Discover Cost-Effective Display Rack China Solutions (2025)

Introduction: Navigating the Global Market for display rack china

In the ever-evolving landscape of global commerce, sourcing display racks from China presents a unique set of challenges for international B2B buyers. With the increasing demand for efficient retail environments, businesses in regions such as Africa, South America, the Middle East, and Europe are seeking reliable suppliers who can provide high-quality display solutions. However, navigating the complexities of supplier selection, quality assurance, and cost management can be daunting. This guide serves as a comprehensive resource for understanding the multifaceted world of display rack sourcing from China.

This B2B guide covers a wide range of topics essential for informed purchasing decisions. From various types of display racks suited for different industries to practical applications that enhance product visibility, we delve into every aspect that matters. Additionally, we provide insights on how to effectively vet suppliers to ensure quality and compliance with international standards. Buyers will find valuable information on cost considerations, logistics, and best practices for negotiating terms that benefit both parties.

Empowering businesses to make strategic decisions, this guide is tailored specifically for buyers in diverse markets, including Poland and Nigeria. By leveraging the actionable insights presented here, international B2B buyers can confidently navigate the global market for display racks, ultimately enhancing their retail strategies and improving operational efficiency.

Understanding display rack china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Slatwall Display Rack | Versatile, customizable panels; various accessories | Retail stores, exhibitions | Pros: Highly adaptable; Cons: Requires regular maintenance. |

| Wire Display Rack | Lightweight, open design; excellent visibility | Trade shows, supermarkets | Pros: Easy to transport; Cons: Less durable than metal racks. |

| Wooden Display Rack | Sturdy, aesthetic appeal; available in various finishes | Boutiques, high-end retail | Pros: Attractive; Cons: Heavier and pricier. |

| Metal Display Rack | Strong, durable construction; suitable for heavy items | Warehouses, industrial settings | Pros: Long-lasting; Cons: Limited design options. |

| Corner Display Rack | Space-efficient design; fits in corners | Small retail spaces, showrooms | Pros: Maximizes space; Cons: Limited display capacity. |

What Are the Characteristics of Slatwall Display Racks?

Slatwall display racks are known for their versatility and adaptability. Comprising panels with horizontal grooves, they can hold various accessories like hooks, shelves, and bins, making them ideal for retail environments. Businesses should consider the ease of customization and the ability to reconfigure the display as product lines change. However, these racks require regular maintenance to keep them looking fresh and functional.

Why Choose Wire Display Racks for Trade Shows?

Wire display racks are lightweight and designed for optimal visibility, making them perfect for trade shows and supermarkets. Their open design allows products to be easily seen from multiple angles, enhancing customer engagement. Buyers should note that while wire racks are easy to transport and set up, they may not withstand heavy usage as well as sturdier options, which could affect long-term investment value.

How Do Wooden Display Racks Enhance Retail Aesthetics?

Wooden display racks offer a unique blend of sturdiness and aesthetic appeal, making them suitable for boutiques and high-end retail stores. They can be customized with various finishes to match a brand’s identity. When considering wooden racks, buyers should evaluate their weight and cost, as they tend to be heavier and more expensive than other materials, which may impact shipping and installation.

What Are the Benefits of Metal Display Racks in Industrial Settings?

Metal display racks are characterized by their strong and durable construction, making them suitable for warehouses and industrial settings where heavy items need to be displayed. Their robustness ensures longevity, which is a significant consideration for B2B buyers looking for long-term solutions. However, potential buyers should be aware that metal racks may have limited design options, which could affect visual merchandising strategies.

How Can Corner Display Racks Maximize Retail Space?

Corner display racks are designed to make efficient use of space, fitting snugly into corners of retail environments. This design is especially beneficial for smaller retail spaces and showrooms where maximizing display area is crucial. While these racks can enhance product visibility, buyers should consider their limited display capacity compared to larger racks, ensuring that they align with their product range and sales strategy.

Related Video: Toyota Prius How-To: Prius Multi-Information Display (MID) | Toyota

Key Industrial Applications of display rack china

| Industry/Sector | Specific Application of display rack china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | In-store product displays | Enhances product visibility and encourages impulse buying | Look for customizable designs to fit brand aesthetics |

| Warehousing | Bulk storage solutions | Maximizes space utilization and improves inventory management | Ensure durability and load-bearing capacity |

| Food and Beverage | Refrigerated display racks | Maintains product freshness while showcasing items | Check for energy efficiency and compliance with safety standards |

| Pharmaceuticals | Medication display and storage solutions | Facilitates easy access and organization of products | Prioritize racks that meet regulatory requirements |

| Electronics | Showroom and exhibition displays | Attracts customers and highlights product features | Consider modular designs for flexibility in layout |

How Are Display Racks Used in the Retail Sector?

In the retail sector, display racks sourced from China are essential for creating in-store product displays. These racks are designed to enhance product visibility, making items more appealing to customers and encouraging impulse buying. International buyers from regions such as Africa and Europe should consider customizable designs that align with their brand aesthetics. Additionally, the ability to adapt the display racks to seasonal promotions can significantly boost sales and customer engagement.

