Cut Costs with the Best Ceramic Tile Supplier Guide (2025)

Introduction: Navigating the Global Market for ceramic tile supplier

Navigating the global market for ceramic tile suppliers can be a daunting task for B2B buyers, especially when sourcing high-quality products that meet diverse regional needs. With the growing demand for aesthetically pleasing and durable flooring solutions across Africa, South America, the Middle East, and Europe, understanding the complexities of the ceramic tile supply chain is crucial. This guide serves as a comprehensive resource, covering various types of ceramic tiles, their applications in both residential and commercial spaces, and essential supplier vetting strategies.

International buyers face unique challenges, such as varying quality standards, shipping logistics, and pricing disparities. This guide empowers B2B purchasers by providing actionable insights into cost considerations, market trends, and effective negotiation tactics. By understanding these elements, buyers can make informed decisions that align with their business objectives and customer preferences.

From discerning the best suppliers to evaluating product specifications, this guide equips you with the knowledge needed to navigate the intricate landscape of ceramic tile sourcing. With a focus on delivering value, we aim to enhance your purchasing strategy, ensuring you select the right ceramic tile suppliers to meet your specific needs, whether you’re in bustling cities like Paris or emerging markets in Nairobi. Explore the insights within and unlock the potential of your ceramic tile purchasing process.

Understanding ceramic tile supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manufacturer | Produces tiles in-house, often offers customization. | Large-scale construction, commercial projects. | Pros: Direct pricing, custom designs. Cons: Minimum order quantities may apply. |

| Wholesaler | Buys in bulk from manufacturers, resells to retailers or contractors. | Retail and distribution networks. | Pros: Competitive pricing, wide selection. Cons: Less control over product quality. |

| Distributor | Acts as an intermediary between manufacturers and retailers, often adds value through logistics. | Regional supply chains, retail stores. | Pros: Reliable delivery, broad market access. Cons: Pricing may include markup. |

| Import/Export Supplier | Specializes in international trade of ceramic tiles, often from specific regions. | Export markets, niche product segments. | Pros: Unique tile options, access to international styles. Cons: Longer lead times, potential tariffs. |

| Online Retailer | E-commerce platforms offering a variety of tiles with user-friendly interfaces. | Small to medium-sized projects, DIY markets. | Pros: Convenience, extensive product range. Cons: Shipping costs, limited personal interaction. |

What Are the Characteristics of Ceramic Tile Manufacturers?

Ceramic tile manufacturers are often the source of high-quality tiles, producing them in-house. They typically have the capability to customize designs, colors, and sizes according to client specifications. This is particularly beneficial for large-scale construction projects that require a specific aesthetic or functional attribute. When considering a manufacturer, B2B buyers should evaluate production capacity, lead times, and the ability to meet custom orders.

How Do Wholesalers Function in the Ceramic Tile Market?

Wholesalers play a crucial role in the ceramic tile supply chain by purchasing large quantities directly from manufacturers and distributing them to retailers or contractors. They usually offer a wide selection of products at competitive prices, making them an attractive option for businesses looking to stock various tile types. However, buyers should be aware that while wholesalers provide cost benefits, they may have less control over the quality of the tiles compared to purchasing directly from manufacturers.

What Are the Advantages of Working with Distributors?

Distributors serve as intermediaries between manufacturers and retailers, often providing added value through logistics and supply chain management. They can offer a reliable delivery service and a broad market access, which is essential for businesses that need to maintain inventory across multiple locations. Buyers should consider the distributor’s reputation, delivery timelines, and the range of products offered, as these factors can significantly impact their operations.

Why Choose Import/Export Suppliers for Unique Tiles?

Import/export suppliers specialize in the international trade of ceramic tiles, often bringing unique styles and designs from specific regions. This can be particularly advantageous for businesses looking to differentiate their offerings in a competitive market. However, buyers should factor in longer lead times and potential tariffs when sourcing from these suppliers. It’s essential to conduct thorough due diligence on the supplier‘s reliability and the quality of their products.

How Do Online Retailers Impact the Ceramic Tile Buying Process?

Online retailers have transformed the ceramic tile purchasing experience by offering a vast array of products through user-friendly e-commerce platforms. They cater to small to medium-sized projects and DIY enthusiasts, providing convenience and accessibility. While the extensive product range is a significant advantage, buyers should be cautious of shipping costs and the potential lack of personal interaction, which can be critical for large purchases. Evaluating customer service and return policies is essential when choosing an online retailer.

Related Video: Basics of Ceramic Glazing: Types & Techniques

Key Industrial Applications of ceramic tile supplier

| Industry/Sector | Specific Application of ceramic tile supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Renovation | Wall and floor coverings in residential and commercial buildings | Enhances aesthetic appeal and durability of spaces | Compliance with local building codes and regulations; availability of diverse styles and sizes; sustainable sourcing options. |

| Hospitality | Flooring and wall tiles in hotels and restaurants | Provides a stylish, easy-to-maintain environment | Resistance to moisture and stains; design compatibility with branding; bulk purchasing options for cost savings. |

| Healthcare | Flooring in hospitals and clinics | Ensures hygiene and easy cleaning | Non-slip surfaces; antimicrobial properties; compliance with health regulations. |

| Retail | Display areas and flooring in shops | Attracts customers and enhances shopping experience | Custom designs to fit brand identity; durability for high foot traffic; timely delivery for project deadlines. |

| Education | Flooring in schools and universities | Supports a conducive learning environment | Safety features such as slip resistance; availability in various colors and patterns; ease of maintenance. |

How is Ceramic Tile Used in Construction and Renovation Projects?

