Cut Costs with Top Solenoid Manufacturer Insights (2025)

Introduction: Navigating the Global Market for solenoid manufacturer

In the rapidly evolving global market, sourcing reliable solenoid manufacturers can be a daunting task for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. Solenoids play a crucial role in a variety of applications, from automotive systems to industrial automation, and understanding the nuances of their manufacturing is essential for making informed procurement decisions. This guide is designed to provide comprehensive insights into the solenoid manufacturing landscape, covering types of solenoids, their applications, supplier vetting processes, and cost considerations.

Navigating this complex market requires a strategic approach to ensure that buyers select the right manufacturers who can deliver high-quality products that meet their specific needs. By diving into the critical factors that influence solenoid performance and reliability, this guide equips B2B buyers with the knowledge needed to assess potential suppliers effectively. Whether you are based in South Africa looking to enhance your industrial operations or in Brazil seeking innovative solenoid solutions for your products, our expert insights will empower you to make strategic purchasing decisions.

Ultimately, this resource aims to streamline your sourcing process, mitigate risks associated with vendor selection, and foster successful partnerships with solenoid manufacturers around the globe. With this knowledge, international buyers can confidently approach the solenoid market, ensuring they meet their operational requirements while optimizing their investment.

Understanding solenoid manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electromagnetic Solenoids | Operate using electromagnetic force; versatile in design. | Automotive, industrial machinery, HVAC systems | Pros: High reliability, fast response. Cons: Sensitive to heat. |

| Latching Solenoids | Maintain position without continuous power; energy-efficient. | Access control, locking mechanisms, automation | Pros: Energy-efficient, low power consumption. Cons: Limited stroke length. |

| Miniature Solenoids | Compact size; ideal for tight spaces and low-power applications. | Medical devices, consumer electronics | Pros: Space-saving, lightweight. Cons: Lower force output. |

| High-Pressure Solenoids | Designed to withstand high pressure; robust construction. | Oil & gas, chemical processing | Pros: Durable, suitable for harsh environments. Cons: Higher cost. |

| Proportional Solenoids | Provide variable control of flow or pressure; precise operation. | Robotics, fluid control systems | Pros: High precision, adaptable. Cons: More complex control systems required. |

What Are Electromagnetic Solenoids and Their B2B Applications?

Electromagnetic solenoids are the most common type, utilizing electromagnetic force to operate. These solenoids can be designed in various configurations, making them suitable for a wide range of applications, including automotive systems, industrial machinery, and HVAC systems. When purchasing, B2B buyers should consider the solenoid’s response time and operational reliability, as these factors can significantly impact system performance.

How Do Latching Solenoids Function in Commercial Settings?

Latching solenoids are unique in that they can maintain their position without continuous power, which makes them energy-efficient. They are widely used in access control systems and locking mechanisms. For B2B buyers, the key considerations include the solenoid’s ability to operate under specific conditions and the mechanical limits of stroke length, which can affect functionality in certain applications.

Why Choose Miniature Solenoids for Space-Constrained Applications?

Miniature solenoids are designed for compactness, making them ideal for applications where space is limited, such as in medical devices and consumer electronics. While they offer the advantage of being lightweight and space-saving, buyers should be aware that they typically have a lower force output. It is crucial to assess the application’s requirements to ensure that the solenoid can meet the necessary force and response specifications.

What Are the Benefits of High-Pressure Solenoids in Harsh Environments?

High-pressure solenoids are specifically engineered to withstand extreme pressures, making them suitable for industries such as oil and gas and chemical processing. Their robust construction ensures durability in harsh environments. However, B2B buyers should be prepared for a higher cost associated with these solenoids, as well as the need for careful installation and maintenance to ensure optimal performance.

How Do Proportional Solenoids Enhance Precision in Fluid Control?

Proportional solenoids are designed to provide variable control over flow or pressure, allowing for precise operation in applications like robotics and fluid control systems. These solenoids enable fine-tuning of system performance, but they require more complex control systems, which can increase the overall cost and complexity of the installation. Buyers should evaluate their control system capabilities to ensure compatibility with proportional solenoids.

Related Video: Purge Valve Solenoid or Vent Valve Solenoid Test and Cleaning Process

Key Industrial Applications of solenoid manufacturer

| Industry/Sector | Specific Application of solenoid manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Engine management systems | Enhances vehicle efficiency and performance | Quality certifications, compatibility with OEM standards |

| Manufacturing | Automated assembly lines | Increases production speed and reduces labor costs | Reliability, durability under continuous use |

| HVAC | Control of heating and cooling systems | Improves energy efficiency and comfort levels | Temperature tolerance, response time, and energy ratings |

| Agriculture | Irrigation control systems | Optimizes water usage and crop yield | Corrosion resistance, pressure ratings, and environmental compliance |

| Medical Devices | Fluid delivery systems in medical equipment | Ensures precise dosing and patient safety | Compliance with medical standards, reliability, and traceability |

How is Solenoid Technology Applied in the Automotive Industry?

In the automotive sector, solenoids play a crucial role in engine management systems, where they control various functions such as fuel injection and variable valve timing. By automating these processes, solenoids contribute to improved fuel efficiency and enhanced vehicle performance. For international B2B buyers, particularly in regions like Africa and South America, sourcing solenoids that meet OEM standards and come with quality certifications is essential. Buyers should also consider the compatibility of solenoids with existing systems to ensure seamless integration.

