Discover Cost-Effective Coffee Machines from China (2025)

Introduction: Navigating the Global Market for coffee machine china

Navigating the global market for coffee machines from China presents a unique set of challenges for international B2B buyers, particularly those based in Africa, South America, the Middle East, and Europe. As the demand for quality coffee continues to rise, sourcing the right coffee machine can become a daunting task. This guide aims to simplify the process by offering comprehensive insights into various types of coffee machines, their applications, and essential considerations for supplier vetting.

Understanding the nuances of the Chinese coffee machine market is crucial for making informed purchasing decisions. This guide delves into factors such as cost analysis, quality assurance, and logistical considerations, empowering buyers to navigate the complexities of international procurement confidently. Whether you are a café owner in the UAE, a distributor in South America, or a restaurant operator in Europe, this resource provides actionable insights tailored to your specific needs.

By equipping you with the knowledge to evaluate different suppliers and products effectively, we aim to enhance your purchasing strategy, ensuring you invest in coffee machines that meet your operational requirements and customer expectations. With this guide, you can unlock the potential of the global coffee machine market, transforming your business offerings and elevating the customer experience.

Understanding coffee machine china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Espresso Machines | High pressure brewing, compact design | Coffee shops, restaurants | Pros: Quick brewing, rich flavor. Cons: Requires skilled operation, maintenance intensive. |

| Drip Coffee Makers | Automatic brewing, large capacity | Offices, hotels | Pros: Easy to use, consistent quality. Cons: Slower than other methods, less flavor complexity. |

| Pod Coffee Machines | Single-serve, pre-packaged coffee pods | Convenience stores, small cafes | Pros: Convenience, minimal cleanup. Cons: Higher cost per cup, limited coffee variety. |

| Turkish Coffee Pots | Traditional brewing method, small capacity | Specialty coffee shops, cultural events | Pros: Unique flavor profile, cultural appeal. Cons: Time-consuming, requires specific skills. |

| Cold Brew Coffee Makers | Steeping method, large batch brewing | Cafes, restaurants, events | Pros: Smooth taste, less acidity. Cons: Longer preparation time, requires planning. |

What Are the Key Characteristics of Espresso Machines?

Espresso machines are designed to brew coffee by forcing hot water through finely-ground coffee under high pressure. This method produces a concentrated coffee shot with a rich flavor and a thick crema on top. Ideal for coffee shops and restaurants, these machines can vary in size and complexity, from compact models for small spaces to larger commercial units. When purchasing, consider the machine’s durability, ease of use, and maintenance requirements, as skilled baristas are often needed to operate them effectively.

How Do Drip Coffee Makers Serve B2B Needs?

Drip coffee makers are widely used in offices and hotels due to their ability to brew large quantities of coffee automatically. They operate by dripping hot water over ground coffee, allowing for a consistent and easy brewing process. Buyers should look for machines with programmable features and thermal carafes to keep coffee warm without burning it. While they offer convenience and reliability, they may lack the flavor complexity found in espresso or specialty brewing methods.

What Advantages Do Pod Coffee Machines Offer?

Pod coffee machines provide a single-serve brewing option using pre-packaged coffee pods, making them popular in convenience stores and small cafes. Their key advantages are convenience and minimal cleanup, appealing to busy consumers and businesses. However, buyers should be aware of the higher cost per cup compared to traditional brewing methods and the limited variety of coffee available in pod form. When selecting a model, consider the range of compatible pods and the machine’s reliability.

Why Choose Turkish Coffee Pots for Specialty Markets?

Turkish coffee pots, known as cezve or ibrik, are used to brew coffee using a traditional method that involves boiling finely ground coffee with water and sugar. This method is particularly suitable for specialty coffee shops and cultural events, where the unique flavor profile and preparation ritual can enhance the customer experience. While they offer a distinctive taste, Turkish coffee pots require skill and time, making them less practical for high-volume environments.

How Do Cold Brew Coffee Makers Fit into B2B Applications?

Cold brew coffee makers are designed for brewing coffee using a steeping method over an extended period, typically 12-24 hours. This process results in a smooth, less acidic coffee that appeals to a growing market segment. Ideal for cafes, restaurants, and events, these machines can brew large batches to meet demand. However, buyers need to account for the longer preparation time and the need for planning, as cold brew cannot be made on the fly like traditional coffee methods.

Related Video: De’Longhi All-in-One Combination Coffee and Espresso Machine Review

Key Industrial Applications of coffee machine china

| Industry/Sector | Specific Application of coffee machine china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Commercial coffee machines for hotels and cafes | Enhances customer satisfaction and loyalty | Durability, warranty, service support, and energy efficiency |

| Retail | Self-service coffee kiosks in supermarkets | Increases foot traffic and impulse purchases | Compact design, ease of use, and maintenance requirements |

| Corporate Offices | Office coffee machines for employee use | Boosts employee morale and productivity | Customization options, size, and coffee variety offered |

| Food and Beverage | Specialty coffee machines for restaurants | Elevates menu offerings and profit margins | Quality of brewing, brand reputation, and supplier reliability |

| Events and Catering | Portable coffee machines for events | Provides high-quality service and experience | Mobility, setup time, and capacity to serve large groups |

How Are Coffee Machines Used in the Hospitality Sector?

