Cut Costs with the Best Terminal Block Supplier Guide (2025)

Introduction: Navigating the Global Market for terminal block supplier

Navigating the intricate landscape of sourcing terminal block suppliers can be a daunting challenge for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. With the increasing demand for reliable electrical connectivity solutions, understanding the nuances of terminal block products is vital. This guide is designed to equip you with the knowledge necessary to make informed purchasing decisions, addressing everything from the various types of terminal blocks and their specific applications to effective supplier vetting processes and cost considerations.

In an era where quality and compliance are paramount, knowing how to evaluate suppliers based on their certifications, manufacturing standards, and customer service can significantly impact your business operations. This comprehensive resource will delve into the essential factors to consider when selecting a terminal block supplier, including regional market trends, logistics, and import regulations that specifically affect buyers in countries like Nigeria and Egypt.

By the end of this guide, you will be empowered with actionable insights and strategies to enhance your procurement process, enabling you to navigate the global market with confidence. Whether you are a seasoned purchasing manager or new to the B2B landscape, the information presented here will help streamline your sourcing efforts and foster successful partnerships with terminal block suppliers around the world.

Understanding terminal block supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Screw Terminal Blocks | Use screws for secure wire connections; versatile | Industrial machinery, electrical panels | Pros: Reliable, easy to assemble; Cons: Slower installation time compared to other types. |

| Spring Terminal Blocks | Utilize spring mechanisms for quick wire insertion | Automation, control systems | Pros: Fast installation, reusable connections; Cons: Limited wire size compatibility. |

| Barrier Terminal Blocks | Offer physical separation between circuits; enhanced safety | Power distribution, safety systems | Pros: Increased safety, clear circuit identification; Cons: Can be bulkier and more expensive. |

| Plug-in Terminal Blocks | Allow for easy removal and replacement of circuits | Telecommunications, modular equipment | Pros: Simplifies maintenance, flexible configuration; Cons: Requires more space and may be less robust. |

| DIN Rail Terminal Blocks | Designed for mounting on DIN rails; standardized sizes | Control cabinets, electrical enclosures | Pros: Space-efficient, organized layout; Cons: May require additional mounting hardware. |

What Are Screw Terminal Blocks and Their B2B Relevance?

Screw terminal blocks are widely recognized for their reliability and versatility. They feature screws that secure wires firmly, making them suitable for high-vibration environments like industrial machinery and electrical panels. When purchasing screw terminal blocks, B2B buyers should consider the ease of assembly and the time required for installation, as these blocks may take longer to set up compared to other types. Their robustness makes them a favored choice for applications where secure connections are paramount.

Why Choose Spring Terminal Blocks for Your Business Needs?

Spring terminal blocks are designed for quick wire insertion, utilizing a spring mechanism that allows for rapid installation and reusability. They are particularly advantageous in automation and control systems where efficiency is critical. Buyers should consider the wire size compatibility and the specific application requirements, as these blocks may not accommodate larger wire gauges. Their speed of installation can significantly reduce labor costs, making them an attractive option for fast-paced environments.

How Do Barrier Terminal Blocks Enhance Safety in B2B Applications?

Barrier terminal blocks provide physical separation between circuits, enhancing safety and preventing accidental short circuits. They are commonly used in power distribution and safety systems, where clear circuit identification is essential. B2B buyers should evaluate the layout and space requirements, as these blocks can be bulkier and more expensive than other options. Their robust design offers peace of mind in critical applications, making them worth the investment for safety-conscious businesses.

What Benefits Do Plug-in Terminal Blocks Offer for Maintenance?

Plug-in terminal blocks facilitate easy removal and replacement of circuits, making them ideal for telecommunications and modular equipment. Their flexibility allows for quick adjustments and repairs, which can minimize downtime. However, buyers must consider the space required for installation, as these blocks may take up more room and may not be as robust as fixed alternatives. For businesses that prioritize maintenance and adaptability, plug-in terminal blocks can streamline operations significantly.

Why Are DIN Rail Terminal Blocks Popular in Control Cabinets?

DIN rail terminal blocks are specifically designed for mounting on standardized DIN rails, providing an organized and space-efficient solution for control cabinets and electrical enclosures. They are favored for their ability to create a neat layout, which can be crucial in complex electrical systems. Buyers should consider the potential need for additional mounting hardware and the overall design of their electrical setups. The convenience and efficiency of DIN rail terminal blocks make them a smart choice for businesses looking to optimize their installations.

Related Video: Terminal Block Connection Types

Key Industrial Applications of terminal block supplier

| Industry/Sector | Specific Application of Terminal Block Supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Electrical Panel Assembly | Streamlined wiring processes, enhanced safety | Compliance with local standards, customization needs |

| Renewable Energy | Solar Power Systems | Improved energy efficiency, reduced installation time | Compatibility with various solar technologies, durability |

| Transportation & Logistics | Automotive Wiring Harnesses | Increased reliability, reduced maintenance costs | Supplier certifications, bulk purchasing options |

| Industrial Automation | Control Systems for Machinery | Enhanced operational efficiency, minimized downtime | Technical support, availability of spare parts |

| Construction & Infrastructure | Building Electrical Systems | Improved safety, adherence to regulations | Local market knowledge, shipping logistics |

How Are Terminal Block Suppliers Used in Manufacturing Electrical Panel Assembly?

