Discover Cost-Effective Heat Exchangers in China (2025)

Introduction: Navigating the Global Market for heat exchangers china

Navigating the global market for heat exchangers from China can be a daunting task for international B2B buyers, especially when considering the vast array of options and potential suppliers available. The challenge of sourcing high-quality heat exchangers that meet specific operational requirements, while balancing cost and reliability, is a critical concern for companies in regions such as Africa, South America, the Middle East, and Europe. This guide aims to provide a comprehensive overview of the heat exchanger landscape, including various types, applications, supplier vetting processes, and cost considerations.

Understanding the nuances of heat exchangers is essential for making informed purchasing decisions. From plate and shell-and-tube designs to air-cooled and double-pipe heat exchangers, each type serves unique purposes across multiple industries, including HVAC, power generation, and food processing. This guide equips buyers with the knowledge necessary to navigate these complexities effectively, ensuring that they can identify suppliers who not only offer competitive pricing but also maintain high standards of quality and compliance.

By addressing key challenges and providing actionable insights, this resource empowers B2B buyers to streamline their sourcing processes, mitigate risks, and ultimately enhance their operational efficiency. Whether you’re in the UAE, Argentina, or any other market, this guide serves as your roadmap to successfully engaging with Chinese suppliers in the heat exchanger sector, ensuring that your procurement strategy aligns with your business goals.

Understanding heat exchangers china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Shell and Tube | Consists of a series of tubes, allowing for high heat transfer efficiency. | Oil refineries, chemical processing | Pros: High durability, easy maintenance. Cons: Larger footprint, potentially higher cost. |

| Plate Heat Exchanger | Composed of thin plates, offering a compact design. | HVAC systems, food processing | Pros: Space-efficient, high thermal efficiency. Cons: Limited pressure handling, potential for fouling. |

| Air-Cooled Heat Exchanger | Uses air as a cooling medium, eliminating the need for water. | Power plants, petrochemical industries | Pros: Water conservation, lower operational costs. Cons: Less efficient in high humidity, larger size. |

| Double Pipe Heat Exchanger | Features two pipes, one for hot fluid and one for cold. | Heating systems, refrigeration | Pros: Simple design, easy to clean. Cons: Lower efficiency, limited capacity. |

| Fin Fan Heat Exchanger | Utilizes fans to enhance air circulation for cooling. | Power generation, industrial cooling | Pros: Effective in large-scale applications, energy-efficient. Cons: Requires maintenance, noise concerns. |

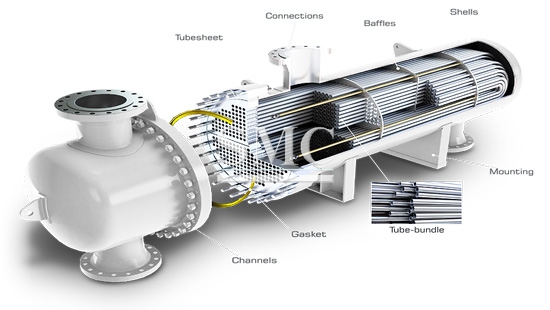

What are the characteristics of Shell and Tube Heat Exchangers?

Shell and tube heat exchangers are among the most widely used types in industrial applications due to their robust design and high thermal efficiency. They consist of a large shell with a series of tubes inside, where one fluid flows through the tubes while another fluid flows outside the tubes within the shell. This design allows for effective heat transfer between the two fluids. Buyers should consider the material compatibility, as these exchangers can be made from various alloys, making them suitable for corrosive environments, such as oil refineries and chemical processing plants.

Why choose Plate Heat Exchangers for specific applications?

Plate heat exchangers are characterized by their compact size and high heat transfer efficiency, achieved through a series of thin plates stacked together. They are particularly suitable for applications requiring space-saving solutions, such as HVAC systems and food processing facilities. When purchasing, buyers should evaluate the pressure and temperature ratings, as well as the potential for fouling, which can impact performance. Their design allows for easy disassembly, facilitating cleaning and maintenance, which is crucial for industries with strict hygiene standards.

What are the advantages of Air-Cooled Heat Exchangers?

Air-cooled heat exchangers use ambient air to cool fluids, making them an excellent choice for locations where water resources are limited. They are primarily used in power plants and petrochemical industries. While they can reduce operational costs by eliminating water usage, buyers must consider their efficiency in high humidity conditions, as performance can decline. The larger size of air-cooled exchangers may also require more space, so buyers should assess site conditions before making a decision.

How does a Double Pipe Heat Exchanger function?

The double pipe heat exchanger features a simple design with two concentric pipes: one carrying the hot fluid and the other carrying the cold fluid. This type is often used in heating systems and refrigeration applications due to its straightforward construction and ease of cleaning. However, its efficiency is generally lower compared to other types, and it is best suited for applications with lower capacity requirements. Buyers should consider the specific heat transfer needs and space constraints when opting for this design.

