Discover Cost-Effective Electric Car Conversion Kit China (2025)

Introduction: Navigating the Global Market for electric car conversion kit china

In the rapidly evolving automotive landscape, sourcing an electric car conversion kit from China presents both immense opportunities and significant challenges for international B2B buyers. The transition towards electric vehicles (EVs) is not just a trend; it’s a necessity driven by environmental concerns and government regulations. However, navigating the complexities of the global market, especially when considering the diverse needs of regions like Africa, South America, the Middle East, and Europe, can be daunting. This guide aims to demystify the process by providing a comprehensive overview of electric car conversion kits from China, including various types, applications, and essential factors for supplier vetting.

Understanding the nuances of electric car conversion kits is crucial for making informed purchasing decisions. This guide will explore the different types of kits available, their specific applications across various vehicle models, and the cost implications involved. Additionally, we will delve into strategies for effectively vetting suppliers to ensure quality and reliability, which are paramount in the B2B sector. By equipping buyers with actionable insights and a clear framework, this resource empowers stakeholders to approach the market confidently, ultimately facilitating a smoother transition to electric mobility solutions tailored to their regional contexts and business needs.

Understanding electric car conversion kit china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Complete Conversion Kits | All-in-one solutions including motor, controller, and battery | Fleet electrification, retrofitting | Pros: Comprehensive; Cons: Higher initial investment. |

| Motor Conversion Kits | Focus on replacing the internal combustion engine with an electric motor | Custom vehicle builds, hobbyist projects | Pros: Cost-effective; Cons: Limited range and performance. |

| Battery Upgrade Kits | Enhanced battery packs for extended range and performance | Commercial vehicle upgrades | Pros: Improved range; Cons: Compatibility issues possible. |

| Hybrid Conversion Kits | Combines electric and gasoline power sources | Urban delivery vehicles, taxis | Pros: Flexibility; Cons: Complexity in installation. |

| Regenerative Braking Kits | Systems that recover energy during braking | Performance enhancement for electric vehicles | Pros: Energy efficiency; Cons: Requires advanced tech. |

What Are the Key Characteristics of Complete Conversion Kits?

Complete conversion kits are designed to transform conventional vehicles into fully electric ones by providing all necessary components, including the electric motor, controller, and battery pack. This type of kit is ideal for businesses looking to electrify their fleets or retrofit existing vehicles. When considering a complete conversion kit, B2B buyers should evaluate the total cost of ownership, including installation and maintenance, as the initial investment can be substantial. However, the comprehensive nature of these kits ensures a seamless transition to electric power.

How Do Motor Conversion Kits Benefit Businesses?

Motor conversion kits are primarily focused on replacing a vehicle’s internal combustion engine with an electric motor. These kits are often more affordable than complete conversion kits, making them attractive for budget-conscious businesses or hobbyists. While motor conversion kits can be suitable for various applications, buyers must consider factors such as compatibility with existing vehicle systems and the potential for reduced performance compared to complete kits. They are particularly advantageous for companies experimenting with electric vehicle technology or those with specific customization needs.

Why Consider Battery Upgrade Kits for Enhanced Performance?

Battery upgrade kits are designed to enhance the battery capacity of electric vehicles, providing extended range and improved performance. These kits are particularly beneficial for commercial applications, such as delivery services, where range anxiety can impact operational efficiency. B2B buyers should assess the compatibility of these kits with their existing vehicles and the expected return on investment from improved range. While these upgrades can significantly enhance performance, potential compatibility issues with existing systems should be carefully evaluated.

What Are the Advantages of Hybrid Conversion Kits?

Hybrid conversion kits allow vehicles to utilize both electric and gasoline power sources, providing flexibility in various driving conditions. This type of kit is particularly useful for urban delivery vehicles or taxis that may benefit from electric operation in congested areas while retaining gasoline backup for longer trips. Businesses should consider the complexity of installation and maintenance when opting for hybrid systems, as they can be more challenging than standard electric conversions. The dual power source can offer significant operational advantages in diverse environments.

How Do Regenerative Braking Kits Improve Energy Efficiency?

Regenerative braking kits are designed to capture energy typically lost during braking and convert it into usable electrical power. This technology is especially valuable for businesses focused on maximizing energy efficiency in their electric vehicles. While regenerative braking systems can enhance overall vehicle performance and reduce energy consumption, they require advanced technology and expertise for installation. B2B buyers should consider the long-term benefits of energy savings against the potential upfront costs and technical requirements.

Related Video: 72V 5000W BLDC ELECTRIC CAR CONVERSION KIT

Key Industrial Applications of electric car conversion kit china

| Industry/Sector | Specific Application of electric car conversion kit china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Public Transportation | Converting buses to electric systems | Reduced operational costs and lower emissions | Compliance with local regulations and warranty terms |

| Logistics and Delivery | Retrofitting delivery vans with electric kits | Enhanced fuel efficiency and reduced maintenance costs | Availability of support services and local infrastructure |

| Agriculture | Electric conversion of farm vehicles | Decreased fuel costs and improved sustainability | Adaptability to local farming conditions and vehicle types |

| Automotive Repair Shops | Offering conversion services for traditional vehicles | New revenue streams and customer diversification | Quality of components and technical training for staff |

| Eco-Tourism | Converting tourist vehicles to electric | Attract environmentally conscious customers | Customization options and partnerships with local guides |

How Can Electric Car Conversion Kits Benefit Public Transportation?