What are the Benefits of Solenoids in Manufacturing Automation?

In manufacturing, solenoids are integral to automated assembly lines, driving mechanisms that enable the swift movement of parts and materials. This automation leads to increased production speeds and significant reductions in labor costs. For businesses in Europe and the Middle East, sourcing solenoids that are reliable and durable under continuous operation is critical. Buyers should also assess the supplier’s ability to provide timely support and replacement parts to minimize downtime in their operations.

How Do Solenoids Improve HVAC Systems?

In HVAC applications, solenoids control the flow of refrigerants and air, which is vital for maintaining optimal heating and cooling conditions. This functionality not only enhances energy efficiency but also improves the overall comfort levels in residential and commercial spaces. B2B buyers from regions with extreme climates, such as the Middle East, should prioritize sourcing solenoids with high-temperature tolerance and fast response times to ensure system reliability and performance.

What Role Do Solenoids Play in Agriculture?

In agriculture, solenoids are used in irrigation control systems to automate the opening and closing of valves, thereby optimizing water usage. This technology is crucial for improving crop yields and managing water resources effectively. Buyers from South Africa and other water-scarce regions should look for solenoids that offer corrosion resistance and are rated for high pressure, as these factors are critical for longevity and performance in harsh environments.

Why are Solenoids Critical in Medical Devices?

In the medical field, solenoids are essential for fluid delivery systems in devices such as infusion pumps and automated syringes. They ensure precise dosing, which is crucial for patient safety and treatment efficacy. For B2B buyers in the healthcare sector, particularly in Europe, it is vital to source solenoids that comply with stringent medical standards and offer high reliability. Traceability and compliance with safety regulations are also key considerations when selecting suppliers in this highly regulated industry.

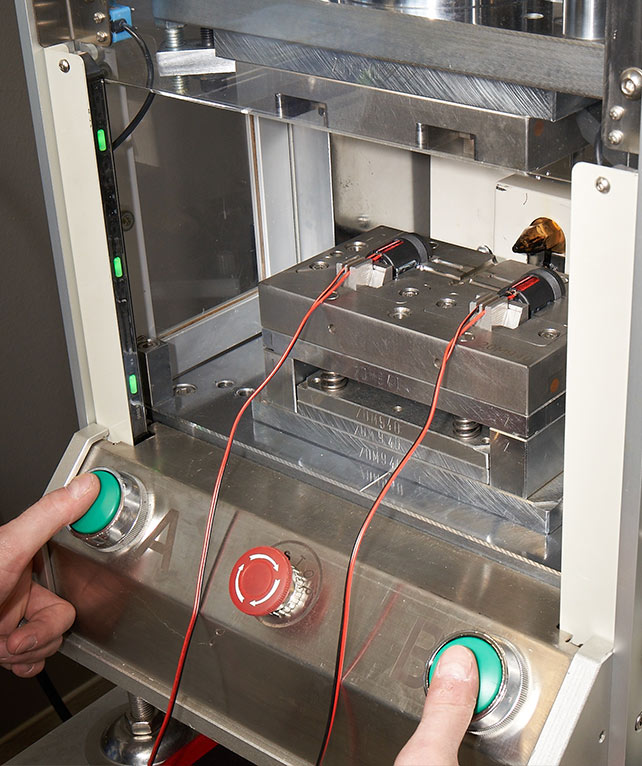

A stock image related to solenoid manufacturer.

Related Video: How Solenoid Valves Work – Basics actuator control valve working principle

3 Common User Pain Points for ‘solenoid manufacturer’ & Their Solutions

Scenario 1: Difficulty in Ensuring Product Reliability in Harsh Environments

The Problem:

Many B2B buyers in industries such as oil and gas, mining, and manufacturing face challenges when sourcing solenoids that can withstand extreme temperatures, humidity, and exposure to corrosive substances. These environmental factors can lead to premature failure of solenoid valves, resulting in costly downtime and repairs. Buyers often struggle to find manufacturers that provide reliable products suitable for their specific operational conditions, which can lead to frustration and financial losses.

The Solution:

To overcome these challenges, it is crucial for buyers to specify their environmental requirements clearly when sourcing solenoids. This means providing potential manufacturers with detailed information about the operating conditions, including temperature ranges, humidity levels, and any exposure to chemicals. Buyers should also look for manufacturers who offer solenoids with certifications for environmental resistance, such as IP ratings for dust and moisture ingress.

In addition, establishing a close relationship with the manufacturer can facilitate the customization of solenoids to meet specific needs. Engaging in collaborative development can yield products that are rigorously tested in conditions that mirror the buyer’s operational environment. Furthermore, requesting detailed documentation on testing standards and performance metrics can help ensure the solenoids will meet the necessary reliability standards.

Scenario 2: High Costs Due to Inefficient Solenoid Selection

The Problem:

Buyers often experience high operational costs when they mistakenly choose solenoids that do not match their application requirements. This includes issues like selecting solenoids with incorrect voltage ratings or insufficient actuation force, leading to system inefficiencies, increased energy consumption, and even equipment damage. For companies operating on tight budgets, these mistakes can be detrimental to profitability.

