Cut Costs with the Right Mobile Crane Supplier (2025)

Introduction: Navigating the Global Market for mobile crane supplier

In today’s dynamic construction landscape, sourcing a reliable mobile crane supplier can be a daunting challenge for international B2B buyers. With diverse regional regulations, varying quality standards, and a plethora of options available globally, making an informed decision is critical. This guide aims to demystify the process of selecting the right mobile crane supplier, providing actionable insights tailored for buyers from Africa, South America, the Middle East, and Europe, including key markets like the UK and Kenya.

Throughout this comprehensive guide, we will explore the different types of mobile cranes available, their specific applications in various industries, and essential criteria for vetting suppliers effectively. Understanding the cost implications, maintenance requirements, and after-sales support will also be crucial for making strategic purchasing decisions. With this knowledge, buyers can navigate the complexities of the global market with confidence, ensuring they choose a supplier that aligns with their operational needs and budget constraints.

By the end of this guide, you will be empowered to tackle the challenges of sourcing mobile cranes, equipping you with the insights necessary to enhance your procurement strategy and optimize project outcomes. Whether you are looking to expand your fleet or invest in a single unit, this resource is designed to support your journey toward successful supplier partnerships in the mobile crane market.

Understanding mobile crane supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| All-Terrain Cranes | Versatile, can operate on various terrains | Construction, oil and gas, mining | Pros: High mobility; Cons: Higher cost |

| Rough Terrain Cranes | Designed for off-road conditions | Infrastructure projects, remote site operations | Pros: Excellent traction; Cons: Limited reach |

| Truck-Mounted Cranes | Mounted on trucks, easy to transport | Urban construction, road maintenance | Pros: Quick setup; Cons: Limited lifting capacity |

| Crawler Cranes | Tracks instead of wheels for stability | Heavy lifting in unstable environments | Pros: Superior stability; Cons: Less mobile |

| Telescopic Cranes | Extendable boom for variable reach | Construction, maintenance, and emergency response | Pros: Versatile reach; Cons: More complex to operate |

What are the characteristics of All-Terrain Cranes and their suitability for B2B buyers?

All-terrain cranes are designed to provide the flexibility needed for various terrains, making them ideal for construction sites that may not have well-maintained access roads. Their ability to switch from on-road to off-road capabilities allows for versatility in applications such as oil and gas projects or mining operations. When considering an all-terrain crane, buyers should evaluate the terrain conditions they will encounter and the crane’s lifting capacity to ensure it meets project demands.

How do Rough Terrain Cranes perform in challenging environments for B2B applications?

Rough terrain cranes are specifically engineered for off-road applications, featuring large tires and a robust suspension system that provides excellent traction on uneven ground. They are particularly suitable for infrastructure projects in remote areas where traditional cranes may struggle. Buyers should consider the crane’s lifting height and weight capacity, as well as its maneuverability, to ensure it can handle the specific challenges of their projects effectively.

What are the advantages of Truck-Mounted Cranes in urban settings for B2B operations?

Truck-mounted cranes offer the advantage of easy transportation and quick setup, making them an excellent choice for urban construction projects and road maintenance tasks. Their compact design allows them to navigate tight spaces, which is often a necessity in city environments. Buyers should assess the crane’s load capacity and the accessibility of job sites to determine if a truck-mounted crane is the right fit for their operational needs.

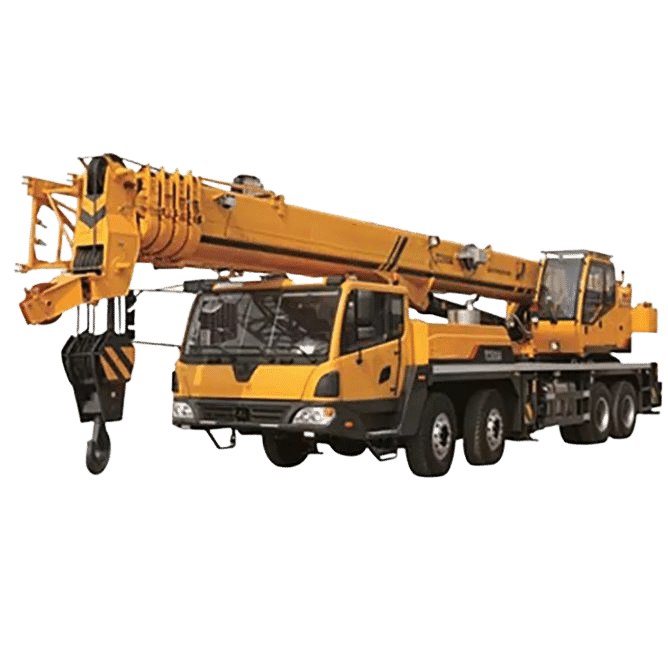

A stock image related to mobile crane supplier.

Why are Crawler Cranes considered a stable choice for heavy lifting in B2B scenarios?

Crawler cranes are distinguished by their use of tracks instead of wheels, providing superior stability on uneven surfaces. This makes them particularly well-suited for heavy lifting tasks in construction or industrial settings where ground conditions may be uncertain. Buyers should focus on the crane’s lifting capacity and operational range, as well as the potential for increased setup time due to their size and weight.

