Discover Cost-Effective Solutions: Fabric China Guide (2025)

Introduction: Navigating the Global Market for fabric china

Navigating the intricate landscape of sourcing fabric from China can be a daunting task for international B2B buyers, especially those from Africa, South America, the Middle East, and Europe. With a multitude of suppliers, varying quality standards, and fluctuating costs, making informed decisions is critical. This guide aims to demystify the process of sourcing high-quality fabric from China by providing a comprehensive overview of the types available, their applications across various industries, and strategies for effective supplier vetting.

Understanding the nuances of fabric types—ranging from cotton and polyester to more specialized textiles—can significantly impact your product offerings and ultimately your business success. This guide also delves into the critical aspects of supplier evaluation, ensuring that you partner with reliable manufacturers who meet your quality and compliance standards. Moreover, it addresses cost considerations, helping you to budget effectively and maximize your profit margins.

By equipping yourself with knowledge from this guide, you will be empowered to make strategic purchasing decisions that align with your business goals. Whether you’re looking to enhance your product line or streamline your supply chain, insights into the global fabric market will serve as a valuable resource for navigating the complexities of sourcing from China.

Understanding fabric china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Silk Fabric | Luxurious feel, smooth texture, lightweight | Fashion, upholstery, luxury goods | Pros: High quality, aesthetic appeal. Cons: Expensive, sensitive to care. |

| Cotton Fabric | Breathable, versatile, durable | Apparel, home textiles, medical | Pros: Cost-effective, easy to maintain. Cons: Less luxurious than silk. |

| Polyester Fabric | Strong, wrinkle-resistant, moisture-wicking | Sportswear, outdoor gear, upholstery | Pros: Durable, low cost. Cons: Less breathable, can feel less natural. |

| Linen Fabric | Natural, breathable, textured | Home textiles, summer apparel | Pros: Eco-friendly, good for warm climates. Cons: Prone to wrinkling, can be stiff. |

| Rayon Fabric | Soft, absorbent, drapes well | Fashion, linings, home textiles | Pros: Comfortable, versatile. Cons: Can shrink, requires careful washing. |

What are the characteristics of Silk Fabric and its B2B suitability?

Silk fabric is renowned for its luxurious feel and smooth texture, making it a preferred choice for high-end fashion and upholstery. Its lightweight nature allows it to drape elegantly, enhancing the aesthetic appeal of garments and home textiles. B2B buyers should consider silk’s suitability for luxury goods where quality and visual impact are paramount. However, its higher cost and sensitivity to care can pose challenges, making it essential to evaluate the target market’s willingness to invest in premium materials.

How does Cotton Fabric serve various industries?

Cotton fabric is one of the most versatile materials available, known for its breathability and durability. It finds extensive applications in apparel, home textiles, and medical supplies due to its comfort and ease of maintenance. For B2B buyers, cotton’s cost-effectiveness and wide availability make it an attractive option, especially for mass production. However, while cotton is durable, it may lack the luxurious feel of silk, which could be a consideration for brands targeting premium markets.

Why choose Polyester Fabric for specific applications?

Polyester fabric is recognized for its strength, wrinkle resistance, and moisture-wicking properties, making it ideal for sportswear and outdoor gear. Its durability and low cost appeal to B2B buyers looking for reliable materials for high-performance applications. While polyester offers practical benefits, it is less breathable compared to natural fibers and may feel less comfortable against the skin. This trade-off should be considered when selecting fabrics for specific uses, especially in climates where breathability is crucial.

What makes Linen Fabric a unique choice for buyers?

Linen fabric is valued for its natural, breathable qualities and textured appearance, making it an excellent choice for summer apparel and home textiles. Its eco-friendly nature appeals to environmentally conscious brands. For B2B buyers, linen’s ability to keep cool in warm climates is a significant advantage, particularly in regions with hot weather. However, linen is prone to wrinkling and can be stiff, which may limit its appeal for certain applications where a softer drape is desired.

How does Rayon Fabric fit into the fabric landscape?

Rayon fabric is soft, absorbent, and drapes beautifully, making it a popular choice for fashion and linings. Its versatility allows it to mimic the feel of silk at a lower price point, which is attractive for B2B buyers in the fashion industry. However, rayon can shrink and requires careful washing, which may pose challenges for manufacturers. Understanding these characteristics is essential for buyers to ensure they meet customer expectations while managing production processes effectively.

Key Industrial Applications of fabric china

| Industry/Sector | Specific Application of fabric china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Textiles and Apparel | Fashion and Clothing Manufacturing | High-quality, diverse fabrics for various styles | Compliance with local regulations and standards |

| Home Décor | Upholstery and Furnishings | Durable and stylish fabrics for home interiors | Fabric durability and maintenance requirements |

| Automotive | Interior Upholstery and Covers | Lightweight, flame-retardant fabrics for safety | Safety certifications and environmental impact |

| Industrial and Safety | Workwear and Protective Clothing | Enhanced safety features and comfort | Certification for safety standards and performance |

| Medical and Healthcare | Medical Textiles and Uniforms | Biocompatibility and easy sterilization | Compliance with health regulations and certifications |

How is ‘fabric china’ Used in the Textiles and Apparel Industry?

In the textiles and apparel sector, ‘fabric china‘ is utilized for producing high-quality garments that cater to diverse fashion trends. The rich variety of textiles, from cotton to silk, allows manufacturers to create unique designs. Buyers from Africa and South America should focus on sourcing fabrics that comply with local fashion standards while ensuring ethical production practices are followed. Furthermore, understanding the supply chain dynamics in China will help mitigate risks related to delays and quality inconsistencies.

