Cut Costs with PCB Manufacturing Custom: The Complete Guide (2025)

Introduction: Navigating the Global Market for pcb manufacturing custom

In today’s fast-paced technological landscape, sourcing custom PCB manufacturing solutions poses a significant challenge for international B2B buyers. With the increasing complexity of electronic devices, businesses from regions like Africa, South America, the Middle East, and Europe must navigate a diverse market filled with various suppliers and manufacturing capabilities. This guide provides a comprehensive overview of the PCB manufacturing process, including the types of PCBs available, their applications across different industries, and essential criteria for vetting suppliers.

By addressing key aspects such as cost considerations, quality assurance, and lead times, this resource empowers B2B buyers to make informed purchasing decisions. Whether you’re based in Nairobi, Kenya, or Madrid, Spain, understanding the nuances of custom PCB manufacturing can significantly impact your product development and supply chain efficiency.

With actionable insights and expert advice, this guide will help you streamline your sourcing process, mitigate risks, and ultimately enhance your competitive edge in the global market. By leveraging this knowledge, you can confidently select the right partners and technologies to meet your unique business needs and drive innovation in your products.

Understanding pcb manufacturing custom Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rigid PCBs | Solid substrate, typically made from fiberglass. | Consumer electronics, automotive, industrial | Pros: Cost-effective, robust. Cons: Limited flexibility. |

| Flexible PCBs | Bendable materials, allowing for complex designs. | Wearable devices, medical equipment, aerospace | Pros: Lightweight, space-saving. Cons: Higher costs. |

| Rigid-Flex PCBs | Combination of rigid and flexible circuits. | High-end electronics, military, medical devices | Pros: Versatile, reduces assembly time. Cons: Complex design. |

| Multilayer PCBs | Layers of circuits stacked together. | High-frequency applications, telecommunications | Pros: Enhanced performance, compact design. Cons: More expensive. |

| High-Frequency PCBs | Designed for minimal signal loss at high frequencies. | RF communication, satellite systems, IoT devices | Pros: Optimized for speed, reliability. Cons: Specialized materials can be costly. |

What Are Rigid PCBs and Their Applications?

Rigid PCBs are the most common type of printed circuit boards, characterized by their solid, inflexible structure. Typically made from fiberglass, they are utilized in a wide range of applications, including consumer electronics, automotive systems, and industrial machinery. When purchasing rigid PCBs, buyers should consider factors such as material quality, manufacturing capabilities, and compliance with industry standards. Their cost-effectiveness and robustness make them a go-to choice for many businesses, though their lack of flexibility can be a drawback in certain applications.

How Do Flexible PCBs Benefit B2B Buyers?

Flexible PCBs are designed to bend and fold, making them suitable for applications where space is limited or where complex shapes are required. Commonly found in wearable devices, medical equipment, and aerospace technology, these boards offer significant advantages in terms of weight and design flexibility. Buyers should weigh the benefits of reduced weight and improved design options against the higher costs associated with flexible PCB manufacturing. Understanding the specific requirements of the end-use application is crucial for making an informed purchasing decision.

What Are the Advantages of Rigid-Flex PCBs?

Rigid-flex PCBs combine the benefits of both rigid and flexible PCBs, allowing for complex layouts in compact spaces. They are often used in high-end electronics, military applications, and advanced medical devices. When considering rigid-flex PCBs, B2B buyers should focus on the design complexity and the potential for reduced assembly time. While they provide versatility and can lead to cost savings in assembly, the complexity of design and manufacturing can increase initial costs.

Why Choose Multilayer PCBs for Advanced Applications?

Multilayer PCBs consist of multiple layers of circuits stacked together, which allows for a compact design and enhanced performance. These boards are ideal for high-frequency applications such as telecommunications and RF devices. For B2B buyers, understanding the nuances of multilayer PCB manufacturing is essential, as these boards can be more expensive but offer improved functionality and space-saving advantages. Buyers should also consider the manufacturer’s experience in multilayer designs to ensure quality and reliability.

What Makes High-Frequency PCBs Unique?

High-frequency PCBs are specifically engineered to minimize signal loss at elevated frequencies, making them essential for RF communication, satellite systems, and IoT devices. When purchasing high-frequency PCBs, buyers must consider the specialized materials and manufacturing processes involved, as these can significantly affect costs. The benefits of optimized speed and reliability in critical applications often justify the investment, but understanding the technical requirements is vital for ensuring the right specifications are met.

Related Video: PCB Manufacturing Process , PCB making

Key Industrial Applications of pcb manufacturing custom

| Industry/Sector | Specific Application of PCB Manufacturing Custom | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Consumer Electronics | Custom PCBs for smartphones and tablets | Enhances device performance and user experience | Quality certifications, lead times, and scalability |

| Automotive | PCBs for electric vehicle (EV) systems | Supports advanced functionalities and safety | Compliance with automotive standards, durability |

| Healthcare | Custom PCBs for medical devices | Ensures reliability and precision in diagnostics | Regulatory compliance, biocompatibility, and reliability |

| Industrial Automation | Custom PCBs for control systems | Increases efficiency and reduces downtime | Customization capabilities, integration support |

| Telecommunications | PCBs for networking equipment | Improves connectivity and data transmission speeds | Supply chain reliability, technical support, and pricing |

How is Custom PCB Manufacturing Applied in Consumer Electronics?

