Discover Cost-Effective Punching Machine China Solutions (2025)

Introduction: Navigating the Global Market for punching machine china

Navigating the complexities of sourcing punching machines from China can be a daunting challenge for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. With a plethora of manufacturers offering various types and specifications, understanding the nuances of the market is crucial. This guide aims to simplify that process, providing insights into the diverse categories of punching machines, their applications across different industries, and the critical factors to consider when vetting suppliers.

As you explore this comprehensive resource, you will gain valuable knowledge about the latest advancements in punching machine technology, ensuring you stay competitive in your field. We will delve into essential considerations such as pricing strategies, potential cost implications, and the impact of shipping logistics on your procurement process. Furthermore, this guide will highlight best practices for assessing supplier reliability and quality assurance, enabling you to make informed purchasing decisions.

By the end of this guide, you will be equipped with the tools and insights necessary to confidently navigate the global market for punching machines from China. Whether you are a seasoned buyer or new to the industry, this resource empowers you to optimize your sourcing strategy, align with reputable suppliers, and ultimately enhance your operational efficiency.

Understanding punching machine china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mechanical Punching Machine | Operates via mechanical force; often more cost-effective. | Sheet metal fabrication, automotive parts. | Pros: Lower initial cost; simpler design. Cons: Limited precision and slower cycle times. |

| Hydraulic Punching Machine | Utilizes hydraulic pressure for greater force and precision. | Aerospace, heavy machinery, and metalworking. | Pros: High precision; capable of handling thicker materials. Cons: Higher maintenance costs. |

| CNC Punching Machine | Computer-controlled for automated and precise punching. | Electronics, custom part manufacturing. | Pros: High efficiency; flexibility in design. Cons: Higher upfront investment; requires skilled operators. |

| Pneumatic Punching Machine | Uses compressed air for operation; faster cycle times. | Packaging, textile, and light metal applications. | Pros: Quick operation; lower energy consumption. Cons: Limited force for thicker materials. |

| Multi-Station Punching Machine | Features multiple stations for various operations in one cycle. | High-volume production lines, automotive industries. | Pros: Increased productivity; reduced labor costs. Cons: Higher complexity; potential for more downtime. |

What Are the Key Characteristics of Mechanical Punching Machines?

Mechanical punching machines are known for their straightforward design and operation. They work by using mechanical force to punch through materials, making them an economical choice for businesses looking to manage costs. These machines are particularly suitable for sheet metal fabrication and automotive part production, where moderate precision is acceptable. When considering a mechanical punching machine, buyers should weigh the lower initial investment against potential limitations in speed and accuracy.

How Do Hydraulic Punching Machines Stand Out?

Hydraulic punching machines are characterized by their ability to generate significant force through hydraulic pressure, which allows for greater precision and the capacity to work with thicker materials. These machines find their primary applications in sectors like aerospace and heavy machinery, where accuracy is critical. Buyers should consider the higher maintenance requirements and costs associated with hydraulic systems, but the investment can pay off in terms of quality and capability.

What Benefits Do CNC Punching Machines Offer?

CNC (Computer Numerical Control) punching machines are revolutionizing the industry by offering automation and precision. They are ideal for custom part manufacturing and electronics, where intricate designs and high efficiency are paramount. However, the initial investment can be substantial, and these machines require skilled operators to maximize their capabilities. B2B buyers should assess their production needs and workforce capabilities before opting for CNC technology.

Why Choose Pneumatic Punching Machines?

Pneumatic punching machines operate using compressed air, which allows for faster cycle times compared to mechanical options. They are particularly effective in industries such as packaging and textiles, where speed is essential. While they consume less energy, buyers should note that pneumatic machines may not provide the force needed for thicker materials. Understanding the specific applications and material requirements will help buyers make informed decisions.

What Are the Advantages of Multi-Station Punching Machines?

Multi-station punching machines incorporate multiple operations within a single cycle, significantly enhancing productivity, especially in high-volume production environments like automotive manufacturing. While they reduce labor costs and increase efficiency, these machines can be more complex and may lead to increased downtime if not properly maintained. B2B buyers should evaluate their production scale and operational capabilities to determine if a multi-station machine aligns with their business goals.

Related Video: The Q5 CNC punching machine with forming and bending capabilities

Key Industrial Applications of punching machine china

| Industry/Sector | Specific Application of Punching Machine China | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Producing metal components for vehicles | Enhanced precision and reduced production time | Supplier reliability, machine durability, and support |

| Electronics Assembly | Creating housings and circuit board components | Improved efficiency and consistent quality | Compliance with international standards and certifications |

| Construction Materials | Fabricating metal sheets for structural use | Cost-effective mass production and material savings | Customization options and after-sales service |

| Aerospace Industry | Manufacturing lightweight structural parts | Increased performance and fuel efficiency | Advanced technology and precision engineering capabilities |

| HVAC Systems | Punching holes in ducts and fittings | Streamlined assembly process and reduced waste | Availability of parts and local support for maintenance |

How is ‘Punching Machine China’ Used in Automotive Manufacturing?