In the construction and renovation sectors, ceramic tiles serve as versatile wall and floor coverings. They are favored for their aesthetic appeal and robust durability, making them suitable for both residential and commercial spaces. Buyers from regions such as Africa and South America should consider local building codes, as well as the variety of styles and sizes available, to ensure compliance and meet design preferences. Sustainable sourcing options are also crucial for businesses aiming to enhance their environmental responsibility.

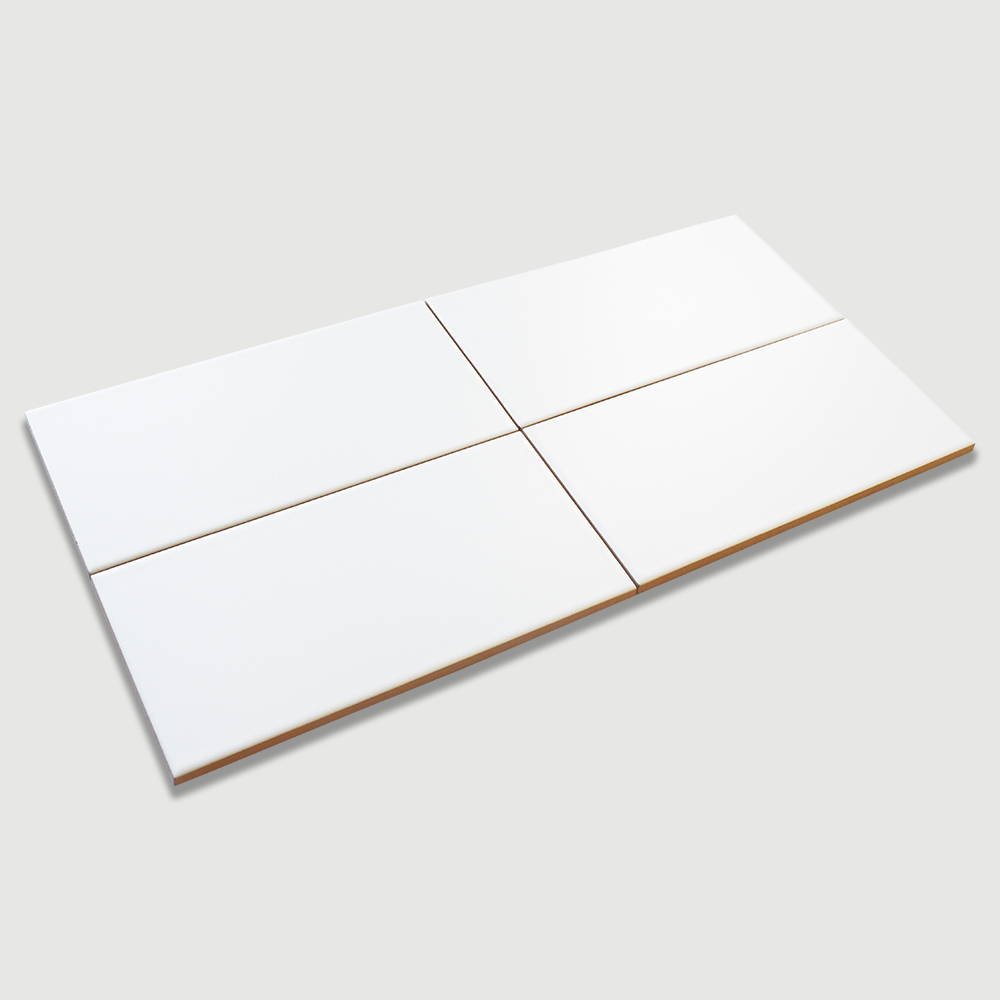

A stock image related to ceramic tile supplier.

What Role Does Ceramic Tile Play in the Hospitality Industry?

Ceramic tiles are extensively used in hotels and restaurants, providing stylish flooring and wall coverings that are also easy to maintain. They offer a polished look that can enhance the overall ambiance of dining and lodging experiences. For international buyers, especially in the Middle East and Europe, key considerations include selecting tiles that resist moisture and stains, aligning with the establishment’s branding, and exploring bulk purchasing options to optimize costs.

Why is Ceramic Tile Important in Healthcare Facilities?

In healthcare settings, ceramic tiles are essential for flooring in hospitals and clinics due to their hygiene and easy cleaning properties. The non-porous surface prevents the accumulation of dirt and bacteria, supporting stringent health standards. Buyers in this sector must prioritize tiles with slip-resistant surfaces and antimicrobial properties to ensure safety and compliance with health regulations, particularly in regions with varying standards, like Africa and South America.

How Can Retailers Benefit from Using Ceramic Tiles?

