutting machines. These innovations allowed businesses to produce intricate designs and higher volumes at a faster pace. Today, the focus is on integrating smart technologies, such as IoT connectivity and AI, to optimize machine performance and predictive maintenance.

For international B2B buyers, understanding this evolution is crucial. It highlights the importance of investing in modern, technologically advanced machines that can adapt to changing market demands and consumer preferences. As the industry continues to innovate, buyers should stay informed about emerging technologies that can enhance their operational efficiency and product offerings.

Frequently Asked Questions (FAQs) for B2B Buyers of paper cutting machine china

-

How do I choose the right paper cutting machine for my business?

Selecting the appropriate paper cutting machine involves assessing your specific production needs. Consider the type of paper you will cut, the volume of production, and the desired precision. It’s essential to evaluate the machine’s specifications, such as cutting width, speed, and power. Additionally, check for features like programmable settings and safety mechanisms. Consulting with suppliers in China who specialize in machinery can provide insights tailored to your requirements. -

What are the key features to look for in a paper cutting machine?

When sourcing a paper cutting machine, prioritize features such as cutting capacity, automation level, and safety features. Look for machines with adjustable cutting settings for various paper types and sizes. A user-friendly interface and reliable after-sales support are also crucial. Additionally, consider machines with energy-efficient designs to minimize operational costs in the long run, especially for businesses in regions like Africa and South America. -

What is the typical lead time for paper cutting machines from China?

Lead times for paper cutting machines can vary based on factors like customization, order size, and supplier location. Generally, expect a lead time of 4-12 weeks from order confirmation to delivery. It’s advisable to discuss timelines with your supplier upfront and factor in potential delays due to shipping or customs clearance, especially when importing to regions such as Europe or the Middle East. -

How can I vet suppliers of paper cutting machines in China?

To effectively vet suppliers, start by researching their business reputation through online platforms and industry forums. Check for certifications, such as ISO, that indicate quality standards. Request references from previous international clients and assess their responsiveness and communication skills. Additionally, consider visiting the factory if possible, or hiring a local agent to conduct a thorough inspection before finalizing any agreements. -

What are the common payment terms for purchasing paper cutting machines from China?

Payment terms can vary but typically include options like a 30% deposit upon order confirmation and the remaining 70% before shipment. Some suppliers may offer letters of credit or escrow services for larger transactions. Always clarify payment methods accepted (e.g., bank transfer, PayPal) and consider negotiating terms that protect your investment, especially for first-time purchases. -

Is customization available for paper cutting machines?

Yes, many suppliers in China offer customization options for paper cutting machines to meet specific business needs. Customizations can include modifications in cutting size, automation features, and branding options. When discussing customization, be clear about your requirements and ensure that the supplier can deliver within your timeline and budget constraints. -

What are the shipping options for importing paper cutting machines from China?

Shipping options include sea freight, air freight, and express courier services. Sea freight is the most cost-effective for larger machines but may take longer. Air freight is faster but can be significantly more expensive. Consider your budget and urgency when selecting a shipping method. Additionally, ensure that your supplier provides all necessary documentation for customs clearance to avoid delays. -

How can I ensure quality assurance for my paper cutting machine?

To ensure quality assurance, request detailed specifications and certifications from your supplier before purchasing. Establish clear quality standards and inspection processes, including pre-shipment inspections. Many suppliers are open to providing sample runs or trial machines. Additionally, consider purchasing from manufacturers with a solid reputation for quality control and customer service in the industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for paper cutting machine china

In navigating the competitive landscape of sourcing paper cutting machines from China, international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, must emphasize strategic sourcing to maximize value. Key takeaways include the importance of understanding supplier capabilities, evaluating product quality, and negotiating favorable terms. Buyers should prioritize building strong relationships with manufacturers, which can lead to enhanced support, better pricing, and improved supply chain reliability.

How Can Strategic Sourcing Enhance Your Procurement Process?

A stock image related to paper cutting machine china.

Strategic sourcing is not merely about obtaining the best prices; it involves a comprehensive assessment of suppliers to ensure alignment with your operational goals. By utilizing detailed market analysis and leveraging technological advancements, businesses can streamline their procurement processes and reduce costs in the long run.

What Should B2B Buyers Consider for Future Sourcing?

Looking ahead, it is crucial for B2B buyers to remain agile and informed about market trends and emerging technologies in the paper cutting machine sector. Engaging in continuous dialogue with suppliers and participating in industry forums can provide invaluable insights and foster innovation.

By taking these proactive steps, buyers can secure a competitive edge in their markets and ensure sustainable growth. Start your journey towards effective strategic sourcing today and unlock the potential of your procurement strategy.