In the automotive sector, punching machines from China are employed to manufacture various metal components, such as brackets, frames, and other structural elements. These machines provide high precision and efficiency, allowing for the production of complex shapes that meet stringent safety and performance standards. For international buyers, especially those in Africa and South America, sourcing reliable punching machines can significantly enhance production capabilities while reducing lead times and costs. It is essential to consider the supplier’s track record in delivering durable machines capable of handling high-volume production.

What Role Does ‘Punching Machine China’ Play in Electronics Assembly?

In electronics assembly, punching machines are vital for creating housings and components for circuit boards. The precision offered by these machines ensures that parts fit together seamlessly, which is critical for the functionality of electronic devices. Buyers from Europe and the Middle East must ensure that the machines comply with international quality standards, as this can impact the overall quality of the final product. Additionally, evaluating the machine’s ability to handle various materials is crucial for versatility in production.

How is ‘Punching Machine China’ Utilized in Construction Materials?

In the construction materials industry, punching machines are used to fabricate metal sheets into structural components, such as beams and columns. This application allows for cost-effective mass production while ensuring structural integrity. For B2B buyers in regions like Egypt and France, sourcing machines that offer customization options can be beneficial, as different construction projects often require unique specifications. Furthermore, after-sales service and support are key considerations to minimize downtime in production.

What Benefits Does ‘Punching Machine China’ Provide to the Aerospace Industry?

In the aerospace industry, punching machines are critical for manufacturing lightweight structural parts that contribute to overall aircraft performance and fuel efficiency. These machines must meet high standards of precision and reliability due to the safety implications involved in aerospace applications. International buyers, particularly in Europe, should focus on suppliers that offer advanced technology and engineering capabilities, ensuring that the machines can produce components that withstand rigorous testing and certification processes.

How Does ‘Punching Machine China’ Enhance HVAC Systems?

Punching machines are extensively used in the HVAC industry for creating holes in ducts and fittings, facilitating efficient airflow and installation. This application helps streamline the assembly process, reducing waste and ensuring that components fit together correctly. For buyers in the Middle East and Africa, it is crucial to evaluate the availability of spare parts and local maintenance support when sourcing these machines, as this can significantly impact operational efficiency and longevity of the equipment.

3 Common User Pain Points for ‘punching machine china’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Punching Machines from China

The Problem: Many B2B buyers from regions like Africa and South America struggle to find reliable suppliers of punching machines in China. They often encounter issues such as subpar quality, misleading specifications, and unreliable delivery times. This can lead to production delays, increased operational costs, and ultimately, a loss of trust with their own customers.

The Solution: To mitigate these issues, buyers should conduct thorough due diligence on potential suppliers. This includes checking online reviews, asking for references from past clients, and verifying certifications such as ISO standards. Utilizing platforms like Alibaba or Global Sources can help in identifying reputable manufacturers. Furthermore, buyers should consider visiting factories in person or hiring third-party inspection services before committing to large orders. Establishing clear communication about specifications and expectations upfront can also significantly reduce misunderstandings and ensure that the punching machines meet quality standards.

Scenario 2: Navigating Language and Cultural Barriers in Procurement

The Problem: Language and cultural differences can create significant hurdles for B2B buyers when negotiating contracts or discussing technical specifications with Chinese manufacturers. Miscommunications can lead to incorrect orders, inappropriate machine specifications, and strained business relationships. This is particularly prevalent among buyers from the Middle East and Europe, where cultural nuances might not be fully understood.

The Solution: To bridge this gap, buyers should consider engaging a local intermediary or a sourcing agent who is fluent in both Chinese and the buyer’s native language. This agent can facilitate smoother negotiations, clarify technical jargon, and ensure that cultural norms are respected during interactions. Additionally, leveraging translation tools and software during communications can help in accurately conveying messages. Buyers should also invest time in understanding basic Chinese business etiquette, which can foster goodwill and improve negotiations.

Scenario 3: Challenges in After-Sales Support and Maintenance

The Problem: Once a punching machine is acquired, many buyers encounter issues related to after-sales support, maintenance, and spare parts availability. Buyers in regions like Europe and Africa often find that manufacturers do not provide adequate technical support or that spare parts are difficult to source. This can lead to prolonged downtimes and increased costs for businesses reliant on these machines for production.

The Solution: To address this concern, buyers should prioritize suppliers who offer comprehensive after-sales service and support agreements. Before finalizing a purchase, it’s crucial to inquire about warranty terms, the availability of spare parts, and the manufacturer’s support capabilities. Establishing a relationship with suppliers who have a proven track record of responsive customer service can ensure that issues are addressed promptly. Additionally, buyers can consider forming partnerships with local service providers who specialize in the maintenance of such machinery, as this can significantly reduce downtime and enhance productivity. Investing in training for in-house technicians can also empower businesses to handle minor repairs and maintenance, further mitigating the risk of operational disruptions.

Strategic Material Selection Guide for punching machine china

When selecting materials for punching machines manufactured in China, it is essential to consider various factors that influence performance, cost, and suitability for specific applications. Below, we analyze four common materials used in the production of punching machines, focusing on their properties, advantages and disadvantages, and implications for international buyers.

