Cut Costs with Quality: Your Guide to Car Lift China (2025)

Introduction: Navigating the Global Market for car lift china

In today’s dynamic automotive landscape, sourcing high-quality car lifts from China presents both opportunities and challenges for international B2B buyers. With the growing demand for efficient and reliable lifting solutions, understanding the nuances of this market is critical. Buyers from Africa, South America, the Middle East, and Europe, particularly in countries like Poland and Germany, face the daunting task of navigating a sea of options while ensuring compliance with varying regulatory standards and quality expectations.

This comprehensive guide aims to demystify the process of sourcing car lifts from China by exploring essential aspects such as types of lifts available, their specific applications, and the intricacies of supplier vetting. Additionally, we will delve into cost considerations, shipping logistics, and after-sales support, providing buyers with a holistic view of the purchasing process. By equipping you with actionable insights and strategic approaches, this guide empowers you to make informed decisions that align with your business goals.

Understanding how to effectively navigate the global market for car lifts can significantly enhance your operational efficiency and competitiveness. Whether you are expanding your service offerings or upgrading your existing equipment, the insights presented here will help you identify the best suppliers and products to meet your unique requirements.

Understanding car lift china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Two-Post Car Lift | Simple design, cost-effective, space-efficient | Small garages, auto repair shops | Pros: Lower cost, easy to install. Cons: Limited lifting height and capacity. |

| Four-Post Car Lift | Offers stability and greater lifting capacity | Dealerships, service centers | Pros: High weight capacity, suitable for larger vehicles. Cons: Requires more space. |

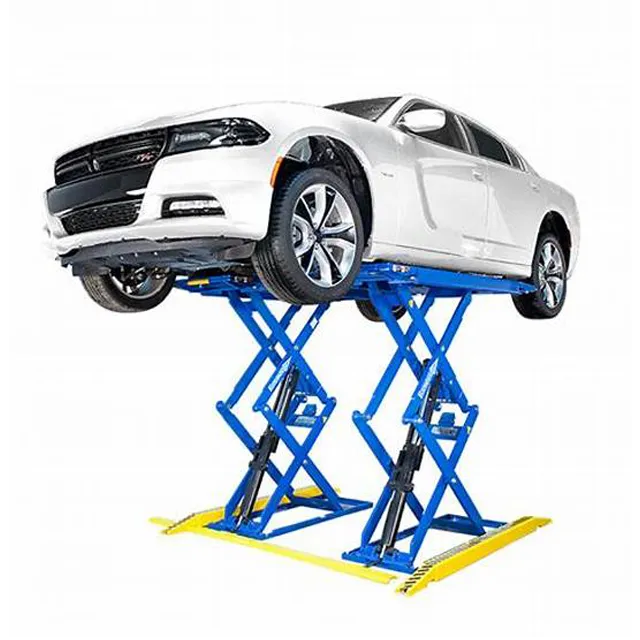

| Scissor Car Lift | Compact design, versatile for various applications | Mobile mechanics, tire shops | Pros: Space-saving, can lift vehicles from below. Cons: May have lower weight capacity compared to others. |

| Portable Car Lift | Lightweight, easy to transport | Mobile service providers, roadside assistance | Pros: Highly portable, quick setup. Cons: Limited lifting height and capacity. |

| In-Ground Car Lift | Installed below ground for aesthetics and space-saving | High-end workshops, luxury vehicle services | Pros: Maximizes floor space, durable. Cons: Higher installation costs, maintenance challenges. |

What Are the Characteristics of Two-Post Car Lifts?

Two-post car lifts are among the most common types found in small garages and auto repair shops. They feature a straightforward design that allows for easy lifting of vehicles using hydraulic mechanisms. This type is particularly suitable for light to medium-duty vehicles, making it ideal for businesses focused on standard car maintenance. B2B buyers should consider the lift’s height and weight capacity to ensure it meets their operational needs. Additionally, the installation process is relatively simple, which can reduce setup costs.

How Do Four-Post Car Lifts Differ from Other Types?

Four-post car lifts provide greater stability and lifting capacity compared to their two-post counterparts. They are designed to accommodate larger vehicles, making them a preferred choice for dealerships and service centers. One of the key advantages is their ability to lift vehicles with minimal risk of tipping, which enhances safety during repairs. However, B2B buyers should be aware that these lifts require more space, which can be a limitation for smaller workshops. When considering a purchase, assess the available floor space and the types of vehicles typically serviced.

Why Choose Scissor Car Lifts for Versatility?

Scissor car lifts are known for their compact design, making them an excellent choice for businesses with limited space. They can be used in various applications, from tire shops to mobile mechanics. Their unique lifting mechanism allows them to lift vehicles from below, providing easy access for repairs. For B2B buyers, the versatility of scissor lifts can be a significant advantage. However, it’s essential to evaluate their weight capacity, as they may not be suitable for heavier vehicles.

What Are the Benefits of Portable Car Lifts?