In the manufacturing sector, terminal blocks are essential for electrical panel assembly. They facilitate the organization and connection of wires, ensuring safety and efficiency in electrical systems. By using terminal blocks, manufacturers can streamline their wiring processes, reducing the risk of errors and enhancing the overall safety of their panels. For international buyers, especially in regions like Africa and South America, sourcing terminal blocks that meet local compliance standards is crucial. Customization options may also be necessary to fit specific manufacturing needs.

What Role Do Terminal Block Suppliers Play in Renewable Energy Systems?

In the renewable energy sector, particularly solar power systems, terminal blocks serve as a critical component for connecting various electrical elements. They help improve energy efficiency by providing reliable connections that minimize energy loss. Buyers from the Middle East and Europe should consider sourcing terminal blocks that are compatible with different solar technologies and are durable enough to withstand environmental conditions. This ensures a long-lasting and efficient solar installation, reducing the need for frequent replacements.

How Are Terminal Blocks Essential in Automotive Wiring Harnesses?

In the transportation and logistics industry, terminal blocks are widely used in automotive wiring harnesses. They ensure reliable connections between various components, which is essential for vehicle performance and safety. By using high-quality terminal blocks, automotive manufacturers can reduce maintenance costs and enhance the reliability of their vehicles. When sourcing these components, international buyers should prioritize suppliers with the necessary certifications and the ability to accommodate bulk orders to meet production demands.

Why Are Terminal Blocks Important for Control Systems in Industrial Automation?

Terminal blocks play a vital role in control systems for machinery within the industrial automation sector. They facilitate secure and organized wiring, which is crucial for enhancing operational efficiency and minimizing downtime. For international B2B buyers, particularly in Europe and the Middle East, it is important to consider suppliers that offer technical support and readily available spare parts. This ensures that any potential issues can be swiftly addressed, maintaining productivity in automated systems.

How Do Terminal Blocks Contribute to Building Electrical Systems in Construction?

In the construction and infrastructure sector, terminal blocks are integral to building electrical systems. They help ensure safe and efficient connections among various electrical components, adhering to strict safety regulations. For buyers in regions like Nigeria and Egypt, sourcing terminal blocks that are tailored to local market conditions and regulations is essential. Additionally, understanding shipping logistics can help streamline the procurement process, ensuring timely delivery and installation of electrical systems.

Related Video: Terminal Blocks Explained

3 Common User Pain Points for ‘terminal block supplier’ & Their Solutions

Scenario 1: Delays in Product Delivery and Supply Chain Disruptions

The Problem:

B2B buyers often face significant challenges related to delays in product delivery. This can be particularly acute for businesses in regions like Africa and South America, where logistics and infrastructure may not be as robust. For instance, a manufacturing company in Nigeria may experience setbacks in their production schedules due to late arrivals of terminal blocks. Such delays can lead to halted operations, increased costs, and strained client relationships, ultimately affecting the bottom line.

The Solution:

To mitigate delivery delays, buyers should establish strong communication channels with their terminal block suppliers. This includes setting clear expectations regarding lead times and delivery schedules. It’s advisable to work with suppliers who offer real-time tracking systems that provide updates on the status of shipments. Additionally, diversifying the supplier base can be beneficial; by having multiple suppliers in different geographical locations, companies can ensure that production isn’t solely dependent on one source. For example, sourcing terminal blocks from both local and international suppliers can reduce lead time and provide more reliable options during peak demand periods.

Scenario 2: Difficulty in Selecting the Right Terminal Block Specifications

The Problem:

Another common pain point for B2B buyers is the complexity involved in selecting the appropriate terminal block specifications for their applications. Buyers from various industries may struggle to understand the technical requirements, such as voltage ratings, current capacities, and material compatibility. A buyer in the Middle East, for instance, might find themselves unsure whether to opt for a screw-type or spring-type terminal block for a specific project, leading to potential mismatches and operational inefficiencies.

The Solution:

To overcome specification challenges, buyers should invest time in understanding their specific needs and the technical characteristics of terminal blocks. Engaging with suppliers who provide comprehensive technical support and product catalogs can be invaluable. It’s advisable to request samples or technical datasheets to gain insights into performance metrics. Additionally, participating in webinars or training sessions offered by suppliers can deepen understanding. Establishing a relationship with a knowledgeable supplier can also facilitate tailored recommendations based on the buyer’s unique application requirements, ensuring optimal product selection.

Scenario 3: Concerns Over Quality Assurance and Compliance Standards

The Problem:

Quality assurance and compliance with industry standards are significant concerns for B2B buyers, especially in regions where regulations can vary widely. Buyers from Europe may demand compliance with specific European standards (like CE marking), while those in South America might have different certification requirements. A terminal block that does not meet local compliance can lead to legal issues, product recalls, and damage to reputation.

