Cut Costs with the Best Roof Sheet Manufacturer Guide (2025)

Introduction: Navigating the Global Market for roof sheet manufacturer

Navigating the complexities of sourcing roof sheets can be a daunting task for international B2B buyers, especially in diverse markets like Africa, South America, the Middle East, and Europe. With a myriad of materials and manufacturers available, making informed decisions is crucial to ensure quality and cost-effectiveness. This guide serves as a comprehensive resource for buyers looking to understand the global market for roof sheet manufacturers. It covers essential aspects such as the various types of roof sheets available, their applications across different industries, and effective strategies for vetting suppliers.

By delving into factors like pricing, material durability, and manufacturing standards, this guide empowers businesses to make informed purchasing decisions that align with their specific needs. Whether you are a construction firm in Italy seeking sustainable solutions or a distributor in South America looking for reliable suppliers, this resource will help you navigate the intricacies of the roof sheet market.

Furthermore, we address common challenges such as understanding local regulations, assessing supplier credibility, and negotiating contracts. With actionable insights tailored for international B2B buyers, this guide is your essential companion for successfully sourcing roof sheets that meet your operational requirements and budget constraints.

Understanding roof sheet manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Metal Roof Sheets | Durable, corrosion-resistant, lightweight, various finishes | Industrial buildings, warehouses, homes | Pros: Long lifespan, low maintenance. Cons: Higher initial cost. |

| Polycarbonate Roof Sheets | Transparent or translucent, UV resistant, lightweight | Greenhouses, skylights, canopies | Pros: Excellent light transmission, impact-resistant. Cons: Can be prone to scratching. |

| Asphalt Shingles | Cost-effective, easy installation, available in many colors | Residential homes, small commercial | Pros: Affordable, good weather resistance. Cons: Shorter lifespan compared to metal. |

| Fiberglass Roof Sheets | Lightweight, flexible, resistant to chemicals | Industrial applications, agricultural | Pros: Non-corrosive, good thermal insulation. Cons: May require more maintenance. |

| PVC Roof Sheets | Flexible, durable, resistant to fire and chemicals | Commercial buildings, flat roofs | Pros: Energy-efficient, easy to install. Cons: Can be more expensive than traditional materials. |

What are the characteristics of Metal Roof Sheets for B2B buyers?

Metal roof sheets are recognized for their durability and resistance to corrosion, making them suitable for various climates. They are lightweight, which simplifies installation and reduces structural load. B2B buyers should consider the different finishes available, such as galvanized or painted options, which can enhance aesthetics and longevity. The primary applications include industrial buildings and warehouses, where long-term investment in roofing is essential. However, the initial cost can be higher than other materials, which may require budget considerations.

How do Polycarbonate Roof Sheets serve specific B2B needs?

Polycarbonate roof sheets stand out for their transparency and UV resistance, making them ideal for applications like greenhouses and skylights. Their lightweight nature facilitates easy handling and installation, appealing to B2B buyers focused on efficiency. These sheets allow natural light while providing protection from harmful UV rays, essential for agricultural settings. Buyers should be aware of their susceptibility to scratches, which can affect long-term performance. Overall, they offer a unique combination of light transmission and durability, suitable for specific commercial applications.

What makes Asphalt Shingles a popular choice among B2B buyers?

Asphalt shingles are a cost-effective roofing solution, particularly favored for residential projects and small commercial buildings. They are easy to install, which can significantly reduce labor costs. Available in a variety of colors, asphalt shingles allow for aesthetic customization. However, their lifespan is shorter compared to metal alternatives, which may influence long-term value considerations. Buyers should weigh the affordability against potential future replacements, especially in regions prone to extreme weather conditions.

Why choose Fiberglass Roof Sheets for industrial applications?

Fiberglass roof sheets are lightweight and flexible, making them an excellent choice for industrial applications where custom shapes are needed. They are resistant to chemicals, which is beneficial in environments where exposure to harsh substances is common. Their thermal insulation properties can also lead to energy savings. However, they may require more maintenance than other materials, which could impact operational costs. B2B buyers should evaluate the trade-offs between flexibility and maintenance needs based on their specific applications.

What advantages do PVC Roof Sheets offer to commercial buyers?

PVC roof sheets are known for their flexibility and durability, making them suitable for flat roofs on commercial buildings. They exhibit excellent resistance to fire and chemicals, enhancing safety and longevity. Energy efficiency is another significant advantage, as they can reflect sunlight and reduce cooling costs. While they may come at a higher price point than traditional roofing materials, the long-term savings and performance benefits can justify the investment. Buyers should consider the specific needs of their projects and the potential for energy savings when evaluating PVC options.

Related Video: HOW? Roof Sheet Making – Factory Tour | Factory Explorer

Key Industrial Applications of roof sheet manufacturer

| Industry/Sector | Specific Application of roof sheet manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Residential and commercial roofing systems | Durability and weather resistance enhance building lifespan | Compliance with local building codes and climate considerations |

| Agriculture | Agricultural sheds and storage facilities | Protection for equipment and livestock, increasing operational efficiency | Material quality and resistance to corrosion and UV degradation |

| Manufacturing | Industrial warehouses and factories | Energy efficiency through insulation, reducing operational costs | Availability of custom sizes and insulation options |

| Infrastructure | Transportation hubs (airports, railway stations) | Safety and structural integrity in high-traffic areas | Fire resistance ratings and maintenance requirements |

| Energy | Solar panel installations on rooftops | Sustainability and reduced energy costs for operations | Compatibility with various solar technologies and weight tolerance |

How Are Roof Sheets Used in the Construction Industry?