In the consumer electronics sector, custom PCB manufacturing is crucial for devices like smartphones and tablets. These PCBs are designed to enhance device performance, enabling features such as faster processing and improved battery life. International buyers, especially from regions like Africa and South America, should prioritize quality certifications and reliable lead times to ensure that their products meet market demands efficiently.

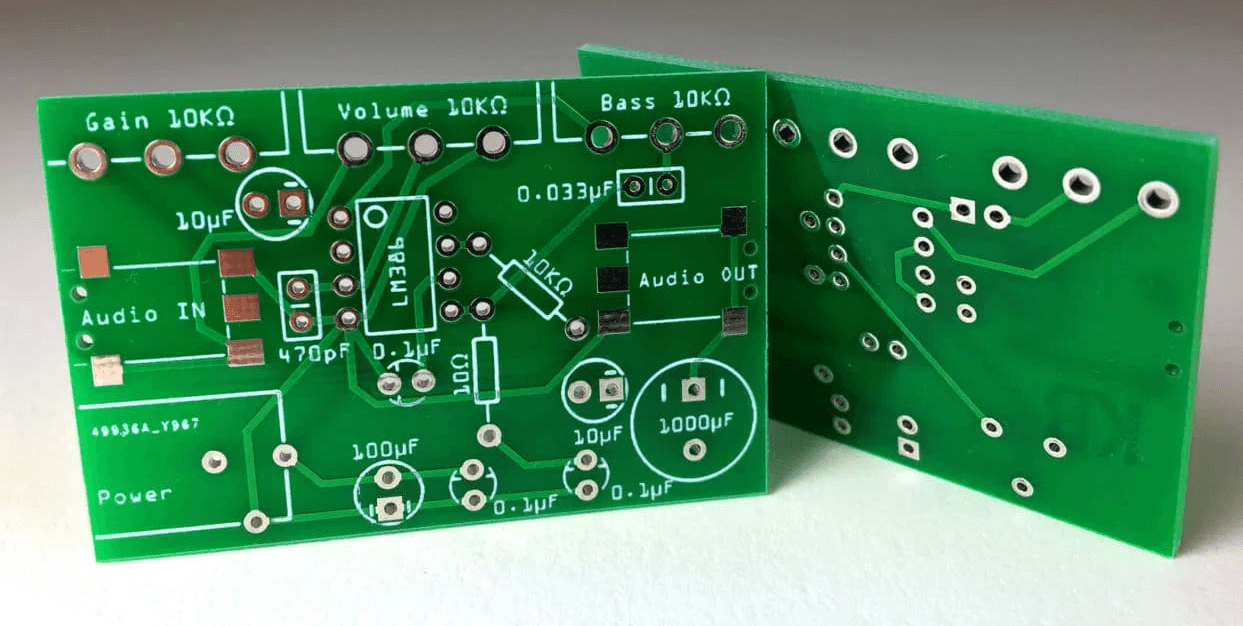

A stock image related to pcb manufacturing custom.

What Role Does Custom PCB Manufacturing Play in the Automotive Industry?

The automotive industry increasingly relies on custom PCBs, particularly for electric vehicles (EVs). These PCBs facilitate advanced functionalities, such as battery management systems and safety features, which are essential for modern vehicles. Buyers should consider compliance with stringent automotive standards and the durability of the PCBs to withstand harsh operating environments, particularly in the Middle East and Europe, where conditions can vary significantly.

Why are Custom PCBs Essential in Healthcare Applications?

In healthcare, custom PCBs are integral to the functionality of medical devices, ensuring they operate reliably and accurately. These PCBs are used in diagnostic equipment, monitoring devices, and surgical instruments, where precision is critical. For international B2B buyers, particularly in Europe and Africa, understanding regulatory compliance and biocompatibility is vital to avoid potential delays in product approvals and market entry.

How Do Custom PCBs Enhance Industrial Automation?

Custom PCBs play a significant role in industrial automation by being used in control systems that manage machinery and processes. These PCBs help increase operational efficiency and reduce downtime, crucial for maintaining productivity in manufacturing environments. Buyers from South America and Africa should focus on the customization capabilities of suppliers and their ability to provide integration support for existing systems.

What Advantages Do Custom PCBs Offer in Telecommunications?

In telecommunications, custom PCBs are essential for networking equipment, enhancing connectivity and improving data transmission speeds. As global demand for faster and more reliable communication grows, the need for high-quality PCBs becomes paramount. International buyers should evaluate the reliability of the supply chain and seek technical support from manufacturers to ensure that their networking solutions can adapt to rapidly changing technological landscapes.

3 Common User Pain Points for ‘pcb manufacturing custom’ & Their Solutions

Scenario 1: Navigating Complex Specifications for Custom PCBs

The Problem:

B2B buyers often face the challenge of translating intricate technical specifications into actionable orders. This complexity can arise from varying standards across different regions, coupled with the need to meet unique product requirements. For instance, a company in Kenya looking to source custom PCBs for a telecommunications project may struggle with ambiguous specifications or differing terminologies used by manufacturers in Europe or the Middle East. This can lead to miscommunications, delays, and potentially costly mistakes.