What Role Do Display Racks Play in Warehousing?

In warehousing, display racks from China are utilized for bulk storage solutions. These racks maximize space utilization, allowing businesses to store more products in a smaller area while improving inventory management. For B2B buyers, particularly from South America and the Middle East, it is crucial to ensure that the racks are durable and have adequate load-bearing capacity to handle heavy items. This not only optimizes warehouse operations but also reduces the risk of product damage.

Why Are Refrigerated Display Racks Important in the Food and Beverage Industry?

In the food and beverage industry, refrigerated display racks are vital for maintaining product freshness while showcasing items to customers. These racks not only provide visibility but also comply with health regulations by ensuring that perishable goods are stored at appropriate temperatures. B2B buyers should prioritize energy-efficient models that lower operational costs and meet safety standards. This is particularly important for businesses in regions like Africa, where energy costs can be a significant concern.

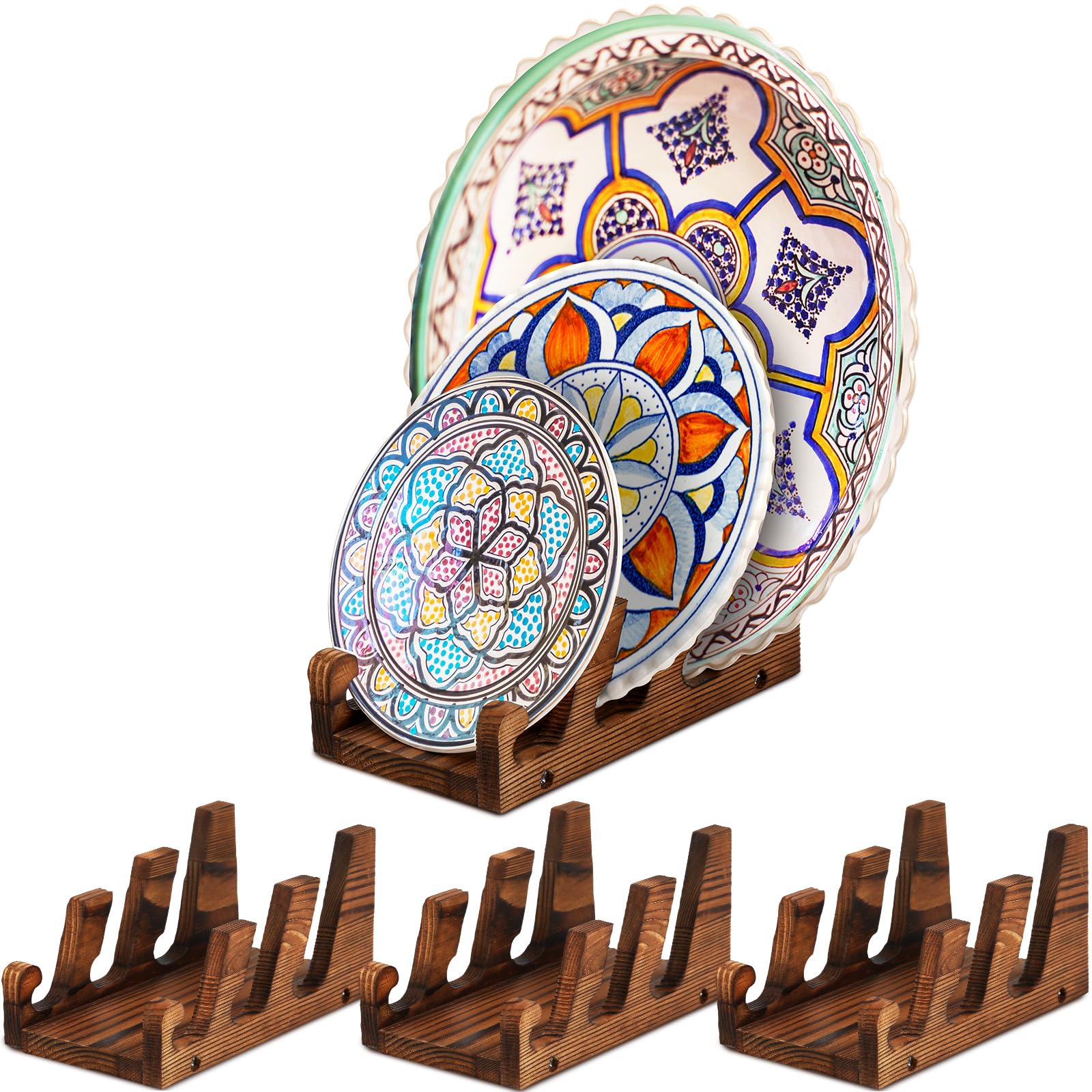

A stock image related to display rack china.

How Do Display Racks Support Pharmaceutical Businesses?

Pharmaceutical companies benefit from display racks designed for medication storage and organization. These racks facilitate easy access to products, which is crucial for quick service and compliance with industry regulations. For international buyers, particularly in Europe, it is essential to prioritize racks that adhere to regulatory requirements, ensuring that they meet safety and storage standards. This attention to detail can enhance operational efficiency and customer trust.