The Solution:

To address quality assurance concerns, buyers should thoroughly vet terminal block suppliers for their compliance with relevant industry standards. This can be achieved by requesting certification documents and quality assurance processes that suppliers adhere to. Engaging in regular audits or requesting third-party certifications can also enhance confidence in product quality. Furthermore, buyers should consider establishing long-term relationships with suppliers that prioritize quality management and demonstrate consistent adherence to both local and international compliance standards. By doing so, they can ensure that their terminal blocks not only meet operational needs but also align with regulatory requirements, safeguarding their business interests.

Strategic Material Selection Guide for terminal block supplier

When selecting terminal blocks, the choice of materials is critical for ensuring optimal performance, longevity, and compliance with industry standards. Here, we analyze four common materials used in terminal block manufacturing, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Polyamide (PA) in Terminal Blocks?

Polyamide, commonly known as nylon, is a widely used thermoplastic in terminal block applications. It offers excellent mechanical strength and durability, with a temperature rating typically ranging from -40°C to 120°C. Additionally, polyamide exhibits good resistance to various chemicals, making it suitable for diverse environments.

Pros & Cons: The key advantage of polyamide is its high impact resistance and flexibility, which allows it to withstand harsh conditions. However, it can be susceptible to UV degradation over time, particularly in outdoor applications, and may require additional treatments for enhanced weather resistance.

Impact on Application: Polyamide is compatible with a range of media, including oils and fuels, making it suitable for automotive and industrial applications.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and DIN, especially in regions with strict regulatory requirements. In Africa and the Middle East, understanding local environmental conditions is crucial for selecting the right material.

How Does Polyvinyl Chloride (PVC) Perform in Terminal Block Applications?

Polyvinyl chloride (PVC) is another popular material for terminal blocks, known for its excellent electrical insulation properties and resistance to moisture. PVC can typically withstand temperatures from -15°C to 70°C, making it suitable for various indoor applications.

Pros & Cons: One of the primary advantages of PVC is its low cost and ease of manufacturing, which makes it an economical choice for many applications. However, it has a lower temperature tolerance compared to other materials and may not perform well in high-heat environments.

Impact on Application: PVC is ideal for applications where moisture resistance is critical, such as in electrical installations in humid climates.

Considerations for International Buyers: Buyers should be aware of the potential for chemical leaching in certain applications, especially in food processing. Compliance with local standards, such as JIS in Japan or EN in Europe, is also essential.

What Benefits Does Thermoplastic Elastomer (TPE) Offer for Terminal Blocks?

Thermoplastic elastomer (TPE) is a versatile material that combines the properties of rubber and plastic. It offers excellent flexibility and can operate within a temperature range of -40°C to 100°C.

Pros & Cons: TPE provides outstanding resistance to abrasion and impact, making it suitable for dynamic applications. However, it can be more expensive than other materials and may require specialized manufacturing processes.

Impact on Application: TPE is particularly effective in applications that require frequent movement or vibration, such as in automotive and robotics sectors.

Considerations for International Buyers: Buyers should consider the specific performance requirements of their applications and ensure that TPE products meet relevant international standards. In regions like Europe, compliance with RoHS and REACH regulations is crucial.

Why Choose Metal (Brass or Copper) for Terminal Blocks?

Metal terminal blocks, particularly those made from brass or copper, are known for their excellent conductivity and strength. They can handle high current loads and typically operate effectively in temperatures ranging from -40°C to 150°C.

Pros & Cons: The primary advantage of metal terminal blocks is their superior electrical conductivity, making them ideal for high-power applications. However, they can be prone to corrosion if not properly coated or treated, which may limit their use in certain environments.

Impact on Application: Metal terminal blocks are essential in applications requiring reliable electrical connections, such as in power distribution systems.

Considerations for International Buyers: Buyers should consider the environmental conditions of their applications, particularly in coastal areas where corrosion is a concern. Compliance with standards such as ASTM for material specifications is also necessary.

Summary Table of Material Properties for Terminal Blocks

| Material | Typical Use Case for terminal block supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyamide (PA) | Automotive and industrial applications | High impact resistance and flexibility | Susceptible to UV degradation | Medium |

| Polyvinyl Chloride (PVC) | Indoor electrical installations | Low cost and excellent moisture resistance | Lower temperature tolerance | Low |

| Thermoplastic Elastomer (TPE) | Dynamic applications in robotics | Outstanding flexibility and abrasion resistance | Higher cost and manufacturing complexity | High |

| Metal (Brass/Copper) | Power distribution systems | Superior electrical conductivity | Prone to corrosion without treatment | Medium |

This guide aims to equip B2B buyers with the necessary insights to make informed decisions regarding material selection for terminal blocks, ensuring compatibility with their specific applications and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for terminal block supplier

What Are the Main Stages of Manufacturing Terminal Blocks?

The manufacturing of terminal blocks involves several critical stages, each contributing to the final product’s quality and performance. Understanding these stages can help international B2B buyers make informed decisions when selecting suppliers.

Material Preparation: What Materials Are Used in Terminal Blocks?

The first step in manufacturing terminal blocks is material preparation. Common materials include:

- Thermoplastics: Used for insulation, these materials provide electrical resistance and durability.

- Copper or Brass: These metals are typically used for the conductive parts due to their excellent electrical properties.

- Plating Materials: Often nickel or tin, these are applied to enhance corrosion resistance and improve conductivity.