In the public transportation sector, electric car conversion kits from China are being utilized to retrofit buses, transforming them from diesel to electric-powered vehicles. This application addresses the pressing need for reduced greenhouse gas emissions and operational costs. For international buyers, especially in regions like Africa and South America, the focus should be on sourcing kits that comply with local environmental regulations and provide robust warranties. Additionally, the capability of the kits to integrate with existing bus models can significantly influence procurement decisions.

What Are the Advantages of Electric Conversion Kits for Logistics and Delivery?

Logistics and delivery companies are increasingly adopting electric conversion kits to retrofit their delivery vans. This shift not only enhances fuel efficiency but also lowers maintenance costs associated with traditional combustion engines. For buyers in the Middle East and Europe, it is crucial to consider the availability of local service support and the infrastructure needed for charging electric vehicles. Investing in these conversion kits can lead to substantial long-term savings and a stronger brand reputation among eco-conscious consumers.

How Does Electric Conversion Enhance Agricultural Vehicles?

In agriculture, converting traditional farm vehicles to electric using conversion kits can significantly cut fuel costs while promoting sustainable farming practices. These kits can be tailored to different vehicle types, ensuring compatibility with various agricultural machinery. Buyers from regions like South Africa should prioritize sourcing kits that are adaptable to local farming conditions and can withstand rugged terrains. This adaptability not only ensures operational efficiency but also aligns with global trends towards sustainability in agriculture.

Why Should Automotive Repair Shops Consider Electric Conversion Services?

Automotive repair shops can diversify their service offerings by providing electric vehicle conversion services. This presents an opportunity to tap into a growing market of eco-conscious consumers looking to transition their traditional vehicles to electric. For B2B buyers in Europe, it is vital to evaluate the quality of components used in these kits, as well as the technical training available for staff to ensure proper installation and maintenance. This initiative can lead to new revenue streams and a competitive edge in the automotive repair industry.

What Role Do Electric Conversion Kits Play in Eco-Tourism?

In the eco-tourism sector, electric conversion kits are being used to convert traditional tourist vehicles into electric ones, appealing to environmentally aware travelers. This application not only enhances the customer experience but also reduces the ecological footprint of tourism operations. International buyers should explore customization options that reflect local culture and landscapes, as well as partnerships with local guides to enhance the tourist experience. By investing in these kits, businesses can attract a niche market of eco-tourists and improve their sustainability credentials.

3 Common User Pain Points for ‘electric car conversion kit china’ & Their Solutions

Scenario 1: Difficulty in Understanding Technical Specifications of Electric Car Conversion Kits

The Problem: Many international B2B buyers, particularly from regions like Africa and South America, often face challenges when it comes to the technical specifications of electric car conversion kits. Given the variations in vehicle models, power requirements, and local regulations, it can be overwhelming to navigate through the intricate details. This confusion can lead to selecting the wrong kit, resulting in wasted resources and potential delays in project timelines.

The Solution: To overcome this challenge, buyers should prioritize sourcing kits from reputable manufacturers in China who provide comprehensive technical documentation. This includes compatibility charts, installation guides, and performance metrics tailored to specific vehicle models. Engage directly with suppliers to discuss your specific needs and request tailored recommendations based on your fleet’s specifications. Additionally, consider investing in training for your technical team to ensure they fully understand how to integrate these conversion kits effectively, thus minimizing the risk of error during installation.

Scenario 2: High Shipping Costs and Import Regulations

The Problem: Another significant pain point for B2B buyers is the high shipping costs and complex import regulations associated with electric car conversion kits from China. Many buyers from the Middle East and Europe experience unexpected tariffs and lengthy customs processes, which can inflate project budgets and timelines, causing frustration and potential financial strain.

The Solution: To mitigate these issues, buyers should conduct thorough research on shipping options and customs regulations specific to their country. Collaborate with logistics companies that specialize in international shipping of automotive parts to find cost-effective solutions. Additionally, consider establishing partnerships with local distributors or warehouses that can hold inventory, reducing the need for direct shipping from China. This not only lowers shipping costs but also streamlines the supply chain, enabling quicker access to conversion kits as needed.

Scenario 3: Limited After-Sales Support and Warranty Issues

The Problem: A common concern for international B2B buyers is the lack of after-sales support and warranty issues related to electric car conversion kits. When problems arise post-purchase, buyers often find it challenging to get timely assistance or service from manufacturers in China, leading to prolonged downtime and frustration.

The Solution: To address this pain point, buyers should seek out manufacturers who offer robust after-sales support, including extended warranties and dedicated customer service teams. Before finalizing any purchase, inquire about the manufacturer’s policies on technical support, spare parts availability, and warranty claims. Establishing a clear communication channel with the manufacturer can also enhance responsiveness to issues as they arise. Furthermore, consider joining industry forums or groups where other users of the same kits share their experiences and solutions, providing a community support network that can be invaluable in troubleshooting and problem-solving.

By taking proactive steps in understanding technical specifications, navigating shipping challenges, and ensuring robust after-sales support, B2B buyers can effectively streamline their acquisition and integration of electric car conversion kits from China, ultimately leading to successful project outcomes.

