Cut Costs with the Best Stainless Steel Pipes Supplier (2025)

Introduction: Navigating the Global Market for stainless steel pipes supplier

Navigating the global market for stainless steel pipes can be a daunting task, especially for international B2B buyers in regions like Africa, South America, the Middle East, and Europe. With diverse applications ranging from construction to manufacturing, the need for reliable stainless steel pipe suppliers is critical. However, sourcing high-quality products at competitive prices poses significant challenges, including identifying reputable suppliers and understanding regional compliance standards.

This guide is designed to empower B2B buyers by providing comprehensive insights into the stainless steel pipe market. We will explore various types of stainless steel pipes, their applications across industries, and the key factors to consider when vetting potential suppliers. Additionally, we will cover cost considerations, shipping logistics, and the importance of quality certifications to ensure that your procurement processes are both efficient and effective.

By equipping you with actionable knowledge and best practices, this guide aims to facilitate informed purchasing decisions that can lead to enhanced operational efficiency and cost savings. Whether you are a buyer in Nairobi looking for local suppliers or a purchasing manager in Istanbul seeking international options, this resource will serve as your roadmap to successfully navigating the complexities of the stainless steel pipes market.

Understanding stainless steel pipes supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Seamless Stainless Steel Pipes | No welded seams, higher pressure resistance | Oil & gas, chemical processing | Pros: High durability, corrosion resistance. Cons: Typically higher cost. |

| Welded Stainless Steel Pipes | Fabricated by welding, available in various sizes | Construction, plumbing | Pros: Cost-effective, customizable. Cons: Lower pressure tolerance than seamless. |

| Schedule 40 Stainless Steel Pipes | Standardized thickness, versatile for various applications | HVAC, water supply, industrial | Pros: Widely available, good balance of cost and strength. Cons: Limited to standard sizes. |

| Duplex Stainless Steel Pipes | Combination of austenitic and ferritic stainless steel | Marine, chemical, and petrochemical industries | Pros: Excellent strength and corrosion resistance. Cons: More expensive and harder to source. |

| High-Performance Stainless Steel Pipes | Designed for extreme conditions, often with specialized coatings | Aerospace, high-temperature applications | Pros: Exceptional performance, tailored for specific environments. Cons: High cost and limited suppliers. |

What are Seamless Stainless Steel Pipes and Their B2B Relevance?

Seamless stainless steel pipes are manufactured without welded seams, making them ideal for high-pressure applications. Their lack of welds provides a stronger structure, which is critical in industries such as oil and gas, where durability is paramount. When sourcing seamless pipes, international buyers should consider the pipe’s grade and finish, as these factors can significantly affect performance and longevity in corrosive environments.

Why Choose Welded Stainless Steel Pipes for Your Projects?

Welded stainless steel pipes are created by joining flat pieces of steel through welding, allowing for a wide range of sizes and thicknesses. These pipes are commonly used in construction and plumbing due to their cost-effectiveness and adaptability. Buyers should assess the quality of the welds and the material grade to ensure they meet project requirements. While they offer flexibility and lower prices, welded pipes may not withstand the same pressures as seamless options.

How Schedule 40 Stainless Steel Pipes Meet Diverse Needs?

Schedule 40 stainless steel pipes are characterized by their standardized wall thickness, making them suitable for a variety of applications, including HVAC and water supply systems. Their availability in various lengths and diameters allows for easy integration into existing systems. Buyers should consider the specific pressure requirements of their applications, as Schedule 40 pipes are designed for moderate pressure levels, offering a good balance of strength and cost.

What Advantages Do Duplex Stainless Steel Pipes Offer?

Duplex stainless steel pipes combine the properties of austenitic and ferritic steels, providing superior strength and resistance to stress corrosion cracking. They are particularly useful in marine and petrochemical applications, where exposure to harsh environments is common. When purchasing duplex pipes, B2B buyers should consider the specific alloy composition and certifications, as these can influence performance and compliance with industry standards. Although they tend to be more expensive, their long-term durability can justify the investment.

Why Consider High-Performance Stainless Steel Pipes?

High-performance stainless steel pipes are engineered for extreme conditions, often featuring specialized coatings to enhance their resistance to heat and corrosion. They are commonly used in aerospace and other high-temperature applications. Buyers should evaluate the specific performance characteristics required for their projects, as these pipes can be tailored to meet unique demands. While they come with a higher price tag, their reliability in critical applications can lead to significant long-term savings.

Related Video: This is How Stainless Steel Pipe Are Manufactured || Production of Pipes

Key Industrial Applications of stainless steel pipes supplier

| Industry/Sector | Specific Application of stainless steel pipes supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil and Gas | Transporting crude oil and natural gas | High corrosion resistance and durability enhance safety | Compliance with international standards and certifications |

| Food and Beverage | Sanitary piping for food processing | Ensures hygiene and prevents contamination | Quality certifications (e.g., FDA, ISO) and traceability |

| Construction | Structural applications in building and infrastructure | Provides strength and longevity to construction projects | Sourcing from reputable suppliers with reliable delivery |

| Chemical Processing | Handling aggressive chemicals | Resistance to chemical corrosion and high pressure | Material specifications (e.g., ASTM, ASME) and sourcing logistics |

| Pharmaceuticals | Piping systems for drug manufacturing | Maintains purity and prevents contamination | Compliance with stringent regulations and quality control |

How Are Stainless Steel Pipes Used in the Oil and Gas Industry?

