Cut Costs with Pressure Washing China: The Ultimate Guide (2025)

Introduction: Navigating the Global Market for pressure washing china

In today’s competitive landscape, sourcing pressure washing equipment from China presents a unique set of challenges for international B2B buyers. Companies in regions like Africa, South America, the Middle East, and Europe often grapple with issues such as quality assurance, supplier reliability, and navigating complex import regulations. This guide serves as a comprehensive resource, designed to help businesses make informed decisions when sourcing pressure washing solutions that meet their specific needs.

From understanding the various types of pressure washers available—ranging from electric to gas-powered models—to exploring their diverse applications across industries such as construction, hospitality, and automotive, this guide covers it all. We delve into critical aspects like supplier vetting processes, ensuring that buyers can identify trustworthy manufacturers and negotiate favorable terms. Furthermore, we address cost considerations, helping businesses budget effectively while maximizing value.

By equipping international B2B buyers with actionable insights and practical strategies, this guide aims to demystify the procurement process for pressure washing equipment from China. Whether you are in Nigeria looking to enhance your cleaning services or in South Africa seeking efficient solutions for industrial applications, this resource will empower you to navigate the global market with confidence and clarity.

Understanding pressure washing china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electric Pressure Washers | Compact, quieter, and suitable for light tasks | Residential cleaning, small commercial jobs | Pros: Easy to use; Cons: Limited power |

| Gas Pressure Washers | High pressure output, portable, and powerful | Heavy-duty cleaning, industrial applications | Pros: Strong performance; Cons: Noisy, requires fuel |

| Hot Water Pressure Washers | Uses heated water for deep cleaning | Food processing, vehicle fleets, industrial cleaning | Pros: Effective on grease; Cons: Higher cost |

| Cold Water Pressure Washers | Uses only cold water, ideal for general cleaning | General maintenance, construction sites | Pros: Cost-effective; Cons: Less effective on tough stains |

| Skid-Mounted Pressure Washers | Mounted on trailers or trucks for mobility | Large-scale operations, remote job sites | Pros: High capacity; Cons: Requires vehicle for transport |

What Are the Key Features of Electric Pressure Washers?

Electric pressure washers are characterized by their compact design and quieter operation compared to gas models. They are ideal for light to moderate cleaning tasks, making them suitable for residential use and small commercial applications. B2B buyers should consider their ease of use and lower maintenance requirements; however, they may not deliver the high pressure needed for tougher jobs.

Why Choose Gas Pressure Washers for Heavy-Duty Tasks?

Gas pressure washers stand out due to their powerful engines, providing high pressure and flow rates. They are portable and can be used in various environments, making them perfect for heavy-duty cleaning tasks in industrial settings. Buyers should weigh the advantages of strong performance against the downsides of noise levels and the need for fuel, which can complicate logistics.

How Do Hot Water Pressure Washers Enhance Cleaning Efficiency?

Hot water pressure washers utilize heated water to tackle tough stains and grease effectively. This makes them particularly valuable in industries such as food processing and automotive cleaning. While they offer superior cleaning capabilities, buyers should consider the higher initial investment and operational costs associated with hot water systems.

What Makes Cold Water Pressure Washers a Cost-Effective Choice?

Cold water pressure washers are designed for general cleaning tasks and are often more affordable than their hot water counterparts. They are suitable for maintenance in construction sites and light industrial applications. While their cost-effectiveness is a significant advantage, buyers should keep in mind that cold water units may struggle with heavy stains and grease.

When Should You Consider Skid-Mounted Pressure Washers?

Skid-mounted pressure washers are designed for mobility, typically mounted on trailers or trucks. This feature is advantageous for large-scale operations and remote job sites, where access to power sources may be limited. However, buyers need to consider that these systems require a vehicle for transport, which could add to overall operational costs.

Related Video: Pressure washer unloader types

Key Industrial Applications of pressure washing china

| Industry/Sector | Specific Application of Pressure Washing China | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Surface preparation for painting and coatings | Ensures better adhesion of paints and coatings, prolonging lifespan | Equipment durability, compatibility with local conditions, and service support |

| Food Processing | Cleaning of processing equipment and surfaces | Maintains hygiene standards, reduces risk of contamination | Compliance with international hygiene standards, ease of use, and availability of parts |

| Automotive | Fleet vehicle cleaning and maintenance | Enhances vehicle appearance, reduces corrosion, and increases resale value | Efficiency of cleaning, water usage, and environmental compliance |

| Manufacturing | Machinery and equipment maintenance | Improves operational efficiency, reduces downtime | Equipment compatibility, ease of maintenance, and sourcing of spare parts |

| Agriculture | Cleaning of farming equipment | Increases equipment lifespan and operational efficiency | Ability to handle various contaminants, portability, and ease of use |

How is Pressure Washing Used in Construction Projects?