Strategic Material Selection Guide for electric car conversion kit china

When selecting materials for electric car conversion kits sourced from China, international B2B buyers must consider several factors that impact performance, cost, and compliance with regional standards. This analysis focuses on four common materials: aluminum, steel, copper, and plastic composites, each with unique properties and implications for electric vehicle applications.

What are the Key Properties of Aluminum in Electric Car Conversion Kits?

Aluminum is a lightweight metal known for its excellent corrosion resistance and thermal conductivity. It typically has a temperature rating up to 600°F (315°C) and can withstand moderate pressures, making it suitable for various components in electric car conversion kits, such as battery enclosures and chassis parts.

Pros & Cons:

– Advantages: Aluminum is durable, lightweight, and offers good thermal management, which is crucial for battery performance. Its resistance to corrosion extends the lifespan of components.

– Disadvantages: The primary limitation is its cost, which can be higher than steel. Additionally, manufacturing processes like welding can be more complex.

Impact on Application: Aluminum’s compatibility with various media, especially in battery applications, makes it a preferred choice for many manufacturers.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that suppliers meet international standards such as ASTM B209 for aluminum alloys. Understanding local tariffs and import regulations is also essential, as these can affect overall costs.

How Does Steel Perform in Electric Car Conversion Kits?

Steel is a widely used material in automotive applications due to its strength and durability. It has a high-temperature rating, generally around 1,500°F (815°C), and can handle significant pressure, making it ideal for structural components.

Pros & Cons:

– Advantages: Steel is cost-effective and provides excellent strength, making it suitable for the frame and support structures of conversion kits.

– Disadvantages: It is heavier than aluminum and can be prone to corrosion if not properly treated or coated.

Impact on Application: Steel’s robustness is beneficial for safety-critical components, but its weight can affect vehicle efficiency.

Considerations for International Buyers: Buyers should be aware of common standards like ASTM A36 for structural steel. Compliance with local regulations regarding emissions and safety is also crucial, especially in Europe.

What Role Does Copper Play in Electric Car Conversion Kits?

Copper is essential for electrical components due to its high electrical conductivity. It has a temperature rating of around 200°F (93°C) and is resistant to corrosion, making it ideal for wiring and connectors in electric vehicles.

Pros & Cons:

– Advantages: Copper’s excellent conductivity ensures efficient power transfer, which is vital for battery performance and overall vehicle efficiency.

– Disadvantages: The cost of copper can be high, and it is heavier than aluminum, which may impact the overall weight of the conversion kit.

Impact on Application: Copper is crucial for any electrical connections and battery systems, directly influencing the performance of electric vehicles.

Considerations for International Buyers: Buyers should look for compliance with standards such as ASTM B170 for copper wire. Understanding the supply chain for copper, particularly in regions with fluctuating prices, is essential.

How are Plastic Composites Used in Electric Car Conversion Kits?

Plastic composites are increasingly used in electric vehicle applications due to their lightweight and corrosion-resistant properties. They can withstand temperatures up to 300°F (149°C) and are often used in non-structural components.

Pros & Cons:

– Advantages: These materials are lightweight, reducing the overall weight of the vehicle and improving efficiency. They also offer design flexibility.

– Disadvantages: Plastic composites may not provide the same level of strength as metals and can be more susceptible to damage from UV exposure.

Impact on Application: Their use in interior components and non-structural parts can enhance aesthetics while maintaining functionality.

Considerations for International Buyers: Buyers should ensure that the composites meet relevant standards like ASTM D638 for tensile properties. Awareness of local recycling regulations is also important, especially in Europe, where sustainability is a key concern.

Summary Table of Material Selection for Electric Car Conversion Kits

| Material | Typical Use Case for electric car conversion kit china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Battery enclosures, chassis parts | Lightweight and corrosion-resistant | Higher cost and complex manufacturing | High |

| Steel | Structural components | Cost-effective and strong | Heavier and prone to corrosion | Medium |

| Copper | Wiring and connectors | Excellent electrical conductivity | High cost and heavier than aluminum | High |

| Plastic Composites | Interior and non-structural components | Lightweight and design flexibility | Less strength and UV sensitivity | Medium |

This material selection guide provides international B2B buyers with critical insights into the properties, advantages, and limitations of common materials used in electric car conversion kits from China. Understanding these factors will aid in making informed purchasing decisions that align with regional standards and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for electric car conversion kit china

What are the Main Manufacturing Processes for Electric Car Conversion Kits in China?

The manufacturing of electric car conversion kits in China involves several critical stages that ensure the final product meets international quality standards. Understanding these processes is essential for B2B buyers, especially those from Africa, South America, the Middle East, and Europe, as it helps in making informed purchasing decisions.

Material Preparation: What Goes into Electric Car Conversion Kits?

The first step in the manufacturing process is material preparation, which involves sourcing high-quality components such as electric motors, battery packs, controllers, and wiring. Chinese manufacturers often leverage local suppliers for raw materials to reduce costs and ensure a steady supply chain.

Key techniques in this phase include:

- Material Inspection: Suppliers conduct thorough inspections of incoming materials to ensure they meet specified standards.

- Inventory Management: Effective inventory systems are employed to track material usage and minimize waste.

Forming: How Are Components Fabricated?