In the oil and gas sector, stainless steel pipes are essential for transporting crude oil and natural gas through pipelines. Their high corrosion resistance and durability are crucial in maintaining safety and efficiency in operations. International buyers, particularly in regions like Africa and the Middle East, must ensure that suppliers comply with international standards and certifications to mitigate risks associated with pipeline failures.

What Role Do Stainless Steel Pipes Play in the Food and Beverage Sector?

Stainless steel pipes are extensively used in the food and beverage industry for sanitary piping systems. These pipes ensure hygiene and prevent contamination during the processing and transportation of food products. Buyers should prioritize suppliers who provide quality certifications, such as FDA or ISO, and can demonstrate traceability of their materials to comply with health and safety regulations.

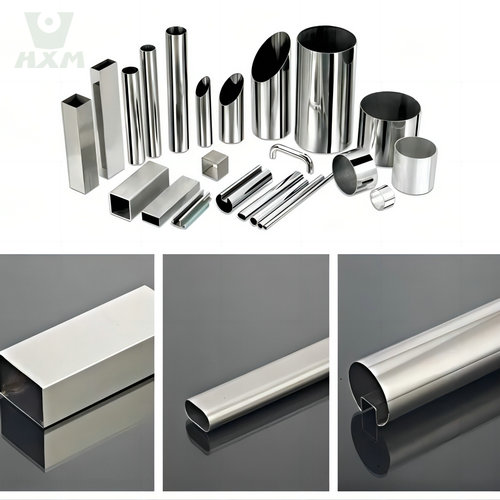

A stock image related to stainless steel pipes supplier.

Why Are Stainless Steel Pipes Important in Construction?

In construction, stainless steel pipes are utilized for structural applications, offering strength and longevity to buildings and infrastructure projects. Their resistance to environmental factors and corrosion extends the lifespan of structures, making them a smart investment. Buyers should focus on sourcing from reputable suppliers known for their reliable delivery and consistent quality to ensure project timelines are met.

How Do Stainless Steel Pipes Benefit Chemical Processing?

In chemical processing, stainless steel pipes are vital for handling aggressive chemicals safely. Their resistance to chemical corrosion and ability to withstand high pressure make them ideal for various applications, from reactors to storage tanks. Buyers must consider material specifications, such as ASTM or ASME standards, and logistics to ensure timely delivery and compliance with industry requirements.

What Is the Significance of Stainless Steel Pipes in Pharmaceuticals?

In the pharmaceutical industry, stainless steel pipes are critical for maintaining the purity of drug manufacturing processes. They prevent contamination and ensure the integrity of sensitive materials. International buyers must navigate stringent regulations and prioritize quality control in their sourcing to guarantee that suppliers adhere to the highest standards of hygiene and safety.

3 Common User Pain Points for ‘stainless steel pipes supplier’ & Their Solutions

Scenario 1: Navigating Quality Assurance in Stainless Steel Pipes Procurement

The Problem:

Many B2B buyers, particularly from regions like Africa and South America, face significant challenges in ensuring the quality of stainless steel pipes. Poor quality materials can lead to project delays, increased costs due to replacements, and potential safety hazards. Buyers often find themselves overwhelmed by the myriad of suppliers, each claiming to offer the best quality. This uncertainty can be particularly pronounced in markets where local regulations and standards may not align with international ones, leading to further complications in sourcing.

The Solution:

To effectively navigate quality assurance, buyers should first establish a comprehensive quality control checklist that aligns with international standards, such as ASTM or ISO certifications. Before committing to a supplier, request samples of their stainless steel pipes and conduct independent material testing to verify claims. Additionally, consider visiting the supplier’s manufacturing facility if possible, or utilize third-party inspection services to ensure compliance with quality standards. Building a relationship with reliable suppliers who have a proven track record in quality assurance can also alleviate concerns. Regular audits and feedback loops with suppliers can ensure ongoing adherence to quality requirements.

Scenario 2: Overcoming Supply Chain Disruptions in Stainless Steel Pipe Delivery

The Problem:

International B2B buyers often encounter supply chain disruptions that can severely impact the delivery timelines of stainless steel pipes. Factors such as political instability, fluctuating shipping costs, and unexpected port delays can hinder timely project completions. Buyers in regions like the Middle East may experience additional challenges due to geopolitical issues, which can further complicate logistics and increase costs.