What Role Does ‘fabric china’ Play in Home Décor?

In home décor, ‘fabric china’ is essential for upholstery and furnishings. The fabrics are designed to be both durable and aesthetically appealing, making them suitable for a range of interior design styles. International buyers, particularly from Europe and the Middle East, should consider the fabric’s resistance to wear and tear, as well as its ease of cleaning. Sourcing from reliable manufacturers that offer a variety of patterns and textures can enhance the overall appeal of home products.

How is ‘fabric china’ Integrated into the Automotive Sector?

The automotive industry utilizes ‘fabric china’ for interior upholstery and covers, prioritizing lightweight materials that do not compromise safety. Flame-retardant properties are particularly important for meeting safety regulations. B2B buyers from Europe and Australia should ensure that the fabrics sourced meet local automotive standards and certifications. Additionally, evaluating the environmental impact of fabric production is becoming increasingly vital in this sector.

What are the Benefits of ‘fabric china’ in Industrial and Safety Applications?

In the industrial sector, ‘fabric china’ is used in workwear and protective clothing, providing enhanced safety features such as fire resistance and durability. Businesses benefit from sourcing high-quality fabrics that ensure worker safety and comfort. Buyers from Africa and South America should prioritize suppliers that comply with international safety standards and can provide certifications. Understanding the specific safety requirements for different industries will aid in selecting the right fabric.

How is ‘fabric china’ Utilized in Medical and Healthcare Applications?

In the medical field, ‘fabric china’ is used for medical textiles and uniforms, where biocompatibility and ease of sterilization are crucial. These fabrics must meet stringent health regulations and standards, ensuring safety for patients and healthcare providers. International buyers, particularly from the Middle East and Europe, should focus on sourcing from manufacturers that guarantee compliance with health and safety certifications. Additionally, understanding the requirements for fabric durability and maintenance in healthcare settings is essential for effective sourcing.

Related Video: Banana Fibre Non Woven Fabric Machine

3 Common User Pain Points for ‘fabric china’ & Their Solutions

Scenario 1: Quality Assurance Challenges in Sourcing Fabric from China

The Problem: International B2B buyers often face significant hurdles when it comes to ensuring the quality of fabric sourced from China. Due to varying standards and practices across manufacturers, buyers may receive products that do not meet their specifications or quality expectations. This can lead to costly returns, production delays, and ultimately damage to their reputation in their respective markets, particularly in regions like Africa and South America where quality assurance processes may not be as robust.

The Solution: To mitigate quality issues, B2B buyers should implement a comprehensive sourcing strategy that includes detailed quality specifications and samples. Prior to placing a bulk order, it is advisable to request pre-production samples to evaluate the fabric’s texture, durability, and colorfastness. Additionally, engaging third-party inspection services can provide an objective assessment of the fabric quality before shipment. Establishing a clear communication channel with the manufacturer regarding quality expectations can also minimize misunderstandings. Buyers should consider using a standardized fabric testing protocol (such as ISO or ASTM standards) to ensure that the fabrics meet the required quality benchmarks.

Scenario 2: Navigating Language and Cultural Barriers in Transactions

The Problem: B2B buyers from Europe, Africa, and the Middle East often encounter language and cultural barriers when dealing with fabric suppliers in China. Miscommunication can lead to errors in orders, misunderstandings regarding product specifications, and frustration in negotiations. This challenge is exacerbated in sectors where precise fabric characteristics, such as weave type or color codes, are critical for meeting customer demands.

The Solution: To overcome these barriers, buyers should consider employing bilingual sourcing agents who understand both the fabric industry and the nuances of cross-cultural communication. Utilizing digital communication tools that facilitate translation can also help ensure clarity in discussions. When drafting contracts, it is essential to include detailed product descriptions and visual references, such as color swatches and fabric samples. Additionally, investing in training for the purchasing team on cultural differences and negotiation styles can enhance their effectiveness in dealing with suppliers.

Scenario 3: Supply Chain Disruptions and Delivery Delays

The Problem: Supply chain disruptions are a common pain point for B2B buyers sourcing fabric from China, particularly given the global challenges of logistics and transportation. Buyers may face unexpected delays in delivery, which can halt production schedules and impact their ability to fulfill customer orders on time. This issue is particularly pressing for businesses in South America and Africa, where logistics infrastructure may not be as developed.

The Solution: To address supply chain vulnerabilities, buyers should diversify their supplier base by establishing relationships with multiple manufacturers and logistics providers. Implementing a just-in-time inventory strategy can also help manage stock levels more effectively, reducing the risk of excess inventory during delays. Furthermore, leveraging technology such as supply chain management software can provide real-time visibility into order status and shipping conditions. Buyers should maintain open lines of communication with suppliers to receive timely updates about potential disruptions and proactively adjust their production plans accordingly. Additionally, considering alternative shipping routes or methods can help mitigate the risks associated with traditional shipping practices.

Strategic Material Selection Guide for fabric china

When selecting materials for fabric china, international B2B buyers must consider various factors that influence the performance, cost, and suitability of the fabrics for their specific applications. Below is an analysis of four common materials used in fabric china, focusing on their properties, advantages, disadvantages, and considerations for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Cotton Fabric in Fabric China?