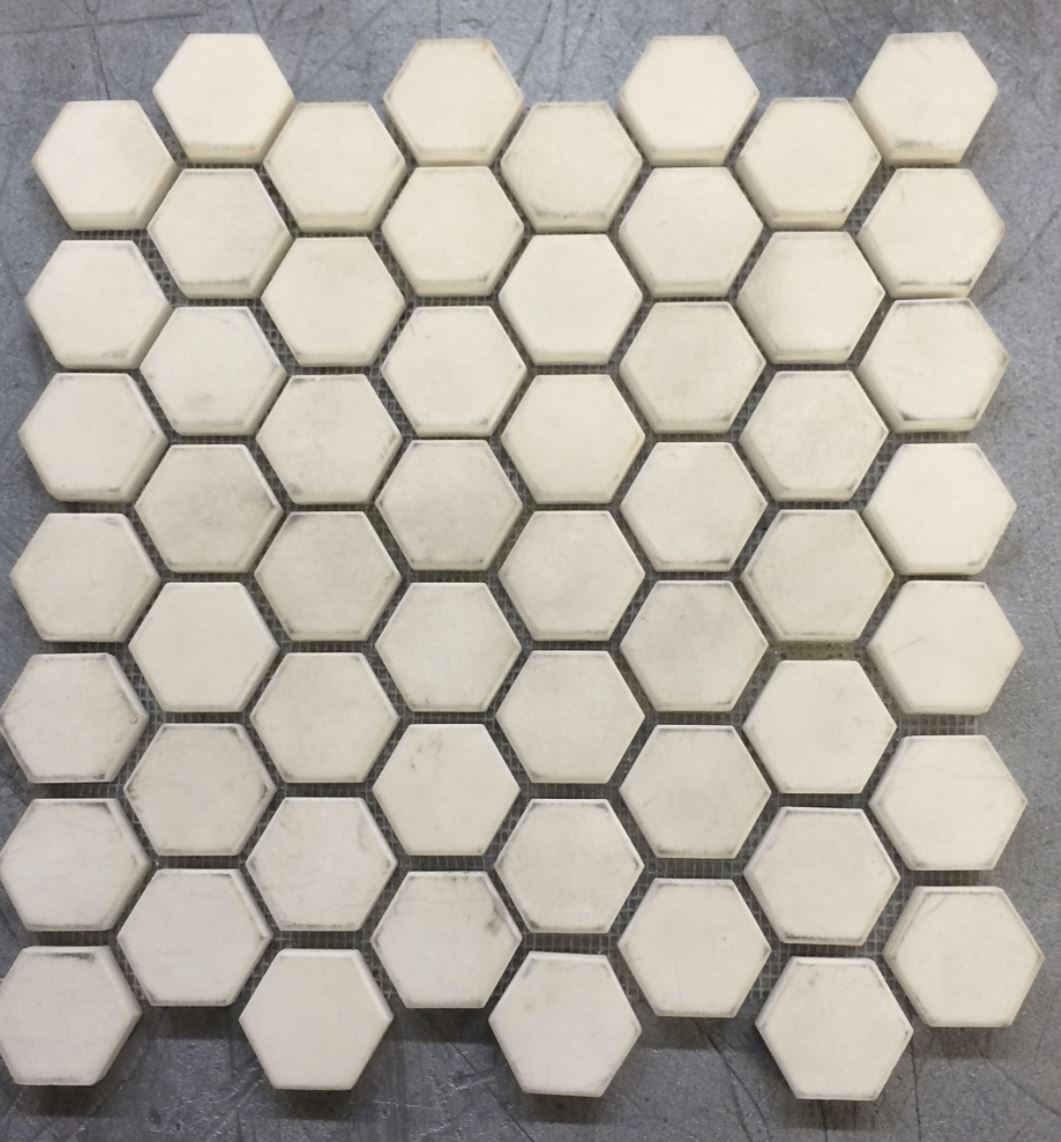

A stock image related to ceramic tile supplier.

Retailers utilize ceramic tiles for their display areas and flooring, as they can significantly enhance the shopping experience by attracting customers. The durability of ceramic tiles is particularly advantageous in high foot traffic areas, reducing maintenance costs over time. Retail buyers should focus on custom designs that fit their brand identity, ensuring timely delivery to meet project deadlines, especially when operating in diverse markets such as Europe and the Middle East.

What Advantages Do Ceramic Tiles Offer in Educational Institutions?

In educational settings, ceramic tiles are employed for flooring in schools and universities, contributing to a conducive learning environment. Their safety features, such as slip resistance, are critical in minimizing accidents. Buyers should look for tiles available in various colors and patterns to create engaging and stimulating spaces, while also considering ease of maintenance to ensure long-term usability in regions with varying climate conditions.

Related Video: Roff New Construction Tile Adhesive (NCA) for ceramic tiles and new floor tiles

3 Common User Pain Points for ‘ceramic tile supplier’ & Their Solutions

Scenario 1: Navigating Quality Assurance in Ceramic Tile Supply

The Problem:

B2B buyers often face the daunting task of ensuring the quality of ceramic tiles before making large orders. Inconsistent quality can lead to issues such as durability failures, aesthetic mismatches, and installation complications. This is particularly challenging for international buyers from regions like Africa and South America, where local regulations and standards may differ significantly from those in Europe or the Middle East. The fear of receiving subpar products can lead to delays in projects, increased costs, and damaged reputations.

The Solution:

To overcome quality assurance challenges, buyers should establish a rigorous vetting process for suppliers. Start by requesting samples of ceramic tiles to evaluate their quality firsthand. This should include checking for variations in color, finish, and texture. Additionally, consider leveraging third-party inspection services that can assess the tiles before shipment. Engaging suppliers with established certifications (like ISO standards) can also provide reassurance. Finally, building strong relationships with suppliers through regular communication can lead to better transparency about product quality and production processes.

Scenario 2: Managing Lead Times and Delivery Logistics

The Problem:

International B2B buyers often struggle with long lead times and unpredictable delivery schedules when ordering ceramic tiles. Factors such as customs regulations, shipping delays, and supplier production timelines can create headaches for project managers who rely on timely deliveries to keep construction schedules on track. This can be particularly critical in regions like the Middle East, where project timelines are often tight and delays can lead to significant financial penalties.

The Solution:

To manage lead times effectively, buyers should engage in proactive planning and communication with suppliers. Clearly outline project timelines and delivery expectations during initial negotiations. It’s beneficial to create a detailed logistics plan that includes potential bottlenecks and alternative solutions. Consider partnering with suppliers who offer transparent tracking systems for shipments, allowing buyers to monitor their orders in real-time. Building contingency plans, such as sourcing from multiple suppliers or keeping an emergency stock of tiles, can also mitigate risks associated with delays.