The Solution:

To mitigate supply chain disruptions, buyers should diversify their supplier base and consider sourcing from multiple countries. Establishing relationships with local suppliers in addition to international ones can help buffer against regional supply chain issues. Implementing a robust logistics management system can also improve visibility and tracking of orders, allowing for proactive adjustments to delivery timelines. Additionally, buyers should negotiate clear terms regarding delivery timelines and penalties for delays in contracts. Building a contingency plan, including alternative suppliers and shipping routes, will provide a safety net against unexpected disruptions.

Scenario 3: Managing Cost Fluctuations in Stainless Steel Pipe Pricing

The Problem:

Cost fluctuations are a common pain point for B2B buyers dealing with stainless steel pipes. Prices can vary significantly due to market demand, raw material costs, and currency fluctuations, especially in regions like Europe and Africa. This unpredictability can strain budgets and complicate project financial planning, making it difficult for buyers to secure the best deals without overextending their budgets.

The Solution:

To effectively manage cost fluctuations, buyers should consider entering into long-term contracts with suppliers that include fixed pricing or price adjustment clauses based on raw material market indexes. This approach can protect against sudden price hikes and provide budget stability. Additionally, regularly monitoring market trends and engaging in forward purchasing can help buyers lock in prices before anticipated increases. Buyers should also explore bulk purchasing options or group buying initiatives with other businesses to take advantage of volume discounts. Building strong relationships with suppliers can lead to better negotiation power and more favorable pricing agreements over time.

Strategic Material Selection Guide for stainless steel pipes supplier

What Are the Key Properties of Common Stainless Steel Pipe Materials?

When selecting stainless steel pipes, understanding the properties of different materials is crucial for ensuring optimal performance in various applications. Here, we analyze four common stainless steel grades used in pipe manufacturing: 304, 316, 321, and Duplex.

1. What Are the Key Properties of 304 Stainless Steel Pipes?

304 stainless steel is one of the most commonly used grades due to its excellent corrosion resistance and formability. It can withstand temperatures up to 870°C (1600°F) and has a pressure rating suitable for most applications. Its primary advantage is its resistance to oxidation and corrosion, making it ideal for environments with moderate corrosive elements.

Pros & Cons:

– Pros: Good corrosion resistance, cost-effective, and easily available.

– Cons: Limited resistance to chlorides, which can lead to pitting in marine environments.

Impact on Application:

304 stainless steel pipes are suitable for food processing, chemical storage, and water systems. However, they may not be the best choice for coastal or marine applications due to their susceptibility to chloride-induced corrosion.

Considerations for International Buyers:

Buyers from regions like Africa and South America should ensure compliance with local standards such as ASTM A312. The availability of 304 pipes is generally high, but buyers should confirm suppliers can meet specific quality certifications.

2. How Does 316 Stainless Steel Compare?

316 stainless steel offers enhanced corrosion resistance compared to 304, particularly against chlorides. It can handle temperatures up to 870°C (1600°F) and is often used in marine applications due to its superior performance in saline environments.

Pros & Cons:

– Pros: Exceptional corrosion resistance, particularly against chlorides; good weldability.

– Cons: Higher cost compared to 304 and slightly lower strength at elevated temperatures.

Impact on Application:

316 stainless steel pipes are ideal for pharmaceutical, marine, and chemical processing industries. Their ability to withstand harsh environments makes them a preferred choice for applications involving seawater or aggressive chemicals.

Considerations for International Buyers:

European buyers should look for compliance with EN 1.4401 standards, while buyers in the Middle East may require adherence to ASME standards. The higher cost may be justified by the long-term savings in maintenance and replacement.

3. What Are the Benefits of Using 321 Stainless Steel?

A stock image related to stainless steel pipes supplier.

321 stainless steel is stabilized with titanium, which enhances its resistance to intergranular corrosion. It can operate effectively at temperatures up to 900°C (1650°F) and is particularly suitable for applications requiring high-temperature stability.

Pros & Cons:

– Pros: Excellent high-temperature performance, good weldability, and resistance to oxidation.

– Cons: Less corrosion-resistant than 316 in chloride environments.

Impact on Application:

321 stainless steel pipes are commonly used in aerospace, automotive exhaust systems, and high-temperature applications. They are not recommended for marine environments due to their susceptibility to pitting.

Considerations for International Buyers:

Buyers in Turkey and the Middle East should ensure compliance with ASTM A312 and other relevant standards. The specialized nature of 321 pipes may limit supplier options, so it’s essential to verify availability.

4. What Is the Advantage of Duplex Stainless Steel?

Duplex stainless steel combines the properties of both austenitic and ferritic stainless steels, offering high strength and excellent corrosion resistance. It can withstand temperatures up to 300°C (572°F) and is particularly effective in environments with high chloride concentrations.

Pros & Cons:

– Pros: High strength-to-weight ratio, excellent resistance to stress corrosion cracking.

– Cons: More complex manufacturing processes, which can lead to higher costs.

Impact on Application:

Duplex stainless steel pipes are ideal for oil and gas applications, chemical processing, and marine environments. Their strength allows for thinner walls, reducing weight without compromising performance.

Considerations for International Buyers:

Buyers should check for compliance with ASTM A790 standards and ensure that suppliers can provide the necessary certifications. The initial higher cost may be offset by reduced maintenance and longer service life.