Portable car lifts are designed for ease of transport, making them a valuable asset for mobile service providers and roadside assistance teams. Their lightweight construction allows for quick setup and takedown, which is ideal for businesses that operate in various locations. However, potential buyers should note that portable lifts typically have limited lifting height and capacity. When considering a purchase, evaluate the specific needs of your service operations to ensure compatibility with the vehicles you service.

When Should You Consider In-Ground Car Lifts?

In-ground car lifts are installed below the shop floor, providing a clean aesthetic and maximizing available space. They are particularly suitable for high-end workshops and services catering to luxury vehicles. While they offer durability and a professional appearance, B2B buyers should be prepared for higher installation costs and potential maintenance challenges. Assessing the long-term benefits versus the initial investment is crucial for businesses looking to enhance their service offerings with this type of lift.

Related Video: I Bought a Chinese Katools Car Scissor Lift and it’s a TOTAL DISASTER! Unboxing & Review Katools X80

Key Industrial Applications of car lift china

| Industry/Sector | Specific Application of car lift china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Vehicle maintenance and repair | Increases efficiency and safety in service operations | Compliance with international safety standards, warranty terms, and after-sales support. |

| Manufacturing | Assembly line operations | Enhances productivity by facilitating quick vehicle access | Customization options for load capacity and height, and availability of spare parts. |

| Logistics and Warehousing | Vehicle storage and retrieval systems | Optimizes space utilization and improves inventory management | Durability for heavy use, ease of operation, and compatibility with existing warehouse systems. |

| Car Dealerships | Showroom vehicle displays and servicing | Attracts customers with accessible vehicle showcases | Aesthetic design, ease of installation, and support for diverse vehicle sizes. |

| Public Transportation | Bus and coach maintenance facilities | Ensures safety and compliance with regulatory standards | Energy efficiency, maintenance support, and adaptability to various vehicle types. |

How is ‘Car Lift China’ Used in Automotive Repair?

In the automotive repair industry, car lifts from China are essential for vehicle maintenance and repair tasks. These lifts allow technicians to easily access the underside of vehicles, facilitating efficient servicing and reducing the risk of workplace injuries. International buyers should consider sourcing lifts that comply with local safety regulations and offer robust after-sales support, ensuring they can maintain operations without disruption. Additionally, understanding the warranty terms is crucial to protect investments.

What Role Does ‘Car Lift China’ Play in Manufacturing?

In manufacturing, particularly in automotive assembly lines, car lifts enhance productivity by providing quick access to vehicles during assembly or quality checks. This application helps streamline workflows and minimizes downtime. Buyers from regions such as Europe and South America should look for customization options that cater to specific load capacities and height requirements, as well as the availability of spare parts for maintenance. This ensures long-term operational efficiency and reliability.

How are ‘Car Lift China’ Solutions Utilized in Logistics and Warehousing?

In logistics and warehousing, car lifts are utilized for vehicle storage and retrieval, optimizing space usage and improving inventory management. By enabling vertical storage solutions, businesses can maximize their facility’s footprint and enhance operational efficiency. B2B buyers should prioritize sourcing durable lifts that can withstand heavy use, as well as those that are easy to operate. Compatibility with existing warehouse systems is another critical factor to consider for seamless integration.

Why are ‘Car Lift China’ Products Important for Car Dealerships?

Car dealerships leverage car lifts to display vehicles effectively in showrooms and facilitate servicing. This not only enhances customer experience but also increases the visibility of vehicles, potentially boosting sales. International buyers should focus on aesthetic design and ease of installation when sourcing these lifts. Additionally, ensuring that the lifts can accommodate a variety of vehicle sizes will enhance dealership operations and customer satisfaction.

How Do ‘Car Lift China’ Solutions Support Public Transportation?

In the public transportation sector, car lifts are vital for maintaining buses and coaches, ensuring safety and compliance with regulatory standards. Regular maintenance facilitated by these lifts can significantly extend the lifespan of vehicles, leading to cost savings over time. Buyers should look for energy-efficient models that require minimal maintenance and can adapt to various vehicle types. This ensures that public transportation fleets remain operational and compliant with local regulations.

Related Video: FANUC Industrial Robots | AUDI Case Study

3 Common User Pain Points for ‘car lift china’ & Their Solutions

Scenario 1: Navigating Quality Assurance for Car Lifts from China

The Problem: One of the most significant challenges faced by B2B buyers sourcing car lifts from China is ensuring product quality. Many buyers have reported receiving subpar equipment that does not meet safety standards, leading to costly repairs and potential liability issues. This risk is particularly pronounced for buyers in Africa and South America, where local regulations may not align with international standards, leaving businesses vulnerable to compliance failures and reputational damage.

The Solution: To mitigate quality assurance risks, buyers should conduct thorough due diligence when selecting suppliers. Start by verifying the manufacturer’s certifications, such as ISO 9001, which indicates adherence to quality management principles. Request samples of the car lifts for hands-on evaluation, and consider visiting the factory if feasible, or employing third-party inspection services. Furthermore, establish clear communication regarding your specifications and quality expectations in the contract. Implementing a robust quality control process, including pre-shipment inspections, can help ensure that the delivered products meet your requirements and industry standards.