During this stage, suppliers should ensure that materials meet international standards and specifications, which can significantly influence the terminal block’s performance and longevity.

How Are Terminal Blocks Formed?

Once materials are prepared, the forming stage begins. Key techniques include:

- Injection Molding: This process is commonly used for creating the plastic housings of terminal blocks. It allows for complex shapes and high precision.

- Stamping and Machining: For metal components, stamping is used to create flat parts, while machining is employed for more intricate designs.

Buyers should inquire about the specific techniques used by suppliers, as these can impact the overall quality and consistency of the terminal blocks produced.

What Does the Assembly Process Involve?

The assembly stage is where the individual components come together. This process typically involves:

- Automated Assembly Lines: Many manufacturers use automation to enhance precision and reduce labor costs.

- Manual Assembly: For more complex terminal blocks, skilled workers may assemble components to ensure high quality.

Buyers should assess whether the supplier uses a combination of both methods, as this can indicate their commitment to quality and efficiency.

How Is the Finishing of Terminal Blocks Performed?

The finishing stage involves several processes to ensure the terminal blocks are ready for market:

- Surface Treatment: Processes such as plating or painting are used to enhance durability and aesthetics.

- Quality Control Checks: Before packaging, terminal blocks undergo rigorous inspections to ensure they meet the required specifications.

Understanding the finishing techniques can help buyers evaluate the longevity and appearance of the terminal blocks they plan to purchase.

What Quality Assurance Standards Should B2B Buyers Look For?

Quality assurance is critical in the manufacturing of terminal blocks. Buyers should familiarize themselves with relevant international and industry-specific standards, as these can indicate a supplier’s commitment to quality.

Which International Standards Are Important for Terminal Block Suppliers?

International standards such as ISO 9001 are essential indicators of a supplier’s quality management system. ISO 9001 certification ensures that the supplier consistently meets customer requirements and enhances customer satisfaction. Buyers should request proof of certification and assess the supplier’s adherence to these standards.

What Industry-Specific Certifications Should Be Considered?

In addition to general quality standards, industry-specific certifications such as CE marking and API certification (for applications in the oil and gas sector) may also be relevant. These certifications demonstrate compliance with safety, health, and environmental protection standards, which are particularly important for buyers operating in regulated industries.

How Are Quality Control Checkpoints Implemented?

Quality control (QC) involves several checkpoints throughout the manufacturing process to catch defects early and ensure product integrity.

What Are the Key Quality Control Checkpoints?

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival. Suppliers should verify that materials meet specified standards before they are used in production.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections should be conducted to monitor compliance with production specifications. This can involve checking dimensions, electrical properties, and assembly integrity.

-

Final Quality Control (FQC): Before terminal blocks are shipped, a final inspection ensures that the products meet all quality and performance standards. This may include functional testing and visual inspections.

What Common Testing Methods Are Used for Terminal Blocks?

To ensure the reliability of terminal blocks, various testing methods are employed. Buyers should understand these methods to evaluate a supplier’s capabilities effectively.

- Electrical Testing: This includes tests for insulation resistance, dielectric strength, and continuity to ensure the terminal block performs reliably under specified conditions.

- Mechanical Testing: Such tests evaluate the physical properties of the terminal block, including tensile strength and durability under stress.

- Environmental Testing: Terminal blocks may undergo exposure to extreme temperatures, humidity, and corrosive environments to assess their performance in real-world applications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

When selecting a terminal block supplier, it is crucial for buyers to validate the supplier’s quality control practices to ensure they meet international standards and specific needs.

What Steps Can Buyers Take to Verify Quality Control?

-

Conduct Audits: Buyers should perform on-site audits of potential suppliers to evaluate their manufacturing processes and quality control systems. This provides firsthand insight into the supplier’s capabilities.

-

Request Quality Assurance Reports: Suppliers should be able to provide detailed reports on their quality control processes and results from any recent inspections or certifications.

-

Utilize Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control measures and product reliability.

What QC and Certification Nuances Should International Buyers Be Aware Of?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certification.

- Regional Compliance: Different regions may have varying compliance requirements. Buyers should ensure that suppliers can meet local regulations in their target markets, such as EMC compliance in Europe or SANS standards in South Africa.

- Cultural Considerations: Understanding the business culture in different regions can help buyers communicate quality expectations effectively and foster better supplier relationships.

By focusing on these critical aspects of manufacturing processes and quality assurance, international B2B buyers can make informed decisions when sourcing terminal blocks, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘terminal block supplier’

To effectively source terminal block suppliers, international B2B buyers must navigate a structured approach that ensures quality, compliance, and alignment with their specific needs. This checklist provides a step-by-step guide to streamline your sourcing process.

Step 1: Define Your Technical Specifications

Before engaging with potential suppliers, clearly outline your technical requirements for terminal blocks. Consider factors such as voltage ratings, current capacity, material specifications, and size dimensions. This step is essential as it ensures that the suppliers you approach can meet your specific product needs and helps in avoiding compatibility issues later in the supply chain.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential terminal block suppliers. Utilize online platforms, industry directories, and trade shows to compile a list of companies. Focus on suppliers with a proven track record in your target regions, such as Africa, South America, the Middle East, and Europe. This initial research phase sets the foundation for finding reliable partners.