Cotton is a widely used material due to its natural properties and versatility. It has excellent breathability and moisture-wicking capabilities, making it suitable for various applications, including clothing and home textiles. Cotton can withstand moderate temperatures but may not perform well under extreme conditions.

Pros: Cotton is durable, easy to dye, and offers a soft feel, enhancing comfort for end users. It is also biodegradable, appealing to environmentally conscious buyers.

Cons: However, cotton is susceptible to shrinkage and can be prone to mildew if not properly cared for. Its cost can vary significantly based on quality, impacting overall pricing strategies.

Impact on Application: Cotton is compatible with a range of dyes and finishes, allowing for customization. However, it may not be suitable for high-performance applications requiring moisture or temperature resistance.

Considerations for Buyers: Buyers should ensure compliance with international standards such as Oeko-Tex for safety and environmental impact, particularly in markets sensitive to sustainability.

How Does Polyester Compare as a Fabric Material for China?

Polyester is a synthetic fabric known for its strength and resistance to shrinking and stretching. It performs well in various conditions, making it a popular choice for outdoor and performance textiles.

Pros: Polyester is highly durable, resistant to wrinkles, and dries quickly, which is advantageous for applications requiring moisture management. Its cost-effectiveness makes it appealing for mass production.

Cons: On the downside, polyester can be less breathable than natural fibers, which may lead to discomfort in warmer climates. Additionally, it is derived from petroleum, raising concerns about sustainability.

Impact on Application: Polyester is suitable for applications that require durability and resistance to environmental factors. However, it may not be the best choice for applications needing high breathability.

Considerations for Buyers: Compliance with standards such as ASTM for textile performance is crucial. Buyers should also consider the environmental regulations in their region, especially in Europe, where sustainability is a key focus.

What Are the Advantages and Disadvantages of Silk in Fabric China?

Silk is a luxurious natural fiber known for its softness and luster. It is often used in high-end textiles, including clothing and home décor.

Pros: Silk is lightweight, breathable, and has excellent draping qualities, making it ideal for elegant designs. It also has natural hypoallergenic properties.

Cons: However, silk is delicate and requires careful handling. It is prone to damage from sunlight and moisture, which can limit its applications.

Impact on Application: While silk is suitable for upscale markets, its fragility may restrict its use in everyday applications or environments with harsh conditions.

Considerations for Buyers: Buyers should be aware of the care requirements and ensure that their target markets appreciate the value of silk. Compliance with quality standards is essential for maintaining brand reputation.

How Does Linen Perform as a Fabric Material for China?

Linen is another natural fiber known for its strength and breathability. It is particularly valued in warmer climates due to its moisture-wicking properties.

Pros: Linen is highly durable and becomes softer with each wash, enhancing its appeal for long-term use. It also has a unique texture that adds aesthetic value to products.

Cons: The main drawback is that linen wrinkles easily, which may deter some buyers. It can also be more expensive than cotton, affecting price competitiveness.

Impact on Application: Linen is ideal for summer clothing and home textiles, but its tendency to wrinkle may limit its use in formal applications.

Considerations for Buyers: Buyers should consider the market demand for linen and its positioning as a premium product. Compliance with international textile standards is also important to ensure quality.

Summary Table of Material Selection for Fabric China

| Material | Typical Use Case for fabric china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cotton | Clothing, home textiles | Breathability and comfort | Susceptible to shrinkage | Medium |

| Polyester | Outdoor gear, performance textiles | Durability and quick-drying | Less breathable | Low |

| Silk | High-end clothing, luxury items | Softness and elegance | Delicate and requires care | High |

| Linen | Summer clothing, home décor | Strength and moisture-wicking | Wrinkles easily | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions based on the properties, advantages, and limitations of each fabric type. Understanding these factors can enhance product offerings and align with market demands across diverse regions.

In-depth Look: Manufacturing Processes and Quality Assurance for fabric china

What Are the Main Stages in the Manufacturing Process of Fabric in China?

The manufacturing of fabric in China involves several critical stages, each crucial for achieving high-quality end products. Understanding these stages can help international B2B buyers make informed decisions when sourcing fabric.

