Cut Costs with Shearing Machine China: The Ultimate Guide (2025)

Introduction: Navigating the Global Market for shearing machine china

Navigating the global market for shearing machines from China presents a unique set of challenges for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. With the rise of manufacturing and construction industries in these regions, sourcing reliable shearing machines has become crucial. However, buyers often face difficulties in identifying trustworthy suppliers, understanding the variety of machine types available, and evaluating the total cost of ownership.

This comprehensive guide delves into the various types of shearing machines, their applications in different industries, and essential criteria for supplier vetting. We will also explore the pricing structures, shipping considerations, and post-purchase support options that can significantly impact your procurement decisions. By providing actionable insights and practical tips, this guide empowers international B2B buyers to make informed purchasing decisions that align with their operational needs and budget constraints.

As you navigate through this guide, you will gain a deeper understanding of the market landscape, helping you to identify potential suppliers that meet your quality and compliance standards. Whether you are looking to enhance your manufacturing capabilities or streamline your operations, this resource is designed to equip you with the knowledge necessary to confidently source shearing machines from China.

Understanding shearing machine china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hydraulic Shearing Machine | High cutting force, adjustable blade gap | Metal fabrication, automotive parts production | Pros: Powerful cutting, precise adjustments. Cons: Higher cost, requires maintenance. |

| Mechanical Shearing Machine | Simple design, lower operational cost | Sheet metal cutting, construction projects | Pros: Cost-effective, easy to operate. Cons: Limited cutting capacity, less precision. |

| CNC Shearing Machine | Automated control, high precision | Aerospace, high-volume production | Pros: High accuracy, programmable settings. Cons: Higher initial investment, complex setup. |

| Pneumatic Shearing Machine | Compressed air operation, portable | Small workshops, light fabrication | Pros: Lightweight, easy to move. Cons: Limited power, not suitable for heavy-duty tasks. |

| Guillotine Shearing Machine | Straight cuts, robust design | Large-scale manufacturing, recycling | Pros: Efficient for large sheets, durable. Cons: Requires significant floor space, safety concerns. |

What Are the Characteristics of Hydraulic Shearing Machines?

Hydraulic shearing machines are renowned for their high cutting force and flexibility. They can handle various materials and thicknesses, making them ideal for metal fabrication and automotive parts production. Buyers should consider the machine’s capacity, blade quality, and hydraulic system efficiency. While they provide precise cutting and adjustable blade gaps, maintenance and initial costs can be higher than other types.

How Do Mechanical Shearing Machines Differ from Others?

Mechanical shearing machines feature a simpler design that is often more affordable and easier to operate. They are commonly used in sheet metal cutting and construction projects. However, they have limitations in cutting capacity and precision compared to hydraulic or CNC models. B2B buyers should weigh the lower operational costs against the potential need for more frequent manual adjustments.

What Advantages Do CNC Shearing Machines Offer for High-Volume Production?

CNC (Computer Numerical Control) shearing machines are distinguished by their automated control systems, allowing for high precision and repeatability in production. They are particularly suitable for industries such as aerospace and high-volume manufacturing, where accuracy is paramount. While they require a higher initial investment and more complex setup, the long-term benefits of reduced labor costs and enhanced productivity make them a favorable choice for serious buyers.

Why Choose Pneumatic Shearing Machines for Small Workshops?

Pneumatic shearing machines operate using compressed air, making them lightweight and portable, which is perfect for small workshops or light fabrication tasks. While they are easy to maneuver and operate, they lack the power necessary for heavy-duty applications. Buyers should consider their specific needs and whether the portability outweighs the limitations in cutting power.

What Are the Key Features of Guillotine Shearing Machines?

Guillotine shearing machines are designed for making straight cuts and are known for their robustness. They are widely used in large-scale manufacturing and recycling operations due to their efficiency in handling large sheets of material. However, they require significant floor space and may pose safety concerns if not operated correctly. B2B buyers should evaluate their workspace and safety measures when considering this option.

Related Video: SHEARING PROCESS | SHEARING MECHANISM | SHEAR FORCE | SHEAR STRENGTH | SHEET METAL OPERATION

Key Industrial Applications of shearing machine china

| Industry/Sector | Specific Application of shearing machine china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Metal Fabrication | Cutting sheet metal for construction | Increases production efficiency and reduces material waste | Consider machine capacity, blade quality, and after-sales support. |

| Automotive Manufacturing | Shearing automotive body panels | Enhances precision in part manufacturing, ensuring fit and finish | Evaluate the machine’s speed, accuracy, and compatibility with materials. |

| Shipbuilding | Shearing steel plates for hull construction | Improves safety and structural integrity of vessels | Focus on durability, corrosion resistance, and supplier reliability. |

| HVAC Industry | Cutting ductwork and fittings | Streamlines production and installation processes | Assess machine versatility, ease of operation, and maintenance services. |

| Aerospace Manufacturing | Shearing lightweight composite materials | Reduces weight, enhancing fuel efficiency and performance | Ensure compliance with industry standards and material specifications. |

How is ‘Shearing Machine China’ Used in Metal Fabrication?

