Discover Cost-Effective Solutions: Brakes China Guide (2025)

Introduction: Navigating the Global Market for brakes china

Navigating the global market for brakes sourced from China presents a unique set of challenges for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. The complexity of sourcing high-quality braking systems while ensuring compliance with regional standards can be daunting. This guide aims to demystify the process, offering a thorough exploration of various brake types, their applications across different industries, and essential strategies for vetting suppliers effectively.

Understanding the intricacies of the brake market in China involves not only identifying the right products but also evaluating potential partners who can meet stringent quality and delivery expectations. From cost considerations to supplier reliability, every aspect plays a crucial role in making informed purchasing decisions. This guide empowers B2B buyers by providing actionable insights into selecting the best braking solutions tailored to their specific operational needs.

Moreover, we delve into the latest trends influencing the brake industry, such as advancements in technology and shifts in consumer preferences. By equipping buyers with knowledge about market dynamics and supplier assessment techniques, this resource serves as a vital tool for businesses looking to enhance their procurement processes and foster successful international trade relationships. Whether you are in the automotive sector or industrial manufacturing, our guide will help you navigate the complexities of sourcing brakes from China with confidence.

Understanding brakes china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Disc Brakes | Uses a rotating disc and a caliper for friction | Automotive, commercial vehicles | Pros: Excellent heat dissipation; reliable performance. Cons: Higher initial cost; requires regular maintenance. |

| Drum Brakes | Consists of a drum and brake shoes that press out | Heavy-duty vehicles, industrial machinery | Pros: Cost-effective; self-adjusting design. Cons: Less effective under high heat; heavier than disc brakes. |

| Hydraulic Brakes | Operated by hydraulic fluid for smooth operation | Buses, trucks, agricultural equipment | Pros: Strong braking force; minimal pedal effort. Cons: Vulnerable to fluid leaks; complex system. |

| Electric Brakes | Uses electric actuators instead of hydraulic force | Electric vehicles, light rail systems | Pros: Energy-efficient; reduced wear on components. Cons: Requires electric power; can be less responsive in some conditions. |

| Air Brakes | Utilizes compressed air to actuate the brakes | Freight trucks, buses | Pros: Powerful braking force; effective for large vehicles. Cons: Air leaks can cause failure; requires air compressor maintenance. |

