Cut Costs with Quality: Sourcing Alternator China (2025)

Introduction: Navigating the Global Market for alternator china

As international B2B buyers increasingly turn to China for sourcing alternators, navigating this vast market can pose significant challenges. The complexity of sourcing quality alternators that meet specific operational needs—whether for automotive, industrial, or renewable energy applications—requires a comprehensive understanding of the landscape. This guide on ‘alternator China’ aims to equip buyers from regions such as Africa, South America, the Middle East, and Europe, including key markets like Nigeria and Mexico, with the insights needed to make informed purchasing decisions.

In the following sections, we will explore various types of alternators available in China, their applications across different industries, and essential supplier vetting practices. Furthermore, we will provide actionable insights into pricing structures, shipping considerations, and quality assurance measures. By consolidating this information, the guide empowers B2B buyers to streamline their sourcing processes, minimize risks, and enhance their competitive edge in the global marketplace.

Understanding the nuances of the Chinese alternator market is crucial for buyers looking to optimize their supply chains and ensure reliability in their operations. This guide will serve as a valuable resource, helping you navigate the complexities of sourcing alternators effectively and efficiently.

Understanding alternator china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Synchronous Alternators | Operate at a constant speed, generating AC power. | Power plants, industrial facilities | Pros: Reliable, efficient power generation. Cons: Higher initial cost, requires precise speed control. |

| Brushless Alternators | No brushes, reducing maintenance needs. | Marine applications, generators | Pros: Lower maintenance, longer lifespan. Cons: More complex design, potentially higher purchase price. |

| Diesel Alternators | Powered by diesel engines, suitable for heavy loads. | Construction, mining, emergency power | Pros: High power output, fuel efficiency. Cons: Noisy operation, emissions regulations may apply. |

| Portable Alternators | Compact and easily transportable for various uses. | Events, outdoor activities | Pros: Versatile, lightweight. Cons: Limited power output, may not withstand heavy-duty applications. |

| Permanent Magnet Alternators | Use permanent magnets for power generation. | Renewable energy systems, small-scale applications | Pros: High efficiency, compact design. Cons: Higher cost, limited to smaller applications. |

What Are the Characteristics of Synchronous Alternators?

Synchronous alternators are designed to operate at a constant speed, making them ideal for applications that require stable AC power generation, such as power plants and industrial facilities. They are characterized by their ability to maintain a steady output voltage, which is crucial in grid-connected systems. When purchasing, B2B buyers should consider the initial investment, as these units typically have a higher upfront cost. However, their reliability and efficiency often justify the expense, especially in large-scale operations.

How Do Brushless Alternators Reduce Maintenance Needs?

Brushless alternators eliminate the need for brushes, which significantly reduces maintenance requirements. This makes them particularly suitable for marine applications and stationary generators where reliability is paramount. While they may come with a more complex design and a higher purchase price, the long-term savings on maintenance and increased lifespan can provide substantial value for B2B buyers. It’s essential to evaluate the specific operational environment to determine if the benefits align with the business’s needs.

What Are the Benefits of Diesel Alternators for Heavy Loads?

Diesel alternators are robust systems designed to handle heavy loads, making them ideal for construction, mining, and emergency power applications. Their high power output and fuel efficiency are key advantages, allowing businesses to operate equipment without interruptions. However, potential buyers should be aware of the noise produced during operation and the need to comply with emissions regulations. Understanding these factors is crucial for businesses operating in regulated environments.

Why Choose Portable Alternators for Versatile Applications?

Portable alternators are compact and designed for easy transport, making them perfect for events and outdoor activities. Their versatility allows businesses to utilize them in various settings, from temporary power solutions to recreational uses. However, buyers should note that these units typically have a limited power output, which may not be suitable for heavy-duty applications. Evaluating the specific power requirements of intended uses is essential before making a purchase.

What Makes Permanent Magnet Alternators Efficient?

Permanent magnet alternators utilize permanent magnets to generate power, resulting in high efficiency and a compact design. They are particularly popular in renewable energy systems and smaller applications where space is a constraint. While the initial cost may be higher than traditional models, the efficiency and reduced operational costs can offer long-term savings. B2B buyers should assess their energy needs and application scale to determine if this type aligns with their objectives.

Related Video: Alternator, How it works?

Key Industrial Applications of alternator china

| Industry/Sector | Specific Application of alternator china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Power Generation | Standby Power Supply Systems | Ensures uninterrupted power supply during outages, enhancing reliability. | Evaluate alternator capacity, efficiency ratings, and compliance with local standards. |

| Construction | Heavy Machinery and Equipment | Provides the necessary power for cranes, excavators, and other machinery. | Consider durability, weight, and compatibility with existing equipment. |

| Agriculture | Irrigation Systems | Powers pumps for irrigation, improving crop yield and efficiency. | Assess energy consumption, maintenance requirements, and local climate adaptability. |

| Marine | Marine Propulsion Systems | Supports propulsion systems for vessels, ensuring operational efficiency. | Check for corrosion resistance, power output, and maritime compliance. |

| Telecommunications | Backup Power for Data Centers | Maintains operations during power failures, protecting critical data. | Focus on reliability, response time, and capacity to handle peak loads. |

How is ‘Alternator China’ Used in Power Generation?