In the metal fabrication industry, shearing machines from China are essential for cutting sheet metal to precise dimensions required for construction projects. These machines tackle challenges such as material wastage and inconsistent cutting quality. International buyers must consider the machine’s capacity to handle various metal thicknesses, the quality of the blades, and the availability of after-sales support when sourcing equipment to ensure optimal performance and longevity.

What Role Does Shearing Machine China Play in Automotive Manufacturing?

In automotive manufacturing, shearing machines are used to cut body panels with high precision, which is crucial for the assembly of vehicles. This application addresses the problem of ensuring that parts fit together seamlessly, thereby enhancing the overall quality of the finished product. Buyers, especially from regions like Africa and Europe, should prioritize machines that offer high speed and accuracy, as well as compatibility with different materials, to maintain a competitive edge in the market.

How is Shearing Machine China Beneficial for Shipbuilding?

In shipbuilding, shearing machines are utilized to cut large steel plates that form the hulls of vessels. This application is vital for ensuring the structural integrity and safety of ships. Buyers should focus on sourcing machines that exhibit durability and corrosion resistance, given the harsh marine environment. Additionally, reliability in the supply chain and the availability of spare parts are critical factors for businesses operating in this sector.

What Applications Does Shearing Machine China Have in the HVAC Industry?

Within the HVAC industry, shearing machines are employed to cut ductwork and fittings, which streamlines the production and installation processes. This application helps address the need for efficiency and precision in creating air distribution systems. International buyers should evaluate the versatility of the machines, ease of operation, and the quality of customer support provided by suppliers to ensure a seamless integration into their production lines.

How Does Shearing Machine China Impact Aerospace Manufacturing?

In aerospace manufacturing, shearing machines are critical for cutting lightweight composite materials used in aircraft construction. This application is essential for reducing weight, thereby enhancing fuel efficiency and overall aircraft performance. When sourcing these machines, buyers must ensure compliance with strict industry standards and specifications regarding materials to maintain safety and performance in aviation applications.

3 Common User Pain Points for ‘shearing machine china’ & Their Solutions

Scenario 1: Quality Assurance Challenges in Shearing Machines from China

The Problem: One of the most significant pain points for B2B buyers of shearing machines from China is the inconsistency in quality. Buyers often receive machinery that does not meet the specified standards, leading to operational inefficiencies and increased maintenance costs. This issue is particularly prevalent when sourcing from multiple suppliers or when dealing with manufacturers that do not adhere to international quality certifications. The consequences can be severe, ranging from production delays to financial losses, and can damage the buyer’s reputation in their respective market.

The Solution: To mitigate quality assurance challenges, buyers should prioritize suppliers with verifiable quality certifications, such as ISO 9001. Conducting thorough due diligence on potential suppliers is crucial. This includes reviewing their production processes, quality control measures, and past customer feedback. Additionally, consider engaging third-party inspection services to evaluate the machinery before shipment. This proactive approach ensures that the shearing machines meet the required specifications and reduces the risk of quality-related issues. Establishing clear communication with the supplier regarding expectations and standards can also prevent misunderstandings and ensure a smoother purchasing process.

Scenario 2: Navigating Complex Import Regulations for Shearing Machines

The Problem: International buyers, especially those from regions like Africa and South America, often face a maze of import regulations when purchasing shearing machines from China. Navigating tariffs, customs duties, and compliance with local regulations can be overwhelming and can lead to unexpected costs or delays in delivery. For example, a buyer might assume a smooth shipping process, only to encounter a hold-up at customs, resulting in operational downtime and financial strain.

The Solution: To effectively navigate these complexities, buyers should invest time in understanding the import regulations specific to their country. Engaging a customs broker with experience in machinery imports can significantly streamline the process. This expert can assist with paperwork, advise on tariffs, and ensure compliance with both local and international regulations. Moreover, it is advisable to maintain open lines of communication with the supplier regarding shipping methods and timelines. Buyers should also consider using Incoterms (International Commercial Terms) to clearly define responsibilities concerning shipping, insurance, and tariffs, which can help prevent misunderstandings and ensure smooth delivery.

Scenario 3: Technical Support and After-Sales Service Gaps

The Problem: After-purchase support is a critical concern for B2B buyers of shearing machines, especially when sourcing from overseas suppliers. Many buyers report difficulties in obtaining timely technical support or spare parts, which can halt production and lead to significant financial losses. This issue is particularly pronounced when the shearing machine requires specialized knowledge for maintenance or troubleshooting, and the supplier is not readily accessible or responsive.

The Solution: To address these after-sales service gaps, buyers should prioritize suppliers who offer robust support services, including comprehensive warranties, readily available spare parts, and dedicated customer service teams. Before finalizing a purchase, inquire about the supplier’s after-sales support structure, response times, and availability of local representatives. Additionally, consider forming partnerships with local service providers who can assist with maintenance and repairs. This hybrid approach ensures that buyers have access to both manufacturer support and local expertise, reducing downtime and enhancing operational efficiency. Lastly, establishing a clear communication channel with the supplier for ongoing support can foster a more reliable partnership, ensuring that buyers feel supported long after the purchase is complete.

