Discover Cost-Effective Solutions for Carbon Fiber Tubes China (2025)

Introduction: Navigating the Global Market for carbon fiber tubes china

The global market for carbon fiber tubes presents both exciting opportunities and significant challenges for international B2B buyers. Sourcing high-quality carbon fiber tubes from China can be particularly daunting, given the complexity of supplier selection, varying product specifications, and fluctuating market prices. This guide aims to demystify the process, offering a thorough exploration of the types of carbon fiber tubes available, their diverse applications across industries, and the crucial steps in vetting suppliers effectively.

By addressing key considerations such as material properties, manufacturing processes, and compliance with international standards, this guide equips buyers from regions like Africa, South America, the Middle East, and Europe—especially in emerging markets like Egypt and Saudi Arabia—with actionable insights to make informed purchasing decisions. Understanding the cost structures associated with carbon fiber tubes, including potential tariffs and shipping considerations, will further empower buyers to negotiate better deals and optimize their supply chain strategies.

In a marketplace characterized by rapid innovation and intense competition, having access to reliable information and expert guidance is essential. This comprehensive resource will serve as a crucial tool for navigating the intricacies of sourcing carbon fiber tubes from China, ultimately enhancing your business’s operational efficiency and product quality. Whether you’re seeking to innovate your product line or enhance your manufacturing capabilities, this guide will illuminate the path forward in the global carbon fiber market.

Understanding carbon fiber tubes china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Carbon Fiber Tubes | High tensile strength, lightweight, and corrosion-resistant | Aerospace, automotive, sports equipment | Pros: Excellent strength-to-weight ratio; Cons: May require specialized fittings. |

| Pultruded Carbon Fiber Tubes | Continuous fiber alignment, uniform cross-section | Construction, marine applications | Pros: High structural integrity; Cons: Limited diameter options. |

| Roll-wrapped Carbon Fiber Tubes | Customizable thickness, varied resin systems | Industrial machinery, robotics | Pros: Versatile design options; Cons: Potentially higher cost for customization. |

| Prepreg Carbon Fiber Tubes | Pre-impregnated fibers for consistent quality | High-performance applications (racing, aerospace) | Pros: Superior mechanical properties; Cons: Requires precise handling and curing. |

| Composite Carbon Fiber Tubes | Combination with other materials for enhanced properties | Electronics, medical devices | Pros: Tailored performance characteristics; Cons: Complexity in sourcing materials. |

What are Standard Carbon Fiber Tubes and Their B2B Relevance?

Standard carbon fiber tubes are characterized by their high tensile strength and lightweight nature, making them ideal for industries that prioritize performance. Commonly used in aerospace and automotive sectors, these tubes offer excellent resistance to corrosion. When purchasing, B2B buyers should consider the specific strength requirements and compatibility with existing components, as standard tubes may need specialized fittings to integrate seamlessly into existing systems.

How Do Pultruded Carbon Fiber Tubes Differ in Application?

Pultruded carbon fiber tubes are known for their continuous fiber alignment, which provides a uniform cross-section and high structural integrity. This makes them suitable for construction and marine applications, where strength and durability are paramount. Buyers should evaluate the diameter options available, as pultruded tubes may have limitations in size, impacting their suitability for certain projects.

What Makes Roll-Wrapped Carbon Fiber Tubes Versatile?

Roll-wrapped carbon fiber tubes offer customizable thickness and varied resin systems, catering to a wide range of industrial applications, including machinery and robotics. The ability to tailor the design to specific needs makes them a popular choice among manufacturers. However, buyers should be mindful of the potentially higher costs associated with customization and the need for precise specifications to ensure optimal performance.

Why Choose Prepreg Carbon Fiber Tubes for High-Performance Needs?

Prepreg carbon fiber tubes utilize pre-impregnated fibers, which ensure consistent quality and superior mechanical properties. These tubes are often found in high-performance applications such as racing and aerospace, where material reliability is crucial. B2B buyers should be aware that handling and curing these tubes require precision and expertise, which can affect lead times and production schedules.

How Do Composite Carbon Fiber Tubes Enhance Performance?

Composite carbon fiber tubes combine carbon fiber with other materials to enhance specific properties, making them suitable for electronics and medical devices. The tailored performance characteristics can meet unique application demands, but buyers should consider the complexity of sourcing materials and the potential for increased costs. Understanding the required specifications and the intended use will help in making informed purchasing decisions.

Related Video: How To Make Carbon Fiber Tubes – 4 different techniques (Tutorial)

Key Industrial Applications of carbon fiber tubes china

| Industry/Sector | Specific Application of carbon fiber tubes china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace and Aviation | Structural components in aircraft and drones | Lightweight properties enhance fuel efficiency and payload capacity | Compliance with aviation safety standards and certifications |

| Automotive | High-performance racing and luxury vehicle components | Improved strength-to-weight ratio enhances performance and handling | Material specifications and customization options |

| Sports and Recreation | Manufacturing of bicycles and sports equipment | Increased durability and reduced weight improve user experience | Supplier reputation and material quality assurance |

| Medical Devices | Production of prosthetics and surgical instruments | Enhanced biocompatibility and strength lead to better patient outcomes | Regulatory compliance and material certifications |

| Construction and Infrastructure | Reinforcement in construction materials | Increased tensile strength and durability for long-lasting structures | Sourcing from certified suppliers and material traceability |

How Are Carbon Fiber Tubes Used in Aerospace and Aviation Applications?