Scenario 2: Understanding Import Regulations and Compliance Challenges

The Problem: International buyers often face complex import regulations when sourcing car lifts from China. These regulations can vary widely depending on the destination country, especially in Europe and the Middle East, where compliance with safety standards, customs duties, and import taxes can complicate the purchasing process. Failure to navigate these regulations can lead to delays, fines, or even confiscation of the goods.

The Solution: To avoid compliance challenges, B2B buyers should invest time in understanding the specific import regulations of their country. This includes researching safety standards for automotive equipment and consulting with local customs brokers who can provide expertise on duties and taxes. Additionally, buyers should work closely with their Chinese suppliers to ensure that all necessary documentation, such as certificates of origin and compliance declarations, are prepared in advance. Utilizing technology, such as supply chain management software, can also help track shipments and ensure compliance with regulatory requirements throughout the import process.

Scenario 3: Managing After-Sales Support and Spare Parts Availability

The Problem: After-sales support can be a significant pain point for businesses that purchase car lifts from China. Buyers often report difficulties in obtaining spare parts and technical support after the initial purchase, which can lead to extended downtimes and loss of revenue. This issue is particularly acute for businesses in regions with limited access to qualified service technicians or suppliers.

The Solution: To address after-sales support concerns, buyers should prioritize suppliers that offer comprehensive service packages, including warranties and readily available spare parts. When negotiating contracts, inquire about the supplier’s commitment to after-sales support and their policies on spare parts availability. It is also beneficial to establish a clear line of communication with the supplier for technical assistance. Consider partnering with local service providers who can offer support and maintenance services, ensuring that your business can quickly address any issues that arise with the car lifts. Building a relationship with your supplier can also facilitate better support in the long run, as they will be more invested in your satisfaction and success.

Strategic Material Selection Guide for car lift china

When selecting materials for car lifts manufactured in China, international B2B buyers must consider various factors that influence performance, durability, and compliance with regional standards. Here, we analyze four common materials used in car lift construction: steel, aluminum, composite materials, and galvanized steel. Each material presents unique properties, advantages, and challenges that can significantly impact the final product’s suitability for specific applications.

A stock image related to car lift china.

What are the Key Properties of Steel for Car Lifts?

Steel is one of the most widely used materials in car lift construction due to its high strength-to-weight ratio. It typically has excellent temperature and pressure ratings, making it suitable for heavy-duty applications. Steel also offers good corrosion resistance when treated properly, which is essential for lifts exposed to various environmental conditions.

Pros and Cons:

The primary advantage of steel is its durability and load-bearing capacity, which allows it to support heavier vehicles. However, it can be more expensive than other materials and may require additional coatings to enhance corrosion resistance. Manufacturing complexity can also increase due to the need for welding and fabrication.

Impact on Application:

Steel is compatible with a wide range of media, including hydraulic fluids, making it ideal for hydraulic lifts. Buyers should ensure that the steel used meets local compliance standards, such as ASTM or DIN, depending on the region.

How Does Aluminum Compare as a Material for Car Lifts?

Aluminum is another popular choice for car lifts, especially in applications where weight reduction is crucial. It has a lower density than steel, which makes it easier to handle and install. Aluminum also offers good corrosion resistance, particularly in humid environments.

Pros and Cons:

The key advantage of aluminum is its lightweight nature, which can lead to lower shipping costs and easier installation. However, aluminum typically has a lower load-bearing capacity compared to steel, which may limit its use in heavy-duty applications. Additionally, the cost of aluminum can be higher than that of steel, impacting overall project budgets.

Impact on Application:

Aluminum is compatible with various hydraulic fluids and is often used in portable car lifts. International buyers should consider the specific grade of aluminum used, as this can affect the lift’s performance and compliance with local standards.

What are the Benefits of Using Composite Materials in Car Lifts?

Composite materials, often made from a combination of plastics and fibers, are gaining traction in the car lift industry. They offer excellent strength-to-weight ratios and can be engineered for specific performance characteristics, such as resistance to chemicals and UV light.

Pros and Cons:

The primary advantage of composites is their versatility and resistance to corrosion, which can extend the lifespan of the lift. However, they may not be suitable for extremely heavy loads and can be more expensive to manufacture due to the complexity of the materials involved.

Impact on Application:

Composites are particularly useful in environments where traditional materials may corrode or degrade quickly. International buyers should ensure that the composites used comply with relevant safety and manufacturing standards.

Why is Galvanized Steel a Good Option for Car Lifts?

Galvanized steel is steel that has been coated with a layer of zinc to enhance its corrosion resistance. This makes it an excellent choice for car lifts that may be exposed to moisture or harsh environments.