Scenario 3: Understanding Compliance and Regulatory Requirements

The Problem:

B2B buyers often encounter confusion regarding the compliance and regulatory requirements for ceramic tiles in their respective markets. Different countries have varying standards for safety, environmental impact, and performance, which can complicate procurement processes. For buyers in Europe or Africa, navigating these regulations can be particularly challenging, leading to potential legal issues, fines, or project delays if products do not meet local standards.

The Solution:

To address compliance issues, buyers should conduct thorough research on the regulatory landscape of their target market. Collaborating with legal experts or consultants familiar with local laws can provide invaluable insights. Additionally, buyers should seek suppliers who have experience exporting to their region and can provide documentation proving compliance with local regulations. This may include certificates for safety standards or eco-labels for sustainability. Establishing a checklist of required documentation before placing an order can streamline the procurement process and reduce the risk of non-compliance.

Strategic Material Selection Guide for ceramic tile supplier

What Are the Key Properties of Common Ceramic Tile Materials?

When selecting materials for ceramic tiles, international B2B buyers must consider various factors that affect performance, durability, and compliance with regional standards. Here, we analyze four common materials used in ceramic tile manufacturing: porcelain, stoneware, terracotta, and earthenware.

How Does Porcelain Compare in Ceramic Tile Applications?

Key Properties: Porcelain tiles are known for their high density and low porosity, making them resistant to water absorption. They can withstand high temperatures and pressures, which is essential for both residential and commercial applications.

Pros & Cons: The durability of porcelain is one of its greatest advantages, as it can endure heavy foot traffic and resist scratches and stains. However, the manufacturing process is complex, resulting in higher costs compared to other materials. Porcelain tiles are suitable for a variety of applications, including flooring and wall coverings, but their weight may require additional structural support.

Impact on Application: Porcelain tiles are particularly compatible with environments that experience moisture, such as bathrooms and kitchens. They also comply with international standards like ASTM C373 for water absorption, making them a reliable choice for buyers in regions with high humidity.

What Are the Benefits of Using Stoneware in Ceramic Tiles?

Key Properties: Stoneware tiles are fired at high temperatures, resulting in a strong and durable product. They exhibit excellent thermal shock resistance and can handle significant temperature fluctuations.

Pros & Cons: The primary advantage of stoneware is its ability to resist chipping and cracking, making it ideal for high-traffic areas. However, it can be more expensive than other materials due to its manufacturing complexity. Additionally, stoneware tiles may require sealing to prevent staining, which can add to maintenance costs.

Impact on Application: Buyers in regions like the Middle East, where temperature variations can be extreme, will find stoneware tiles particularly beneficial. Compliance with standards such as DIN EN 14411 ensures that stoneware tiles meet performance requirements for various applications.

Why Choose Terracotta for Ceramic Tile Projects?

Key Properties: Terracotta tiles are made from natural clay and are characterized by their porous nature. They are typically fired at lower temperatures, which gives them a distinct aesthetic appeal.

Pros & Cons: The main advantage of terracotta is its rustic charm and ability to provide excellent thermal insulation. However, their porosity makes them less durable than porcelain or stoneware, and they can be prone to staining without proper sealing. This limits their application in high-moisture environments.

Impact on Application: Terracotta tiles are often favored in Mediterranean-style architecture and can add warmth to spaces. Buyers should ensure compliance with local standards, as terracotta may not be suitable for all climates, particularly in regions with heavy rainfall.

What Are the Key Considerations for Earthenware in Ceramic Tiles?

Key Properties: Earthenware tiles are made from red or brown clay and are fired at lower temperatures. They are generally softer and more porous than other ceramic materials.

Pros & Cons: The softness of earthenware allows for easy cutting and shaping, making it a cost-effective option for decorative applications. However, its low durability and high porosity limit its use in high-traffic or moisture-prone areas.

Impact on Application: Earthenware is often used for decorative purposes, such as in mosaics or wall tiles. Buyers should consider local climate conditions and ensure compliance with standards like ASTM C648 to avoid issues with water absorption and durability.

Summary Table of Ceramic Tile Materials

| Material | Typical Use Case for ceramic tile supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Porcelain | High-traffic flooring and wall coverings | High durability and low porosity | Higher manufacturing complexity | High |

| Stoneware | Commercial and residential spaces | Excellent thermal shock resistance | Requires sealing to prevent staining | Medium |

| Terracotta | Rustic flooring and decorative applications | Aesthetic appeal and thermal insulation | Prone to staining and lower durability | Low |

| Earthenware | Decorative tiles and mosaics | Easy to cut and shape | Low durability and high porosity | Low |

This guide provides actionable insights for international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, to make informed decisions when selecting ceramic tile materials.

In-depth Look: Manufacturing Processes and Quality Assurance for ceramic tile supplier

What Are the Main Stages of Manufacturing Ceramic Tiles?

The manufacturing process of ceramic tiles consists of several critical stages, each designed to ensure the final product meets the required specifications for durability, aesthetics, and functionality. Understanding these stages is vital for international B2B buyers looking to source high-quality tiles.

-

Material Preparation

The first step involves sourcing raw materials, primarily clay, feldspar, and silica. These materials are carefully selected based on their properties and intended application. Once sourced, they undergo a grinding process to achieve a uniform particle size, which is crucial for consistency in the final product. Additionally, additives may be introduced to enhance specific characteristics such as color, strength, or water resistance. -

Forming

After material preparation, the next stage is forming. There are several techniques used in this process, including:

– Pressing: In this widely used method, the prepared mixture is placed into molds and subjected to high pressure to form the tile shape.

– Extrusion: This technique is used for producing larger formats or special shapes, where the mixture is forced through a die.

– Casting: This method is suitable for intricate designs and involves pouring the slurry into molds to set and dry.