How do Telescopic Cranes enhance versatility for B2B buyers?

Telescopic cranes are equipped with extendable booms that allow for variable reach, making them ideal for a wide range of applications, from construction to emergency response. Their versatility is a significant advantage for buyers who require flexibility in their operations. However, it is crucial to consider the complexity of operation and the training required for personnel, as these factors can impact overall project efficiency and safety.

Related Video: Aicrane Portable Gantry Crane, Small Mobile Gantry Crane 3D Video

Key Industrial Applications of mobile crane supplier

| Industry/Sector | Specific Application of mobile crane supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Lifting and placing heavy materials | Increased efficiency and reduced labor costs | Load capacity, boom length, and operational reach |

| Oil and Gas | Installing large equipment on offshore platforms | Enhanced safety and operational reliability | Corrosion resistance, stability, and mobility in harsh environments |

| Infrastructure Development | Erecting bridges and high-rise buildings | Timely project completion and structural integrity | Compliance with local regulations, terrain adaptability |

| Mining | Transporting heavy machinery and materials | Improved productivity and reduced downtime | Durability, load handling capabilities, and ease of transport |

| Renewable Energy | Installing wind turbine components | Support for sustainable projects and cost savings | Weight distribution, lifting capacity, and environmental compliance |

How are Mobile Cranes Utilized in the Construction Industry?

In the construction sector, mobile cranes are essential for lifting and placing heavy materials, such as steel beams and concrete panels. Their ability to operate in confined spaces and their flexibility make them ideal for various construction sites. By utilizing mobile cranes, businesses can significantly increase operational efficiency, reduce labor costs, and expedite project timelines. International buyers should consider load capacity, boom length, and operational reach when sourcing cranes to ensure they meet specific project requirements.

What Role Do Mobile Cranes Play in the Oil and Gas Sector?

Mobile cranes are crucial in the oil and gas industry for installing large equipment on offshore platforms. These cranes enhance safety by allowing operators to handle heavy loads with precision and control, reducing the risk of accidents. For businesses in this sector, sourcing cranes that offer corrosion resistance and stability in harsh environments is vital. Buyers should prioritize suppliers with a proven track record in the oil and gas sector to ensure reliability and compliance with safety standards.

How are Mobile Cranes Beneficial for Infrastructure Development?

In infrastructure development, mobile cranes are employed to erect bridges and high-rise buildings. Their versatility allows for the lifting of heavy components while maintaining structural integrity. Timely project completion is crucial in this sector, and mobile cranes help achieve that by streamlining the lifting process. Buyers should focus on sourcing cranes that comply with local regulations and can adapt to varying terrains, especially in regions with diverse geographic challenges.

Why are Mobile Cranes Important in Mining Operations?

Mobile cranes are vital for transporting heavy machinery and materials in mining operations. They improve productivity by facilitating the movement of large equipment to and from the site, thereby reducing downtime. Buyers in the mining sector should seek cranes that offer durability and robust load handling capabilities, as well as ease of transport across rugged terrains. Understanding these requirements can help international buyers select the right mobile crane supplier for their specific needs.

How Do Mobile Cranes Support Renewable Energy Projects?

In the renewable energy sector, mobile cranes are used extensively for installing wind turbine components. This application supports sustainable projects and can lead to significant cost savings by optimizing installation processes. When sourcing cranes for renewable energy projects, businesses should assess weight distribution, lifting capacity, and environmental compliance to ensure that the equipment meets the unique demands of this industry.

3 Common User Pain Points for ‘mobile crane supplier’ & Their Solutions

Scenario 1: Navigating Compliance and Regulatory Challenges in Mobile Crane Operations

The Problem: International B2B buyers often face significant hurdles related to compliance with local regulations and safety standards when acquiring mobile cranes. This is especially true for buyers in regions like Africa and the Middle East, where regulations may vary widely and frequently change. Failure to comply can lead to costly fines, project delays, and reputational damage, putting a strain on both the financial and operational aspects of a business.

The Solution: To effectively navigate compliance challenges, buyers should conduct thorough research on local regulations before engaging with a mobile crane supplier. This includes understanding the specific certifications required for mobile cranes in the respective country, such as ISO standards or local safety regulations. Buyers can collaborate with suppliers who have a proven track record of adhering to these standards and can provide documentation that verifies compliance. Additionally, seeking legal advice or working with local consultants can help ensure that all aspects of the crane’s operation align with regulations, thereby minimizing risk and enhancing project reliability.

Scenario 2: Dealing with Unforeseen Downtime and Maintenance Costs

The Problem: Another common pain point for B2B buyers is the unexpected downtime of mobile cranes due to mechanical failures or inadequate maintenance. This issue can significantly disrupt project timelines, especially in industries such as construction and logistics, where time is money. Buyers in regions like South America and Europe may find that the cost of repairs and lost productivity can quickly escalate, leading to budget overruns.

The Solution: To mitigate the risk of downtime, buyers should prioritize selecting suppliers who offer comprehensive maintenance packages and support services. This includes understanding the warranty terms and the availability of spare parts. Buyers should also consider investing in predictive maintenance technologies, which utilize sensors and data analytics to anticipate potential failures before they occur. Establishing a proactive maintenance schedule with the supplier can also be beneficial. By doing so, buyers can ensure that their cranes remain in optimal condition, reducing the likelihood of unexpected breakdowns and associated costs.