The forming stage involves shaping and processing the raw materials into usable components. This may include stamping, machining, and molding of parts.

Techniques commonly used include:

- CNC Machining: Computer Numerical Control (CNC) machines are utilized for precision cutting and shaping of metal components.

- Injection Molding: This technique is often employed for creating plastic parts, ensuring uniformity and strength.

Assembly: What is Involved in the Assembly Process?

After the components are formed, the next stage is assembly. This is where all parts are put together to create the complete electric car conversion kit.

Key aspects of the assembly process include:

- Automated Assembly Lines: Many manufacturers use automated systems to enhance efficiency and reduce labor costs.

- Manual Assembly: Skilled workers may be employed for complex assembly tasks that require a higher degree of precision.

Finishing: How is Quality Enhanced in the Final Stages?

The finishing stage involves surface treatment, painting, and quality checks to ensure that the product is ready for market.

Important techniques in this phase include:

- Coating and Painting: Protective coatings are applied to prevent corrosion and enhance aesthetics.

- Final Inspection: Each kit undergoes a thorough inspection to verify that it meets all specifications before shipping.

What Quality Assurance Practices are Essential for Electric Car Conversion Kits?

Quality assurance is a vital component in the manufacturing of electric car conversion kits. It ensures that products are not only safe but also perform efficiently.

International Standards: Which Certifications Should Buyers Look For?

International standards such as ISO 9001 are crucial for ensuring quality management systems are in place. In addition to ISO, industry-specific certifications such as CE (Conformité Européenne) are also important, especially for buyers in Europe. Other certifications might include:

- API Standards: Relevant for manufacturers dealing with electronic components.

- UL Certification: Ensures the safety of electrical components.

Quality Control Checkpoints: What Are the Key Stages?

The quality control process typically involves several checkpoints:

- Incoming Quality Control (IQC): This stage checks the quality of raw materials before they enter the production line.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to detect any defects early.

- Final Quality Control (FQC): A comprehensive assessment of the finished product to ensure it meets all regulatory requirements.

Common Testing Methods: How Are Products Tested?

Testing methods play a crucial role in quality assurance. Common tests include:

- Electrical Testing: Ensures that all electrical components function correctly and safely.

- Durability Testing: Assesses the longevity of components under various conditions.

- Performance Testing: Verifies that the conversion kit performs as expected under real-world conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control processes of suppliers is essential to mitigate risks. Here are some actionable strategies:

Conducting Audits: What Should Buyers Look For?

Buyers should consider conducting audits of potential suppliers. This includes:

- On-Site Audits: Visiting the manufacturing facility to assess the production process and quality control measures firsthand.

- Document Review: Reviewing quality control documents, including inspection reports and certificates of compliance.

Requesting Reports: How to Obtain Quality Assurance Documentation?

B2B buyers should request detailed reports on quality assurance practices, which may include:

- Production Samples: Requesting samples from the production line to assess quality.

- Third-Party Inspection Reports: Engaging independent inspectors to validate the quality claims made by suppliers.

What Are the Quality Control Nuances for International Buyers?

Understanding the nuances of quality control can help international buyers navigate the complexities of sourcing from China.

Compliance with Local Regulations: What Should Buyers Know?

Different regions have varying standards and regulations. Buyers must ensure that the products they import comply with local laws. For instance:

- African Markets: Buyers should be aware of regional standards set by organizations like the African Organization for Standardization (ARSO).

- European Markets: Compliance with EU regulations is mandatory, particularly concerning safety and environmental impact.

Cultural Considerations: How Do They Impact Quality Assurance?

Cultural differences may affect communication and expectations regarding quality. It is advisable for buyers to:

- Establish Clear Communication: Ensure that quality expectations are explicitly communicated to suppliers.

- Build Relationships: Foster relationships with suppliers to enhance trust and reliability in quality assurance practices.

By understanding the manufacturing processes and quality assurance practices involved in electric car conversion kits from China, B2B buyers can make informed decisions that align with their business needs. This knowledge not only helps in selecting the right supplier but also ensures that the products meet the required standards for safety and performance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric car conversion kit china’

The following guide is designed to assist international B2B buyers in sourcing electric car conversion kits from China. By following this checklist, businesses can ensure they make informed purchasing decisions, thus minimizing risks and maximizing value.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it is essential to have a clear understanding of the technical specifications required for the electric car conversion kit. This includes battery capacity, motor type, control systems, and compatibility with existing vehicle models.

– Why it matters: Clear specifications help in communicating your needs to suppliers, ensuring that the products you receive meet your expectations.

– What to look for: Research industry standards and regulations relevant to your target market to ensure compliance.

Step 2: Conduct Market Research

Investigate the current market landscape for electric car conversion kits in China. Look into the leading manufacturers, their product offerings, and market prices.

– Why it matters: Understanding market dynamics enables you to identify competitive pricing and innovative features that can benefit your business.

– What to look for: Utilize trade platforms, industry reports, and local trade shows to gather insights.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Why it matters: Supplier reliability can significantly impact your project’s success, so ensuring that they have a good track record is vital.

– What to look for: Assess their production capacity, quality control processes, and after-sales support.

Step 4: Verify Certifications and Compliance

Ensure that the suppliers hold necessary certifications such as ISO, CE, or RoHS, which validate the quality and safety of their products.