Summary Table of Stainless Steel Pipe Materials

| Material | Typical Use Case for stainless steel pipes supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 304 | Food processing, chemical storage | Good corrosion resistance | Limited resistance to chlorides | Medium |

| 316 | Marine, pharmaceutical, chemical processing | Exceptional corrosion resistance | Higher cost compared to 304 | High |

| 321 | Aerospace, automotive exhaust systems | Excellent high-temperature performance | Less corrosion-resistant in chlorides | Medium |

| Duplex | Oil & gas, chemical processing, marine environments | High strength-to-weight ratio | Complex manufacturing, higher costs | High |

In-depth Look: Manufacturing Processes and Quality Assurance for stainless steel pipes supplier

What Are the Main Manufacturing Processes for Stainless Steel Pipes?

The manufacturing of stainless steel pipes involves several critical stages, each designed to ensure that the final product meets the required specifications for durability and performance. Understanding these processes can help international B2B buyers make informed decisions when selecting suppliers.

How Is Material Prepared for Stainless Steel Pipe Manufacturing?

The first stage in the manufacturing process is material preparation, which involves sourcing high-quality stainless steel alloys. The most common grades used include 304 and 316, chosen for their corrosion resistance and mechanical properties. Suppliers often procure raw materials from established steel mills, ensuring that they meet the required chemical composition and mechanical properties.

Once the materials are acquired, they undergo testing to confirm their quality. Buyers should verify that suppliers perform rigorous checks, such as spectrometry tests, to ensure compliance with industry standards. This initial step is crucial as it lays the foundation for the entire manufacturing process.

What Forming Techniques Are Used in Stainless Steel Pipe Production?

The next stage is forming, where the prepared stainless steel is shaped into pipes. Two primary techniques are employed:

-

Seamless Pipe Formation: This involves the extrusion of heated metal billets through a die, creating a pipe without seams. Seamless pipes are preferred in high-pressure applications due to their uniform strength and resistance to cracking.

-

Welded Pipe Formation: This method involves rolling flat sheets of stainless steel into a cylindrical shape and welding the edges together. While welded pipes are often more cost-effective, they may be less durable under certain conditions compared to seamless pipes.

B2B buyers should inquire about the forming techniques used by suppliers, as the choice between seamless and welded pipes can significantly impact the application and longevity of the product.

What Are the Key Finishing Processes for Stainless Steel Pipes?

After the pipes have been formed, they undergo finishing processes to enhance their surface quality and performance. Common finishing techniques include:

- Pickling and Passivation: This chemical process removes oxides and impurities from the pipe’s surface, improving corrosion resistance.

- Polishing: A mechanical process that enhances surface smoothness and aesthetic appeal.

- Coating: In some cases, protective coatings are applied to enhance durability in specific environments.

Buyers should verify that suppliers adhere to industry standards for finishing processes, which can affect both the performance and longevity of the pipes.

What Quality Assurance Practices Should B2B Buyers Look For?

Quality assurance is paramount in the manufacturing of stainless steel pipes, ensuring that products meet stringent international standards. B2B buyers should familiarize themselves with key quality assurance practices and certifications.

Which International Standards Should Be Considered?

Several international standards are relevant to the manufacturing and quality assurance of stainless steel pipes:

- ISO 9001: This standard ensures that suppliers have a quality management system in place, focusing on customer satisfaction and continuous improvement.

- CE Marking: Required for products sold in the European Economic Area, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: For pipes used in the oil and gas industry, compliance with API (American Petroleum Institute) standards is critical.

Understanding these standards helps buyers assess the credibility of potential suppliers and their commitment to quality.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are vital throughout the manufacturing process. These typically include:

- Incoming Quality Control (IQC): Initial inspections of raw materials to ensure they meet specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during manufacturing to catch defects early.

- Final Quality Control (FQC): Comprehensive testing of the finished product before shipment.

B2B buyers should request documentation of these QC processes from suppliers, including inspection reports and non-conformance records.

What Testing Methods Are Commonly Used for Stainless Steel Pipes?

Various testing methods are employed to assess the quality and performance of stainless steel pipes. Common tests include:

- Hydrostatic Testing: This involves filling the pipe with water and pressurizing it to check for leaks and structural integrity.

- Ultrasonic Testing: A non-destructive method that uses high-frequency sound waves to detect internal flaws.

- Eddy Current Testing: This technique assesses the conductivity of the material, useful for detecting surface cracks.

Buyers should ensure that suppliers perform these tests and provide certification that confirms compliance with relevant standards.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying the quality control processes of suppliers is essential for B2B buyers, especially when sourcing from different regions. Here are key strategies:

-

Conduct Supplier Audits: Regular audits help assess the manufacturing processes, quality management systems, and adherence to standards.

-

Request Quality Reports: Suppliers should provide detailed quality reports that outline testing results, compliance with standards, and any corrective actions taken.