Roof sheets are crucial in both residential and commercial construction, providing a protective layer against the elements. They are designed to withstand harsh weather conditions, thereby prolonging the lifespan of buildings. For international buyers, especially in regions like Africa and the Middle East, sourcing roof sheets that comply with local building codes and are tailored to specific climate conditions is essential. Buyers should prioritize manufacturers that offer products with proven durability and weather resistance.

What Role Do Roof Sheets Play in Agriculture?

In agriculture, roof sheets are widely used for constructing sheds and storage facilities that protect livestock and equipment from harsh weather. This application enhances operational efficiency by safeguarding valuable assets. Buyers in South America and Africa should consider sourcing roof sheets that are resistant to corrosion and UV degradation to ensure longevity, especially in regions with high humidity or intense sunlight.

How Do Roof Sheets Benefit the Manufacturing Sector?

Manufacturing facilities utilize roof sheets for industrial warehouses and factories, where energy efficiency is critical. Insulated roof sheets can significantly reduce heating and cooling costs, providing a direct impact on operational expenses. Buyers should look for manufacturers that can provide custom sizes and insulation options to meet specific facility requirements, ensuring that the products align with their energy efficiency goals.

How Are Roof Sheets Applied in Infrastructure Projects?

In the infrastructure sector, roof sheets are vital for transportation hubs such as airports and railway stations. These structures require materials that ensure safety and structural integrity in high-traffic areas. International buyers must consider sourcing roof sheets with appropriate fire resistance ratings and maintenance requirements, especially in regions prone to extreme weather or heavy usage.

What Is the Importance of Roof Sheets in Energy Solutions?

Roof sheets are increasingly utilized in solar panel installations, enabling sustainable energy solutions for businesses. By integrating solar panels with roof sheets, companies can significantly reduce their energy costs and environmental footprint. Buyers should ensure that the roof sheets are compatible with various solar technologies and can support the additional weight, especially in European markets where sustainability is a key focus.

3 Common User Pain Points for ‘roof sheet manufacturer’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Roof Sheet Material

The Problem: Many B2B buyers struggle with the overwhelming variety of roof sheet materials available in the market. For instance, a construction manager in South America may face challenges when trying to choose between galvanized steel, aluminum, or PVC roofing sheets, each with different properties, costs, and suitability for various climates. This decision can have long-term implications on durability, maintenance costs, and overall project budgets, causing significant stress and uncertainty.

The Solution: To effectively select the right roofing material, buyers should conduct thorough research on local environmental conditions and project requirements. Start by consulting with a roof sheet manufacturer that offers a comprehensive range of materials tailored to specific climates. Create a checklist that includes factors such as thermal efficiency, weight, corrosion resistance, and local availability. Additionally, request samples and detailed product specifications to assess how well each material meets your project needs. Engaging with manufacturers who provide expert consultations can also help in making an informed decision that aligns with your budget and performance expectations.

Scenario 2: Challenges in Ensuring Quality and Compliance

The Problem: A frequent pain point for B2B buyers is ensuring that the roofing sheets meet local building codes and quality standards. For example, a buyer in Africa may find that imported roof sheets do not comply with national regulations, leading to costly project delays and potential legal issues. This situation can arise from a lack of clear communication about specifications between manufacturers and buyers, resulting in mismatched expectations.

The Solution: To navigate this challenge, buyers should prioritize sourcing roof sheets from manufacturers who are well-versed in local regulations and quality standards. Before placing an order, request documentation that verifies compliance with relevant codes and certifications. Establish a strong line of communication with the manufacturer, asking for detailed product descriptions and quality assurance processes. Furthermore, consider visiting the manufacturing facility or arranging third-party inspections to ensure that the products meet your expectations. Collaborating with local engineers or consultants can also provide additional insights into compliance requirements and help mitigate risks.

Scenario 3: Logistics and Delivery Issues

The Problem: Timely delivery of roof sheets is crucial for construction projects, yet many B2B buyers experience significant delays due to logistics issues. A contractor in the Middle East might face unexpected shipping delays from suppliers located in Europe, leading to project setbacks and financial losses. This disruption can stem from various factors, including customs clearance, transportation failures, or inadequate supply chain management.

The Solution: To address logistical challenges, B2B buyers should develop a clear logistics plan in collaboration with their roof sheet manufacturer. Begin by discussing delivery timelines and potential risks during the initial negotiation phase. Opt for manufacturers who have established logistics networks and proven track records of timely deliveries. Additionally, consider using local suppliers or manufacturers to reduce shipping times and costs. Implementing a robust inventory management system can also help anticipate demand and streamline the ordering process. Lastly, maintaining regular communication with the manufacturer regarding shipment status can help you proactively address any potential delays before they impact your project schedule.

Strategic Material Selection Guide for roof sheet manufacturer

When selecting materials for roof sheet manufacturing, it is essential to consider various factors that affect performance, durability, and compliance with international standards. Below is an analysis of four common materials used in the industry, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What Are the Key Properties of Steel Roof Sheets?