How Are Display Racks Used in the Electronics Sector?

In the electronics sector, display racks are integral for showroom and exhibition displays. They attract customers by highlighting product features and facilitating product interaction. B2B buyers, particularly from regions like Europe and Africa, should consider modular designs that offer flexibility in layout. This adaptability allows businesses to change displays according to product launches or seasonal trends, ensuring that their offerings remain fresh and engaging to potential customers.

Related Video: China is Building Gravity Batteries

3 Common User Pain Points for ‘display rack china’ & Their Solutions

Scenario 1: Managing Inventory Space with Display Racks

The Problem:

B2B buyers often face challenges with inventory management, especially when space is limited. For businesses in sectors such as retail or warehousing in Africa or Europe, maximizing vertical space with display racks can be crucial. However, many buyers struggle to find display racks that fit their specific dimensions and weight requirements. This mismatch can lead to inefficient use of space, cluttered environments, and ultimately, lost sales opportunities.

The Solution:

To effectively manage inventory space, buyers should begin by conducting a thorough assessment of their available space and inventory types. Measure the height, width, and depth of the area where the display rack will be placed. Look for suppliers in China that offer customizable display racks to meet specific dimensional needs. Consider solutions such as adjustable shelving or modular racks that can be reconfigured as inventory changes. Additionally, ensure that the chosen display rack can accommodate the weight of the products to avoid safety hazards. By prioritizing space optimization through tailored solutions, businesses can enhance their operational efficiency and improve customer experience.

Scenario 2: Ensuring Display Rack Durability for Varied Products

The Problem:

In industries where products vary significantly in size and weight, durability is a common concern. For instance, a buyer in South America may require display racks for both lightweight items like cosmetics and heavier goods like electronics. Many B2B buyers have encountered racks that fail under the weight of their products, leading to product damage and safety risks.

The Solution:

Buyers should seek out display racks made from high-quality materials designed to withstand different weights and stresses. Look for manufacturers that provide detailed specifications regarding load capacity and material strength. Additionally, consider investing in racks with a powder-coated finish, as this adds an extra layer of protection against wear and tear. Request samples or product demonstrations to assess durability before placing bulk orders. Establishing a relationship with reputable suppliers who understand diverse product needs can also ensure that the racks meet the required standards, ultimately preventing costly damages and ensuring customer satisfaction.

Scenario 3: Navigating Import Regulations for Display Racks

The Problem:

Importing display racks from China can be complicated due to varying regulations and customs requirements across different regions. For B2B buyers in the Middle East or Europe, missteps in compliance can lead to delays, increased costs, or even confiscation of goods, creating significant logistical headaches.

The Solution:

To navigate these complexities, buyers should conduct thorough research on the import regulations specific to their country or region. This includes understanding tariffs, safety standards, and required certifications for display racks. Collaborating with a freight forwarder or customs broker who specializes in international trade can be invaluable. They can provide insights into the documentation needed and help streamline the shipping process. Additionally, suppliers in China should be transparent about their compliance with international standards; always request documentation that confirms product safety and material specifications. By proactively managing import regulations and working with experts, buyers can minimize risks and ensure a smooth procurement process.

Strategic Material Selection Guide for display rack china

When selecting materials for display racks in China, B2B buyers must consider various factors that influence product performance, cost, and compliance with international standards. This guide analyzes four common materials used in display rack manufacturing: steel, aluminum, wood, and plastic. Each material has unique properties and implications for international buyers, particularly those from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Steel for Display Racks?

Steel is one of the most commonly used materials for display racks due to its strength and durability. It typically has a high tensile strength, making it suitable for heavy loads. Steel also offers good corrosion resistance when treated with coatings such as galvanization or powder coating. However, it is susceptible to rust if not properly maintained, particularly in humid environments.

Pros & Cons of Steel:

– Pros: High durability, excellent load-bearing capacity, and availability in various finishes.

– Cons: Heavier than other materials, which can complicate shipping and installation. Additionally, it may require more complex manufacturing processes, increasing costs.

Impact on Application:

Steel display racks are ideal for retail environments that require robust solutions for heavy merchandise. However, buyers should consider the local climate, as humid conditions in regions like Nigeria may necessitate additional protective coatings.

How Does Aluminum Compare for Display Rack Applications?

Aluminum is a lightweight alternative to steel, offering good strength-to-weight ratios. It is naturally corrosion-resistant, making it an excellent choice for environments with high moisture levels. Aluminum can be anodized or painted to enhance its aesthetic appeal and durability.

Pros & Cons of Aluminum:

– Pros: Lightweight, corrosion-resistant, and easy to fabricate.

– Cons: Generally more expensive than steel and may not support as much weight.

Impact on Application:

Aluminum racks are suitable for retail displays where mobility is essential, such as in trade shows or temporary setups. Buyers in Europe may prefer aluminum for its sleek look and lightweight nature, facilitating easier transport.

What Are the Benefits of Using Wood in Display Racks?