Strategic Material Selection Guide for shearing machine china

What Are the Key Materials Used in Shearing Machines from China?

When selecting materials for shearing machines, international B2B buyers must consider various factors including durability, cost, and application suitability. Here, we analyze four common materials used in shearing machines, focusing on their properties, advantages, disadvantages, and considerations for buyers from Africa, South America, the Middle East, and Europe.

How Does Steel Perform in Shearing Machines?

Key Properties: Steel is renowned for its high tensile strength and durability. It can withstand high temperatures and pressures, making it suitable for heavy-duty applications. Corrosion-resistant steel variants, such as stainless steel, offer additional protection against oxidation.

Pros & Cons: Steel’s primary advantage is its strength and longevity, which translates to lower maintenance costs over time. However, it can be more expensive than other materials, particularly when opting for high-grade or specialized types. Manufacturing complexity is moderate, depending on the steel grade.

Impact on Application: Steel is compatible with a wide range of media, including metals and plastics, making it versatile for various shearing tasks.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM A36 for structural steel or ASTM A240 for stainless steel. It’s essential to consider local availability and the cost implications of importing high-grade steel.

What Role Does Aluminum Play in Shearing Machines?

Key Properties: Aluminum is lightweight yet strong, with excellent corrosion resistance. It performs well under moderate temperatures and is less prone to rust compared to steel.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which can enhance machine efficiency and reduce operational costs. However, it is generally less durable than steel and may not withstand extreme conditions, leading to potential wear issues over time.

Impact on Application: Aluminum is suitable for applications where weight reduction is critical, such as portable shearing machines. However, it may not be ideal for heavy-duty operations involving thick materials.

Considerations for International Buyers: Buyers should be aware of the specific aluminum grades (e.g., 6061 or 7075) and their corresponding standards (like ASTM B221). The cost of aluminum can vary significantly based on global market conditions.

Why Is Cast Iron a Popular Choice for Shearing Machines?

Key Properties: Cast iron is known for its excellent wear resistance and ability to absorb vibrations, which can enhance machine stability during operation. It is also capable of withstanding high temperatures.

Pros & Cons: The durability of cast iron makes it a cost-effective option for heavy-duty applications. However, it is brittle and can crack under excessive stress, which limits its use in certain scenarios. Manufacturing processes can also be complex and time-consuming.

Impact on Application: Cast iron is particularly effective in applications requiring stability and precision, such as in industrial shearing machines.

Considerations for International Buyers: Compliance with standards such as ASTM A48 is crucial. Buyers should also consider the logistics of sourcing cast iron, as it may be heavier and more expensive to transport.

How Does Plastic Composite Material Fit into Shearing Machines?

Key Properties: Plastic composites are lightweight, corrosion-resistant, and can be engineered for specific applications. They perform well in a range of temperatures and are often used in non-metallic applications.

Pros & Cons: The primary advantage of plastic composites is their resistance to corrosion and chemicals, making them suitable for specific environments. However, they may not offer the same level of durability as metals and can be more expensive to produce.

Impact on Application: Plastic composites are ideal for applications where weight and corrosion resistance are critical, such as in marine environments or for shearing softer materials.

Considerations for International Buyers: Buyers should ensure that the chosen composite material meets relevant standards and specifications, such as ASTM D638 for tensile properties. The cost of composites can be higher, but their longevity in corrosive environments can justify the investment.

Summary Table of Material Selection for Shearing Machines

| Material | Typical Use Case for shearing machine china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty industrial shearing applications | High strength and durability | Higher cost for specialized grades | High |

| Aluminum | Portable shearing machines | Lightweight and corrosion-resistant | Less durable than steel | Medium |

| Cast Iron | Industrial shearing machines | Excellent wear resistance | Brittle and can crack under stress | Medium |

| Plastic Composite | Non-metallic applications | Corrosion resistance | Less durable than metals | High |

This guide serves as a strategic overview for international B2B buyers looking to make informed decisions about material selection for shearing machines sourced from China. Understanding the properties and implications of each material will facilitate better purchasing decisions tailored to specific operational needs.

In-depth Look: Manufacturing Processes and Quality Assurance for shearing machine china

What Are the Key Manufacturing Processes for Shearing Machines in China?

Understanding the manufacturing processes of shearing machines in China is crucial for international B2B buyers. The production of these machines typically involves several main stages: material preparation, forming, assembly, and finishing.

-

Material Preparation

The manufacturing process begins with selecting high-quality raw materials, predominantly steel, which is essential for durability and performance. Suppliers often source materials that comply with international standards, ensuring they can withstand operational stresses. Pre-processing steps may include cutting, cleaning, and inspecting materials for defects. -

Forming Techniques

After preparation, the next phase is forming, which is critical for creating the machine’s structure. Common techniques include:

– Laser Cutting: Offers precision and efficiency, ideal for complex shapes.