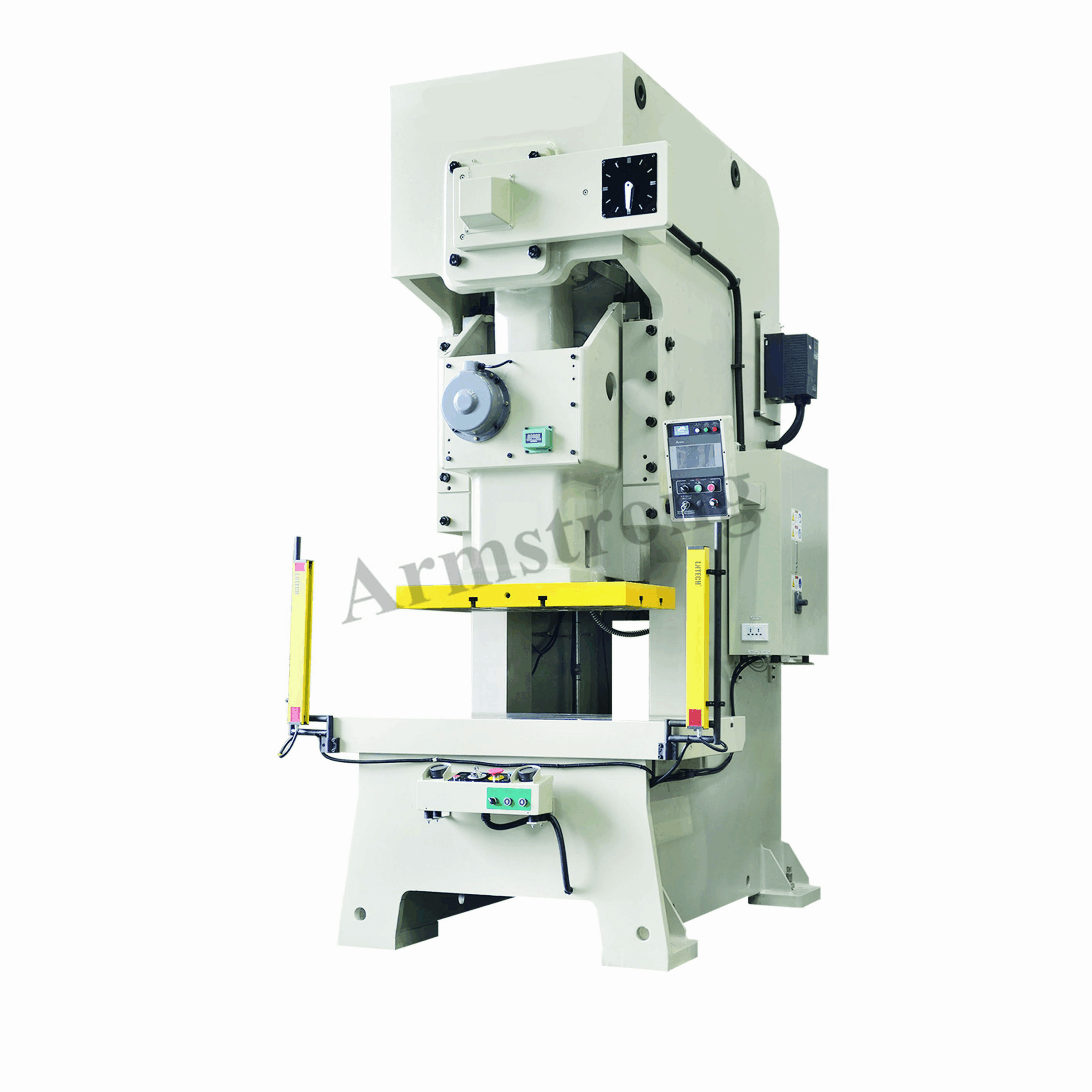

A stock image related to punching machine china.

What Are the Key Properties of Steel in Punching Machines?

Steel is one of the most widely used materials in punching machine construction due to its strength and versatility. It typically exhibits excellent tensile strength, making it ideal for handling high pressure and heavy-duty applications. Steel also offers good corrosion resistance when treated, which is crucial for machines operating in humid or corrosive environments.

Pros & Cons:

Steel’s durability is a significant advantage; however, it can be heavy, which may complicate transportation and installation. The cost of steel can vary based on the grade, with high-carbon steels being more expensive but offering superior performance. Manufacturing complexity can also increase with the need for additional treatments to enhance corrosion resistance.

Impact on Application:

Steel is compatible with a wide range of media, making it suitable for various industrial applications. However, buyers must ensure that the specific grade of steel meets the requirements for their intended use.

Considerations for International Buyers:

Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of compliance with international standards like ASTM and DIN. Additionally, understanding local regulations regarding steel imports is crucial.

How Does Aluminum Compare as a Material for Punching Machines?

Aluminum is another popular choice, particularly for applications requiring lightweight solutions. It offers excellent corrosion resistance and is relatively easy to machine, which can reduce manufacturing complexity.

Pros & Cons:

The primary advantage of aluminum is its weight, making machines easier to handle and transport. However, aluminum is generally less durable than steel and may not withstand high-pressure applications as effectively. The cost of aluminum can be moderate to high, depending on the alloy used.

Impact on Application:

Aluminum is suitable for applications where weight reduction is critical, such as in portable punching machines. However, it may not be ideal for heavy-duty industrial applications.