Step 3: Evaluate Supplier Experience and Reputation

Assess the experience and reputation of the shortlisted suppliers. Look for companies that have been in the industry for several years and have positive feedback from previous clients. It’s beneficial to request case studies or testimonials from other businesses in your industry to gauge their reliability and quality of service.

Step 4: ✅ Verify Supplier Certifications

Ensure that your potential suppliers possess relevant certifications, such as ISO 9001 or UL certification. These certifications indicate adherence to international quality standards and safety regulations. In regions like Nigeria or Egypt, compliance with local regulations is also crucial, so verify that the suppliers meet these requirements.

Step 5: Request Samples for Testing

Before making a large order, request samples of the terminal blocks for testing. This allows you to evaluate the quality, compatibility, and performance of the products in your specific application. Testing samples can save you from costly mistakes and ensure that you are making a well-informed decision.

Step 6: Understand Pricing and Payment Terms

Engage in discussions about pricing and payment terms early in the process. Compare quotes from multiple suppliers but remember that the lowest price may not always reflect the best value. Look for transparency in pricing structures and consider the total cost of ownership, including shipping and potential tariffs, especially when dealing with international suppliers.

Step 7: Establish Clear Communication Channels

Effective communication is vital for successful sourcing. Establish clear channels for ongoing dialogue with your chosen supplier. Discuss expectations regarding lead times, order fulfillment, and after-sales support. A supplier that values communication will likely provide better service and address any issues promptly, fostering a long-term partnership.

By following this checklist, international B2B buyers can navigate the complexities of sourcing terminal blocks with confidence, ensuring they partner with reliable suppliers who can meet their specific needs.

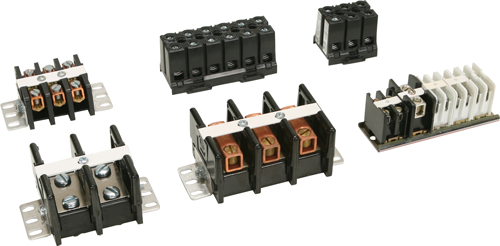

A stock image related to terminal block supplier.

Comprehensive Cost and Pricing Analysis for terminal block supplier Sourcing

What Are the Key Cost Components in Terminal Block Supplier Sourcing?

Understanding the cost structure of terminal block suppliers is essential for effective budgeting and procurement. The primary components include:

-

Materials: The type and quality of materials used in manufacturing terminal blocks significantly impact costs. Common materials like thermoplastics and metals vary in price based on market conditions and sourcing locations.

-

Labor: Labor costs can differ based on geographical location and the skill level required for production. Regions with lower labor costs may offer competitive pricing, but this can also affect the quality of workmanship.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and administrative expenses associated with the manufacturing facility. Efficient operations can help keep these costs low.

-

Tooling: Initial tooling costs for custom terminal blocks can be substantial. Understanding the tooling requirements is crucial for any customization, as these costs are often spread over the production volume.

-

Quality Control (QC): Implementing robust QC processes ensures that products meet industry standards, which can increase costs but ultimately saves money by reducing defects and returns.

-

Logistics: Shipping and handling costs are critical, especially for international buyers. Factors like distance, mode of transport, and customs duties can add to the overall expense.

-

Margin: Suppliers typically include a profit margin that reflects their business model and market conditions. This margin can vary widely based on competition and supplier positioning.

How Do Price Influencers Affect Terminal Block Costs?

Several factors influence the pricing of terminal blocks, making it essential for buyers to be aware of them:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower unit prices due to economies of scale. Understanding the MOQ can help buyers negotiate better deals.

-

Specifications and Customization: Custom terminal blocks tailored to specific applications can incur additional costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials Used: The choice of materials not only affects the price but also the performance characteristics of the terminal blocks. Buyers should balance cost with the necessary durability and functionality.

-

Quality Certifications: Certifications such as ISO or UL can add to the cost but may be necessary for compliance in certain markets. Buyers should evaluate the importance of these certifications against their budget.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge a premium, but they often provide better quality assurance and support.

-

Incoterms: Understanding Incoterms is crucial for international transactions, as they define the responsibilities of buyers and sellers regarding shipping costs, insurance, and risk. This can greatly affect the total landed cost.

What Are the Best Negotiation Strategies for International B2B Buyers?

For international buyers, particularly from Africa, South America, the Middle East, and Europe, employing effective negotiation strategies can lead to significant cost savings:

-

Research the Market: Understand current market prices and trends to negotiate from a position of knowledge. This includes knowing the average costs for different specifications and volumes.

-

Highlight Long-Term Relationships: Emphasizing the potential for ongoing business can persuade suppliers to offer better pricing. Suppliers value stable partnerships and may be willing to lower prices for guaranteed future orders.

-

Consider Total Cost of Ownership (TCO): Instead of focusing solely on upfront costs, evaluate the TCO, which includes maintenance, logistics, and potential downtime costs. This perspective can justify higher initial investments if they lead to lower overall expenses.

-

Be Open to Multiple Suppliers: Having alternative suppliers can provide leverage in negotiations. If a supplier knows you have other options, they may be more inclined to offer competitive pricing.