– Bending and Pressing: Utilizes hydraulic or mechanical presses to shape metal sheets accurately.

– Welding: Ensures strength and integrity in joints, often using MIG or TIG welding methods. -

Assembly Process

Following forming, the assembly stage integrates various components, such as blades, frames, and hydraulic systems. This process may involve:

– Sub-Assembly: Individual components are first assembled into sub-units, which are then combined into the final product.

– Alignment and Calibration: Ensuring all parts are correctly aligned is vital for operational efficiency and safety. -

Finishing Techniques

The final stage involves finishing processes like painting, coating, or galvanizing to protect against corrosion and enhance aesthetics. Quality control checks are performed at this stage to ensure the machine meets specifications.

How Is Quality Assurance Implemented in Shearing Machine Manufacturing?

Quality assurance (QA) is integral to manufacturing shearing machines, with various international standards and checkpoints established to maintain product integrity.

-

International Standards for Quality Control

Manufacturers in China often adhere to ISO 9001, a standard that ensures effective quality management systems. Compliance with additional certifications such as CE (Conformité Européenne) for European markets or API (American Petroleum Institute) for specific industrial applications may also be required, depending on the end-use of the machines. -

Quality Control Checkpoints

Quality control typically involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): Inspecting raw materials upon delivery to ensure they meet required specifications.

– In-Process Quality Control (IPQC): Monitoring production stages to catch defects early. This can include measuring dimensions and testing weld strength.

– Final Quality Control (FQC): Conducting comprehensive tests on finished products, including functionality tests, load tests, and safety inspections. -

Common Testing Methods

Various testing methods are employed to ensure product reliability:

– Non-Destructive Testing (NDT): Techniques such as ultrasonic testing, magnetic particle testing, and dye penetrant testing help identify internal and surface defects without damaging the product.

– Performance Testing: Simulating operational conditions to ensure that the shearing machine performs as expected under load.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for ensuring product reliability. Here are some actionable steps:

-

Conduct Supplier Audits

Before placing orders, buyers should conduct audits of potential suppliers. This includes visiting manufacturing facilities, reviewing their quality control processes, and assessing compliance with international standards. -

Request Quality Assurance Reports

Suppliers should provide detailed quality assurance reports, including results from IQC, IPQC, and FQC. These documents should outline testing methods used, results obtained, and any corrective actions taken for non-conformities. -

Engage Third-Party Inspection Services

Utilizing third-party inspection agencies can provide unbiased verification of quality control processes. These agencies can conduct inspections at various stages of production and deliver detailed reports that help buyers make informed decisions. -

Understand Certification Nuances

Buyers should familiarize themselves with the nuances of quality certifications relevant to their markets. For example, CE certification is essential for products sold in Europe, while API certification is critical for equipment used in the oil and gas industry.

Why Is Continuous Improvement Important in Shearing Machine Manufacturing?

Continuous improvement is a vital component of the manufacturing process for shearing machines. Manufacturers often implement methodologies such as Lean Manufacturing and Six Sigma to enhance efficiency and reduce waste. This commitment to ongoing improvement not only boosts productivity but also leads to higher quality products, ultimately benefiting B2B buyers through increased reliability and performance.

In conclusion, understanding the manufacturing processes and quality assurance measures for shearing machines in China equips international B2B buyers with the knowledge needed to make informed purchasing decisions. By focusing on the key stages of production, quality control standards, and verification practices, buyers can ensure they select reliable suppliers that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘shearing machine china’

Introduction

Sourcing a shearing machine from China can be a strategic decision for international B2B buyers looking to enhance their manufacturing capabilities. This checklist provides actionable insights to streamline your procurement process, ensuring you select a supplier that meets your technical needs and business standards.

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is essential before initiating contact with suppliers. This includes determining the machine’s size, cutting capacity, and any specialized features you require. Having precise specifications helps suppliers provide accurate quotes and ensures that you receive a machine that meets your operational demands.

Step 2: Conduct Market Research on Suppliers

Research the landscape of manufacturers specializing in shearing machines in China. Use platforms such as Alibaba, Made-in-China, and Global Sources to identify potential suppliers. Look for reviews, ratings, and trade history to gauge the reliability and reputation of each manufacturer.

Step 3: Verify Supplier Certifications

Before entering negotiations, ensure that your potential suppliers have the necessary certifications. Important certifications may include ISO 9001 for quality management systems or CE marking for compliance with European safety standards. This step is crucial as it guarantees that the machines meet international quality and safety regulations.

Step 4: Request and Evaluate Quotations

Once you have identified suitable suppliers, request detailed quotations that outline pricing, payment terms, and lead times. Compare these quotes not only on price but also on the value offered, such as warranty terms and after-sales support. This comprehensive evaluation will help you make a more informed decision.