What are the key considerations for Fin Fan Heat Exchangers?

Fin fan heat exchangers employ fans to enhance air circulation, making them effective for cooling in large-scale industrial applications such as power generation. They are energy-efficient and can handle high volumes of air, but buyers should be aware of potential noise issues and the maintenance required for fan operation. The design’s effectiveness can be influenced by environmental conditions, so understanding the operational context is essential for B2B buyers looking to implement this technology.

Related Video: Heat Exchangers Types | How Many Types of Heat Exchanger |

Key Industrial Applications of heat exchangers china

| Industry/Sector | Specific Application of heat exchangers china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Chemical Processing | Cooling and heating in chemical reactors | Enhanced process efficiency and reduced energy costs | Ensure compliance with international standards and materials |

| Oil and Gas | Heat recovery in refining processes | Increased output and reduced environmental impact | Evaluate durability and resistance to corrosive substances |

| Food and Beverage | Pasteurization and cooling of products | Improved product quality and extended shelf life | Focus on hygiene standards and materials suitable for food |

| HVAC Systems | Temperature regulation in building systems | Energy savings and improved indoor air quality | Consider local regulations and climate adaptability |

| Power Generation | Heat recovery from turbines | Increased energy efficiency and reduced operational costs | Assess compatibility with existing systems and technologies |

How are Heat Exchangers Used in Chemical Processing?

In the chemical processing sector, heat exchangers from China are pivotal in controlling the temperature of chemical reactors. They facilitate the heating or cooling of reactants, which is crucial for maintaining optimal reaction conditions. This application not only enhances process efficiency but also significantly lowers energy costs. International buyers should ensure that the heat exchangers comply with international standards and materials suited for specific chemical environments to prevent breakdowns and maintain safety.

What Role Do Heat Exchangers Play in Oil and Gas?

In the oil and gas industry, heat exchangers are employed primarily in refining processes to recover heat from various stages of production. This application leads to increased output and a reduction in environmental impact by optimizing energy use. For buyers, it is essential to evaluate the durability of these heat exchangers and their resistance to corrosive substances, which are common in oil and gas operations, ensuring long-term reliability and efficiency.

How Are Heat Exchangers Essential in Food and Beverage Applications?

In the food and beverage industry, heat exchangers are critical for processes such as pasteurization and cooling. These systems help in maintaining product quality while extending shelf life, thereby enhancing consumer safety and satisfaction. B2B buyers must prioritize hygiene standards and select materials that are suitable for food contact to comply with health regulations and maintain quality assurance throughout the supply chain.

Why Are Heat Exchangers Important for HVAC Systems?

Heat exchangers are integral to HVAC systems, providing temperature regulation for indoor environments. They help in achieving energy savings and improving indoor air quality, which is increasingly important in today’s eco-conscious market. Buyers from various regions should consider local regulations regarding energy efficiency and climate adaptability when sourcing these systems to ensure compliance and optimal performance.

How Do Heat Exchangers Improve Power Generation Efficiency?

In power generation, heat exchangers play a crucial role in recovering heat from turbines, which can then be reused in various processes. This application significantly boosts energy efficiency and reduces operational costs. Buyers should assess the compatibility of heat exchangers with existing systems and technologies, ensuring seamless integration and maximum return on investment in their energy production facilities.

3 Common User Pain Points for ‘heat exchangers china’ & Their Solutions

Scenario 1: Navigating Quality Assurance Challenges in Sourcing Heat Exchangers from China

The Problem: One significant challenge faced by B2B buyers in Africa, South America, the Middle East, and Europe is ensuring the quality of heat exchangers sourced from China. There is a prevalent concern regarding the inconsistency in manufacturing standards and materials used, which can lead to product failures and increased operational costs. Buyers often find themselves questioning the reliability of suppliers, especially when they lack a robust local presence or established reputation.

The Solution: To mitigate quality assurance issues, buyers should conduct thorough due diligence on potential suppliers. Start by requesting certifications that demonstrate compliance with international quality standards, such as ISO 9001. Additionally, engage in factory audits, either virtually or in-person, to assess manufacturing processes and quality control measures. Collaborating with a trusted third-party inspection service can also help in verifying product quality before shipment. Moreover, consider establishing a trial order with clear quality benchmarks to evaluate performance before committing to larger purchases. This approach not only secures product reliability but also builds a stronger relationship with suppliers.

Scenario 2: Overcoming Language Barriers in Communication with Chinese Manufacturers

The Problem: Language barriers can pose a significant challenge in negotiations and communications with Chinese manufacturers, leading to misunderstandings about specifications, delivery timelines, and pricing. For B2B buyers from regions like the Middle East or Africa, these communication gaps can result in delays and additional costs, complicating the procurement process.