Scenario 3: Overcoming Limitations in Crane Selection for Diverse Projects

The Problem: B2B buyers often struggle with selecting the right type of mobile crane for varied project requirements. This challenge is amplified in industries where project specifications change frequently, such as in construction and infrastructure development. Buyers may find themselves with a crane that is either over-specified, leading to unnecessary costs, or under-specified, resulting in inadequate performance and safety risks.

The Solution: To address the challenge of crane selection, buyers should engage in a comprehensive needs assessment before making a purchase. This involves clearly defining the project requirements, such as load capacity, lifting height, and mobility needs. Collaborating with suppliers who provide expert consultation can help buyers identify the most suitable crane models for their specific applications. Additionally, buyers should consider suppliers that offer rental options, allowing them to test different models on-site before committing to a purchase. This approach not only ensures that the selected crane meets project demands but also optimizes budget allocation by avoiding unnecessary expenditures on equipment that may not be fully utilized.

By addressing these common pain points with strategic solutions, international B2B buyers can enhance their procurement processes and achieve greater operational efficiency when working with mobile crane suppliers.

Strategic Material Selection Guide for mobile crane supplier

What Are the Key Materials Used in Mobile Crane Manufacturing?

When selecting materials for mobile cranes, understanding the properties, advantages, and limitations of each material is crucial for ensuring performance, safety, and compliance with international standards. Here, we analyze four common materials used in mobile crane manufacturing: Steel, Aluminum, Composite Materials, and Rubber.

How Does Steel Impact Mobile Crane Performance?

Key Properties: Steel is known for its high tensile strength, durability, and excellent load-bearing capabilities. It can withstand extreme temperatures and pressures, making it suitable for heavy-duty applications. Steel also offers good corrosion resistance when treated with appropriate coatings.

Pros & Cons: The primary advantage of steel is its durability and strength, which ensure longevity in harsh operating conditions. However, steel can be heavy, which may impact the crane’s mobility and fuel efficiency. Additionally, manufacturing complexity can increase costs, especially for specialized steel grades.

Impact on Application: Steel is compatible with various lifting and construction applications, especially in heavy industries. It performs well in environments with high loads and stress, making it a preferred choice for mobile cranes operating in construction and mining sectors.

Considerations for International Buyers: Buyers from regions like Africa and South America should consider local availability and the cost of steel. Compliance with standards such as ASTM and DIN is essential to ensure safety and performance. Additionally, understanding local corrosion factors is crucial for selecting the right steel grade.

What Are the Advantages of Using Aluminum in Mobile Cranes?

Key Properties: Aluminum is lightweight, resistant to corrosion, and offers good strength-to-weight ratios. It performs well in moderate temperature ranges and is often used in applications where weight savings are critical.

Pros & Cons: The key advantage of aluminum is its lightweight nature, which enhances mobility and reduces fuel consumption. However, aluminum is generally less strong than steel, which may limit its use in heavy-duty applications. The manufacturing process can also be more complex and costly.

Impact on Application: Aluminum is particularly suitable for mobile cranes that require high maneuverability and lower weight, such as those used in urban construction or maintenance tasks. Its corrosion resistance makes it ideal for coastal or humid environments.

Considerations for International Buyers: Buyers in Europe and the Middle East should be aware of aluminum’s performance in high-temperature conditions. Compliance with industry standards is crucial, and understanding local material preferences can influence procurement decisions.

How Do Composite Materials Enhance Mobile Crane Design?

Key Properties: Composite materials, often made from a combination of fibers and resins, offer excellent strength-to-weight ratios and corrosion resistance. They can be engineered to withstand specific stresses and environmental conditions.

Pros & Cons: The primary advantage of composites is their lightweight nature and resistance to environmental degradation. However, they can be more expensive to produce and may require specialized manufacturing techniques. Additionally, their performance under extreme loads can vary based on the specific composite formulation.

Impact on Application: Composites are increasingly used in mobile cranes for components that require both strength and lightweight properties, such as boom extensions and panels. They are particularly beneficial in industries where weight savings are critical.

Considerations for International Buyers: Buyers should consider the availability of composite materials in their regions and any associated certification requirements. Understanding local manufacturing capabilities is also essential, as not all suppliers may have the expertise to work with advanced composites.

What Role Does Rubber Play in Mobile Crane Functionality?

Key Properties: Rubber is primarily used in tires and cushioning components of mobile cranes. It offers excellent elasticity, shock absorption, and resistance to wear and tear.

Pros & Cons: The main advantage of rubber is its ability to provide traction and reduce vibrations, enhancing the crane’s stability during operation. However, rubber can degrade over time, especially when exposed to extreme temperatures or chemicals, necessitating regular maintenance and replacement.

Impact on Application: Rubber is critical for mobile cranes operating on uneven or soft surfaces, where traction is essential. Its shock-absorbing properties also improve operator comfort and equipment longevity.

Considerations for International Buyers: Buyers should be aware of the specific rubber grades suitable for their operating environments, particularly in regions with extreme weather conditions. Compliance with local standards for tires and rubber components is also vital.