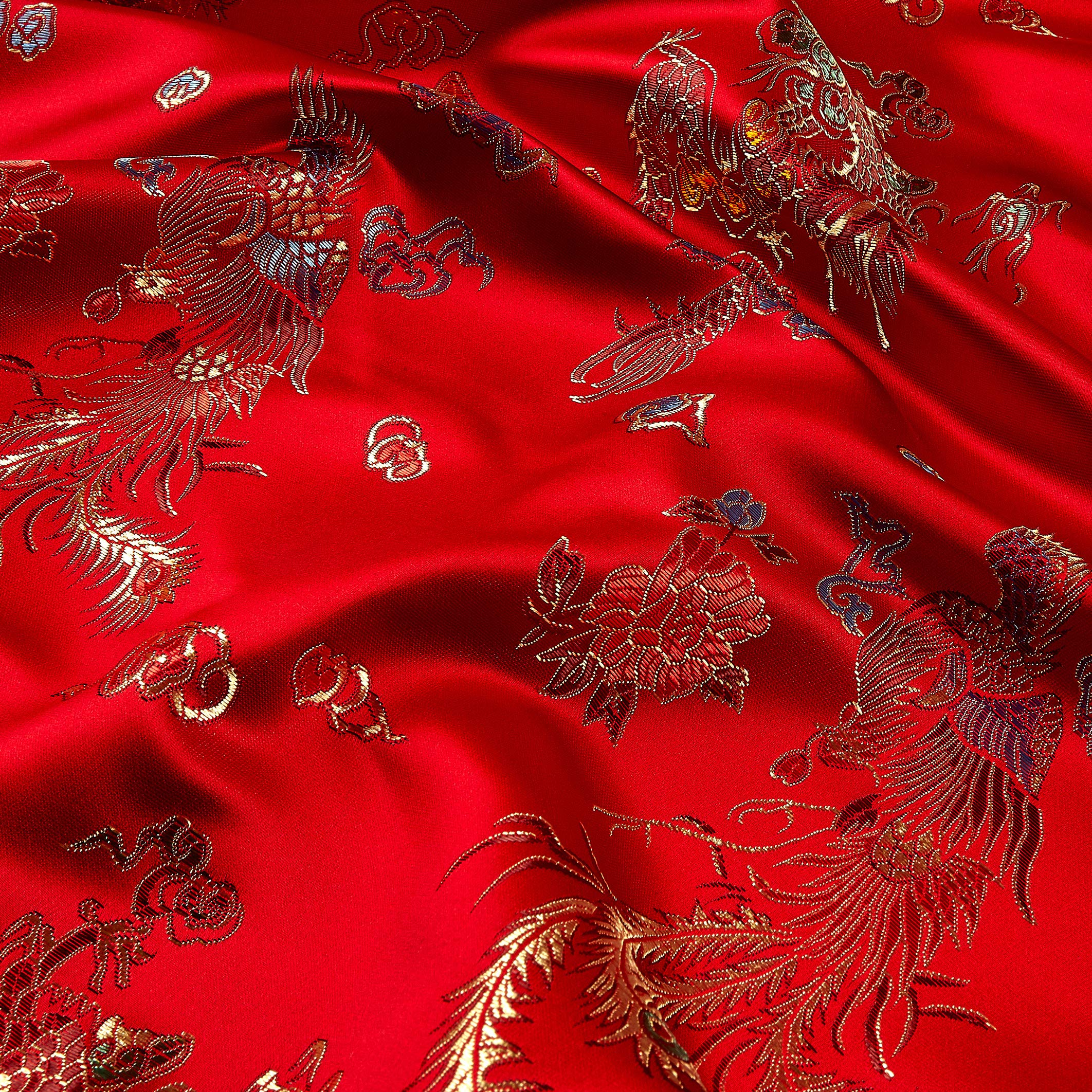

A stock image related to fabric china.

-

Material Preparation

– Fiber Selection: The process begins with selecting the appropriate fibers, such as cotton, polyester, or blends. Buyers should consider the properties required for their end products, such as durability, texture, and cost.

– Spinning: Fibers are spun into yarn, which can vary in thickness and strength. Spinning methods, such as ring spinning or open-end spinning, influence the fabric’s texture and durability.

– Dyeing and Finishing: Pre-treatment processes, including bleaching and dyeing, prepare the yarn for weaving. Chemical treatments can enhance colorfastness and resistance to environmental factors. -

Forming

– Weaving and Knitting: Depending on the desired fabric type, yarns are woven or knitted. Weaving techniques (e.g., plain, twill, satin) create different patterns and textures, while knitting provides stretch and flexibility.

– Non-Woven Fabrics: For specific applications, non-woven techniques, such as bonding and felting, are used to create fabrics without the traditional weaving process. -

Assembly

– Cutting: Once the fabric is produced, it is cut according to specifications. This stage requires precision to ensure minimal waste and adherence to design patterns.

– Sewing and Finishing: Final assembly includes sewing the fabric into desired shapes or products. Additional finishing processes, such as steaming or pressing, enhance the fabric’s appearance and performance. -

Finishing

– Coating and Laminating: Fabrics may undergo additional treatments to impart specific qualities, such as water resistance or increased strength. These processes are essential for technical textiles used in various industries.

How Is Quality Assurance Implemented in the Fabric Manufacturing Process?

A stock image related to fabric china.

Quality assurance (QA) is a pivotal aspect of fabric manufacturing, ensuring products meet international standards and customer expectations. The following outlines the key quality control measures in place during the manufacturing process.

-

International Standards for Quality Assurance

– ISO 9001: This widely recognized standard focuses on quality management systems and is essential for manufacturers aiming to enhance customer satisfaction and operational efficiency. Buyers should verify that their suppliers are ISO 9001 certified.

– Industry-Specific Certifications: Depending on the application, certifications like CE (for products sold in Europe) or API (for petroleum industry textiles) may be relevant. Buyers should inquire about these certifications to ensure compliance with regional regulations. -

Quality Control Checkpoints

– Incoming Quality Control (IQC): This initial checkpoint assesses raw materials for defects before production. Buyers should request IQC reports to confirm the quality of the inputs.

– In-Process Quality Control (IPQC): During manufacturing, IPQC monitors the production process for adherence to specifications. Regular inspections can catch defects early, reducing waste and rework.

– Final Quality Control (FQC): Once production is complete, FQC evaluates the finished products against quality standards. Buyers can request FQC reports and samples for inspection before shipment. -

Common Testing Methods for Fabrics

– Physical Tests: These include tensile strength, abrasion resistance, and colorfastness tests. Buyers should inquire about the specific tests conducted and their results.