In the construction industry, pressure washing is primarily utilized for surface preparation before applying paints and coatings. This process effectively removes dirt, grime, and old paint, ensuring a clean surface for better adhesion. For international B2B buyers, particularly from Africa and South America, sourcing robust pressure washing equipment is vital, as it needs to withstand diverse environmental conditions. Additionally, buyers should consider the availability of spare parts and service support to minimize downtime on construction sites.

What Role Does Pressure Washing Play in Food Processing?

In food processing, pressure washing is crucial for cleaning machinery and surfaces to uphold hygiene standards. This application helps mitigate contamination risks and ensures compliance with food safety regulations. For B2B buyers in the Middle East and Europe, it is essential to ensure that the pressure washing equipment meets international hygiene standards and is user-friendly. The availability of parts and maintenance services is also a key factor in the sourcing decision to maintain operational efficiency.

How Can Pressure Washing Enhance Fleet Maintenance in the Automotive Sector?

Pressure washing is widely used in the automotive industry for cleaning fleet vehicles, which enhances their appearance and helps prevent corrosion. Regular cleaning contributes to higher resale values and extends vehicle lifespan. Buyers from regions like South Africa and Nigeria should prioritize equipment efficiency and water usage, ensuring compliance with local environmental regulations. Additionally, the ability to service and maintain the equipment easily is crucial for long-term operational success.

What Benefits Does Pressure Washing Offer to Manufacturing Operations?

In manufacturing, pressure washing is employed for machinery and equipment maintenance, effectively removing built-up grime and residues that can hinder performance. This application boosts operational efficiency and minimizes downtime, which is critical in competitive markets. Buyers in Europe and South America should look for pressure washing systems that are compatible with their existing machinery and easy to maintain, ensuring a reliable supply chain for spare parts and service support.

Why is Pressure Washing Important for Agricultural Equipment?

In agriculture, pressure washing is essential for cleaning farming equipment, which helps increase its lifespan and operational efficiency. This application is particularly important after harvesting or using equipment in muddy conditions. International B2B buyers from Africa should consider pressure washing systems that can handle various contaminants and are portable for use in the field. Additionally, ease of use and maintenance will significantly enhance productivity in agricultural operations.

Related Video: The Best Chemicals For Pressure Washing (Complete Guide)

3 Common User Pain Points for ‘pressure washing china’ & Their Solutions

Scenario 1: Inconsistent Quality of Pressure Washing Equipment

The Problem:

B2B buyers sourcing pressure washing equipment from China often face significant quality inconsistencies. This issue can lead to equipment that either underperforms or fails prematurely, resulting in lost time and increased operational costs. Buyers in regions like South Africa or Nigeria may find that the equipment they receive does not meet the specifications promised by suppliers, causing frustration and jeopardizing their service delivery commitments.

The Solution:

To mitigate quality issues, B2B buyers should conduct thorough due diligence before making a purchase. This includes researching suppliers through platforms like Alibaba or Global Sources, and checking their certifications, customer reviews, and production capabilities. Buyers should request product samples and detailed specifications to ensure the equipment meets their operational standards. Additionally, establishing clear communication with suppliers about quality expectations and utilizing third-party inspection services can help verify product quality before shipment. Implementing a quality assurance protocol upon receipt of the equipment can further safeguard against inconsistencies.

Scenario 2: Navigating Language Barriers in Supplier Communication

The Problem:

Language barriers can pose a significant challenge for international buyers, particularly those from South America and the Middle East, when dealing with Chinese suppliers. Misunderstandings can arise during negotiations, leading to incorrect orders, misinterpretation of product features, or even contract disputes. This can result in costly delays and strain supplier relationships, ultimately affecting the buyer’s ability to deliver services to their clients.

The Solution:

To overcome language barriers, buyers should consider employing professional translators or using bilingual intermediaries who understand both the industry terminology and cultural nuances. Utilizing communication tools that include visual aids, such as diagrams or videos, can also help bridge understanding gaps. It is advisable to draft contracts and specifications in both languages to minimize miscommunication. Furthermore, leveraging technology through platforms that offer integrated translation services can facilitate smoother interactions with suppliers, ensuring clarity in every transaction.

Scenario 3: Understanding Regulatory Compliance for Pressure Washing Equipment

The Problem:

B2B buyers often struggle with the regulatory compliance requirements associated with importing pressure washing equipment from China. Different regions, including Europe and the Middle East, have specific regulations regarding safety standards, emissions, and equipment certifications. Failing to comply can lead to fines, equipment confiscation, or even legal ramifications, which can significantly impact the buyer’s business operations.

The Solution:

To navigate regulatory compliance, buyers must familiarize themselves with the specific requirements of their respective regions before purchasing. This can be achieved by consulting with local regulatory bodies or industry associations that provide guidance on compliance standards. Buyers should ensure that the pressure washing equipment they intend to purchase meets the necessary certifications, such as CE marking for Europe or local environmental standards. Engaging with suppliers who are knowledgeable about these requirements can also streamline the process. Buyers should keep all documentation related to compliance readily available and consider implementing an internal compliance checklist to ensure all future purchases adhere to regulatory standards.