Wood offers a warm, natural aesthetic that appeals to many retailers. It is highly customizable and can be finished in various ways to match branding needs. However, wood is less durable than metal options and can be affected by moisture, leading to warping or decay.

Pros & Cons of Wood:

– Pros: Attractive appearance, easy to customize, and sustainable options available.

– Cons: Less durable than metal, susceptible to damage from moisture and pests.

Impact on Application:

Wooden display racks are often used in boutique stores and high-end retail environments. Buyers in South America may appreciate the availability of local wood species, which can reduce costs and support local economies.

Why Consider Plastic for Display Racks?

Plastic is a versatile and lightweight option for display racks. It is resistant to corrosion and can be produced in various colors and styles. However, plastic may not support heavy loads as effectively as metal, and its durability can vary based on the type of plastic used.

Pros & Cons of Plastic:

– Pros: Lightweight, corrosion-resistant, and available in diverse designs.

– Cons: Limited load capacity and potential for fading or cracking over time.

Impact on Application:

Plastic racks are often used in environments where weight is a concern, such as in schools or temporary displays. Buyers from the Middle East may find plastic solutions appealing due to their resistance to high temperatures.

Summary Table of Material Selection for Display Racks

| Material | Typical Use Case for display rack china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty retail environments | High durability and load capacity | Heavier, requires protective coatings | Medium |

| Aluminum | Trade shows and mobile displays | Lightweight and corrosion-resistant | More expensive, lower load capacity | High |

| Wood | Boutique stores and high-end retail | Attractive and customizable | Less durable, moisture-sensitive | Medium |

| Plastic | Schools and temporary displays | Lightweight and diverse designs | Limited load capacity, durability varies | Low |

By understanding the properties, pros and cons, and specific applications of these materials, international B2B buyers can make informed decisions that align with their operational needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for display rack china

What Are the Main Stages of Manufacturing Display Racks in China?

The manufacturing of display racks in China involves a series of well-defined stages that ensure efficiency and quality. Understanding these stages can help international B2B buyers identify reliable suppliers and anticipate lead times.

Material Preparation: What Materials Are Used?

The first step in the manufacturing process is material preparation, where raw materials such as metal, wood, or plastic are sourced. For metal racks, cold-rolled steel or stainless steel is commonly used due to its durability. Wood and composite materials may also be chosen for aesthetic appeal and flexibility in design.

During this stage, suppliers must ensure that materials meet international quality standards. Buyers should inquire about the suppliers’ sourcing practices, including whether materials are sustainably sourced and compliant with regulations in their target markets.

How Are Display Racks Formed?

Once the materials are prepared, the next phase is forming. This process involves cutting, bending, and welding materials to create the initial structure of the display rack. Key techniques include laser cutting for precision, CNC machining for complex shapes, and robotic welding for consistent quality.

Buyers should look for manufacturers that utilize advanced machinery and technology, as these can significantly enhance the accuracy and quality of the final product. It is beneficial to ask suppliers about the equipment they use and the skills of their workforce.

What Does the Assembly Process Involve?

Following the forming stage, the assembly process takes place. This step includes fitting together various components, such as shelves, brackets, and supports. The assembly may be manual or automated, depending on the complexity of the design and the manufacturer’s capabilities.

During assembly, quality checks should be conducted to ensure that all parts fit correctly and that the rack meets design specifications. Buyers should consider requesting detailed assembly guidelines and any certifications that verify the assembly process’s integrity.

What Finishing Techniques Are Commonly Used?

The final stage in manufacturing is finishing, which enhances the display rack’s appearance and durability. Common finishing techniques include powder coating, painting, and galvanization. Powder coating is particularly favored for its resistance to chipping and fading.

B2B buyers should inquire about the types of finishes available and the environmental impact of the finishing processes. Additionally, understanding the supplier’s compliance with international environmental standards can be crucial for markets in Europe and other regions.

How Is Quality Assurance Implemented in Display Rack Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process that ensures products meet specific standards before they reach the market. For international buyers, understanding QA processes can lead to better purchasing decisions.

What International Standards Should Buyers Look For?

International standards, such as ISO 9001, are essential for ensuring quality management systems are in place. This certification indicates that the manufacturer follows systematic processes to enhance customer satisfaction and product quality.

Additionally, industry-specific certifications such as CE marking (for compliance with European health and safety standards) and API (for petroleum and natural gas industries) may also be relevant, depending on the intended use of the display racks.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are integral to the manufacturing process. Typically, these checkpoints include:

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon delivery to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing stages help identify and rectify issues early.

- Final Quality Control (FQC): A thorough examination of the completed display racks before shipment ensures they meet all quality standards.

Buyers should ask suppliers about their QC procedures and how they document compliance at each checkpoint.

What Common Testing Methods Are Used for Display Racks?

Testing methods play a vital role in validating the durability and safety of display racks. Common methods include:

- Load Testing: Assessing the weight-bearing capacity of the racks to ensure they can hold the intended products.

- Stability Testing: Evaluating the rack’s resistance to tipping or collapsing under load.

- Corrosion Resistance Testing: For metal racks, this test checks how well the finish holds up against environmental conditions.