– Chemical Tests: Tests for harmful substances, such as formaldehyde or heavy metals, ensure compliance with health and safety regulations. Certifications like Oeko-Tex Standard 100 indicate that fabrics are free from harmful chemicals.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must take proactive steps to verify the quality control practices of their fabric suppliers. Here are some strategies to ensure quality assurance in the sourcing process.

-

Conducting Supplier Audits

– On-site audits allow buyers to evaluate the manufacturing processes, quality control systems, and compliance with standards. This firsthand inspection provides insights into the supplier’s operations and commitment to quality. -

Requesting Quality Reports and Documentation

– Buyers should ask for detailed quality reports, including IQC, IPQC, and FQC documentation. This transparency helps buyers assess the supplier’s quality assurance processes. -

Engaging Third-Party Inspection Services

– Third-party inspection services can conduct independent evaluations of suppliers’ quality control practices. This adds a layer of credibility to the quality assurance claims made by suppliers.

What Are the Nuances of Quality Control for International B2B Buyers?

International B2B buyers must navigate specific nuances when dealing with quality control in fabric manufacturing, especially from regions like Africa, South America, the Middle East, and Europe.

-

Understanding Regional Standards and Regulations

– Different regions may have varying quality standards and regulations. For example, fabrics sold in Europe must comply with REACH regulations concerning chemical safety. Buyers should familiarize themselves with these requirements to avoid compliance issues. -

Cultural Considerations in Quality Assurance

– Cultural differences can influence quality perceptions and practices. Buyers should engage in open communication with suppliers to align expectations regarding quality standards and practices. -

Building Long-term Relationships with Suppliers

– Establishing strong relationships with suppliers fosters better communication and collaboration on quality issues. Long-term partnerships can lead to improved quality control as suppliers become more attuned to the buyer’s specific needs and standards.

In conclusion, understanding the manufacturing processes and quality assurance measures in fabric production in China is vital for international B2B buyers. By focusing on the manufacturing stages, implementing robust quality control practices, and actively verifying supplier standards, buyers can secure high-quality fabric products that meet their specific requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fabric china’

In today’s competitive global market, sourcing high-quality fabric from China can significantly enhance your product offerings. This practical sourcing guide serves as a comprehensive checklist for international B2B buyers from Africa, South America, the Middle East, and Europe, ensuring a streamlined procurement process.

Step 1: Define Your Technical Specifications

Understanding your fabric needs is critical. Clearly outline the technical specifications required for your products, such as fabric type (cotton, polyester, silk), weight, color, and any specific finishes. This clarity helps suppliers provide accurate quotes and ensures you receive the right materials.

- Considerations: Are there specific industry standards or certifications your fabric must meet? Document these requirements to facilitate a smoother sourcing process.

Step 2: Research and Identify Reputable Suppliers

Conduct thorough research on potential suppliers. Use platforms like Alibaba, Global Sources, or industry-specific directories to compile a list of manufacturers. Look for suppliers with a proven track record and positive reviews from international buyers.

- Tip: Focus on suppliers that specialize in your required fabric type, as they are more likely to understand your needs and offer tailored solutions.

Step 3: Evaluate Potential Suppliers

Before committing, vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; a comprehensive evaluation can save you from potential pitfalls.

- Verification: Look for third-party audits or certifications, such as ISO or Oeko-Tex, which can indicate a supplier’s commitment to quality and sustainability.

Step 4: Request Samples and Conduct Quality Checks

Always request fabric samples before placing a bulk order. This step allows you to assess the quality, texture, and color accuracy firsthand. It also provides an opportunity to check for defects or inconsistencies.

- Follow-Up: Ensure that the samples reflect the specifications outlined in your initial discussions. If possible, conduct tests such as colorfastness and durability to verify quality.

Step 5: Negotiate Terms and Conditions

Engage in clear negotiations regarding pricing, payment terms, and delivery schedules. Establishing transparent terms is vital for fostering a positive supplier relationship. Be upfront about your budget and any limitations.

- Consider: Discuss potential discounts for bulk orders, payment methods (e.g., Letter of Credit, PayPal), and the implications of delays in delivery.

Step 6: Finalize Contracts and Agreements

Once satisfied, draft a formal contract. This document should outline all agreed-upon terms, including product specifications, pricing, delivery timelines, and penalties for non-compliance. A well-structured contract protects both parties and clarifies expectations.

- Legal Review: If possible, have the contract reviewed by a legal professional familiar with international trade to ensure compliance with relevant laws and regulations.

Step 7: Establish a Communication Plan

Maintaining open lines of communication is essential throughout the sourcing process. Set regular check-in points to discuss progress, address any issues, and ensure both parties are aligned.

- Tools: Utilize communication tools like WhatsApp, WeChat, or email to facilitate quick and effective discussions, especially considering time zone differences.

By following this checklist, international B2B buyers can navigate the complexities of sourcing fabric from China, ensuring a successful procurement process that meets their business needs.

Comprehensive Cost and Pricing Analysis for fabric china Sourcing

What Are the Key Cost Components in Fabric Sourcing from China?

When sourcing fabric from China, understanding the cost structure is crucial for international B2B buyers. The major cost components include:

-

Materials: The type of fabric significantly impacts cost. Natural fibers like cotton or silk tend to be more expensive than synthetic options. Buyers should evaluate material quality against their budget.

-

Labor: Labor costs in China are relatively lower compared to Western countries, but they vary by region and the complexity of the manufacturing process. Skilled labor for intricate designs or high-quality fabrics can drive up costs.