Pros and Cons:

The key advantage of galvanized steel is its durability and resistance to rust, making it suitable for outdoor applications. However, it can be heavier than aluminum, which may impact installation. Additionally, the galvanizing process can add to manufacturing costs.

Impact on Application:

Galvanized steel is compatible with hydraulic systems and is often used in environments where moisture is a concern. Buyers should verify that the galvanization meets local standards for corrosion resistance.

Summary of Material Selection for Car Lifts

| Material | Typical Use Case for car lift china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty hydraulic lifts | High strength and durability | Higher cost and manufacturing complexity | Medium |

| Aluminum | Portable car lifts | Lightweight and easy to handle | Lower load capacity | High |

| Composite | Specialized applications | Corrosion resistance and versatility | Higher manufacturing costs | High |

| Galvanized Steel | Outdoor and moisture-prone areas | Excellent corrosion resistance | Heavier than aluminum | Medium |

By understanding the properties, advantages, and limitations of these materials, international B2B buyers can make informed decisions that align with their specific needs, ensuring compliance with local regulations and optimizing the performance of car lifts sourced from China.

In-depth Look: Manufacturing Processes and Quality Assurance for car lift china

What Are the Key Manufacturing Processes for Car Lifts in China?

The manufacturing of car lifts in China involves several critical stages, each designed to ensure the final product meets high standards of quality and performance. Understanding these stages can help international B2B buyers make informed decisions when selecting suppliers.

How Is Material Prepared in the Manufacturing of Car Lifts?

The first step in the manufacturing process is material preparation. High-strength steel is typically used for the structural components of car lifts due to its durability and load-bearing capacity. Manufacturers source raw materials from reputable suppliers to ensure consistency and quality. This stage includes cutting, bending, and shaping materials to precise specifications, which are crucial for the integrity of the final product.

What Forming Techniques Are Commonly Used in Car Lift Manufacturing?

Once materials are prepared, the forming process begins. This can involve various techniques, including:

- Hydraulic Pressing: Used for creating complex shapes and forms that require high precision.

- Welding: Essential for joining different components, ensuring that connections are robust and can withstand heavy loads.

- Stamping: Often used for creating flat components like platforms and bases.

These techniques not only enhance the structural integrity of car lifts but also contribute to their overall functionality.

How Is the Assembly Process Conducted for Car Lifts?

After forming, the assembly stage involves bringing together all manufactured parts. This is a critical phase where attention to detail is paramount. Assemblers use detailed schematics to ensure that each component is correctly placed and secured. Advanced technologies such as automated assembly lines may be employed to improve efficiency and consistency.

Additionally, manufacturers often implement modular designs, allowing for easier assembly and maintenance. This is especially beneficial for international buyers who may need to perform repairs or replacements in their respective markets.

What Finishing Processes Are Involved in Car Lift Manufacturing?

The final stage of the manufacturing process is finishing, which includes painting, coating, and surface treatment. These processes not only enhance the aesthetic appeal of the car lifts but also provide protective layers against rust and wear. Common techniques include:

- Powder Coating: Offers a durable finish that is resistant to chipping and fading.

- Galvanization: Involves coating steel with zinc to prevent corrosion, crucial for lifts operating in humid or coastal environments.

How Is Quality Assurance Implemented in Car Lift Manufacturing?

Quality assurance is a vital aspect of the manufacturing process, ensuring that car lifts meet both international standards and customer expectations.

What International Standards Should B2B Buyers Look For?

B2B buyers should familiarize themselves with relevant international standards such as ISO 9001, which focuses on quality management systems, and industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute). These certifications indicate that the manufacturer adheres to rigorous safety and quality protocols.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are established throughout the manufacturing process to maintain high standards. Key checkpoints include:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet required specifications.

- In-Process Quality Control (IPQC): Monitoring production processes to catch defects early.

- Final Quality Control (FQC): Conducting comprehensive tests on the finished product before shipment.

Each checkpoint serves as a safeguard against defects and ensures that only high-quality products reach the market.

What Common Testing Methods Are Used for Car Lifts?

Testing methods play a crucial role in validating the performance and safety of car lifts. Common methods include:

- Load Testing: Ensures the lift can handle specified weight capacities without failure.

- Safety Feature Testing: Verifies the functionality of emergency stops, safety locks, and other critical components.

- Durability Testing: Simulates long-term use to assess wear and tear.

These tests not only ensure compliance with regulations but also provide peace of mind to buyers regarding the reliability of their investments.

How Can B2B Buyers Verify Supplier Quality Control?

Verification of a supplier’s quality control measures is essential for B2B buyers, especially those operating in diverse regulatory environments. Here are actionable steps buyers can take:

- Conduct Audits: Schedule regular audits of the manufacturing facility to assess compliance with quality standards and practices.

- Request Quality Reports: Suppliers should provide documentation detailing their quality control processes and results from recent tests.

- Engage Third-Party Inspectors: Hiring independent inspectors can offer an unbiased assessment of the supplier’s quality assurance measures.