Steel is one of the most widely used materials for roof sheets due to its strength and versatility. It typically has a high temperature and pressure rating, making it suitable for various climates. Steel sheets can be coated with materials like zinc (galvanized) or aluminum to enhance corrosion resistance, which is particularly important in humid or coastal environments.

Pros: Steel roof sheets are highly durable, with a lifespan that can exceed 50 years. They are also relatively easy to manufacture and install, making them a popular choice for both residential and commercial applications.

Cons: The primary disadvantage of steel is its susceptibility to rust if not adequately coated. Additionally, steel can be more expensive than other materials like aluminum or PVC, particularly when considering the cost of protective coatings.

Impact on Application: Steel roof sheets are compatible with a wide range of applications, including industrial buildings and residential homes. However, they may not be suitable for areas with extreme corrosive environments unless properly treated.

Considerations for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should ensure compliance with relevant standards such as ASTM and DIN. In regions with high humidity, selecting galvanized or pre-painted steel is advisable.

How Do Aluminum Roof Sheets Compare in Performance?

Aluminum roof sheets are known for their lightweight and excellent corrosion resistance. They typically have a lower temperature rating compared to steel but are still suitable for various applications.

Pros: The primary advantage of aluminum is its resistance to corrosion, making it ideal for coastal areas. It is also lightweight, which can reduce transportation and installation costs.

Cons: Aluminum sheets are generally less durable than steel and can be more expensive. They may also require additional support in certain applications due to their lower strength.

Impact on Application: Aluminum is suitable for residential and commercial roofing but may not be the best choice for heavy industrial applications where strength is paramount.

Considerations for International Buyers: Buyers should look for compliance with JIS standards for aluminum products. In regions like Europe and the Middle East, aluminum is often preferred for its aesthetic appeal and lightweight properties.

What Are the Benefits of PVC Roof Sheets?

PVC (Polyvinyl Chloride) roof sheets are gaining popularity due to their excellent weather resistance and low maintenance requirements. They are particularly effective in areas with high UV exposure.

Pros: PVC sheets are highly resistant to chemicals, making them suitable for industrial applications. They are also lightweight and easy to install, which can reduce labor costs.

Cons: One limitation of PVC is its susceptibility to damage from extreme temperatures, which can lead to brittleness over time. Additionally, the initial cost can be higher than traditional materials.

Impact on Application: PVC is ideal for flat or low-slope roofs and is often used in commercial buildings. However, it may not be suitable for steep-pitched roofs.

Considerations for International Buyers: Buyers should ensure that PVC sheets meet local environmental regulations, especially in Europe, where sustainability is a priority. Compliance with ASTM standards is also essential.

Why Consider Bitumen Roof Sheets?

Bitumen roof sheets, commonly used in flat roofing systems, provide excellent waterproofing properties. They are often used in commercial and industrial applications.

Pros: Bitumen sheets are highly durable and can withstand various weather conditions. They are also relatively inexpensive compared to metal options.

Cons: The primary drawback is that bitumen can become brittle over time, especially in colder climates. Additionally, installation can be more complex, requiring skilled labor.

Impact on Application: Bitumen is particularly effective for flat roofs but may not be suitable for sloped applications due to drainage concerns.

Considerations for International Buyers: Buyers should check for compliance with local building codes and standards, especially in regions like Africa and the Middle East, where extreme temperatures can affect performance.

Summary of Material Selection for Roof Sheet Manufacturers

| Material | Typical Use Case for Roof Sheet Manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Industrial and commercial roofing | High durability and strength | Susceptible to rust without coating | Medium |

| Aluminum | Residential and commercial roofing | Excellent corrosion resistance | Less durable than steel | High |

| PVC | Flat and low-slope commercial roofs | Low maintenance and lightweight | Susceptible to extreme temperature damage | Medium |

| Bitumen | Flat roofing systems in commercial buildings | Excellent waterproofing | Can become brittle over time | Low |

This guide provides a comprehensive overview of material options for roof sheet manufacturers, helping international B2B buyers make informed decisions based on performance, cost, and regional compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for roof sheet manufacturer

What Are the Key Stages in the Manufacturing Process of Roof Sheets?

The manufacturing process of roof sheets involves several critical stages that ensure the final product meets quality and performance standards. Understanding these stages is essential for international B2B buyers, especially when sourcing from diverse regions like Africa, South America, the Middle East, and Europe.

-

Material Preparation

– The process begins with the selection of raw materials, typically metal sheets made of materials like galvanized steel, aluminum, or zinc. Each material offers different benefits, such as corrosion resistance or weight considerations.

– The raw materials undergo treatment processes, including cleaning and coating, to enhance their durability and performance. This step is crucial as it directly impacts the lifespan and reliability of the roof sheets. -

Forming

– Once prepared, the materials are fed into forming machines that utilize techniques such as roll forming or press forming. Roll forming is particularly popular as it allows for continuous production and the creation of complex profiles.

– The forming stage shapes the sheets into the desired profiles, such as corrugated or flat designs, which are tailored to specific applications and aesthetic preferences. -

Assembly

– In some cases, roof sheets may require assembly with other components, such as flashing or insulation. This is particularly relevant for products designed for commercial or industrial applications where integration with other building systems is necessary.