Strategic Material Selection Guide for pressure washing china

What Are the Key Materials Used in Pressure Washing China?

When selecting materials for pressure washing equipment, several factors must be considered, including performance, durability, and compliance with international standards. Below, we analyze four common materials used in pressure washing applications, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Does Stainless Steel Perform in Pressure Washing Applications?

Stainless steel is a popular choice for pressure washing equipment due to its excellent corrosion resistance and durability. It can withstand high temperatures and pressures, making it suitable for various cleaning tasks. Specifically, stainless steel pressure washers can handle water temperatures up to 150°C and pressures exceeding 3000 PSI.

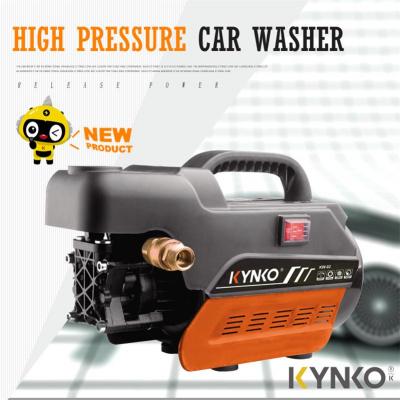

A stock image related to pressure washing china.

Pros: The primary advantage of stainless steel is its longevity and resistance to rust and corrosion, which is crucial for equipment exposed to harsh environments. Additionally, it requires minimal maintenance, reducing long-term operational costs.

Cons: The main drawback is the higher initial cost compared to other materials like aluminum or plastic. Furthermore, the manufacturing complexity can lead to longer lead times, which may be a consideration for buyers needing quick delivery.

Impact on Application: Stainless steel is compatible with a wide range of cleaning media, including detergents and solvents, making it versatile for different applications.

Considerations for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should ensure that the stainless steel used complies with relevant standards such as ASTM A240. Additionally, they should consider local sourcing to reduce import costs and lead times.

What Are the Benefits of Aluminum in Pressure Washing Equipment?

Aluminum is another common material used in pressure washing equipment, known for its lightweight nature and resistance to corrosion. Aluminum pressure washers typically operate at temperatures up to 100°C and pressures around 2000 PSI.

Pros: The main advantage of aluminum is its lightweight, which makes it easier to transport and maneuver. It is also generally less expensive than stainless steel, making it a cost-effective option for many businesses.

Cons: However, aluminum is less durable than stainless steel and may not withstand extreme conditions as effectively. It can also be prone to denting and scratching, which can affect its appearance and performance over time.

Impact on Application: Aluminum is suitable for light to moderate cleaning tasks, especially where portability is essential. However, it may not be ideal for heavy-duty applications involving aggressive cleaning agents.

Considerations for International Buyers: Buyers should be aware of the specific aluminum grades used, as they can vary significantly in performance. Compliance with standards such as ASTM B221 is essential to ensure quality.

Why Choose Plastic for Pressure Washing Components?

Plastic materials, particularly high-density polyethylene (HDPE) and polypropylene, are increasingly used in pressure washing components due to their resistance to chemicals and lightweight properties. These materials can typically handle temperatures up to 80°C and pressures around 1500 PSI.

Pros: The primary advantage of plastic is its resistance to a wide variety of chemicals, making it ideal for use with various cleaning agents. Additionally, it is cost-effective and lightweight, enhancing portability.

Cons: However, plastic components may not be as durable as metal alternatives and can degrade over time when exposed to UV light or extreme temperatures. This can lead to increased replacement costs.

Impact on Application: Plastic is often used for hoses, tanks, and other non-structural components, where chemical resistance is more critical than structural integrity.

Considerations for International Buyers: Buyers should verify that the plastic materials comply with relevant standards, such as ASTM D638, to ensure they meet performance expectations.

What Role Does Composite Material Play in Pressure Washing Equipment?

Composite materials, which combine various substances to enhance performance, are becoming more common in pressure washing equipment. These materials can offer high strength and durability, withstanding pressures up to 3000 PSI and temperatures around 100°C.

Pros: The key advantage of composites is their ability to provide excellent strength-to-weight ratios, making them ideal for portable pressure washing solutions. They also offer good resistance to corrosion and chemicals.

Cons: The downside is that composite materials can be more expensive and complex to manufacture, potentially leading to higher costs for end-users.

Impact on Application: Composites are suitable for high-performance applications requiring lightweight yet durable solutions.

Considerations for International Buyers: Buyers should ensure that composite materials meet international standards such as ISO 9001 for quality management, as this can impact performance and safety.