What Are the Nuances of QC and Certification for International Buyers?

For international buyers, understanding the nuances of quality control and certification is crucial. Different regions may have varying standards, and it’s important to ensure that the car lifts comply with local regulations in the buyer’s market. For instance, European buyers must be particularly attentive to CE certification, which ensures products meet EU safety, health, and environmental protection standards.

Furthermore, buyers from Africa and South America should be aware of local import regulations that may require additional certifications or tests to be conducted. This knowledge can help avoid costly delays and ensure compliance with local laws.

Conclusion

In summary, the manufacturing processes and quality assurance measures for car lifts in China are designed to meet high standards of performance and safety. By understanding these processes, international B2B buyers can make informed decisions, ensuring they select reliable suppliers that provide high-quality products. Engaging in thorough verification and understanding regional regulations will further enhance the purchasing experience, ultimately leading to successful business operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘car lift china’

In the dynamic landscape of international B2B procurement, sourcing car lifts from China requires a strategic approach to ensure quality, compliance, and cost-effectiveness. This practical checklist serves as a comprehensive guide for buyers, particularly those from Africa, South America, the Middle East, and Europe, to navigate the complexities of sourcing car lifts.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to articulate your specific technical requirements. Consider factors such as load capacity, lift height, and the type of vehicles the lift will accommodate. This clarity will guide your search for suppliers who can meet these precise needs and help avoid costly errors later in the procurement process.

Step 2: Conduct Market Research on Suppliers

Thorough market research is critical to identify potential suppliers in China. Utilize platforms such as Alibaba, Global Sources, or industry-specific directories to compile a list of manufacturers. Pay attention to supplier ratings, customer reviews, and their experience in exporting to your region, as these factors can indicate reliability and service quality.

Step 3: ✅ Verify Supplier Certifications

Supplier certifications, such as ISO 9001 or CE marking, are crucial indicators of quality management and product safety. Request copies of these certifications and verify them through the issuing bodies. Compliance with international standards not only ensures product quality but also mitigates risks associated with liability and safety regulations in your home country.

Step 4: Request Samples for Quality Assessment

Before finalizing an order, request product samples to evaluate quality firsthand. This step allows you to assess the craftsmanship, materials used, and overall functionality of the car lift. Conduct tests to ensure it meets your operational needs and standards. A sample can also help you identify any potential issues before placing a bulk order.

Step 5: Negotiate Terms and Pricing

Engage in negotiations to secure favorable terms, including pricing, payment methods, and delivery timelines. Be transparent about your budget and expectations. Understanding the typical pricing structure for car lifts in China will empower you to negotiate effectively and avoid overpaying.

Step 6: Review Shipping and Import Regulations

Familiarize yourself with the shipping and import regulations specific to your country. This includes understanding tariffs, customs duties, and compliance requirements for importing heavy machinery. Collaborating with a freight forwarder who specializes in your region can streamline this process and ensure compliance with all regulations.

Step 7: Establish a Communication Plan

Effective communication with your supplier is vital throughout the sourcing process. Set clear expectations regarding updates, timelines, and any potential issues that may arise. Regular check-ins can help maintain transparency and build a solid working relationship, which is essential for long-term collaboration.

By following this step-by-step checklist, B2B buyers can confidently navigate the complexities of sourcing car lifts from China, ensuring they select the right suppliers and products to meet their business needs.

Comprehensive Cost and Pricing Analysis for car lift china Sourcing

What Are the Key Cost Components in Sourcing Car Lifts from China?

When sourcing car lifts from China, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. Steel, for instance, is commonly used for structural components, while hydraulic systems may require specialized alloys. Buyers should consider the quality and sourcing of these materials to ensure durability and safety.

-

Labor: Labor costs in China are generally lower than in Europe or the Americas; however, skilled labor for assembly and quality control can command higher wages. It’s essential to factor in labor expenses, especially for complex models that require expertise.

-

Manufacturing Overhead: This includes utilities, rent, and other operational costs incurred during production. Understanding a supplier’s overhead can provide insight into their pricing strategy and overall efficiency.

-

Tooling: Custom tooling can be a significant upfront cost, particularly for bespoke designs. Buyers should evaluate the necessity of custom tooling versus off-the-shelf solutions to optimize costs.

-

Quality Control (QC): Investing in quality control is vital to ensure product safety and compliance with international standards. Incorporating QC costs into your pricing analysis can help mitigate risks associated with defective products.

-

Logistics: Shipping costs, including freight and insurance, can vary widely depending on the destination and shipping method. It’s important to consider both the direct costs and the time involved in logistics to calculate the total landed cost.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding industry standards for margins can help buyers negotiate better deals.

How Do Price Influencers Affect Car Lift Costs in International Markets?

Several factors influence the pricing of car lifts from China, particularly for buyers in Africa, South America, the Middle East, and Europe:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should assess their needs against MOQs to maximize cost-efficiency.