– Why it matters: Certifications indicate adherence to international standards, which is especially important when selling in regulated markets.

– What to look for: Request copies of certifications and verify them with issuing bodies to ensure authenticity.

Step 5: Request Samples for Testing

Before finalizing your order, request samples of the electric car conversion kits for testing. This will allow you to evaluate the quality and functionality firsthand.

– Why it matters: Testing samples can uncover potential issues that may not be evident from specifications alone.

– What to look for: Assess the performance, durability, and ease of installation of the conversion kits.

Step 6: Negotiate Terms and Pricing

Once you have identified suitable suppliers and tested samples, engage in negotiations regarding pricing, payment terms, and delivery schedules.

– Why it matters: Effective negotiation can lead to cost savings and better payment terms, improving your overall profitability.

– What to look for: Aim for transparency in pricing and flexibility in terms to foster a long-term relationship with the supplier.

Step 7: Plan Logistics and Shipping

Consider the logistics involved in importing the conversion kits from China, including shipping methods, customs clearance, and delivery timelines.

– Why it matters: Proper logistics planning can prevent delays and additional costs associated with transportation and customs.

– What to look for: Collaborate with freight forwarders who have experience with electric vehicle components to streamline the process.

By following this structured checklist, B2B buyers can navigate the complexities of sourcing electric car conversion kits from China with confidence and clarity, ultimately leading to successful procurement outcomes.

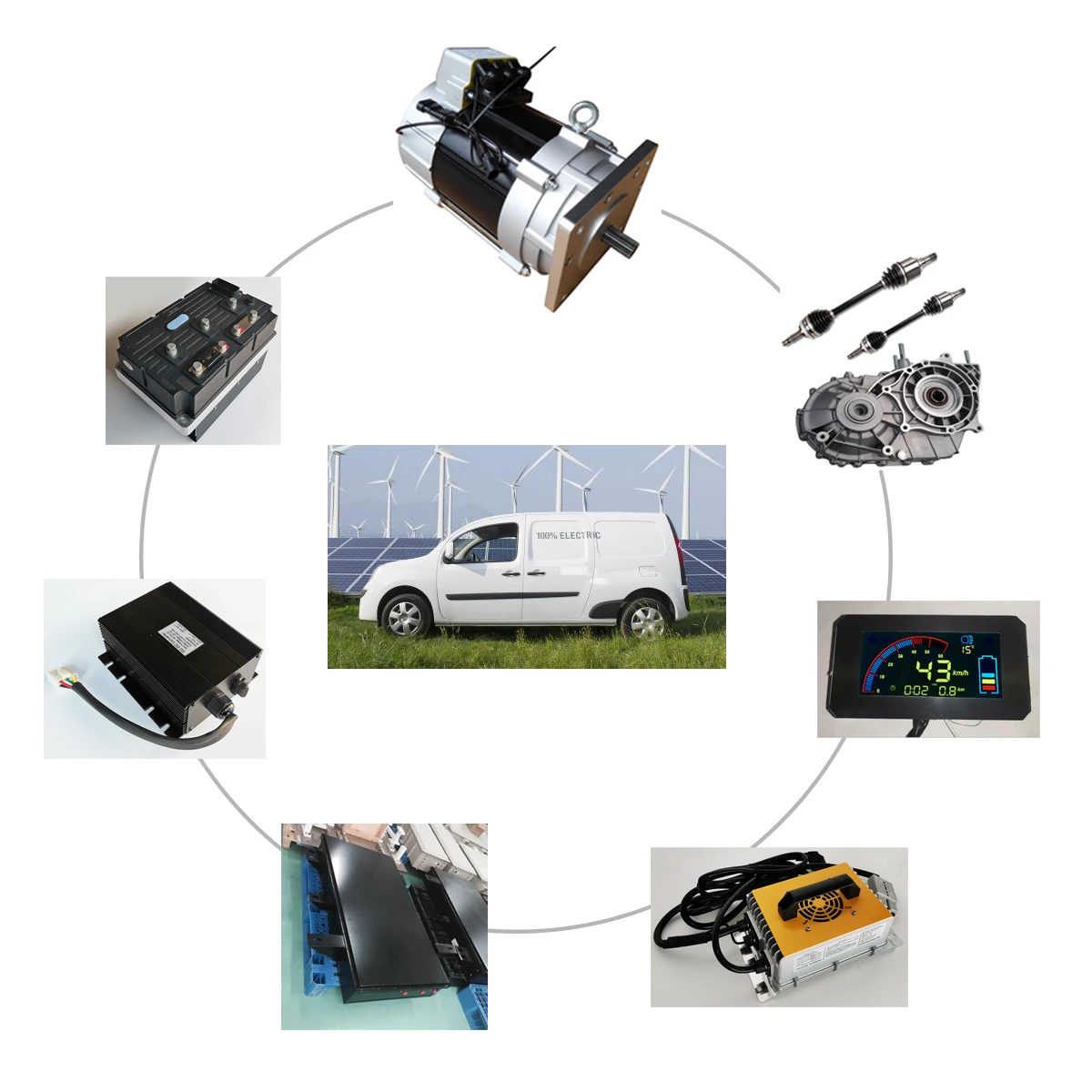

A stock image related to electric car conversion kit china.