-

Manufacturing Overhead: This includes factory costs, utilities, and administrative expenses. Efficient manufacturing processes can reduce these costs, making it essential to select suppliers with streamlined operations.

-

Tooling: Custom tooling for unique designs or specifications can represent a significant upfront cost. Buyers should consider whether the tooling costs can be amortized over larger orders to justify the investment.

-

Quality Control (QC): Implementing stringent QC measures is vital to ensure product quality. This can add to costs but is essential for maintaining standards, especially for buyers from markets with strict quality regulations.

-

Logistics: Shipping costs can vary greatly based on volume and destination. Understanding Incoterms (International Commercial Terms) is crucial, as they dictate who is responsible for shipping, insurance, and tariffs.

-

Margin: Suppliers will add a margin to cover their costs and profit. Understanding market rates can help buyers negotiate better terms.

How Do Price Influencers Affect Fabric Costs in China?

Several factors can influence pricing when sourcing fabric from China:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should assess their needs carefully to avoid excess inventory.

-

Specifications and Customization: Customized fabrics with unique designs or specifications will generally cost more. Clear communication about requirements can help manage costs.

-

Materials and Quality Certifications: Fabrics that require certifications (e.g., organic, eco-friendly) can incur additional costs. Buyers should weigh the benefits against the higher price tag.

-

Supplier Factors: Supplier reputation, experience, and reliability can impact pricing. Conducting thorough due diligence can help buyers find suppliers that offer good value for money.

-

Incoterms: The choice of Incoterms can affect total costs, including shipping and insurance. Familiarizing oneself with these terms can prevent unexpected expenses.

What Buyer Tips Can Help Optimize Costs When Sourcing Fabric from China?

International B2B buyers can leverage several strategies to optimize their sourcing costs:

-

Effective Negotiation: Building a strong relationship with suppliers can lead to better negotiation outcomes. Discussing long-term partnerships or larger orders can provide leverage for lower prices.

-

Cost-Efficiency: Analyze the Total Cost of Ownership (TCO) rather than just the initial purchase price. This includes factoring in shipping, customs, and potential wastage during production.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and tariffs that can impact overall costs. Understanding local regulations can also prevent costly compliance issues.

-

Market Research: Regularly conduct market research to stay updated on fabric trends and pricing changes. This knowledge can help in making informed purchasing decisions.

Disclaimer on Pricing

While this analysis provides a framework for understanding costs associated with fabric sourcing from China, prices may vary based on specific requirements, supplier negotiations, and market conditions. Buyers are encouraged to conduct their own market research and obtain quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing fabric china With Other Solutions

Understanding Alternatives to Fabric China

When sourcing materials for manufacturing or production, B2B buyers often face the challenge of selecting the best solution that balances performance, cost, and implementation ease. Fabric China is a popular choice due to its quality and variety, but there are several alternatives worth considering. This analysis will compare Fabric China with two viable alternatives: Synthetic Fabrics and Organic Cotton. Each alternative offers distinct advantages and disadvantages depending on the specific needs of the buyer.

Comparison Table of Fabric China and Alternatives

| Comparison Aspect | Fabric China | Synthetic Fabrics | Organic Cotton |

|---|---|---|---|

| Performance | High durability and variety | Excellent durability, water-resistant | Soft and breathable, but less durable |

| Cost | Moderate to high | Low to moderate | Moderate to high |

| Ease of Implementation | Requires quality checks | Easy to source and produce | Requires certification and sourcing |

| Maintenance | Low maintenance, machine washable | Low maintenance, easy care | Moderate, requires specific care |

| Best Use Case | Fashion and upholstery | Sportswear and outdoor gear | Eco-friendly fashion and textiles |

What Are the Pros and Cons of Synthetic Fabrics?

Synthetic fabrics, such as polyester and nylon, are widely used in various industries due to their affordability and durability. These materials are water-resistant, making them ideal for outdoor and sportswear applications. However, while they offer excellent performance and low maintenance, synthetic fabrics are derived from petroleum, raising environmental concerns. Additionally, they may not provide the same level of comfort as natural fibers, which could be a drawback for certain applications, particularly in fashion where feel and breathability are paramount.

How Does Organic Cotton Compare?

Organic cotton is another alternative that has gained popularity, especially among environmentally conscious brands. This natural fiber is grown without synthetic pesticides and fertilizers, making it a sustainable choice. It offers softness and breathability, which are highly valued in consumer textiles. However, organic cotton can be more expensive and requires careful handling to maintain its quality. It is less durable compared to synthetic options, which may limit its use in high-wear applications. Therefore, it is best suited for eco-friendly fashion lines or products that prioritize comfort over durability.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right fabric solution depends on the specific requirements of your business and target market. If durability and cost-effectiveness are your primary concerns, synthetic fabrics might be the best choice. However, if you are looking to enhance your brand’s sustainability credentials, organic cotton could be the way forward. Fabric China remains a strong contender for those prioritizing quality and variety in textiles. Ultimately, understanding the unique advantages and limitations of each option will empower B2B buyers to make informed decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for fabric china

What Are the Key Technical Properties of Fabric China?

When sourcing fabric from China, international B2B buyers should familiarize themselves with several critical technical properties that impact product quality and usability. Understanding these specifications helps in making informed purchasing decisions.