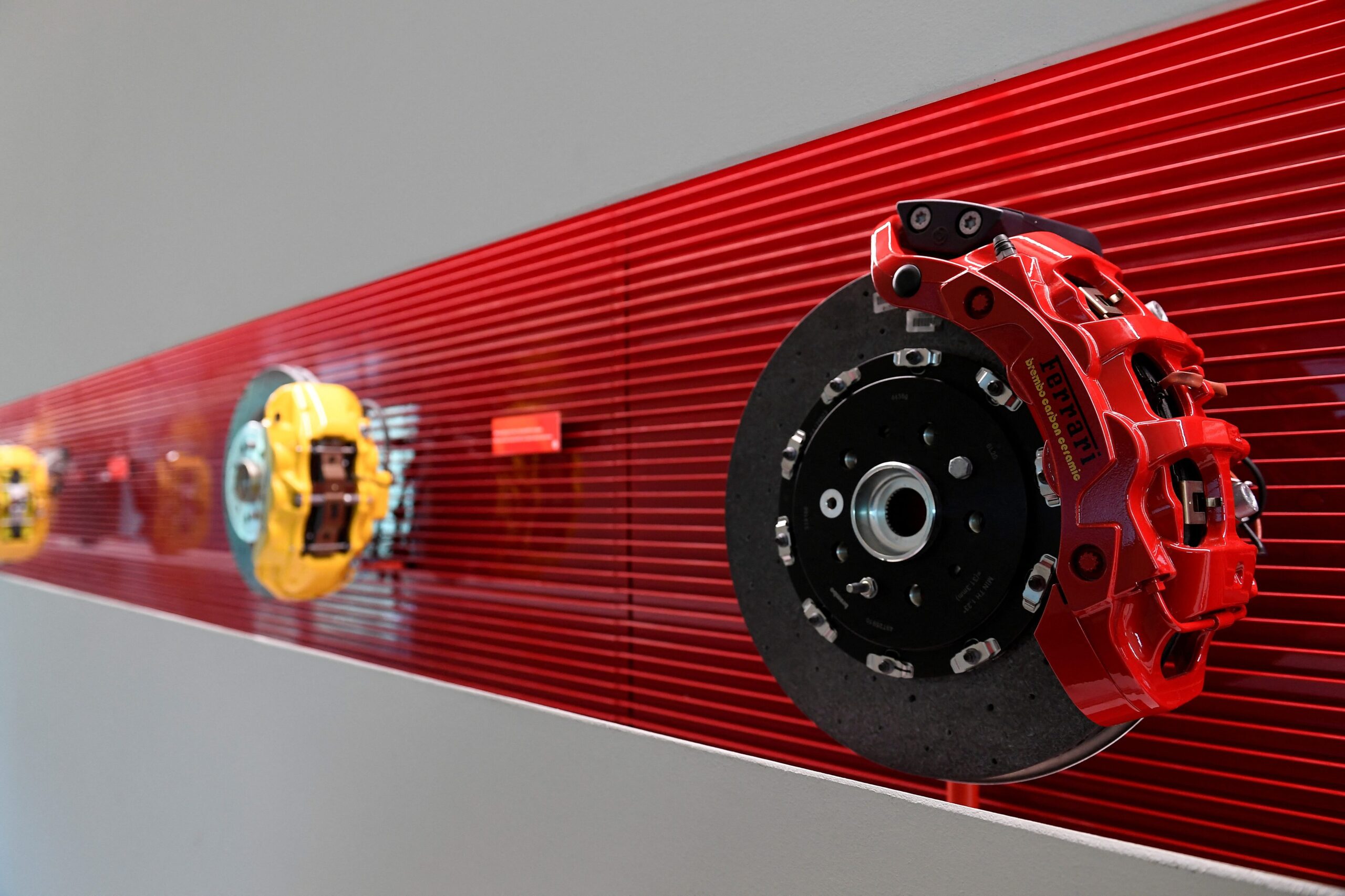

What are the Characteristics of Disc Brakes?

Disc brakes are characterized by their use of a rotating disc and a caliper that houses brake pads. They are widely favored in automotive applications due to their superior heat dissipation and consistent performance under high-stress conditions. When considering a purchase, B2B buyers should evaluate the cost versus the long-term reliability and maintenance needs, as disc brakes generally require more frequent servicing compared to other types.

How do Drum Brakes Function and Where are They Used?

Drum brakes consist of a drum that rotates with the wheel and brake shoes that press outward against the drum when activated. They are particularly suitable for heavy-duty vehicles and industrial machinery where cost-effectiveness is essential. Buyers should consider the weight and performance characteristics of drum brakes, especially in environments where heat buildup is a concern, as they can be less effective than disc brakes under such conditions.

What Makes Hydraulic Brakes a Preferred Choice for Heavy Vehicles?

Hydraulic brakes operate using hydraulic fluid to transmit force from the brake pedal to the brake components, providing smooth and efficient braking. They are commonly used in larger vehicles like buses and trucks, as well as agricultural equipment. B2B buyers should be aware of the potential for fluid leaks and the complexity of hydraulic systems, which can impact maintenance costs and operational reliability.

Why are Electric Brakes Gaining Popularity in Modern Applications?

Electric brakes utilize electric actuators to engage the braking system, making them increasingly popular in electric vehicles and light rail systems. They offer energy efficiency and reduced component wear, aligning well with sustainability goals. However, potential buyers should consider the need for a reliable electric power source and the responsiveness of electric brakes under various conditions, which may vary depending on the application.

What are the Key Advantages and Challenges of Air Brakes?

Air brakes operate using compressed air to activate the braking system, providing powerful braking force ideal for large vehicles like freight trucks and buses. They are known for their effectiveness in heavy-duty applications. However, buyers must be mindful of the maintenance requirements for the air compressor and the risk of air leaks, which can lead to braking failures if not properly managed.

Related Video: EU SLAMS Brakes China’s C919 – COMAC is DONE!

Key Industrial Applications of brakes china

| Industry/Sector | Specific Application of brakes china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Disc and drum brakes for vehicles | Enhanced safety and performance in braking systems | Quality certifications, compatibility with local standards |

| Industrial Machinery | Brakes for conveyor systems | Improved operational efficiency and safety | Durability, maintenance requirements, and load capacity |

| Rail Transportation | Braking systems for trains | Increased safety and reliability in public transport | Compliance with international safety regulations |

| Construction Equipment | Hydraulic and mechanical brakes for heavy machinery | Higher productivity and reduced downtime | Supplier reliability, product lifespan, and after-sales support |

| Aerospace | Aircraft braking systems | Critical safety and performance in aviation | Advanced technology, weight considerations, and certification standards |

How Are Brakes Used in the Automotive Industry in China?

In the automotive sector, ‘brakes china’ refers to high-performance disc and drum brakes designed for a wide range of vehicles. These braking systems are crucial for enhancing safety and performance, especially in urban environments where quick stopping is necessary. International B2B buyers should focus on suppliers who offer quality certifications and ensure compatibility with local automotive standards. Additionally, understanding the specific braking requirements based on vehicle types can lead to better sourcing decisions.

What Role Do Brakes Play in Industrial Machinery?

In industrial settings, brakes are essential for conveyor systems that transport materials. The use of ‘brakes china’ in these systems improves operational efficiency by ensuring precise stopping and starting, which minimizes material loss and accidents. Buyers from Africa, South America, and Europe should prioritize sourcing durable brakes that can withstand heavy loads and frequent use. Maintenance requirements and the ability to integrate with existing machinery are also critical factors to consider.

How Are Brakes Applied in Rail Transportation?

Rail transportation relies heavily on effective braking systems to ensure the safety and reliability of trains. ‘Brakes china’ used in this context must meet stringent safety standards and provide consistent performance under various conditions. International buyers need to be aware of compliance with international safety regulations and the importance of sourcing components that enhance the overall reliability of rail systems. This can significantly reduce operational risks and enhance passenger safety.