-

Negotiate Payment Terms: Flexible payment terms can alleviate cash flow pressures and may influence pricing. Suppliers might offer discounts for upfront payments or longer payment periods.

What Pricing Nuances Should International Buyers Be Aware Of?

International buyers must navigate various pricing nuances to ensure cost efficiency:

-

Currency Fluctuations: Exchange rates can significantly affect pricing. Buyers should consider locking in rates or negotiating prices in their local currency to mitigate risks.

-

Import Duties and Taxes: Understanding local regulations regarding import duties and taxes is essential, as these can add to the total cost significantly.

-

Shipping and Handling: Be aware of shipping methods and their implications on pricing. Air freight may be faster but more expensive than sea freight, impacting overall costs.

-

Local Regulations: Different countries have varying standards and regulations for electrical components. Ensure that the chosen supplier complies with local requirements to avoid costly penalties or rework.

Disclaimer on Indicative Prices

Prices for terminal blocks can vary widely based on numerous factors outlined above. It is advisable for buyers to obtain quotes from multiple suppliers to ensure they are receiving competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing terminal block supplier With Other Solutions

When evaluating terminal block suppliers, it’s crucial to consider various alternatives that may fulfill your business needs. Each solution offers distinct advantages and drawbacks, which can significantly impact your project’s efficiency, cost, and implementation timeline. This analysis will help you understand how terminal block suppliers compare to other viable options in the market.

Comparison Table of Terminal Block Supplier and Alternatives

| Comparison Aspect | Terminal Block Supplier | Alternative 1: Wire-to-Board Connectors | Alternative 2: PCB Mount Connectors |

|---|---|---|---|

| Performance | High reliability and durability | Moderate reliability; suited for low to moderate current applications | High performance; ideal for compact designs |

| Cost | Moderate to high | Generally lower cost | Moderate cost; depends on design complexity |

| Ease of Implementation | Requires specific tools for installation | Simple installation with minimal tools needed | Requires PCB design considerations |

| Maintenance | Low maintenance; durable materials | Moderate maintenance; depends on usage | Low maintenance but may need replacement over time |

| Best Use Case | Industrial applications, heavy machinery | Consumer electronics, prototyping | High-density applications, compact devices |

What Are the Advantages and Disadvantages of Wire-to-Board Connectors?

Wire-to-board connectors serve as an alternative to terminal blocks, especially in consumer electronics and prototyping scenarios. These connectors are typically less expensive and easier to install, requiring minimal tools. However, they may not offer the same level of reliability for high-current applications, making them less suitable for industrial uses. Their moderate performance and potential limitations in durability may necessitate more frequent replacements, which can add to long-term costs.

How Do PCB Mount Connectors Compare to Terminal Block Suppliers?

PCB mount connectors are another alternative that excels in high-density designs. They are particularly effective in applications where space is at a premium. These connectors can deliver high performance, especially in compact devices. However, they require careful PCB design and layout considerations, making them less straightforward to implement compared to terminal blocks. While they also offer low maintenance, the complexity of the design may lead to higher initial costs and necessitate specialized engineering expertise.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between a terminal block supplier and alternative solutions, B2B buyers should consider several factors, including the specific application, budget constraints, and ease of implementation. Each alternative presents unique benefits that may align better with certain project requirements. For instance, if your project demands high reliability in an industrial setting, terminal blocks may be the best option. Conversely, for consumer electronics or prototyping, wire-to-board connectors could provide a more cost-effective and efficient solution. Ultimately, understanding the nuances of each option will empower buyers to make informed decisions that best suit their operational needs.

Essential Technical Properties and Trade Terminology for terminal block supplier

What Are the Key Technical Properties of Terminal Blocks That B2B Buyers Should Know?

When sourcing terminal blocks, understanding their essential technical properties can significantly impact product performance and reliability. Here are some critical specifications to consider:

1. Material Grade: Why Does It Matter?

The material used in terminal blocks primarily affects their durability and conductivity. Common materials include polyamide (PA), thermoplastic, and metal alloys. For instance, polyamide is favored for its high thermal stability and resistance to chemicals, while copper is often used for its excellent conductivity. Selecting the right material grade ensures that the terminal blocks can withstand environmental stresses, making them suitable for various applications, especially in harsh conditions found in regions like Africa and the Middle East.

2. Current Rating: How Does It Influence Performance?

The current rating of a terminal block indicates the maximum current it can safely handle. This specification is vital to prevent overheating and potential circuit failures. For B2B buyers, understanding the current requirements of their specific applications is crucial. Terminal blocks are available in various ratings, typically ranging from a few amperes to several hundred, allowing for a wide range of applications in industrial and commercial environments.

3. Voltage Rating: What Should You Be Aware Of?

The voltage rating defines the maximum voltage that a terminal block can accommodate without risk of electrical breakdown. It is essential for ensuring safety and compliance with industry standards. Buyers must match the voltage rating of terminal blocks with the operational requirements of their equipment, particularly in sectors like telecommunications and manufacturing, where high voltages are common.