– Automated assembly lines can enhance efficiency and precision during this phase, minimizing human error and ensuring consistency. -

Finishing

– The final stage involves finishing processes such as cutting to size, edge treatment, and coating. Coatings can include paint or protective films that add aesthetic value and enhance corrosion resistance.

– Quality checks are integrated into this stage to ensure that all sheets meet specified dimensions and visual standards before packaging and shipping.

How Is Quality Assurance Implemented in Roof Sheet Manufacturing?

Quality assurance (QA) is a crucial aspect of the manufacturing process, ensuring that products meet both international and industry-specific standards. For international B2B buyers, understanding these QA processes is vital for making informed sourcing decisions.

-

What International Standards Are Relevant?

– Many roof sheet manufacturers adhere to international quality standards such as ISO 9001, which outlines the criteria for a quality management system. This certification indicates a manufacturer’s commitment to consistent quality and continuous improvement.

– Additionally, industry-specific certifications may apply, such as CE marking in Europe, which signifies compliance with health, safety, and environmental protection standards, and API standards for products intended for the oil and gas sector. -

What Are the Key QC Checkpoints?

– Quality Control (QC) is typically segmented into three critical checkpoints:- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, periodic inspections are conducted to monitor production quality and adherence to specifications.

- Final Quality Control (FQC): Before packaging, finished products undergo rigorous testing to confirm they meet all criteria, including dimensional accuracy and surface finish.

-

What Common Testing Methods Are Used?

– Common testing methods include:- Visual Inspection: Checking for surface defects or inconsistencies.

- Dimensional Testing: Ensuring that products meet specified measurements.

- Material Testing: Assessing the strength and durability of materials through tensile and impact tests.

- Corrosion Resistance Testing: Evaluating the performance of coatings under simulated environmental conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, verifying the quality control processes of potential suppliers is crucial. Here are actionable insights on how to effectively assess supplier QC:

-

Conducting Audits

– Regular audits of suppliers can provide insights into their manufacturing processes and quality assurance practices. Buyers should consider conducting both initial audits before engagement and periodic audits throughout the partnership to ensure ongoing compliance with standards. -

Requesting Quality Reports

– Buyers should request detailed quality assurance reports, including results from various tests conducted during the manufacturing process. These documents can help buyers assess whether the manufacturer adheres to international standards and best practices. -

Engaging Third-Party Inspectors

– Utilizing third-party inspection services can offer an unbiased assessment of a supplier’s quality control processes. This is particularly beneficial for buyers unfamiliar with local manufacturing practices or standards. -

Understanding Certification Nuances

– Different regions may have unique certification requirements, and understanding these nuances is essential for compliance. For example, while ISO 9001 is a widely recognized standard, certain countries may have specific regulations that must also be met. Buyers should familiarize themselves with these regional differences to ensure their suppliers are compliant.

Conclusion: Why Quality Assurance Matters for B2B Buyers in Roof Sheet Manufacturing

Quality assurance in roof sheet manufacturing is not merely a regulatory necessity but a foundational element that influences product performance and buyer satisfaction. By understanding the manufacturing processes, relevant standards, and quality assurance checkpoints, B2B buyers can make informed decisions that ensure they source reliable, high-quality products suitable for their specific needs. Engaging in thorough verification processes will further enhance confidence in supplier partnerships, ultimately leading to successful project outcomes and long-term relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘roof sheet manufacturer’

This practical sourcing guide is designed to assist international B2B buyers in efficiently procuring roof sheets from manufacturers. By following this step-by-step checklist, buyers can ensure they make informed decisions, minimizing risks and maximizing quality.

Step 1: Define Your Technical Specifications

Before reaching out to manufacturers, it’s crucial to have a clear understanding of your requirements. Define the materials, dimensions, and any specific performance standards your roof sheets must meet. This step helps you communicate effectively with potential suppliers and ensures that you receive products that fit your project needs.

- Material Type: Consider whether you need metal, plastic, or composite materials based on durability and climate considerations.

- Dimensions: Specify the length, width, and thickness required for your application.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential roof sheet manufacturers. Look for suppliers with a solid reputation in the market, particularly those experienced in serving your region, such as Africa, South America, the Middle East, or Europe.

- Online Directories: Utilize platforms like Alibaba or Global Sources to find verified suppliers.

- Industry Recommendations: Engage with industry associations or forums for recommendations on reliable manufacturers.

Step 3: Evaluate Supplier Certifications

It’s essential to verify that potential suppliers hold the necessary certifications and adhere to industry standards. This step ensures that the products meet safety and quality regulations.

- ISO Certifications: Look for manufacturers with ISO 9001 certification, which indicates a commitment to quality management systems.

- Local Compliance: Ensure that the supplier complies with local regulations in your country regarding construction materials.

Step 4: Request Samples

Before finalizing any agreements, request samples of the roof sheets from your shortlisted suppliers. This allows you to assess the quality and suitability of the materials firsthand.

- Quality Assessment: Check for consistency in thickness, finish, and any coatings that may be applied.

- Testing: If possible, conduct tests to evaluate the performance of the samples under conditions similar to your project.