Each forming technique influences the tile’s final characteristics, including its density and surface texture. -

Drying

Once formed, the tiles must be dried to remove excess moisture. This is typically done in a controlled environment to prevent cracking or warping. The drying process can take several hours and is crucial for preparing the tiles for firing. -

Firing

The dried tiles are then subjected to high temperatures in a kiln, which is essential for transforming the raw materials into durable ceramic. Firing not only solidifies the tiles but also enhances their color and surface properties. Different firing temperatures and atmospheres can produce a variety of finishes, such as matte or glossy. -

Finishing

The final stage involves applying glazes or surface treatments to enhance the aesthetic appeal and functionality of the tiles. This can include polishing, coating with protective layers, or printing designs. The finishing process is key for adding value to the tiles and can significantly influence a buyer’s choice.

How Is Quality Assurance Implemented in Ceramic Tile Manufacturing?

Quality assurance (QA) is essential in the ceramic tile industry to ensure products meet international standards and customer expectations. For B2B buyers, understanding these QA processes can help in selecting reliable suppliers.

-

International Standards Compliance

Many ceramic tile manufacturers adhere to international quality standards, such as ISO 9001, which emphasizes a quality management system (QMS) that ensures consistent product quality and continuous improvement. Additionally, certifications like CE (Conformité Européenne) signify compliance with European health, safety, and environmental protection standards. -

Quality Control Checkpoints

Effective quality control involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During production, regular checks are performed to monitor quality at various stages, such as forming and drying.

– Final Quality Control (FQC): After firing and finishing, the final products undergo rigorous testing for defects, dimensions, and surface quality before being packaged and shipped. -

Common Testing Methods

Various testing methods are employed to verify the quality of ceramic tiles, including:

– Water Absorption Test: Measures the porosity of the tiles, which is crucial for their durability and suitability for different environments.

– Breaking Strength Test: Assesses the load-bearing capacity of the tiles, ensuring they can withstand everyday use.

– Frost Resistance Test: Determines how well tiles can endure freezing and thawing cycles, particularly important for outdoor applications.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is essential for ensuring product reliability.

-

Conducting Audits

Buyers should consider conducting regular audits of potential suppliers to assess their manufacturing processes and quality control systems. This can include visiting the manufacturing facility, reviewing their QMS, and evaluating compliance with international standards. -

Requesting Quality Reports

Suppliers should provide quality reports that detail their testing methods, results, and compliance with relevant standards. These reports are invaluable for buyers looking to ensure that products meet their specific requirements. -

Utilizing Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. These inspections can be conducted at various stages of production and can offer additional peace of mind regarding product quality.

What Are the Specific Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate specific quality control nuances that can vary significantly by region. Understanding these differences is crucial for successful sourcing.

-

Regional Standards and Compliance

Different regions may have distinct standards and regulations governing ceramic tile quality. For instance, European buyers may require CE marking, while buyers in Africa or South America might need to comply with local regulations. It’s essential for buyers to communicate their specific compliance needs to suppliers. -

Cultural Considerations

Cultural differences can influence quality expectations and communication styles. Buyers should be aware of these nuances to foster better relationships with suppliers and ensure that quality standards are clearly understood and met. -

Logistics and Shipping Impacts

The journey from manufacturer to buyer can introduce potential quality issues, such as damage during transit. Buyers should discuss packaging standards with suppliers and consider insurance options to mitigate risks associated with shipping.

Conclusion

Understanding the manufacturing processes and quality assurance measures in ceramic tile production is crucial for B2B buyers. By focusing on the main stages of production, quality control standards, and how to verify supplier practices, buyers from Africa, South America, the Middle East, and Europe can make informed decisions when sourcing ceramic tiles. This knowledge not only enhances product selection but also strengthens supplier relationships, ultimately leading to successful procurement strategies.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ceramic tile supplier’

This practical sourcing guide is designed to assist international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, in effectively procuring ceramic tiles from reliable suppliers. Following this checklist will help ensure that you choose the right supplier to meet your business needs while minimizing risks.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for identifying the right ceramic tile supplier. Consider factors such as tile size, material type, finish, and design. By having precise requirements, you can communicate effectively with suppliers and ensure they can meet your needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential ceramic tile suppliers. Look for manufacturers with a proven track record in the industry, particularly those that cater to your specific market or region. Utilize online directories, trade shows, and industry forums to gather a list of suppliers.

Step 3: Verify Supplier Certifications

Before proceeding, it’s essential to verify the certifications of potential suppliers. Look for industry-standard certifications, such as ISO 9001 for quality management and CE marking for European compliance. These certifications indicate that the supplier adheres to recognized quality standards, reducing the risk of receiving subpar products.

Step 4: Request Product Samples

Requesting samples is a critical step in assessing the quality of ceramic tiles. Examine the samples for durability, color consistency, and finish quality. This hands-on evaluation will help you determine if the supplier’s products align with your expectations and requirements.

Step 5: Evaluate Supplier Experience and Reputation

Assess the experience and reputation of potential suppliers in the ceramic tile industry. Look for reviews, testimonials, and case studies from previous clients, particularly those in similar markets. A supplier with a strong reputation is more likely to deliver quality products and reliable service.

Step 6: Negotiate Terms and Conditions

Once you have shortlisted potential suppliers, engage in discussions to negotiate terms and conditions. Focus on pricing, payment terms, delivery timelines, and warranty provisions. A well-structured agreement can mitigate risks and ensure clarity in your business relationship.

Step 7: Establish a Communication Plan

Finally, create a communication plan with your chosen supplier. Set expectations for regular updates on production status, shipment tracking, and any potential issues. Clear communication fosters a strong partnership and helps address any concerns proactively.