4. Tolerance: Why Is It Important for Quality Control?

Tolerance refers to the permissible limit of variation in dimensions and characteristics of terminal blocks. Tight tolerances are essential for ensuring reliable electrical connections and minimizing the risk of failure. For international B2B buyers, particularly those in Europe, adherence to strict quality standards is non-negotiable, making tolerance a crucial aspect to discuss with suppliers.

5. Thermal Stability: How Does It Affect Longevity?

Thermal stability indicates how well a terminal block can operate under varying temperature conditions. High thermal stability is critical for applications in extreme climates, such as those experienced in Africa and the Middle East. Buyers should inquire about the thermal properties of terminal blocks to ensure they can maintain performance over time, reducing the need for frequent replacements.

What Are the Common Trade Terms Used in the Terminal Block Industry?

Understanding industry jargon can streamline communication and negotiation processes. Here are some essential terms that B2B buyers should be familiar with:

1. OEM (Original Equipment Manufacturer): What Is Its Role?

An OEM produces components that are used in the manufacturing of another company’s final product. In the context of terminal blocks, working with an OEM can ensure that the components meet specific design and performance requirements, which is crucial for creating reliable electrical systems.

2. MOQ (Minimum Order Quantity): How Does It Affect Purchasing Decisions?

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for budgeting and inventory management. Buyers from regions with varying production capacities, like South America and Africa, should negotiate MOQs to align with their operational needs and financial constraints.

3. RFQ (Request for Quotation): Why Is It Important?

An RFQ is a formal process where buyers request pricing and terms from suppliers. It helps in comparing offers from multiple vendors to ensure competitive pricing and quality. This process is crucial for B2B buyers looking to make informed purchasing decisions.

4. Incoterms (International Commercial Terms): How Do They Affect Shipping?

Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms is essential for international transactions, as they can significantly impact costs and logistics. For B2B buyers, understanding Incoterms ensures smoother cross-border trade, reducing potential disputes.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing terminal blocks, ultimately enhancing the reliability and efficiency of their electrical systems.

Navigating Market Dynamics and Sourcing Trends in the terminal block supplier Sector

What Are the Key Market Dynamics and Trends Affecting Terminal Block Suppliers?

The terminal block supplier sector is currently experiencing significant transformation influenced by global drivers such as technological advancements, regulatory changes, and evolving customer preferences. One of the primary trends is the increasing demand for automation and smart manufacturing technologies. As industries in Africa, South America, the Middle East, and Europe embrace Industry 4.0, terminal blocks are becoming integral components in electrical and electronic systems. This shift is prompting suppliers to innovate and offer more versatile, modular solutions that cater to diverse applications.

Moreover, digitalization is reshaping sourcing trends. International B2B buyers are leveraging e-commerce platforms and digital marketplaces to streamline their procurement processes. This is particularly relevant for buyers in emerging markets who may have limited access to traditional supply chains. Enhanced online visibility allows buyers to compare products, assess supplier credibility, and make informed purchasing decisions. Additionally, the rise of data analytics is enabling suppliers to better understand market demand, optimize inventory management, and respond swiftly to changes in buyer preferences.

Another notable trend is the increasing focus on localization. Companies are looking to source terminal blocks closer to their manufacturing sites to reduce lead times and costs. For buyers in regions such as Nigeria or Egypt, partnering with local suppliers can enhance supply chain resilience and facilitate better communication. Understanding these market dynamics is essential for international B2B buyers seeking to make strategic sourcing decisions in the terminal block sector.

How Are Sustainability and Ethical Sourcing Impacting Terminal Block Suppliers?

Sustainability and ethical sourcing are becoming paramount considerations for international B2B buyers in the terminal block supplier sector. As environmental concerns continue to rise, businesses are increasingly prioritizing suppliers that demonstrate a commitment to reducing their ecological footprint. Terminal block suppliers are responding by adopting ‘green’ materials and manufacturing processes that minimize waste and energy consumption. For instance, using recyclable plastics and metals in the production of terminal blocks is gaining traction, aligning with global sustainability goals.

Ethical supply chains are equally critical, particularly for buyers in regions like South America and Africa, where social responsibility is increasingly influencing purchasing decisions. Suppliers that can provide transparency regarding their sourcing practices, labor conditions, and adherence to ethical standards are more likely to earn the trust of conscientious buyers. Certifications such as ISO 14001 (Environmental Management) and ISO 26000 (Social Responsibility) are becoming essential credentials that buyers should look for when evaluating potential suppliers.

Furthermore, as governments and organizations implement stricter regulations around sustainability, suppliers must stay ahead of compliance requirements. This not only mitigates risk for buyers but also enhances their brand reputation in a competitive marketplace. By prioritizing sustainability and ethical sourcing, international B2B buyers can not only contribute to environmental preservation but also foster stronger partnerships with suppliers committed to responsible practices.

What Is the Historical Context of the Terminal Block Supplier Sector?

The terminal block supplier sector has evolved significantly over the past few decades, reflecting broader changes in technology and industrial practices. Initially, terminal blocks were simple components used primarily in electrical panels. However, as industries advanced, so did the complexity and functionality of these components. The rise of automation and digital technologies in the late 20th century led to the development of more sophisticated terminal blocks that could accommodate a wider range of applications, from industrial machinery to consumer electronics.