Step 5: Negotiate Terms and Pricing

Once you have evaluated potential suppliers and their samples, it’s time to negotiate terms. Discuss pricing, delivery schedules, and payment terms to ensure they align with your project timeline and budget.

- Bulk Pricing: Inquire about discounts for larger orders or long-term contracts.

- Payment Flexibility: Consider payment terms that allow you to maintain cash flow while ensuring timely delivery.

Step 6: Check References and Reviews

Before making a final decision, check references and reviews from other clients. This can provide insights into the supplier’s reliability and customer service.

- Client Testimonials: Look for feedback on the supplier’s responsiveness and support during the purchasing process.

- Past Projects: Ask for case studies or examples of previous projects similar to yours to gauge their experience.

Step 7: Finalize the Contract

Once you have selected a supplier, finalize the contract with all agreed-upon terms. Ensure that it includes warranties, delivery timelines, and quality assurance measures.

- Legal Review: Consider having a legal expert review the contract to protect your interests.

- Clear Terms: Make sure all specifications, including any penalties for non-compliance, are clearly outlined in the agreement.

By following these steps, international B2B buyers can streamline the procurement process for roof sheets, ensuring they find the best manufacturers to meet their specific needs.

Comprehensive Cost and Pricing Analysis for roof sheet manufacturer Sourcing

What Are the Key Cost Components for Roof Sheet Manufacturing?

When sourcing roof sheets, understanding the cost structure is crucial. The primary components influencing the overall cost include:

-

Materials: The type of raw materials significantly affects the pricing. Common materials include galvanized steel, aluminum, and PVC. Prices can fluctuate based on market demand and availability, impacting the manufacturer’s cost.

-

Labor: Labor costs vary by region and can be influenced by local wage rates, skill levels, and labor regulations. In developing markets, labor costs may be lower, but it’s essential to consider the trade-off in quality and expertise.

-

Manufacturing Overhead: This encompasses utilities, rent, equipment maintenance, and administrative costs. Efficient operations can minimize overhead, contributing to competitive pricing.

-

Tooling: Investment in tooling is necessary for customization and high-quality production. Costs can vary based on the complexity of the tooling required for specific designs.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability and compliance with international standards, which may add to the cost but is essential for quality assurance.

-

Logistics: Transportation costs depend on distance, shipping methods, and the efficiency of the supply chain. Incoterms also play a significant role in determining who bears these costs.

-

Margin: The manufacturer’s profit margin will be influenced by all the above factors, as well as market competition and perceived value.

How Do Price Influencers Impact Roof Sheet Sourcing?

Several factors can significantly influence the pricing of roof sheets:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically result in lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their project needs to optimize costs.

-

Specifications and Customization: Custom designs or specific material requirements can increase costs. Buyers should be clear about their specifications from the outset to avoid unexpected charges.

-

Material Quality and Certifications: Higher-quality materials or those with specific certifications (e.g., ISO, CE) may command a premium. Buyers should assess whether the additional cost aligns with their project requirements.

-

Supplier Factors: The reliability and reputation of the supplier can influence pricing. Established suppliers may offer better warranties and service, justifying a higher price.

-

Incoterms: Understanding Incoterms is crucial as they determine who is responsible for shipping, insurance, and tariffs. This can affect the total landed cost of goods.

What Buyer Tips Can Enhance Cost-Efficiency in Roof Sheet Sourcing?

To optimize costs and improve sourcing efficiency, international B2B buyers should consider the following strategies:

-

Negotiation: Engage in open discussions with suppliers regarding pricing, especially for large orders. Leverage competition among suppliers to negotiate better terms.

-

Total Cost of Ownership (TCO): Evaluate the full lifecycle costs of roof sheets, including installation, maintenance, and potential replacements. A lower upfront cost may not always translate to savings in the long run.

-

Understand Pricing Nuances for International Markets: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional pricing differences and currency fluctuations. Tailoring sourcing strategies to local market conditions can yield better financial outcomes.

-

Leverage Technology: Utilize procurement platforms and tools to compare prices and suppliers efficiently. This can help identify cost-saving opportunities.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing and service as suppliers are more inclined to offer discounts and favorable terms to loyal customers.

Conclusion

Sourcing roof sheets involves navigating a complex landscape of costs and pricing influencers. By understanding the key components and employing strategic negotiation and sourcing techniques, international B2B buyers can secure favorable terms that align with their project needs while ensuring quality and compliance. Always remember to assess the total cost of ownership to make informed purchasing decisions.

Alternatives Analysis: Comparing roof sheet manufacturer With Other Solutions

Introduction: What Are the Alternatives to Roof Sheet Manufacturers?

When it comes to roofing solutions, international B2B buyers have a variety of choices beyond traditional roof sheet manufacturers. Understanding the alternatives is crucial for making informed decisions that align with your business needs, budget constraints, and project specifications. In this analysis, we will compare roof sheet manufacturing with two viable alternatives: metal roofing systems and green roofing solutions. Each option has unique advantages and challenges that can impact long-term performance and sustainability.