Step 5: Assess Supplier Communication and Responsiveness

Effective communication is vital in any B2B relationship. Assess how promptly and thoroughly suppliers respond to your inquiries. A responsive supplier is likely to provide better customer service throughout the procurement process, including addressing any issues that may arise post-purchase.

Step 6: Plan for Quality Control Inspections

Before finalizing your order, establish a plan for quality control inspections either through third-party services or by conducting on-site inspections. This ensures that the machine meets your specifications before shipment. Consider arranging for a pre-shipment inspection to mitigate risks associated with receiving substandard equipment.

Step 7: Understand Shipping and Customs Regulations

Finally, familiarize yourself with shipping logistics and customs regulations related to importing machinery from China to your region. Ensure that you understand the associated costs, such as tariffs and taxes, which can significantly affect your total procurement budget. Proper planning in this area will help avoid unexpected delays and expenses.

By following this comprehensive checklist, B2B buyers can navigate the complexities of sourcing shearing machines from China with greater confidence and success.

Comprehensive Cost and Pricing Analysis for shearing machine china Sourcing

In the world of B2B sourcing, particularly for shearing machines from China, understanding the comprehensive cost structure and pricing analysis is essential for making informed purchasing decisions. This section delves into the key components that contribute to pricing, factors influencing costs, and actionable tips for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Sourcing Shearing Machines from China?

When analyzing the cost structure of shearing machines, several components come into play:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality steel, for instance, may be more expensive but can enhance the durability and efficiency of the shearing machine.

-

Labor: Labor costs in China have been relatively low, but they can vary based on the region and skill level required. Skilled labor may lead to higher initial costs but can yield better craftsmanship.

-

Manufacturing Overhead: This includes costs related to factory maintenance, utilities, and equipment depreciation. Efficient factories often have lower overhead costs, which can translate into lower prices for buyers.

-

Tooling: The cost of specialized tools and dies needed for manufacturing shearing machines can be significant, especially for customized specifications. Buyers should inquire about tooling costs early in the negotiation process.

-

Quality Control (QC): Ensuring that products meet international quality standards involves additional QC costs. Implementing rigorous QC processes can save money in the long run by reducing the likelihood of defects.

-

Logistics: Shipping costs, tariffs, and handling fees can add up quickly. It’s crucial to factor in logistics, especially for international shipments, as these can significantly affect the total cost.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. Understanding the average margins in the industry can provide leverage during negotiations.

What Influences the Pricing of Shearing Machines from China?

Several factors influence the pricing of shearing machines, including:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to discounts. Buyers should assess their needs to negotiate better pricing based on volume.

-

Specifications and Customization: Customized machines that meet specific operational requirements may incur higher costs. Buyers should clearly define their specifications to avoid unexpected costs.

-

Materials and Quality Certifications: Machines made from higher-grade materials or those that come with quality certifications (like ISO) may command higher prices. Buyers should weigh the benefits of quality against cost.

-

Supplier Factors: The reputation, experience, and reliability of the supplier can affect pricing. Established suppliers may charge more but can offer better service and quality assurance.

-

Incoterms: Understanding the terms of shipping and delivery (like FOB, CIF, etc.) is vital, as they can affect the total cost and risk involved in the transaction.

How Can International B2B Buyers Negotiate Better Prices for Shearing Machines?

International buyers can employ several strategies to negotiate effectively:

-

Understand Total Cost of Ownership (TCO): Instead of focusing solely on purchase price, consider the TCO, which includes maintenance, operational costs, and potential downtime. This holistic view can justify a higher upfront investment for better quality machines.

-

Leverage Competitive Quotes: Gathering multiple quotes from different suppliers can provide leverage in negotiations. It allows buyers to compare not only prices but also service levels and quality.

-

Build Long-Term Relationships: Establishing a solid relationship with suppliers can lead to better terms and pricing in the future. Consider long-term partnerships rather than one-off transactions.

-

Clarify Payment Terms: Flexible payment terms can enhance cash flow and reduce the financial burden. Discussing options like staggered payments or early payment discounts may yield savings.

What Are the Pricing Nuances for Buyers from Africa, South America, the Middle East, and Europe?

International buyers need to be aware of regional nuances that can affect pricing. For example, shipping times and costs can vary widely depending on the destination. Additionally, tariffs and import duties in different regions can influence the final price. Buyers should also consider currency fluctuations that may impact costs over time.

Disclaimer on Indicative Prices

Prices for shearing machines can vary significantly based on the aforementioned factors, and the figures provided in this analysis are indicative. It’s advisable for buyers to conduct thorough market research and obtain detailed quotations tailored to their specific requirements.