In the power generation sector, alternators from China are integral to standby power supply systems. They provide a reliable backup during outages, ensuring that businesses can maintain operations without interruption. For international buyers, particularly in regions like Africa and the Middle East, sourcing alternators that meet local energy demands and regulatory standards is crucial. Buyers should evaluate the alternator’s capacity and efficiency ratings to align with their power requirements.

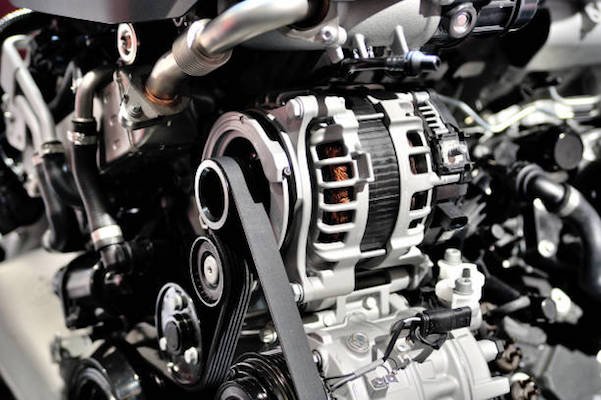

A stock image related to alternator china.

What Role Does ‘Alternator China’ Play in Construction?

In construction, alternators are essential for powering heavy machinery such as cranes and excavators. They provide the necessary electricity to operate these machines, significantly enhancing productivity on job sites. For buyers in South America and Europe, it’s important to consider the durability and compatibility of the alternator with existing machinery. This ensures seamless integration and reduces downtime during projects.

How Does ‘Alternator China’ Benefit Agriculture?

In agriculture, alternators are used to power irrigation systems, which are vital for maintaining crop health and maximizing yields. By ensuring consistent water supply, these alternators help farmers in regions like Nigeria and Mexico overcome challenges related to water scarcity. Buyers should assess the energy consumption and maintenance requirements of the alternators to ensure they are suitable for the local climate and operational needs.

Why is ‘Alternator China’ Important in Marine Applications?

For the marine industry, alternators are crucial in propulsion systems, providing the necessary power for vessels to operate efficiently. This application is particularly relevant for buyers in regions with significant maritime activity, such as Europe and the Middle East. When sourcing alternators, it is essential to check for corrosion resistance and compliance with maritime standards to ensure longevity and reliability in harsh marine environments.

How Does ‘Alternator China’ Support Telecommunications?

In telecommunications, alternators are vital for backup power systems in data centers, ensuring continuous operation during power failures. This is particularly important for businesses that rely on uninterrupted data access, especially in regions with unstable power supplies. International buyers should focus on the reliability and response time of the alternators, ensuring they can handle peak loads without compromising data integrity.

3 Common User Pain Points for ‘alternator china’ & Their Solutions

Scenario 1: Sourcing Quality Alternators from China

The Problem:

B2B buyers often face challenges in sourcing high-quality alternators from Chinese manufacturers. Many buyers report receiving products that do not meet their specifications, leading to operational disruptions and financial losses. In regions like Africa and South America, where supply chains may already be stretched thin, the risk of importing faulty or substandard alternators can significantly impact project timelines and operational efficiency. Additionally, language barriers and varying quality standards can complicate communication, making it difficult for buyers to ensure they are making informed decisions.

The Solution:

To effectively source quality alternators from China, buyers should conduct thorough due diligence on potential suppliers. Start by verifying the manufacturer’s credentials and certifications, such as ISO 9001 for quality management systems. Utilizing platforms like Alibaba or Global Sources can help in filtering suppliers based on ratings and customer reviews. Moreover, engaging a third-party inspection service before shipping can safeguard against receiving defective products. This proactive approach not only mitigates risk but also builds a reliable supply chain that can adapt to the specific needs of your business.

Scenario 2: Navigating Language and Cultural Barriers in Supplier Communication

The Problem:

Communication barriers can be a significant pain point when dealing with Chinese suppliers. Misunderstandings regarding product specifications, shipping terms, and payment processes can lead to costly errors. For B2B buyers from regions like the Middle East and Europe, where business practices may differ, these barriers can exacerbate frustrations, resulting in delays and strained relationships with suppliers.