-

Specifications and Customization: Customized car lifts that meet specific requirements may incur additional costs. Buyers should balance their need for customization against budget constraints.

-

Material Quality and Certifications: Higher quality materials and certifications (such as ISO or CE) can increase costs but may provide long-term savings through durability and compliance with local regulations.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge a premium for their proven track record, while newer entrants may offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for determining who bears the cost and risk at different stages of shipping. This knowledge can help buyers avoid unexpected expenses.

What Tips Can Help Buyers Negotiate Better Prices for Car Lifts?

When negotiating prices for car lifts, international B2B buyers should consider the following strategies:

-

Research Market Prices: Conduct thorough market research to understand the price range for similar products. This knowledge will empower you during negotiations and help you identify fair pricing.

-

Leverage Total Cost of Ownership (TCO): Consider not just the purchase price but also the total cost of ownership, including maintenance, energy consumption, and lifespan. Presenting a TCO analysis can strengthen your negotiation position.

-

Establish Long-term Relationships: Building a strong relationship with suppliers can lead to better pricing and terms over time. Regular communication and trust can yield long-term benefits.

-

Be Open to Multiple Suppliers: Engaging with multiple suppliers can create competitive pressure, potentially lowering prices. However, ensure that all suppliers meet quality and safety standards.

-

Negotiate Payment Terms: Discussing favorable payment terms can reduce upfront costs and improve cash flow. Options like staggered payments or payment upon delivery can be beneficial.

Disclaimer on Indicative Prices

While this analysis provides a comprehensive overview of cost components and pricing influences for car lifts sourced from China, it is important to note that prices can vary significantly based on market conditions, supplier negotiations, and specific buyer requirements. Always seek updated quotes directly from suppliers to get the most accurate and relevant pricing information.

Alternatives Analysis: Comparing car lift china With Other Solutions

Understanding the Importance of Comparing Car Lift Solutions

When considering a car lift from China, it’s essential for international B2B buyers to evaluate various alternatives that may offer similar functionalities. By comparing different car lift solutions, businesses can make informed decisions that align with their operational needs, budget constraints, and market conditions. This section will analyze ‘Car Lift China’ against two viable alternatives: hydraulic car lifts and scissor car lifts.

Comparison Table of Car Lift Solutions

| Comparison Aspect | Car Lift China | Hydraulic Car Lifts | Scissor Car Lifts |

|---|---|---|---|

| Performance | High lifting capacity with various models | Excellent for heavy vehicles; consistent performance | Limited height but good for compact spaces |

| Cost | Generally lower priced due to manufacturing scale | Moderate to high, depending on model and capacity | Cost-effective for smaller operations |

| Ease of Implementation | Usually straightforward installation | Requires professional installation | Easy installation, often portable |

| Maintenance | Low maintenance needs but parts may be harder to source | Moderate maintenance; parts readily available | Low maintenance; fewer moving parts |

| Best Use Case | Suitable for high-volume workshops | Ideal for commercial garages and heavy-duty applications | Best for small workshops or home garages |

In-Depth Analysis of Alternatives

What Are the Benefits and Drawbacks of Hydraulic Car Lifts?

Hydraulic car lifts are recognized for their robust lifting capabilities, particularly for heavy vehicles. They provide a stable and safe lifting experience, making them a preferred choice for commercial garages and heavy-duty applications. However, the initial investment can be higher compared to ‘Car Lift China’, and professional installation is often required, adding to overall costs. Maintenance is moderate, but with readily available parts, repairs can be managed efficiently.

How Do Scissor Car Lifts Compare in Terms of Cost and Space Efficiency?

Scissor car lifts are known for their compact design and cost-effectiveness, making them ideal for small workshops or home garages. They require less floor space and can often be portable, which adds flexibility to their use. However, their lifting height is generally limited, which may not suit all vehicle types. They also have fewer moving parts, leading to low maintenance needs, but their performance may not match that of hydraulic lifts for heavier vehicles.

Conclusion: How to Choose the Right Car Lift Solution for Your Business

When selecting the right car lift solution, B2B buyers must consider their specific operational requirements, budget, and the types of vehicles they typically service. If your business deals with heavier vehicles frequently, investing in hydraulic car lifts might be more beneficial despite the higher costs. Conversely, for smaller operations or those with space constraints, scissor lifts could provide the necessary functionality at a lower price point. Ultimately, understanding the unique advantages and limitations of each alternative will empower businesses to make a decision that maximizes efficiency and cost-effectiveness.

Essential Technical Properties and Trade Terminology for car lift china

What Are the Essential Technical Properties of Car Lifts from China?

When sourcing car lifts from China, international B2B buyers should be aware of several critical technical specifications that directly affect performance, safety, and longevity. Here are some of the essential properties to consider:

1. Load Capacity

The load capacity of a car lift is a fundamental specification that determines how much weight the lift can safely handle. Common capacities range from 2 tons to over 5 tons. For B2B buyers, understanding this property is crucial to ensure the lift meets the demands of their operations, especially when dealing with heavier vehicles. Choosing a lift with insufficient load capacity can lead to equipment failure and safety hazards.