By following this checklist, international B2B buyers can effectively navigate the sourcing process for ceramic tiles, ensuring they select reliable suppliers that align with their business needs and standards.

Comprehensive Cost and Pricing Analysis for ceramic tile supplier Sourcing

What Are the Key Cost Components in Sourcing Ceramic Tiles?

When sourcing ceramic tiles, understanding the cost structure is essential for B2B buyers. The main components of costs include:

- Materials: The quality and type of clay, glazes, and other raw materials significantly impact pricing. Higher quality materials often lead to higher costs but can enhance durability and aesthetics.

- Labor: Labor costs vary widely depending on the region. For instance, labor-intensive processes in Europe might be more expensive than in Asia or Africa. Skilled labor for intricate designs can also add to the cost.

- Manufacturing Overhead: This includes expenses related to utilities, equipment maintenance, and factory operations. Efficient manufacturing processes can help reduce these costs.

- Tooling: The setup and maintenance of molds and machinery for tile production contribute to initial costs. Custom designs may require additional tooling, affecting pricing.

- Quality Control (QC): Implementing rigorous QC processes ensures that products meet industry standards. This can add to costs but is crucial for maintaining a reputable brand.

- Logistics: Shipping and transportation costs can be significant, especially for international buyers. Factors such as distance, shipping method, and import duties can greatly influence final costs.

- Margin: Suppliers typically add a profit margin, which can vary based on market conditions and competition. Understanding these margins can help buyers negotiate better prices.

How Do Price Influencers Affect Ceramic Tile Sourcing?

Several factors influence the pricing of ceramic tiles, impacting international B2B buyers:

- Volume and Minimum Order Quantity (MOQ): Larger orders often lead to discounts. Understanding MOQ requirements can help buyers negotiate better terms.

- Specifications and Customization: Custom designs or specific sizes can increase costs due to additional tooling and labor. Buyers should clearly define their needs to avoid unexpected charges.

- Materials Used: The choice of materials affects not only the cost but also the tile’s performance and aesthetic appeal. High-end materials may justify a higher price.

- Quality and Certifications: Tiles that meet international standards or have certifications for sustainability can be priced higher. Buyers should consider the long-term benefits of investing in certified products.

- Supplier Factors: The supplier’s reputation, reliability, and financial stability can influence pricing. Engaging with established suppliers can mitigate risks and ensure consistent quality.

- Incoterms: Understanding the Incoterms (International Commercial Terms) is crucial for managing shipping responsibilities and costs. Different terms can shift financial obligations between buyers and suppliers.

What Tips Should International B2B Buyers Consider for Cost Efficiency?

To optimize sourcing costs, international B2B buyers should consider the following strategies:

- Negotiate Effectively: Building a strong relationship with suppliers can lead to better pricing. Be prepared to discuss volume commitments and payment terms to negotiate favorable conditions.

- Evaluate Total Cost of Ownership (TCO): Beyond initial costs, consider long-term factors such as durability, maintenance, and potential waste. A higher upfront cost may lead to savings over time through lower maintenance needs.

- Be Aware of Pricing Nuances: International markets can have varying pricing structures due to local economic conditions. Research the market in specific regions like Africa, South America, the Middle East, and Europe to understand pricing trends.

- Request Samples: Before committing to large orders, request samples to assess quality. This practice can help prevent costly mistakes and ensure that the products meet your expectations.

- Monitor Market Trends: Stay informed about global ceramic tile market trends, including shifts in supply chain dynamics, raw material prices, and emerging technologies that could affect pricing.

Disclaimer for Indicative Prices

Pricing for ceramic tiles can fluctuate based on a multitude of factors, including economic conditions, material availability, and supplier negotiations. The insights provided here are indicative and should be used as a guideline rather than a definitive pricing structure. Always conduct thorough market research and engage directly with suppliers to obtain the most accurate and current pricing information.

Alternatives Analysis: Comparing ceramic tile supplier With Other Solutions

When considering ceramic tile suppliers, it’s essential for international B2B buyers to explore various alternatives that may meet their project requirements more effectively or economically. These alternatives can range from other types of flooring materials to innovative technologies that serve similar purposes. Below is a comparison of ceramic tile suppliers against two viable alternatives: vinyl flooring and porcelain tiles.

| Comparison Aspect | Ceramic Tile Supplier | Vinyl Flooring | Porcelain Tiles |

|---|---|---|---|

| Performance | Durable and water-resistant | Good for moderate traffic; less durable than ceramic | Highly durable, suitable for high-traffic areas |

| Cost | Generally higher initial cost | Lower initial cost, but may require replacement sooner | Similar to ceramic but can be more cost-effective in the long term |

| Ease of Implementation | Requires skilled labor for installation | Easier to install with DIY options | Similar installation requirements to ceramic |

| Maintenance | Low maintenance; needs occasional sealing | Easy to clean; may require replacement | Low maintenance; resistant to staining |

| Best Use Case | Residential and commercial spaces | Residential areas, light commercial | High-traffic areas, commercial spaces |

What Are the Pros and Cons of Vinyl Flooring as an Alternative to Ceramic Tiles?

Vinyl flooring is an attractive alternative for buyers looking for a cost-effective solution. It boasts lower initial costs and offers a variety of designs that mimic natural materials. Vinyl is easier to install, making it suitable for DIY projects, and requires minimal maintenance. However, it is less durable compared to ceramic tiles, especially in high-traffic areas, and may need replacement sooner, which can incur additional costs over time.

Why Consider Porcelain Tiles Over Ceramic Tiles?