The Solution:

To navigate these challenges, buyers should consider employing a bilingual sourcing agent who is familiar with both the local language and the nuances of Chinese business culture. This agent can facilitate clear communication, ensuring that all specifications and expectations are thoroughly understood by both parties. Additionally, using visual aids like diagrams and charts can help bridge comprehension gaps. Establishing clear terms of agreement and using standardized templates for contracts can further reduce the risk of miscommunication. By investing in effective communication strategies, buyers can foster better relationships and streamline their procurement processes.

Scenario 3: Dealing with Unforeseen Shipping Delays and Customs Issues

The Problem:

Shipping delays are a common issue when importing alternators from China, particularly for buyers in remote areas of Africa or South America where logistics networks may be less developed. Unexpected customs inspections or clearance delays can lead to extended lead times, jeopardizing project deadlines and increasing costs. This unpredictability can erode trust between buyers and suppliers, making it crucial to find a reliable shipping method.

The Solution:

To mitigate shipping delays, B2B buyers should work closely with logistics providers who specialize in international freight and have experience in navigating the complexities of customs regulations. It’s advisable to choose suppliers who can provide comprehensive shipping documentation to expedite customs clearance. Buyers can also consider using incoterms like DDP (Delivered Duty Paid), where the seller assumes responsibility for shipping and customs duties, thereby minimizing surprises on arrival. Keeping an open line of communication with both the supplier and the logistics provider can help buyers stay informed about potential delays and adjust their plans accordingly. By taking these proactive steps, buyers can enhance their supply chain resilience and maintain operational continuity.

Strategic Material Selection Guide for alternator china

What Are the Common Materials Used in Alternators from China?

When sourcing alternators from China, international B2B buyers must consider the materials used in their construction. The choice of materials impacts performance, durability, and overall cost. Here, we analyze four common materials used in alternators, focusing on their properties, advantages, disadvantages, and relevance to specific markets.

How Do Copper Windings Affect Alternator Performance?

Key Properties: Copper is known for its excellent electrical conductivity, which is crucial for the efficiency of alternators. It can withstand high temperatures and has a melting point of approximately 1,085°C.

Pros & Cons: The primary advantage of copper windings is their superior conductivity, leading to higher efficiency and lower energy losses. However, copper is relatively expensive compared to alternatives like aluminum, which can increase the overall cost of the alternator. Additionally, copper is prone to corrosion if not properly insulated, which can affect longevity.

Impact on Application: Copper windings are suitable for high-performance applications where efficiency is critical, such as in automotive and industrial settings. However, buyers must ensure that the insulation materials used can withstand the specific operational conditions.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local electrical standards (e.g., IEC, NEMA) when sourcing alternators with copper windings. The higher cost may be justified in applications requiring reliability and efficiency.

What Role Does Aluminum Play in Alternator Manufacturing?

Key Properties: Aluminum is lightweight and has good electrical conductivity, though not as high as copper. Its melting point is around 660°C, which is adequate for many alternator applications.

Pros & Cons: The main advantage of aluminum is its lower cost and lighter weight, making it an attractive option for cost-sensitive applications. However, its lower conductivity can lead to increased energy losses, and it is less durable than copper, especially in high-temperature environments.

Impact on Application: Aluminum is often used in applications where weight is a critical factor, such as in automotive alternators for smaller vehicles. However, it may not be suitable for heavy-duty industrial applications where efficiency and durability are paramount.

Considerations for International Buyers: Buyers in Europe and the Middle East should be aware of the varying standards for aluminum components. Compliance with ASTM and DIN standards is essential to ensure product reliability.

Why Is Steel Used in Alternator Housing?

Key Properties: Steel offers excellent strength and durability, with good resistance to mechanical stress. It can withstand high temperatures and pressures, making it a reliable choice for housing.

Pros & Cons: The durability of steel provides significant protection for internal components, reducing the risk of damage. However, steel is heavier than aluminum, which can affect the overall weight of the alternator. Additionally, it may require protective coatings to prevent rust and corrosion.

Impact on Application: Steel is ideal for heavy-duty applications where robustness is essential, such as in industrial machinery. However, the added weight may be a disadvantage in automotive applications where fuel efficiency is a concern.

Considerations for International Buyers: Buyers should ensure that the steel used complies with local standards and regulations. In regions like Africa, where environmental conditions may be harsh, selecting corrosion-resistant coatings is crucial.

How Do Plastics Enhance Alternator Design?

Key Properties: Plastics are lightweight and can be molded into complex shapes. They offer good electrical insulation properties and can withstand moderate temperatures.

Pros & Cons: The primary advantage of plastics is their versatility and low cost. They can reduce the overall weight of the alternator and are resistant to corrosion. However, plastics may not withstand high temperatures as well as metals, potentially limiting their use in high-performance applications.

Impact on Application: Plastics are often used in non-structural components of alternators, such as covers and insulators. They are suitable for applications where weight savings are essential, but buyers must consider temperature ratings.