Summary Table of Material Selection for Mobile Crane Suppliers

| Material | Typical Use Case for mobile crane supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty cranes in construction and mining | High strength and durability | Heavy, impacting mobility | Medium |

| Aluminum | Urban construction cranes requiring mobility | Lightweight, enhances fuel efficiency | Less strong than steel | High |

| Composite Materials | Boom extensions and panels in modern cranes | Excellent strength-to-weight ratio | Higher production costs | High |

| Rubber | Tires and cushioning components for stability | Provides traction and shock absorption | Degrades over time | Medium |

By understanding these materials’ properties and implications, international B2B buyers can make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for mobile crane supplier

What Are the Key Stages of Mobile Crane Manufacturing?

The manufacturing process of mobile cranes involves several critical stages that ensure the final product meets the necessary performance and safety standards. Understanding these stages is essential for B2B buyers looking to source reliable equipment.

Material Preparation

The first step in the manufacturing process is the preparation of raw materials. High-strength steel is commonly used in the construction of mobile cranes due to its durability and load-bearing capabilities. Suppliers often conduct metallurgical tests to ensure that the materials meet specific chemical and mechanical properties. Buyers should inquire about the sources of materials and whether they come from certified suppliers to ensure quality.

Forming Techniques in Mobile Crane Manufacturing

The forming stage involves shaping the prepared materials into components. Techniques such as welding, bending, and machining are employed to create the crane’s frame, boom, and chassis. Advanced technologies like Computer Numerical Control (CNC) machining enhance precision, allowing for tighter tolerances that improve overall performance. Buyers should ask suppliers about the specific forming techniques used and whether they employ modern technologies to ensure high-quality components.

What Does the Assembly Process Entail?

A stock image related to mobile crane supplier.

After forming, the components undergo assembly. This stage involves joining the various parts, including the hydraulic systems, controls, and safety features. A systematic approach is crucial here; many manufacturers utilize modular assembly techniques to facilitate efficient construction and maintenance. B2B buyers should assess the supplier’s assembly process, looking for adherence to best practices and the use of skilled labor.

Finishing Processes That Ensure Longevity

The final stage is finishing, which includes painting, coating, and corrosion protection. These processes are vital for ensuring the crane can withstand environmental challenges, especially in regions with harsh weather conditions. Suppliers may use powder coating or galvanization to enhance durability. B2B buyers should verify the finishing techniques and materials used, ensuring they are suitable for the intended operational environment.

How is Quality Assurance Integrated into Mobile Crane Manufacturing?

Quality assurance (QA) is a critical component of the mobile crane manufacturing process. It ensures that the cranes not only meet industry standards but also customer expectations regarding safety and reliability.

What Are the Relevant International Standards for Mobile Cranes?

International standards play a vital role in quality assurance. ISO 9001 is the foundational standard for quality management systems, ensuring that suppliers maintain consistent quality across their operations. Additionally, mobile cranes may need to comply with specific industry standards such as the European CE marking, which verifies that products meet EU safety requirements, and the American Petroleum Institute (API) standards for cranes used in oil and gas applications. Buyers should ensure that their suppliers are certified and compliant with these standards.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are established throughout the manufacturing process to identify and rectify any defects. These typically include:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon receipt to ensure they meet specifications.

-

In-Process Quality Control (IPQC): Throughout the manufacturing stages, ongoing inspections are performed to monitor processes and ensure compliance with quality standards.

-

Final Quality Control (FQC): Once the crane is assembled, a thorough inspection is conducted to verify that it meets all operational and safety standards before delivery.

B2B buyers should request detailed QC documentation from suppliers, including inspection reports and records of any corrective actions taken.

What Testing Methods Are Commonly Used in Mobile Crane Manufacturing?

Various testing methods are implemented to validate the functionality and safety of mobile cranes:

-

Load Testing: This involves applying a load that exceeds the crane’s rated capacity to ensure structural integrity and performance under extreme conditions.

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or radiographic testing are used to detect internal flaws without damaging the components.

-

Functional Testing: This ensures that all operational aspects of the crane, including controls and safety mechanisms, function correctly.

Buyers should inquire about the specific testing methods used and request certification of test results to ensure the cranes meet performance standards.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control practices of mobile crane suppliers is crucial for mitigating risks. Here are some actionable strategies:

Conducting Supplier Audits

Regular audits can provide insights into a supplier’s manufacturing processes and quality control measures. B2B buyers, especially those from Africa, South America, the Middle East, and Europe, should consider conducting on-site audits to assess the production facilities, quality management systems, and compliance with international standards.

Requesting Quality Reports and Certifications

Buyers should actively request quality reports and certifications related to the manufacturing processes. This may include ISO certifications, CE markings, and any industry-specific compliance documents. These reports can provide a clear picture of the supplier’s commitment to quality.

Engaging Third-Party Inspection Services

Utilizing third-party inspection services can offer an unbiased assessment of the supplier’s quality control measures. These services can conduct pre-shipment inspections and provide detailed reports, ensuring that the cranes meet the required specifications before they leave the manufacturing facility.

What Are the Quality Control Nuances for International Buyers?