The Solution:

To mitigate these risks, buyers should invest time in thoroughly understanding their application requirements before making a purchase. This includes assessing the necessary voltage specifications, required actuation forces, and the specific functions that the solenoid must perform.

Creating a comprehensive requirements document can be extremely helpful. This document should outline all specifications and operational needs, which can then be shared with potential manufacturers to ensure they provide suitable options. Moreover, engaging with manufacturers who offer consultation services can provide invaluable insights into the best products for specific applications.

Buyers should also consider the total cost of ownership (TCO) when evaluating solenoid options, factoring in energy efficiency and maintenance costs over the product lifecycle. This holistic approach will lead to better decision-making and ultimately lower operational costs.

Scenario 3: Challenges in Global Sourcing and Compliance

The Problem:

For international B2B buyers, navigating the complexities of global sourcing for solenoids can be daunting. Differences in regulatory standards, compliance requirements, and trade regulations can create significant barriers. Buyers from regions like Africa and South America may face additional challenges in ensuring that imported products meet local safety and operational standards, risking compliance issues and potential fines.

The Solution:

To effectively manage global sourcing challenges, buyers should prioritize manufacturers who are well-versed in international compliance and regulatory standards. This includes understanding local laws and certifications required for solenoids in their respective markets.

Conducting thorough research on potential suppliers is vital; buyers should seek out manufacturers that have a proven track record of exporting to their region and can provide documentation proving compliance with local standards.

Engaging with local trade organizations or industry associations can also provide buyers with resources and insights about navigating compliance issues. Additionally, buyers should leverage digital tools for supply chain transparency, enabling them to track product origins and compliance statuses throughout the sourcing process.

By proactively addressing these challenges and aligning with knowledgeable manufacturers, B2B buyers can streamline their sourcing processes and reduce the risks associated with international procurement.

Strategic Material Selection Guide for solenoid manufacturer

When selecting materials for solenoid manufacturing, international B2B buyers must consider various factors that influence both performance and compliance with regional standards. Below is an analysis of four common materials used in solenoid production, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

What are the Key Properties of Copper in Solenoid Manufacturing?

Copper is a widely used material in solenoid manufacturing due to its excellent electrical conductivity and thermal properties. It typically has a high melting point of around 1,984°F (1,085°C) and can withstand significant pressure, making it suitable for various applications.

Pros:

– High electrical and thermal conductivity, which enhances performance.

– Good corrosion resistance when properly treated.

– Relatively easy to machine and form.

Cons:

– Prone to oxidation, which can affect performance if not coated.

– Higher cost compared to some alternatives like aluminum.

– Limited mechanical strength compared to steel.

Impact on Application:

Copper is ideal for applications requiring efficient energy transfer, such as in automotive and industrial solenoids. However, its oxidation can limit its use in corrosive environments.

Considerations for International Buyers:

Buyers should ensure compliance with standards such as ASTM B170 for copper and its alloys. In regions like South Africa and Brazil, understanding local sourcing and availability of treated copper is essential.

How Does Stainless Steel Perform in Solenoid Applications?

Stainless steel is another popular choice for solenoid components, particularly for housing and structural parts. It offers excellent corrosion resistance and can operate effectively in a wide range of temperatures.

Pros:

– High durability and resistance to corrosion, making it suitable for harsh environments.

– Good mechanical strength, which enhances the longevity of solenoids.

– Can be easily welded and fabricated.

Cons:

– Higher manufacturing complexity due to the need for specialized machining tools.

– Generally more expensive than carbon steel.

– Can be heavier, which may impact the overall design.

Impact on Application:

Stainless steel solenoids are well-suited for applications in the chemical and food processing industries, where corrosion resistance is critical.

Considerations for International Buyers:

Compliance with standards such as ASTM A276 is vital. Buyers in the Middle East and Europe should also consider local regulations regarding food-safe materials.

What Role Does Aluminum Play in Solenoid Manufacturing?

Aluminum is increasingly used in solenoid manufacturing due to its lightweight nature and good corrosion resistance. It has a melting point of approximately 1,221°F (660.3°C), making it suitable for various applications.

Pros:

– Lightweight, which helps reduce overall system weight.

– Good corrosion resistance, especially when anodized.

– Cost-effective compared to copper and stainless steel.

Cons:

– Lower strength compared to steel, which may limit its use in high-stress applications.

– Can be less durable under extreme conditions.

– Requires careful design to avoid galling during assembly.

Impact on Application:

Aluminum is ideal for automotive and aerospace applications where weight savings are crucial. However, it may not be suitable for high-pressure environments.

Considerations for International Buyers:

Buyers should be aware of the standards such as ASTM B221 for aluminum extrusions. In regions like South America, ensuring local availability of aluminum grades is important.

Why is Plastic an Emerging Material in Solenoid Manufacturing?

Plastics, particularly engineering plastics like polycarbonate and nylon, are gaining traction in solenoid applications due to their lightweight and insulating properties. These materials can operate effectively in a range of temperatures and pressures.

Pros:

– Excellent electrical insulation properties.

– Lightweight and cost-effective.

– Resistant to corrosion and chemicals.

Cons:

– Limited mechanical strength compared to metals.

– Temperature sensitivity, which may restrict application in high-heat environments.

– Potential for degradation over time under UV exposure.