Summary of Material Properties for Pressure Washing Equipment

| Material | Typical Use Case for pressure washing china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Heavy-duty pressure washers | Excellent corrosion resistance | Higher initial cost | High |

| Aluminum | Portable pressure washing equipment | Lightweight and cost-effective | Less durable than stainless steel | Medium |

| Plastic | Hoses and non-structural components | Resistant to chemicals | Can degrade under UV exposure | Low |

| Composite | High-performance portable washers | High strength-to-weight ratio | More expensive and complex to manufacture | High |

This guide provides a foundational understanding of material selection for pressure washing equipment, enabling international B2B buyers to make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for pressure washing china

What Are the Key Manufacturing Processes for Pressure Washing Equipment in China?

The manufacturing of pressure washing equipment in China involves several critical stages, each contributing to the overall quality and performance of the final product. Understanding these processes can help B2B buyers make informed decisions when sourcing equipment.

How Is Material Prepared for Pressure Washing Equipment?

The first stage in manufacturing pressure washing equipment is material preparation. Manufacturers typically use high-grade metals, plastics, and rubber components, which are sourced based on specifications. The materials undergo rigorous inspection to ensure they meet the required standards for durability and performance. For B2B buyers, verifying the quality of raw materials can be done through supplier certifications and material test reports.

What Forming Techniques Are Commonly Used?

Once the materials are prepared, the next step is forming. This stage involves various techniques such as:

- Stamping and Cutting: Used for creating metal components like the chassis and frame.

- Injection Molding: Commonly employed for plastic parts, ensuring precision and scalability.

- Casting: Often used for complex metal components that require intricate designs.

Each technique has its advantages, and selecting a supplier with expertise in the relevant forming methods can significantly affect the quality of the final product.

How Is Assembly Performed in Pressure Washing Manufacturing?

Assembly is a crucial stage where all individual components come together. Typically, manufacturers follow standardized assembly procedures to ensure consistency and quality. This stage may involve:

- Mechanical Assembly: Where parts are joined using screws, bolts, and adhesives.

- Electrical Assembly: Integration of motors, switches, and wiring.

For B2B buyers, understanding a manufacturer’s assembly process can provide insights into their operational efficiency and product reliability. Requesting detailed assembly documentation can help verify that the supplier adheres to industry best practices.

What Finishing Techniques Are Used to Enhance Product Quality?

Finishing processes are vital to the aesthetic and functional quality of pressure washing equipment. Common finishing techniques include:

- Powder Coating: Provides a durable, weather-resistant finish.

- Plating: Enhances corrosion resistance, crucial for equipment exposed to water and chemicals.

- Quality Testing: Ensures that the finishing meets specific standards before the product is packaged.

B2B buyers should inquire about the finishing processes used by suppliers, as these can significantly impact the equipment’s longevity and performance.

What Quality Assurance Practices Are Essential for Pressure Washing Equipment?

Quality assurance (QA) is fundamental to ensuring that pressure washing equipment meets international standards and customer expectations. A robust QA process typically involves several key components.

Which International Standards Should B2B Buyers Be Aware Of?

Many manufacturers in China adhere to international quality standards such as ISO 9001, which outlines criteria for an effective quality management system. In addition, compliance with industry-specific standards such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) certifications for specific applications can be crucial for ensuring product safety and reliability.

B2B buyers should request certification documentation from suppliers to verify compliance with these standards, which can also enhance credibility in their respective markets.

What Are the Key QC Checkpoints in Manufacturing?

Quality control (QC) is typically divided into several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Involves the inspection of raw materials upon arrival at the facility.

- In-Process Quality Control (IPQC): Conducted during manufacturing to ensure that each stage meets quality standards.

- Final Quality Control (FQC): Performed on completed products before shipment to catch any defects.

These checkpoints are essential for maintaining product quality and can be a significant factor in a buyer’s decision-making process.

What Common Testing Methods Are Used for Pressure Washing Equipment?

Various testing methods are employed to ensure that pressure washing equipment performs reliably under different conditions. Some common tests include:

- Hydrostatic Testing: Ensures the equipment can withstand high pressure without leaking.

- Performance Testing: Assesses the efficiency and effectiveness of the equipment in real-world scenarios.

- Durability Testing: Evaluates how well the equipment can perform over time under stress.

B2B buyers should inquire about the specific testing methods used by manufacturers and consider requesting test reports as part of their due diligence.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verifying a supplier’s QC practices is critical for B2B buyers looking to source pressure washing equipment. Here are some actionable steps:

- Conduct Supplier Audits: Regular audits can help assess the supplier’s adherence to quality standards and manufacturing practices.

- Request Quality Control Reports: Suppliers should be willing to share detailed QC reports that outline their processes and results.

- Engage Third-Party Inspection Services: Utilizing independent inspection services can provide an unbiased evaluation of the supplier’s quality practices.

What Are the QC and Certification Nuances for International Buyers?

For international buyers, especially from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of QC and certification is essential. Each region may have specific requirements that manufacturers must meet to ensure compliance with local regulations.

Buyers should consider the following:

- Documentation Requirements: Ensure that all necessary certifications and documentation are provided to facilitate customs clearance and regulatory compliance.