In the hospitality industry, coffee machines from China are vital for hotels and cafes. They not only provide high-quality beverages but also enhance the overall guest experience. By investing in commercial-grade coffee machines, establishments can ensure consistency in flavor and presentation. Key considerations for international buyers include the durability of machines, warranty terms, and the availability of service support, particularly for regions in Africa and the Middle East where maintenance services may be less accessible.

What Role Do Coffee Machines Play in Retail Environments?

Self-service coffee kiosks equipped with coffee machines from China are becoming increasingly popular in supermarkets. These machines attract customers and encourage impulse purchases, significantly boosting sales. Retailers must focus on sourcing compact machines that are user-friendly and easy to maintain, as well as ensuring they comply with local health regulations. Buyers from South America should consider the local market preferences for coffee types and flavors to maximize customer satisfaction.

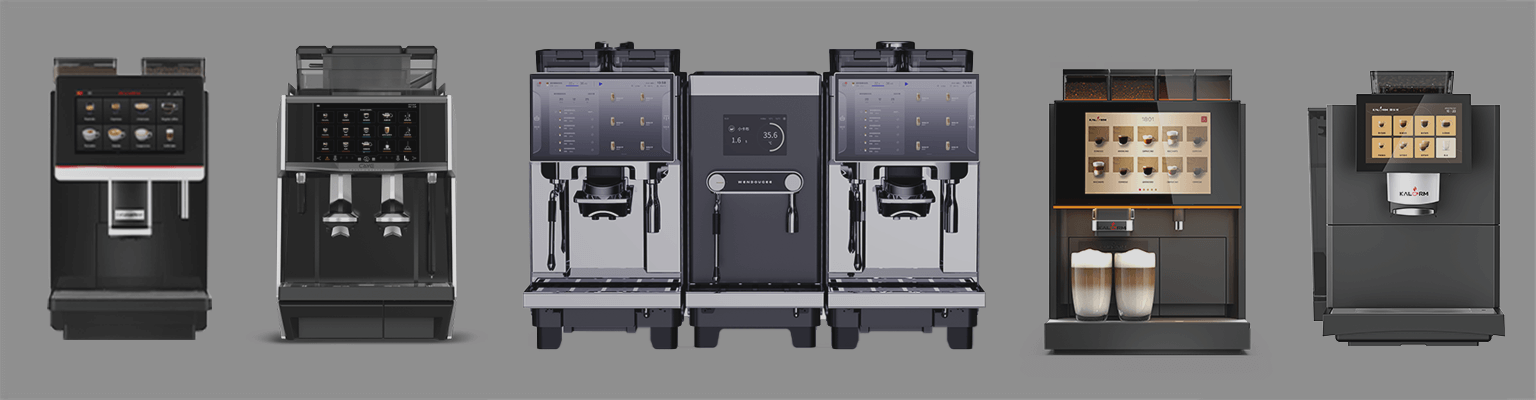

A stock image related to coffee machine china.

How Do Coffee Machines Enhance Corporate Workplaces?

Corporate offices are increasingly adopting coffee machines to improve employee morale and productivity. Access to quality coffee can enhance workplace satisfaction, leading to higher retention rates. When sourcing coffee machines, companies should consider customization options, such as branding and size, to fit their specific office environment. In Europe, where remote work is prevalent, compact and versatile machines that require minimal maintenance are particularly appealing.

Why Are Specialty Coffee Machines Important for Restaurants?

Specialty coffee machines are essential for restaurants looking to elevate their menu offerings. These machines allow establishments to serve unique coffee beverages, which can differentiate them from competitors and increase profit margins. Buyers should prioritize the quality of brewing and the reputation of the brand when sourcing these machines. In regions like the Middle East, where coffee culture is deeply ingrained, ensuring that the machines can handle high volumes during peak hours is crucial.

What Are the Benefits of Portable Coffee Machines for Events?

Portable coffee machines are a game-changer for event organizers, providing high-quality coffee service at weddings, conferences, and other gatherings. They enhance the attendee experience, making events more memorable. When sourcing these machines, considerations include mobility, setup time, and capacity to serve large groups efficiently. Buyers from Africa should look for suppliers who can offer robust machines that can withstand varying power supply conditions often encountered in remote areas.

Related Video: Bühler RoastMasterTM60 Coffee Roaster

3 Common User Pain Points for ‘coffee machine china’ & Their Solutions

Scenario 1: Navigating Quality Assurance Challenges with Coffee Machines from China

The Problem:

International B2B buyers often struggle with ensuring the quality and reliability of coffee machines sourced from China. With various manufacturers offering competitive prices, buyers may find it challenging to distinguish between reputable suppliers and those that compromise on quality. This uncertainty can lead to issues such as equipment malfunctions, inconsistent coffee quality, and ultimately, customer dissatisfaction. Buyers in regions like Africa and South America, where access to on-ground inspections may be limited, face heightened risks in this area.