Why Are Brakes Important for Construction Equipment?

Construction equipment, such as excavators and cranes, utilize hydraulic and mechanical brakes to ensure operator safety and equipment longevity. ‘Brakes china’ in this sector contribute to higher productivity by allowing for quick and controlled movements, which are essential in dynamic job sites. When sourcing, buyers should evaluate supplier reliability, product lifespan, and the availability of after-sales support to ensure minimal downtime and optimal performance on-site.

What Are the Requirements for Aerospace Braking Systems?

In the aerospace industry, braking systems are critical for the safe operation of aircraft. ‘Brakes china’ designed for aviation must adhere to advanced technology standards that prioritize weight reduction without compromising safety. International B2B buyers should focus on sourcing brakes that meet stringent certification standards, as well as those that offer innovative features for enhanced performance. Understanding the specific needs of different aircraft models will also aid in making informed purchasing decisions.

Related Video: Permanent Magnet Brakes – How it works

3 Common User Pain Points for ‘brakes china’ & Their Solutions

Scenario 1: Inconsistent Quality of Brake Components from Chinese Suppliers

The Problem:

International B2B buyers often face challenges with the inconsistent quality of brake components sourced from China. This can lead to significant issues in the supply chain, including delays, increased costs due to returns, and potential safety hazards if substandard parts are used in vehicles or machinery. Buyers may find it difficult to evaluate the quality of products before shipment, especially if they do not have established relationships with manufacturers or lack the ability to conduct on-site inspections.

The Solution:

To mitigate these quality issues, buyers should prioritize establishing robust supplier relationships and conducting thorough due diligence. Start by requesting detailed product specifications and certifications from potential suppliers. Utilize platforms like Alibaba or Made-in-China, where supplier ratings and reviews can provide insights into their reliability. Consider implementing a vendor scorecard system to evaluate suppliers based on key performance indicators such as delivery time, quality consistency, and communication effectiveness.

Furthermore, if feasible, engage third-party quality assurance services to perform inspections prior to shipment. These services can verify that the products meet the required standards and specifications, thus reducing the risk of receiving subpar components. Regularly revisiting these assessments can help maintain a consistent quality benchmark.

Scenario 2: Complicated Logistics and Shipping Processes for Brake Parts

The Problem:

Another common challenge faced by B2B buyers is navigating the complex logistics and shipping processes when importing brake parts from China. Issues such as customs delays, unexpected tariffs, and unreliable shipping timelines can disrupt supply chains, leading to stockouts and dissatisfied customers. Additionally, buyers may not be familiar with the regulatory requirements for importing automotive components, which can complicate the process further.

The Solution:

To streamline the logistics process, buyers should engage with experienced freight forwarders who specialize in international shipping and are familiar with the regulations for automotive parts. These professionals can provide valuable guidance on customs documentation, import tariffs, and compliance with local regulations in the buyer’s country.

Furthermore, it is beneficial to create a detailed shipping schedule that accounts for potential delays and builds in buffer time to avoid disruptions. Consider using technology solutions that offer real-time tracking and updates on shipments, enabling buyers to stay informed about their orders’ status. Establishing clear communication channels with suppliers regarding shipping expectations can also help in managing timelines effectively.

Scenario 3: Difficulty in Customizing Brake Solutions for Specific Needs

The Problem:

B2B buyers often require brake components that meet specific performance criteria or application needs. However, many manufacturers in China offer standardized products that may not fully align with the buyer’s requirements. This lack of customization can lead to performance issues, increased wear and tear, and reduced operational efficiency, especially in specialized industries like construction or heavy machinery.

The Solution:

To overcome customization challenges, buyers should communicate their specific needs clearly to potential suppliers from the outset. Providing detailed technical drawings, performance specifications, and usage scenarios can help manufacturers understand the required customization. Engaging in open dialogue about the feasibility of modifications can also lead to innovative solutions that meet the buyer’s needs.

Additionally, consider collaborating with suppliers who have a history of providing tailored solutions or those who have R&D capabilities. This collaboration can lead to the development of bespoke products that not only meet operational requirements but also enhance the overall performance of the equipment. Regularly reviewing and testing the customized components can ensure they meet performance benchmarks and provide feedback to suppliers for future improvements.

Strategic Material Selection Guide for brakes china

What Are the Key Materials Used in Brakes for China?

When selecting materials for brake systems in China, understanding the properties, advantages, and limitations of various materials is crucial for international B2B buyers. Here, we analyze four common materials used in brake manufacturing, focusing on their performance characteristics and implications for buyers from Africa, South America, the Middle East, and Europe.

How Does Cast Iron Perform in Brake Applications?

Key Properties: Cast iron is known for its excellent wear resistance and high thermal conductivity, making it suitable for high-temperature applications. It typically withstands temperatures up to 600°C and offers good pressure ratings.

Pros & Cons: The primary advantage of cast iron is its durability and ability to dissipate heat effectively, which prevents brake fade during prolonged use. However, it is relatively heavy, which can affect vehicle performance. Additionally, the manufacturing process can be complex and costly.