Understanding the testing methods used by suppliers can provide buyers with confidence in the product’s reliability and longevity.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control measures is crucial for international B2B buyers. Here are some actionable steps:

-

Conduct Supplier Audits: Regular audits can help assess the manufacturing processes and QA practices. Buyers can request an audit report or even conduct an on-site visit if possible.

-

Request Quality Assurance Reports: Suppliers should provide documentation showing compliance with relevant standards and the results of any testing conducted.

-

Third-Party Inspections: Engaging a third-party inspection service can provide an unbiased assessment of the manufacturing processes and product quality. This is particularly useful for buyers from regions like Africa and South America, where local regulations may vary.

What Are the Quality Control Nuances for International B2B Buyers?

Navigating quality control in international trade can be complex. Buyers from diverse regions, such as Europe and the Middle East, should consider the following nuances:

- Cultural Differences: Understanding local manufacturing practices and quality perceptions can help in establishing better communication with suppliers.

- Regulatory Compliance: Different regions have unique regulatory requirements. Buyers must ensure that products meet the standards of their respective markets to avoid legal complications.

- Shipping and Handling: Quality assurance should extend beyond manufacturing. Buyers should inquire about how products are packaged and transported to prevent damage during shipping.

By being informed about these aspects, B2B buyers can make more educated decisions when sourcing display racks from China, ensuring that they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘display rack china’

In the competitive landscape of B2B procurement, sourcing display racks from China requires a strategic approach. This guide aims to provide international buyers, particularly those from Africa, South America, the Middle East, and Europe, with a structured checklist to streamline the sourcing process. By following these actionable steps, you can ensure a successful procurement experience that meets your specific needs.

Step 1: Define Your Technical Specifications

Before starting the sourcing process, it is essential to clearly outline your technical requirements. This includes dimensions, weight capacity, materials (e.g., metal, wood, plastic), and design features (e.g., adjustable shelves, branding options). A detailed specification will help you communicate effectively with suppliers and avoid misunderstandings later on.

- Consider your target market: Different regions may have specific preferences for display rack styles and functionalities.

- Identify compliance needs: Ensure that your specifications align with local regulations and safety standards in your market.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers in China. Utilize online platforms such as Alibaba, Global Sources, and trade directories to find manufacturers specializing in display racks. Pay attention to supplier ratings, customer reviews, and years in business, as these factors can indicate reliability.

- Check for industry experience: Suppliers with a proven track record in your specific product category are more likely to meet your quality expectations.

- Assess production capabilities: Ensure the supplier can handle your order volume and has the necessary technology and facilities.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; a comprehensive evaluation can reveal much about their operations and reliability.

- Ask for samples: Requesting product samples allows you to assess quality firsthand before placing a larger order.

- Inquire about lead times: Understanding production and shipping timelines is critical for planning your inventory needs.

Step 4: Verify Supplier Certifications

Ensure that the suppliers you consider have the necessary certifications and compliance documents. Look for ISO certifications, CE markings, or other relevant industry standards that demonstrate quality assurance.

- Request documentation: Ask for copies of certifications and verify their authenticity.

- Understand the implications: Certifications can significantly affect your product’s acceptance in your target market, particularly in Europe where regulations are strict.

Step 5: Negotiate Pricing and Terms

Once you have shortlisted suppliers, enter negotiations regarding pricing, payment terms, and shipping options. Aim for a balance between cost and quality, and be open to discussing bulk order discounts or other incentives.

- Consider total landed cost: Factor in shipping, customs duties, and other fees to understand the true cost of procurement.

- Establish clear payment terms: Specify payment methods (e.g., letter of credit, PayPal) and conditions to protect your investment.

Step 6: Plan for Quality Control

Implement a quality control plan to monitor the production process. You may want to hire a third-party inspection service to conduct quality checks at various stages, ensuring that the products meet your specifications before shipping.

- Set clear quality benchmarks: Define what constitutes acceptable quality levels for your display racks.

- Schedule inspections: Plan for inspections at critical points, such as pre-production and pre-shipment.

Step 7: Establish Logistics and Shipping Arrangements

Finally, coordinate the logistics of shipping your display racks to your location. Choose a reliable freight forwarder who understands the complexities of international shipping, including customs clearance procedures.

- Understand shipping options: Compare air freight and sea freight based on cost and delivery time.

- Prepare for customs: Ensure all documentation is complete to prevent delays at customs upon arrival.

By following these steps, B2B buyers can effectively navigate the complexities of sourcing display racks from China, ensuring a smooth procurement process that aligns with their business goals.

Comprehensive Cost and Pricing Analysis for display rack china Sourcing

What Are the Key Cost Components in Sourcing Display Racks from China?

When sourcing display racks from China, understanding the cost structure is essential for effective budgeting and planning. The primary cost components include:

-

Materials: The type of materials used for display racks significantly impacts the overall cost. Common materials include metal, wood, and plastic. Opting for higher-quality materials can increase the initial expenditure but may lead to lower maintenance costs in the long run.

-

Labor: Labor costs in China can vary widely based on the region and the complexity of the display rack design. Skilled labor may command higher wages, but investing in skilled craftsmanship can yield better quality and durability.