- Cultural and Language Barriers: Communication with suppliers may be affected by language differences, so it’s important to establish clear expectations and documentation standards.

- Local Standards: Familiarize yourself with local standards in your target market to ensure that the products meet both international and regional requirements.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make more informed decisions when sourcing pressure washing equipment from China, ensuring that they receive high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pressure washing china’

This practical sourcing guide aims to assist international B2B buyers in effectively procuring pressure washing equipment from China. With a clear step-by-step checklist, buyers from regions such as Africa, South America, the Middle East, and Europe will be equipped with actionable insights to make informed purchasing decisions.

Step 1: Define Your Technical Specifications

Before initiating your sourcing journey, it’s essential to clarify your technical requirements for pressure washing equipment. This includes factors such as pressure levels, flow rates, and any specific features (e.g., portability or energy efficiency) that meet your operational needs. By having a precise specification, you can streamline your search and communicate effectively with potential suppliers.

Step 2: Research and Identify Reputable Suppliers

Conduct thorough research to identify suppliers with a solid reputation in the pressure washing market. Utilize platforms like Alibaba, Made-in-China, or industry-specific directories to find manufacturers with positive reviews and a history of reliability. Look for suppliers that specialize in pressure washing equipment to ensure they possess the necessary expertise.

Step 3: Verify Supplier Certifications and Compliance

✅ Verify Supplier Certifications

It’s crucial to confirm that your potential suppliers hold the necessary certifications and comply with international standards. Look for certifications such as ISO 9001 for quality management and CE marking for compliance with European safety standards. These certifications ensure that the products meet specific quality and safety benchmarks, protecting your investment.

Step 4: Request Product Samples

Before finalizing any orders, always request product samples from your shortlisted suppliers. This allows you to evaluate the quality, functionality, and durability of the pressure washing equipment. Pay attention to the materials used, ease of use, and overall construction, as these factors can significantly impact your operational efficiency.

Step 5: Assess Payment Terms and Shipping Options

Discuss and clarify payment terms and shipping arrangements with your chosen supplier. Ensure that the payment methods are secure and favorable for your business. Additionally, explore shipping options to determine costs and timelines, as these can vary widely based on the supplier’s location and your destination.

Step 6: Negotiate Terms and Conditions

Engage in negotiations to establish mutually beneficial terms and conditions. This includes discussing pricing, warranty periods, and after-sales support. Strong negotiation can lead to better pricing and service agreements, ensuring that you receive the best value for your procurement.

Step 7: Plan for After-Sales Support and Maintenance

Finally, consider the after-sales support offered by the supplier. Inquire about warranty services, spare parts availability, and technical support. Reliable after-sales service is crucial for minimizing downtime and ensuring the longevity of your pressure washing equipment.

By following these structured steps, B2B buyers can navigate the complexities of sourcing pressure washing equipment from China effectively, leading to successful procurement outcomes.

Comprehensive Cost and Pricing Analysis for pressure washing china Sourcing

What Are the Key Cost Components in Sourcing Pressure Washing Equipment from China?

When sourcing pressure washing equipment from China, understanding the cost structure is crucial for international B2B buyers. The main components affecting the total cost include:

-

Materials: The type and quality of materials used in manufacturing pressure washers significantly impact costs. Stainless steel, for example, is more expensive than plastic but offers better durability and longevity.

-

Labor: Labor costs in China are generally lower than in many Western countries, but they can vary by region and factory. Skilled labor may command higher wages, particularly in specialized production processes.

-

Manufacturing Overhead: This includes costs related to factory maintenance, utilities, and equipment depreciation. Efficient manufacturing practices can help reduce these costs, but buyers should assess the supplier’s operational efficiency.

-

Tooling: Custom tooling for specialized designs or features can add to initial costs. Buyers should evaluate whether the investment in tooling aligns with their volume and long-term needs.

-

Quality Control (QC): Implementing rigorous QC processes can incur additional expenses but is vital for ensuring product reliability. Buyers should inquire about the supplier’s QC measures to mitigate risks associated with poor quality.

A stock image related to pressure washing china.

-

Logistics: Shipping costs, which are influenced by the method (air, sea, or rail) and distance, play a crucial role in total costs. Understanding Incoterms is essential for clarifying responsibilities and costs between buyers and suppliers.

-

Margin: Suppliers will typically add a margin to cover their costs and ensure profit. This margin can vary widely based on the supplier’s positioning and market strategy.

How Do Price Influencers Affect Pressure Washing Equipment Costs?

Several factors can influence the pricing of pressure washing equipment sourced from China:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically lead to lower per-unit costs. Buyers should negotiate MOQs to maximize their purchasing power without overcommitting.

-

Specifications and Customization: Customized equipment or specific features can increase costs. Buyers should assess whether these enhancements are necessary for their market needs.

-

Materials and Quality Certifications: Higher-quality materials and certifications (like CE, ISO) often come at a premium. Buyers must balance their quality requirements with budget constraints.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more but offer better quality assurance and service.