Porcelain tiles are often seen as a premium alternative to traditional ceramic tiles. They offer similar aesthetics and durability but are denser and less porous, making them ideal for high-traffic commercial spaces. Porcelain tiles are also resistant to water and stains, ensuring low maintenance over their lifespan. The downside is that they can be more expensive upfront, and their installation requires skilled labor, similar to ceramic tiles.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When deciding between ceramic tile suppliers and alternative flooring solutions, B2B buyers should carefully assess their specific project requirements. Consider factors such as the intended use of the space, budget constraints, and long-term maintenance capabilities. It’s crucial to evaluate not only the initial costs but also the performance and longevity of the materials. By balancing these aspects, buyers can make informed decisions that align with their operational needs and financial goals.

Essential Technical Properties and Trade Terminology for ceramic tile supplier

What Are the Key Technical Properties of Ceramic Tiles?

Ceramic tiles are critical components in various construction and design projects, and understanding their technical properties is essential for B2B buyers. Here are some vital specifications to consider:

1. Material Grade

Material grade refers to the quality and type of clay and other materials used in tile manufacturing. Higher-grade ceramics typically exhibit superior durability, aesthetic appeal, and resistance to wear and tear. B2B buyers should prioritize material grade to ensure the tiles meet the required performance standards for their specific applications, whether in commercial, residential, or industrial environments.

2. Water Absorption Rate

The water absorption rate indicates how much moisture the tile can absorb, typically expressed as a percentage. This property is crucial for determining the suitability of tiles in wet environments, such as bathrooms and kitchens. Tiles with a lower absorption rate (less than 0.5%) are more resistant to moisture and are less likely to crack or warp, making them a better choice for humid regions.

3. PEI Rating (Porcelain Enamel Institute)

The PEI rating measures a tile’s resistance to scratching and wear, ranging from 1 (light residential use) to 5 (heavy commercial use). Understanding the PEI rating helps buyers select the appropriate tile for high-traffic areas, ensuring longevity and reduced maintenance costs. For instance, a PEI rating of 4 or 5 is advisable for commercial spaces that experience heavy foot traffic.

4. Tile Size and Thickness

Tile dimensions, including size and thickness, significantly impact installation and performance. Larger tiles can reduce grout lines, providing a more seamless look, while thicker tiles often offer greater durability. Buyers should consider the specific requirements of their projects, including the substrate and intended use, to select the optimal tile size and thickness.

5. Surface Finish

The surface finish of ceramic tiles affects both aesthetics and functionality. Common finishes include matte, glossy, and textured, each providing different levels of slip resistance and maintenance requirements. For example, glossy tiles may enhance visual appeal but could pose slip hazards in wet areas. Buyers must evaluate the intended use to choose the appropriate finish.

What Are Common Trade Terms in the Ceramic Tile Industry?

Understanding industry jargon is vital for effective communication between suppliers and buyers. Here are some common terms that are essential in the ceramic tile trade:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are used in another company’s end product. In the ceramic tile industry, an OEM may manufacture tiles for a brand that sells them under its label. Buyers often engage with OEMs to ensure product customization and quality control.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers as it impacts inventory management and costs. Understanding the MOQ can help buyers negotiate better deals and avoid overstock situations, particularly in international trade.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers use to solicit price quotes from suppliers for specific products or services. Crafting a clear RFQ can lead to better pricing and terms, allowing buyers to compare offers effectively. It is advisable to include detailed specifications to ensure accurate quotations.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in the shipping process. Familiarity with Incoterms helps buyers understand their obligations regarding transportation, insurance, and customs clearance, which is crucial for international procurement.

5. Lead Time

Lead time refers to the duration between placing an order and receiving the goods. For ceramic tiles, lead times can vary based on production schedules and shipping logistics. Buyers should consider lead times in their project timelines to avoid delays in construction or renovation.

By grasping these essential technical properties and trade terminology, B2B buyers can make informed decisions when sourcing ceramic tiles, ensuring they meet both performance and aesthetic requirements while navigating the complexities of international trade.

Navigating Market Dynamics and Sourcing Trends in the ceramic tile supplier Sector

What Are the Current Market Dynamics and Key Trends in the Ceramic Tile Supplier Sector?

The ceramic tile supplier market is experiencing significant transformations driven by various global factors. The increasing demand for innovative and aesthetically pleasing flooring solutions is fueled by a robust construction sector, particularly in emerging markets across Africa, South America, and the Middle East. In Europe, sustainability trends are shaping the purchasing decisions of B2B buyers, leading to a surge in demand for eco-friendly tiles that utilize recycled materials or are produced with low environmental impact.

Moreover, advancements in technology are revolutionizing sourcing strategies. Digital platforms are facilitating easier access to suppliers and enabling buyers to compare products and prices in real time. The rise of e-commerce has also led suppliers to adopt more flexible distribution channels, enhancing their ability to meet the needs of international buyers swiftly. Additionally, customization capabilities are becoming essential, as businesses seek unique designs to differentiate themselves in competitive markets.

How Is Sustainability and Ethical Sourcing Impacting the Ceramic Tile Industry?

Sustainability is no longer an optional consideration; it is a critical factor influencing sourcing decisions in the ceramic tile industry. The environmental impact of tile production—including water usage, energy consumption, and emissions—has prompted buyers to seek suppliers committed to reducing their carbon footprint. As a result, many manufacturers are investing in greener production processes, such as using renewable energy sources and implementing water recycling systems.

Ethical sourcing practices are equally important, as international buyers increasingly prioritize suppliers who adhere to fair labor practices and environmental stewardship. Certifications such as LEED (Leadership in Energy and Environmental Design) and ISO 14001 (Environmental Management) are becoming vital indicators for B2B buyers assessing suppliers’ commitment to sustainability. Choosing suppliers with these certifications not only enhances a company’s reputation but also aligns with the growing consumer demand for responsible sourcing.

What Is the Brief Evolution and History of the Ceramic Tile Supplier Sector?