-

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities, equipment maintenance, and facility rent. Factories with modern machinery may have higher overheads but can offer better efficiency and lower defect rates.

-

Tooling: If custom designs are required, tooling costs can be a significant factor. This includes molds, dies, and any specialized equipment necessary for production. Understanding these costs upfront is crucial for accurate pricing.

-

Quality Control (QC): Implementing robust QC measures ensures that the final product meets specifications and quality standards. While this incurs additional costs, it can prevent costly returns and reputational damage in the market.

-

Logistics: Shipping costs can fluctuate based on the mode of transport (air vs. sea), distance, and freight rates. Additionally, customs duties and taxes must be considered as they vary by destination, impacting the overall cost.

-

Margin: Suppliers typically apply a profit margin to their costs. This can vary based on the supplier’s reputation, market demand, and competition.

How Do Price Influencers Affect the Sourcing of Display Racks?

Several factors can influence the pricing of display racks, which international B2B buyers should consider:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to lower per-unit costs due to economies of scale. Buyers should evaluate their needs carefully and consider combining orders with other products to meet MOQs.

-

Specifications and Customization: Custom designs or specific features will increase costs. Buyers should clearly communicate their requirements to get accurate quotes and avoid surprises.

-

Materials and Quality Certifications: The choice of materials and certifications (such as ISO or CE) can affect the price. Buyers looking for higher quality or certified products should expect to pay a premium.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a proven track record may charge more but offer better service and quality assurances.

-

Incoterms: The agreed-upon Incoterms (International Commercial Terms) dictate the responsibilities of buyers and sellers regarding shipping costs and risks. Understanding these terms is vital to avoid unexpected expenses.

What Are Some Buyer Tips for Cost-Efficiency in Display Rack Sourcing?

For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency:

-

Negotiate Wisely: Leverage your buying power and market knowledge to negotiate better prices. Establishing long-term relationships with suppliers can also lead to more favorable terms over time.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but the total cost of ownership, including maintenance, shipping, and potential tariffs. This holistic view can lead to smarter purchasing decisions.

-

Understand Pricing Nuances: Be aware that prices may vary significantly based on regional economic conditions and supplier practices. This is particularly relevant when sourcing from different countries in Asia.

-

Stay Informed About Market Trends: Keeping abreast of industry trends and pricing fluctuations can provide leverage during negotiations. This knowledge allows buyers to time their purchases more effectively.

Disclaimer

The prices mentioned in this analysis are indicative and can vary based on numerous factors including market conditions, supplier negotiations, and currency fluctuations. Always seek current quotes from multiple suppliers to ensure competitive pricing and accurate budgeting.

Alternatives Analysis: Comparing display rack china With Other Solutions

When evaluating display solutions for retail or warehouse environments, it’s essential to consider various options available in the market. International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, must analyze how ‘Display Rack China’ stacks up against alternative solutions. This comparison will focus on performance, cost, ease of implementation, maintenance, and best use cases to help buyers make informed decisions.

| Comparison Aspect | Display Rack China | Alternative 1: Mobile Shelving | Alternative 2: Pallet Racking |

|---|---|---|---|

| Performance | High load capacity and customizable designs | Flexible storage options with easy access | Optimized for bulk storage and heavy items |

| Cost | Competitive pricing, especially in bulk | Moderate initial investment, can save space | Higher initial cost, but high ROI for large inventories |

| Ease of Implementation | Generally straightforward installation | Requires professional setup for best results | Can be complex; may need structural modifications |

| Maintenance | Low maintenance; durable materials | Moderate; requires regular checks for mobility | Low, but inspections for safety compliance are necessary |

| Best Use Case | Ideal for retail and display environments | Suitable for dynamic storage needs in small spaces | Best for warehouses with heavy inventory turnover |

What are the advantages and disadvantages of mobile shelving as an alternative?

Mobile shelving systems are designed for flexibility and space efficiency. They allow for compact storage by reducing aisle space, which is particularly beneficial in environments where maximizing square footage is essential, such as small retail shops or archives. However, while they provide high accessibility and can be customized to specific needs, they often require a moderate initial investment. The installation may necessitate professional assistance to ensure stability and mobility, which can increase costs and lead times.

How does pallet racking compare as a solution for display needs?

Pallet racking is another viable alternative that excels in bulk storage applications. It is particularly suited for warehouses with heavy inventory, as it supports high weight loads and allows for easy access to stored goods. The primary drawback of pallet racking is its higher initial cost and the potential complexity of installation, which may require structural modifications to the building. However, for businesses with significant inventory turnover and heavy items, the long-term return on investment can justify the upfront expense.

Conclusion: How can B2B buyers select the right display solution?

Choosing the right display solution depends on various factors, including the type of products, space availability, budget constraints, and operational needs. For businesses focusing on retail environments with a need for visual appeal and customization, ‘Display Rack China’ may be the best fit. Conversely, if flexibility and space optimization are priorities, mobile shelving could be more advantageous. For those dealing with large quantities of heavy items, pallet racking offers robust support. Ultimately, understanding your specific requirements and evaluating the trade-offs of each option will lead to the best decision for your business needs.