The Solution: To overcome language barriers, it is advisable to engage bilingual staff or hire professional translators familiar with technical jargon relevant to heat exchangers. Additionally, utilizing communication tools that support multiple languages can facilitate clearer discussions. Another effective strategy is to request detailed technical documentation and specifications in both English and Chinese. This can help ensure all parties have a mutual understanding of the requirements. Building a rapport with suppliers through regular communication can also aid in bridging any gaps, fostering a collaborative environment that encourages transparency and efficiency.

Scenario 3: Managing Logistics and Shipping Complexities for Heat Exchangers from China

The Problem: International B2B buyers often encounter logistical challenges when importing heat exchangers from China, including delays in shipping, complex customs regulations, and high freight costs. These issues can significantly impact project timelines and budgets, particularly for companies in Europe or South America that depend on timely delivery for their operations.

The Solution: To streamline logistics, buyers should partner with experienced freight forwarders who specialize in handling shipments from China. These professionals can provide valuable insights into the best shipping routes and methods to minimize costs and transit times. Furthermore, it is crucial to familiarize oneself with customs regulations in both China and the destination country to avoid unexpected delays. Engaging in proactive communication with suppliers about shipping timelines and ensuring all documentation is accurate and complete can facilitate smoother customs clearance. Lastly, consider using Incoterms (International Commercial Terms) to clearly define the responsibilities of both parties regarding shipping and logistics, which can prevent misunderstandings and potential delays.

Strategic Material Selection Guide for heat exchangers china

When selecting materials for heat exchangers, international B2B buyers must consider various factors, including the operational environment, media compatibility, and local regulations. Here, we analyze four common materials used in heat exchangers manufactured in China, providing insights tailored to buyers from Africa, South America, the Middle East, and Europe.

What are the Key Properties of Stainless Steel in Heat Exchangers?

Stainless steel is one of the most widely used materials for heat exchangers due to its excellent corrosion resistance and mechanical properties. It can withstand high temperatures and pressures, making it suitable for a variety of applications. Common grades include 304 and 316, with 316 offering superior resistance to chlorides, which is crucial in coastal regions.

Pros & Cons: Stainless steel is durable and has a long service life, but it can be more expensive than other materials. Manufacturing complexity is moderate, as it requires specialized welding techniques. For buyers in regions with stringent quality standards, such as Europe, stainless steel’s compliance with ASTM and DIN standards is a significant advantage.

Impact on Application: Stainless steel is compatible with a wide range of media, including water, oil, and chemicals, making it versatile for various industries, including food processing and petrochemicals.

How Does Copper Perform as a Heat Exchanger Material?

Copper is renowned for its excellent thermal conductivity, which allows for efficient heat transfer. It is often used in applications where rapid heat exchange is critical, such as in refrigeration and air conditioning systems.

Pros & Cons: While copper has a high initial cost, its efficiency can lead to lower energy consumption over time. However, it is less resistant to corrosion compared to stainless steel, particularly in saline environments. For B2B buyers in coastal regions of Africa and South America, this can be a limiting factor.

Impact on Application: Copper is particularly effective with water-based media but may not be suitable for aggressive chemicals or high-pressure environments. Buyers must assess the compatibility of copper with the specific media used in their operations.

Why is Aluminum a Popular Choice for Heat Exchangers?

Aluminum is lightweight and offers good thermal conductivity, making it an attractive option for applications where weight is a concern, such as in automotive and aerospace industries. It is also resistant to corrosion, particularly when anodized.

Pros & Cons: The lower cost of aluminum compared to stainless steel makes it appealing for budget-conscious projects. However, its lower melting point limits its use in high-temperature applications. Manufacturing processes for aluminum can also be more complex, requiring specialized techniques.

Impact on Application: Aluminum is generally suitable for water and air media but may not perform well in high-pressure applications. Buyers in Europe and the UAE should ensure compliance with relevant standards when selecting aluminum heat exchangers.

What Role Does Carbon Steel Play in Heat Exchanger Applications?

Carbon steel is often used for heat exchangers in less corrosive environments due to its strength and durability. It is typically employed in applications involving water or steam.

Pros & Cons: Carbon steel is cost-effective and has excellent mechanical properties, making it a popular choice for large-scale applications. However, its susceptibility to corrosion limits its use in aggressive environments, necessitating protective coatings or linings.

Impact on Application: Carbon steel is suitable for applications where the media is non-corrosive, but buyers must consider the potential for rust and corrosion in humid environments, particularly in tropical regions of Africa and South America.

Summary Table of Material Selection for Heat Exchangers

| Material | Typical Use Case for heat exchangers china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, petrochemicals | Excellent corrosion resistance | Higher cost than other materials | High |

| Copper | Refrigeration, air conditioning | High thermal conductivity | Less corrosion resistance | Med |

| Aluminum | Automotive, aerospace | Lightweight and cost-effective | Lower melting point | Med |

| Carbon Steel | Water and steam applications | Cost-effective and durable | Susceptible to corrosion | Low |

This strategic material selection guide provides essential insights for international B2B buyers to make informed decisions when sourcing heat exchangers from China, ensuring that they choose materials that align with their operational needs and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for heat exchangers china

What Are the Key Stages in the Manufacturing Process of Heat Exchangers in China?