Comparison Table of Roofing Solutions

| Comparison Aspect | Roof Sheet Manufacturer | Metal Roofing Systems | Green Roofing Solutions |

|---|---|---|---|

| Performance | Durable and lightweight | Highly durable, energy-efficient | Provides insulation, absorbs rainwater |

| Cost | Moderate initial cost | Higher initial investment | Varies; can be high due to installation |

| Ease of Implementation | Straightforward installation | Requires skilled labor | Complex installation process |

| Maintenance | Low maintenance | Moderate maintenance needs | High maintenance for plants |

| Best Use Case | Industrial and commercial buildings | Residential and commercial | Urban areas, eco-friendly projects |

In-Depth Analysis of Alternative Solutions

What Are Metal Roofing Systems and Their Advantages?

Metal roofing systems are increasingly popular among B2B buyers due to their longevity and energy efficiency. They typically offer a lifespan of 40-70 years, significantly outlasting traditional roofing materials. Additionally, metal roofs reflect solar heat, which can lead to lower energy costs over time. However, the initial investment is considerably higher than that of roof sheets. Installation also requires skilled labor, which may not be readily available in all regions, potentially delaying project timelines.

How Do Green Roofing Solutions Compare?

Green roofing solutions, which involve growing vegetation on rooftops, are an innovative alternative that provides numerous environmental benefits. They enhance insulation, reduce urban heat, and manage stormwater effectively. However, the complexity of installation and the need for ongoing maintenance to ensure plant health can be significant drawbacks. The costs can vary greatly, often requiring a higher initial investment due to the specialized labor and materials involved. For businesses in urban areas looking to enhance sustainability, green roofs can be a valuable investment.

Conclusion: How to Choose the Right Roofing Solution for Your Needs?

Selecting the right roofing solution requires a thorough assessment of your specific requirements, including budget, project scope, and long-term goals. Roof sheet manufacturers offer a cost-effective and easy-to-install option for many industrial applications, while metal roofing systems provide durability and energy efficiency for both residential and commercial buildings. On the other hand, green roofing solutions are ideal for eco-conscious businesses aiming for sustainability, albeit at a higher cost and maintenance commitment. By carefully weighing these alternatives, B2B buyers can make informed decisions that align with their strategic objectives and operational needs.

Essential Technical Properties and Trade Terminology for roof sheet manufacturer

What Are the Key Technical Properties for Roof Sheet Manufacturers?

When sourcing roof sheets, international B2B buyers should be aware of several essential technical properties that directly impact product quality and suitability for specific applications. Here are the critical specifications to consider:

-

Material Grade

– Definition: This refers to the type and quality of materials used in manufacturing roof sheets, such as galvanized steel, aluminum, or polycarbonate.

– B2B Importance: Material grade affects the durability, weight, and resistance to environmental factors like corrosion and UV exposure. Buyers must ensure that the material grade aligns with their project requirements, especially in harsh climates typical in Africa, South America, or the Middle East. -

Thickness

– Definition: The thickness of the roof sheet, usually measured in millimeters.

– B2B Importance: Thickness influences the strength and insulation properties of the roof sheet. Thicker sheets generally offer better structural integrity, which is crucial for regions prone to heavy rainfall or snow. -

Tolerance

– Definition: This refers to the allowable deviation from specified dimensions during manufacturing.

– B2B Importance: Tight tolerances ensure that roof sheets fit correctly during installation, reducing the risk of leaks and structural failures. For large-scale projects, maintaining consistent tolerances is essential for long-term performance. -

Coating Type

– Definition: The type of protective coating applied to the roof sheet, such as polyester or PVDF (polyvinylidene fluoride).

– B2B Importance: Coating types impact the lifespan and maintenance needs of the roof sheets. For instance, PVDF coatings offer superior UV resistance and longevity, making them suitable for regions with intense sunlight. -

Fire Resistance Rating

– Definition: A measure of how well the roof sheet can withstand fire.

– B2B Importance: This rating is critical for compliance with local building codes and regulations, especially in commercial or industrial applications. Buyers should verify that the fire resistance meets or exceeds local standards to ensure safety.

Which Trade Terms Should B2B Buyers Understand When Purchasing Roof Sheets?

Understanding industry jargon is essential for effective communication and negotiation in the roof sheet market. Here are some common trade terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Buyers should know if the manufacturer operates as an OEM to ensure they are sourcing genuine products that meet quality standards. -

MOQ (Minimum Order Quantity)

– Definition: The smallest number of units a supplier is willing to sell.

– Importance: Understanding MOQ helps buyers plan their budgets and inventory. It can also influence pricing—higher MOQs often lead to lower per-unit costs. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to request pricing and other information for a specific quantity of goods.

– Importance: Issuing an RFQ allows buyers to compare prices and terms from multiple suppliers, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A series of predefined international sales terms published by the International Chamber of Commerce (ICC).

– Importance: Understanding Incoterms is vital for clarifying the responsibilities of buyers and sellers, particularly in terms of shipping, insurance, and tariffs, which can significantly affect overall costs. -

Lead Time

– Definition: The time it takes from placing an order until the goods are delivered.

– Importance: Knowing the lead time is crucial for project planning and scheduling, especially in regions where delays can result in increased costs or project disruptions.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make more informed decisions when sourcing roof sheets, ultimately ensuring they select products that meet their specific needs and project requirements.