The Solution:

To mitigate this issue, buyers should invest time in creating a comprehensive specification document that clearly outlines all technical requirements, including dimensions, materials, and performance criteria. Additionally, leveraging digital tools like CAD software can help visualize designs and ensure all stakeholders are aligned. When engaging with manufacturers, consider conducting a preliminary meeting to discuss the specifications in detail and clarify any ambiguities. This proactive approach not only builds trust but also ensures that both parties are on the same page, ultimately reducing the risk of errors and enhancing the efficiency of the manufacturing process.

Scenario 2: Overcoming Lead Time Challenges in PCB Manufacturing

The Problem:

Another significant pain point for international B2B buyers is managing lead times, which can vary greatly depending on the complexity of the PCB design and the manufacturer’s location. A South American firm may require a quick turnaround for a new product launch but find that manufacturers in Asia have extended lead times due to supply chain disruptions or high demand. This mismatch can jeopardize project timelines and result in lost business opportunities.

The Solution:

To address lead time challenges, buyers should establish relationships with multiple PCB manufacturers across different regions. This diversification allows for flexibility and quicker sourcing options. Moreover, buyers can implement a Just-In-Time (JIT) inventory strategy, which involves ordering PCBs as closely as possible to the time they are needed in production. This not only helps in managing costs but also aligns with the production schedule, reducing the risk of holding excess inventory. Buyers should also inquire about the manufacturer’s capabilities to expedite orders, such as prioritizing specific projects or using expedited shipping options.

Scenario 3: Ensuring Quality Control in Custom PCB Orders

The Problem:

Quality assurance is a critical concern when sourcing custom PCBs, especially for B2B buyers who depend on high reliability in their products. A European electronics company may receive a batch of PCBs that do not meet the required standards, leading to product failures and damage to their reputation. These quality issues can stem from inadequate testing procedures or variations in manufacturing processes, making it essential for buyers to ensure that their suppliers adhere to stringent quality control measures.

The Solution:

To ensure quality control, buyers should demand transparency from manufacturers regarding their testing and quality assurance processes. Requesting certifications, such as IPC standards, and conducting audits or site visits can provide insights into the manufacturing practices employed. Establishing a clear communication channel for feedback during the production phase is also crucial; this allows for immediate rectification of any issues that may arise. Additionally, incorporating a pilot run before full-scale production can help identify potential problems early on, allowing for adjustments to be made and ensuring that the final product meets the desired quality standards.

Strategic Material Selection Guide for pcb manufacturing custom

When selecting materials for custom PCB manufacturing, understanding the properties, advantages, and limitations of various materials is crucial for international B2B buyers. This section analyzes four common materials used in PCB manufacturing, focusing on their performance characteristics, suitability for specific applications, and considerations for buyers from regions such as Africa, South America, the Middle East, and Europe.

What are the Key Properties of FR-4 in PCB Manufacturing?

FR-4 is one of the most widely used materials in PCB manufacturing. It is a composite of woven fiberglass and epoxy resin, offering excellent electrical insulation and mechanical strength. FR-4 can withstand temperatures up to 130°C and provides good resistance to moisture and chemicals, making it suitable for various electronic applications.

Pros: FR-4 is relatively low-cost and easy to manufacture, making it a popular choice for mass production. Its durability ensures long-lasting performance in many environments.

Cons: However, FR-4 has limitations in high-frequency applications due to its dielectric properties. It can also be less effective in extreme temperatures, which may affect performance in specific applications.

Impact on Application: FR-4 is compatible with most soldering processes and is widely accepted in various industries, including consumer electronics and automotive.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as IPC-4101 and ASTM D579. In regions like Kenya and Spain, local regulations may also dictate specific material standards.

How Does Polyimide Compare as a PCB Material?

Polyimide is another advanced material known for its thermal stability and flexibility. It can operate effectively at temperatures exceeding 200°C, making it ideal for high-temperature applications.

Pros: Polyimide offers excellent chemical resistance and is suitable for flexible PCB applications. Its lightweight nature also contributes to reduced overall product weight.

Cons: The primary drawback of polyimide is its higher cost compared to FR-4. Additionally, its manufacturing process can be more complex, which may lead to longer lead times.

Impact on Application: Polyimide is particularly well-suited for aerospace and military applications where high performance under extreme conditions is required.

Considerations for International Buyers: Buyers should be aware of compliance with standards like MIL-PRF-31032 for military applications. Understanding local market preferences in regions such as the Middle East and South America can also guide material selection.

What are the Benefits of Using Aluminum in PCB Manufacturing?

Aluminum PCBs are known for their excellent thermal conductivity, making them ideal for applications requiring effective heat dissipation, such as LED lighting.

Pros: Aluminum provides a robust platform that enhances durability and reduces the risk of warping. Its thermal properties allow for efficient heat management, leading to longer product lifespans.

Cons: The main limitation of aluminum PCBs is the higher manufacturing complexity and cost. They may also require specialized soldering techniques, which can increase production time.

Impact on Application: Aluminum is particularly effective in applications involving high power or heat, such as in automotive and industrial electronics.

Considerations for International Buyers: Compliance with relevant standards like ASTM B209 for aluminum alloys is essential. Buyers in Europe may also need to consider RoHS compliance for environmental regulations.

Why Choose Rogers Material for High-Frequency Applications?

Rogers materials are designed specifically for high-frequency applications, offering superior dielectric properties and thermal stability.