The Solution:

To mitigate quality assurance challenges, buyers should implement a thorough supplier evaluation process. Start by researching potential suppliers’ backgrounds, checking for certifications such as ISO 9001, and reading reviews or testimonials from other B2B clients. It’s also beneficial to request samples of coffee machines to evaluate their functionality and build quality firsthand before making large orders. Additionally, consider leveraging third-party inspection services that can perform quality checks at the manufacturing facility in China. This proactive approach not only helps ensure product quality but also builds a trustworthy relationship with suppliers, which is crucial for long-term partnerships.

Scenario 2: Overcoming Language and Cultural Barriers in Communication

The Problem:

Communication barriers can be a significant hurdle for B2B buyers when dealing with Chinese manufacturers. Language differences may lead to misunderstandings regarding product specifications, pricing, and delivery schedules. Cultural nuances in business practices can also complicate negotiations, causing delays or misalignment in expectations. This challenge is particularly pronounced for buyers in the Middle East and Europe, where business etiquette may differ significantly from that in China.

The Solution:

To overcome these communication barriers, buyers should consider engaging a local intermediary or a sourcing agent familiar with both Chinese culture and the nuances of the coffee machine industry. This intermediary can facilitate clear communication, help bridge cultural gaps, and provide insights into negotiation strategies that resonate with Chinese manufacturers. Additionally, employing technology tools such as translation software or apps can enhance real-time communication. Establishing clear, written agreements detailing all specifications, terms, and conditions can further minimize misunderstandings and ensure that all parties are aligned on expectations.

Scenario 3: Managing Logistics and Import Regulations Effectively

The Problem:

Another common pain point for B2B buyers sourcing coffee machines from China is managing logistics and navigating complex import regulations. Delays due to customs clearance, shipping mishaps, or unexpected tariffs can disrupt supply chains and lead to financial losses. Buyers from regions like Europe and Africa, where import regulations can vary significantly, often find themselves unprepared for the complexities involved in international shipping.

The Solution:

To effectively manage logistics and import regulations, buyers should work closely with logistics experts or freight forwarders who specialize in international shipments from China. These professionals can provide guidance on the most efficient shipping routes, help navigate customs requirements, and advise on documentation needed for smooth clearance. It’s also advisable to stay updated on trade agreements and tariffs that may impact costs. Buyers can streamline the process by preparing all necessary import documentation in advance and maintaining open communication with their logistics partner throughout the shipping process. This proactive approach can significantly reduce delays and ensure that coffee machines arrive on schedule.

Strategic Material Selection Guide for coffee machine china

What Are the Key Materials Used in Coffee Machine Manufacturing?

When selecting materials for coffee machines, it’s crucial to consider their properties, advantages, and disadvantages. Here, we analyze four common materials: stainless steel, aluminum, plastic, and ceramic. Each material has unique characteristics that can significantly impact performance, durability, and overall suitability for international markets.

How Does Stainless Steel Benefit Coffee Machine Production?

Key Properties: Stainless steel is renowned for its high corrosion resistance, strength, and ability to withstand high temperatures and pressures. It typically has a temperature rating of up to 500°F (260°C) and can endure pressures exceeding 100 psi.

Pros & Cons: The durability of stainless steel makes it a top choice for coffee machines, as it can withstand frequent use without degrading. However, it is more expensive than other materials and can be complex to manufacture due to the need for specialized welding techniques.

Impact on Application: Stainless steel is compatible with various media, including water, steam, and coffee oils, ensuring that the flavor and quality of the coffee are preserved.

Considerations for International Buyers: Buyers from regions like the Middle East and Europe should ensure that the stainless steel used complies with standards such as ASTM A240 or EN 10088. Additionally, the aesthetic appeal of stainless steel may be preferred in high-end markets.

What Role Does Aluminum Play in Coffee Machine Design?

Key Properties: Aluminum is lightweight and has excellent thermal conductivity, making it suitable for rapid heating and cooling processes. It can handle temperatures up to 400°F (204°C) but is less effective under high pressure compared to stainless steel.

Pros & Cons: The primary advantage of aluminum is its cost-effectiveness and ease of manufacturing. However, its susceptibility to corrosion and lower strength compared to stainless steel can limit its use in high-end machines.

Impact on Application: Aluminum is suitable for components that require quick temperature changes but may not be ideal for parts exposed to high pressure or corrosive environments.

Considerations for International Buyers: Buyers should be aware of the alloy specifications and ensure compliance with local standards, such as JIS for Japan or ASTM for the U.S. markets.

How Do Plastics Enhance Coffee Machine Functionality?

Key Properties: Modern engineering plastics, such as polycarbonate and polypropylene, offer good thermal stability and resistance to chemicals. They can typically handle temperatures up to 250°F (121°C).

Pros & Cons: Plastics are lightweight and cost-effective, allowing for intricate designs and reduced manufacturing costs. However, they may not withstand high temperatures or pressures as effectively as metals, leading to potential durability issues.

Impact on Application: Plastics are often used in non-structural components like water reservoirs and drip trays, where corrosion resistance is essential, but high strength is not critical.