Considerations for International Buyers: Buyers should verify that the plastics used meet relevant standards for fire resistance and durability, particularly in markets with stringent regulations like Europe.

Summary Table of Material Properties for Alternators

| Material | Typical Use Case for alternator china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | High-performance automotive alternators | Excellent electrical conductivity | Higher cost and corrosion susceptibility | High |

| Aluminum | Lightweight automotive applications | Cost-effective and lightweight | Lower conductivity and durability | Medium |

| Steel | Heavy-duty industrial machinery | Strong and durable | Heavier weight and corrosion risk | Medium |

| Plastics | Non-structural components | Lightweight and versatile | Limited high-temperature performance | Low |

This strategic material selection guide provides international B2B buyers with essential insights into the materials used in alternators from China, helping them make informed purchasing decisions tailored to their specific needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for alternator china

What Are the Main Stages in the Manufacturing Process of Alternators in China?

The manufacturing process for alternators in China involves several critical stages, each designed to ensure the final product meets quality and performance standards expected by international buyers.

Material Preparation

The initial stage in the alternator manufacturing process focuses on material preparation. High-quality materials, such as copper for windings and high-grade steel for rotors and housings, are sourced from reputable suppliers. Before production, materials undergo rigorous testing to verify their mechanical and electrical properties. This step is crucial as it sets the foundation for the alternator’s efficiency and durability.

Forming Techniques Used in Alternator Production

Once materials are prepared, the forming stage begins. Key techniques include:

- Stamping: This method is used to shape the metal components, such as the rotor and stator laminations, which are critical for electromagnetic performance.

- Winding: Copper wire is wound around the stator, which is essential for generating electrical energy. Advanced winding techniques, including automated winding machines, are often employed to ensure precision and consistency.

- Casting: For components like the housing, casting techniques are utilized to create complex shapes that are both lightweight and strong.

These forming techniques are integral to producing alternators that meet the required specifications for power generation.

How Is the Assembly Process Conducted for Alternators?

The assembly process is where all components come together. This stage typically involves the following steps:

- Component Assembly: Individual parts, including the rotor, stator, and bearings, are assembled into the alternator housing.

- Electrical Connections: Wiring is meticulously connected to ensure proper functionality. Automated systems often assist in this process to minimize human error.

- Quality Checks: After assembly, each unit undergoes initial quality checks to ensure that all components are correctly installed and operational.

This systematic approach ensures that the assembled alternators are ready for the finishing touches.

What Are the Finishing Processes in Alternator Manufacturing?

The finishing stage is crucial for the aesthetic and functional quality of the alternators. It typically includes:

- Painting and Coating: Alternators are often coated with protective finishes to resist corrosion and wear, enhancing their longevity.

- Labeling: Clear labeling of each unit, including specifications and compliance marks, is performed to facilitate identification and quality assurance.

- Final Inspection: Before shipping, a final inspection checks for surface imperfections, assembly errors, and functional performance.

These finishing processes not only improve the product’s appearance but also ensure compliance with international standards.

What International Standards Govern Quality Assurance in Alternator Manufacturing?

Quality assurance in alternator manufacturing is vital for international B2B buyers, especially those from Africa, South America, the Middle East, and Europe. Key international standards include:

- ISO 9001: This standard outlines the requirements for a quality management system, ensuring that organizations can consistently provide products that meet customer and regulatory requirements.

- CE Marking: Required for products sold within the European Economic Area, CE marking indicates compliance with safety, health, and environmental protection standards.

- API (American Petroleum Institute): For alternators used in the oil and gas industry, compliance with API standards may be necessary.

Adhering to these standards not only ensures product quality but also facilitates smoother trade across borders.

How Are Quality Control Checkpoints Implemented in the Manufacturing Process?

Quality control (QC) is a critical component of the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted at various stages to identify and rectify issues early in the process.

- Final Quality Control (FQC): After assembly, a comprehensive inspection is performed to ensure that the finished product meets all quality and performance specifications.

These checkpoints are essential for maintaining high-quality standards throughout the manufacturing process.

What Common Testing Methods Are Used to Ensure Product Quality?

Various testing methods are employed to verify the performance and reliability of alternators:

- Electrical Testing: This includes measuring voltage output, current, and resistance to ensure the alternator performs as expected under load conditions.

- Thermal Testing: Alternators are subjected to temperature variations to assess performance under extreme conditions.

- Vibration Testing: This helps identify potential issues related to mechanical integrity and durability.

These testing methods provide critical data that informs quality assurance and product reliability.

How Can B2B Buyers Verify Supplier Quality Control Practices?

International buyers can take several steps to verify a supplier’s quality control practices:

- Conduct Audits: Regular audits of the manufacturing facility can provide insights into the supplier’s adherence to quality standards and processes.

- Request Quality Reports: Suppliers should provide detailed quality reports that document the results of inspections and tests conducted throughout the manufacturing process.