Impact on Application:

Plastics are suitable for low-pressure applications and environments where electrical insulation is paramount, such as in consumer electronics.

Considerations for International Buyers:

Compliance with standards like ASTM D638 for plastics is essential. Buyers in Europe should also consider REACH regulations regarding chemical safety.

Summary Table of Material Selection for Solenoid Manufacturing

| Material | Typical Use Case for Solenoid Manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Electrical components in automotive solenoids | High conductivity and thermal performance | Prone to oxidation | Medium |

| Stainless Steel | Chemical processing solenoids | Excellent corrosion resistance | Higher manufacturing complexity | High |

| Aluminum | Aerospace and automotive solenoids | Lightweight and cost-effective | Lower strength under high-stress | Low |

| Plastic | Consumer electronics solenoids | Excellent electrical insulation | Limited mechanical strength | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for solenoid manufacturer

What Are the Key Stages in the Manufacturing Process of Solenoids?

The manufacturing process for solenoids is intricate and involves multiple stages that ensure the final product meets quality and performance standards. Understanding these stages is crucial for B2B buyers looking to source reliable solenoids from manufacturers.

-

Material Preparation

– The initial phase involves selecting high-quality raw materials such as copper wire for coils, steel for the casing, and plastic for insulation. The quality of these materials directly impacts the solenoid’s performance, durability, and reliability.

– Buyers should inquire about the source and grade of materials used, as well as any certifications the materials may have. -

Forming

– This stage includes winding the copper wire into coils and shaping the metal components. Advanced techniques such as CNC machining and automated winding machines are commonly employed to ensure precision.

– Precision in forming is critical, as any deviation can lead to performance issues. B2B buyers should ask potential suppliers about the machinery used and the tolerances they can achieve. -

Assembly

– After forming, components are assembled, which includes inserting the coil into the casing and integrating any required electronic controls. This stage often employs automated assembly lines to enhance efficiency and consistency.

– Buyers should ensure that the assembly processes minimize the risk of human error, which can affect product quality. -

Finishing

– The finishing process includes applying protective coatings, conducting surface treatments, and performing additional quality checks. This step is essential to enhance corrosion resistance and overall durability.

– Buyers may want to know about the finishing techniques used, such as powder coating or anodizing, which can impact the solenoid’s lifespan in various environments.

How Is Quality Assurance Implemented in Solenoid Manufacturing?

Quality assurance (QA) is a critical aspect of the solenoid manufacturing process, ensuring that products meet international standards and client specifications.

-

International Standards for Quality Assurance

– Most reputable solenoid manufacturers adhere to international quality management standards such as ISO 9001, which focuses on effective quality management systems. Compliance with these standards demonstrates a commitment to quality and continuous improvement.

– In addition, industry-specific certifications like CE (Conformité Européenne) for the European market and API (American Petroleum Institute) for oil and gas applications may also be relevant. -

What Are the Key Quality Control Checkpoints?

– The quality control process typically involves several checkpoints:- Incoming Quality Control (IQC): This step verifies the quality of raw materials before they enter the production process.

- In-Process Quality Control (IPQC): During manufacturing, random sampling and inspections ensure that the processes are followed correctly.

- Final Quality Control (FQC): Once the solenoids are assembled, they undergo rigorous testing to ensure they meet performance specifications.

-

Common Testing Methods for Solenoids

– Various testing methods are employed to verify functionality, including:- Electrical testing to ensure proper coil resistance and current draw.

- Pressure testing for solenoids used in fluid applications, ensuring they can withstand operational pressures without leaks.

- Thermal cycling tests to assess performance under varying temperature conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a manufacturer’s quality control processes is essential for ensuring product reliability.

-

Conducting Supplier Audits

– Buyers should consider conducting on-site audits of potential suppliers. This allows them to observe manufacturing processes, quality control measures, and overall operational practices firsthand.

– During audits, focus on the cleanliness of the facility, the professionalism of the staff, and the availability of documentation supporting their quality control processes. -

Requesting Quality Assurance Reports

– Suppliers should provide detailed quality assurance reports that outline their QA processes, testing results, and compliance with relevant standards. These documents can help buyers assess the supplier’s commitment to quality.

– Look for historical data on defect rates and customer complaints, which can provide insight into the reliability of the supplier’s products. -

Engaging Third-Party Inspection Services

– Utilizing third-party inspection services can offer an unbiased assessment of the manufacturer’s quality assurance processes. These services can conduct inspections at various stages of production, from raw material sourcing to final assembly.

– This added layer of verification can significantly reduce risks associated with sourcing from international suppliers.

What Are the Quality Control Nuances for International Buyers?

International B2B buyers must navigate various quality control nuances when sourcing solenoids from manufacturers in different regions.

-

Understanding Regional Standards

– Different regions may have specific quality standards that manufacturers must adhere to. For instance, European buyers should be familiar with CE marking requirements, while buyers in North America might focus on UL (Underwriters Laboratories) certifications.

– Buyers should ensure that the manufacturer complies with the relevant regulations for their specific market. -

Cultural Considerations in Quality Assurance

– Cultural differences can impact manufacturing and quality assurance practices. For example, some regions may prioritize speed over quality, leading to potential trade-offs.