Considerations for International Buyers:

International buyers should consider the availability of specific aluminum alloys and their compliance with standards like JIS. Additionally, understanding the local market for aluminum can help in negotiating better pricing.

What Role Does Stainless Steel Play in Punching Machine Manufacturing?

Stainless steel is favored for its superior corrosion resistance and aesthetic appeal. It is an excellent choice for environments where hygiene is paramount, such as food processing or pharmaceuticals.

Pros & Cons:

The key advantage of stainless steel is its ability to resist rust and corrosion, extending the machine’s lifespan. However, it is typically more expensive than both carbon steel and aluminum, which can affect budget considerations. Manufacturing with stainless steel can also be more complex due to its hardness.

Impact on Application:

Stainless steel is highly compatible with various media, especially in sensitive applications. Its durability makes it suitable for long-term use in challenging environments.

Considerations for International Buyers:

Buyers should ensure that the stainless steel grades comply with local and international standards, such as ASTM A240. Awareness of the local supply chain for stainless steel is also essential to avoid delays.

What Are the Advantages of Using Composite Materials in Punching Machines?

Composite materials, such as reinforced plastics, are gaining popularity in specific applications due to their lightweight and corrosion-resistant properties. They can be engineered to provide specific performance characteristics tailored to particular needs.

Pros & Cons:

Composites are often lighter than metals and can be produced at a lower cost. However, they may not offer the same level of durability and strength as metals, limiting their use in heavy-duty applications.

Impact on Application:

Composites are suitable for applications where weight savings are critical, but they may not be ideal for high-stress environments.

Considerations for International Buyers:

Buyers should assess the availability of composite materials in their region and ensure compliance with relevant standards. Understanding the manufacturing capabilities of suppliers in China is also important for securing quality products.

Summary Table of Material Selection for Punching Machines

| Material | Typical Use Case for punching machine china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty industrial applications | High strength and durability | Heavier, potential corrosion issues | Medium |

| Aluminum | Portable and lightweight machines | Lightweight and easy to machine | Less durable under high pressure | Medium to High |

| Stainless Steel | Hygiene-sensitive environments | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Composite | Specialized lightweight applications | Lightweight and customizable | Limited strength and durability | Low to Medium |

This comprehensive analysis provides international B2B buyers with actionable insights into material selection for punching machines manufactured in China, ensuring informed decisions that align with their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for punching machine china

What Are the Key Stages in the Manufacturing Process of Punching Machines in China?

The manufacturing process of punching machines in China involves several critical stages, each designed to ensure the final product meets the necessary standards of performance and durability. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first step in manufacturing punching machines involves selecting high-quality raw materials, typically steel or aluminum, which are essential for the machine’s structure and functionality. Manufacturers often source these materials locally or internationally, depending on availability and cost.

Once the materials are selected, they undergo processes such as cutting, shearing, or laser cutting to prepare them for the forming stage. This preparation ensures that the dimensions are precise, which is crucial for the machine’s overall efficiency and effectiveness.

How Are Punching Machines Formed?

The forming stage utilizes various techniques, including stamping, bending, and machining. Advanced CNC (Computer Numerical Control) machines are often employed to achieve high precision in shaping the components of the punching machine.

During this phase, manufacturers also apply techniques like deep drawing and hydroforming, which are especially important for producing complex geometries. The use of hydraulic presses in this stage ensures that the components are formed without defects, maintaining the integrity of the material.

What Happens During Assembly and Finishing?

After the components are formed, they move to the assembly stage. Here, skilled technicians assemble the parts, integrating electrical systems, controls, and safety features. The assembly process is critical, as improper assembly can lead to operational failures.

The finishing stage involves processes such as painting, coating, or anodizing to protect the machine from wear and corrosion. This step is crucial for enhancing the machine’s lifespan and ensuring that it can withstand various operational environments, which is particularly relevant for buyers in diverse climates across Africa, South America, the Middle East, and Europe.

How Is Quality Assurance Implemented in the Manufacturing of Punching Machines?

Quality assurance (QA) is a vital aspect of manufacturing punching machines in China. It ensures that each machine meets international standards and specific client requirements.

Which International Standards Should B2B Buyers Be Aware Of?

Manufacturers typically adhere to several international quality standards, with ISO 9001 being the most recognized. This standard focuses on quality management systems and ensures that manufacturers consistently provide products that meet customer and regulatory requirements.

Additionally, industry-specific certifications such as CE marking (for compliance with European health, safety, and environmental protection standards) and API (American Petroleum Institute) certifications for equipment used in the oil and gas sector are also significant. Buyers should look for these certifications when evaluating potential suppliers.

What Are the Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is integrated into various checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, random checks are performed to monitor the production quality. This includes checking dimensions, tolerances, and assembly accuracy.

-

Final Quality Control (FQC): Before shipping, a comprehensive evaluation of the finished punching machine is conducted. This includes functional testing, ensuring that all features work as intended.

What Common Testing Methods Are Used for Punching Machines?

Testing methods employed during the QC process can include:

- Functional Testing: Verifying that all operational features of the punching machine work correctly under load.