-

Engage Third-Party Inspectors: Independent inspections can provide unbiased evaluations of product quality and manufacturing processes.

-

Examine Certification Documents: Ensure that suppliers have valid certifications that demonstrate compliance with international standards.

B2B buyers from regions such as Africa, South America, the Middle East, and Europe (e.g., Kenya, Turkey) should prioritize these verification steps to ensure they are partnering with reliable suppliers who prioritize quality.

Conclusion

Understanding the manufacturing processes and quality assurance practices for stainless steel pipes is crucial for international B2B buyers. By focusing on material preparation, forming techniques, finishing processes, and rigorous quality control measures, buyers can make informed decisions that ensure the integrity and performance of their piping solutions. Engaging with suppliers who uphold international standards and provide transparent quality assurance documentation will contribute to successful procurement and long-term partnerships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘stainless steel pipes supplier’

In today’s global marketplace, sourcing stainless steel pipes requires a strategic approach, especially for international B2B buyers from regions like Africa, South America, the Middle East, and Europe. This checklist will guide you through the essential steps to ensure that you select the right supplier for your needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s crucial to clarify your specific requirements. This includes determining the size, grade, and type of stainless steel pipes needed for your project. Having a detailed specification helps suppliers provide accurate quotations and ensures that the materials meet your operational standards.

– Key Considerations:

– Corrosion resistance levels

– Pressure ratings and temperature limits

Step 2: Conduct Market Research

Understanding the market landscape is vital. Research potential suppliers by exploring online directories, trade shows, and industry publications. This step helps you identify reputable suppliers and understand pricing trends in different regions.

– Research Tips:

– Look for reviews and testimonials from previous customers.

– Identify suppliers that specialize in your industry’s requirements.

Step 3: Evaluate Potential Suppliers

Before committing, thoroughly vet your shortlisted suppliers. Request company profiles, case studies, and references from buyers in similar industries. A reliable supplier should have a proven track record of quality and service.

– Evaluation Criteria:

– Production capacity and lead times

– Quality control processes and certifications (ISO, ASTM)

Step 4: Verify Supplier Certifications

Ensure that your potential suppliers hold the necessary certifications and comply with international standards. Certifications not only demonstrate a commitment to quality but also ensure that the products meet safety and regulatory requirements in your region.

– Important Certifications:

– ISO 9001 for quality management systems

– Relevant industry standards such as ASTM A312 for stainless steel pipes

Step 5: Request Samples for Testing

Before making a bulk purchase, ask for samples of the stainless steel pipes. Testing the samples for durability, corrosion resistance, and compliance with your specifications is a crucial step to mitigate risks associated with material quality.

– Testing Methods:

– Laboratory analysis for chemical composition

– Physical testing for strength and flexibility

Step 6: Negotiate Terms and Conditions

Once you’ve selected a supplier, negotiate terms that protect your interests. This includes pricing, payment terms, delivery schedules, and after-sales support. Clear agreements help avoid misunderstandings and ensure a smooth transaction.

– Negotiation Points:

– Bulk order discounts and payment options

– Warranty and return policies

Step 7: Establish a Communication Plan

Effective communication is essential for successful sourcing. Set up regular check-ins and updates with your supplier to monitor progress and address any issues that may arise during the order process.

– Communication Strategies:

– Utilize project management tools for tracking orders

– Schedule periodic reviews to assess supplier performance

By following this structured checklist, you can confidently navigate the sourcing process for stainless steel pipes, ensuring that you select a supplier that meets your technical and logistical requirements.

Comprehensive Cost and Pricing Analysis for stainless steel pipes supplier Sourcing

What Are the Key Cost Components for Sourcing Stainless Steel Pipes?

When sourcing stainless steel pipes, international B2B buyers must understand the various cost components that contribute to the overall pricing. These include:

-

Materials: The primary cost driver, stainless steel prices fluctuate based on market conditions, alloy composition, and global demand. Buyers should monitor commodity markets to anticipate changes in pricing.

-

Labor: Labor costs vary significantly by region. In developing economies like Kenya or Turkey, labor may be less expensive than in Europe, impacting overall pricing. However, skilled labor for quality assurance can increase costs.

-

Manufacturing Overhead: This encompasses costs related to utilities, maintenance, and factory management. Efficient production processes can help minimize overhead and reduce overall costs.

-

Tooling: The initial investment in tooling can be substantial, especially for customized pipe specifications. Buyers should consider how tooling costs are amortized over production runs.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability but adds to the overall cost. Certifications, especially for industries like oil and gas, can elevate prices but are often essential.

-

Logistics: Shipping costs can vary based on distance, mode of transport, and delivery timelines. International buyers should evaluate logistics partners to optimize shipping routes and costs.

-

Margin: Supplier profit margins can differ widely. Understanding the margin expectations of suppliers can help buyers negotiate better deals.

How Do Price Influencers Impact the Cost of Stainless Steel Pipes?

Several factors influence the pricing of stainless steel pipes, and recognizing these can aid in strategic sourcing:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically yield lower per-unit costs. Negotiating favorable MOQs can lead to significant savings.