The manufacturing of heat exchangers in China involves several critical stages that ensure the final product meets the required performance standards. Understanding these stages can help international B2B buyers make informed decisions when selecting suppliers.

-

Material Preparation

– The process begins with the selection and preparation of raw materials, typically stainless steel, copper, or aluminum. Suppliers must ensure that the materials meet international standards and specifications. Quality assurance starts here, as impurities can significantly affect the heat exchanger’s performance. -

Forming

– Once materials are prepared, they undergo various forming techniques such as welding, stamping, or rolling. This step is crucial for shaping the components that will make up the heat exchanger. Advanced technologies like CNC machining are often employed to enhance precision and reduce material waste. -

Assembly

– After forming, the components are assembled into the final product. This stage often involves fitting together multiple parts, including tubes, plates, and casings. Assembly techniques may vary depending on the type of heat exchanger, whether it’s a shell and tube, plate, or finned type. Skilled labor and automated systems are typically used to ensure high-quality assembly. -

Finishing

– The final stage includes surface treatment processes such as polishing, painting, or coating to enhance corrosion resistance and aesthetic appeal. This stage may also involve pressure testing to ensure that the heat exchangers can withstand operational pressures without leaking.

How Is Quality Assurance Implemented in Heat Exchanger Manufacturing?

Quality assurance (QA) is integral to the manufacturing process of heat exchangers, ensuring that products meet both domestic and international standards. Understanding the QA measures can aid B2B buyers in assessing potential suppliers.

-

What International Standards Should You Look For?

– Suppliers should comply with international standards like ISO 9001, which outlines the requirements for a quality management system. Additionally, industry-specific certifications such as CE marking for compliance with European safety standards and API (American Petroleum Institute) certifications for petroleum applications are essential indicators of quality. -

What Are the Key QC Checkpoints in the Manufacturing Process?

– Quality control is typically implemented at several checkpoints:- Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet the required specifications.

- In-Process Quality Control (IPQC): During manufacturing, periodic inspections are conducted to monitor process consistency and product quality.

- Final Quality Control (FQC): Before shipment, the finished products are subjected to rigorous testing, including performance testing and pressure testing.

-

What Common Testing Methods Are Used?

– Various testing methods are employed to validate the quality and efficiency of heat exchangers:- Hydrostatic Testing: Used to check for leaks and ensure structural integrity.

- Thermal Performance Testing: Assesses the heat transfer efficiency of the exchanger.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic or radiographic testing help identify internal defects without damaging the product.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is critical to ensuring product reliability.

-

Conducting Supplier Audits

– Regular audits of manufacturing facilities can provide insights into the supplier’s quality management practices. Buyers should request to see audit reports from third-party inspections or conduct their own audits to assess compliance with international standards. -

Requesting Quality Control Documentation

– Buyers should ask for detailed QC documentation, including inspection reports, testing results, and certifications. This documentation can help verify that the products meet the required specifications and standards. -

Utilizing Third-Party Inspection Services

– Engaging third-party inspection services can provide an unbiased assessment of the manufacturing and quality assurance processes. These services can conduct inspections at various stages of production, ensuring that the products meet the buyer’s quality expectations.

What Are the Quality Control Nuances for International B2B Buyers?

Navigating the quality control landscape can be challenging for international B2B buyers, particularly those from diverse regions. Here are some nuances to consider:

-

Regional Standards and Compliance

– Different regions may have varying compliance requirements. For instance, products intended for the European market must meet CE marking standards, while those aimed at the Middle East may require compliance with local regulations. Understanding these nuances helps buyers avoid costly compliance issues. -

Cultural Considerations

– Cultural factors can influence manufacturing practices and quality control. Buyers should be aware of how local customs and business practices may affect supplier communications and transparency regarding quality assurance. -

Supplier Relationships

– Building strong relationships with suppliers can foster better communication and trust. This is crucial for ensuring that quality control processes are adhered to consistently. Regular visits and open dialogues can enhance collaboration and resolve potential quality issues proactively.

Conclusion

Understanding the manufacturing processes and quality assurance measures for heat exchangers in China is essential for international B2B buyers. By focusing on key manufacturing stages, verifying supplier quality control, and navigating regional nuances, buyers can make informed decisions that ensure the reliability and efficiency of their heat exchangers. This knowledge not only mitigates risks but also enhances the overall purchasing experience in the competitive global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘heat exchangers china’

This guide provides a structured approach for international B2B buyers interested in sourcing heat exchangers from China. By following this checklist, buyers can ensure they make informed decisions, minimize risks, and secure quality products that meet their specific needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements. This includes the type of heat exchanger needed (e.g., shell and tube, plate, air-cooled), materials, pressure ratings, and any industry standards that must be met. A precise specification helps suppliers provide accurate quotes and ensures compatibility with your systems.