Pros: These materials excel in RF and microwave applications, providing low signal loss and high reliability. They are also resistant to moisture, enhancing their performance in various environments.

Cons: However, Rogers materials are significantly more expensive than traditional options like FR-4. Their specialized manufacturing processes can also lead to longer lead times.

Impact on Application: Rogers materials are ideal for telecommunications, aerospace, and medical devices, where performance is critical.

Considerations for International Buyers: Buyers should consider certifications like ISO 9001 and IPC standards when sourcing Rogers materials, particularly in regulated markets in Europe and the Middle East.

Summary Table of Material Selection for PCB Manufacturing

| Material | Typical Use Case for pcb manufacturing custom | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| FR-4 | General electronics, consumer products | Low cost, good mechanical strength | Limited high-frequency performance | Low |

| Polyimide | Aerospace, military applications | High thermal stability | Higher cost, complex manufacturing | High |

| Aluminum | LED lighting, automotive applications | Excellent thermal conductivity | Higher manufacturing complexity | Medium |

| Rogers | RF/microwave applications | Low signal loss, high reliability | High cost, longer lead times | High |

A stock image related to pcb manufacturing custom.

This guide serves as a strategic resource for international B2B buyers looking to make informed decisions regarding material selection for custom PCB manufacturing, ensuring compliance and suitability for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for pcb manufacturing custom

What Are the Main Stages in the Custom PCB Manufacturing Process?

The custom PCB (Printed Circuit Board) manufacturing process involves several critical stages that ensure the final product meets the specific needs of B2B buyers. Understanding these stages is essential for international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe.

1. Material Preparation

The first step in PCB manufacturing involves selecting high-quality materials, including copper-clad laminate, prepreg, and solder mask. These materials are crucial for ensuring the durability and performance of the PCB.

- Key Techniques:

- Laser Cutting: Precise cutting of copper sheets and substrate materials.

- Deposition Techniques: Application of copper layers through electroplating or chemical vapor deposition.

2. Forming

Once materials are prepared, the next step is forming the PCB. This stage includes etching and drilling processes that create the necessary pathways for electrical connectivity.

- Key Techniques:

- Etching: A chemical process used to remove unwanted copper from the board, creating the required circuit patterns.

- Drilling: High-speed drilling machines are used to create holes for vias and component mounting.

3. Assembly

After forming, the PCB moves to the assembly stage, where electronic components are mounted onto the board. This stage is critical for functionality and requires precision.

- Key Techniques:

- Surface Mount Technology (SMT): Components are placed on the surface of the PCB using automated pick-and-place machines.

- Through-Hole Technology: Components with leads are inserted into holes and soldered onto the board.

4. Finishing

The final stage of PCB manufacturing involves finishing processes that protect the board and enhance its performance.

- Key Techniques:

- Solder Mask Application: A protective layer that prevents solder from bridging between conductive pathways.

- Surface Finishing: Techniques like ENIG (Electroless Nickel Immersion Gold) enhance solderability and corrosion resistance.

How Is Quality Assurance Implemented in PCB Manufacturing?

Quality assurance (QA) is integral to PCB manufacturing, ensuring that each board meets international standards and specific customer requirements.

Relevant International Standards for PCB Quality Assurance

International standards play a significant role in maintaining quality in PCB manufacturing. Buyers should be familiar with the following:

- ISO 9001: A widely recognized quality management system standard that outlines the criteria for an effective quality management system.

- IPC Standards: Industry-specific standards for PCBs, including IPC-A-600 for acceptability of printed boards and IPC-610 for acceptability of electronic assemblies.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are essential for identifying defects early in the manufacturing process. The primary checkpoints include:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to catch defects in real-time.

- Final Quality Control (FQC): Comprehensive testing of the finished product to ensure it meets all quality standards.

What Testing Methods Are Commonly Used in PCB Quality Control?

Testing methods are critical for verifying the quality and functionality of PCBs. B2B buyers should be aware of the following common testing methods:

- Electrical Testing: Ensures all electrical pathways are functional. Methods include:

- Flying Probe Testing: A non-contact method that checks for open and short circuits.

-

Bed-of-Nails Testing: Utilizes a fixture with multiple probes to test the electrical connections.

-

Visual Inspection: Manual or automated inspections to identify physical defects such as solder quality and component placement.

-

Thermal Cycling Tests: Assess the durability of PCBs under varying temperature conditions, simulating real-world applications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to verify the QC practices of their PCB suppliers to ensure they align with their quality expectations.

Conducting Supplier Audits

Regular audits can provide insights into a supplier’s manufacturing processes and quality control systems. Key areas to focus on during an audit include:

- Compliance with International Standards: Verify certifications for ISO and IPC standards.

- Production Processes: Review the methods and technologies used in manufacturing.

- Quality Control Documentation: Request documentation on QC processes, including inspection reports and defect rates.

Requesting Quality Reports and Certifications

Buyers should ask for detailed quality reports and certifications from their suppliers. This documentation should include:

- Test Reports: Results from electrical and mechanical testing.

- Certifications: Proof of compliance with relevant industry standards.

Utilizing Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s manufacturing quality. This is particularly beneficial for international buyers who may not be able to conduct on-site inspections.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers should consider specific nuances related to quality control when sourcing PCBs from different regions:

- Cultural Differences: Understand how cultural attitudes towards quality may differ and how this impacts manufacturing processes.