-

Specifications and Customization: Custom dimensions or unique specifications can increase costs. Buyers should balance customization needs with budget constraints.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., ISO, ASTM) can drive up costs. Buyers must assess whether the additional investment aligns with their project requirements.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge a premium for quality assurance, while lesser-known suppliers might offer lower prices with higher risks.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF) affects the overall cost. Understanding these terms can help buyers better manage shipping responsibilities and associated costs.

What Negotiation Tips Can Help B2B Buyers Secure Better Pricing?

Effective negotiation strategies can enhance cost-efficiency for international buyers:

-

Conduct Market Research: Understand current market trends and pricing benchmarks to empower your negotiation position.

-

Emphasize Long-term Relationships: Suppliers value steady business. Highlighting the potential for ongoing orders can motivate them to offer better pricing.

-

Leverage Competitive Quotes: Obtain multiple quotes to create a competitive atmosphere. This can be a powerful negotiation tool.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. Factor in logistics, maintenance, and potential downtime costs to evaluate the true value of the supplier’s offer.

What Are the Pricing Nuances for International Buyers from Diverse Regions?

For B2B buyers from Africa, South America, the Middle East, and Europe, understanding regional pricing nuances is crucial:

-

Currency Fluctuations: Exchange rate volatility can significantly impact costs. Buyers should consider hedging strategies to mitigate risks.

-

Regulatory Compliance: Different regions have varying regulations, which can affect pricing. Buyers should ensure their suppliers comply with local standards to avoid additional costs.

-

Cultural Differences in Negotiation: Understanding cultural negotiation styles can improve communication and lead to better outcomes.

Disclaimer: Prices for stainless steel pipes can vary widely based on market conditions, supplier capabilities, and specific project requirements. It is advisable to conduct thorough research and seek multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing stainless steel pipes supplier With Other Solutions

In the global market for industrial materials, particularly in regions like Africa, South America, the Middle East, and Europe, the choice of suppliers for stainless steel pipes can significantly impact project outcomes. Buyers often seek alternatives that may provide comparable performance, cost-effectiveness, and suitability for their specific applications. This analysis will explore how stainless steel pipes suppliers measure up against two viable alternatives: PVC piping and carbon steel piping.

Comparison Table of Stainless Steel Pipes Supplier with Alternatives

| Comparison Aspect | Stainless Steel Pipes Supplier | PVC Piping | Carbon Steel Piping |

|---|---|---|---|

| Performance | High corrosion resistance, durability, and strength | Good for low-pressure applications, but less durable | Strong and robust, suitable for high-pressure systems |

| Cost | Generally higher initial cost, but lower long-term costs | Low initial cost, but may require frequent replacements | Moderate initial cost, but prone to corrosion without protective coatings |

| Ease of Implementation | Requires specialized skills for installation | Easy to install; lightweight and flexible | Requires skilled labor for installation, heavier than PVC |

| Maintenance | Low maintenance, long lifespan | Moderate maintenance; can degrade under UV light | Requires regular maintenance to prevent rust and corrosion |

| Best Use Case | Ideal for high-pressure, corrosive environments | Best for drainage and irrigation | Suitable for high-pressure systems, oil and gas applications |

What Are the Pros and Cons of PVC Piping?

PVC piping is a popular alternative due to its low cost and ease of installation. It is lightweight and flexible, making it an attractive option for projects requiring quick assembly. However, PVC is less durable than stainless steel, especially in high-temperature and high-pressure applications. Additionally, it can degrade under UV light, necessitating more frequent replacements and leading to higher long-term costs despite its lower initial price. Thus, while PVC is suitable for drainage and irrigation systems, it is not recommended for applications requiring high durability.

How Does Carbon Steel Piping Compare?

Carbon steel piping is another alternative that offers robust strength, making it suitable for high-pressure applications. Its moderate initial cost can be appealing, especially for larger projects. However, carbon steel is prone to corrosion and typically requires protective coatings or regular maintenance to ensure longevity. In environments where corrosion is a concern, carbon steel may not be the best choice. Despite its advantages in strength, the need for maintenance can lead to increased operational costs over time.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When evaluating options between a stainless steel pipes supplier and alternatives like PVC or carbon steel piping, B2B buyers should carefully consider the specific requirements of their projects. Factors such as performance needs, budget constraints, installation capabilities, and maintenance commitments are crucial in making an informed decision. For projects demanding high durability and resistance to corrosion, stainless steel remains the superior choice. Conversely, for less demanding applications where cost is a primary concern, PVC may suffice. Carbon steel can serve as a middle-ground option but requires diligent maintenance to ensure its effectiveness. By weighing these aspects, buyers from diverse regions can select the solution that aligns best with their operational objectives and environmental conditions.

Essential Technical Properties and Trade Terminology for stainless steel pipes supplier

What Are the Key Technical Properties of Stainless Steel Pipes?