Essential Technical Properties and Trade Terminology for display rack china

What Are the Key Technical Properties of Display Racks from China?

When sourcing display racks from China, understanding the technical properties can significantly impact your purchasing decisions. Here are some critical specifications to consider:

-

Material Grade

Display racks are typically made from materials such as steel, aluminum, or wood. The material grade indicates the strength, durability, and weight capacity of the rack. For instance, a higher-grade steel (like ASTM A36) will offer better structural integrity, making it suitable for heavier items. Buyers must assess their product weight requirements to select the appropriate material grade. -

Load Capacity

This specification defines how much weight a display rack can support without compromising its structure. Load capacity is crucial for ensuring safety and preventing product damage. B2B buyers should always verify load capacity ratings to align with their inventory needs, particularly in retail environments where heavy merchandise is displayed. -

Tolerance Levels

Tolerance refers to the allowable deviation in dimensions during manufacturing. It is vital for ensuring that components fit together correctly. For display racks, tighter tolerances can lead to better stability and aesthetics. Buyers should inquire about tolerance levels to ensure that the racks will fit their space and function as intended. -

Finish Type

The finish of a display rack can influence both its appearance and longevity. Common finishes include powder coating, galvanizing, or painting. Each finish type offers different levels of corrosion resistance and aesthetic appeal. B2B buyers should consider their environment (e.g., indoor vs. outdoor use) when selecting the finish type. -

Assembly Requirements

Understanding how a display rack assembles can save time and labor costs. Some racks come pre-assembled, while others may require on-site assembly. Knowing the assembly requirements can help buyers plan accordingly, especially if they have limited manpower or need quick installation.

What Are Common Trade Terms Related to Display Racks from China?

Navigating the international trade landscape can be daunting, especially with specific jargon that may not be familiar to all buyers. Here are some common terms used in the industry:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of display racks, sourcing from an OEM can allow buyers to customize designs to meet specific branding or functionality needs. Understanding OEM relationships can lead to better pricing and quality control. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. It is crucial for buyers to know the MOQ as it can affect inventory management and cash flow. For international buyers, negotiating lower MOQs might be necessary, especially for new products or startups. -

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products. For display racks, an RFQ helps buyers compare prices and specifications from different manufacturers. Crafting a clear and detailed RFQ can facilitate better responses and negotiations. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for managing shipping costs and risks. Buyers should clarify Incoterms in their contracts to avoid misunderstandings regarding delivery responsibilities. -

Lead Time

Lead time is the period between placing an order and receiving the goods. For display racks, this can vary based on customization, production schedules, and shipping logistics. Buyers should factor in lead times when planning inventory to avoid stockouts, especially in competitive markets.

Understanding these technical properties and trade terminologies can empower international B2B buyers to make informed decisions when sourcing display racks from China, ultimately leading to better purchasing outcomes and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the display rack china Sector

What Are the Current Market Dynamics and Key Trends in the Display Rack Sector?

The display rack sector in China is undergoing significant transformation driven by several global factors. Increased urbanization, particularly in developing regions like Africa and South America, is pushing the demand for effective retail solutions, including display racks that enhance product visibility and customer engagement. Additionally, the rise of e-commerce has led to a shift in purchasing behaviors, prompting businesses to invest in versatile display solutions that can cater to both physical and online retail environments.

Emerging technologies such as augmented reality (AR) and artificial intelligence (AI) are influencing sourcing trends. These innovations enable businesses to visualize and customize display rack designs before production, minimizing waste and ensuring tailored solutions. Furthermore, the integration of smart technologies in display racks is becoming increasingly popular, allowing retailers to monitor customer interactions and optimize product placement based on real-time data.

International B2B buyers, especially from regions like the Middle East and Europe, should be aware of the competitive pricing offered by Chinese manufacturers. However, navigating the market requires an understanding of local regulations, trade agreements, and tariffs that may affect sourcing costs. Additionally, building relationships with suppliers who have a deep understanding of regional market demands can provide a competitive edge.

How Does Sustainability Impact Sourcing in the Display Rack Sector?

Sustainability is no longer just a buzzword; it is a critical factor for B2B buyers in the display rack sector. As environmental concerns grow, companies are increasingly prioritizing eco-friendly materials and sustainable manufacturing processes. The sourcing of display racks made from recycled or sustainably sourced materials not only reduces environmental impact but also appeals to a growing consumer base that values corporate responsibility.

Ethical sourcing is becoming paramount, especially for international buyers. Ensuring that suppliers adhere to fair labor practices and environmental standards is essential. B2B buyers should look for suppliers with recognized certifications such as ISO 14001 (Environmental Management) and FSC (Forest Stewardship Council) to ensure compliance with sustainability benchmarks.

Additionally, investing in ‘green’ display racks can enhance brand reputation and customer loyalty. Consumers are more likely to support brands that demonstrate a commitment to sustainability. Therefore, B2B buyers in regions like Europe and Africa should prioritize partnerships with manufacturers who are transparent about their sourcing practices and committed to reducing their carbon footprint.