Alternatives Analysis: Comparing shearing machine china With Other Solutions

When considering the acquisition of a shearing machine, international B2B buyers must evaluate various alternatives that can provide similar functionalities. Understanding the different options available is crucial for making informed purchasing decisions that align with operational needs and budget constraints. This analysis will compare the ‘Shearing Machine China’ with two viable alternatives: Hydraulic Shearing Machines and Plasma Cutting Machines.

| Comparison Aspect | Shearing Machine China | Hydraulic Shearing Machine | Plasma Cutting Machine |

|---|---|---|---|

| Performance | High speed, precision cutting | Moderate speed, high accuracy | Very high speed, versatile cutting |

| Cost | Generally lower initial investment | Higher initial cost, but lower operational costs | High initial investment, variable operational costs |

| Ease of Implementation | Simple setup, requires basic training | Moderate setup complexity, needs skilled operation | Complex setup, requires specialized training |

| Maintenance | Low maintenance needs | Moderate maintenance required | High maintenance due to consumable parts |

| Best Use Case | Sheet metal cutting in bulk | Thick materials and large sheets | Intricate designs and various materials |

What Are the Advantages and Disadvantages of Hydraulic Shearing Machines?

Hydraulic Shearing Machines are a popular alternative to shearing machines from China. They offer moderate speed and high accuracy, making them suitable for cutting thicker materials and larger sheets. The initial investment is typically higher than that of Chinese shearing machines, but they tend to have lower operational costs due to their energy efficiency. However, the complexity of setup and the requirement for skilled operators can be a drawback for some businesses, particularly smaller operations that may not have access to trained personnel.

How Do Plasma Cutting Machines Compare to Shearing Machines from China?

Plasma Cutting Machines provide an advanced alternative with very high cutting speeds and versatility across different materials. They excel in intricate designs and can cut through various thicknesses, making them ideal for detailed projects. However, they come with a high initial investment and ongoing operational costs can vary significantly based on the materials and the type of work being done. The setup process is more complex, and specialized training is essential, which may limit their adoption among businesses with less technical expertise.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right shearing solution involves analyzing your specific operational requirements, budget, and the technical expertise available within your organization. For businesses focused on high-volume production with lower initial costs, the ‘Shearing Machine China’ may be the best option. Conversely, companies dealing with thicker materials or requiring high precision may benefit more from Hydraulic Shearing Machines, while those needing to perform intricate cuts on various materials might find Plasma Cutting Machines to be the most suitable. Ultimately, understanding the pros and cons of each option will empower B2B buyers to make decisions that align with their strategic objectives.

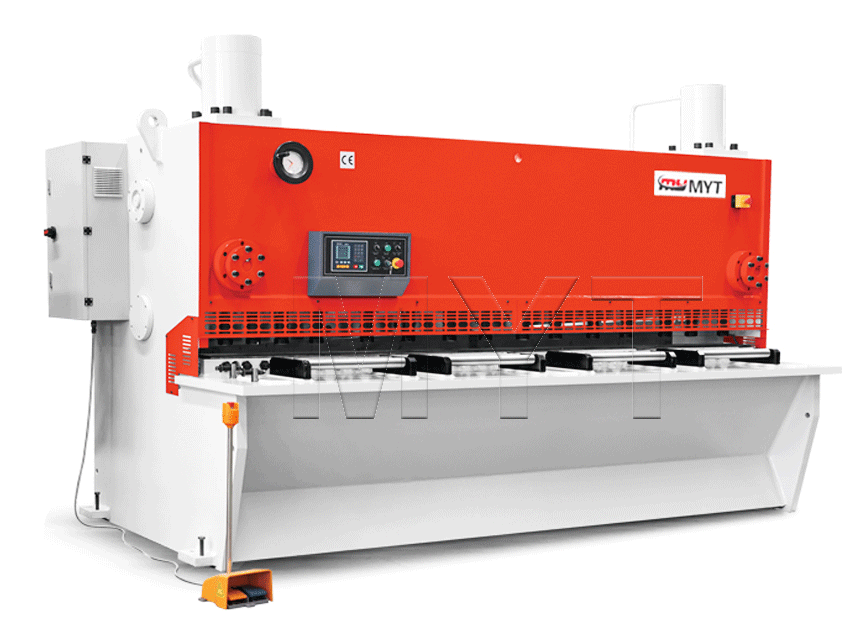

A stock image related to shearing machine china.

Essential Technical Properties and Trade Terminology for shearing machine china

What Are the Essential Technical Properties of Shearing Machines from China?

When sourcing shearing machines from China, understanding the essential technical properties is crucial for making informed purchasing decisions. Here are some key specifications that international B2B buyers should prioritize:

-

Material Grade

– The material grade of the shearing machine components, such as blades and frames, significantly impacts durability and performance. Common materials include high-carbon steel and alloy steel, which provide excellent hardness and wear resistance. Selecting the appropriate material ensures the machine can withstand heavy use, reducing downtime and maintenance costs. -

Cutting Capacity

– This specification refers to the maximum thickness and type of material the shearing machine can cut. It is typically measured in millimeters or inches and varies based on the machine design. Understanding the cutting capacity is essential for buyers to ensure the machine meets their production requirements and can handle the materials they intend to process. -

Tolerance Levels

– Tolerance levels indicate the precision of the cuts made by the shearing machine. A tighter tolerance means less deviation from the desired dimensions, which is crucial in industries where precision is paramount, such as automotive and aerospace. Buyers should inquire about the tolerance specifications to ensure the shearing machine can meet their quality standards. -

Speed and Efficiency

– The operational speed of a shearing machine affects productivity. Measured in strokes per minute, a higher speed can lead to increased output. However, it is essential to balance speed with the quality of the cut to avoid compromising material integrity. Understanding the machine’s speed capabilities helps buyers assess its suitability for their production line. -

Power Consumption

– Power consumption indicates the energy efficiency of the shearing machine. Machines designed with energy-saving technologies can significantly reduce operational costs over time. For international buyers, especially from regions where energy costs are high, selecting a machine with optimal power consumption can lead to substantial savings.