In recent years, the emergence of smart technologies and the Internet of Things (IoT) has further transformed the sector. Terminal blocks now integrate features that support connectivity and data transmission, aligning with the needs of modern electrical systems. This evolution has created new opportunities for international B2B buyers, enabling them to source more advanced solutions that enhance their operational efficiency and adaptability in a rapidly changing market landscape. Understanding this historical context is vital for buyers seeking to navigate current trends and make informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of terminal block supplier

-

How do I choose the right terminal block supplier for my business needs?

Selecting the right terminal block supplier involves several critical steps. First, assess the supplier’s industry experience and reputation through online reviews and testimonials. Ensure they offer a range of products that meet your specific technical requirements, including size, material, and certification standards. Request samples to evaluate product quality and check if they can accommodate your customization needs. Finally, consider their logistics capabilities to ensure timely delivery, especially if you are sourcing from regions like Africa or South America. -

What factors should I consider when negotiating payment terms with a terminal block supplier?

When negotiating payment terms, consider factors such as order size, supplier reputation, and your company’s cash flow needs. Aim for flexible terms that align with your procurement cycle, such as net 30 or net 60 days. Additionally, inquire about discounts for upfront payments or bulk orders. Ensure clarity on currency exchange rates and any potential fees, especially when dealing with suppliers from different continents. Building a good rapport can also lead to more favorable terms. -

What are the minimum order quantities (MOQ) for terminal blocks from suppliers?

Minimum order quantities (MOQ) can vary significantly between suppliers. Many manufacturers set MOQs to cover production costs, which could range from a few hundred to several thousand units. If you have a smaller project, discuss your needs with the supplier; some may be willing to lower their MOQ for first-time buyers or offer a trial order. Understanding MOQs is crucial for budgeting and planning your inventory effectively, especially in regions with limited access to components. -

How can I ensure the quality of terminal blocks from my supplier?

To ensure product quality, request certifications that demonstrate compliance with international standards, such as UL or IEC. It’s beneficial to conduct factory audits or third-party inspections, especially for large orders. Discuss the supplier’s quality assurance processes and ask for samples before placing a bulk order. Establishing a quality control agreement can also help mitigate risks. This is particularly important for buyers from Africa or South America, where sourcing practices may differ. -

What customization options are available for terminal blocks?

Customization options for terminal blocks often include specific sizes, colors, materials, and configurations tailored to your application. Many suppliers offer the ability to modify terminal blocks to fit unique specifications, such as integrating additional features like labeling or connectors. When inquiring about customization, provide detailed information about your requirements and ask for a prototype to evaluate before full-scale production. This ensures the final product meets your expectations. -

How do logistics and shipping impact my sourcing decisions for terminal blocks?

Logistics and shipping can significantly affect lead times and overall costs when sourcing terminal blocks. Consider the supplier’s location and their ability to manage international shipping, including customs clearance processes. Evaluate freight options such as air freight for urgent needs versus sea freight for cost savings on larger orders. Additionally, inquire about the supplier’s experience with logistics in your region, as this can influence delivery reliability and timelines. -

What are the common challenges faced when sourcing terminal blocks internationally?

Common challenges in international sourcing include language barriers, cultural differences, and varying quality standards. Time zone differences can complicate communication and response times. Additionally, international buyers may encounter issues related to customs regulations, tariffs, and import/export restrictions, especially in regions like the Middle East or Africa. To mitigate these challenges, work with suppliers who have experience in your target market and ensure clear communication from the outset. -

How can I build a long-term relationship with my terminal block supplier?

Building a long-term relationship with your terminal block supplier involves consistent communication and mutual trust. Regularly provide feedback on product quality and service, and be transparent about your needs and challenges. Consider collaborating on product development or joint marketing initiatives to strengthen the partnership. Attend industry events together to enhance the relationship further. Establishing a strong rapport can lead to better pricing, priority service, and more favorable terms over time.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for terminal block supplier

In the dynamic landscape of terminal block supply, strategic sourcing emerges as a pivotal strategy for international B2B buyers seeking to optimize their procurement processes. By focusing on quality, supplier reliability, and innovation, businesses can not only enhance their operational efficiency but also reduce costs and mitigate risks associated with supply chain disruptions.

How Can Strategic Sourcing Enhance Supply Chain Resilience?

For buyers in Africa, South America, the Middle East, and Europe, the importance of building strong relationships with terminal block suppliers cannot be overstated. Engaging with suppliers who understand local market demands and regulatory requirements can lead to more tailored solutions and quicker response times. Moreover, leveraging technology and data analytics can provide insights into supplier performance, facilitating informed decision-making.

What Should International Buyers Consider for Future Procurement?

As we look ahead, the focus should shift towards sustainable sourcing practices and the integration of advanced technologies in procurement. By prioritizing suppliers who demonstrate a commitment to sustainability and innovation, buyers can position themselves competitively in their respective markets.

In conclusion, international B2B buyers are encouraged to adopt a proactive approach in their sourcing strategies. By aligning with reputable terminal block suppliers and embracing strategic sourcing principles, businesses can navigate the complexities of global supply chains and drive long-term success. Now is the time to evaluate your sourcing strategies and explore partnerships that will empower your organization in the evolving market landscape.