- Pressure Testing: Ensuring that hydraulic systems can withstand high-pressure conditions without leaks or failures.

- Durability Testing: Simulating extended use to assess how the machine performs over time and under stress.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s QC processes is crucial. Here are some strategies to consider:

Conducting Supplier Audits

Regular audits are essential for ensuring that suppliers adhere to their stated QC processes. Buyers can establish a schedule for periodic audits, assessing both the manufacturing facility and the quality management system in place.

Requesting Quality Reports

Buyers should request detailed QC reports from suppliers, including data on past performance, defect rates, and compliance with international standards. These reports provide insights into the manufacturer’s reliability and commitment to quality.

Engaging Third-Party Inspection Services

Utilizing third-party inspection services can offer an impartial assessment of the manufacturer’s quality control processes. These firms can conduct inspections at various stages of the manufacturing process, ensuring that the final product meets the agreed-upon specifications.

What Are the Nuances of Quality Control for International Buyers?

B2B buyers must be aware of the nuances in quality control that may vary by region. For instance, European buyers may emphasize strict adherence to CE standards, while buyers in the Middle East might prioritize compliance with local regulations and safety standards.

Furthermore, language barriers and cultural differences can affect communication regarding quality expectations. Establishing clear lines of communication and understanding the local business practices can help mitigate these challenges.

In conclusion, understanding the manufacturing processes and quality assurance practices for punching machines in China is crucial for international B2B buyers. By focusing on the manufacturing stages, quality control checkpoints, and verification methods, buyers can make informed decisions, ensuring they invest in reliable and high-quality machinery that meets their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘punching machine china’

Introduction: Why a Sourcing Checklist is Essential for B2B Buyers

In the competitive landscape of international manufacturing, sourcing machinery such as punching machines from China requires a meticulous approach. This guide provides a step-by-step checklist designed specifically for B2B buyers from Africa, South America, the Middle East, and Europe. By following these steps, you can ensure a smooth procurement process, mitigate risks, and secure high-quality equipment that meets your operational needs.

Step 1: Define Your Technical Specifications

Before you begin sourcing, it’s essential to clearly outline the technical specifications of the punching machine you need. This includes parameters such as the type of materials you’ll be working with, the thickness of the materials, and the production capacity. Having precise specifications will help you filter suppliers who can meet your requirements and avoid costly miscommunications.

Step 2: Conduct Market Research on Suppliers

Take the time to research potential suppliers in China. Use platforms like Alibaba, Made-in-China, and Global Sources to find manufacturers specializing in punching machines. Look for suppliers with a solid reputation, positive customer reviews, and a history of exporting to your region. Understanding the market landscape will empower you to make informed decisions.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Focus on the following:

– Quality Assurance: Inquire about their quality control processes and certifications such as ISO 9001.

– Experience: Assess how long they have been in the industry and their experience with international clients.

Step 4: Verify Supplier Certifications

Ensure that the suppliers you are considering possess the necessary certifications and compliance documents. This includes CE marking for European standards, ISO certifications, and any other relevant industry standards. Validating these certifications not only confirms the quality of the machine but also ensures compliance with your local regulations, which is vital for smooth importation.

Step 5: Request and Analyze Quotations

Once you have shortlisted potential suppliers, request detailed quotations. Look for transparency in pricing, including shipping, taxes, and any potential hidden costs. Compare these quotations based on:

– Cost vs. Features: Ensure that the price aligns with the features and specifications you require.

– Payment Terms: Understand the payment structure to avoid any financial risks.

Step 6: Arrange for Factory Visits or Virtual Inspections

If feasible, arrange for a factory visit to inspect the manufacturing process and quality standards firsthand. If travel is not an option, consider virtual inspections using video calls. This step allows you to assess the facility’s capabilities and ensures that they are equipped to meet your production needs.

Step 7: Finalize Contracts and Terms of Delivery

Once you are satisfied with a supplier, finalize the contract, ensuring all terms are clearly outlined. Pay particular attention to:

– Delivery timelines: Confirm lead times and penalties for delays.

– After-sales support: Understand the warranty and support services available post-purchase.

By following this comprehensive checklist, B2B buyers can effectively navigate the complexities of sourcing punching machines from China, ensuring a successful procurement process that aligns with their business goals.

Comprehensive Cost and Pricing Analysis for punching machine china Sourcing

What Are the Key Cost Components in Punching Machine Sourcing from China?

When sourcing punching machines from China, international buyers should be aware of the various cost components that contribute to the total expenditure. The primary cost factors include:

-

Materials: The choice of materials significantly impacts the cost. High-quality steel and advanced components can raise the price but often lead to better performance and longevity. It’s essential to assess the material specifications based on your operational needs.

-

Labor: Labor costs in China are generally lower compared to Western countries, but they can vary based on the region and skill level required for production. Skilled labor involved in precision machining may increase overall costs.

-

Manufacturing Overhead: This encompasses expenses related to factory operation, maintenance, utilities, and administrative costs. Understanding a supplier’s overhead structure can provide insights into pricing.

-

Tooling: Custom tooling for specific punching machine requirements can represent a significant upfront cost. This is particularly relevant for specialized applications where standard tooling may not suffice.