2. Material Grade

The material grade used in the construction of a car lift affects its durability and performance. High-grade steel, for instance, is often used for its strength and resistance to corrosion. For buyers, specifying the material grade is essential to ensure that the lift can withstand the rigors of daily use, particularly in environments with varying climates, which can be a consideration for buyers in Africa and the Middle East.

3. Lifting Height

The lifting height refers to the maximum elevation the car lift can achieve. This specification is particularly relevant for buyers who deal with larger vehicles or require access to the undercarriage for servicing. Typical lifting heights range from 1.5 to 2.5 meters. Buyers should assess their operational requirements to ensure they select a lift that provides adequate clearance for their applications.

4. Power Supply

Car lifts can operate on different power supply configurations, such as 220V or 380V. Understanding the power supply is vital for ensuring compatibility with existing electrical systems. International buyers should verify the local voltage requirements and consider the implications of power supply on installation and operation costs.

5. Safety Features

Safety features such as automatic locking mechanisms, emergency stop buttons, and overload protection are critical for safe operations. Buyers should prioritize lifts that adhere to international safety standards, as this not only protects personnel but also minimizes liability risks.

What Trade Terminology Should B2B Buyers Know When Sourcing Car Lifts?

Familiarity with industry jargon and trade terminology can streamline the procurement process for B2B buyers. Here are some essential terms to understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the context of car lifts, sourcing from an OEM can ensure that buyers receive high-quality, compatible components that meet industry standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is crucial for budgeting and inventory management. Buyers should negotiate MOQs that align with their operational needs while considering cost-effectiveness.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. For buyers, issuing an RFQ is a key step in the sourcing process, as it allows for comparisons across different suppliers and helps in making informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with terms like FOB (Free On Board) and CIF (Cost, Insurance, and Freight) can help buyers understand shipping costs and risk management.

5. Lead Time

Lead time refers to the time it takes from placing an order to the delivery of the product. Understanding lead times is essential for inventory planning and ensuring that operations run smoothly without delays.

Conclusion

A stock image related to car lift china.

For B2B buyers sourcing car lifts from China, understanding the essential technical properties and trade terminology is crucial for making informed decisions. By focusing on specifications such as load capacity, material grade, and safety features, along with mastering key terms like OEM, MOQ, and Incoterms, buyers can navigate the complexities of international procurement effectively. This knowledge not only enhances operational efficiency but also contributes to long-term business success.

Navigating Market Dynamics and Sourcing Trends in the car lift china Sector

What Are the Current Market Dynamics and Key Trends in the Car Lift Sector in China?

The car lift market in China is experiencing robust growth, driven by several global and regional factors. The increasing demand for automotive services, particularly in emerging markets like Africa and South America, is pushing for more efficient and advanced car maintenance solutions. Moreover, the rapid expansion of the automotive industry in China itself is making it a significant player in the global car lift market.

International B2B buyers should note the growing trend toward digitalization, with many manufacturers adopting advanced technologies such as IoT and AI for smart lifts. These innovations not only enhance operational efficiency but also improve safety standards. Furthermore, the integration of e-commerce platforms for sourcing car lifts is revolutionizing how buyers interact with suppliers, providing more transparency and competitive pricing.

As sustainability becomes a focal point for businesses worldwide, car lift manufacturers are also adapting by incorporating eco-friendly materials and energy-efficient designs. This shift is particularly relevant for buyers from Europe and the Middle East, where stringent environmental regulations are in place. Understanding these dynamics can help international buyers make informed decisions when sourcing car lifts from China.

How Can Sustainability and Ethical Sourcing Impact Your B2B Decisions in the Car Lift Sector?

Sustainability is no longer just a buzzword; it’s a crucial factor for international B2B buyers in the car lift market. The environmental impact of manufacturing processes and materials used in car lifts is significant, and buyers need to be aware of this when making procurement decisions. Companies that prioritize sustainability are not only reducing their carbon footprint but also appealing to a growing segment of environmentally conscious consumers.

Ethical sourcing plays a pivotal role in this context. Buyers should seek suppliers that adhere to ethical labor practices and provide transparency in their supply chains. Certifications such as ISO 14001 for environmental management and other ‘green’ certifications can serve as indicators of a supplier’s commitment to sustainable practices.

Incorporating eco-friendly materials, such as recycled steel or low-emission coatings, can also influence the overall lifecycle of car lifts, making them a more sustainable choice. For international buyers, especially those operating in regions with strict environmental regulations like Europe, aligning with suppliers who prioritize sustainability can mitigate risks and enhance brand reputation.

What is the Historical Context of the Car Lift Industry in China and Its Relevance for B2B Buyers?

The car lift industry in China has evolved significantly over the past few decades. Initially, the market was characterized by basic hydraulic systems, primarily catering to domestic demand. However, as China’s automotive sector expanded, so did the sophistication of car lift technology.