What Is the Evolution of the Display Rack Sector and Its Importance for B2B Buyers?

The display rack sector has evolved considerably over the past few decades. Initially, display racks were primarily wooden structures, but advancements in materials and design have led to the introduction of metal, plastic, and hybrid options. This evolution reflects not only changes in consumer preferences but also the growing need for versatility and efficiency in retail environments.

In recent years, the emphasis on modular and customizable designs has gained traction, allowing retailers to adapt their displays to different product lines and seasonal promotions. For B2B buyers, understanding this evolution is crucial as it informs purchasing decisions. Selecting suppliers who can provide innovative solutions tailored to specific market needs can significantly enhance product presentation and sales performance.

As the sector continues to grow, international buyers must stay informed about the latest trends and innovations to make strategic sourcing decisions that align with their business goals.

Frequently Asked Questions (FAQs) for B2B Buyers of display rack china

-

How do I select the right display rack for my business needs?

Choosing the right display rack involves assessing your specific needs, such as the type of products you intend to display, the available space, and your target audience. Consider factors like load capacity, material durability, and design aesthetics. Engage with suppliers for product samples and technical specifications to ensure the display rack aligns with your branding and logistical requirements. Additionally, researching industry standards and customer preferences can help inform your decision. -

What are the customization options available for display racks from China?

Many Chinese manufacturers offer extensive customization options for display racks, including size, color, material, and design. When sourcing, inquire about the supplier’s capability to tailor products to your specifications. Providing detailed drawings and design concepts can facilitate the customization process. Additionally, confirm the minimum order quantities (MOQs) for custom designs, as these may vary significantly between suppliers. -

What is the minimum order quantity (MOQ) for display racks from Chinese suppliers?

The MOQ for display racks varies by supplier and can depend on factors such as the complexity of the design and the materials used. Generally, you can expect MOQs to range from 50 to 100 units for standard designs. For custom orders, MOQs may be higher. It’s advisable to discuss your requirements with multiple suppliers to find a balance between your budget and the quantity needed for your operations. -

What payment terms should I negotiate with Chinese display rack suppliers?

When negotiating payment terms, consider options like a 30% deposit with the balance due upon shipment or a letter of credit for larger orders. Ensure that the terms are clear and mutually agreed upon to avoid disputes. It’s also wise to utilize secure payment methods, such as PayPal or escrow services, especially when dealing with new suppliers. Always conduct thorough background checks to mitigate the risk of fraud. -

How can I ensure quality assurance when sourcing display racks from China?

To ensure quality, request product samples before placing a large order. Establish a clear quality control process by discussing inspection protocols with your supplier. Consider hiring a third-party inspection service to conduct factory audits and product checks before shipment. Additionally, familiarize yourself with relevant international quality standards to ensure compliance and minimize potential issues upon receipt. -

What logistics considerations should I keep in mind when importing display racks from China?

Logistics is crucial when importing display racks. Assess shipping options such as air freight versus sea freight based on urgency and budget. Calculate total landed costs, including shipping, duties, and taxes. It is also essential to understand the customs regulations in your country to avoid delays. Collaborating with a reliable freight forwarder can streamline the process and help navigate complex shipping logistics. -

What are the common challenges faced by B2B buyers when sourcing display racks from China?

Common challenges include language barriers, cultural differences, and varying quality standards. Establishing clear communication and building relationships with suppliers can mitigate these issues. Additionally, be prepared for potential delays in production and shipping. Conducting thorough research and having contingency plans can help manage these risks effectively. -

How do I verify the credibility of a display rack supplier from China?

Verifying a supplier’s credibility involves several steps. Start by checking their business licenses and certifications. Look for customer reviews and testimonials on platforms like Alibaba or Global Sources. Conduct video calls or visits to the factory if possible. Additionally, consider requesting references from other clients and assessing their responsiveness and professionalism during your interactions. This diligence will help ensure you partner with a reputable supplier.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for display rack china

In navigating the dynamic landscape of display rack sourcing from China, international B2B buyers from regions such as Africa, South America, the Middle East, and Europe must prioritize strategic sourcing to maximize value. By understanding the intricacies of supply chain management, buyers can mitigate risks associated with quality, lead times, and costs. Leveraging China’s manufacturing capabilities not only enhances product diversity but also offers competitive pricing, making it an attractive option for businesses aiming to scale efficiently.

What key factors should B2B buyers consider in their sourcing strategy? Buyers should conduct thorough market research to identify reliable suppliers, evaluate their production capabilities, and assess the quality of materials used. Establishing clear communication channels with suppliers can further streamline the procurement process, ensuring alignment on specifications and timelines.

Looking ahead, the trend towards sustainable practices is likely to reshape sourcing strategies. Buyers should consider suppliers who prioritize eco-friendly materials and practices, as this not only meets growing consumer demand but also enhances brand reputation. By adopting a forward-thinking approach to sourcing display racks from China, businesses can position themselves for long-term success and adaptability in a competitive marketplace. Embrace these insights to make informed decisions that drive growth and innovation in your supply chain.