- Engage Third-Party Inspectors: Hiring third-party inspection services can offer an unbiased assessment of the supplier’s quality control practices and product quality.

These measures can help mitigate risks and ensure that the products meet the buyer’s specifications.

What Nuances Should International Buyers Consider Regarding QC and Certification?

When engaging with suppliers in China, international buyers should be aware of specific nuances regarding QC and certification:

- Cultural Differences: Understanding cultural differences in business practices can help in establishing effective communication and expectations regarding quality.

- Certification Validity: Ensure that certifications are up-to-date and relevant to the product being purchased. Request copies of certification documents for verification.

- Local Regulations: Familiarize yourself with local regulations in your own country that may affect the import of alternators, including compliance with safety and environmental standards.

By considering these factors, buyers can enhance their procurement strategies and ensure they receive high-quality products that meet their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘alternator china’

In the dynamic landscape of global trade, sourcing alternators from China can be a strategic move for businesses seeking quality and cost-effectiveness. This practical sourcing guide provides a step-by-step checklist designed specifically for international B2B buyers from Africa, South America, the Middle East, and Europe. By following these actionable insights, you can streamline your procurement process and ensure that you select the right supplier for your needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to have a clear understanding of your technical requirements. Define the specifications of the alternators you need, such as power output, size, and compatibility with existing systems.

– Why it matters: Clear specifications help avoid misunderstandings with suppliers and ensure that the products meet your operational needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers in China. Utilize platforms such as Alibaba, Global Sources, or trade fairs to gather information about various manufacturers.

– What to look for: Focus on suppliers with a proven track record, positive customer reviews, and relevant industry certifications. This will help ensure reliability and quality.

Step 3: Verify Supplier Certifications

Before entering negotiations, verify that potential suppliers hold necessary certifications, such as ISO 9001 or CE marking.

– Importance of certification: Certifications indicate adherence to international quality standards and can serve as a quality assurance measure.

Step 4: Request Samples for Evaluation

Once you have shortlisted a few suppliers, request samples of their alternators to assess quality firsthand. This step is critical in determining whether the products meet your specifications.

– Key considerations: Evaluate the samples for build quality, performance, and durability. Make sure the samples align with your initial specifications.

Step 5: Assess Pricing and Terms of Trade

Engage in discussions about pricing and terms of trade with your selected suppliers. Compare quotes and be aware of additional costs such as shipping, customs, and duties.

– Negotiation tips: Don’t hesitate to negotiate prices and payment terms. Consider exploring options like volume discounts or long-term contracts for better pricing.

Step 6: Conduct Factory Visits or Virtual Inspections

If feasible, arrange for a factory visit or a virtual inspection of the supplier’s production facility. This allows you to assess their manufacturing processes and quality control measures.

– Why this is crucial: A factory visit can reveal insights into the supplier’s operational capabilities and reliability, helping to build confidence in your choice.

Step 7: Finalize Contracts and Payment Terms

Once you are satisfied with the supplier’s capabilities and product quality, finalize contracts that clearly outline payment terms, delivery schedules, and return policies.

– Contract essentials: Ensure that all agreements are documented to protect both parties and mitigate risks related to non-compliance or product issues.

By following this practical checklist, international B2B buyers can effectively navigate the complexities of sourcing alternators from China, ensuring quality products that meet their business needs.

Comprehensive Cost and Pricing Analysis for alternator china Sourcing

What Are the Key Cost Components in Alternator Sourcing from China?

When sourcing alternators from China, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

- Materials: The choice of raw materials significantly affects pricing. High-quality copper and steel are essential for durability and performance, but prices fluctuate based on market conditions.

- Labor: Labor costs in China are generally lower than in Western countries. However, skilled labor for specialized manufacturing processes may command higher wages, impacting overall costs.

- Manufacturing Overhead: This encompasses utilities, factory maintenance, and other operational expenses. Efficient manufacturing processes can help reduce these costs.

- Tooling: Initial tooling costs for custom alternator designs can be substantial. These costs are typically amortized over large production runs, so minimum order quantities (MOQs) are crucial for cost management.

- Quality Control (QC): Implementing strict QC measures ensures product reliability but adds to the overall cost. Certifications such as ISO or CE can also influence pricing.

- Logistics: Shipping costs from China vary based on the chosen Incoterms, shipping method (air vs. sea), and distance to the buyer’s location. Customs duties and tariffs should also be factored into the total logistics cost.

- Margin: Suppliers typically include a margin to cover risks and profit. Understanding the margin expectations can aid in negotiations.

How Do Price Influencers Affect Alternator Costs?

Several factors can influence the pricing of alternators sourced from China:

- Volume and Minimum Order Quantity (MOQ): Larger orders often lead to better pricing. Understanding the supplier’s MOQ can help in negotiating better terms.