Considerations for International Buyers: Buyers must ensure that the plastics used are food-safe and compliant with regulations such as FDA standards in the U.S. or EU regulations in Europe.

What Advantages Does Ceramic Offer in Coffee Machine Manufacturing?

Key Properties: Ceramic materials are known for their excellent thermal insulation properties and resistance to chemical corrosion. They can typically handle temperatures up to 1,500°F (815°C) but are brittle and can break under mechanical stress.

Pros & Cons: Ceramics provide a unique aesthetic appeal and can enhance the flavor of coffee by preventing metallic tastes. However, their brittleness limits their application in high-stress areas of coffee machines.

Impact on Application: Ceramics are often used for heating elements and decorative components, where high temperatures are present but mechanical stress is minimal.

Considerations for International Buyers: Buyers should consider the fragility of ceramics and ensure they meet local safety and quality standards, especially in regions with stringent regulations.

Summary Table of Material Selection for Coffee Machines

| Material | Typical Use Case for coffee machine china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Boiler and brewing components | High durability and corrosion resistance | Higher cost and complex manufacturing | High |

| Aluminum | Heating elements and housing | Lightweight and cost-effective | Lower strength and corrosion issues | Medium |

| Plastic | Water reservoirs and drip trays | Lightweight and versatile design | Limited thermal and pressure resistance | Low |

| Ceramic | Heating elements and aesthetic components | Excellent thermal insulation and flavor preservation | Brittle and prone to breakage | Medium |

This guide provides essential insights into material selection for coffee machines, helping international B2B buyers make informed decisions based on performance, cost, and compliance with industry standards.

In-depth Look: Manufacturing Processes and Quality Assurance for coffee machine china

What Are the Main Stages of Manufacturing Coffee Machines in China?

The manufacturing of coffee machines in China typically involves several key stages, each essential for ensuring the quality and performance of the final product. Understanding these stages can help international B2B buyers make informed decisions when sourcing coffee machines.

Material Preparation: What Raw Materials Are Used?

The manufacturing process begins with material preparation. Common materials for coffee machines include stainless steel, aluminum, and plastic. Stainless steel is favored for its durability and resistance to corrosion, while aluminum is lightweight and offers excellent thermal conductivity. Plastic components are often used for aesthetic and functional parts, such as water reservoirs and buttons.

During this stage, suppliers must ensure that materials meet industry standards. For instance, stainless steel should be of food-grade quality to avoid contamination, especially for machines intended for commercial use. B2B buyers should inquire about material certifications to verify compliance with international safety standards.

How Are Coffee Machines Formed?

The forming stage involves shaping the raw materials into the desired components. This is typically accomplished through processes such as stamping, injection molding, and CNC machining.

- Stamping is used for metal parts like chassis and covers, where sheets of metal are cut and shaped.

- Injection molding is ideal for plastic components, allowing for complex shapes and designs.

- CNC machining provides precision for parts that require tight tolerances, such as pumps and valves.

Each of these techniques plays a crucial role in ensuring that the components fit together seamlessly in the assembly stage. B2B buyers should assess the manufacturing capabilities of their suppliers to ensure they utilize modern and efficient forming techniques.

What Does the Assembly Process Look Like?

The assembly stage is where all the formed components come together. This process can be manual or automated, depending on the scale of production. In high-volume manufacturing, automated assembly lines are common, utilizing robots for tasks such as welding and component placement.

A stock image related to coffee machine china.

Quality control measures are critical during assembly. Workers should follow detailed assembly instructions and check for defects at each step. B2B buyers should request information about the assembly process from their suppliers, including any specific quality checks performed.

How Is the Finishing of Coffee Machines Achieved?

Finishing involves adding final touches to the coffee machines, such as painting, polishing, and applying protective coatings. This stage not only enhances the aesthetic appeal but also contributes to the durability of the machines.

Different finishing techniques can be employed, such as powder coating for durability and aesthetics or anodizing for aluminum parts to enhance corrosion resistance. Buyers should inquire about the finishing processes used by suppliers, as these can significantly affect the longevity and performance of the machines.

What Quality Assurance Standards Are Relevant for Coffee Machines?

Quality assurance (QA) is vital in the manufacturing of coffee machines to ensure that they meet both customer expectations and regulatory requirements. International standards such as ISO 9001 are often adopted by manufacturers to demonstrate their commitment to quality management systems.

Which International Standards Should B2B Buyers Look For?

In addition to ISO 9001, coffee machines may need to comply with other industry-specific standards, including:

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Standards: Relevant for machines that incorporate specific components like pumps and valves.

Buyers should verify that the suppliers have the necessary certifications and that the machines they produce meet these standards.

What Are the Key Quality Control Checkpoints in Coffee Machine Manufacturing?

Quality control is integrated throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to catch defects early.

- Final Quality Control (FQC): A thorough inspection of the finished product before it is packaged and shipped.

B2B buyers should inquire about the specific quality control measures in place at their suppliers’ facilities, including the frequency of inspections and the criteria used for acceptance.

What Common Testing Methods Are Employed for Coffee Machines?