By the early 2000s, China emerged as a manufacturing hub for car lifts, leading to a surge in exports to international markets. The introduction of advanced technologies such as electro-hydraulic systems and digital controls has further transformed the industry, allowing for more efficient and safer operations.

For B2B buyers, understanding this evolution is crucial. It highlights the rapid advancements in technology and the competitive landscape of suppliers in China. Buyers can leverage this historical context to assess current offerings and identify suppliers that are not only innovative but also capable of meeting international quality and safety standards.

Frequently Asked Questions (FAQs) for B2B Buyers of car lift china

-

How do I ensure the quality of car lifts sourced from China?

To ensure the quality of car lifts, it’s essential to conduct thorough due diligence on potential suppliers. Request samples or visit factories if possible, and check for certifications such as ISO or CE that indicate compliance with international standards. Additionally, consider engaging third-party inspection services to verify product quality before shipment. Establishing a clear communication channel with suppliers can also help in addressing any concerns and ensuring that specifications are met. -

What are the most important factors when choosing a car lift supplier in China?

When selecting a car lift supplier, consider their experience in the industry, production capacity, and reputation. Look for suppliers with positive reviews and a history of reliable deliveries. Evaluate their ability to customize products to meet your specific needs and inquire about their after-sales service and support. It’s also wise to assess their compliance with safety standards and regulations relevant to your market. -

What is the typical minimum order quantity (MOQ) for car lifts from Chinese suppliers?

The MOQ for car lifts can vary significantly among suppliers, typically ranging from 1 to 50 units, depending on the type of lift and the manufacturer. Smaller suppliers may offer lower MOQs, while larger manufacturers might require higher orders to justify production costs. When negotiating, it’s crucial to communicate your purchasing capacity and explore flexible options, especially if you’re looking to test the market before committing to larger orders. -

What payment terms should I expect when buying car lifts from China?

Payment terms can vary by supplier but commonly include options like a 30% deposit with the balance due before shipment or a letter of credit. It’s essential to negotiate terms that protect your interests while ensuring the supplier is comfortable with the arrangement. Familiarize yourself with payment methods such as bank transfers, PayPal, or escrow services, which can offer varying levels of security. Always clarify any additional costs like taxes or duties that may apply upon import. -

How can I customize car lifts to fit my business needs?

Most Chinese manufacturers are open to customization, but you must clearly communicate your requirements. Discuss specific dimensions, weight capacities, and any additional features you need. Providing detailed specifications or examples of similar products can facilitate the process. Keep in mind that customization may impact lead times and pricing, so it’s essential to plan accordingly and factor this into your overall project timeline. -

What logistics considerations should I keep in mind when importing car lifts from China?

Logistics is crucial when importing car lifts. Consider shipping methods, such as sea freight for bulk orders or air freight for smaller, urgent shipments. Ensure you understand incoterms (e.g., FOB, CIF) that dictate shipping responsibilities. Working with a reliable freight forwarder can help navigate customs clearance and reduce delays. Additionally, factor in lead times for production and shipping to ensure timely delivery for your business operations. -

How do I handle warranty and service issues with car lifts purchased from China?

Before finalizing your purchase, clarify warranty terms with your supplier, including coverage duration and conditions. A reputable supplier should offer a warranty that covers manufacturing defects. Ensure you have a clear understanding of the process for claiming warranty repairs or replacements. Establishing a good relationship with the supplier can facilitate smoother communication in case service issues arise, so maintain ongoing contact and document all agreements. -

What should I do if I encounter issues with my car lift shipment?

If you encounter issues with your shipment, such as delays or damage, immediately contact your supplier to address the problem. Document any issues with photographs and detailed descriptions to support your case. If necessary, engage your freight forwarder for assistance in resolving shipping-related problems. It’s also wise to familiarize yourself with dispute resolution processes, whether through negotiation, mediation, or legal channels, to protect your investment effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for car lift china

As international B2B buyers navigate the dynamic landscape of car lift sourcing from China, the importance of strategic sourcing cannot be overstated. By understanding market trends, evaluating supplier capabilities, and assessing logistical considerations, businesses can significantly reduce costs while enhancing operational efficiency. Key takeaways include the necessity of thorough supplier vetting, leveraging technology for seamless transactions, and fostering long-term partnerships that transcend geographical boundaries.

What should B2B buyers prioritize when sourcing car lifts from China? It is crucial to focus on quality assurance measures, compliance with international standards, and transparent communication with suppliers. This proactive approach not only mitigates risks but also builds trust, ensuring that buyers receive the best value for their investment.

Looking ahead, the car lift market in China is poised for growth, driven by advancements in technology and increasing demand across emerging markets. International buyers, particularly from Africa, South America, the Middle East, and Europe, should seize this opportunity to capitalize on competitive pricing and innovative solutions. Engage with trusted suppliers now to secure a competitive edge in your market. Your strategic sourcing decisions today will pave the way for sustainable growth tomorrow.