Comprehensive Cost and Pricing Analysis for electric car conversion kit china Sourcing

What Are the Key Cost Components of Electric Car Conversion Kits from China?

When sourcing electric car conversion kits from China, understanding the cost structure is crucial for B2B buyers. The primary components of the cost include:

-

Materials: This includes batteries, electric motors, and other electronic components. Prices can vary significantly based on the quality and specifications. High-performance materials often come at a premium but can enhance the conversion kit’s effectiveness.

-

Labor: Labor costs in China are generally lower compared to Western countries, but they can vary by region and supplier. Skilled labor may be required for complex assembly processes, which can influence overall costs.

-

Manufacturing Overhead: This includes the costs related to the operation of the manufacturing facility, such as utilities, rent, and administrative expenses. Understanding a supplier’s overhead can provide insights into their pricing strategy.

-

Tooling: If the conversion kit requires specialized tooling or molds, these costs must be factored in. Initial investments in tooling can be significant, especially for custom designs.

-

Quality Control (QC): Ensuring the quality of the conversion kits is essential, especially for international buyers. Investing in robust QC processes may increase costs but can save money in the long run by reducing defects and returns.

-

Logistics: Shipping costs, including freight and insurance, play a significant role in the total cost. Buyers should consider the distance from the supplier and the chosen shipping method, as these can substantially affect the final price.

-

Margin: Suppliers will typically add a margin to cover their costs and ensure profitability. Understanding the typical mark-up in the industry can help buyers negotiate better prices.

How Do Price Influencers Affect the Cost of Electric Car Conversion Kits?

Several factors can influence the pricing of electric car conversion kits, which B2B buyers should consider:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes typically lead to lower per-unit costs. Negotiating better terms can yield significant savings for bulk orders.

-

Specifications and Customization: Customizing kits to meet specific requirements can increase costs. Buyers should assess whether the added features justify the price increase.

-

Materials Quality and Certifications: High-quality materials and certifications (like ISO standards) can affect the price. Buyers should evaluate if the certifications are necessary for their market or if they can accept lower-cost options.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more for their experience and reliability, while newer entrants may offer lower prices to gain market share.

-

Incoterms: The terms of shipping can significantly affect total costs. Understanding the responsibilities of each party under various Incoterms (like FOB, CIF) can help buyers avoid unexpected charges.

What Are the Best Buyer Tips for Negotiating Prices and Ensuring Cost-Efficiency?

-

Negotiation Strategies: Engage in open communication with suppliers about pricing. Highlight your potential for future orders to encourage better terms. Always be prepared to walk away if the deal doesn’t meet your expectations.

-

Focus on Total Cost of Ownership (TCO): Evaluate the long-term costs associated with the conversion kits, including maintenance, performance, and resale value. A slightly higher upfront cost might be justified if the kit offers better efficiency and lower operational costs.

-

Understand Pricing Nuances for International Markets: When sourcing from China, international buyers should be aware of currency fluctuations, tariffs, and trade regulations that can affect costs. It’s advisable to work with suppliers who are experienced in international shipping and regulations.

-

Request Indicative Pricing: Suppliers may provide indicative prices based on current market conditions. However, these are not final quotes and can change. Always request updated quotes before finalizing any orders to ensure accurate budgeting.

By focusing on these aspects, international B2B buyers can make informed decisions when sourcing electric car conversion kits from China, ensuring they achieve the best possible value for their investment.

Alternatives Analysis: Comparing electric car conversion kit china With Other Solutions

Exploring Alternatives to Electric Car Conversion Kits from China

When considering electric vehicle (EV) solutions, international B2B buyers must evaluate various options to find the most suitable technology for their specific needs. The electric car conversion kit from China presents a popular solution for retrofitting traditional vehicles into electric ones. However, alternative methods and technologies may also meet the requirements of businesses looking to transition to electric mobility. This section explores key alternatives, comparing their performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Electric Car Conversion Kit China | Alternative 1: Fully Electric Vehicles | Alternative 2: Hybrid Vehicles |

|---|---|---|---|

| Performance | Moderate range; depends on battery quality | High range; optimized for performance | Good range; efficient fuel use |

| Cost | Generally lower initial investment | Higher upfront cost; long-term savings | Moderate cost; fuel-efficient |

| Ease of Implementation | Requires technical expertise for installation | Ready to use; no installation needed | Easier to implement than full EVs |

| Maintenance | Regular checks needed for battery and motor | Standard vehicle maintenance | Requires both electric and combustion maintenance |

| Best Use Case | Retrofitting older vehicles; cost-effective for fleets | New vehicle purchases; maximum efficiency | Versatile use; transitional technology |

What Are the Pros and Cons of Fully Electric Vehicles?

Fully electric vehicles (EVs) are purpose-built to run on electric power, offering high performance and efficiency. Their primary advantage lies in their range and performance, often exceeding that of converted vehicles. However, the upfront investment is significantly higher, which may deter some businesses. Additionally, fully electric vehicles require a robust charging infrastructure, which may not be readily available in all regions, particularly in developing markets like parts of Africa and South America.

How Do Hybrid Vehicles Compare?