-

Incoterms: The chosen Incoterms (e.g., FOB, CIF) can influence the overall cost structure. Understanding these terms can help buyers avoid unexpected charges and optimize shipping costs.

What Tips Can Help Buyers Negotiate Better Prices for Pressure Washing Equipment?

For B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, effective negotiation and cost management strategies are essential:

-

Understand Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, operation, and potential repair costs to evaluate the overall value of the equipment.

-

Negotiate Volume Discounts: If planning to place large orders, leverage this to negotiate better pricing or payment terms. Suppliers may be more willing to offer discounts for bulk purchases.

-

Research Market Prices: Conduct thorough market research to compare prices from multiple suppliers. This knowledge can empower buyers during negotiations.

-

Be Clear About Requirements: Providing detailed specifications can minimize misunderstandings and additional costs later in the process. Clear communication helps ensure suppliers meet expectations.

-

Consider Local Regulations: Be aware of import duties, taxes, and local regulations that may affect total costs. This knowledge can help in negotiations and planning.

Disclaimer on Indicative Pricing

Prices for pressure washing equipment can fluctuate based on market conditions, material costs, and geopolitical factors. It is essential for buyers to conduct their own research and obtain quotes from multiple suppliers to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing pressure washing china With Other Solutions

Introduction: Why Explore Alternatives to Pressure Washing China?

In the competitive landscape of industrial cleaning solutions, understanding the alternatives to pressure washing China is crucial for international B2B buyers. This analysis provides insights into various methods that can serve similar purposes, enabling businesses to make informed decisions based on performance, cost, and operational efficiency.

Comparison Table: Pressure Washing China vs. Alternatives

| Comparison Aspect | Pressure Washing China | Steam Cleaning | Chemical Cleaning |

|---|---|---|---|

| Performance | High-pressure jets remove tough stains and grime effectively | Excellent for sanitizing and removing grease; less effective on heavy debris | Effective on specific stains; relies on chemical reactions |

| Cost | Moderate initial investment; operational costs can vary | Higher upfront costs for equipment; lower ongoing costs | Variable costs depending on chemical choice; potential environmental fees |

| Ease of Implementation | Requires trained personnel; setup can be complex | Generally straightforward but needs training for safe operation | Requires careful handling of chemicals; may need permits |

| Maintenance | Requires regular maintenance of pumps and hoses | Low maintenance; occasional descaling needed | Maintenance of chemical storage and safety equipment |

| Best Use Case | Ideal for heavy-duty industrial applications and large surfaces | Best for sanitizing food processing facilities and hospitals | Suitable for specialized cleaning tasks in sensitive environments |

What Are the Pros and Cons of Steam Cleaning as an Alternative?

Steam cleaning utilizes high-temperature steam to clean and disinfect surfaces. One of its significant advantages is its ability to sanitize without the need for chemicals, making it an environmentally friendly option. It is particularly effective for grease removal and is widely used in food processing and healthcare industries. However, steam cleaning may not be as effective for heavy debris or large-scale outdoor applications, which are better suited for pressure washing.

How Does Chemical Cleaning Compare to Pressure Washing China?

Chemical cleaning involves using specially formulated cleaning agents to break down stains and contaminants. The primary benefit of this method is its effectiveness against specific stains, particularly in environments where delicate surfaces need to be preserved. However, the reliance on chemicals can raise safety concerns and may require regulatory compliance, particularly in regions with stringent environmental laws. Additionally, operational costs can fluctuate based on the chemical agents used, which can impact budgeting for B2B buyers.

Conclusion: How to Choose the Right Cleaning Solution for Your Business

When selecting the best cleaning solution for your B2B operations, it is essential to assess your specific needs, including the types of surfaces you will be cleaning, the scale of your operations, and your budget constraints. Pressure washing China offers robust performance for heavy-duty applications, while steam and chemical cleaning provide viable alternatives for specialized tasks. By carefully weighing the pros and cons of each option, international buyers from Africa, South America, the Middle East, and Europe can make informed decisions that align with their operational goals and regulatory requirements.

Essential Technical Properties and Trade Terminology for pressure washing china

What Are the Key Technical Properties of Pressure Washing Equipment?

When sourcing pressure washing equipment from China, understanding the critical technical properties can significantly impact your purchasing decisions. Here are some essential specifications to consider:

1. Material Grade

The material grade of pressure washers typically refers to the quality of the components used, such as the frame, pump, and nozzle. Common materials include stainless steel and high-grade aluminum, known for their durability and resistance to corrosion. For B2B buyers, selecting high-grade materials ensures a longer lifespan of the equipment, reducing replacement costs and downtime.

2. Pressure Rating

Measured in PSI (pounds per square inch), the pressure rating indicates the force with which water is expelled from the nozzle. Typical ratings range from 1,500 PSI for residential models to over 4,000 PSI for commercial machines. Understanding the pressure requirements for specific cleaning tasks is crucial for buyers, as it affects cleaning efficiency and effectiveness.