Testing methods are crucial to ensure that coffee machines operate safely and effectively. Common tests include:

- Functional Testing: Ensuring that all features work as intended, such as brewing, steaming, and grinding mechanisms.

- Durability Testing: Assessing the machine’s performance under various conditions to ensure long-term reliability.

- Safety Testing: Checking for electrical safety, thermal stability, and other safety concerns.

Buyers should request documentation of testing procedures and results to verify the reliability and safety of the machines.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure a reliable supply chain, B2B buyers should take proactive steps to verify the quality control practices of their suppliers. Recommended actions include:

- Conducting Audits: Regular audits of suppliers’ facilities can help assess their compliance with quality standards.

- Requesting Quality Reports: Buyers should ask for detailed quality reports that outline testing methods, results, and corrective actions taken for any identified issues.

- Utilizing Third-Party Inspections: Engaging third-party inspection agencies can provide unbiased evaluations of supplier quality and manufacturing processes.

What Are the QC and Certification Nuances for International B2B Buyers?

B2B buyers from regions like Africa, South America, the Middle East, and Europe should be aware of specific nuances in quality control and certification requirements.

- Regulatory Compliance: Different regions have varying regulations regarding electrical safety and product standards. Understanding these can help avoid compliance issues.

- Cultural Expectations: Expectations regarding product quality and service levels may vary by region. Buyers should communicate their specific needs clearly to suppliers to ensure alignment.

By thoroughly understanding the manufacturing processes and quality assurance protocols, international B2B buyers can confidently source coffee machines from China that meet their operational requirements and customer expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘coffee machine china’

To successfully procure coffee machines from China, international B2B buyers must navigate a complex landscape of suppliers, regulations, and market demands. This checklist aims to streamline the sourcing process, ensuring you make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is the first step in sourcing coffee machines. Consider factors such as capacity, brewing method, energy efficiency, and additional features like programmable settings or built-in grinders. Understanding your requirements will help you communicate effectively with suppliers and ensure you receive products that meet your operational needs.

Step 2: Conduct Market Research on Suppliers

Before reaching out to potential suppliers, conduct thorough market research. Look for manufacturers with a proven track record in producing coffee machines, particularly those that cater to your specific market demands. Utilize platforms like Alibaba or Made-in-China, and pay attention to reviews and ratings from other buyers to gauge supplier reliability.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Consider the following:

– Factory Audits: If possible, conduct on-site inspections or virtual tours to assess production capabilities.

– Quality Control Processes: Inquire about their quality assurance methods and certifications (e.g., ISO 9001) to ensure product reliability.

Step 4: Verify Compliance with Regional Standards

Understanding compliance with local regulations and standards is essential. Different regions may have specific safety or environmental certifications required for coffee machines. Verify that the supplier’s products meet these standards to avoid legal issues or costly delays upon importation. Ask for documentation and check for certifications relevant to your region, such as CE for Europe or GCC for the Middle East.

Step 5: Request Samples Before Bulk Orders

Always request product samples before placing a large order. This step allows you to evaluate the quality, performance, and suitability of the coffee machines for your business. When testing samples, consider:

– Functionality: Ensure that all features work as expected.

– Build Quality: Assess the materials used and overall craftsmanship.

Step 6: Negotiate Terms and Pricing

Once you’ve identified a suitable supplier, enter negotiations regarding pricing, payment terms, and delivery timelines. Be clear about your expectations and inquire about discounts for bulk purchases or long-term partnerships. Establishing favorable terms can significantly affect your overall cost and profitability.

Step 7: Finalize Logistics and Shipping Arrangements

Effective logistics are crucial for timely delivery and cost efficiency. Discuss shipping options with your supplier and decide whether you’ll handle freight forwarding or if the supplier will manage it. Ensure you understand:

– Incoterms: Clarify the responsibilities of both parties regarding shipping and risk.

– Customs Procedures: Familiarize yourself with the customs clearance process in your country to avoid potential delays.

By following this practical sourcing guide, B2B buyers can navigate the complexities of procuring coffee machines from China effectively, ensuring a successful and profitable partnership.

Comprehensive Cost and Pricing Analysis for coffee machine china Sourcing

What Are the Key Cost Components in Coffee Machine Sourcing from China?

When sourcing coffee machines from China, understanding the cost structure is crucial for B2B buyers. The primary components that contribute to the overall cost include:

- Materials: The choice of materials significantly affects the cost. High-grade stainless steel or specialized components can drive up prices, while standard materials may offer cost savings.

- Labor: Labor costs in China are generally lower than in Europe or North America. However, the complexity of the machine can increase labor costs due to skilled labor requirements.

- Manufacturing Overhead: This includes factory utilities, maintenance, and management costs, which can vary by region and manufacturing facility.

- Tooling: Custom tooling for specific designs can lead to high initial costs but may reduce per-unit costs in larger production runs.

- Quality Control (QC): Investing in quality assurance processes can enhance product reliability but will add to the overall sourcing costs.

- Logistics: Shipping, handling, and customs duties must be factored into the total cost. Incoterms like FOB (Free on Board) can influence who bears the costs at different stages.