Step 2: Conduct Market Research on Chinese Suppliers

Research the landscape of heat exchanger manufacturers in China. Utilize online platforms, industry reports, and trade shows to identify potential suppliers. Pay attention to their market reputation, production capacity, and expertise in your specific application area. This groundwork is essential for narrowing down your options and understanding the competitive environment.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for:

– Certifications: Ensure they have ISO or equivalent certifications to validate their quality management systems.

– Experience: Suppliers with a proven track record in your industry can better meet your needs.

Step 4: Request and Compare Quotes

Once you have shortlisted suppliers, request detailed quotations. Include all necessary specifications and ask for information on lead times, payment terms, and delivery options. Comparing quotes allows you to assess not just pricing but also the value offered, such as warranty terms and after-sales support.

Step 5: Verify Supplier Certifications

Certifications are a critical indicator of a supplier’s credibility. Verify that they possess relevant international certifications (like CE, ASME, or API) that ensure compliance with global standards. This step is essential to mitigate risks associated with quality and safety, particularly when sourcing from overseas.

Step 6: Assess Logistics and Shipping Options

Consider the logistics involved in importing heat exchangers from China. Evaluate shipping methods, delivery times, and potential tariffs or customs duties. Understanding these factors early on can help you budget accurately and avoid unexpected delays that can disrupt your operations.

Step 7: Establish Clear Communication Channels

Effective communication is key to a successful sourcing process. Set up regular check-ins with your supplier to discuss progress, address concerns, and ensure all specifications are being met. Utilize tools like video calls and project management software to maintain clarity and foster a good working relationship.

By following this checklist, international B2B buyers can navigate the complexities of sourcing heat exchangers from China more effectively, ensuring they make informed decisions that align with their operational needs.

Comprehensive Cost and Pricing Analysis for heat exchangers china Sourcing

What Are the Key Cost Components in Sourcing Heat Exchangers from China?

When sourcing heat exchangers from China, understanding the cost structure is vital for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts costs. Common materials used in heat exchangers include stainless steel, copper, and aluminum. Prices fluctuate based on global market trends, so buyers should stay informed about material costs and seek suppliers that offer competitive pricing.

-

Labor: Labor costs in China are generally lower than in many Western countries. However, the complexity of the heat exchanger design can affect labor costs. More intricate designs require skilled labor, which can increase overall expenses.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can lower these costs, making it crucial to select suppliers with a strong track record of operational efficiency.

-

Tooling: Custom tooling for specialized heat exchangers can be a significant upfront cost. Buyers should consider whether they need custom designs and factor these costs into their budgeting.

-

Quality Control (QC): Implementing rigorous QC processes is essential to ensure product reliability. This may involve additional costs, but it is a worthwhile investment to prevent future losses due to faulty products.

-

Logistics: Shipping costs, including freight and insurance, can vary widely based on the destination and shipping method. Buyers must assess these costs early in the procurement process.

-

Margin: Suppliers will typically apply a margin to cover their costs and ensure profitability. Understanding the typical margins in the industry can help buyers gauge whether they are receiving fair pricing.

How Do Price Influencers Affect Heat Exchanger Costs?

Several factors can influence the pricing of heat exchangers sourced from China:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to lower unit prices. Buyers should negotiate MOQs that align with their purchasing capacity to maximize cost efficiency.

-

Specifications and Customization: Custom specifications can increase costs. Buyers need to balance their technical requirements with budget constraints, ensuring they only pay for necessary features.

-

Materials and Quality Certifications: The choice of materials directly affects pricing. Additionally, certifications like ISO or CE can add to costs but are essential for ensuring product quality and compliance with international standards.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record but often provide better service and quality assurance.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can affect overall costs. Terms like FOB (Free on Board) and CIF (Cost, Insurance, Freight) dictate who bears transportation costs and risks, impacting the final price.

What Are Effective Buyer Tips for Cost-Efficient Sourcing of Heat Exchangers?

International B2B buyers should adopt several strategies to enhance cost efficiency when sourcing heat exchangers from China:

-

Negotiate Wisely: Always negotiate prices and payment terms with suppliers. Building a good relationship can lead to better deals and more favorable terms in future transactions.

-

Consider Total Cost of Ownership (TCO): Beyond the initial purchase price, consider factors like maintenance, energy efficiency, and potential downtime costs. A more expensive heat exchanger may offer lower TCO over its lifespan.

-

Understand Pricing Nuances: Familiarize yourself with the pricing structure specific to the Chinese market. This knowledge will empower you to identify reasonable offers and avoid overpaying.