-

Quality Control (QC): Rigorous quality control measures are essential to ensure that the punching machines meet international standards. This could involve additional costs for inspections, testing, and certifications.

-

Logistics: Shipping costs, including freight charges, customs duties, and insurance, can add substantially to the final price. The choice of Incoterms can influence logistics costs and responsibilities.

-

Supplier Margin: Suppliers typically build a margin into their pricing to cover risks and ensure profitability. Understanding how this margin correlates with the quality and reliability of the supplier can guide negotiations.

How Do Price Influencers Affect Punching Machine Costs?

Several factors influence the pricing of punching machines that international buyers should consider:

-

Volume/MOQ (Minimum Order Quantity): Bulk orders often attract discounts, making it essential for buyers to consider their production needs and negotiate favorable terms.

-

Specifications and Customization: Custom features or specifications can drive up costs. Clearly defining requirements upfront can help manage expectations and budgeting.

-

Material Quality and Certifications: Machines certified for international standards (e.g., ISO) may command higher prices but can reduce the risk of non-compliance and associated penalties.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more, but they often provide better service and quality assurance.

-

Incoterms: Understanding the implications of different Incoterms (e.g., FOB, CIF) is crucial, as they dictate shipping responsibilities and costs, which can significantly affect the total purchase price.

What Tips Can Buyers Utilize for Cost-Efficiency in Punching Machine Sourcing?

To achieve cost-efficiency in sourcing punching machines from China, consider the following actionable tips:

-

Negotiate Wisely: Leverage your purchasing power when negotiating prices. Building a long-term relationship with suppliers can also lead to better deals and preferential treatment.

-

Calculate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, operational efficiency, and potential downtime costs associated with the machine. This holistic approach helps in evaluating the true value of the investment.

-

Research Local Market Conditions: For buyers in Africa, South America, the Middle East, and Europe, understanding local market dynamics can provide leverage in negotiations. Factors such as currency fluctuations, import tariffs, and regional demand can all influence pricing.

-

Consider Post-Purchase Support: Factor in the availability of after-sales service, spare parts, and technical support. A slightly higher upfront cost may be justified by the potential for reduced operational disruptions.

Conclusion: Navigating the Cost Landscape in Punching Machine Sourcing

While sourcing punching machines from China can offer significant cost advantages, it is crucial for international B2B buyers to conduct thorough due diligence on the cost structure and pricing influencers. By understanding the components involved and leveraging negotiation strategies, buyers can make informed decisions that align with their operational goals. Always keep in mind that prices are indicative and can fluctuate based on market conditions, so maintaining flexibility in budgeting is advisable.

Alternatives Analysis: Comparing punching machine china With Other Solutions

Introduction: Why Consider Alternatives to Punching Machines from China?

In the global marketplace, international B2B buyers must evaluate various options when selecting machinery for their operations. While punching machines from China offer competitive pricing and decent performance, it is essential to consider alternative solutions that may better fit specific operational needs, budgets, and quality standards. This analysis will compare punching machines from China with other viable alternatives, including hydraulic presses and laser cutting machines, providing insights into their respective advantages and drawbacks.

Comparison Table

| Comparison Aspect | Punching Machine China | Hydraulic Press | Laser Cutting Machine |

|---|---|---|---|

| Performance | Moderate speed and precision | High force, versatile applications | High precision, versatile materials |

| Cost | Generally low cost | Moderate to high cost | High upfront investment |

| Ease of Implementation | Relatively simple setup | Requires training | Requires skilled operators |

| Maintenance | Low to moderate | Moderate, parts can be costly | High, specialized maintenance needed |

| Best Use Case | Sheet metal fabrication | Heavy-duty forming | Intricate designs on various materials |

What Are the Advantages and Disadvantages of Hydraulic Presses?

Hydraulic presses are a strong alternative to punching machines, particularly for tasks requiring significant force. They excel in applications such as metal forming and stamping, making them suitable for industries like automotive and aerospace. The primary advantage of hydraulic presses is their ability to manipulate materials with high precision and force, allowing for complex shapes and designs. However, they come with a higher initial investment and may require specialized training for operators, which could lead to higher overall costs in the long run.

How Does a Laser Cutting Machine Compare?

Laser cutting machines provide another innovative solution for cutting and shaping materials. They are renowned for their exceptional accuracy and versatility, capable of working with a variety of materials, including metals, plastics, and wood. The precision of laser cutting allows for intricate designs that may be difficult to achieve with traditional punching machines. However, the cost of laser cutting machines is typically higher, and they require skilled operators to maximize their capabilities. Additionally, maintenance can be more complex and costly, which may not be ideal for all businesses.

Conclusion: How to Choose the Right Solution for Your Business Needs

When selecting between a punching machine from China and alternative solutions like hydraulic presses or laser cutting machines, B2B buyers should consider their specific operational requirements. Factors such as production volume, material types, budget constraints, and workforce capabilities play a crucial role in the decision-making process. By carefully evaluating these aspects, international buyers from regions like Africa, South America, the Middle East, and Europe can make informed choices that align with their business goals, ensuring long-term satisfaction and efficiency in their operations.

Essential Technical Properties and Trade Terminology for punching machine china

What Are the Key Technical Properties of Punching Machines from China?