Impact on Application: Cast iron is compatible with various media, including oil and water, making it versatile for different brake systems. However, its susceptibility to corrosion necessitates protective coatings, especially in humid climates.

Considerations for International Buyers: Buyers should ensure compliance with local standards such as ASTM or DIN, particularly regarding material specifications and performance testing. In regions with high humidity, additional corrosion-resistant treatments may be required.

What Are the Benefits of Carbon-Composite Materials?

Key Properties: Carbon-composite materials offer high strength-to-weight ratios and excellent thermal stability, withstanding temperatures up to 1,000°C. They are also resistant to thermal expansion, which helps maintain performance under varying conditions.

Pros & Cons: The lightweight nature of carbon-composite materials enhances vehicle performance and fuel efficiency. However, they are significantly more expensive than traditional materials and may require specialized manufacturing processes.

Impact on Application: These materials are particularly effective in high-performance and racing applications, where weight reduction is critical. However, they may not be suitable for standard vehicles due to their cost.

Considerations for International Buyers: Buyers should be aware of the limited availability of carbon-composite parts in some regions. Compliance with international standards for high-performance materials is essential, and buyers should evaluate suppliers’ capabilities in producing these advanced materials.

Why Is Steel a Popular Choice for Brake Components?

Key Properties: Steel offers excellent tensile strength and resistance to wear, with temperature ratings typically up to 400°C. It is also relatively easy to manufacture and shape, making it a common choice for various brake components.

Pros & Cons: The main advantage of steel is its cost-effectiveness and availability. However, it is heavier than alternatives like aluminum or composites, which can impact overall vehicle weight and efficiency.

Impact on Application: Steel is compatible with a wide range of brake fluids and applications, making it a versatile choice. However, it may require additional treatments to prevent rust and corrosion, particularly in coastal or humid environments.

Considerations for International Buyers: Buyers from different regions should consider local standards for steel grades and treatments. Understanding the specific requirements for corrosion resistance in their climate will help in selecting the right steel type.

What Role Does Aluminum Play in Brake Manufacturing?

Key Properties: Aluminum is lightweight and offers good corrosion resistance, withstanding temperatures up to 300°C. It is also easier to machine than many other metals, allowing for more complex designs.

Pros & Cons: The lightweight nature of aluminum contributes to better fuel efficiency and performance. However, it may not be as durable as steel or cast iron under extreme conditions, leading to potential wear issues.

Impact on Application: Aluminum is often used in applications where weight reduction is a priority, such as in electric vehicles. However, it may not be suitable for high-performance applications that require maximum durability.

Considerations for International Buyers: Buyers should ensure that aluminum components meet relevant international standards for safety and performance. Additionally, they should consider the potential need for protective coatings to enhance durability in specific environments.

Summary Table of Material Selection for Brakes in China

| Material | Typical Use Case for brakes china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cast Iron | Standard vehicle brake systems | Excellent heat dissipation | Heavy and complex to manufacture | Medium |

| Carbon-Composite | High-performance and racing brakes | Lightweight and high thermal stability | High cost and specialized manufacturing | High |

| Steel | General brake components | Cost-effective and widely available | Heavier than alternatives | Low |

| Aluminum | Lightweight vehicle applications | Lightweight and good corrosion resistance | Less durable under extreme conditions | Medium |

This guide provides essential insights for international B2B buyers looking to make informed decisions regarding brake materials in China, ensuring compliance with local standards and suitability for specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for brakes china

What Are the Key Stages in the Manufacturing Process of Brakes in China?

The manufacturing process for brakes in China typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage is critical to ensuring the final product meets the required performance and safety standards.

Material Preparation: This initial stage includes sourcing high-quality raw materials, such as cast iron, aluminum, and various composite materials. Suppliers often conduct rigorous material testing to confirm that the materials meet specified standards for durability and performance. Buyers should inquire about the origin of these materials and any certifications that validate their quality.

Forming: In this phase, the raw materials are shaped into the desired components using various techniques such as casting, forging, and machining. Advanced technologies like CNC machining are commonly employed to achieve precise dimensions. It’s crucial for international buyers to understand the forming techniques used, as they directly influence the quality and performance of the brakes.

Assembly: After the individual components are formed, they are assembled into complete brake systems. This process may involve manual labor and automated systems, with a focus on precision and attention to detail. Buyers should assess the assembly techniques used, as improper assembly can lead to product failures.

Finishing: The final stage includes surface treatments, such as coating and polishing, which enhance durability and aesthetics. Techniques like powder coating or anodizing are often employed to protect against corrosion and wear. B2B buyers should ask for details on the finishing processes, as these can significantly affect the lifespan of the brakes.

How is Quality Assurance Implemented in Brake Manufacturing?

Quality assurance in brake manufacturing is paramount, especially given the critical safety implications of these components. Manufacturers in China often adhere to several international and industry-specific standards to ensure product quality.

International Standards: Many manufacturers comply with ISO 9001, which outlines the requirements for a quality management system. This standard emphasizes continuous improvement, ensuring that processes remain efficient and effective. Additionally, certifications like CE mark for the European market or API standards for certain applications can be crucial indicators of quality.