- Specifications and Customization: Customized alternators may incur additional costs. Buyers should clarify their specifications to avoid unexpected expenses.

- Materials and Quality Certifications: The choice of materials and required quality certifications directly impacts pricing. Higher quality materials and certifications usually lead to increased costs.

- Supplier Factors: The reputation and experience of the supplier can affect pricing. Established suppliers may charge more due to their reliability and quality assurance.

- Incoterms: Different Incoterms (e.g., FOB, CIF) shift responsibility for shipping costs and risks between buyer and seller, affecting the overall cost structure.

What Are Essential Buyer Tips for Cost-Efficiency in Alternator Sourcing?

International B2B buyers from regions such as Africa, South America, the Middle East, and Europe should consider the following tips for effective sourcing:

- Negotiation Skills: Cultivating strong negotiation skills can lead to significant cost savings. Be prepared to discuss pricing based on volume, long-term partnerships, and market conditions.

- Understanding Total Cost of Ownership (TCO): Evaluate not just the purchase price but the TCO, which includes maintenance, energy consumption, and potential downtime costs. This holistic approach can lead to better purchasing decisions.

- Pricing Nuances: Be aware that prices may vary based on the buyer’s location and currency exchange rates. It’s essential to account for these factors when budgeting.

- Research and Due Diligence: Conduct thorough research on suppliers, including reviews and past performance. This diligence helps avoid costly mistakes and ensures a reliable sourcing partner.

- Long-Term Relationships: Establishing long-term relationships with suppliers can lead to better pricing, priority service, and improved product quality.

Disclaimer on Indicative Prices

While the insights provided here offer a comprehensive view of cost components and pricing strategies, actual prices may vary significantly based on specific negotiations, market conditions, and supplier capabilities. Buyers should seek detailed quotes and conduct market comparisons to ensure they receive competitive pricing tailored to their needs.

Alternatives Analysis: Comparing alternator china With Other Solutions

When considering the purchase of alternators, particularly from China, it’s essential to evaluate alternative solutions that may provide similar benefits. This analysis will focus on two viable alternatives: European-made alternators and Indian-made alternators. By comparing these options, international B2B buyers can make informed decisions that align with their operational needs and budget constraints.

Comparison Table of Alternator Solutions

| Comparison Aspect | Alternator China | European-Made Alternators | Indian-Made Alternators |

|---|---|---|---|

| Performance | High efficiency, wide range of models | Superior durability, high performance | Good efficiency, moderate durability |

| Cost | Generally lower price point | Higher price, premium quality | Competitive pricing |

| Ease of Implementation | Standardized designs, often requires adaptation for local standards | Direct fit for European systems | Some adaptation may be needed |

| Maintenance | Moderate, parts widely available | Low, with premium parts availability | Moderate, parts availability varies |

| Best Use Case | Cost-sensitive projects, diverse applications | High-end applications requiring reliability | Budget-conscious projects with reasonable performance needs |

What are the Advantages and Disadvantages of European-Made Alternators?

European-made alternators are renowned for their durability and high performance. They are often engineered to meet stringent quality standards, making them ideal for applications where reliability is critical. However, the cost is significantly higher compared to their Chinese counterparts. This premium pricing can be a barrier for budget-conscious buyers. Additionally, while they may offer superior performance, they might not be readily available in all markets, leading to potential delays in procurement.

How Do Indian-Made Alternators Compare?

Indian-made alternators provide a balance between cost and performance. They are typically priced lower than European models but may not achieve the same level of durability. This makes them a viable option for projects that are budget-sensitive yet require a reasonable level of efficiency. However, the availability of parts for maintenance can be inconsistent, which may lead to longer downtimes if repairs are needed. They are best suited for markets where cost is a major factor but where some compromise on longevity is acceptable.

Conclusion: How Should B2B Buyers Choose the Right Alternator Solution?

Choosing the right alternator involves assessing both the technical specifications and the financial implications of each option. Buyers from regions such as Africa, South America, the Middle East, and Europe should consider their specific operational needs, the environmental conditions where the alternator will be used, and their budget constraints. For cost-sensitive projects, Chinese alternators may be the most appealing, while European options could be justified in high-stakes applications where reliability is paramount. Indian alternatives can serve as a middle ground, offering decent performance at competitive prices. Ultimately, the decision should reflect a balance between performance requirements and budgetary limits, ensuring that the chosen solution aligns with long-term operational goals.

Essential Technical Properties and Trade Terminology for alternator china

What Are the Key Technical Properties of Alternators from China?

When sourcing alternators from China, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications that B2B buyers should consider:

1. Material Grade

The material used in alternators significantly affects their durability and performance. Common materials include copper for windings due to its excellent conductivity and aluminum for the casing, which is lightweight and corrosion-resistant. Buyers should ensure that the alternator meets industry standards, as the material grade directly impacts efficiency and lifespan.