When sourcing mobile cranes internationally, buyers must navigate various quality control nuances:

-

Cultural Differences in Quality Standards: Different regions may have varying expectations regarding quality and safety standards. Buyers should familiarize themselves with local regulations and standards to ensure compliance.

-

Language Barriers: Clear communication is essential for quality assurance. Buyers should consider working with suppliers who can provide documentation in a language they understand to avoid misinterpretations.

-

Logistical Challenges: International shipping can introduce risks related to product damage or delays. Buyers should ensure that suppliers have robust logistical plans that include quality checks during transit.

By understanding the manufacturing processes and quality assurance measures involved in mobile crane production, international B2B buyers can make informed decisions when selecting suppliers, ultimately ensuring the reliability and safety of their equipment.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘mobile crane supplier’

The procurement of mobile cranes is a significant investment for any business, especially for international buyers from diverse markets such as Africa, South America, the Middle East, and Europe. This guide offers a structured checklist to streamline the sourcing process, ensuring you find a reliable supplier that meets your operational needs.

Step 1: Define Your Technical Specifications

Clearly outline the specifications of the mobile crane you require. Consider factors such as lifting capacity, boom length, and operational environment (e.g., urban construction sites vs. rural settings). This step is crucial as it helps narrow down potential suppliers who can meet your exact requirements.

- Lifting Capacity: Determine the maximum weight the crane must lift.

- Boom Type: Decide between telescopic, lattice, or hydraulic booms based on your operational needs.

Step 2: Conduct Market Research for Suppliers

Invest time in researching potential suppliers. Look for companies with a solid reputation in the mobile crane market, particularly those with experience in your region. This will not only help identify reliable vendors but also provide insights into market pricing and product availability.

- Industry Directories: Utilize resources like industry associations and trade shows.

- Online Reviews: Check platforms such as LinkedIn and industry forums for feedback from other buyers.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; explore their track record and customer satisfaction levels.

- Client References: Ask for contacts of previous clients to gauge their satisfaction.

- Case Studies: Review documented projects to see how the supplier handled similar requirements.

Step 4: Verify Supplier Certifications and Compliance

Ensure that the suppliers you consider comply with international safety and quality standards. This includes certifications such as ISO, CE marking, and any local compliance required in your region. Compliance is essential to ensure the safety and reliability of the cranes.

- Quality Assurance: Look for suppliers with robust quality control measures.

- Safety Standards: Ensure they adhere to safety regulations relevant to your operational area.

Step 5: Request Detailed Quotes and Terms

Once you have a shortlist of suppliers, request detailed quotes that outline all costs involved, including delivery, installation, and after-sales service. Understanding the total cost of ownership will help you make an informed decision.

- Transparent Pricing: Ensure quotes include all potential costs to avoid hidden fees later.

- Payment Terms: Clarify payment conditions and financing options available.

Step 6: Assess After-Sales Support and Service

After-sales support is critical when purchasing heavy machinery like mobile cranes. Evaluate the supplier’s ability to provide maintenance, spare parts, and technical support. A reliable supplier will offer comprehensive service packages.

- Service Agreements: Inquire about warranty terms and service contracts.

- Availability of Parts: Confirm the supplier’s capacity to provide spare parts promptly.

Step 7: Finalize the Contract and Purchase Agreement

Once you’ve selected a supplier, ensure that all terms are clearly outlined in a written contract. This should include delivery timelines, payment schedules, and service agreements to protect your interests.

- Legal Review: Consider having the contract reviewed by a legal expert to ensure compliance with local laws.

- Performance Metrics: Include performance metrics to hold the supplier accountable for quality and service delivery.

By following these steps, B2B buyers can effectively navigate the complexities of sourcing mobile cranes, ensuring they make informed decisions that align with their operational needs and budget constraints.

Comprehensive Cost and Pricing Analysis for mobile crane supplier Sourcing

When sourcing mobile cranes, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers. This analysis delves into the various cost components, price influencers, and practical tips to optimize procurement strategies, particularly for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Mobile Crane Sourcing?

The cost structure of mobile cranes comprises several critical components that buyers need to consider:

-

Materials: The choice of materials significantly impacts the cost. High-strength steel and advanced composites may increase upfront costs but can enhance durability and reduce long-term maintenance expenses.

-

Labor: Skilled labor is essential for manufacturing mobile cranes. Labor costs vary by region, with some countries offering lower wages but potentially compromising quality. Understanding local labor market conditions is vital.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and equipment depreciation. A higher overhead can indicate a supplier’s investment in quality and technology.

-

Tooling: Initial tooling costs for custom designs can be substantial. Buyers should weigh these costs against the potential benefits of tailored solutions.

-

Quality Control (QC): Rigorous QC processes ensure product reliability, impacting both the cost and the perceived value of the cranes. Suppliers with robust QC measures may charge more but could save buyers from costly failures.

-

Logistics: Shipping costs can vary significantly depending on the origin and destination of the cranes. For international buyers, understanding Incoterms and associated logistics costs is crucial to avoid unexpected expenses.

-

Margin: Supplier margins can fluctuate based on market demand and competition. Buyers should seek transparency in pricing to understand the markup on quoted prices.

How Do Price Influencers Affect Mobile Crane Costs?