Quality Control Checkpoints: The quality control process typically includes several checkpoints:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, inspections are conducted to monitor quality at various stages. This may include dimensional checks and functional testing.

- Final Quality Control (FQC): Once the brakes are assembled, a comprehensive inspection is performed to ensure the final product meets all specifications and safety standards.

What Testing Methods Are Commonly Used in Brake Manufacturing?

Testing methods play a crucial role in validating the quality and performance of brake systems. Manufacturers often employ a range of techniques, including:

- Static and Dynamic Testing: Static tests evaluate the material strength and wear resistance, while dynamic tests assess performance under real-world conditions.

- Fatigue Testing: This simulates the stresses that brakes will experience over time, ensuring they can withstand repeated use without failure.

- Thermal Testing: Given that brakes generate significant heat, thermal testing ensures that components can operate effectively under high-temperature conditions.

International B2B buyers should request detailed reports on these tests to verify compliance with safety standards.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is essential for international buyers, particularly those from Africa, South America, the Middle East, and Europe. Here are some actionable strategies:

- Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. Buyers can assess compliance with international standards and identify areas for improvement.

- Request Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including test results and compliance certifications. These documents serve as a crucial reference for buyers.

- Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of a supplier’s quality control practices. This is particularly important for buyers unfamiliar with local manufacturing standards.

What Are the Quality Control Nuances for International Buyers?

When sourcing brakes from China, international buyers must navigate several nuances related to quality control. These include:

- Cultural Differences: Understanding local manufacturing practices and quality expectations can vary significantly. Buyers should invest time in building relationships with suppliers to facilitate clearer communication.

- Regulatory Compliance: Different regions have varying regulatory requirements. For instance, European buyers must ensure that products comply with EU regulations, which may differ from those in the Middle East or Africa.

- Supply Chain Transparency: A transparent supply chain allows buyers to track the quality of materials and processes. This can be crucial in ensuring that the final product meets their standards.

By being proactive in these areas, international B2B buyers can significantly reduce the risks associated with sourcing brakes from China, ensuring they receive high-quality products that meet safety and performance standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘brakes china’

To successfully procure brakes from China, a structured approach is essential. This checklist will guide international B2B buyers through the critical steps to ensure they make informed decisions, mitigate risks, and achieve cost-effective sourcing.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial to ensure the brakes meet your operational needs. Consider factors such as:

– Material requirements: Identify whether you need ceramic, semi-metallic, or organic brake pads.

– Performance standards: Specify the required stopping distance, heat resistance, and durability.

Having well-defined specifications helps suppliers provide accurate quotes and reduces the risk of receiving subpar products.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to compile a list of potential suppliers in China. Utilize platforms like Alibaba, Global Sources, and industry-specific directories. Look for:

– Company background: Verify how long they’ve been in business and their industry reputation.

– Product range: Ensure they specialize in the specific type of brakes you need.

An extensive list allows you to compare options and find suppliers that align with your requirements.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Request:

– Company profiles and certifications: Check for ISO certifications and industry standards compliance.

– References: Ask for case studies or testimonials from other B2B clients in your sector.

A rigorous vetting process helps you gauge reliability and quality, minimizing the risks associated with international transactions.

Step 4: Request Samples and Conduct Quality Tests

Always request samples before placing a bulk order. Quality testing of samples can include:

– Performance testing: Assess their functionality under various conditions.

– Material inspection: Ensure the materials used meet your specifications.

Testing samples allows you to confirm product quality and compatibility with your systems before making a larger investment.

Step 5: Negotiate Terms and Conditions

Effective negotiation can lead to better pricing and favorable terms. Focus on:

– Payment terms: Discuss options like letters of credit or escrow services to secure your investment.

– Delivery timelines: Establish clear expectations on lead times and shipping methods.

Negotiating these terms upfront can prevent misunderstandings and ensure smoother transactions.

Step 6: Understand Import Regulations and Duties

Familiarize yourself with import regulations and duties in your country. Key considerations include:

– Customs documentation: Ensure all necessary paperwork is prepared for smooth clearance.

– Tariffs and taxes: Research applicable tariffs to avoid unexpected costs.

Understanding these regulations helps you plan your budget accurately and avoid delays in receiving your products.

Step 7: Establish a Clear Communication Plan

Maintaining clear communication with your supplier is vital throughout the sourcing process. Consider:

– Regular updates: Schedule regular check-ins to track production progress.

– Language barriers: Ensure both parties understand key terms and specifications.

An effective communication plan fosters transparency, reduces misunderstandings, and strengthens the supplier relationship.

By following this checklist, B2B buyers can confidently navigate the complexities of sourcing brakes from China, ensuring they secure high-quality products that meet their business needs.

Comprehensive Cost and Pricing Analysis for brakes china Sourcing

What Are the Key Cost Components in Sourcing Brakes from China?

When sourcing brakes from China, understanding the cost structure is vital for international B2B buyers. The primary components include:

-

Materials: The quality of raw materials used in brake manufacturing significantly impacts the overall cost. Common materials include cast iron, aluminum alloys, and various friction materials. Buyers should consider whether they prefer standard materials or higher-grade options that may enhance performance.