2. Voltage Rating

Alternators are designed to operate at specific voltage levels, typically ranging from 12V to 48V for automotive applications. Understanding the voltage rating is essential to ensure compatibility with the intended application, whether it’s for vehicles or industrial machinery. Mismatched voltage ratings can lead to equipment failure and safety hazards.

3. Tolerance Levels

Tolerance levels indicate the allowable variation in the alternator’s dimensions and performance parameters. For instance, a tolerance of ±0.1mm in the rotor’s diameter can affect the efficiency of energy conversion. Accurate tolerances are vital for ensuring that the alternator fits properly within its designated application, minimizing the risk of mechanical failure.

4. Efficiency Rating

Efficiency ratings express how effectively an alternator converts mechanical energy into electrical energy. Higher efficiency ratings (typically above 90%) mean less energy waste and better overall performance. For B2B buyers, selecting high-efficiency alternators can translate into cost savings over time through reduced energy consumption.

5. Cooling System Design

Alternators often include specific cooling designs, such as air-cooled or liquid-cooled systems. A well-designed cooling system helps maintain optimal operating temperatures, enhancing reliability and performance. Buyers should assess cooling specifications, especially for applications in high-temperature environments.

Which Trade Terms Should B2B Buyers Understand When Sourcing Alternators?

Navigating the international trade landscape requires familiarity with specific jargon and terms. Here are common trade terms relevant to sourcing alternators from China:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products based on the specifications of another company, often to be branded and sold under the latter’s name. Understanding OEM practices is crucial for buyers looking to source high-quality alternators that meet their specific requirements.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell in a single order. Knowing the MOQ helps buyers plan their inventory and budget effectively. It’s essential for buyers, particularly in regions like Africa and South America, to negotiate favorable MOQs to avoid excess inventory costs.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to solicit price quotes for specific products. It typically includes details about the required specifications, quantities, and delivery timelines. Using RFQs helps buyers compare offers and negotiate better deals.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, covering aspects like shipping, insurance, and tariffs. Familiarity with terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for understanding the total cost of ownership and potential liabilities during transit.

5. Lead Time

Lead time refers to the period between placing an order and receiving the goods. This metric is crucial for B2B buyers who must plan their supply chains effectively. Understanding lead times helps businesses manage their production schedules and avoid disruptions.

Conclusion

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, understanding the technical properties and trade terminology related to alternators is essential. This knowledge not only facilitates better purchasing decisions but also fosters stronger supplier relationships and efficient supply chain management. By prioritizing these elements, buyers can ensure they are sourcing quality products that meet their operational needs.

Navigating Market Dynamics and Sourcing Trends in the alternator china Sector

What Are the Current Market Dynamics and Key Trends in the Alternator Sector from China?

The alternator market is witnessing substantial growth driven by several global factors. Increased demand for renewable energy sources and electric vehicles (EVs) is reshaping the landscape. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, look for reliable power solutions, the focus is shifting towards high-efficiency alternators that can support both traditional and renewable energy systems.

Emerging technologies such as IoT integration in alternators are enabling real-time monitoring and predictive maintenance, enhancing operational efficiency. This trend is particularly relevant for buyers looking to minimize downtime and reduce maintenance costs. Additionally, the rise of smart grids is pushing for advanced alternator designs that can adapt to fluctuating energy demands.

International sourcing dynamics are also evolving. Chinese manufacturers are increasingly adopting automation and advanced manufacturing techniques, which improve product quality and reduce lead times. B2B buyers should be aware of these developments to negotiate better terms and ensure they are sourcing from manufacturers who invest in technology and quality control.

How Important Is Sustainability and Ethical Sourcing in the Alternator Supply Chain?

Sustainability has become a critical consideration in the global supply chain, especially for B2B buyers. The environmental impact of manufacturing processes and materials used in alternators cannot be overlooked. Buyers from Africa, South America, the Middle East, and Europe are now prioritizing suppliers who demonstrate a commitment to sustainable practices.

Ethical sourcing involves selecting suppliers who adhere to strict environmental regulations and labor laws. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are becoming essential for ensuring that suppliers maintain high standards. Furthermore, many manufacturers are now focusing on using ‘green’ materials and processes, which can significantly reduce the carbon footprint associated with alternator production.

Incorporating sustainability into procurement strategies not only enhances brand reputation but also aligns with increasing regulatory pressures in many markets, especially in Europe. B2B buyers should actively seek out suppliers who can provide transparency regarding their supply chain practices and sustainability certifications.

What Is the Brief Evolution of the Alternator Market in China?

The alternator market in China has evolved significantly over the past few decades. Initially, the sector was characterized by low-cost manufacturing and limited technological innovation. However, as global demand for high-performance and efficient energy solutions grew, Chinese manufacturers began to invest in research and development.