In the aerospace sector, carbon fiber tubes are utilized in the construction of structural components for aircraft and drones. Their lightweight nature significantly reduces overall aircraft weight, which enhances fuel efficiency and allows for increased payload capacity. For international buyers, particularly from regions like the Middle East and Europe, it’s essential to ensure that the sourced materials comply with stringent aviation safety standards and certifications, as these can vary by region and impact overall project timelines.

What Are the Benefits of Carbon Fiber Tubes in the Automotive Industry?

In the automotive industry, carbon fiber tubes are integral to high-performance racing and luxury vehicles. They contribute to a superior strength-to-weight ratio, which enhances performance, acceleration, and handling. Buyers from Africa and South America should focus on specific material specifications and customization options to meet their unique vehicle requirements, as well as consider the supplier’s ability to provide ongoing support for automotive applications.

How Do Carbon Fiber Tubes Enhance Sports and Recreation Equipment?

For the sports and recreation industry, carbon fiber tubes are widely used in bicycles and various sports equipment. Their increased durability and reduced weight provide a significant advantage, improving user experience and performance. International buyers should prioritize supplier reputation and material quality assurance to ensure that the products meet the high-performance standards expected in competitive sports.

What Role Do Carbon Fiber Tubes Play in Medical Devices?

In the medical device sector, carbon fiber tubes are essential for creating prosthetics and surgical instruments. Their enhanced biocompatibility and strength lead to better patient outcomes and longer-lasting devices. Buyers from regions such as Africa and the Middle East must ensure that their suppliers adhere to regulatory compliance and material certifications to guarantee the safety and efficacy of medical products.

How Are Carbon Fiber Tubes Used in Construction and Infrastructure?

In construction and infrastructure, carbon fiber tubes are employed as reinforcements in various building materials. Their ability to increase tensile strength and durability makes them invaluable for long-lasting structures. For B2B buyers in Europe and South America, it is crucial to source from certified suppliers who can provide material traceability and demonstrate compliance with local building codes and regulations.

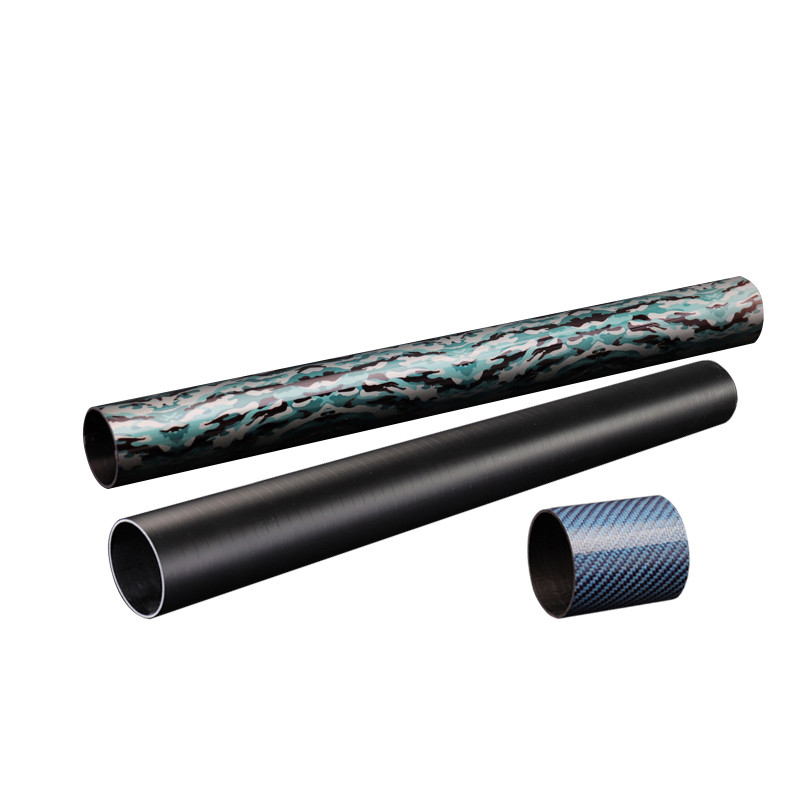

A stock image related to carbon fiber tubes china.

3 Common User Pain Points for ‘carbon fiber tubes china’ & Their Solutions

Scenario 1: Quality Assurance Challenges in Sourcing Carbon Fiber Tubes from China

The Problem: Many B2B buyers experience significant challenges in ensuring the quality of carbon fiber tubes sourced from China. Given the diverse manufacturing standards and the prevalence of counterfeit products, buyers often find themselves receiving materials that do not meet their specifications or industry standards. This can lead to project delays, increased costs for replacements, and ultimately, damage to their reputation in the market.