Several factors can influence the pricing of mobile cranes, which buyers must navigate effectively:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often result in lower per-unit prices. However, understanding the MOQ required by suppliers is essential to maximize cost efficiency.

-

Specifications and Customization: Custom-built cranes tailored to specific needs will typically incur higher costs. Clearly defining requirements upfront can help manage expectations and budgets.

-

Material Quality and Certifications: Cranes that meet international safety and quality certifications may come at a premium but can offer peace of mind and compliance with regulations in different markets.

-

Supplier Factors: The reputation, experience, and location of the supplier can significantly affect pricing. Established suppliers with a track record may charge more but can provide superior reliability and support.

-

Incoterms: Understanding the implications of various Incoterms can help buyers manage total landed costs, including shipping, insurance, and duties.

What Are the Best Negotiation Strategies for Buyers?

To optimize the procurement of mobile cranes, buyers should consider the following strategies:

-

Understand Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, operational efficiency, and potential resale value. A more expensive crane may offer lower TCO if it is more durable or efficient.

-

Leverage Competitive Quotes: Obtaining multiple quotes allows for better negotiation leverage. It also provides insight into market pricing and helps identify outliers.

-

Seek Long-term Relationships: Establishing a long-term partnership with a supplier can lead to better pricing, priority service, and access to new products or technologies.

-

Be Transparent About Needs: Clear communication about requirements, budgets, and timelines can foster a more productive negotiation process and help suppliers tailor their proposals effectively.

-

Consider Local Market Dynamics: For buyers in Africa, South America, the Middle East, and Europe, understanding local market conditions, currency fluctuations, and geopolitical factors can provide an edge in negotiations.

Conclusion

Sourcing mobile cranes requires a comprehensive understanding of cost structures and pricing dynamics. By considering the various cost components, price influencers, and employing effective negotiation strategies, international B2B buyers can make informed decisions that align with their operational needs and budget constraints. Keep in mind that prices can vary widely based on many factors, so conducting thorough research and due diligence is crucial for successful procurement.

Alternatives Analysis: Comparing mobile crane supplier With Other Solutions

Understanding the Importance of Alternative Solutions in Mobile Crane Procurement

In the competitive landscape of B2B procurement, particularly for industries reliant on heavy lifting and material handling, exploring alternative solutions to mobile cranes can lead to significant cost savings and operational efficiency. As international buyers from regions such as Africa, South America, the Middle East, and Europe assess their needs, understanding the capabilities and limitations of various lifting solutions becomes crucial.

Comparison Table: Evaluating Mobile Crane Suppliers Against Alternatives

| Comparison Aspect | Mobile Crane Supplier | Telehandler | Forklift Truck |

|---|---|---|---|

| Performance | High lifting capacity, versatile | Moderate lifting capacity, good for rough terrain | Limited lifting height and capacity |

| Cost | High initial investment | Moderate cost, but higher operational costs | Lower upfront costs, but limited functionality |

| Ease of Implementation | Requires specialized training and setup | Easy to operate, minimal training needed | Simple operation, widely understood |

| Maintenance | Requires regular servicing and inspections | Low maintenance needs | Moderate maintenance requirements |

| Best Use Case | Large construction sites, heavy industrial applications | Construction sites with uneven terrain | Warehousing, light construction tasks |

What Are the Advantages and Disadvantages of Using a Telehandler?

Telehandlers are versatile machines that combine the capabilities of a crane and a forklift. They are particularly effective on construction sites where uneven terrain poses challenges for traditional cranes. Their moderate lifting capacity allows them to handle various materials, making them a flexible option. However, while they are easier to operate and require less training, they can incur higher operational costs over time due to fuel consumption and wear and tear.

How Do Forklift Trucks Compare to Mobile Crane Suppliers?

Forklift trucks are a staple in material handling, particularly within warehouses and for light construction tasks. Their lower upfront costs make them an attractive option for businesses with budget constraints. They are also user-friendly, requiring minimal training for operators. However, their limitations in lifting height and capacity can hinder their effectiveness in more demanding construction environments where mobile cranes excel. This makes them less suitable for heavy industrial applications.

Choosing the Right Solution for Your Needs

When evaluating options between mobile crane suppliers and alternative solutions like telehandlers and forklift trucks, B2B buyers must consider several factors, including the specific requirements of their projects, budget constraints, and the operational environment. Assessing performance needs and operational costs alongside ease of implementation and maintenance will guide buyers in making informed decisions. Ultimately, selecting the right solution hinges on aligning the capabilities of the equipment with the demands of the job at hand, ensuring both efficiency and cost-effectiveness in their operations.

Essential Technical Properties and Trade Terminology for mobile crane supplier

Understanding the key technical properties and trade terminology associated with mobile cranes is crucial for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. This knowledge not only facilitates informed purchasing decisions but also enhances communication with suppliers and manufacturers.

What are the Essential Technical Specifications for Mobile Cranes?

1. Load Capacity

Load capacity refers to the maximum weight a crane can safely lift. It is typically measured in tons and is crucial for determining whether a crane can handle the specific loads required for a project. Buyers must assess their lifting needs carefully to avoid operational failures and ensure compliance with safety regulations.