-

Labor: Labor costs in China can vary based on the region and the complexity of the manufacturing process. While China is known for its competitive labor rates, fluctuations in wages can affect pricing, especially if suppliers need to hire skilled workers for specialized tasks.

-

Manufacturing Overhead: This includes costs related to factory maintenance, utilities, and administrative expenses. Understanding the supplier’s overhead can provide insight into their pricing strategies. Efficient operations may lead to lower overhead costs, which can be beneficial for buyers.

-

Tooling: Investment in tooling can be significant, especially for custom brake designs. Tooling costs are often amortized over the production run, meaning larger orders may reduce the per-unit cost significantly.

-

Quality Control (QC): Implementing quality assurance processes ensures that products meet specified standards. While this adds to the cost, it can prevent future expenses associated with defects or recalls.

-

Logistics: Shipping and handling costs play a crucial role in the overall expenditure. Factors such as distance, shipping method, and insurance can influence logistics expenses. Buyers must consider these costs when evaluating total pricing.

A stock image related to brakes china.

- Margin: Suppliers will include a profit margin in their pricing, which can vary based on market demand, competition, and perceived value. Buyers should be aware of the typical margins in the brakes industry to gauge fair pricing.

How Do Price Influencers Affect Brake Sourcing Costs?

Several factors influence the pricing of brakes sourced from China, including:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often provide better pricing for larger orders. Understanding the MOQ can help buyers negotiate better rates, especially for bulk purchases.

-

Specifications and Customization: Custom designs or specific performance standards can increase costs. Buyers should clearly communicate their requirements to avoid unexpected charges.

-

Materials and Quality Certifications: Higher-quality materials or certifications (like ISO or TS) can elevate prices. Buyers should assess their quality needs versus budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Well-established suppliers may charge more due to their proven track record, while lesser-known suppliers might offer lower prices but come with increased risk.

-

Incoterms: The chosen Incoterm affects the total cost of logistics and responsibilities during shipping. Understanding terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) is essential for accurate cost calculation.

What Are the Best Negotiation Tips for International B2B Buyers?

To maximize cost efficiency when sourcing brakes from China, buyers should consider the following strategies:

-

Conduct Thorough Research: Familiarize yourself with market prices and competitor offerings. This knowledge will empower you during negotiations.

-

Negotiate Terms: Beyond price, discuss payment terms, delivery schedules, and warranty conditions. Flexible terms can add significant value.

-

Calculate Total Cost of Ownership (TCO): Assess not just the purchase price but also long-term costs associated with maintenance, logistics, and potential defects. This holistic view can guide better purchasing decisions.

-

Build Relationships: Establishing a good rapport with suppliers can lead to better pricing and service. Long-term relationships often result in favorable terms.

-

Stay Informed About Market Trends: Awareness of global supply chain trends, material costs, and economic conditions can provide leverage in negotiations.

Conclusion

Navigating the complexities of sourcing brakes from China requires a comprehensive understanding of cost structures and pricing influencers. By employing strategic negotiation tactics and being mindful of the total cost of ownership, international B2B buyers can make informed decisions that enhance their procurement processes. While indicative prices can vary, thorough research and relationship building remain key to achieving competitive pricing.

Alternatives Analysis: Comparing brakes china With Other Solutions

In the competitive landscape of the brake manufacturing industry, international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, often seek efficient solutions that meet their operational needs. Evaluating alternatives to ‘brakes china’ can help businesses make informed decisions that align with their budget, performance expectations, and operational requirements.

Comparison Table of Brakes China and Alternatives

| Comparison Aspect | Brakes China | Alternative 1: European Brake Systems | Alternative 2: American Brake Technologies |

|---|---|---|---|

| Performance | High efficiency, reliable under various conditions | Superior stopping power, optimized for heavy-duty vehicles | Consistent performance, emphasis on safety features |

| Cost | Competitive pricing, cost-effective for bulk purchases | Higher upfront costs, justified by longevity and reliability | Moderate pricing, value for advanced features |

| Ease of Implementation | Simple integration into existing systems | May require additional training for optimal use | User-friendly with comprehensive support resources |

| Maintenance | Moderate, parts readily available | Low maintenance due to durable materials | Regular maintenance needed, but parts easily sourced |

| Best Use Case | Ideal for standard vehicles and commercial fleets | Best suited for heavy-duty and high-performance vehicles | Recommended for safety-conscious applications, especially in urban areas |

What Are the Advantages and Disadvantages of European Brake Systems?

European Brake Systems are known for their advanced engineering and superior stopping power, making them an excellent choice for heavy-duty vehicles. The primary advantage is their exceptional reliability, which is crucial for safety in high-stress situations. However, the downside is the higher upfront cost, which may not be feasible for all businesses, particularly smaller operations or those in developing regions.

How Do American Brake Technologies Compare?

American Brake Technologies prioritize safety features and consistent performance, making them suitable for urban environments where braking efficiency is paramount. They offer a moderate price point, providing good value for their advanced features. Nevertheless, they require regular maintenance, which can add to the overall cost of ownership. Additionally, while parts are readily available, the need for ongoing upkeep might not appeal to all buyers.