-

Research Supplier Backgrounds: Conduct thorough due diligence on suppliers. Look for reviews, certifications, and past client testimonials to ensure they meet your quality and reliability standards.

-

Be Aware of Currency Fluctuations: Currency exchange rates can affect pricing significantly, especially for buyers in Africa, South America, the Middle East, and Europe. Consider pricing in your local currency or hedging strategies to mitigate risks.

Conclusion

Sourcing heat exchangers from China presents both opportunities and challenges for international B2B buyers. By understanding the cost components, recognizing price influencers, and employing effective sourcing strategies, buyers can make informed decisions that align with their operational goals. Always remember to account for variances in pricing and seek comprehensive quotes to ensure a transparent purchasing process.

Alternatives Analysis: Comparing heat exchangers china With Other Solutions

In the rapidly evolving industrial landscape, B2B buyers must assess various solutions to optimize their operations. Heat exchangers from China are a popular choice due to their competitive pricing and diverse applications. However, it is crucial to evaluate alternative technologies to ensure the best fit for specific business needs. This analysis compares heat exchangers from China with two viable alternatives: plate heat exchangers and air-cooled heat exchangers.

Comparison Table of Heat Exchangers

| Comparison Aspect | Heat Exchangers China | Plate Heat Exchangers | Air-Cooled Heat Exchangers |

|---|---|---|---|

| Performance | High efficiency; suitable for various fluids | Excellent thermal efficiency; compact design | Dependent on ambient air; efficiency varies |

| Cost | Generally lower initial cost | Moderate cost; higher than traditional designs | Competitive pricing; lower operating costs |

| Ease of Implementation | Quick to install; adaptable designs | Requires precise installation; may need more space | Simple setup; requires adequate airflow |

| Maintenance | Moderate maintenance; parts readily available | Low maintenance; easy to clean | Low maintenance; seasonal checks needed |

| Best Use Case | Industrial applications with varying fluid types | Food processing, pharmaceuticals, and HVAC | Power generation and oil & gas industries |

What Are the Advantages and Disadvantages of Plate Heat Exchangers?

Plate heat exchangers are known for their high thermal efficiency and compact design. Their large surface area allows for effective heat transfer, making them suitable for industries like food processing and pharmaceuticals where hygiene is paramount. However, they can be more expensive than traditional heat exchangers, and their installation requires precise alignment and adequate space. Additionally, plate heat exchangers are sensitive to pressure drops, which may limit their application in some industrial scenarios.

How Do Air-Cooled Heat Exchangers Compare?

Air-cooled heat exchangers offer a different approach by utilizing ambient air to cool fluids, making them an energy-efficient option, particularly in industries like power generation and oil & gas. Their operational costs tend to be lower due to the absence of cooling water requirements. However, their efficiency can significantly fluctuate based on environmental conditions, leading to potential performance issues during extreme weather. Furthermore, air-cooled systems require adequate airflow, which may necessitate additional space or infrastructure.

How Can B2B Buyers Choose the Right Heat Exchanger Solution?

When selecting a heat exchanger solution, B2B buyers should consider their specific operational needs, budget constraints, and the environmental conditions of their industry. Heat exchangers from China may provide a cost-effective and versatile option, particularly for diverse fluid types. However, if high thermal efficiency and compactness are critical, plate heat exchangers may offer superior performance. Conversely, for operations where water availability is a concern, air-cooled heat exchangers could be the best choice.

In summary, a careful analysis of these alternatives will empower international B2B buyers from Africa, South America, the Middle East, and Europe to make informed decisions that align with their strategic goals and operational requirements.

Essential Technical Properties and Trade Terminology for heat exchangers china

What Are the Key Technical Properties of Heat Exchangers from China?

When sourcing heat exchangers from China, understanding the technical properties is essential for making informed purchasing decisions. Here are some critical specifications that international B2B buyers should consider:

-

Material Grade

The material used in heat exchangers significantly impacts their performance and durability. Common materials include stainless steel, copper, and aluminum. Each material has unique thermal conductivity, corrosion resistance, and strength properties. For example, stainless steel is preferred for its corrosion resistance and longevity, making it suitable for various industrial applications. Buyers must evaluate the appropriate material based on the specific environmental conditions and fluid types they will encounter. -

Heat Transfer Efficiency

This property measures the effectiveness of a heat exchanger in transferring heat between two or more fluids. It is typically expressed as a coefficient (U-value). Higher efficiency indicates better performance, which can lead to reduced energy costs and improved operational efficiency. Buyers should ask suppliers about the U-value of their products to ensure they meet the required performance standards for their applications. -

Pressure Rating

The pressure rating of a heat exchanger indicates the maximum pressure it can safely handle. This is crucial for applications involving high-pressure fluids, as exceeding this limit can lead to catastrophic failures. International buyers should verify the pressure rating and ensure it aligns with their operational requirements to maintain safety and compliance with industry standards. -

Tolerance and Manufacturing Precision

Tolerance refers to the allowable variation in dimensions during manufacturing. High precision in manufacturing is vital for optimal performance and fitting within existing systems. Tighter tolerances often result in higher costs, but they can significantly affect efficiency and reliability. Buyers should assess the tolerances offered by suppliers to ensure compatibility with their systems. -

Size and Configuration

Heat exchangers come in various sizes and configurations, such as shell-and-tube, plate, and finned-tube designs. The choice of size and configuration affects installation space, efficiency, and maintenance. Buyers must evaluate their facility’s specific requirements and space constraints to select the most appropriate design.