- Margin: Suppliers typically include a profit margin that can vary based on negotiation and the perceived value of the product.

How Do Price Influencers Affect the Cost of Coffee Machines?

Several factors can influence the pricing of coffee machines, making it essential for international buyers to consider these elements:

- Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower unit prices due to economies of scale. Negotiating favorable terms based on your anticipated needs can yield significant savings.

- Specifications and Customization: Customized machines with specific features or branding will typically cost more. Buyers should weigh the importance of customization against potential cost increases.

- Materials and Quality Certifications: Machines made from higher-quality materials or those that meet international quality certifications (like CE or ISO) can attract a premium price.

- Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may offer higher quality and better service but at a higher cost.

- Incoterms: Understanding the responsibilities for shipping, insurance, and duties is crucial. Terms like CIF (Cost, Insurance, and Freight) can lead to different pricing dynamics compared to FOB.

What Are Effective Buyer Tips for Negotiating Coffee Machine Prices?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, employing strategic negotiation tactics can lead to better pricing outcomes:

- Leverage Total Cost of Ownership (TCO): Evaluate not just the purchase price but the entire cost of ownership, including maintenance, energy consumption, and potential downtime. This perspective can justify higher upfront costs for better quality machines.

- Conduct Market Research: Understanding market trends and competitor pricing can empower you during negotiations. Knowledge of local market conditions in China can also provide leverage.

- Build Long-Term Relationships: Establishing a good rapport with suppliers can lead to better pricing and priority treatment in future transactions.

- Be Clear on Specifications: Providing detailed specifications upfront minimizes misunderstandings and potential cost escalations due to changes during production.

- Consider Payment Terms: Negotiating favorable payment terms, such as extended payment periods or discounts for upfront payments, can improve cash flow management.

What Should Buyers Keep in Mind About Pricing Nuances?

B2B buyers must remain aware of the complexities surrounding pricing when sourcing coffee machines from China. Fluctuations in raw material prices, changes in labor costs, and shifts in exchange rates can all affect final pricing. Furthermore, the evolving regulatory landscape regarding international trade can introduce unforeseen costs, making it essential to stay informed about changes that could impact sourcing strategies.

Disclaimer on Indicative Prices

Prices for coffee machines sourced from China can vary widely based on the aforementioned factors. It is recommended that buyers conduct thorough due diligence and obtain multiple quotes to ensure they are receiving competitive pricing that aligns with their specific needs and budget constraints.

Alternatives Analysis: Comparing coffee machine china With Other Solutions

When considering coffee machines for commercial use, international B2B buyers often seek alternatives that can meet their specific operational needs. The growing coffee culture in regions such as Africa, South America, the Middle East, and Europe has led to a diverse range of coffee machines and brewing technologies. Evaluating these alternatives is crucial for making informed purchasing decisions.

Comparison of Coffee Machine China with Alternative Solutions

| Comparison Aspect | Coffee Machine China | Alternative 1: Espresso Machine | Alternative 2: Pour-Over Brewer |

|---|---|---|---|

| Performance | High, consistent quality | Exceptional flavor extraction | Manual control over brewing process |

| Cost | Generally affordable | Higher initial investment | Moderate cost, variable depending on brand |

| Ease of Implementation | Simple setup | Requires skilled barista | Requires training for consistency |

| Maintenance | Moderate upkeep | High maintenance, regular cleaning | Low maintenance, minimal parts to clean |

| Best Use Case | High volume settings | Specialty coffee shops | Cafés focusing on artisanal brews |

What Are the Pros and Cons of Espresso Machines as an Alternative?

Espresso machines are renowned for their ability to produce rich and concentrated coffee shots, making them ideal for specialty coffee shops. They offer exceptional flavor extraction, which is a significant advantage for businesses aiming to provide high-quality beverages. However, the initial investment can be steep, often requiring a budget that may exceed that of a standard coffee machine from China. Moreover, espresso machines typically necessitate skilled baristas who can operate them effectively, which may increase labor costs.

How Do Pour-Over Brewers Compare in Terms of Usability and Cost?

Pour-over brewers provide a unique manual brewing experience that allows baristas to control every aspect of the brewing process. This method is perfect for cafés focusing on artisanal coffee, as it enhances flavor and aroma. Additionally, pour-over systems are generally more affordable than espresso machines, making them accessible for smaller businesses. The downside, however, is that this method requires significant training and practice to achieve consistency in taste, which could lead to variability in product quality if not executed properly.

How Can International B2B Buyers Choose the Right Coffee Machine?

Choosing the right coffee machine depends on various factors such as budget, target market, and operational capacity. For B2B buyers, understanding the specific needs of their business is essential. If the goal is to serve high volumes of coffee quickly, a coffee machine from China may be the most efficient option. However, if the focus is on quality and customer experience, investing in an espresso machine or pour-over system might be more beneficial. Evaluating the total cost of ownership, including maintenance and training, will further aid in making an informed decision that aligns with business objectives.

In summary, the choice between coffee machine China and its alternatives should be driven by performance expectations, budget constraints, and the desired customer experience. By carefully analyzing these factors, international B2B buyers can select the coffee brewing solution that best meets their operational needs and enhances their service offerings.