-

Material Grade: This refers to the quality of the fabric, determined by factors such as fiber content, weave, and finish. For example, cotton, polyester, and blends each have distinct characteristics. Material grade affects durability, comfort, and cost, making it essential for buyers to specify their requirements clearly.

-

Tolerance: Tolerance indicates the acceptable variation in fabric dimensions, weight, and color. For instance, a 5% tolerance in width allows for slight discrepancies in production. Understanding tolerance is crucial for ensuring that the fabric meets the needs of specific applications, such as apparel or upholstery.

-

Thread Count: This metric measures the number of threads woven together per square inch of fabric. A higher thread count often signifies better quality and softness, which is particularly important for luxury textiles. Buyers should consider thread count when sourcing materials for high-end products.

-

Weight: Fabric weight is typically measured in grams per square meter (GSM). Heavier fabrics may be more suitable for outerwear or upholstery, while lighter fabrics are preferred for summer clothing. Knowing the weight helps buyers assess the fabric’s appropriateness for their intended use.

-

Abrasion Resistance: This property assesses how well the fabric withstands wear and tear. Fabrics with higher abrasion resistance are ideal for items subjected to frequent friction, such as workwear or upholstery. Buyers should inquire about this property to ensure longevity in their products.

What Trade Terminology Should B2B Buyers Understand When Sourcing Fabric from China?

Navigating the fabric trade requires familiarity with specific industry jargon. Here are essential terms that international buyers should know:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce goods based on the specifications provided by another company. In the fabric industry, buyers may work with OEMs to create custom designs or blends, allowing for unique product offerings.

-

MOQ (Minimum Order Quantity): MOQ indicates the smallest order size a supplier is willing to accept. Understanding MOQ is vital for buyers to ensure they can meet their production needs without incurring excessive costs or inventory.

-

RFQ (Request for Quotation): An RFQ is a document that buyers send to suppliers to request pricing information for specific products. Including detailed specifications in an RFQ ensures that suppliers provide accurate quotes, streamlining the procurement process.

-

Incoterms (International Commercial Terms): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Key Incoterms like FOB (Free On Board) and CIF (Cost, Insurance, and Freight) clarify who pays for shipping and insurance, impacting total costs.

-

Lead Time: This term refers to the time it takes from placing an order to receiving the goods. Understanding lead times is essential for inventory planning and ensuring that production schedules are met.

-

Sourcing Agent: A sourcing agent is an intermediary who assists buyers in finding suppliers, negotiating prices, and managing logistics. Utilizing a sourcing agent can help international buyers navigate the complexities of the Chinese fabric market more efficiently.

By grasping these essential technical properties and trade terminologies, international B2B buyers can enhance their procurement strategies and foster successful relationships with suppliers in China.

Navigating Market Dynamics and Sourcing Trends in the fabric china Sector

What Are the Key Market Dynamics and Sourcing Trends in the Fabric China Sector?

The fabric China sector is witnessing significant growth driven by globalization, technological advancements, and evolving consumer preferences. International B2B buyers, especially from Africa, South America, the Middle East, and Europe, are increasingly leveraging digital platforms for sourcing, leading to a more streamlined procurement process. The rise of e-commerce in B2B transactions has facilitated direct access to manufacturers, reducing intermediary costs and enhancing transparency.

Emerging trends such as smart textiles and sustainable fabrics are reshaping the market landscape. Buyers are now more inclined to seek innovative materials that integrate technology, such as moisture-wicking fabrics or textiles with embedded sensors. Moreover, the demand for customization is on the rise, with businesses looking for fabrics that can be tailored to specific applications or branding requirements.

Additionally, the geopolitical climate, including trade agreements and tariffs, significantly influences sourcing strategies. Buyers must stay informed about changes in policies that could impact supply chain dynamics, such as the ongoing trade tensions between major economies and their implications on pricing and availability of fabric products. Understanding these market dynamics is crucial for making informed sourcing decisions in the fabric China sector.

How Is Sustainability Impacting the Fabric China Sector?

Sustainability has become a critical focal point in the fabric China sector, as environmental concerns and ethical sourcing practices gain traction among B2B buyers. The textile industry is one of the largest polluters globally, prompting businesses to prioritize sustainable sourcing strategies. This shift is not just a trend but a necessity for companies aiming to meet regulatory requirements and consumer expectations for environmentally friendly products.

International buyers are increasingly seeking suppliers that offer ‘green’ certifications and sustainable materials, such as organic cotton, recycled polyester, and low-impact dyes. Certifications like Global Organic Textile Standard (GOTS) and OEKO-TEX® Standard 100 are becoming benchmarks for verifying the sustainability of textiles.

Moreover, ethical supply chains are a key consideration, with buyers wanting assurance that their sourcing practices do not exploit workers or harm local communities. As a result, companies that can demonstrate a commitment to ethical sourcing not only enhance their brand image but also gain a competitive edge in the global market. This focus on sustainability and ethics is reshaping the sourcing landscape, making it essential for buyers to align with suppliers that share these values.

What Is the Historical Context of the Fabric China Sector for B2B Buyers?

The fabric China sector has evolved significantly over the past few decades, transitioning from traditional textile manufacturing to a modern, technology-driven industry. Initially, China’s fabric production was heavily reliant on cheap labor, which positioned the country as the world’s leading textile exporter. However, as labor costs rose and consumer preferences shifted towards quality and sustainability, the industry began adapting.