What Trade Terminology Should B2B Buyers Know When Purchasing Shearing Machines?

Familiarity with common trade terms is vital for effective communication and negotiation in the B2B environment. Here are several key terms relevant to purchasing shearing machines:

-

OEM (Original Equipment Manufacturer)

– An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial, as it affects the quality and reliability of the shearing machines. Buyers should verify whether the manufacturer is an OEM or a distributor to ensure they are receiving genuine products. -

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is essential for buyers, especially smaller businesses, as it impacts initial investment and inventory management. Knowing the MOQ helps buyers plan their purchases and manage cash flow effectively. -

RFQ (Request for Quotation)

– An RFQ is a document issued by a buyer to solicit price quotes from suppliers. It typically includes specifications, quantities, and delivery requirements. Crafting a comprehensive RFQ is critical for obtaining accurate pricing and terms from multiple suppliers, enabling better comparison and negotiation. -

Incoterms (International Commercial Terms)

– Incoterms are a set of international rules that define the responsibilities of sellers and buyers in international transactions. Understanding these terms, such as FOB (Free On Board) and CIF (Cost, Insurance, and Freight), is crucial for determining shipping costs, risk management, and delivery responsibilities. -

Lead Time

– Lead time refers to the duration from placing an order to receiving the goods. For B2B buyers, understanding lead times is essential for planning production schedules and managing customer expectations. Longer lead times can impact cash flow and inventory levels, making it a critical factor in purchasing decisions.

By grasping these technical properties and trade terms, international B2B buyers can navigate the complexities of sourcing shearing machines from China more effectively, ensuring they make informed decisions that align with their operational needs.

Navigating Market Dynamics and Sourcing Trends in the shearing machine china Sector

What Are the Current Market Dynamics and Key Trends in the Shearing Machine Sector from China?

The global shearing machine market is undergoing significant transformation driven by technological advancements and evolving buyer preferences. One of the key trends is the increased adoption of automation and smart technologies in manufacturing processes. This trend is particularly prominent among international B2B buyers from regions like Africa, South America, the Middle East, and Europe, where the demand for efficient and precise cutting solutions is on the rise. Automation not only enhances productivity but also reduces labor costs, making it an attractive option for businesses looking to scale operations.

Additionally, the shift towards Industry 4.0 is influencing sourcing strategies. Buyers are increasingly interested in suppliers that integrate IoT (Internet of Things) capabilities into their shearing machines, allowing for real-time monitoring and predictive maintenance. This capability can minimize downtime and improve operational efficiency, which is vital for businesses aiming to remain competitive in their respective markets.

Another important dynamic is the growing emphasis on customization. International buyers are looking for suppliers who can provide tailored solutions that meet specific industry requirements. This trend is particularly noticeable in sectors such as automotive and aerospace, where precision is crucial. Suppliers who can offer flexible manufacturing processes and rapid prototyping will likely gain a competitive edge.

Lastly, geopolitical factors and trade regulations are shaping sourcing decisions. International buyers need to navigate tariffs and trade agreements that could impact the cost and availability of shearing machines. Establishing strong relationships with suppliers and understanding local market conditions can help mitigate these risks.

How Are Sustainability and Ethical Sourcing Influencing B2B in the Shearing Machine Sector?

Sustainability is becoming a critical factor in the decision-making process for B2B buyers in the shearing machine sector. The environmental impact of manufacturing processes is under scrutiny, prompting companies to seek out suppliers who prioritize eco-friendly practices. Buyers are increasingly asking for transparency regarding the materials used in production and the overall carbon footprint of the manufacturing process.

Ethical sourcing is also gaining traction as consumers demand more accountability from businesses. Suppliers that adhere to stringent ethical standards, such as fair labor practices and responsible sourcing of raw materials, are more likely to attract international buyers. Certifications like ISO 14001 (Environmental Management) and ISO 9001 (Quality Management) are becoming essential for suppliers aiming to demonstrate their commitment to sustainability and quality.

Moreover, there is a growing trend towards the use of recycled materials in the production of shearing machines. Buyers are encouraged to inquire about the availability of ‘green’ certifications for materials, as this can significantly enhance their brand image and appeal to environmentally-conscious consumers. By prioritizing sustainability and ethical sourcing, international B2B buyers not only contribute to environmental preservation but also position themselves as responsible market players.