Hybrid vehicles combine an internal combustion engine with an electric motor, providing a versatile solution for businesses. Their cost is typically lower than that of fully electric vehicles but higher than conversion kits. They offer improved fuel efficiency and reduced emissions, making them a suitable transitional technology for fleets looking to gradually shift to electric mobility. However, maintenance can be more complex due to the dual systems, and they may not provide the same environmental benefits as fully electric alternatives.

How Should B2B Buyers Choose the Right Solution?

When selecting the appropriate technology for electric mobility, B2B buyers should consider several factors. Assessing the total cost of ownership—including initial investment, maintenance, and operating costs—can provide insights into the long-term financial implications of each option. Additionally, evaluating the infrastructure available in the target market is crucial; for instance, areas with limited charging stations may benefit more from hybrid solutions. Ultimately, businesses should align their choice with operational goals, environmental commitments, and customer expectations to maximize their investment in electric mobility.

Essential Technical Properties and Trade Terminology for electric car conversion kit china

What Are the Essential Technical Properties of Electric Car Conversion Kits from China?

When considering electric car conversion kits, international B2B buyers should focus on several critical technical properties to ensure compatibility, performance, and durability. Here are the key specifications to evaluate:

-

Material Grade

– Definition: This refers to the quality of materials used in the manufacturing of the conversion kit components, such as the battery housing, motor casing, and wiring.

– Importance: Higher-grade materials enhance longevity, performance, and safety. Buyers should seek materials that meet international standards to avoid premature failures, especially in varying climates found in Africa, South America, and the Middle East. -

Power Output (kW)

– Definition: Measured in kilowatts (kW), this specification indicates the maximum power the electric motor can deliver.

– Importance: Understanding power output is crucial for buyers to match the conversion kit with their vehicle’s requirements. Insufficient power can lead to poor performance, while excessive power may require additional modifications to the vehicle. -

Battery Capacity (Ah)

– Definition: Ampere-hours (Ah) measure the battery’s energy storage capacity.

– Importance: A higher capacity allows for longer driving ranges between charges, which is particularly important in regions with limited charging infrastructure. Buyers should consider their operational needs and select kits that provide adequate range. -

Tolerance Levels

– Definition: Tolerance refers to the permissible limits of variation in a physical dimension or measured value of components.

– Importance: Accurate tolerances ensure that all components fit together correctly and function optimally. For international buyers, ensuring these tolerances align with local standards can prevent costly modifications or failures. -

Weight of Components

– Definition: The overall weight of the conversion kit affects the vehicle’s handling and efficiency.

– Importance: Buyers should assess the weight in relation to the vehicle’s original specifications. A heavier kit may require additional modifications to the vehicle’s suspension or braking systems, impacting overall performance.

What Are Common Trade Terms Relevant to Electric Car Conversion Kits?

Understanding trade terminology is essential for smooth transactions and effective communication in international B2B dealings. Here are some common terms you may encounter:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Relevance: Buyers should be aware of OEM status when sourcing kits, as it often ensures quality and compatibility with existing vehicle systems. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Understanding MOQ is critical for budgeting and planning inventory. Buyers should negotiate these terms to align with their operational needs and financial capacity. -

RFQ (Request for Quotation)

– Definition: A document that solicits a quote from suppliers for specific products or services.

– Relevance: Issuing an RFQ allows buyers to compare prices and terms from multiple suppliers, ensuring they make informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) relating to international commercial law.

– Relevance: Familiarity with Incoterms helps buyers understand shipping responsibilities and liabilities. This is especially important for international transactions to avoid disputes over freight and insurance costs. -

Lead Time

– Definition: The amount of time taken between the initiation of a process and its completion, particularly in manufacturing and shipping.

– Relevance: Knowing the lead time helps buyers plan their inventory and ensure that they can meet market demands without delays.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing electric car conversion kits from China, ensuring they select the best products for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the electric car conversion kit china Sector

What Are the Key Market Dynamics and Trends in the Electric Car Conversion Kit Sector in China?

The electric car conversion kit sector in China is rapidly evolving, driven by global shifts towards sustainable transportation and increased regulatory support for electric vehicles (EVs). As international B2B buyers from regions like Africa, South America, the Middle East, and Europe look to enter this market, understanding key trends is crucial. Notably, the demand for electric conversion kits is rising due to the growing interest in retrofitting existing internal combustion engine vehicles. This trend is particularly prominent in regions with limited access to new electric vehicles, making conversion kits a cost-effective solution.

Technological advancements are also reshaping the landscape. Manufacturers are increasingly incorporating smart technologies, such as IoT-enabled monitoring systems, which enhance the efficiency and performance of conversion kits. Moreover, the push for cost reduction through local sourcing and production is becoming common as buyers seek to mitigate supply chain risks. For instance, sourcing components locally within Africa or South America can reduce lead times and import tariffs, making conversion kits more accessible and affordable.

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing in the Electric Car Conversion Kit Market?

Sustainability is paramount in the electric car conversion kit sector, reflecting the broader trend towards green technologies. B2B buyers must consider the environmental impact of the materials used in conversion kits. Sourcing from suppliers that prioritize eco-friendly practices is essential. Buyers should look for certifications such as ISO 14001, which indicates adherence to environmental management standards, and products that utilize recycled or sustainable materials.