2. Boom Length

The boom length is the distance from the crane’s base to the tip of the boom when fully extended. It affects the crane’s reach and lifting height. Understanding boom length specifications helps buyers select a crane that can effectively operate in their project environment, especially in constrained spaces or high-rise developments.

3. Operating Radius

The operating radius is the maximum horizontal distance from the center of the crane to the load. This specification is vital for planning lifts and ensuring that the crane can reach the intended load without compromising stability. Buyers should consider this when evaluating site layouts and lift plans.

4. Material Grade

The material grade of a crane refers to the quality and strength of the materials used in its construction, particularly in the boom and chassis. Higher material grades ensure durability and resistance to wear and tear, which is essential for long-term investment. Buyers should inquire about material certifications to ensure they meet industry standards.

5. Tolerance

Tolerance in crane specifications refers to the permissible limit of variation in dimensions and weight. This is crucial for ensuring that all components fit together correctly and operate safely. A clear understanding of tolerance levels can help buyers assess the reliability of a crane’s performance over time.

Which Trade Terms Should B2B Buyers Be Familiar With?

What is OEM (Original Equipment Manufacturer)?

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the mobile crane industry, understanding OEM relationships can help buyers identify reputable suppliers and ensure they receive quality products that meet specific standards.

What Does MOQ (Minimum Order Quantity) Mean?

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budget planning and inventory management. Buyers should negotiate MOQs based on their project needs to avoid overstocking or underutilizing resources.

How is RFQ (Request for Quotation) Used in Procurement?

RFQ is a document sent to suppliers to request pricing and other terms for specific products or services. It is a standard practice in B2B procurement, allowing buyers to compare offers and make informed decisions. A well-prepared RFQ can lead to better pricing and terms.

What are Incoterms and Why Are They Important?

Incoterms (International Commercial Terms) are a set of predefined commercial terms published by the International Chamber of Commerce. They define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Understanding Incoterms is crucial for B2B buyers to clarify costs and responsibilities in their contracts.

What Does Lead Time Imply in Mobile Crane Supply?

Lead time refers to the time it takes from placing an order to receiving the product. It is an essential consideration for project planning and scheduling. Buyers should communicate their deadlines to suppliers to ensure timely delivery and avoid project delays.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can navigate the mobile crane market more effectively, make informed purchasing decisions, and establish stronger relationships with suppliers.

Navigating Market Dynamics and Sourcing Trends in the mobile crane supplier Sector

What Are the Current Market Dynamics in the Mobile Crane Supplier Sector?

The mobile crane supplier sector is undergoing significant transformation driven by technological advancements, changing consumer preferences, and global economic fluctuations. In emerging markets like Africa and South America, increasing infrastructure development projects are stimulating demand for mobile cranes. The construction and mining industries are particularly robust in these regions, as governments invest in large-scale projects to bolster economic growth.

In Europe and the Middle East, there is a notable trend towards digitization in procurement processes. B2B buyers are increasingly leveraging platforms that offer real-time data analytics and inventory management systems. These technologies enable more informed purchasing decisions, allowing companies to respond swiftly to market demands. Additionally, the rise of e-commerce platforms is reshaping how mobile cranes are sourced, making it easier for international buyers to connect with suppliers globally.

Moreover, the mobile crane market is witnessing a shift toward hybrid and electric models, driven by the need for efficiency and sustainability. As global awareness of environmental issues grows, buyers are prioritizing suppliers who offer innovative, eco-friendly solutions. This shift not only meets regulatory requirements but also enhances the overall brand image of businesses in a competitive marketplace.

How Important Is Sustainability and Ethical Sourcing in the Mobile Crane Sector?

Sustainability and ethical sourcing have become paramount in the mobile crane supplier sector. The environmental impact of manufacturing cranes, including resource depletion and emissions, is under scrutiny. International B2B buyers are increasingly demanding transparency regarding the sourcing of materials and the production processes employed by suppliers.

Ethical supply chains are critical in fostering trust and enhancing brand reputation. Buyers should prioritize suppliers who adhere to recognized sustainability standards and certifications, such as ISO 14001 for environmental management systems. Furthermore, the use of ‘green’ materials, such as recycled steel and sustainable composites, can significantly reduce the carbon footprint of mobile cranes.

Investing in suppliers who demonstrate a commitment to sustainability not only aligns with corporate social responsibility goals but can also lead to long-term cost savings. Efficient supply chains reduce waste and energy consumption, ultimately benefiting both the environment and the bottom line. B2B buyers should actively seek partnerships with suppliers who prioritize sustainability, as this will become a key differentiator in the competitive landscape.

What Is the Historical Context of Mobile Crane Suppliers?

The mobile crane industry has evolved significantly since its inception in the early 20th century. Initially, cranes were primarily steam-powered and limited in mobility. Over the decades, technological advancements have led to the development of hydraulic and electric cranes, enhancing lifting capacities and operational efficiency.

The globalization of trade and manufacturing has further transformed the mobile crane supplier landscape. As international trade barriers diminished, suppliers began sourcing materials and components from various regions, optimizing production costs. This evolution has made it imperative for B2B buyers to understand the global supply chain intricacies and the impact of geopolitical factors on sourcing.