What Are Common Trade Terms in the Heat Exchanger Industry?

Navigating trade terminology is crucial for successful procurement of heat exchangers. Here are some common terms that international B2B buyers should be familiar with:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the heat exchanger industry, sourcing from OEMs ensures that buyers receive high-quality components that meet industry standards. Understanding the relationship between OEMs and suppliers can help buyers ensure product reliability. -

MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a supplier is willing to sell. This is particularly relevant for international buyers who may be considering bulk purchases. Knowing the MOQ helps in budgeting and assessing whether a supplier aligns with your purchasing strategy. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing for specific products or services. Including detailed specifications in the RFQ ensures that suppliers provide accurate quotes, helping buyers make informed comparisons. This process is essential for achieving competitive pricing and understanding available options. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping responsibilities, risk management, and cost allocation. Common Incoterms include FOB (Free On Board) and CIF (Cost, Insurance, and Freight), which clarify who bears costs and risks at various stages of the shipping process. -

Lead Time

Lead time is the time taken from placing an order to receiving the goods. Understanding lead times helps buyers plan their projects and inventory needs effectively. In the heat exchanger market, lead times can vary based on material availability and manufacturing schedules, making it a crucial factor in procurement planning.

By grasping these essential technical properties and trade terminology, international B2B buyers can make more informed decisions when sourcing heat exchangers from China, ultimately leading to better operational efficiency and cost-effectiveness.

Navigating Market Dynamics and Sourcing Trends in the heat exchangers china Sector

What Are the Current Market Dynamics and Key Trends in the Heat Exchangers Sector in China?

The heat exchangers market in China is witnessing significant growth driven by several global factors, including industrial expansion, rising energy efficiency standards, and the increasing need for sustainable solutions. As industries across Africa, South America, the Middle East, and Europe seek to optimize their processes, the demand for innovative heat exchanger solutions is surging. Key trends include the adoption of advanced technologies such as IoT-enabled systems for real-time monitoring and predictive maintenance, which enhance operational efficiency and reduce downtime.

Furthermore, the integration of artificial intelligence and machine learning into the design and manufacturing processes of heat exchangers is transforming sourcing strategies. International buyers are increasingly looking for suppliers that leverage these technologies to provide customized solutions that meet specific industry requirements. Additionally, the trend towards modular heat exchangers is gaining traction, allowing for easier installation and maintenance, which is particularly appealing to buyers in regions with evolving infrastructure needs, such as the Middle East and Africa.

How Is Sustainability and Ethical Sourcing Shaping the Heat Exchangers Market in China?

Sustainability is becoming a cornerstone of B2B procurement strategies in the heat exchangers sector. Buyers are now more aware of the environmental impact of their sourcing choices, making it essential to prioritize suppliers who demonstrate a commitment to sustainable practices. This includes the use of eco-friendly materials and processes that minimize waste and energy consumption during production.

Ethical sourcing practices are also gaining importance, particularly in regions where social responsibility is a growing concern. International buyers are encouraged to seek suppliers that hold ‘green’ certifications, such as ISO 14001, which indicates an effective environmental management system. Additionally, the use of recyclable and sustainable materials in heat exchanger manufacturing can significantly enhance a company’s marketability and align with global sustainability goals. By focusing on these aspects, B2B buyers can not only reduce their carbon footprint but also enhance their brand reputation in increasingly eco-conscious markets.

What Is the Brief Evolution of the Heat Exchangers Market in China?

The heat exchangers market in China has evolved dramatically over the past few decades. Initially dominated by basic designs focused on functionality, the sector has transformed into a highly competitive landscape characterized by innovation and technological advancement. The entry of international players and the growing emphasis on energy efficiency have prompted local manufacturers to enhance their offerings, leading to improved designs and materials.

In recent years, China has positioned itself as a global hub for heat exchanger production, benefiting from its robust manufacturing infrastructure and skilled workforce. This evolution has enabled Chinese manufacturers to not only meet domestic demand but also cater to international markets, making China a pivotal player in the global heat exchangers sector. As international B2B buyers continue to explore sourcing options, understanding this historical context can provide valuable insights into the capabilities and potential of Chinese suppliers.

Frequently Asked Questions (FAQs) for B2B Buyers of heat exchangers china

-

How do I solve quality assurance issues when sourcing heat exchangers from China?