By the early 2000s, the focus shifted towards producing alternators that could meet international quality standards. This transition was fueled by the rapid growth of the automotive and renewable energy sectors, which demanded more reliable and efficient power generation solutions. Today, China stands as a leading manufacturer of alternators, known for its ability to deliver both affordability and advanced technology.

In conclusion, international B2B buyers must navigate a complex landscape characterized by technological advancements, sustainability considerations, and evolving market dynamics. By staying informed and strategically sourcing from reputable manufacturers, businesses can leverage the strengths of the Chinese alternator market to meet their energy needs effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of alternator china

-

How do I ensure the quality of alternators sourced from China?

To ensure the quality of alternators sourced from China, it is essential to conduct thorough supplier vetting. Request certifications such as ISO 9001, which indicates adherence to quality management standards. Additionally, consider visiting the manufacturing facility or hiring a third-party inspection service to verify production processes and product specifications. Prioritize suppliers who offer a warranty and have a transparent return policy to safeguard your investment. -

What is the best way to find reliable alternator suppliers in China?

The best way to find reliable alternator suppliers in China is through reputable B2B platforms like Alibaba, Global Sources, or Made-in-China. Look for suppliers with high ratings, positive reviews, and a substantial transaction history. Networking through industry trade shows or forums can also yield valuable contacts. Always request references from previous clients and verify their business licenses to ensure legitimacy. -

What customization options are available when ordering alternators from China?

Many Chinese manufacturers offer customization options for alternators, including modifications to specifications, branding, and packaging. It’s crucial to communicate your requirements clearly, including voltage, power output, and size. Discuss the minimum order quantities (MOQ) for customized products, as some suppliers may have higher MOQs for bespoke items. Be prepared to share detailed technical drawings or samples to facilitate the customization process. -

What are the typical payment terms when sourcing alternators from China?

Typical payment terms when sourcing alternators from China include a 30% deposit upon order confirmation and the remaining 70% before shipping. Some suppliers may offer more flexible terms based on your negotiation skills and relationship with them. It is advisable to use secure payment methods, such as PayPal or letters of credit, to protect your funds during transactions. Always clarify payment terms in your contract to avoid misunderstandings. -

What should I know about minimum order quantities (MOQ) when sourcing alternators?

Minimum order quantities (MOQ) can vary significantly among suppliers, typically ranging from 50 to several hundred units. Understanding the MOQ is vital to ensure it aligns with your business needs and budget. If the MOQ is too high, consider negotiating with the supplier or looking for manufacturers that cater to lower quantities. Some suppliers may also offer samples at a lower MOQ to allow you to assess quality before committing to larger orders. -

How can I effectively manage logistics when importing alternators from China?

To manage logistics effectively when importing alternators from China, start by selecting a reliable freight forwarder familiar with international shipping regulations. Discuss shipping options, such as air freight for faster delivery or sea freight for cost-effectiveness. Ensure that all customs documentation is prepared correctly to avoid delays. Additionally, track your shipment closely and maintain communication with your supplier and freight forwarder throughout the process. -

What quality assurance measures should I implement when sourcing alternators?

Implementing quality assurance measures when sourcing alternators involves setting clear quality expectations in your contracts and conducting regular inspections. Utilize third-party inspection services to perform quality checks at various production stages. Establish a system for product testing upon arrival to ensure compliance with your specifications. Request samples before full-scale production to evaluate quality firsthand. -

How do I handle disputes with Chinese suppliers regarding alternator quality?

Handling disputes with Chinese suppliers regarding alternator quality requires a proactive approach. Start by documenting all communications and agreements related to the order. If a quality issue arises, contact the supplier immediately to discuss the problem and seek resolution. If necessary, refer to the terms outlined in your contract regarding returns or refunds. For unresolved issues, consider mediation or arbitration as a last resort, ensuring you understand the legal framework governing your agreement.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for alternator china

In conclusion, strategic sourcing for alternators from China presents a robust opportunity for international B2B buyers, especially those in Africa, South America, the Middle East, and Europe. By leveraging China’s extensive manufacturing capabilities, businesses can access high-quality products at competitive prices. It is crucial for buyers to conduct thorough due diligence, focusing on supplier reliability, compliance with international standards, and the ability to meet specific requirements.

How can international B2B buyers optimize their sourcing strategies for alternators from China? The key lies in building strong relationships with trusted suppliers, utilizing technology for efficient communication, and staying updated on market trends and regulatory changes. By doing so, companies can mitigate risks and enhance their supply chain resilience.

Looking ahead, as the global demand for reliable power solutions continues to rise, the importance of strategic sourcing will only grow. B2B buyers are encouraged to act proactively—explore partnerships, negotiate favorable terms, and invest in quality to secure their competitive edge in the market. Embrace the future of sourcing, and position your business to thrive in this dynamic landscape.