Ethical sourcing also plays a critical role. Ensuring that supply chains are free from human rights violations, such as forced labor, is increasingly important to consumers and regulators alike. Buyers should conduct thorough due diligence on their suppliers, verifying their labor practices and environmental commitments. Engaging with manufacturers who are transparent about their sourcing processes not only enhances brand reputation but also aligns with the values of a growing segment of environmentally conscious consumers.

What Is the Evolution of the Electric Car Conversion Kit Market?

The evolution of the electric car conversion kit market can be traced back to the early 2000s when environmental concerns began to rise, prompting innovations in electric mobility. Initially, conversion kits were rudimentary, designed primarily for hobbyists and early adopters. However, as technology advanced and the demand for sustainable transportation grew, manufacturers began to develop more sophisticated kits that included advanced battery management systems and integration with existing vehicle electronics.

By the late 2010s, the market gained momentum with increased interest from commercial enterprises seeking to reduce their carbon footprints. Today, electric car conversion kits are not only seen as a viable alternative for individual consumers but also as strategic assets for businesses looking to transition their fleets to electric power. This historical trajectory underscores the growing relevance of electric conversion kits in the global push towards sustainable transportation, making it a pivotal area for B2B engagement.

By understanding these market dynamics, trends, and the importance of sustainability, international B2B buyers can make informed decisions in the electric car conversion kit sector, enhancing their competitive edge in a rapidly changing landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of electric car conversion kit china

-

How do I select the right electric car conversion kit from China?

Choosing the right electric car conversion kit involves assessing compatibility with your vehicle model, required power output, and specific features like battery type and charging capabilities. Research different suppliers, focusing on their product specifications, customer reviews, and previous projects. Additionally, consider the technical support offered by the manufacturer, as this can be crucial for installation and future troubleshooting. -

What is the average lead time for electric car conversion kits from Chinese suppliers?

Lead times for electric car conversion kits can vary widely depending on the supplier and the complexity of the order. Typically, you can expect a lead time of 4 to 12 weeks. It’s advisable to communicate directly with suppliers to get precise timelines, especially if you have specific project deadlines or need to plan for logistics and customs clearance. -

What customization options are available for electric car conversion kits?

Many Chinese manufacturers offer customization options for electric car conversion kits, including battery capacity, motor specifications, and control systems. When negotiating with suppliers, clearly define your needs and inquire about the extent of customization they can provide. This can include adaptations for different climates, performance requirements, or specific vehicle models. -

What are the minimum order quantities (MOQ) for electric car conversion kits?

Minimum order quantities (MOQ) can vary significantly among suppliers in China, often ranging from 10 to 100 units for electric car conversion kits. Some manufacturers may offer lower MOQs for trial orders or sample kits. It’s essential to discuss your needs upfront, as some suppliers may be flexible with MOQs depending on your business relationship and order volume. -

How can I verify the credibility of a Chinese supplier for electric car conversion kits?

To verify a supplier’s credibility, conduct thorough research, including checking their business licenses, certifications, and industry reputation. Utilize platforms like Alibaba or Global Sources to read reviews and ratings from other buyers. Additionally, consider requesting references or visiting the supplier’s facility if possible, as this can provide insights into their manufacturing capabilities and quality control processes. -

What payment terms are typically offered by Chinese suppliers for electric car conversion kits?

Payment terms can vary, but most Chinese suppliers typically require a deposit of 30% to 50% upfront, with the balance due before shipment. Options may include bank transfers, letters of credit, or secure payment platforms. Always clarify payment terms in advance and ensure they align with your financial capabilities and risk management practices. -

What quality assurance processes should I expect when sourcing electric car conversion kits?

Reputable suppliers should have rigorous quality assurance (QA) processes in place, including testing of components and final products. Ask about their QA certifications, such as ISO 9001, and request details on their testing protocols. Additionally, consider arranging third-party inspections to verify product quality before shipment, especially for large orders. -

How do I manage logistics and shipping for electric car conversion kits from China?

Managing logistics involves selecting reliable freight forwarders experienced in international shipping. Discuss options for sea, air, or rail transport based on your budget and urgency. Be aware of customs regulations in your destination country, and ensure that all necessary documentation is prepared. Collaborating with your supplier on shipping terms (like Incoterms) can help streamline the process and avoid unexpected costs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for electric car conversion kit china

As the global demand for sustainable transportation solutions continues to rise, the electric car conversion kit market in China presents a wealth of opportunities for international B2B buyers. Strategic sourcing from Chinese manufacturers can not only provide access to innovative technologies but also facilitate cost-effective solutions that align with local regulations and environmental goals.

What are the key benefits of sourcing electric car conversion kits from China? Buyers can leverage competitive pricing, advanced manufacturing capabilities, and a diverse range of product offerings. This approach not only enhances supply chain resilience but also supports the transition to greener transportation methods across emerging markets in Africa, South America, the Middle East, and Europe.

Looking ahead, it is essential for B2B buyers to stay informed about evolving industry trends and technological advancements in electric vehicle conversion. Engaging with reputable suppliers and establishing robust partnerships will be crucial in navigating the complexities of this dynamic market. By prioritizing strategic sourcing, businesses can not only meet their sustainability targets but also gain a competitive edge in the rapidly growing electric vehicle sector.

Take the next step—explore potential suppliers and begin your journey towards a greener, more sustainable future today.