- Regulatory Compliance: Be aware of local regulations and standards that may affect PCB quality in different regions.

- Communication Barriers: Ensure clear communication regarding quality expectations and standards to avoid misunderstandings.

By understanding the manufacturing processes and quality assurance practices in PCB manufacturing, international B2B buyers can make informed decisions that align with their quality and performance requirements, ensuring successful procurement and partnership with suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pcb manufacturing custom’

Introduction

In the competitive landscape of custom PCB manufacturing, international B2B buyers need a structured approach to sourcing. This checklist is designed to guide you through essential steps to ensure you select the right supplier, meet your technical requirements, and achieve cost-effectiveness. Whether you are based in Africa, South America, the Middle East, or Europe, following these steps will help streamline your procurement process.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline the technical requirements of your PCB. This includes dimensions, layer counts, material specifications, and any required certifications. Establishing detailed specifications helps prevent miscommunication and ensures that suppliers understand your needs from the outset.

- Considerations:

- Are there specific industry standards (e.g., IPC) that your PCB must adhere to?

- What is the expected lifespan and environmental conditions the PCB will face?

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers specializing in custom PCB manufacturing. Utilize online platforms, industry forums, and trade shows to gather information about potential partners. A strong reputation and track record can significantly reduce risks in the sourcing process.

- Key Sources:

- Industry-specific directories

- Reviews and testimonials from existing clients

Step 3: Evaluate Supplier Certifications

It’s essential to verify that potential suppliers hold relevant certifications, such as ISO 9001 or IPC-A-600. These certifications indicate adherence to quality management systems and manufacturing standards, which are crucial for reliable PCB production.

- Action Points:

- Request copies of certifications and verify their validity.

- Understand the implications of each certification and how it aligns with your requirements.

Step 4: Request Samples and Prototypes

Before making a bulk order, request samples or prototypes of the PCB. This step allows you to assess the quality of the manufacturing process and ensure that the product meets your specifications.

- What to Look For:

- Precision in dimensions and layout

- Quality of materials used

Step 5: Assess Lead Times and Production Capacity

Discuss lead times with potential suppliers to ensure they can meet your project timelines. Understanding their production capacity is critical, especially if you anticipate future orders or scaling up production.

- Important Questions:

- What are the standard lead times for your specific PCB requirements?

- Can the supplier accommodate urgent requests or changes in order volume?

Step 6: Review Pricing Models and Payment Terms

Analyze the pricing structures of different suppliers to ensure competitiveness. Look beyond just the unit cost; consider factors such as payment terms, discounts for bulk orders, and additional fees for services like expedited shipping.

- Financial Considerations:

- Are there hidden costs that could affect your budget?

- What are the payment options, and do they align with your cash flow requirements?

Step 7: Establish Communication Protocols

Once you select a supplier, establish clear communication protocols to facilitate ongoing collaboration. Regular updates and feedback loops can help address issues proactively and ensure that production stays on track.

- Best Practices:

- Schedule regular check-ins during the production process.

- Use project management tools to streamline communication and document changes.

By following these steps, international B2B buyers can ensure a more efficient and effective sourcing process for custom PCB manufacturing, ultimately leading to better product quality and stronger supplier relationships.

Comprehensive Cost and Pricing Analysis for pcb manufacturing custom Sourcing

What Are the Key Cost Components in Custom PCB Manufacturing?

Understanding the cost structure of custom PCB manufacturing is vital for international B2B buyers. The main cost components include:

-

Materials: The choice of materials significantly affects the overall cost. Common materials like FR-4 for standard PCBs are more affordable, while specialized materials, such as high-frequency laminates, can increase costs considerably.

-

Labor: Labor costs vary based on the region of manufacturing. Countries with a lower cost of living, such as those in parts of Africa and South America, may offer competitive labor rates, impacting the overall pricing.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and maintenance. A well-optimized manufacturing facility can lower overhead costs, thus affecting the final price of PCBs.

-

Tooling: Initial tooling costs for custom designs can be substantial. These costs are often amortized over larger production runs, making it essential to consider Minimum Order Quantities (MOQs) when assessing pricing.

-

Quality Control (QC): Implementing stringent QC measures ensures product reliability but adds to the cost. Buyers should weigh the importance of certifications and testing against their budget.

-

Logistics: Transportation and shipping costs can fluctuate based on the distance from the manufacturer to the buyer, as well as the chosen Incoterms. Buyers in Africa or South America may face higher logistics costs if sourcing from Asia or Europe.

-

Margin: Suppliers will factor in their profit margin, which can vary widely based on the supplier’s market position and the complexity of the order.

How Do Price Influencers Affect Custom PCB Costs?

Several factors influence the pricing of custom PCBs beyond the basic cost components:

-

Volume and Minimum Order Quantities (MOQs): Higher volumes typically lead to lower per-unit costs due to economies of scale. However, buyers must balance their needs against the commitment to larger orders.

-

Specifications and Customization: Custom features, such as size, layer count, and special finishes, can drive up costs. Buyers should clearly define their specifications to receive accurate quotes.

-

Material Quality and Certifications: Higher quality materials and compliance with international standards (e.g., ISO, IPC) can increase prices. Buyers should assess whether these certifications align with their product requirements.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge a premium for their proven track record, while newer suppliers might offer lower prices to attract business.