The Solution: To mitigate quality assurance issues, it is crucial for buyers to engage in thorough due diligence when selecting suppliers. Start by requesting samples of carbon fiber tubes before placing bulk orders. This allows for firsthand evaluation of the material’s properties, including tensile strength and weight. Additionally, consider partnering with third-party inspection services that can conduct quality checks at the manufacturing facility. Utilize platforms like Alibaba or Global Sources to access verified suppliers and read reviews from previous clients. Establishing clear communication regarding quality expectations and performance standards in the purchase agreement will also help ensure that the products meet your specifications.

Scenario 2: Navigating Shipping and Customs Complications

The Problem: International buyers often face logistical hurdles when importing carbon fiber tubes from China, including shipping delays and customs clearance issues. These challenges can lead to extended lead times, which can jeopardize project schedules and increase operational costs. Furthermore, mismanagement of shipping documentation can result in additional tariffs or even confiscation of goods.

The Solution: To streamline the shipping and customs process, it’s vital to work closely with logistics experts who specialize in international trade. Establish a reliable freight forwarder who can guide you through the complexities of shipping regulations and customs procedures specific to your region (e.g., Africa, South America, the Middle East, or Europe). Ensure that all shipping documents, including commercial invoices and packing lists, are accurately prepared and comply with the destination country’s regulations. Additionally, consider using Incoterms (International Commercial Terms) to clarify responsibilities related to shipping costs and risks, which can prevent misunderstandings with your supplier.

Scenario 3: Understanding Technical Specifications and Compatibility

The Problem: B2B buyers often struggle with understanding the technical specifications of carbon fiber tubes, including sizing, types of resin used, and compatibility with existing systems or products. This lack of clarity can result in selecting the wrong type of tube, leading to performance issues or increased costs for modifications.

The Solution: To effectively navigate technical specifications, buyers should invest time in researching the different types of carbon fiber tubes available and their specific applications. Create a checklist of required specifications, such as diameter, wall thickness, and resin type, based on your project needs. Engaging with technical representatives from the supplier can provide valuable insights into the best options for your specific application. Furthermore, consider collaborating with engineers or material scientists who can provide guidance on material compatibility and performance expectations. Utilizing online forums and industry groups can also yield useful advice and best practices from other buyers who have faced similar challenges.

Strategic Material Selection Guide for carbon fiber tubes china

When selecting materials for carbon fiber tubes manufactured in China, international B2B buyers must consider various factors that impact performance, cost, and application suitability. Below is an analysis of four common materials used in the production of carbon fiber tubes, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Carbon Fiber Composites?

1. Carbon Fiber Reinforced Polymer (CFRP)

CFRP is a composite material that combines carbon fibers with a polymer matrix, typically epoxy. This combination provides exceptional strength-to-weight ratios, making CFRP ideal for applications requiring lightweight yet strong components. It exhibits high corrosion resistance and can withstand temperatures up to 120°C, depending on the resin used.

Pros:

– Excellent mechanical properties, including high tensile strength and stiffness.

– Lightweight, which reduces overall project weight and improves efficiency.

– Corrosion-resistant, suitable for harsh environments.

Cons:

– Higher manufacturing complexity can lead to increased costs.

– Limited impact resistance compared to metals, necessitating careful handling.

Impact on Application:

CFRP is widely used in aerospace, automotive, and sporting goods industries where weight savings and strength are critical. Its compatibility with various media makes it suitable for diverse applications.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM D3039 for tensile properties. Understanding local regulations regarding material safety and environmental impact is crucial, especially in regions like the Middle East and Europe.

2. Glass Fiber Reinforced Polymer (GFRP)

GFRP utilizes glass fibers instead of carbon fibers, offering a cost-effective alternative for many applications. It has good tensile strength and is resistant to chemical corrosion, making it suitable for various industrial applications.

Pros:

– Lower cost compared to CFRP, making it accessible for budget-conscious projects.

– Good corrosion resistance, particularly in chemical applications.

– Easier to manufacture, leading to lower production costs.

Cons:

– Heavier than CFRP, which may not be suitable for weight-sensitive applications.

– Lower strength-to-weight ratio, potentially limiting performance in high-stress environments.

Impact on Application:

GFRP is commonly used in construction, marine, and electrical applications where corrosion resistance is vital but weight is less of a concern.

Considerations for International Buyers:

Buyers should be aware of standards such as ASTM D638 for tensile properties and ensure that GFRP meets local compliance requirements, particularly in South America and Africa, where regulations may vary.

3. Aluminum Composite Material (ACM)

ACM combines aluminum with a polymer core, providing a lightweight yet sturdy option. While not a pure carbon fiber tube, it is often used in applications where carbon fiber might be overkill.

Pros:

– Good strength-to-weight ratio, making it versatile for various applications.

– Cost-effective compared to pure carbon fiber solutions.

– Easy to fabricate and machine.