When considering the procurement of punching machines from China, understanding the essential technical properties is crucial for making informed purchasing decisions. Here are some critical specifications to consider:

1. Material Grade

The material grade of a punching machine refers to the quality and type of metals used in its construction, such as carbon steel or alloy steel. High-grade materials ensure durability and longevity, which translates into lower maintenance costs and reduced downtime. For B2B buyers, selecting machines made from reputable material grades can significantly impact the overall efficiency and output of manufacturing processes.

2. Tolerance

Tolerance indicates the permissible limit of variation in a physical dimension or measured value of a component. It is a critical specification in the precision manufacturing industry. A machine with tight tolerances can produce parts that meet stringent quality standards, essential for industries like automotive and aerospace. Buyers must ensure that the punching machine meets their specific tolerance requirements to avoid costly reworks.

3. Stroke Length

Stroke length refers to the distance the punching tool travels during operation. This specification influences the depth and size of the holes or shapes punched into the material. A longer stroke length can accommodate thicker materials, making it vital for buyers to match this property with their production needs to optimize performance and reduce operational costs.

4. Punching Speed

Punching speed is the rate at which the machine can perform punches, typically measured in strokes per minute (SPM). High-speed punching machines can significantly increase production efficiency, making them ideal for high-volume manufacturing. For international buyers, understanding the relationship between punching speed and their production requirements can help in choosing a machine that maximizes output while maintaining quality.

5. Control System

The control system of a punching machine can vary from manual to fully automated CNC (Computer Numerical Control) systems. Automated systems provide greater precision, repeatability, and flexibility in production, essential for adapting to varying production needs. Buyers should evaluate the complexity and capabilities of the control system to ensure it aligns with their operational goals and workforce skills.

What Are Common Trade Terminology and Jargon in the Punching Machine Industry?

Understanding the jargon and trade terms associated with punching machines is equally important for B2B buyers to navigate contracts and negotiations effectively. Here are some commonly used terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. When purchasing punching machines, buyers may deal directly with OEMs, ensuring they receive high-quality, authentic products tailored to their specifications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For buyers, understanding the MOQ is essential for budgeting and inventory management. Negotiating favorable MOQs can help manage cash flow while ensuring a steady supply of machines or parts.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. For B2B buyers, issuing an RFQ can lead to competitive pricing, allowing for better negotiation and selection of suppliers based on quality and cost.

4. Incoterms

Incoterms (International Commercial Terms) are a set of predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risk management, and insurance responsibilities, making it vital for international procurement.

5. Lead Time

Lead time refers to the time taken from placing an order to the delivery of goods. In the context of punching machines, understanding lead time is crucial for production planning and scheduling. Buyers should always clarify lead times with suppliers to ensure timely delivery and avoid disruptions in their manufacturing processes.

Conclusion

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, having a clear understanding of the technical properties and trade terminology related to punching machines from China is essential. This knowledge not only aids in making informed purchasing decisions but also enhances negotiations and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the punching machine china Sector

What Are the Key Market Dynamics and Trends in the Punching Machine Sector?

The global market for punching machines, particularly those manufactured in China, is undergoing significant transformation driven by technological advancements and changing buyer preferences. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe (including France and Egypt) seek to optimize their production processes, they are increasingly drawn to automation and smart manufacturing solutions. The integration of Industry 4.0 technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), is enhancing machine capabilities, leading to improved efficiency, precision, and reduced operational costs.

In addition to technological advancements, sustainability has become a critical factor influencing purchasing decisions. Buyers are now prioritizing suppliers that not only provide high-quality machinery but also demonstrate a commitment to sustainable manufacturing practices. The rise of e-commerce platforms tailored for B2B transactions has also changed the dynamics of sourcing, enabling buyers to easily compare products, prices, and supplier credentials from the comfort of their offices. As a result, the competitive landscape is evolving, with more emphasis on transparency and supplier reliability.

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing in Punching Machine Procurement?

Sustainability and ethical sourcing are paramount concerns for modern B2B buyers. The environmental impact of manufacturing processes in the punching machine sector is under scrutiny, prompting buyers to seek out suppliers who adhere to green practices. These practices include minimizing waste, utilizing energy-efficient machinery, and sourcing raw materials responsibly.

To ensure compliance with sustainability standards, B2B buyers should look for suppliers that possess relevant certifications such as ISO 14001 (Environmental Management) and ISO 50001 (Energy Management). These certifications indicate that a manufacturer has implemented effective environmental management systems and is committed to continuous improvement. Additionally, buyers should inquire about the use of eco-friendly materials in machine production, such as recyclable components or non-toxic coatings, which can significantly reduce the overall environmental footprint of their operations.

Moreover, establishing long-term relationships with ethically responsible suppliers can enhance brand reputation and consumer trust. Buyers from regions like Africa and South America can particularly benefit from partnerships that emphasize fair labor practices and community engagement, contributing positively to their corporate social responsibility (CSR) initiatives.

How Has the Punching Machine Industry Evolved Over Time?

The punching machine industry has evolved dramatically over the last few decades. Initially dominated by manual and mechanical machines, the sector has transitioned towards fully automated systems that leverage advanced technology. This evolution has been driven by the increasing demand for precision and efficiency in manufacturing processes.