What Is the Brief Evolution of the Shearing Machine Sector?

The shearing machine sector has evolved significantly over the past few decades, transitioning from manual, labor-intensive processes to highly automated and sophisticated solutions. Early models were primarily mechanical, relying on manual operation and basic hydraulic systems. As technology advanced, the introduction of CNC (Computer Numerical Control) systems revolutionized the industry, allowing for greater precision and efficiency in cutting operations.

In recent years, the focus has shifted towards integrating advanced technologies such as AI and IoT, enabling predictive analytics and real-time data monitoring. This evolution reflects the broader trends in manufacturing, where automation and smart technologies are reshaping operational paradigms. For international B2B buyers, understanding this evolution is crucial for making informed purchasing decisions that align with modern manufacturing demands.

Frequently Asked Questions (FAQs) for B2B Buyers of shearing machine china

-

How do I select the right shearing machine for my business needs?

Choosing the right shearing machine involves assessing your specific requirements, including the materials you’ll be cutting, the thickness of those materials, and the desired production volume. Consider machines with adjustable shear angles for versatility and those that offer programmable controls for automation. Additionally, evaluate the machine’s durability and maintenance needs. Consulting with suppliers in China can help clarify which models align best with your operational goals. -

What are the typical payment terms when sourcing shearing machines from China?

Payment terms can vary widely among suppliers, but common practices include a 30% deposit upon order confirmation and the remaining 70% before shipment. Some suppliers may offer more flexible terms based on your business relationship. It’s crucial to negotiate terms that protect your interests, such as using a letter of credit or escrow service, especially for significant investments. -

What is the minimum order quantity (MOQ) for shearing machines from Chinese manufacturers?

The MOQ for shearing machines typically ranges from one unit to several, depending on the manufacturer. Larger manufacturers may have higher MOQs due to production costs, while smaller or specialized manufacturers may accommodate lower MOQs. If you’re starting small, inquire about the possibility of negotiating MOQs or collaborating with other buyers to meet minimum requirements. -

How do I ensure the quality of shearing machines sourced from China?

To ensure quality, begin by conducting thorough research on potential suppliers. Look for certifications such as ISO 9001 and check for reviews or testimonials from previous customers. Request samples or visit the factory if possible. Additionally, consider hiring a third-party inspection service to evaluate the machine before shipment, ensuring it meets your specifications and quality standards. -

What customization options are available for shearing machines from Chinese suppliers?

Many Chinese manufacturers offer customization options based on specific operational needs. This may include modifications to machine size, cutting capacity, or additional features such as automatic feeding systems. Clearly outline your requirements during initial discussions and request detailed specifications to ensure the customization aligns with your production processes. -

How can I navigate logistics when importing shearing machines from China?

Navigating logistics involves selecting a reliable freight forwarder familiar with international shipping regulations. Discuss shipping methods (air vs. sea) based on cost and urgency. Ensure you understand customs requirements in your country to avoid delays. It’s also beneficial to ask suppliers about their experience with logistics and whether they provide assistance in coordinating shipments. -

What should I know about warranty and after-sales support for shearing machines?

Warranties for shearing machines typically range from one to three years, covering manufacturing defects. Inquire about the specifics of the warranty, including what it includes and how claims are processed. After-sales support is also crucial; ensure the supplier offers technical assistance, spare parts availability, and maintenance services to minimize downtime in your operations. -

How do I vet suppliers when sourcing shearing machines from China?

Vetting suppliers is essential for ensuring reliability and quality. Start by checking their business licenses and certifications, and verify their manufacturing capabilities. Use platforms like Alibaba or Global Sources to read reviews and ratings. Consider conducting video calls to assess their facilities and quality control processes. Establishing a relationship through smaller orders can also help gauge their responsiveness and service quality before making larger investments.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for shearing machine china

In conclusion, strategic sourcing of shearing machines from China presents a multitude of benefits for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. By leveraging China’s robust manufacturing capabilities and competitive pricing, businesses can enhance their operational efficiency and reduce costs. It is essential for buyers to conduct thorough market research, assess supplier reliability, and prioritize quality assurance to maximize their investment.

What Are the Key Benefits of Strategic Sourcing for Shearing Machines?

The strategic sourcing process allows buyers to build long-term relationships with manufacturers, ensuring consistent product quality and timely delivery. Additionally, engaging in direct communication with suppliers can lead to customized solutions that cater to specific business needs, fostering innovation and competitiveness.

How Can International Buyers Prepare for Future Opportunities?

Looking ahead, B2B buyers should stay informed about emerging trends in manufacturing technology and sustainability practices within the shearing machine industry. By doing so, they can position themselves to take advantage of new opportunities that arise as the market evolves.

We encourage international buyers to take the next step in their sourcing journey by exploring partnerships with reputable Chinese manufacturers. Embrace the potential for growth and efficiency that strategic sourcing offers, ensuring your business stays ahead in a competitive landscape.