Cons:

– Lower corrosion resistance compared to CFRP and GFRP.

– Limited temperature resistance, which may restrict its use in high-heat environments.

Impact on Application:

ACM is often used in signage, architectural applications, and transportation where a balance of weight, cost, and durability is required.

Considerations for International Buyers:

Buyers should check compliance with standards like ASTM B209 for aluminum alloys and be aware of specific regional preferences, especially in Europe and the Middle East.

4. Thermoplastic Carbon Fiber Composites

These composites utilize thermoplastic matrices, providing advantages in terms of recyclability and processing speed. They are gaining traction in industries looking for sustainable options.

Pros:

– Recyclable, appealing to environmentally conscious buyers.

– Faster processing times compared to thermoset composites.

– Good impact resistance, enhancing durability.

Cons:

– Generally higher costs due to advanced manufacturing techniques.

– Limited high-temperature performance compared to thermoset composites.

Impact on Application:

Thermoplastic composites are increasingly used in automotive and aerospace applications where sustainability and performance are prioritized.

Considerations for International Buyers:

Understanding the specific thermoplastic standards (like ISO 527 for tensile properties) is essential, particularly for buyers in Europe where sustainability regulations are stringent.

Summary Table of Material Selection for Carbon Fiber Tubes

| Material | Typical Use Case for carbon fiber tubes china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Fiber Reinforced Polymer (CFRP) | Aerospace, automotive, sporting goods | Exceptional strength-to-weight ratio | Higher manufacturing complexity | High |

| Glass Fiber Reinforced Polymer (GFRP) | Construction, marine, electrical | Lower cost, good corrosion resistance | Heavier than CFRP | Medium |

| Aluminum Composite Material (ACM) | Signage, architectural, transportation | Good strength-to-weight ratio | Lower corrosion resistance | Medium |

| Thermoplastic Carbon Fiber Composites | Automotive, aerospace | Recyclable, faster processing | Limited high-temperature performance | High |

This guide provides a comprehensive overview of material options for carbon fiber tubes manufactured in China, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for carbon fiber tubes china

What Are the Main Stages in the Manufacturing Process of Carbon Fiber Tubes in China?

The manufacturing process for carbon fiber tubes in China typically involves several key stages: material preparation, forming, assembly, and finishing. Understanding these stages is crucial for international B2B buyers seeking high-quality products.

-

Material Preparation: The process begins with the selection of carbon fiber pre-preg (pre-impregnated) materials or raw carbon fibers. Manufacturers often use high-quality epoxy resins to ensure optimal bonding and strength. Proper storage and handling of these materials are essential to prevent degradation.

-

Forming: This stage involves shaping the carbon fiber into tubes using techniques such as filament winding or braiding. Filament winding is particularly popular due to its ability to create tubes with specific mechanical properties by adjusting the fiber orientation. In contrast, braiding offers a more uniform distribution of fibers, which can enhance the structural integrity of the final product.

-

Assembly: After forming, the tubes may require further assembly, especially if they are part of a more complex structure or product. This can involve joining multiple tubes or integrating them with other components. Specialized adhesives or bonding techniques are typically employed to ensure a strong and durable connection.

-

Finishing: The final stage includes surface finishing, which may involve sanding, coating, or painting the tubes. This not only enhances aesthetic appeal but also provides additional protection against environmental factors. Quality finishing is vital for applications in industries such as aerospace and automotive, where performance and appearance are both critical.

How Is Quality Assurance Implemented in Carbon Fiber Tube Manufacturing?

Quality assurance (QA) is paramount in the manufacturing of carbon fiber tubes, particularly for international markets. Companies often adhere to international standards, such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards helps ensure consistency, reliability, and customer satisfaction.

What International Standards Should B2B Buyers Consider for Carbon Fiber Tubes?

International B2B buyers should be aware of various quality certifications that manufacturers may hold. Aside from ISO 9001, industry-specific certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for oil and gas applications can be critical. These certifications demonstrate compliance with safety and performance standards, which are essential for ensuring product reliability.

What Are the Key Quality Control Checkpoints in Carbon Fiber Tube Manufacturing?

Quality control (QC) is integrated throughout the manufacturing process, with specific checkpoints established to catch defects early. The main QC checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards. For carbon fiber tubes, this might include checking the tensile strength and elasticity of the fibers.

-

In-Process Quality Control (IPQC): During the manufacturing stages, ongoing inspections are conducted to monitor production processes. This helps identify any deviations from established procedures or specifications early in the process.

-

Final Quality Control (FQC): Once the manufacturing process is complete, a comprehensive inspection of the finished products is performed. This can involve dimensional checks, visual inspections, and mechanical testing to confirm that the tubes meet the required standards and specifications.

What Common Testing Methods Are Used for Quality Assurance in Carbon Fiber Tubes?

Several testing methods are commonly employed to assess the quality of carbon fiber tubes. These include:

- Tensile Testing: This measures the strength and ductility of the material, ensuring that it can withstand the required loads in its intended application.