Essential Technical Properties and Trade Terminology for coffee machine china

What Are the Essential Technical Properties of Coffee Machines from China?

When sourcing coffee machines from China, understanding the technical specifications is crucial for making informed purchasing decisions. Here are some critical properties to consider:

1. Material Grade

The material grade of a coffee machine significantly influences its durability and performance. Stainless steel is often the preferred choice due to its resistance to corrosion and ease of cleaning. Additionally, high-grade plastics may be used for certain components to reduce weight while maintaining functionality. Buyers should verify that the materials meet international standards to ensure longevity and safety.

2. Power Consumption

Power consumption is a vital specification that directly affects operational costs. Coffee machines typically range from 800 to 2000 watts, depending on their size and functionality. B2B buyers should assess the energy efficiency of the machines, as higher efficiency can lead to significant cost savings over time, particularly for high-volume operations.

3. Temperature Control

Precision in temperature control is essential for brewing high-quality coffee. Advanced machines often feature digital thermostats and PID controllers that maintain consistent brewing temperatures. Understanding this specification helps buyers choose machines that meet their specific coffee brewing requirements, ensuring optimal flavor extraction.

4. Water Pressure

Water pressure affects the extraction process of coffee. Machines designed for commercial use typically operate at pressures between 9 to 15 bars. Knowing the required water pressure helps buyers select machines that can consistently deliver the quality of coffee desired, especially for espresso-based drinks.

5. Tolerance Levels

Tolerance levels refer to the allowable variation in machine dimensions and performance specifications. For example, precise tolerance in brewing components ensures consistent water flow and extraction rates. Understanding these specifications can help buyers evaluate the quality control processes of manufacturers, which is crucial for ensuring reliability.

What Common Trade Terms Should B2B Buyers Know When Purchasing Coffee Machines?

Familiarity with industry terminology is essential for effective communication and negotiation with suppliers. Here are some key terms that international B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. Buyers often work with OEMs to customize machines according to their specifications. Understanding this term allows buyers to better negotiate terms and conditions of their contracts.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest order size that a supplier is willing to accept. This is crucial for B2B buyers as it affects inventory management and cash flow. Buyers should assess their needs against the MOQ set by suppliers to avoid overstocking or incurring higher costs.

3. RFQ (Request for Quotation)

An RFQ is a document that solicits quotes from suppliers for specific goods or services. It is an essential step in the procurement process, as it helps buyers compare prices and terms. A well-structured RFQ can lead to better pricing and terms from suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international rules that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps B2B buyers understand their obligations and reduce risks associated with international transactions.

5. Lead Time

Lead time refers to the time taken from placing an order to delivery. Understanding lead times is crucial for inventory management and planning. Buyers should communicate clearly with suppliers about expected lead times to ensure timely delivery of coffee machines.

By grasping these essential technical properties and trade terms, B2B buyers can make more informed decisions when sourcing coffee machines from China, ultimately enhancing their purchasing strategy and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the coffee machine china Sector

What Are the Current Market Dynamics and Key Trends in the Coffee Machine Sector?

The global coffee machine market is experiencing rapid growth, driven by several key factors. The increasing coffee consumption rates in emerging markets such as Africa and South America, coupled with a growing café culture in the Middle East and Europe, are propelling demand for innovative coffee brewing solutions. In particular, B2B buyers are now more focused on sourcing high-quality, multifunctional machines that can cater to diverse consumer preferences.

Current trends include the rise of smart coffee machines equipped with IoT technology, enabling remote control and customization options. These innovations are appealing to businesses looking to enhance customer experience and operational efficiency. Additionally, there is a noticeable shift toward single-serve and pod-based machines, which cater to the fast-paced lifestyle of modern consumers, particularly in urban centers.

International buyers should also keep an eye on regional market dynamics. For instance, the Middle East is increasingly investing in high-end coffee machines, reflecting a preference for luxury café experiences. Conversely, buyers in Africa and South America may prioritize cost-effective solutions that do not compromise on quality, creating a unique demand for value-driven products. Understanding these regional nuances is crucial for successful sourcing strategies in the coffee machine sector.

How Can Sustainability and Ethical Sourcing Impact Your Business Decisions?

Sustainability has become a critical consideration for B2B buyers in the coffee machine sector. As environmental concerns grow, companies are increasingly seeking suppliers that adhere to sustainable practices. This includes the use of eco-friendly materials in manufacturing, as well as energy-efficient technologies that reduce the carbon footprint of coffee machines.

Ethical sourcing is also paramount. Buyers must ensure that their suppliers maintain transparent supply chains, avoiding practices that exploit labor or harm the environment. Certifications like Fair Trade, Rainforest Alliance, and Energy Star can serve as indicators of a supplier’s commitment to ethical practices.

Moreover, opting for machines that utilize recyclable materials and have a longer lifespan can enhance brand reputation and customer loyalty. By prioritizing sustainability and ethical sourcing, B2B buyers not only contribute to global environmental efforts but also position themselves as responsible business leaders, appealing to a growing segment of eco-conscious consumers.