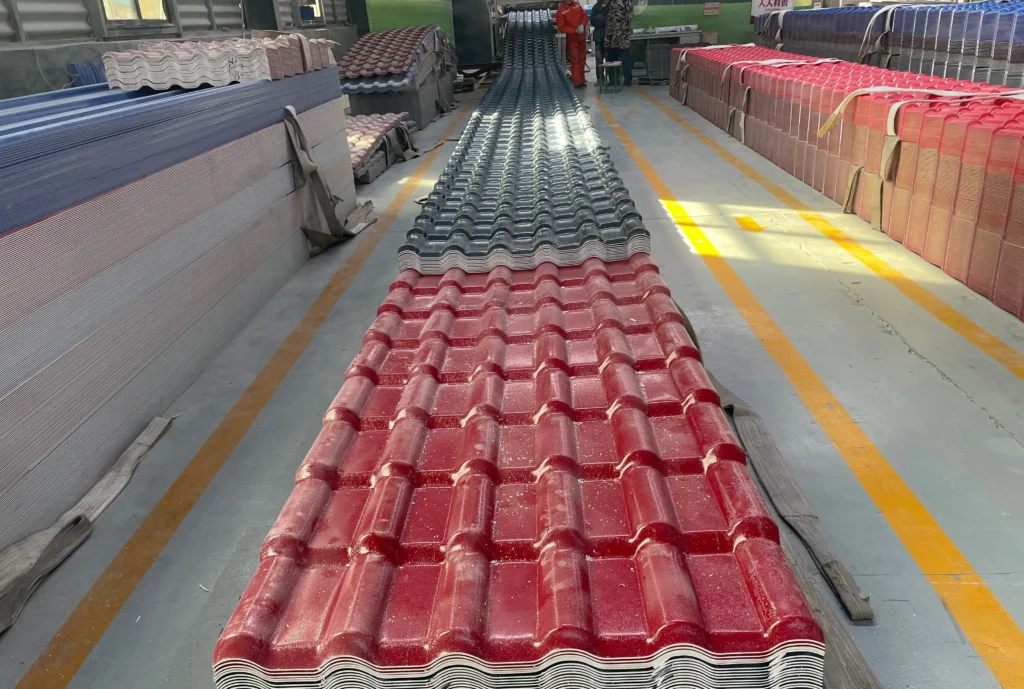

A stock image related to roof sheet manufacturer.

Navigating Market Dynamics and Sourcing Trends in the roof sheet manufacturer Sector

What Are the Current Market Dynamics and Key Trends in the Roof Sheet Manufacturing Sector?

The roof sheet manufacturing sector is experiencing significant shifts driven by global economic changes and advancements in technology. Key trends include the rising demand for lightweight and durable roofing materials, fueled by urbanization and infrastructure development, especially in Africa and South America. As these regions invest in housing and commercial projects, international B2B buyers are prioritizing suppliers who can offer innovative products that meet local climate challenges.

Emerging technologies, such as automated manufacturing processes and digital supply chain management, are transforming sourcing strategies. Buyers are increasingly looking for manufacturers that leverage Industry 4.0 technologies to enhance production efficiency and reduce lead times. Additionally, e-commerce platforms are gaining traction, enabling easier access to global suppliers and a broader selection of roofing materials.

A stock image related to roof sheet manufacturer.

In Europe and the Middle East, there is a notable trend towards adopting advanced materials like polycarbonate and metal composites, which offer superior energy efficiency and sustainability. International buyers are encouraged to engage with manufacturers that can provide these innovative solutions while ensuring compliance with regional building codes and standards. Understanding these dynamics is critical for B2B buyers aiming to make informed sourcing decisions in a competitive market.

How Is Sustainability Shaping the Roof Sheet Manufacturing Sector?

Sustainability is becoming a core consideration for B2B buyers in the roof sheet manufacturing sector. The environmental impact of roofing materials has led to a heightened focus on ethical sourcing and sustainable practices. Buyers are increasingly demanding transparency in the supply chain, seeking out manufacturers that can demonstrate responsible sourcing of raw materials.

The importance of ethical supply chains cannot be overstated. Suppliers who prioritize eco-friendly practices, such as using recycled materials or adopting renewable energy sources in production, are more likely to gain the trust and loyalty of international buyers. Certifications like LEED (Leadership in Energy and Environmental Design) and other green building certifications are essential indicators of a supplier’s commitment to sustainability.

Moreover, using sustainable materials not only minimizes environmental impact but also appeals to a growing segment of consumers who are conscious of their ecological footprint. As a result, B2B buyers should prioritize partnerships with manufacturers that offer green certifications and materials, ensuring their projects contribute positively to the environment while meeting regulatory standards.

What Is the Historical Context of the Roof Sheet Manufacturing Sector?

The roof sheet manufacturing sector has evolved significantly over the past few decades. Initially dominated by traditional materials such as asphalt and wood, the industry has witnessed a shift towards more innovative and sustainable options. The introduction of metal roofing in the late 20th century marked a turning point, providing enhanced durability and energy efficiency.

In recent years, globalization has played a crucial role in shaping the market. Increased competition has led to the adoption of advanced manufacturing technologies and practices. Today, the sector is characterized by a diverse range of materials, including PVC, TPO, and eco-friendly composites, catering to the varied needs of international B2B buyers. Understanding this historical evolution is vital for buyers to appreciate current trends and anticipate future developments in the roofing materials market.