- Impact Testing: This evaluates the material’s resistance to sudden forces, which is critical for applications in dynamic environments.

- Ultrasonic Testing: A non-destructive testing method that detects internal flaws or inconsistencies in the material, ensuring structural integrity.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, verifying a supplier’s quality control processes is essential to mitigate risks associated with sourcing. Here are several strategies:

-

Conduct Audits: Regular audits of potential suppliers can provide insight into their manufacturing practices and quality control measures. This can include reviewing their certifications and compliance with international standards.

-

Request Quality Reports: Suppliers should be able to provide detailed quality reports and testing results. These documents should outline the methodologies used and the outcomes of various tests conducted on the products.

-

Engage Third-Party Inspectors: Hiring independent third-party inspectors to evaluate a supplier’s facilities and processes can offer an unbiased perspective on the quality control measures in place. This is particularly important for buyers from regions with stringent quality requirements.

What Are the Quality Control Nuances for International B2B Buyers from Africa, South America, the Middle East, and Europe?

When sourcing carbon fiber tubes from China, international buyers must consider regional nuances in quality control. For instance, buyers from Africa and South America may face challenges related to shipping and logistics that can affect product quality during transit. It is advisable to discuss packaging and handling procedures with suppliers to ensure that the products arrive in optimal condition.

In the Middle East, where harsh environmental conditions can affect material performance, buyers should emphasize the need for rigorous testing and quality assurance tailored to these conditions. Additionally, European buyers may have more stringent regulatory requirements, necessitating a thorough understanding of compliance standards.

Conclusion

Understanding the manufacturing processes and quality assurance measures for carbon fiber tubes in China is crucial for international B2B buyers. By familiarizing themselves with the key stages of production, relevant standards, QC checkpoints, and verification strategies, buyers can make informed decisions and ensure they procure high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘carbon fiber tubes china’

When sourcing carbon fiber tubes from China, international B2B buyers must navigate a complex landscape of suppliers, regulations, and quality standards. This guide provides a step-by-step checklist to streamline the sourcing process, ensuring that buyers from Africa, South America, the Middle East, and Europe can make informed decisions.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it is essential to clearly define your technical specifications. This includes dimensions, weight, tensile strength, and intended application of the carbon fiber tubes. Having precise specifications not only helps in identifying the right suppliers but also ensures that the products meet your project requirements.

- Consider application needs: Identify the specific use cases to inform material requirements.

- Document standards: Create a detailed product specification sheet to share with potential suppliers.

Step 2: Conduct Market Research

Understanding the market landscape is crucial when sourcing from China. Conduct thorough research on suppliers, industry trends, and pricing benchmarks. This knowledge will empower you to negotiate effectively and avoid overpaying.

- Use online platforms: Leverage platforms like Alibaba, Made-in-China, and Global Sources for supplier insights.

- Stay informed about trends: Monitor industry reports and trade publications to understand market dynamics.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conducting a thorough evaluation is vital. Request company profiles, case studies, and references from buyers in similar industries or regions. This due diligence will help you gauge the reliability and expertise of the supplier.

- Check certifications: Ensure suppliers have relevant certifications such as ISO 9001 for quality management.

- Review customer feedback: Look for reviews and testimonials from past clients to assess supplier credibility.

Step 4: Request Samples for Testing

Once you’ve shortlisted potential suppliers, request samples of the carbon fiber tubes. Testing samples allows you to evaluate the quality, performance, and compatibility with your requirements before placing a bulk order.

- Specify testing parameters: Clearly outline the tests you intend to conduct, such as strength and flexibility.

- Assess consistency: Ensure that samples reflect the quality you expect from the final product.

Step 5: Negotiate Terms and Pricing

Negotiation is a critical step in the sourcing process. Aim to establish favorable terms that cover pricing, payment methods, lead times, and shipping arrangements. Clear communication during this phase can prevent misunderstandings later on.

- Discuss volume discounts: Inquire about pricing structures based on order quantities.

- Clarify payment terms: Ensure that payment methods are secure and align with your financial policies.

Step 6: Verify Compliance with Import Regulations

Before finalizing your order, ensure that the carbon fiber tubes comply with import regulations in your country. This includes checking for necessary certifications and understanding tariffs or duties that may apply.

- Consult local regulations: Research import restrictions and standards that your products must meet.

- Plan for customs clearance: Engage with a customs broker if necessary to facilitate the import process.

Step 7: Establish a Quality Control Plan

A robust quality control plan is vital to ensure that the products received meet your specifications. Outline the quality assurance processes you expect from the supplier, including inspections and testing protocols.

- Define quality benchmarks: Set clear quality metrics that the products must meet.

- Schedule inspections: Consider third-party inspections during production and before shipment to verify compliance.

By following this comprehensive checklist, international B2B buyers can effectively source carbon fiber tubes from China, mitigating risks and enhancing the likelihood of successful procurement.

Comprehensive Cost and Pricing Analysis for carbon fiber tubes china Sourcing

What Are the Key Cost Components in Sourcing Carbon Fiber Tubes from China?