In recent years, advancements in technology have revolutionized production processes, allowing for greater efficiency and innovation. The integration of automation and digital tools in manufacturing has enabled suppliers to respond quickly to market demands and customize products for buyers.

This evolution is particularly relevant for international B2B buyers who must navigate a landscape that is increasingly competitive and conscious of sustainability. Understanding the historical shifts within the fabric China sector can provide valuable insights into current sourcing trends and future opportunities. By aligning with suppliers that have embraced innovation and ethical practices, buyers can ensure a more resilient and responsible supply chain.

Frequently Asked Questions (FAQs) for B2B Buyers of fabric china

-

How do I ensure the quality of fabric sourced from China?

To ensure the quality of fabric sourced from China, start by thoroughly vetting suppliers. Request samples to assess the fabric’s texture, durability, and color fidelity. It’s also advisable to check for certifications such as ISO or Oeko-Tex, which indicate compliance with international standards. Establish a quality assurance process that includes inspections at various production stages. Additionally, consider hiring a third-party inspection agency to conduct pre-shipment inspections, ensuring that the final product meets your specifications before it arrives. -

What is the typical minimum order quantity (MOQ) for fabric from Chinese suppliers?

The typical minimum order quantity (MOQ) for fabric from Chinese suppliers can vary significantly based on the type of fabric and supplier. Generally, MOQs range from 100 to 1,000 meters. However, some manufacturers may offer lower MOQs for specific types of fabrics or when they have excess stock. It’s essential to communicate your needs clearly and negotiate MOQs that align with your purchasing capabilities, especially if you are a smaller business or a startup. -

What payment terms should I expect when sourcing fabric from China?

When sourcing fabric from China, payment terms typically include a 30% deposit upfront with the remaining 70% due before shipment. Some suppliers may offer flexible terms based on your relationship and order volume, such as letters of credit or extended payment terms. Always ensure that payment terms are clearly outlined in the contract to avoid misunderstandings. Additionally, consider using secure payment methods like PayPal or Alibaba Trade Assurance to protect your transaction. -

How can I customize fabric designs when sourcing from China?

Customizing fabric designs when sourcing from China is a straightforward process. Most suppliers offer design services where you can submit your artwork or specifications. Discuss your design requirements, including colors, patterns, and fabric types, during initial communications. Be prepared to provide detailed mock-ups or samples for clarity. Keep in mind that customization may involve higher costs and longer lead times, so factor this into your planning. -

What are the best practices for vetting fabric suppliers in China?

To effectively vet fabric suppliers in China, start by checking their business licenses and certifications to ensure legitimacy. Use platforms like Alibaba, Global Sources, or Made-in-China to read reviews and ratings from other buyers. Conduct video calls or site visits to assess their production facilities and capabilities. Additionally, ask for references from previous clients and verify their experiences. This thorough vetting process minimizes risks and enhances the likelihood of a successful partnership. -

What logistics considerations should I keep in mind when importing fabric from China?

When importing fabric from China, consider logistics factors such as shipping methods, lead times, and customs regulations. Choose between air freight for faster delivery or sea freight for cost-effective bulk shipping. Factor in the time required for customs clearance and ensure that all necessary documentation, including invoices and certificates of origin, is in order. Collaborating with a reliable freight forwarder can streamline the shipping process and help navigate any potential challenges. -

How do I handle disputes with Chinese fabric suppliers?

Handling disputes with Chinese fabric suppliers requires clear communication and documentation. Start by addressing the issue directly with the supplier, outlining your concerns and referencing any contractual agreements. If the situation does not improve, consider escalating the matter through platforms like Alibaba, which offer dispute resolution services. Always maintain a professional demeanor and be open to negotiation, as this can lead to a mutually beneficial resolution without damaging the relationship. -

What are the common fabric types available from Chinese manufacturers?

Chinese manufacturers offer a wide range of fabric types, including cotton, polyester, silk, linen, and blends. Specialty fabrics such as denim, lace, and technical textiles are also widely available. When sourcing, clearly define your requirements regarding fabric type, weight, and intended use. Suppliers can often recommend suitable options based on your specifications. Understanding the characteristics of each fabric type will help you make informed decisions that align with your product goals.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for fabric china

Why is Strategic Sourcing Crucial for International Fabric Buyers?

In conclusion, strategic sourcing remains a pivotal element for international B2B buyers looking to procure fabric from China. By understanding the complexities of the supply chain, buyers can leverage relationships with reputable suppliers, ensuring quality and reliability. Key takeaways include the importance of conducting thorough supplier evaluations, embracing technology for better visibility, and fostering long-term partnerships that can adapt to changing market dynamics.

How Can Buyers Prepare for Future Trends in Fabric Sourcing?

As we look to the future, it is essential for buyers from Africa, South America, the Middle East, and Europe to remain agile and responsive to emerging trends such as sustainable sourcing and digital transformation. Engaging in proactive risk management strategies and staying informed about geopolitical shifts will enable businesses to navigate challenges effectively.

What Steps Should Buyers Take to Enhance Their Sourcing Strategy?

To capitalize on the opportunities presented by the Chinese fabric market, international buyers should consider diversifying their supplier base and investing in local market insights. This approach not only mitigates risks but also enhances competitiveness in a rapidly evolving global landscape.

In summary, embracing a strategic sourcing mindset will empower buyers to optimize their procurement processes and drive sustainable growth. Now is the time to take action—evaluate your current sourcing strategies and explore the vast potential that fabric sourcing from China offers.