3. Flow Rate

The flow rate, expressed in gallons per minute (GPM), determines how much water is used during operation. A higher flow rate can lead to quicker cleaning times but may also increase water usage. B2B buyers should consider the balance between efficiency and resource consumption, especially in regions where water conservation is a priority.

4. Tolerance Levels

Tolerance levels refer to the acceptable deviations in the manufacturing process. For pressure washing equipment, this can pertain to dimensions of hoses, fittings, and connectors. Tight tolerances ensure better fit and function, which is essential for optimal performance. Buyers should inquire about these specifications to avoid compatibility issues with existing equipment.

5. Energy Source

Pressure washers can be powered by electricity, gasoline, or diesel. Each energy source has its advantages and disadvantages. For instance, electric models are quieter and more suited for indoor use, while gasoline-powered units offer portability and higher pressure capabilities. Understanding the energy source is vital for buyers to align with operational needs and environmental considerations.

What Are Common Trade Terms in the Pressure Washing Industry?

Navigating the international trade landscape requires familiarity with specific jargon. Here are several key terms relevant to pressure washing equipment procurement:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand. In the context of pressure washing equipment, understanding OEM relationships can lead to better pricing and quality assurance. B2B buyers should consider sourcing from reputable OEMs for reliable products.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For pressure washing equipment, MOQs can vary significantly between manufacturers. Knowing the MOQ helps buyers gauge their purchasing power and inventory management, particularly when dealing with suppliers in different regions.

3. RFQ (Request for Quotation)

An RFQ is a document issued by potential buyers to solicit price offers from suppliers. For international B2B transactions, a well-structured RFQ can facilitate better negotiation terms and ensure that all specifications are clearly outlined. This is essential for securing favorable pricing and terms.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs. Familiarity with Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can aid buyers in understanding their liabilities and costs during the procurement process.

5. Lead Time

Lead time refers to the duration between placing an order and receiving the product. In the context of pressure washing equipment, lead times can be affected by factors such as manufacturing capacity and shipping logistics. Understanding lead times is crucial for B2B buyers to plan their operations effectively and avoid project delays.

By grasping these essential technical properties and trade terminologies, international B2B buyers can make informed decisions when sourcing pressure washing equipment from China, ultimately enhancing operational efficiency and profitability.

Navigating Market Dynamics and Sourcing Trends in the pressure washing china Sector

What Are the Key Market Dynamics and Trends in the Pressure Washing Sector?

The global pressure washing market has been experiencing significant growth, driven by increasing demand for cleanliness and hygiene across various sectors, including residential, commercial, and industrial applications. The rise of urbanization, particularly in emerging markets in Africa, South America, the Middle East, and Europe, has heightened the need for effective cleaning solutions. In regions like Nigeria and South Africa, the expansion of infrastructure projects is propelling the demand for pressure washing services.

One of the most prominent trends in the pressure washing sector is the integration of advanced technology. B2B buyers are increasingly seeking equipment that incorporates IoT capabilities, allowing for remote monitoring and maintenance. This trend is particularly relevant for companies looking to optimize operations and reduce downtime. Moreover, the shift towards eco-friendly solutions is reshaping purchasing decisions, with buyers prioritizing machines that use less water and energy while still delivering high performance.

The competitive landscape is also evolving, with manufacturers in China focusing on innovation and cost-effectiveness. International buyers can benefit from sourcing high-quality, affordable pressure washing equipment from Chinese suppliers who are investing in R&D to enhance product features and durability. Buyers should consider engaging with suppliers who offer customization options to better meet their specific operational needs.

How Is Sustainability Impacting Sourcing Decisions in the Pressure Washing Sector?

Sustainability is becoming a crucial factor in the B2B sourcing process, especially for companies focused on maintaining a positive brand image and complying with regulatory standards. The environmental impact of pressure washing practices, particularly in terms of water usage and chemical runoff, has prompted buyers to seek out equipment that minimizes ecological footprints.

Ethical sourcing is equally important, as buyers are increasingly aware of the implications of their purchasing decisions on global supply chains. Suppliers that demonstrate commitment to sustainable practices, such as using recyclable materials and ensuring fair labor practices, are more likely to attract international buyers from Africa, South America, the Middle East, and Europe.

Buyers should look for ‘green’ certifications, such as Energy Star or EcoLabel, which indicate that the equipment meets specific environmental standards. Additionally, opting for machines that utilize biodegradable detergents can help companies further reduce their environmental impact, making a significant difference in their operational sustainability.

How Has the Pressure Washing Sector Evolved Over Time?

The pressure washing industry has seen considerable evolution over the past few decades, transitioning from basic manual cleaning methods to advanced, automated solutions. Initially dominated by small-scale operators, the market has expanded significantly with the advent of high-pressure technology and specialized cleaning agents.