When considering the sourcing of carbon fiber tubes from China, understanding the comprehensive cost structure is crucial. The primary cost components include:

-

Materials: The cost of raw materials, including high-modulus carbon fiber and resin, can significantly impact the overall price. Market fluctuations in these materials often reflect changes in global supply and demand.

-

Labor: Labor costs in China are generally lower than in many Western countries, but they can vary by region and the complexity of manufacturing processes. Skilled labor is necessary for the production of high-quality carbon fiber tubes, and this can add to costs.

-

Manufacturing Overhead: This includes costs associated with factory operations such as utilities, maintenance, and equipment depreciation. Efficient manufacturing processes can help reduce overhead expenses.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. These costs are typically amortized over large production runs, making it essential to consider minimum order quantities (MOQs).

-

Quality Control (QC): Implementing a robust QC process is crucial to ensure product quality and compliance with international standards. This may involve additional costs, but it can prevent costly defects and returns.

-

Logistics: Shipping costs from China to the buyer’s location can vary widely based on distance, shipping method, and current freight rates. International buyers should also consider customs duties and taxes.

-

Margin: Suppliers will add a profit margin to cover their risks and business expenses. This margin can vary based on the supplier’s reputation, the complexity of the product, and market conditions.

How Do Price Influencers Affect Carbon Fiber Tube Sourcing?

Several factors can influence the pricing of carbon fiber tubes sourced from China:

-

Volume/MOQ: Bulk orders often lead to discounts, as suppliers are more willing to negotiate prices for larger quantities. Understanding your needs and aligning them with supplier capabilities can lead to significant savings.

-

Specifications and Customization: Custom specifications can increase costs due to the need for specialized tooling and processes. Buyers should assess whether standard products could meet their needs to avoid unnecessary expenses.

-

Materials Quality and Certifications: Higher quality materials and certifications (like ISO or ASTM) often come at a premium. Buyers should weigh the benefits of superior quality against the added costs.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but offer better service and quality assurance.

-

Incoterms: Understanding the chosen Incoterms (e.g., FOB, CIF) is critical, as they define responsibilities for shipping and insurance. This can significantly impact the overall cost and risk management.

What Are Effective Buyer Tips for Carbon Fiber Tube Procurement?

To ensure cost-effective sourcing of carbon fiber tubes from China, international buyers should consider the following tips:

-

Negotiate Wisely: Approach negotiations with a clear understanding of your budget and desired specifications. Building a good relationship with suppliers can lead to better terms and pricing.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the purchase price. Consider logistics, customs duties, and potential costs related to defects or returns. A lower initial price may not always translate to lower overall costs.

-

Understand Pricing Nuances: Prices may fluctuate based on market conditions, seasonal demand, and geopolitical factors. Staying informed about these dynamics can help buyers make timely purchasing decisions.

-

Perform Due Diligence: Conduct thorough research on potential suppliers, including their financial stability, production capabilities, and customer reviews. Engaging in site visits or third-party inspections can provide additional assurance.

-

Leverage Technology: Utilize online platforms for supplier discovery and price comparison. These tools can streamline the sourcing process and enhance transparency.

Disclaimer on Indicative Prices

Prices for carbon fiber tubes can vary widely based on the factors discussed above. It is advisable for buyers to request quotes from multiple suppliers to obtain a clearer picture of the current market rates.

Alternatives Analysis: Comparing carbon fiber tubes china With Other Solutions

Understanding Alternatives to Carbon Fiber Tubes from China

When evaluating materials for industrial applications, it’s crucial to consider all available options. Carbon fiber tubes manufactured in China have gained traction due to their strength-to-weight ratio and versatility. However, other alternatives may suit specific applications or budget constraints better. This section provides a detailed comparison of carbon fiber tubes from China against two notable alternatives: aluminum tubes and fiberglass tubes.

Comparison Table of Carbon Fiber Tubes and Alternatives

| Comparison Aspect | Carbon Fiber Tubes China | Aluminum Tubes | Fiberglass Tubes |

|---|---|---|---|

| Performance | High tensile strength, lightweight, excellent fatigue resistance | Good strength, heavier than carbon fiber | Moderate strength, lightweight, good corrosion resistance |

| Cost | Higher initial investment | Generally lower cost | Moderate cost |

| Ease of Implementation | Requires specialized handling | Easy to work with, widely available | Moderate, requires specific tools for installation |

| Maintenance | Low maintenance, resistant to corrosion | Moderate, prone to oxidation | Low maintenance, but can degrade with UV exposure |

| Best Use Case | Aerospace, automotive, and high-performance applications | Structural applications, automotive | Marine, electrical, and construction industries |

What Are the Advantages and Disadvantages of Aluminum Tubes?

Aluminum tubes are a popular alternative due to their availability and cost-effectiveness. They offer a good balance of strength and weight, making them suitable for structural applications. However, they are generally heavier than carbon fiber tubes and may be prone to corrosion if not properly treated. Their ease of implementation and lower costs make them ideal for projects with budget constraints, but they may not provide the same performance benefits as carbon fiber in high-stress applications.