-

Incoterms: Understanding shipping terms is crucial for calculating total costs. Terms like FOB (Free On Board) and CIF (Cost Insurance and Freight) can affect the overall pricing strategy.

What Are Effective Buyer Tips for Negotiating PCB Prices?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, here are actionable tips for negotiating PCB prices:

-

Leverage Volume Discounts: If you anticipate future orders, negotiate for better pricing based on your expected volume. Suppliers are often willing to offer discounts for larger commitments.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the upfront cost but also the long-term implications of your purchase. Factors like durability and performance can lead to cost savings over time.

-

Be Transparent About Specifications: Clearly communicate your needs and expectations to avoid misunderstandings that could lead to increased costs later in the process.

-

Request Multiple Quotes: Don’t settle for the first quote. Obtaining multiple offers can provide leverage in negotiations and help identify competitive pricing.

-

Understand Pricing Nuances: Be aware of potential hidden costs, such as customs duties or taxes, that can significantly affect the final price.

Disclaimer on Indicative Prices

Prices for custom PCB manufacturing can vary significantly based on the factors discussed above. The information provided serves as a guideline and should be confirmed with suppliers for accurate and current pricing. Buyers are encouraged to conduct thorough research and engage in discussions to obtain the best possible terms for their specific needs.

Alternatives Analysis: Comparing pcb manufacturing custom With Other Solutions

In the world of electronics, the choice of manufacturing methods can significantly impact both product quality and overall costs. When considering PCB (Printed Circuit Board) manufacturing, businesses often evaluate custom solutions against alternative approaches. Understanding these alternatives is essential for B2B buyers looking to optimize their production processes.

| Comparison Aspect | Pcb Manufacturing Custom | Alternative 1: PCB Assembly Services | Alternative 2: 3D Printed Circuits |

|---|---|---|---|

| Performance | High precision and flexibility in design | Good for standard designs, moderate flexibility | Limited performance for complex circuits |

| Cost | Higher initial investment, but cost-effective for large volumes | Lower initial costs, scalable for small batches | Cost-effective for prototyping but expensive for mass production |

| Ease of Implementation | Requires specialized knowledge and equipment | Easier implementation, especially for small businesses | Simple for basic designs but may require additional post-processing |

| Maintenance | Generally low, but dependent on equipment | Low, as service providers manage maintenance | Moderate; 3D printers require regular upkeep |

| Best Use Case | Custom, high-volume production with unique specifications | Production of standard PCB designs in varying quantities | Rapid prototyping and low-volume production of simple circuits |

What Are the Advantages and Disadvantages of PCB Assembly Services?

PCB assembly services are an attractive alternative for businesses that prioritize efficiency and cost. They allow companies to outsource assembly processes, which can lead to reduced labor costs and increased production speed. However, this option is best suited for standard designs, as customization may be limited. Assembly services can also lead to longer lead times if specific components are required, which may not be ideal for businesses needing rapid production.

How Do 3D Printed Circuits Compare?

3D printed circuits are an innovative solution that offers unique advantages, especially in rapid prototyping. They enable designers to quickly test concepts without extensive tooling or setup costs. However, while the technology is evolving, 3D printed circuits may not yet match the performance and reliability of traditional PCB manufacturing methods for complex designs. They are generally more suited for simpler projects or low-volume production runs where speed and flexibility are paramount.

Conclusion: How Should B2B Buyers Choose the Right PCB Manufacturing Solution?

Choosing the right PCB manufacturing solution depends on various factors, including the specific needs of the project, budget constraints, and production volume. For high-volume, custom designs, investing in PCB manufacturing custom is often the best choice due to its precision and adaptability. Conversely, for companies focusing on standard designs or needing quick turnaround times, PCB assembly services or 3D printed circuits may provide more cost-effective and efficient solutions. Ultimately, B2B buyers should assess their unique requirements and weigh the pros and cons of each option to make an informed decision that aligns with their operational goals.

Essential Technical Properties and Trade Terminology for pcb manufacturing custom

What Are the Essential Technical Properties in PCB Manufacturing?

In the realm of custom PCB (Printed Circuit Board) manufacturing, understanding technical specifications is crucial for B2B buyers. These properties not only influence the performance of the final product but also affect cost, manufacturability, and reliability. Here are some critical specifications to consider:

1. Material Grade: Why Is It Important?

The choice of material is paramount in PCB manufacturing. Common materials include FR-4 (a glass-reinforced epoxy laminate), Rogers, and aluminum. Each material has different thermal, electrical, and mechanical properties that impact the board’s performance. For instance, FR-4 is widely used for its balance of cost and performance, while Rogers materials are preferred for high-frequency applications. Selecting the right material grade can enhance durability, signal integrity, and overall functionality.

2. Tolerance: How Does It Affect Your PCB Design?

Tolerance refers to the allowable variation in dimensions and characteristics of the PCB. It is crucial for ensuring that components fit correctly and function as intended. Common tolerances range from ±0.1mm to ±0.5mm, depending on the complexity of the design. Tight tolerances may lead to higher manufacturing costs but are often necessary for high-precision applications. Understanding tolerance requirements helps in optimizing designs while managing costs effectively.