Conclusion: How Can B2B Buyers Choose the Right Brake Solution?

When selecting the right brake solution, B2B buyers must consider their specific operational needs, budget constraints, and performance requirements. ‘Brakes china’ offers a competitive solution for standard applications, while European Brake Systems excel in heavy-duty scenarios. American Brake Technologies provide a balanced option focused on safety. Ultimately, buyers should assess their unique use cases, the importance of maintenance, and cost-effectiveness to make an informed decision that enhances their operational efficiency and safety.

Essential Technical Properties and Trade Terminology for brakes china

What Are the Essential Technical Properties of Brakes in China?

When sourcing brakes from China, understanding the technical specifications is crucial for ensuring product quality and compliance with industry standards. Here are some key properties you should consider:

-

Material Grade

– The material grade of brake components, such as cast iron or carbon composite, determines their durability, heat resistance, and overall performance. High-grade materials are essential for heavy-duty applications, ensuring safety and longevity. Buyers must evaluate material certifications to confirm compliance with international standards. -

Tolerance Levels

– Tolerance refers to the permissible limit of variation in a physical dimension. In brake systems, tight tolerances are critical for ensuring proper fitment and functionality. A deviation can lead to performance issues or even safety hazards. International buyers should specify tolerance requirements in their purchase orders to avoid quality discrepancies. -

Friction Coefficient

– This property indicates the effectiveness of the brake material in converting kinetic energy into thermal energy. A higher friction coefficient typically results in better stopping power. Understanding the required friction levels for specific applications will help buyers select the appropriate brake components for their needs. -

Heat Dissipation Capacity

– Brakes generate significant heat during operation, which can lead to brake fade if not managed properly. The ability of a brake system to dissipate heat efficiently is vital for maintaining performance. Buyers should inquire about the heat dissipation capabilities of brake products, particularly for high-performance or heavy-duty applications. -

Wear Resistance

– The wear rate of brake components affects their longevity and maintenance costs. High wear resistance translates to longer service intervals and lower replacement frequency. Evaluating the wear characteristics of brake materials can lead to cost savings and improved operational efficiency.

What Are Common Trade Terms Used in the Brake Industry?

Understanding industry jargon is essential for effective communication with suppliers and manufacturers. Here are some common terms you will encounter:

-

OEM (Original Equipment Manufacturer)

– OEM refers to companies that produce parts that are used in the manufacturing of vehicles or machinery. When sourcing brakes, buyers often seek OEM parts to ensure compatibility and quality that meets original specifications. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is crucial for budgeting and inventory management. Buyers should negotiate MOQs based on their needs to avoid overstocking or underordering. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting a quote for specific products or services. It typically includes details such as product specifications, quantities, and delivery timelines. Properly structured RFQs can help buyers obtain competitive pricing and terms. -

Incoterms (International Commercial Terms)

– Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) helps buyers understand shipping costs and risk management during transportation. -

Lead Time

– Lead time refers to the time it takes from placing an order to receiving the goods. Understanding lead times is vital for planning and ensuring that products arrive when needed. Buyers should factor in lead times when making purchasing decisions to avoid disruptions in their supply chain. -

Certification Standards

– Various certification standards, such as ISO or TS16949, indicate the quality management systems of manufacturers. Buyers should verify that their suppliers meet relevant certification standards to ensure compliance with safety and quality regulations.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing brakes from China, ensuring they obtain high-quality products that meet their specific needs.

Navigating Market Dynamics and Sourcing Trends in the brakes china Sector

What Are the Current Market Dynamics and Key Trends in the Brakes China Sector?

The brakes sector in China is experiencing significant transformation, driven by global economic shifts, technological advancements, and increasing demand for high-quality automotive components. Key trends include the rise of electric and hybrid vehicles, which necessitate innovative braking solutions that can accommodate new performance standards. Additionally, the integration of smart technology into braking systems is becoming prevalent, enhancing safety and efficiency. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of these shifts as they influence sourcing strategies and supplier relationships.

Furthermore, increased competition within the market is prompting Chinese manufacturers to prioritize quality and cost-efficiency, which is crucial for international buyers seeking reliable partnerships. The emphasis on digital transformation—such as the use of AI and IoT for predictive maintenance—also shapes sourcing decisions, enabling buyers to opt for suppliers who leverage these technologies for enhanced product performance and service reliability.

How Is Sustainability and Ethical Sourcing Impacting the Brakes China Sector?

Sustainability has become a pivotal concern in the brakes sector, with environmental impact and ethical sourcing taking center stage. The production processes of brake components are scrutinized for their carbon footprint, prompting manufacturers to adopt greener practices. International buyers should prioritize suppliers who are committed to reducing waste and utilizing eco-friendly materials.

A stock image related to brakes china.

Certifications such as ISO 14001 (Environmental Management Systems) and adherence to RoHS (Restriction of Hazardous Substances) standards are indicators of a supplier’s commitment to sustainability. Additionally, the use of recycled materials and the development of low-emission brake pads are gaining traction. For B2B buyers, aligning with ethically responsible suppliers not only enhances corporate social responsibility (CSR) efforts but also caters to the growing consumer demand for sustainable products, particularly in regions like Europe where regulatory frameworks are stringent.