How Do Fiberglass Tubes Compare to Carbon Fiber Tubes?

Fiberglass tubes are another viable alternative, particularly in industries where corrosion resistance is crucial. They are lightweight and can be manufactured in various shapes and sizes, making them versatile. However, their strength is moderate compared to carbon fiber tubes, and they may not perform well under high-stress conditions. The installation process for fiberglass can be more complicated, requiring specific tools and expertise. While they are generally low-maintenance, exposure to UV light can lead to degradation over time, making them less suitable for long-term applications.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting between carbon fiber tubes from China and alternative solutions like aluminum or fiberglass tubes, B2B buyers must assess their specific application requirements. Consider performance needs, budget constraints, and the environment in which the materials will be used. For high-performance applications where weight and strength are critical, carbon fiber is often the best choice despite its higher cost. Conversely, for structural projects where budget and ease of installation are paramount, aluminum may be more suitable. Fiberglass serves as a middle ground, offering corrosion resistance and versatility but may not meet performance demands in high-stress environments.

Ultimately, understanding the strengths and weaknesses of each option will enable buyers to make informed decisions that align with their operational goals and budgetary considerations.

Essential Technical Properties and Trade Terminology for carbon fiber tubes china

What Are the Key Technical Properties of Carbon Fiber Tubes?

When sourcing carbon fiber tubes from China, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications to consider:

1. Material Grade

Material grade refers to the quality and type of carbon fibers used in the manufacturing of the tubes. Common grades include T300, T700, and T800, each offering different strength-to-weight ratios and stiffness. For international buyers, especially from regions like Europe and the Middle East, selecting the right material grade directly impacts the performance of the final product in its intended application, whether in aerospace, automotive, or sporting goods.

2. Tolerance

Tolerance is the allowable deviation from a specified dimension. In carbon fiber tubes, this is critical for ensuring that the tubes fit seamlessly into existing structures or components. Tolerances are usually expressed in millimeters or inches. Buyers from South America and Africa should be aware that tighter tolerances may lead to higher costs, but they are essential for precision engineering applications.

3. Fiber Orientation

Fiber orientation indicates the direction in which the carbon fibers are aligned within the composite material. Common orientations include unidirectional, bidirectional, and woven. The choice of fiber orientation affects the strength and flexibility of the tube. For B2B buyers, understanding fiber orientation is vital, as it can influence the performance characteristics required for specific applications.

4. Weight

Weight is a fundamental property of carbon fiber tubes, which is significantly lighter than metals like aluminum or steel. This property is especially important for industries where weight reduction is critical, such as aerospace and automotive. Buyers should consider the weight specifications relative to their application to ensure optimal performance without compromising structural integrity.

5. Thermal Conductivity

Thermal conductivity measures how well a material can conduct heat. For carbon fiber tubes, this property can vary based on the resin system used. High thermal conductivity can be advantageous in applications where heat dissipation is crucial, such as in electronic housings. Understanding this property helps buyers from diverse sectors, including electronics and energy, make more informed decisions.

What Are Common Trade Terminology and Jargon in the Carbon Fiber Industry?

Navigating the trade terminology associated with carbon fiber tubes can be challenging. Here are some essential terms that B2B buyers should familiarize themselves with:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding the OEM landscape in China is vital for buyers who may require custom products or specific branding on their carbon fiber tubes.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers, particularly in regions with varying demand levels. Knowing the MOQ helps in planning inventory and cost management.

3. RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers. Including detailed specifications when issuing an RFQ for carbon fiber tubes ensures that suppliers provide accurate pricing and timelines, facilitating smoother negotiations.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international trade terms that define the responsibilities of buyers and sellers. Understanding these terms is essential for B2B transactions involving carbon fiber tubes, as they dictate shipping costs, risk transfer, and delivery points. Common Incoterms include FOB (Free On Board) and CIF (Cost, Insurance, and Freight).

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. For international buyers, particularly in fast-paced industries, understanding lead times is crucial for effective project management and inventory planning.

Conclusion

By grasping the essential technical properties and trade terminology associated with carbon fiber tubes from China, international B2B buyers can make informed decisions that align with their specific needs and industry requirements. This knowledge not only aids in selecting the right products but also enhances negotiation and procurement processes, ultimately contributing to successful business outcomes.

Navigating Market Dynamics and Sourcing Trends in the carbon fiber tubes china Sector

What are the Current Market Dynamics and Key Trends in the Carbon Fiber Tubes Sector?

The carbon fiber tubes market in China has witnessed robust growth, driven by an increasing demand across various industries such as aerospace, automotive, and renewable energy. Factors such as lightweight materials contributing to energy efficiency, coupled with a global push for advanced manufacturing technologies, are reshaping the landscape. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for strategic sourcing.