In recent years, the focus has shifted toward innovation and sustainability, with suppliers increasingly investing in research and development to meet the evolving needs of the market. This historical context highlights the importance of adaptability and foresight for B2B buyers seeking reliable mobile crane suppliers in a rapidly changing environment. Understanding these dynamics can help buyers make informed decisions that align with their strategic goals.

Frequently Asked Questions (FAQs) for B2B Buyers of mobile crane supplier

-

How do I choose the right mobile crane supplier for my business needs?

Choosing the right mobile crane supplier involves evaluating several factors. Start by assessing their industry experience and reputation. Look for suppliers with a proven track record in your specific region, whether it’s Africa, South America, the Middle East, or Europe. Check for certifications and compliance with local regulations. Request references and case studies to understand their capability in meeting your requirements. Finally, consider their after-sales support, including maintenance services and spare parts availability, which are crucial for long-term operations. -

What are the most important factors to consider when sourcing mobile cranes internationally?

When sourcing mobile cranes internationally, key factors include compliance with local regulations, delivery timelines, and total cost of ownership. Investigate the supplier’s quality assurance processes and warranty offerings. Pay attention to logistics, including shipping costs and potential customs duties. Additionally, consider the supplier’s ability to provide technical support and training, which can be vital in ensuring that your team can operate the equipment safely and efficiently. -

What is the typical minimum order quantity (MOQ) for mobile cranes?

Minimum order quantities (MOQs) for mobile cranes can vary significantly based on the supplier and the specific model. Generally, MOQs may range from one unit for smaller suppliers to larger quantities for major manufacturers. It’s advisable to discuss your needs directly with the supplier, as many are willing to negotiate MOQs, especially for first-time buyers or bulk orders. Additionally, consider whether the supplier offers rental options, which can be a flexible solution for businesses with fluctuating demand. -

What payment terms should I expect from mobile crane suppliers?

Payment terms for mobile crane purchases typically vary by supplier but often include options such as upfront payment, installment plans, or letters of credit. It’s essential to clarify these terms before finalizing any agreement. Some suppliers may offer financing options or leasing arrangements, especially for larger equipment. Ensure that you understand the implications of each payment option, including interest rates and potential penalties for late payments, to make an informed decision. -

How can I ensure quality assurance when sourcing mobile cranes?

To ensure quality assurance, request detailed specifications and certifications from your supplier that align with international standards. Conduct factory audits or inspections if possible, or consider hiring third-party inspection services to assess the equipment before shipment. Inquire about the supplier’s quality control processes, including testing procedures and warranty terms. Establish clear communication about your quality expectations to mitigate risks associated with equipment performance and safety. -

What are the logistics considerations for importing mobile cranes?

Logistics considerations for importing mobile cranes include shipping methods, lead times, and customs clearance processes. Determine the best mode of transport (e.g., sea, air) based on your budget and urgency. Understand the required documentation for customs clearance, such as bills of lading and import permits, to avoid delays. Collaborate with a logistics partner experienced in heavy equipment transport to streamline the process and ensure compliance with local regulations. -

Can mobile cranes be customized to meet specific project requirements?

Yes, many mobile crane suppliers offer customization options to meet specific project needs. Customization can include modifications to crane capacity, boom length, or additional features such as specialized attachments. Discuss your requirements with potential suppliers to understand their capabilities and any associated costs or lead times for customization. Ensure that any modifications comply with safety standards and local regulations to maintain operational integrity. -

What support services should I expect from a mobile crane supplier post-purchase?

Post-purchase support services from a mobile crane supplier should include maintenance services, spare parts availability, and operator training. A reputable supplier will provide a comprehensive warranty that covers parts and labor for a specified period. Inquire about the supplier’s response times for service calls and the availability of technical support. Additionally, consider whether they offer training programs for your operators, which can enhance safety and efficiency in crane operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for mobile crane supplier

Why is Strategic Sourcing Crucial for Mobile Crane Suppliers?

In the dynamic landscape of mobile crane procurement, strategic sourcing emerges as a pivotal element for international B2B buyers. By leveraging a well-structured sourcing strategy, companies can optimize costs, enhance supplier relationships, and ensure access to high-quality equipment tailored to their specific operational needs. This approach not only mitigates risks associated with supply chain disruptions but also fosters innovation by integrating diverse supplier capabilities.

What Key Takeaways Should B2B Buyers Consider?

International buyers, particularly in regions like Africa, South America, the Middle East, and Europe, should prioritize the evaluation of suppliers based on their reliability, technological advancements, and compliance with regional regulations. Fostering partnerships with suppliers who demonstrate a commitment to sustainability and ethical practices can also yield long-term benefits, aligning procurement strategies with global standards and consumer expectations.

How Can B2B Buyers Position Themselves for Future Success?

As we look to the future, the mobile crane market is poised for growth driven by infrastructure development and technological advancements. Buyers should embrace digital tools for enhanced procurement visibility and data analytics to make informed decisions. Engaging in ongoing supplier assessments and adapting sourcing strategies to evolving market conditions will be crucial for maintaining a competitive edge.

In conclusion, by adopting a strategic sourcing mindset, international B2B buyers can not only streamline their procurement processes but also position themselves for sustainable success in the mobile crane industry. Take action today to evaluate your sourcing strategies and strengthen your supplier relationships to meet the challenges of tomorrow.