What Is the Historical Context of the Brakes China Sector?

The brakes sector in China has evolved considerably over the past few decades, transitioning from a focus on basic manufacturing to a landscape characterized by innovation and technological advancement. Initially, the industry was heavily reliant on traditional manufacturing methods, but as the automotive market expanded, so did the demand for advanced braking systems.

The entry of foreign investment and technology in the early 2000s marked a turning point, leading to enhanced quality and performance standards. Today, Chinese manufacturers are not only key players in the domestic market but are also increasingly competitive on the global stage, exporting high-quality braking solutions worldwide. This evolution highlights the importance for international B2B buyers to engage with suppliers who are not only aware of historical trends but are also positioned to adapt to future market dynamics.

Frequently Asked Questions (FAQs) for B2B Buyers of brakes china

-

How do I verify the credibility of a brake supplier in China?

To ensure the credibility of a brake supplier in China, start by conducting thorough research. Look for verified business licenses, certifications, and customer testimonials. Utilize platforms like Alibaba or Global Sources, where suppliers are rated by buyers. It’s also beneficial to request references and conduct video calls to gauge their facilities and operations. If possible, consider visiting the supplier in person or employing third-party inspection services to validate their claims. -

What are the most common quality certifications for brake products from China?

Common quality certifications for brake products sourced from China include ISO 9001, which indicates a quality management system, and TS 16949, specifically for automotive components. Additionally, look for certifications like CE marking for European markets, and RoHS compliance to ensure products are free from hazardous substances. Suppliers with these certifications demonstrate a commitment to quality and safety standards, which is essential for international B2B transactions. -

What is the typical minimum order quantity (MOQ) for brake components in China?

The typical MOQ for brake components in China can vary significantly depending on the supplier and the type of brake product. Generally, MOQs range from 100 to 1,000 units. However, some suppliers may offer lower MOQs for first-time buyers or for specific products. It’s advisable to negotiate MOQs based on your purchasing needs while considering the balance between cost-efficiency and inventory management. -

How do I navigate payment terms when sourcing brakes from China?

When sourcing brakes from China, payment terms are crucial for mitigating risk. Common practices include a 30% deposit upfront with the remaining 70% due before shipment. Additionally, consider using secure payment methods such as PayPal, Alibaba Trade Assurance, or letters of credit for larger orders. Always clarify terms in the contract to avoid misunderstandings and ensure that the payment structure aligns with your cash flow capabilities. -

What should I include in my quality assurance (QA) process for imported brakes?

Your QA process for imported brakes should include several key steps. Begin with pre-shipment inspections to check for product specifications and compliance with standards. Establish a clear testing protocol for performance and durability, ideally in collaboration with third-party testing labs. Additionally, maintain open communication with suppliers to address any discrepancies promptly and conduct periodic audits to ensure ongoing compliance with quality standards. -

How can I ensure timely logistics for brake shipments from China?

To ensure timely logistics for brake shipments from China, partner with reputable freight forwarders who specialize in international shipping. Discuss shipping options, including air freight for faster delivery or sea freight for cost-effectiveness. Plan shipments well in advance to account for potential delays, and keep abreast of customs regulations in your destination country. Implement tracking systems to monitor shipments in real-time, allowing for proactive management of any issues that arise. -

What customization options are typically available for brake products?

Customization options for brake products sourced from China can include modifications in design, materials, and specifications to meet specific operational needs. Many suppliers offer custom branding, sizes, and performance characteristics tailored to your market requirements. Discuss your needs early in the negotiation process and request samples to evaluate the customization quality before placing larger orders. -

What are the best practices for building long-term relationships with Chinese brake suppliers?

Building long-term relationships with Chinese brake suppliers involves consistent communication, transparency, and mutual respect. Regularly visit suppliers to strengthen personal connections and show commitment. Provide constructive feedback on product quality and service, and be open to negotiations on pricing and terms as your relationship develops. Additionally, consider establishing contracts that outline expectations and performance metrics to foster accountability and continuous improvement.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for brakes china

How Can Strategic Sourcing Enhance Your Brake Procurement?

In conclusion, the strategic sourcing of brake components from China presents a multitude of benefits for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. By leveraging China’s robust manufacturing capabilities, businesses can access high-quality products at competitive prices. Establishing strong relationships with reliable suppliers not only ensures consistent supply but also fosters innovation and customization tailored to specific market needs.

What Are the Key Takeaways for International Buyers?

International buyers must prioritize thorough supplier evaluation and risk management to navigate the complexities of global sourcing. Engaging in strategic sourcing practices allows companies to optimize their procurement processes, reduce costs, and enhance supply chain resilience. Furthermore, maintaining clear communication channels with suppliers is vital for addressing quality issues and ensuring compliance with international standards.

What Should You Do Next?

As you consider your next steps in sourcing brakes from China, embrace the opportunities presented by this dynamic market. Conduct comprehensive market research, establish partnerships with trusted suppliers, and remain adaptable to changing market conditions. By doing so, you position your business for sustained growth and success in the competitive landscape of brake procurement. Take action today to secure your supply chain and drive your business forward.