3. Layer Count: What Does It Mean for Your PCB?

The layer count indicates how many conductive layers are present in the PCB. Single-layer boards are simpler and less expensive, while multi-layer boards can accommodate more complex circuitry. The choice between these layers is vital for your application. For example, high-frequency devices typically require multi-layer boards to reduce electromagnetic interference. Knowing the layer count aids in determining both the technical capabilities and the budget for your project.

4. Surface Finish: Why Is It Crucial for PCB Longevity?

Surface finish affects solderability and corrosion resistance. Common types include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), and OSP (Organic Solderability Preservative). Each finish has different properties that can influence the soldering process and the longevity of the PCB. For instance, ENIG offers excellent corrosion resistance and is ideal for fine-pitch components, making it a popular choice for high-reliability applications.

5. Aspect Ratio: What Is Its Role in PCB Design?

Aspect ratio is the ratio of the thickness of the PCB to the diameter of the smallest hole. A higher aspect ratio indicates a thicker board with smaller holes, which can complicate manufacturing. Understanding aspect ratio is essential for ensuring that your PCB can be fabricated reliably. It influences drilling processes and can affect costs, making it a key consideration in the design phase.

What Are Common Trade Terms in PCB Manufacturing?

Navigating the PCB manufacturing landscape requires familiarity with industry-specific jargon. Here are some essential terms that every B2B buyer should know:

1. OEM (Original Equipment Manufacturer): What Does It Mean?

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In PCB manufacturing, this often refers to companies that design and produce PCBs for other businesses. Understanding OEM relationships can help you identify reliable partners for custom manufacturing needs.

2. MOQ (Minimum Order Quantity): Why Is It Significant?

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. In PCB manufacturing, this can vary significantly based on the complexity of the board and the supplier’s capabilities. Knowing the MOQ is essential for budgeting and ensuring that your production requirements align with supplier capabilities.

3. RFQ (Request for Quotation): How Do You Use It?

An RFQ is a document sent to suppliers to request pricing for specific quantities of products or services. In the PCB sector, issuing an RFQ allows you to compare costs and services among different manufacturers, ensuring you get the best value for your investment.

4. Incoterms: How Do They Affect Your Shipping Costs?

Incoterms (International Commercial Terms) are a set of rules that define the responsibilities of sellers and buyers in international transactions. They specify who pays for shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for B2B buyers to avoid unexpected costs and ensure smooth logistics in international PCB procurement.

By understanding these essential technical properties and trade terminologies, B2B buyers can make informed decisions that align with their project requirements and budget constraints.

Navigating Market Dynamics and Sourcing Trends in the pcb manufacturing custom Sector

What Are the Current Market Dynamics and Sourcing Trends in PCB Manufacturing?

The printed circuit board (PCB) manufacturing sector is witnessing significant transformations driven by technological advancements and evolving market demands. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, must navigate these dynamics effectively. A key driver is the growing demand for miniaturization and high-density interconnections, spurred by the rise of IoT devices, automotive electronics, and wearable technology. The market is also shifting towards increased customization, allowing businesses to tailor PCBs to specific applications, thereby enhancing performance and reducing costs.

Emerging trends include the adoption of advanced materials such as flexible substrates and high-frequency laminates, which cater to next-generation applications. Additionally, automation and Industry 4.0 technologies are being integrated into PCB manufacturing processes, improving efficiency and reducing lead times. For B2B buyers, understanding these trends is crucial for identifying suppliers who can meet their evolving needs and maintain competitive advantages.

Furthermore, geopolitical factors are influencing sourcing strategies. For instance, buyers in Europe and the Middle East are increasingly looking to diversify their supply chains beyond traditional hubs in Asia to mitigate risks associated with trade tensions and tariffs. This has led to a rise in regional manufacturing initiatives, particularly in Africa and South America, where local production capabilities are being developed.

How Important Is Sustainability and Ethical Sourcing in PCB Manufacturing?

Sustainability is becoming a central theme in the PCB manufacturing industry, with an increasing number of companies prioritizing environmentally friendly practices. The environmental impact of PCB production—ranging from waste generation to hazardous material usage—has prompted many B2B buyers to seek suppliers committed to sustainable practices. This shift is not merely a trend but a necessity, as regulations around electronic waste and materials continue to tighten globally.

Ethical sourcing is equally important, with buyers increasingly favoring suppliers who adhere to responsible labor practices and environmental stewardship. Certifications such as ISO 14001 (Environmental Management) and RoHS (Restriction of Hazardous Substances) are becoming essential for suppliers aiming to prove their commitment to sustainability. Moreover, the use of ‘green’ materials, such as lead-free solder and recyclable substrates, is gaining traction, aligning with the global push for reduced environmental footprints.

For international B2B buyers, engaging with suppliers who prioritize sustainability not only enhances their corporate social responsibility (CSR) profile but also positions them favorably in a market where consumers are increasingly eco-conscious. This transition towards sustainability can lead to long-term cost savings, improved brand loyalty, and compliance with evolving regulations.

What Is the Brief Evolution of PCB Manufacturing?

The PCB manufacturing sector has undergone significant evolution since its inception in the mid-20th century. Initially, PCBs were simple and rudimentary, primarily used in basic electronic devices. However, the advent of new technologies and the demand for more complex electronics led to advancements in manufacturing processes and materials.