Understanding the essential technical properties of stainless steel pipes is crucial for B2B buyers seeking to make informed purchasing decisions. Here are some critical specifications that you should consider:

-

Material Grade

Stainless steel pipes are available in various grades, such as 304, 316, and 321. Each grade has unique properties suited for specific applications. For example, Grade 316 is more resistant to corrosion, making it ideal for marine environments. Buyers should choose the appropriate grade based on environmental factors and the intended use of the pipes. -

Wall Thickness

The wall thickness of stainless steel pipes affects their strength and durability. Common standards include Schedule 40 and Schedule 80, with thicker walls providing higher pressure ratings. Understanding the wall thickness helps buyers ensure that the pipes can withstand the required pressure and temperature conditions in their applications. -

Diameter

The diameter of the pipes is another critical property that impacts flow rates and system design. Buyers should specify both outer diameter (OD) and inner diameter (ID) to ensure compatibility with existing systems. A mismatch can lead to inefficiencies or system failures. -

Tolerance

Tolerance refers to the allowable variation in dimensions of the pipes. Tight tolerances are essential for applications requiring precise fittings. Buyers should inquire about the manufacturer’s tolerance specifications to ensure that the pipes will fit seamlessly within their systems. -

Finish

The surface finish of stainless steel pipes can range from mill finish to polished or brushed. The finish affects not only the aesthetic appeal but also the corrosion resistance and ease of cleaning. Buyers in industries such as food processing or pharmaceuticals should prioritize smoother finishes to meet hygiene standards. -

Yield Strength

Yield strength indicates the maximum stress a material can withstand without permanent deformation. For stainless steel pipes, this property is crucial for structural integrity, especially in high-pressure applications. Buyers should check the yield strength to ensure the pipes will perform adequately under load.

What Are Common Trade Terms in the Stainless Steel Pipe Industry?

Familiarity with industry jargon is essential for effective communication and negotiation with suppliers. Here are some common terms you should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers source quality components that meet their specifications. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is vital for budgeting and inventory management, especially for international buyers who may face additional shipping costs for smaller orders.

-

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. It is essential for buyers to prepare detailed RFQs to obtain accurate quotes and compare suppliers effectively. -

Incoterms (International Commercial Terms)

These are predefined commercial terms published by the International Chamber of Commerce (ICC) that outline the responsibilities of buyers and sellers in international transactions. Understanding Incoterms helps buyers clarify shipping responsibilities, costs, and risk management in their contracts. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. For B2B buyers, understanding lead times is crucial for project planning and ensuring that materials arrive when needed. -

Certification

Certifications, such as ASTM or ISO standards, indicate that the products meet specific quality and safety standards. Buyers should verify the certifications of their suppliers to ensure compliance with industry regulations.

In conclusion, being well-versed in the technical properties and trade terminology related to stainless steel pipes can significantly enhance your procurement strategy. By considering these factors, international B2B buyers can make more informed decisions that align with their operational needs and industry standards.

Navigating Market Dynamics and Sourcing Trends in the stainless steel pipes supplier Sector

What Are the Key Market Trends Impacting the Stainless Steel Pipes Supplier Sector?

The stainless steel pipes supplier sector is experiencing dynamic changes driven by various global factors. One significant driver is the increasing demand for corrosion-resistant materials across multiple industries, including construction, oil and gas, and food processing. Emerging markets in Africa and South America are witnessing infrastructural growth, which fuels the demand for durable and reliable piping solutions. Additionally, advancements in manufacturing technologies, such as automation and 3D printing, are enhancing production efficiency and reducing lead times, making it easier for suppliers to respond to international buyers’ needs.

International B2B buyers are also increasingly leveraging digital platforms for sourcing. The rise of e-commerce and online marketplaces allows for greater transparency and easier comparison of suppliers. This trend is particularly relevant in regions like the Middle East and Europe, where buyers are seeking competitive pricing and quality assurance. Furthermore, the integration of Artificial Intelligence (AI) and data analytics in supply chain management is enabling suppliers to predict market trends, optimize inventory levels, and improve customer service.

How Is Sustainability Shaping the Sourcing Strategies for Stainless Steel Pipes?

Sustainability has become a central focus in the sourcing strategies of stainless steel pipe suppliers. The environmental impact of manufacturing processes is under scrutiny, and buyers are increasingly prioritizing suppliers who demonstrate commitment to sustainable practices. This includes reducing carbon footprints, minimizing waste, and utilizing energy-efficient production methods.

Ethical sourcing is also gaining traction. B2B buyers are now more aware of the importance of traceability in supply chains, ensuring that materials are sourced responsibly. Certifications such as ISO 14001 for environmental management and other ‘green’ certifications serve as benchmarks for suppliers. By choosing suppliers with these credentials, international buyers can align their procurement processes with corporate social responsibility goals and enhance their brand reputation in the market.

What Is the Historical Context of Stainless Steel Pipes in B2B Markets?

The stainless steel pipes sector has evolved significantly since the mid-20th century when stainless steel was first introduced as a viable material for piping. Initially utilized in specialized applications, its popularity surged due to its inherent properties like strength, corrosion resistance, and longevity. Over the decades, advancements in metallurgy and processing techniques have expanded its applications across various industries.