In recent years, the rise of e-commerce has revolutionized how buyers access pressure washing products and services. International B2B buyers now have the convenience of sourcing equipment from global suppliers, including those in China, through online platforms. This shift not only facilitates competitive pricing but also encourages innovation as manufacturers strive to meet diverse customer needs across different regions.

As the market continues to grow, the focus on efficiency, sustainability, and technological integration will likely shape the future landscape of the pressure washing sector, providing ample opportunities for international B2B buyers to optimize their operations and enhance service delivery.

Frequently Asked Questions (FAQs) for B2B Buyers of pressure washing china

-

How do I ensure quality when sourcing pressure washers from China?

To ensure quality when sourcing pressure washers from China, start by requesting samples before placing bulk orders. Verify the manufacturer’s certifications, such as ISO 9001, which indicate adherence to international quality standards. Consider visiting the factory or using a third-party inspection service to assess production practices and quality control measures. Additionally, read reviews and seek testimonials from previous clients to gauge the reliability of the supplier. -

What are the best pressure washing machines for commercial use?

The best pressure washing machines for commercial use typically feature high PSI (pounds per square inch) ratings and durable construction. Look for models with adjustable pressure settings, multiple nozzle options, and easy maintenance features. Brands like Karcher and Nilfisk offer robust options, while Chinese manufacturers such as Lavor and Sun Joe provide competitive pricing and customization capabilities. Always assess your specific cleaning requirements to select the most suitable model. -

What should I know about Minimum Order Quantities (MOQ) when sourcing from China?

When sourcing pressure washers from China, it’s essential to inquire about the Minimum Order Quantity (MOQ) set by the supplier. MOQs can vary significantly based on the manufacturer and product type. Some suppliers may allow lower MOQs for first-time buyers, while others may require higher quantities for competitive pricing. Understanding the MOQ helps you budget effectively and ensures you have enough stock to meet demand without overcommitting financially. -

How can I vet suppliers of pressure washers from China effectively?

To vet suppliers effectively, start by researching their company background, including years in business, client portfolio, and product offerings. Use platforms like Alibaba or Global Sources to check reviews and ratings from previous customers. Request references and contact them to understand their experiences. Additionally, consider conducting a factory audit or hiring a third-party inspection company to verify the supplier’s production capabilities and compliance with international standards. -

What payment terms are common when sourcing pressure washers from China?

Common payment terms when sourcing pressure washers from China include a deposit (usually 30%) upfront, with the remaining balance paid before shipment. Some suppliers may offer flexible terms like letter of credit or payment through platforms like Alibaba Trade Assurance for added security. It’s crucial to negotiate favorable terms that protect your interests while ensuring the supplier feels secure in the transaction. -

How do logistics and shipping work for importing pressure washers from China?

Logistics and shipping for importing pressure washers from China involve several steps. First, choose between air freight for faster delivery or sea freight for cost savings. Coordinate with your supplier to determine packaging and labeling requirements. Engage a freight forwarder to handle customs clearance, documentation, and transport logistics. Be aware of import duties and taxes in your country, as they can significantly impact overall costs. -

What customization options are available when ordering pressure washers from China?

Many Chinese manufacturers offer customization options for pressure washers, including branding, specific features, and color choices. Discuss your requirements with potential suppliers to explore available modifications. Some manufacturers may also provide tailored solutions, such as different pump types or pressure settings to meet specific market needs. Ensure that you clearly communicate your specifications to avoid misunderstandings. -

How can I address potential language barriers when sourcing from Chinese suppliers?

Addressing potential language barriers can be crucial in ensuring smooth communication with Chinese suppliers. Utilize professional translation services or hire bilingual staff if necessary. Many Chinese manufacturers have English-speaking representatives, but it’s advisable to confirm this beforehand. Additionally, using clear and concise language in emails and documentation can help minimize misunderstandings. Establishing a good rapport with the supplier can also facilitate smoother interactions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for pressure washing china

In the evolving landscape of pressure washing equipment, international B2B buyers from Africa, South America, the Middle East, and Europe must embrace strategic sourcing to enhance their procurement processes. By understanding the diverse offerings from China, businesses can tap into a vast array of high-quality products at competitive prices. Key takeaways include the importance of thorough supplier vetting, leveraging local partnerships for better logistics, and utilizing technological tools to streamline operations.

How can strategic sourcing enhance your supply chain efficiency? By focusing on building long-term relationships with reliable Chinese manufacturers, buyers can ensure consistent quality and timely delivery. Furthermore, aligning with suppliers who understand the unique demands of your regional market can lead to tailored solutions that drive business growth.

Looking ahead, the pressure washing industry is poised for innovation, with advancements in eco-friendly technologies and automated systems. International buyers are encouraged to stay informed about these trends and adapt their sourcing strategies accordingly. Engage with trusted suppliers, participate in trade shows, and explore joint ventures to seize emerging opportunities. The future of pressure washing in your market is bright—act now to position your business at the forefront of this dynamic sector.