The ceramic tile industry has evolved significantly over the centuries, transitioning from traditional handcrafted techniques to modern automated manufacturing processes. Initially, tiles were primarily used for functional purposes, but as aesthetics gained prominence, the focus shifted toward decorative designs and innovative materials.

In the late 20th century, globalization facilitated the expansion of the ceramic tile market, allowing suppliers to reach international buyers. The advent of technology has played a crucial role in this evolution, with digital tools enabling greater customization and efficiency in production and distribution. Today, the sector is characterized by a mix of tradition and innovation, catering to diverse market needs while striving for sustainability and ethical practices.

Conclusion

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding these market dynamics, sustainability imperatives, and the historical context of the ceramic tile supplier sector is essential for making informed purchasing decisions. As the industry continues to evolve, staying abreast of these trends will enhance buyers’ ability to source effectively and ethically.

Frequently Asked Questions (FAQs) for B2B Buyers of ceramic tile supplier

-

How do I choose the right ceramic tile supplier for my business?

When selecting a ceramic tile supplier, consider their product range, quality certifications, and reputation within the industry. Look for suppliers who offer samples, allowing you to assess the tile quality firsthand. Additionally, investigate their manufacturing processes and sustainability practices, which can influence product durability and environmental impact. Finally, read reviews from other B2B buyers and check their compliance with international trade regulations, especially if you’re importing from regions like Europe or Asia. -

What are the typical minimum order quantities (MOQs) for ceramic tiles?

MOQs for ceramic tiles can vary widely depending on the supplier and the type of tile. Generally, for bulk orders, you might encounter MOQs ranging from 100 to 1,000 square meters. Some suppliers may offer lower MOQs for specific collections or promotional items. It’s essential to communicate your needs clearly and discuss potential flexibility with the supplier, especially if you are a new buyer or testing a new market. -

What payment terms should I expect when dealing with ceramic tile suppliers?

Payment terms can differ significantly among suppliers. Common arrangements include upfront payments, deposits (usually 30% to 50%), and the balance due before shipping. Some suppliers may offer net payment terms, allowing you to pay within a specified period after receiving the goods. It’s advisable to negotiate terms that suit your cash flow while ensuring you establish trust with the supplier. Always request a pro forma invoice to clarify payment expectations. -

How can I ensure quality assurance when sourcing ceramic tiles internationally?

To ensure quality assurance, first, request samples before placing a bulk order. Establish clear specifications for the tiles, including size, color, and finish. Consider third-party inspections during production and pre-shipment to verify that the tiles meet your standards. Additionally, familiarize yourself with the supplier’s quality control processes and certifications (like ISO), as this can provide insight into their commitment to quality. -

What are the logistics considerations for importing ceramic tiles?

Logistics for importing ceramic tiles involve several key factors. Assess the supplier’s ability to handle shipping and customs clearance, as well as their experience with international logistics. Consider the shipping methods (ocean freight is common for bulk orders) and associated costs, including insurance. Additionally, account for lead times, as ceramic tiles are often heavy and may require specialized handling. Collaborate with a logistics partner familiar with your destination market to streamline the process. -

Can I customize ceramic tiles to meet specific design requirements?

Many ceramic tile suppliers offer customization options, including bespoke sizes, colors, patterns, and finishes. Discuss your design needs with potential suppliers early in the negotiation process to understand their capabilities. Keep in mind that custom orders often come with higher costs and longer lead times. Providing detailed specifications and possibly collaborating with the supplier’s design team can help achieve the desired outcome. -

What certifications should I look for in a reputable ceramic tile supplier?

When sourcing ceramic tiles, look for suppliers with certifications that indicate adherence to industry standards. Relevant certifications include ISO 9001 for quality management systems, ISO 14001 for environmental management, and specific regional certifications like CE marking in Europe. These certifications not only ensure product quality but also demonstrate the supplier’s commitment to sustainable practices, which is increasingly important to B2B buyers globally. -

What are the common challenges faced when sourcing ceramic tiles internationally?

Sourcing ceramic tiles internationally can present several challenges, including language barriers, varying quality standards, and potential delays in shipping. Additionally, navigating customs regulations and tariffs can complicate the import process. To mitigate these issues, conduct thorough research on the supplier’s background, communicate clearly, and consider engaging a local sourcing agent or freight forwarder who understands the local market dynamics and regulations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for ceramic tile supplier

What Are the Key Takeaways for B2B Buyers in Ceramic Tile Sourcing?

In conclusion, strategic sourcing in the ceramic tile industry offers international buyers a pathway to ensure quality, cost-effectiveness, and sustainability. Understanding regional market dynamics, particularly in Africa, South America, the Middle East, and Europe, is crucial for making informed procurement decisions. By establishing strong relationships with suppliers, buyers can negotiate better terms and access innovative designs that meet their specific needs.

How Can Buyers Enhance Their Sourcing Strategies?

Investing in supplier audits and leveraging technology for supply chain transparency are key actions buyers should consider. This not only mitigates risks associated with product quality and delivery timelines but also enhances overall operational efficiency. Additionally, focusing on suppliers that prioritize sustainable practices can align with global trends towards environmental responsibility, thus boosting brand reputation.

What Should Buyers Anticipate in the Future of Ceramic Tile Supply?

As market demands evolve, staying ahead of trends—such as eco-friendly materials and digital design tools—will be essential. Buyers should remain adaptable and proactive in their sourcing strategies. Engaging with suppliers who are committed to innovation can lead to a competitive edge in the marketplace.

In this dynamic landscape, we encourage international B2B buyers to explore diverse supplier options and prioritize strategic partnerships that foster mutual growth and success. Your next step could redefine your sourcing strategy—embrace the opportunities that lie ahead!