The globalization of supply chains in the late 20th century further transformed the market, enabling suppliers from different regions to compete on a global scale. Today, the sector is characterized by a mix of established players and emerging suppliers, creating a competitive landscape that benefits international buyers. This historical evolution underscores the importance of understanding market dynamics and sourcing trends to make informed purchasing decisions.

In conclusion, international B2B buyers in regions like Africa, South America, the Middle East, and Europe must navigate these market dynamics thoughtfully. By staying informed about technological advancements, sustainability initiatives, and historical context, they can enhance their sourcing strategies and foster long-term partnerships with reliable suppliers in the stainless steel pipes sector.

Frequently Asked Questions (FAQs) for B2B Buyers of stainless steel pipes supplier

-

How do I choose the right stainless steel pipes supplier for my business?

When selecting a stainless steel pipes supplier, consider their industry experience, product range, and reputation. Verify their certifications and compliance with international quality standards, such as ISO 9001. Additionally, assess their ability to meet your specific needs, including material grades and sizes. Engaging with existing customers for testimonials can also provide insight into their reliability and service levels. -

What is the minimum order quantity (MOQ) for stainless steel pipes?

Minimum order quantities can vary significantly among suppliers. Typically, MOQs range from a few tons to several hundred tons depending on the supplier’s production capabilities and inventory policies. It’s advisable to discuss your project requirements directly with potential suppliers to negotiate terms that align with your purchasing needs while considering your budget and storage capacity. -

What payment terms should I expect when sourcing stainless steel pipes internationally?

Payment terms for international transactions can vary based on the supplier’s policies and the buyer’s creditworthiness. Common options include advance payment, letter of credit, or payment upon delivery. It’s important to clarify these terms upfront to avoid misunderstandings. Additionally, ensure you understand any currency exchange implications and transaction fees that may arise. -

How can I ensure the quality of stainless steel pipes before purchase?

To ensure quality, request certifications and test reports that verify compliance with relevant standards, such as ASTM or EN. Consider conducting independent inspections during production and before shipment. Some suppliers may offer samples for evaluation prior to a larger order. Establishing a clear quality assurance process is crucial for mitigating risks related to product defects. -

What customization options are available for stainless steel pipes?

Many suppliers offer customization options, including specific dimensions, wall thicknesses, and finishes tailored to your project’s requirements. Inquire about the availability of specialized grades for particular applications, such as corrosion resistance or high-temperature performance. Providing detailed specifications to the supplier will help them understand your needs and deliver the right product. -

How does logistics work for international shipments of stainless steel pipes?

Logistics for international shipments typically involves coordinating with freight forwarders, customs brokers, and shipping lines. Discuss with your supplier how they handle logistics, including packaging, labeling, and documentation. Understanding delivery timelines, shipping costs, and customs duties is essential to ensure smooth transportation and compliance with local regulations in your country. -

What should I consider when vetting a stainless steel pipes supplier?

When vetting a supplier, evaluate their production capacity, lead times, and reliability. Assess their financial stability by reviewing their business history and credit ratings. Additionally, look into their customer service responsiveness and post-sale support. Engaging in direct communication can provide valuable insights into their professionalism and willingness to meet your needs. -

What are the common applications for stainless steel pipes in various industries?

Stainless steel pipes are widely used across several industries, including construction, oil and gas, food processing, and pharmaceuticals. Their corrosion resistance and strength make them ideal for transporting fluids and gases. Additionally, they are often utilized in structural applications and as part of equipment manufacturing. Identifying the specific application for your project can guide you in selecting the appropriate type of stainless steel pipe.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for stainless steel pipes supplier

What Are the Key Takeaways for International B2B Buyers of Stainless Steel Pipes?

In today’s competitive landscape, the value of strategic sourcing for stainless steel pipes cannot be overstated. Buyers from Africa, South America, the Middle East, and Europe must prioritize suppliers who not only offer high-quality materials but also demonstrate reliability and flexibility in meeting diverse project needs. Understanding the intricacies of global supply chains, including logistics and compliance with local regulations, is essential for minimizing risks and optimizing procurement processes.

How Can Strategic Sourcing Impact Your Procurement Strategy?

By leveraging strategic sourcing, businesses can foster long-term partnerships with suppliers, ensuring better pricing, quality assurance, and more responsive service. It enables companies to adapt to market fluctuations and enhances their ability to innovate, ultimately leading to a competitive edge. For instance, buyers in Kenya and Turkey can benefit from local suppliers who understand regional challenges and can provide tailored solutions.

What Should You Do Next?

As you navigate the sourcing landscape, consider engaging with suppliers who align with your strategic goals. Evaluate their capabilities, certifications, and customer service track records to ensure alignment with your business needs. The future of sourcing stainless steel pipes lies in collaboration and transparency—embrace these principles to drive your procurement success. Start building those vital connections today to secure a robust supply chain for tomorrow.