In the early 2000s, the introduction of CNC (Computer Numerical Control) technology revolutionized the production capabilities of punching machines, allowing for greater customization and rapid prototyping. Today, manufacturers in China are at the forefront of this evolution, producing machines equipped with IoT capabilities that enable remote monitoring and predictive maintenance. This historical progression underscores the importance of staying abreast of technological innovations for international buyers seeking to enhance their operational efficiency and competitiveness in the global marketplace.

By understanding these market dynamics and trends, B2B buyers can make informed decisions that align with their operational goals and sustainability objectives, ultimately securing a competitive advantage in their respective industries.

Frequently Asked Questions (FAQs) for B2B Buyers of punching machine china

-

How do I ensure the quality of punching machines from China?

To ensure quality, start by verifying the manufacturer’s certifications, such as ISO 9001 or CE marks. Request samples or visit the factory if possible. Additionally, consider third-party inspection services that can evaluate the machines before shipment. It’s essential to establish clear quality assurance criteria in your contract, specifying acceptable tolerances and testing methods. Engaging with other buyers who have experience with the supplier can also provide valuable insights into their reliability and product quality. -

What is the best punching machine for small-scale manufacturing?

For small-scale manufacturing, consider a hydraulic punching machine due to its versatility and efficiency. Hydraulic machines can handle various materials and thicknesses, making them suitable for diverse applications. Look for models that offer adjustable stroke lengths and speeds to cater to different production needs. When sourcing, check for local suppliers who can provide after-sales support, or choose manufacturers that offer robust customer service and spare parts availability. -

What are the common payment terms for purchasing punching machines from China?

Payment terms can vary widely, but most suppliers offer options like T/T (telegraphic transfer) or L/C (letter of credit). A common approach is to pay 30% upfront as a deposit and the remaining 70% before shipment. It’s advisable to negotiate terms that protect your investment, such as escrow services or payment upon inspection. Ensure that all payment terms are clearly outlined in the contract to avoid misunderstandings. -

How can I customize my punching machine to meet specific production needs?

Customization options often include adjustments to machine size, punch type, and additional features like automatic feeding systems or enhanced safety measures. Discuss your requirements with the supplier early in the negotiation process. Many manufacturers in China are open to customizing their products, but this may affect lead times and costs. Ensure that you have a detailed specification sheet and that all custom features are documented in the contract. -

What is the minimum order quantity (MOQ) for punching machines from Chinese suppliers?

MOQs can vary significantly depending on the manufacturer and the specific machine model. Generally, you might encounter MOQs ranging from one unit for smaller suppliers to several units for larger manufacturers. If you’re a small or medium-sized enterprise, it’s beneficial to discuss your needs directly with suppliers. Some may be flexible with MOQs, especially if you are willing to pay a premium or if they are looking to establish a long-term relationship. -

What logistics considerations should I be aware of when importing punching machines from China?

When importing, consider shipping methods (sea freight vs. air freight), which can impact cost and delivery time. Ensure you understand customs duties and taxes applicable in your country, as these can add to your overall cost. Working with a reliable freight forwarder can streamline the logistics process, handling documentation, and ensuring compliance with local regulations. Also, discuss with your supplier about packaging to prevent damage during transit. -

How do I vet a supplier when purchasing punching machines from China?

Start by checking the supplier’s business license and certifications. Utilize platforms like Alibaba or Global Sources to read reviews and assess their reputation. Conduct a background check to confirm their operational history and financial stability. If feasible, request references from other buyers. A factory visit can provide firsthand insight into their operations, or consider using third-party verification services for added assurance. -

What are the warranty and after-sales support options for punching machines from China?

Most reputable manufacturers offer warranties ranging from one to three years, covering defects in materials and workmanship. Before finalizing your purchase, clarify the warranty terms, including what is covered and the process for claiming repairs or replacements. Additionally, inquire about after-sales support, such as technical assistance, availability of spare parts, and training for your staff. A solid after-sales support system is crucial for minimizing downtime and ensuring efficient operation.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for punching machine china

In the dynamic landscape of manufacturing, strategic sourcing for punching machines from China offers significant advantages for international B2B buyers. By prioritizing quality, cost-efficiency, and supplier reliability, businesses can secure the machinery necessary for enhanced productivity and competitive edge. The Chinese market stands out not only for its vast array of innovative technologies but also for its ability to cater to specific needs, which is crucial for buyers across diverse regions such as Africa, South America, the Middle East, and Europe.

A stock image related to punching machine china.

What are the key considerations for successful sourcing? Buyers should focus on establishing strong relationships with reputable suppliers, understanding the intricacies of import regulations, and leveraging technological advancements to optimize their procurement processes. Additionally, engaging in thorough market research can help identify emerging trends and innovations, ensuring that businesses remain at the forefront of the industry.

As the global manufacturing sector evolves, the outlook for sourcing punching machines from China remains promising. International B2B buyers are encouraged to take proactive steps in their sourcing strategies, utilizing this opportunity to enhance their operational capabilities. Embrace the future of manufacturing by exploring the potential of Chinese suppliers to propel your business forward in a competitive marketplace.