– Building strong relationships with suppliers can help mitigate misunderstandings and ensure that quality remains a priority. -

Logistics and Supply Chain Factors

– Shipping times and customs regulations can affect the delivery of quality products. Buyers should account for potential delays and ensure that their supply chain is robust enough to handle these challenges.

– It’s advisable to maintain open lines of communication with suppliers to stay informed about any issues that may arise during the shipping process.

By understanding the manufacturing processes and quality assurance measures in solenoid production, B2B buyers can make informed decisions, ensuring they partner with reliable manufacturers who meet their specific needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘solenoid manufacturer’

To successfully procure solenoids from manufacturers, international B2B buyers must navigate a series of critical steps. This checklist is designed to streamline the sourcing process, ensuring that you select the right supplier to meet your operational needs.

Step 1: Define Your Technical Specifications

Before reaching out to manufacturers, clearly outline your technical requirements. Consider the application of the solenoids, including size, voltage, and type (e.g., direct-acting, pilot-operated). Providing precise specifications helps suppliers understand your needs and deliver suitable products.

- Identify Application Needs: Determine where the solenoid will be used (e.g., automotive, industrial automation).

- Consider Environmental Factors: Assess if the solenoid needs to withstand harsh conditions like temperature extremes or moisture.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable solenoid manufacturers. Look for companies with experience in your specific industry or application.

- Check Industry Credentials: Look for certifications such as ISO 9001, which indicates a commitment to quality management.

- Explore Online Reviews and Feedback: Utilize platforms like LinkedIn or industry-specific forums to gather insights from previous buyers.

Step 3: Evaluate Supplier Capabilities

Assess the capabilities of potential suppliers to ensure they can meet your production requirements. This includes examining their manufacturing processes, technology, and capacity.

- Request Product Samples: Ask for samples to evaluate the quality and performance of their solenoids.

- Inquire About Production Lead Times: Understand their capacity to meet your delivery timelines, especially if you have urgent needs.

Step 4: Verify Supplier Certifications

Ensuring that your chosen supplier has the necessary certifications is crucial for compliance and quality assurance.

- Request Certification Documentation: Ask for copies of relevant certifications that verify their manufacturing standards.

- Confirm Compliance with Local Regulations: Especially important for buyers in regions with strict import regulations, such as the EU or Middle East.

Step 5: Assess After-Sales Support

A reliable after-sales service can significantly impact your operational efficiency. Evaluate the support options offered by the supplier.

- Inquire About Warranty Policies: Understand the warranty terms for the solenoids you are purchasing.

- Check for Technical Support Availability: Ensure that the supplier provides adequate support for installation and troubleshooting.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, negotiate terms that align with your business needs. This includes pricing, payment terms, and delivery schedules.

- Discuss Bulk Order Discounts: If you plan to order in large quantities, inquire about potential discounts.

- Clarify Shipping and Handling Fees: Ensure you understand the total cost involved, including shipping, to avoid surprises.

Step 7: Establish a Trial Order

Before committing to a long-term partnership, consider placing a trial order. This step allows you to evaluate the supplier’s performance and product quality firsthand.

- Monitor Order Fulfillment: Assess the supplier’s ability to meet timelines and quality standards during this initial order.

- Gather Feedback from Your Team: Involve your technical team in the evaluation process to ensure the solenoids meet operational requirements.

By following this checklist, you can effectively navigate the complexities of sourcing solenoids from manufacturers, ensuring that you make informed decisions that align with your business objectives.

Comprehensive Cost and Pricing Analysis for solenoid manufacturer Sourcing

What Are the Key Cost Components in Solenoid Manufacturing?

When sourcing solenoids, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The type of materials used (e.g., copper wire for coils, steel for housings) significantly affects pricing. High-quality materials enhance durability and performance, but they also increase costs.

-

Labor: Labor costs vary by region and can be influenced by local wage standards and the complexity of the manufacturing process. Skilled labor is often required for assembly and quality control, impacting overall expenses.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and equipment depreciation. Efficient manufacturing practices can help minimize these costs.

-

Tooling: Custom tooling for specific solenoid designs can be a substantial upfront investment. However, this cost can be amortized over larger production runs, making it more economical in the long run.

-

Quality Control (QC): Rigorous QC processes ensure that the solenoids meet industry standards. These procedures can add to the cost but are essential for maintaining product reliability and compliance.

-

Logistics: Shipping and handling costs should not be overlooked. International shipping can incur significant expenses, especially for bulky or heavy products.

-

Margin: Manufacturers typically add a profit margin to cover business risks and operational costs. This margin can fluctuate based on market conditions and competition.

How Do Price Influencers Affect Solenoid Costs?

Several factors can influence the pricing of solenoids, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Higher purchase volumes often lead to lower per-unit costs due to economies of scale. Understanding a supplier’s MOQ can help buyers plan their orders more effectively.

-

Specifications and Customization: Customized solenoids designed for specific applications may incur additional costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Choices: The selection of materials can dramatically affect pricing. For instance, opting for standard materials over specialized ones can yield cost savings.

-

Quality Certifications: Solenoids that meet international quality standards (e.g., ISO, CE) may come at a premium. However, these certifications can provide assurance of reliability and performance, which is vital for critical applications.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their proven track record, while newer suppliers might offer competitive rates to build their client base.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for international buyers. They dictate the responsibilities of buyers and sellers in shipping, insurance, and tariffs, which can affect the total landed cost.