What Is the Evolution of Coffee Machines and Its Relevance to Today’s Market?

The evolution of coffee machines dates back to the early 20th century when the first espresso machine was patented in Italy. Over the decades, coffee machines have undergone significant transformations, from manual brewing systems to fully automated machines. The introduction of capsule technology in the late 20th century revolutionized home and commercial brewing, catering to convenience-driven consumers.

Today, the coffee machine market is characterized by advanced technologies such as programmable settings, touchless operation, and integration with mobile applications. This evolution is relevant for B2B buyers as it reflects changing consumer preferences and the need for businesses to adapt to these trends. Understanding the historical context of coffee machines can provide valuable insights into future developments, allowing buyers to make informed decisions about their sourcing strategies in a competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of coffee machine china

-

How do I ensure the quality of coffee machines sourced from China?

To guarantee the quality of coffee machines from China, start by vetting suppliers through certifications like ISO 9001 or CE. Request samples to evaluate the machines firsthand, and consider third-party quality inspections before shipping. Establish clear quality assurance (QA) standards in your contract, including specific performance benchmarks and warranty terms. Engaging in regular communication with the supplier can also help address any issues promptly and ensure compliance with your quality expectations. -

What is the best type of coffee machine for my business needs?

The best coffee machine for your business depends on factors such as your target market, volume of sales, and types of coffee beverages offered. For high-volume cafes, commercial espresso machines with high output capabilities are ideal. If you’re targeting offices or smaller cafes, consider automatic drip coffee makers or single-serve machines. Evaluate features like ease of use, maintenance requirements, and customization options to select a machine that aligns with your business model. -

What are the minimum order quantities (MOQs) when sourcing coffee machines from China?

Minimum order quantities (MOQs) for coffee machines can vary significantly among suppliers, typically ranging from 100 to 1,000 units. It’s crucial to discuss MOQs during initial negotiations, as some suppliers may be flexible depending on your order size and relationship with them. If you are just starting out, look for suppliers who offer lower MOQs or consider joining forces with other businesses to meet higher quantity requirements. -

How can I customize coffee machines for my brand?

Customization options for coffee machines may include branding with your logo, color schemes, and specific features tailored to your market needs. When discussing customization with suppliers, be clear about your requirements and request detailed mock-ups or prototypes. Some manufacturers may require minimum quantities for customized orders, so ensure you understand the implications on pricing and lead times. Collaborating closely with the supplier throughout the process can help achieve the desired outcomes. -

What payment terms should I expect when sourcing from Chinese suppliers?

Payment terms can vary, but common practices include a 30% upfront deposit with the remaining 70% due before shipping. Some suppliers may also offer letters of credit or payment through platforms like Alibaba for added security. Always clarify payment methods, currency exchanges, and any additional fees upfront to avoid surprises. Establishing a good relationship with your supplier may also lead to more favorable terms as your business grows. -

How do I handle logistics and shipping for imported coffee machines?

Managing logistics for importing coffee machines involves coordinating with freight forwarders for shipping arrangements, understanding customs regulations, and planning for delivery timelines. Ensure that your supplier is familiar with international shipping processes and can provide necessary documentation. Consider insurance for your shipment to protect against potential damages during transit. It’s also wise to factor in additional costs such as tariffs, duties, and handling fees when calculating overall expenses. -

What should I include in my supplier vetting process for coffee machines?

Your supplier vetting process should include checking for industry certifications, reviewing customer testimonials, and assessing their production capabilities. Conduct site visits, if possible, to inspect manufacturing facilities and gauge their operational standards. It’s beneficial to request references from other international buyers who have previously worked with the supplier. This comprehensive approach helps mitigate risks and ensures that you are partnering with a reliable manufacturer. -

How can I navigate international trade regulations when importing coffee machines?

To navigate international trade regulations, start by researching the import requirements specific to your country and the type of coffee machines you intend to import. Familiarize yourself with tariffs, import duties, and any compliance certifications required for electrical appliances. Engaging a customs broker can streamline the process, ensuring that all documentation is accurate and complete. Staying updated on trade policies between your country and China will also help you avoid potential legal issues.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for coffee machine china

In conclusion, effective strategic sourcing of coffee machines from China offers significant advantages for international B2B buyers, particularly in Africa, South America, the Middle East, and Europe. By understanding the nuances of the Chinese market, buyers can leverage competitive pricing, advanced technology, and diverse product options to enhance their offerings and optimize operational efficiency.

What are the key factors influencing your sourcing decisions? As highlighted throughout this guide, maintaining strong supplier relationships and conducting thorough due diligence are essential for mitigating risks and ensuring consistent quality. Additionally, staying informed about market trends and technological advancements can provide a competitive edge.

Looking ahead, the coffee machine market is poised for growth, driven by increasing consumer demand for quality coffee experiences. International buyers should proactively engage with suppliers, explore innovative solutions, and consider sustainable practices to meet evolving market expectations. Now is the time to capitalize on the opportunities presented by strategic sourcing from China. Embrace this dynamic landscape, and position your business for success in the global coffee market.