In the 1980s and 1990s, the introduction of surface mount technology (SMT) revolutionized PCB design, allowing for smaller, more efficient circuits. The shift towards multilayer boards further enabled the integration of sophisticated components, catering to the burgeoning tech industry. Today, PCB manufacturing is characterized by high precision, customization, and rapid prototyping, driven by the demands of industries such as telecommunications, automotive, and consumer electronics.

As B2B buyers navigate this complex landscape, understanding the historical context of PCB manufacturing can provide valuable insights into current capabilities and future trends, ultimately aiding in more informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of pcb manufacturing custom

-

How do I choose the right PCB manufacturer for my custom needs?

Choosing the right PCB manufacturer involves several key considerations. First, assess their capabilities in terms of technology and production methods to ensure they can meet your specific requirements. Next, review their past projects and client testimonials to gauge their reliability and quality. Additionally, consider their location, as this can impact shipping costs and lead times. It’s crucial to communicate your design specifications clearly and inquire about their design support services. Lastly, evaluate their compliance with international standards, which is especially important for buyers from diverse regions such as Africa, South America, the Middle East, and Europe. -

What are the minimum order quantities (MOQ) for custom PCB manufacturing?

Minimum order quantities (MOQ) can vary significantly between manufacturers. Typically, MOQs can range from a few pieces to thousands, depending on the complexity of the design and the manufacturer’s production capacity. For B2B buyers, it’s essential to discuss your specific needs with potential suppliers and negotiate MOQs that align with your project scale. Smaller manufacturers may offer more flexible MOQs, which can be beneficial for startups or smaller businesses looking to test products before committing to larger orders.

-

What payment terms should I expect when sourcing custom PCBs internationally?

Payment terms can differ widely based on the manufacturer and your negotiation. Common practices include upfront deposits (often 30-50%) with the balance due upon completion or before shipping. For international transactions, consider using secure payment methods such as letters of credit or escrow services to protect your investment. It’s advisable to clarify these terms upfront and ensure they are documented in the contract to avoid any misunderstandings later. -

How can I ensure quality assurance in my custom PCB orders?

Quality assurance is vital in PCB manufacturing to prevent costly errors. Begin by verifying that the manufacturer adheres to international quality standards, such as ISO 9001. Request detailed inspection reports, including IPC-A-600 and IPC-A-610 certifications, which provide guidelines for PCB acceptability. Additionally, consider establishing a quality control process where you can inspect samples before full-scale production. Regular communication during the manufacturing process can also help address any issues promptly. -

What logistics considerations should I keep in mind when importing custom PCBs?

Logistics play a crucial role in the timely delivery of custom PCBs. When sourcing internationally, consider shipping methods (air vs. sea), which impact both cost and delivery time. Be aware of customs regulations in your country, as this can affect lead times and additional costs. Establish a reliable shipping partner familiar with international trade to streamline the process. Additionally, ensure that the supplier provides adequate packaging to protect your PCBs during transit. -

How can I customize my PCB design for specific applications?

Customization of PCB designs starts with understanding your application’s requirements, such as size, shape, and functionality. Collaborate closely with your manufacturer during the design phase to discuss materials, layer counts, and component placements. Utilize design software that allows for simulation and testing of the PCB layout before production. Most manufacturers also offer engineering support to help refine your design and ensure that it meets both performance and regulatory standards. -

What are the common challenges faced when sourcing custom PCBs internationally?

B2B buyers often encounter challenges such as communication barriers, differing quality standards, and varying lead times when sourcing custom PCBs internationally. It’s crucial to establish clear communication channels and to use precise specifications in your orders. Additionally, cultural differences can influence business practices, so understanding the local market dynamics is beneficial. Conducting thorough supplier vetting and establishing a strong relationship with your manufacturer can help mitigate these challenges. -

How do I handle disputes or issues with my PCB supplier?

Handling disputes with a PCB supplier requires a strategic approach. Begin by documenting all communications and agreements to have a clear record of expectations. If an issue arises, address it promptly and directly with the supplier, aiming for a collaborative resolution. Consider involving a third-party mediator if necessary. If the dispute cannot be resolved amicably, refer to the terms outlined in your contract regarding dispute resolution mechanisms, which may include arbitration or legal recourse.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for pcb manufacturing custom

How Can Strategic Sourcing Enhance PCB Manufacturing for International Buyers?

In the dynamic landscape of custom PCB manufacturing, strategic sourcing emerges as a critical factor for international B2B buyers. By leveraging global networks, businesses can secure high-quality materials and innovative technologies while optimizing costs. For buyers in regions such as Africa, South America, the Middle East, and Europe, understanding local suppliers and market dynamics can lead to significant competitive advantages.

Identifying and collaborating with reliable manufacturers not only ensures product quality but also fosters sustainable relationships that can adapt to changing market demands. Buyers should prioritize suppliers that demonstrate flexibility, technological expertise, and a commitment to customer service.

As we look to the future, the emphasis on sustainability and innovation will shape the PCB manufacturing landscape. Buyers are encouraged to explore partnerships that not only meet current needs but also align with long-term growth strategies. By embracing strategic sourcing, companies can position themselves effectively in the global marketplace, driving efficiency and enhancing their product offerings.

Take proactive steps today to reassess your sourcing strategies and build partnerships that will support your business objectives in the evolving PCB industry.