Frequently Asked Questions (FAQs) for B2B Buyers of roof sheet manufacturer

-

How do I choose the right roof sheet manufacturer for my project?

Selecting the right roof sheet manufacturer involves several key factors. First, evaluate their experience and reputation in the industry; look for established companies with positive reviews and successful case studies. Second, consider the range of materials offered, such as galvanized steel, aluminum, or polycarbonate, to ensure they meet your project specifications. Third, assess their production capacity and lead times to ensure timely delivery. Finally, request samples to evaluate quality firsthand and inquire about their certifications to confirm compliance with international standards. -

What is the typical minimum order quantity (MOQ) for roof sheets?

Minimum order quantities for roof sheets can vary significantly by manufacturer and material type. Generally, MOQs may range from 500 to 1,000 square meters. However, some manufacturers may offer lower MOQs for specific products or during promotional periods. It’s essential to communicate your project needs directly with potential suppliers to negotiate terms that align with your requirements and budget. Additionally, consider the cost implications of ordering at or below the MOQ, as shipping and handling costs can influence overall pricing. -

What customization options are available when sourcing roof sheets?

Many roof sheet manufacturers offer customization options to meet specific project needs. Customizations can include varying thicknesses, colors, finishes, and coatings to enhance durability and aesthetics. Some manufacturers may also provide custom sizes to fit unique architectural designs. When discussing your project with suppliers, clearly outline your requirements and ask for design samples or prototypes to ensure the final product meets your expectations. Additionally, confirm any extra costs associated with custom orders, as these may vary based on complexity. -

What payment terms should I expect from roof sheet manufacturers?

Payment terms can vary widely among roof sheet manufacturers and may depend on your location, order size, and the supplier’s policies. Common payment structures include a deposit of 30-50% upfront, with the balance due upon delivery or after the production phase. Some suppliers may also offer credit terms for established businesses. It’s crucial to discuss payment methods (e.g., bank transfer, credit card, or letter of credit) upfront and ensure that the terms are clearly documented in the purchase agreement to avoid misunderstandings. -

How can I ensure quality assurance when sourcing roof sheets internationally?

To ensure quality assurance when sourcing roof sheets internationally, start by requesting certifications from the manufacturer, such as ISO 9001 or relevant industry-specific standards. Conduct thorough supplier vetting by checking references and reviewing customer testimonials. If possible, arrange for an on-site inspection or hire a third-party inspection service to assess the production process and final products before shipment. Additionally, consider requesting quality control reports, including material tests and compliance documentation, to verify that the products meet your specifications. -

What logistics considerations should I keep in mind when importing roof sheets?

Importing roof sheets involves several logistical considerations. First, determine the most cost-effective shipping method based on your budget and timeline—options typically include sea freight, air freight, or land transportation. Next, familiarize yourself with customs regulations and import duties in your country to avoid unexpected fees. Establish a reliable shipping schedule with your supplier and track shipments to ensure timely delivery. Finally, consider warehousing options if you require storage upon arrival, as this can impact your overall logistics strategy. -

What are the common delivery times for roof sheet orders?

Delivery times for roof sheet orders can vary based on several factors, including the manufacturer’s location, production capacity, and order size. Typically, standard lead times range from 4 to 12 weeks. For customized orders, it may take longer due to additional manufacturing processes. To avoid delays, communicate your project timeline to the supplier and request an estimated delivery schedule during the negotiation phase. Additionally, consider potential disruptions in supply chains that may affect timelines, such as political or economic factors in the supplier’s region. -

What factors affect the price of roof sheets from manufacturers?

Several factors influence the price of roof sheets, including material type, thickness, and coating options. Steel and aluminum sheets typically have different price points due to raw material costs. Additionally, customization options such as color, size, and finish can lead to price variations. Production volume also plays a role; larger orders may qualify for bulk pricing discounts. Lastly, logistics costs, including shipping and customs fees, should be factored into the overall price. Always request a detailed quote that breaks down costs to understand the pricing structure fully.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for roof sheet manufacturer

What Are the Key Takeaways for Strategic Sourcing in Roof Sheet Manufacturing?

Strategic sourcing in the roof sheet manufacturing sector is essential for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. Buyers must prioritize partnerships with manufacturers who demonstrate a commitment to quality, sustainability, and innovation. By leveraging local suppliers, businesses can reduce costs and enhance supply chain resilience, which is crucial in an unpredictable global market.

How Can B2B Buyers Enhance Their Sourcing Strategies?

Investing in technology and data analytics can provide insights into supplier performance and market trends, enabling buyers to make informed decisions. Additionally, fostering long-term relationships with suppliers can lead to better pricing, improved quality, and collaborative product development. Understanding regional market dynamics will also empower buyers to negotiate more effectively and align their sourcing strategies with local demands.

What Is the Future Outlook for Roof Sheet Manufacturers?

As the demand for sustainable building materials increases, roof sheet manufacturers will need to adapt by embracing eco-friendly practices and innovations. Buyers should stay ahead of these trends to ensure they partner with manufacturers who align with their values and business goals. By actively engaging in strategic sourcing, international B2B buyers can position themselves to capitalize on emerging opportunities in this evolving market.

In conclusion, the path forward is ripe with potential for proactive buyers. Embrace strategic sourcing today to secure a competitive advantage in the roof sheet manufacturing landscape.