What Are the Best Negotiation Strategies for B2B Buyers?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, here are actionable negotiation tips:

-

Leverage Volume Discounts: If possible, consolidate orders to meet or exceed MOQs, allowing for better pricing.

-

Conduct Total Cost of Ownership (TCO) Analysis: Consider not just the purchase price but also long-term costs associated with maintenance, energy consumption, and reliability.

-

Build Relationships: Establishing a strong relationship with suppliers can lead to better pricing and terms. Open communication about expectations can foster trust.

-

Explore Multiple Suppliers: Don’t settle on the first offer. Comparing quotes from multiple manufacturers can provide leverage during negotiations.

-

Be Aware of Pricing Nuances: Understand that regional pricing can vary significantly. Factors such as local economic conditions, currency fluctuations, and logistics can influence costs.

Disclaimer on Pricing

Prices for solenoids can vary widely based on the factors mentioned above. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure they receive competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing solenoid manufacturer With Other Solutions

In the industrial sector, selecting the appropriate technology for automation and control systems is crucial. Solenoids are widely used for their reliability and efficiency, but there are alternative solutions that may offer specific advantages depending on the application. Understanding these alternatives can help international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, make informed purchasing decisions.

Comparison Table of Solenoid Manufacturer and Alternatives

| Comparison Aspect | Solenoid Manufacturer | Pneumatic Actuators | Electric Motors |

|---|---|---|---|

| Performance | High precision; quick response time | Moderate precision; slower than solenoids | High torque; variable speed control |

| Cost | Moderate initial cost; lower long-term maintenance | Generally lower cost, but may require additional components | Higher initial investment; variable operational costs |

| Ease of Implementation | Simple integration; requires electrical connections | Requires air supply setup; more complex | Requires more extensive setup and control systems |

| Maintenance | Low maintenance; reliable over time | Moderate maintenance; potential for air leaks | Higher maintenance; wear and tear on moving parts |

| Best Use Case | Ideal for rapid switching applications | Best for large-scale machinery with consistent pressure | Suitable for applications needing variable speed and torque |

What Are the Advantages and Disadvantages of Pneumatic Actuators?

Pneumatic actuators use compressed air to create mechanical motion. They are advantageous in applications where high force and speed are necessary, such as in packaging and assembly lines. They tend to have lower initial costs compared to solenoids and are suitable for environments where electric sparks might pose a risk. However, they require a reliable air supply and regular maintenance to prevent leaks, which can lead to inefficiencies and increased operational costs. Their response time is generally slower compared to solenoids, making them less ideal for applications requiring rapid actuation.

How Do Electric Motors Compare to Solenoids?

Electric motors provide variable speed control and high torque, making them suitable for applications that demand precise motion control, such as conveyor systems and robotics. They can be more expensive to implement due to the need for additional components, such as controllers and feedback systems. Maintenance can be more intensive as motors have moving parts that wear over time. While they offer flexibility in terms of speed and torque, their complexity and higher costs may deter buyers looking for straightforward solutions.

Making the Right Choice: How Should B2B Buyers Decide?

When choosing between solenoids, pneumatic actuators, and electric motors, B2B buyers should carefully consider their specific application requirements. Solenoids are ideal for fast, reliable switching in compact spaces. Pneumatic actuators are suitable for larger, force-demanding operations but come with additional maintenance needs. Electric motors excel in applications requiring variable control but involve a higher initial investment and more complex integration.

Ultimately, the decision should align with the operational goals, budget constraints, and maintenance capabilities of the buyer’s organization. By understanding the strengths and weaknesses of each option, buyers can select the solution that best fits their needs, ensuring efficiency and effectiveness in their operations.

Essential Technical Properties and Trade Terminology for solenoid manufacturer

What Are the Essential Technical Properties of Solenoids for B2B Buyers?

When sourcing solenoids, understanding their technical properties is crucial for making informed purchasing decisions. Here are some key specifications that international B2B buyers should consider:

1. Material Grade: Why Does It Matter?

The material grade of solenoids typically refers to the type of metal used in their construction, which can include stainless steel, brass, or plastic. The choice of material affects not only the durability and corrosion resistance of the solenoid but also its suitability for various applications. For instance, stainless steel solenoids are preferable in corrosive environments, making them ideal for industries like oil and gas. Understanding material grades helps buyers select solenoids that meet their operational demands while ensuring longevity.

2. Tolerance: How Does It Impact Performance?

Tolerance refers to the permissible limits of variation in a physical dimension of the solenoid. High tolerance levels are crucial for applications requiring precise control, such as automotive or aerospace systems. A solenoid with poor tolerance can lead to malfunctions or failures, resulting in costly downtime. Therefore, buyers should inquire about tolerance specifications to ensure compatibility with their systems.

3. Voltage and Current Ratings: What Are the Key Considerations?

Solenoids operate on specific voltage and current ratings, usually expressed in volts (V) and amperes (A). Understanding these ratings is vital for ensuring that the solenoid can function within the electrical parameters of the intended application. Incorrect voltage or current can lead to overheating or failure. B2B buyers should always match these ratings with their application needs to avoid operational issues.