To address quality assurance issues when sourcing heat exchangers from China, it is crucial to establish a robust vetting process for suppliers. This includes requesting certifications such as ISO 9001 and conducting on-site inspections or audits when possible. Utilize third-party inspection services to verify product quality before shipment. Additionally, consider requesting samples to assess the performance and durability of the heat exchangers. Building a solid relationship with your supplier can also enhance communication and accountability regarding quality standards. -

What is the best way to identify reliable heat exchanger suppliers in China?

Identifying reliable heat exchanger suppliers in China involves thorough research and due diligence. Start by leveraging platforms like Alibaba or Global Sources, which feature verified suppliers. Check online reviews and ratings to gauge supplier reputation. It’s also beneficial to attend industry trade shows in China to meet potential suppliers face-to-face. Networking with industry peers who have experience sourcing from China can provide valuable recommendations. Always request references and follow up with them to ensure the supplier’s credibility. -

What customization options are available for heat exchangers sourced from China?

Many Chinese manufacturers offer extensive customization options for heat exchangers, including size, material, and design modifications tailored to specific applications. When discussing your requirements with suppliers, be clear about your technical specifications and performance expectations. This may include adjustments to heat transfer surfaces or different configurations for integration with existing systems. Some suppliers might also offer design support, so inquire about their capabilities in engineering and prototyping to ensure your needs are met effectively. -

What are the typical minimum order quantities (MOQs) for heat exchangers from China?

Minimum order quantities (MOQs) for heat exchangers can vary widely among suppliers and depend on factors like design complexity and material costs. Generally, MOQs can range from a few units to several hundred. Larger orders often benefit from better pricing, so consider your projected demand. If you are uncertain about committing to high MOQs, discuss options for smaller test orders or pilot runs with suppliers to gauge quality and performance before scaling up. -

What payment terms should I expect when sourcing heat exchangers from China?

Payment terms for sourcing heat exchangers from China typically involve a combination of upfront payments and balance payments upon delivery. Common arrangements include a 30% deposit before production and 70% upon shipment. Some suppliers may offer more flexible terms for established relationships. Always negotiate payment terms that protect your interests, such as using escrow services or letters of credit, especially for larger transactions. Understanding the supplier’s payment policies upfront can prevent misunderstandings later. -

How can I ensure timely logistics and delivery of heat exchangers from China?

To ensure timely logistics and delivery of heat exchangers from China, start by discussing lead times with your supplier early in the negotiation process. Select a reliable freight forwarder experienced in handling industrial equipment. Consider air freight for urgent shipments, though it may be more costly than sea freight. Track your shipments closely and maintain open communication with your supplier and freight forwarder to address any potential delays. Establishing clear timelines and expectations can help minimize disruptions.

A stock image related to heat exchangers china.

A stock image related to heat exchangers china.

-

What are the common certifications required for heat exchangers in international markets?

When sourcing heat exchangers from China for international markets, common certifications may include ASME (American Society of Mechanical Engineers), PED (Pressure Equipment Directive), and CE (Conformité Européenne) markings for the European market. Depending on your target region, additional certifications may be necessary, such as API (American Petroleum Institute) standards for the oil and gas sector. Verify with your supplier that they comply with the relevant regulations and can provide necessary documentation to facilitate smooth customs clearance. -

How do I handle after-sales support and warranty issues with Chinese suppliers?

Handling after-sales support and warranty issues with Chinese suppliers requires clear communication and documentation from the outset. Ensure that warranty terms are explicitly stated in your contract, including coverage duration and procedures for claims. Establish a direct line of communication for support issues and request contact details for a dedicated support team. It’s also prudent to discuss repair and replacement policies upfront, ensuring you understand the process for addressing any potential defects or failures post-purchase.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for heat exchangers china

As international B2B buyers increasingly seek reliable partners in the heat exchanger market, strategic sourcing emerges as a vital component for success. By understanding the unique manufacturing capabilities and competitive pricing offered by Chinese suppliers, businesses from Africa, South America, the Middle East, and Europe can optimize their procurement strategies. Key takeaways include the importance of assessing supplier certifications, establishing robust communication channels, and leveraging local market insights to foster long-term partnerships.

Investing in strategic sourcing not only enhances operational efficiency but also mitigates risks associated with supply chain disruptions. Buyers should prioritize suppliers who demonstrate innovation in product development and sustainability practices, as these factors are becoming essential in a competitive landscape.

Looking ahead, the demand for heat exchangers is poised for growth, driven by advancements in technology and increasing energy efficiency standards. International B2B buyers should seize this opportunity to engage with Chinese manufacturers, ensuring they are well-positioned to capitalize on emerging trends. As you explore sourcing options, remember that proactive engagement and thorough due diligence are key to securing advantageous contracts and establishing a resilient supply chain.