4. Response Time: Why Is It Critical for Automation?

Response time is the duration it takes for a solenoid to actuate after receiving an electrical signal. In automated systems, a quick response time is essential for maintaining efficiency and accuracy. A solenoid with a fast response time can improve overall system performance, making it a key consideration for buyers in fast-paced industries like manufacturing or robotics.

5. Coil Resistance: What Role Does It Play?

Coil resistance is a measure of how much electrical resistance the solenoid’s coil offers. It affects the power consumption and efficiency of the solenoid. Lower resistance typically means higher efficiency, which is crucial for reducing operational costs. Buyers should evaluate coil resistance to ensure optimal energy use, especially in large-scale applications.

What Common Trade Terminology Should B2B Buyers Understand?

Familiarity with industry-specific terminology can significantly streamline the purchasing process. Here are some essential terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer): What Is Its Significance?

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable suppliers who provide quality components that meet industry standards.

2. MOQ (Minimum Order Quantity): How Does It Affect Your Purchase?

MOQ represents the smallest quantity of a product that a supplier is willing to sell. This can impact procurement strategies, especially for smaller companies or those looking to test new products. Knowing the MOQ helps buyers plan their inventory and budget effectively.

3. RFQ (Request for Quotation): Why Is It Important?

An RFQ is a document that solicits bids from suppliers to provide specific products or services. It is essential for buyers to issue RFQs to obtain competitive pricing and ensure they are sourcing the best value for their investments.

4. Incoterms: What Do They Mean for International Trade?

Incoterms (International Commercial Terms) are a set of rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps buyers navigate shipping, insurance, and risk management, ultimately facilitating smoother international trade.

5. Lead Time: How Does It Impact Delivery?

Lead time refers to the time taken from placing an order to receiving it. Understanding lead times is crucial for planning and managing supply chains effectively. Buyers should always inquire about lead times to ensure that they can meet their operational deadlines.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing solenoids, ultimately leading to better outcomes for their projects and operations.

Navigating Market Dynamics and Sourcing Trends in the solenoid manufacturer Sector

What are the Key Trends Shaping the Solenoid Manufacturer Market?

The global solenoid manufacturer market is experiencing significant growth driven by automation and the increasing demand for precision control in various applications. Key drivers include the rise of smart technologies and Industry 4.0, which emphasize efficiency and automation across sectors such as automotive, HVAC, and industrial machinery. For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for making informed sourcing decisions.

Emerging trends in the market include the integration of IoT (Internet of Things) technologies into solenoid designs, enabling real-time monitoring and control. This shift is particularly relevant for industries that require high reliability and performance, such as manufacturing and energy management. Additionally, there is a growing preference for customized solenoid solutions that cater to specific operational needs, enhancing product differentiation and competitive advantage.

Furthermore, buyers should be aware of the geographical shifts in manufacturing hubs. While traditional manufacturing centers like Europe and North America remain significant, emerging markets in Asia and Latin America are becoming increasingly important due to lower production costs and expanding capabilities. This trend presents opportunities for B2B buyers to diversify their supplier base and negotiate better terms.

How Can Sustainability and Ethical Sourcing Impact Solenoid Manufacturing?

Sustainability has emerged as a critical concern in the solenoid manufacturing sector. The environmental impact of production processes, from raw material extraction to manufacturing waste, is under scrutiny. International buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices. This includes adopting energy-efficient manufacturing processes, minimizing waste, and using eco-friendly materials.

Ethical sourcing is equally important. B2B buyers should evaluate their supply chains for compliance with labor laws and ethical standards. Suppliers that possess certifications for sustainable practices, such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety, are often viewed more favorably. These certifications not only mitigate risks but also enhance brand reputation in increasingly eco-conscious markets.

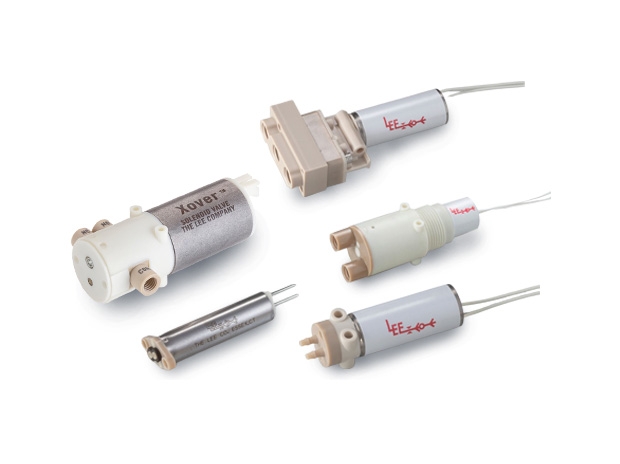

A stock image related to solenoid manufacturer.

Incorporating ‘green’ materials into solenoid products is becoming a competitive differentiator. Buyers can look for suppliers using recyclable materials or those that have developed innovative manufacturing techniques to reduce carbon footprints. By aligning with ethical and sustainable suppliers, B2B buyers can contribute to broader environmental goals while also meeting regulatory requirements in their respective markets.

What is the Evolution of the Solenoid Manufacturing Sector?

The solenoid manufacturing sector has evolved significantly over the past few decades, driven by technological advancements and changing industrial needs. Initially, solenoids were primarily used in simple electromechanical applications, such as locking mechanisms and basic control systems. However, as industries have progressed, the demand for more sophisticated solenoid solutions has surged.

The introduction of digital technologies has revolutionized the design and functionality of solenoids. Today, solenoids are integrated into complex systems that require precise control and real-time feedback. This evolution has prompted manufacturers to invest in R&D, leading to innovations that enhance performance, reliability, and energy efficiency.

Moreover, the historical focus on cost has shifted towards value, with buyers now seeking high-quality, durable solenoids that offer long-term savings. This transformation highlights the importance of understanding market dynamics and sourcing trends for international B2B buyers, as they navigate a landscape increasingly defined by technological integration and sustainability imperatives.

Frequently Asked Questions (FAQs) for B2B Buyers of solenoid manufacturer

-

How do I troubleshoot solenoid valve issues in my applications?

Troubleshooting solenoid valve issues often starts with identifying the symptoms. Common problems include failure to open or close, leaking, or erratic operation. Begin by checking the power supply to the solenoid, ensuring it’s within the required voltage range. Inspect the wiring for any damage or loose connections. If the valve is stuck, it may require cleaning or replacing the internal components. Additionally, consider using a flyback diode to protect against voltage spikes, which can cause premature failure. -

What is the best solenoid valve for high-pressure applications?

For high-pressure applications, solenoid valves made from robust materials like stainless steel or brass are recommended. Look for valves specifically designed for high-pressure environments, typically rated above 150 psi. Additionally, consider valves with a direct-acting mechanism, as they tend to perform better under high-pressure conditions. Brands that offer customizable pressure ratings can be beneficial for unique applications, ensuring safety and reliability in your operations. -

What are the key factors to consider when sourcing solenoids internationally?

When sourcing solenoids internationally, consider factors such as the manufacturer’s experience, certifications (like ISO 9001), and their ability to meet local standards. Evaluate their production capacity and lead times, especially if you require large orders. It’s essential to assess their quality assurance processes and after-sales support. Additionally, understanding the logistics involved, including shipping costs and customs regulations, is crucial to ensure timely delivery and compliance. -

How can I customize solenoids for specific applications?

Customizing solenoids involves discussing your specific requirements with manufacturers. Key aspects to consider include voltage specifications, size, mounting options, and material choices. Some manufacturers offer design services that allow you to collaborate on creating a solenoid tailored to your application. Ensure to communicate any unique operational conditions, such as temperature extremes or exposure to corrosive substances, to guarantee the solenoid’s durability and functionality.

- What are the minimum order quantities (MOQs) for solenoids from manufacturers?

Minimum order quantities can vary significantly between manufacturers and depend on factors like production capabilities and the complexity of the solenoid. Generally, MOQs for custom solenoids can range from 50 to several hundred units. For standard models, some manufacturers may accommodate smaller orders. It’s advisable to discuss your specific needs with potential suppliers to negotiate MOQs that align with your business requirements.

-

What payment terms are common when purchasing solenoids internationally?

Common payment terms in international B2B transactions include advance payment, letter of credit (LC), or net 30/60 days after delivery. Advance payments are often required for custom orders, while LCs provide security for both parties. Always clarify payment terms before finalizing any agreements to avoid misunderstandings. It’s also wise to consider using escrow services for large transactions to ensure safety and trust in the deal. -

How do I ensure quality assurance when sourcing solenoids?

Ensuring quality assurance involves several steps. First, verify that the manufacturer has quality certifications, such as ISO 9001. Request samples before placing a large order to assess the quality of the solenoids. Establish clear quality control criteria and discuss them with the supplier. Additionally, consider conducting factory audits or hiring third-party inspection services to ensure that manufacturing processes meet your standards. -

What logistics considerations should I keep in mind when importing solenoids?

When importing solenoids, factor in shipping methods, delivery times, and costs. Evaluate whether air freight or sea freight is more suitable for your needs, considering urgency and budget. Understand customs regulations and ensure all necessary documentation is prepared to avoid delays. Additionally, consider working with a freight forwarder who can assist with the logistics process, ensuring smooth transportation and handling of your orders.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for solenoid manufacturer

In conclusion, strategic sourcing is paramount for international B2B buyers looking to optimize their procurement of solenoids. As highlighted throughout this guide, establishing strong relationships with reliable manufacturers can lead to significant cost savings, enhanced product quality, and improved supply chain resilience. Buyers from Africa, South America, the Middle East, and Europe should focus on assessing suppliers not just on price, but also on their technological capabilities, certifications, and responsiveness to market demands.

How Can International Buyers Enhance Their Sourcing Strategy for Solenoids?

Investing time in thorough supplier evaluations, including site visits and product trials, can uncover potential partnerships that align with your operational goals. Additionally, leveraging digital platforms for sourcing can streamline the procurement process, providing access to a broader array of manufacturers and innovative solutions.

What’s Next for the Solenoid Market?

Looking ahead, the solenoid market is poised for growth driven by advancements in automation and smart technology. As industries increasingly adopt these innovations, buyers should stay informed about emerging trends and technological advancements to ensure they are sourcing the most effective solutions. Engage with manufacturers who demonstrate a commitment to innovation, sustainability, and customer service excellence.

By strategically sourcing solenoids now, businesses can position themselves for success in a competitive landscape. Take action today to enhance your supply chain and drive operational efficiencies.