Emerging trends include the integration of automation and digital technologies in production processes. This shift not only enhances efficiency but also reduces lead times, making it easier for businesses to respond to market demands. Furthermore, the rise of e-commerce platforms dedicated to industrial materials is changing how buyers interact with suppliers, offering greater transparency and accessibility. Buyers are encouraged to leverage these platforms to compare suppliers and negotiate better terms, ensuring they remain competitive in their respective markets.

Another significant trend is the growing focus on customization. Suppliers are increasingly offering bespoke solutions that cater to specific application needs, which is particularly advantageous for industries requiring specialized carbon fiber tubes. Buyers should actively seek suppliers that can provide tailored products, as this can lead to enhanced performance and reduced waste in their operations.

How is Sustainability Influencing Sourcing Decisions in the Carbon Fiber Tubes Market?

Sustainability has become a paramount concern for international buyers. The environmental impact of manufacturing processes and the materials used is under scrutiny, compelling businesses to adopt more responsible sourcing practices. In the carbon fiber tubes sector, this means prioritizing suppliers who utilize eco-friendly materials and production methods.

Ethical sourcing is not just a trend; it’s a requirement for companies aiming to maintain a positive brand image and meet regulatory standards. Buyers should look for suppliers that hold certifications such as ISO 14001, which indicate a commitment to environmental management systems. Additionally, the use of recycled carbon fibers is gaining traction, providing an opportunity for buyers to source products that reduce their carbon footprint.

Investing in ‘green’ certifications can also enhance a company’s appeal in markets that are increasingly valuing sustainability. Buyers from regions like Europe, where environmental regulations are stringent, should prioritize partnerships with suppliers who demonstrate a clear commitment to sustainability. This not only supports ethical business practices but also aligns with the global shift towards a circular economy.

What is the Historical Context of Carbon Fiber Tubes Manufacturing in China?

The evolution of carbon fiber tubes manufacturing in China dates back to the early 1990s when the country began investing heavily in advanced materials technology. Initially, the focus was on developing domestic capabilities to reduce reliance on foreign imports. Over the years, as global demand for high-performance materials surged, Chinese manufacturers adopted cutting-edge technologies and expanded their production capacities.

By the 2000s, China had established itself as a leading player in the carbon fiber market, leveraging its manufacturing prowess and competitive pricing. This historical context is essential for B2B buyers, as it highlights the importance of understanding the supplier landscape. Many established manufacturers now have a wealth of experience and are equipped to meet the complex demands of international buyers, making them valuable partners for businesses looking to source high-quality carbon fiber tubes.

Frequently Asked Questions (FAQs) for B2B Buyers of carbon fiber tubes china

-

How do I choose the right supplier for carbon fiber tubes in China?

When selecting a supplier for carbon fiber tubes in China, consider their industry experience, reputation, and compliance with international quality standards. Request samples to evaluate product quality and ensure they have robust quality assurance processes in place. Verify their certifications, such as ISO 9001, and seek references from other international buyers. Additionally, assess their production capacity to meet your volume requirements and ensure they can provide timely deliveries. -

What are the common specifications for carbon fiber tubes, and how can I customize them?

Common specifications for carbon fiber tubes include diameter, wall thickness, length, and fiber orientation. Many suppliers offer customization options, allowing you to specify these parameters based on your project needs. When discussing customization, communicate your requirements clearly and inquire about the supplier’s capabilities in tailoring materials to meet specific performance characteristics, such as strength, weight, and flexibility. Ensure that you understand any associated costs and lead times for custom orders. -

What is the minimum order quantity (MOQ) for carbon fiber tubes from Chinese suppliers?

The MOQ for carbon fiber tubes can vary significantly among suppliers, typically ranging from 50 to several hundred pieces. It is essential to discuss your specific needs with potential suppliers to understand their MOQ policies. Some suppliers may be open to negotiating lower MOQs for first-time buyers or sample orders. Be aware that larger orders often result in better pricing and may lead to more favorable terms in future transactions. -

What payment terms should I expect when sourcing carbon fiber tubes from China?

Payment terms for carbon fiber tubes can vary, but common practices include a 30% deposit upon order confirmation and the remaining 70% before shipment. Some suppliers may offer alternative terms such as Letter of Credit or payment through platforms like PayPal for smaller orders. Always ensure that payment terms are clearly outlined in your contract to avoid misunderstandings. It’s advisable to work with suppliers who have a transparent payment process and are willing to negotiate terms that suit both parties. -

How can I ensure the quality of carbon fiber tubes sourced from China?

To ensure the quality of carbon fiber tubes, request detailed product specifications and certifications from the supplier. Conduct factory audits, if feasible, to observe their manufacturing processes and quality control measures. Consider third-party inspections before shipment to verify that products meet your standards. Establish a clear communication channel for feedback and concerns throughout the production process to address any issues promptly. -

What are the logistics considerations when importing carbon fiber tubes from China?

Logistics for importing carbon fiber tubes from China involve understanding shipping options, customs regulations, and potential tariffs. Work with a reliable freight forwarder familiar with international shipping to navigate these complexities. Ensure that you have all necessary documentation, such as commercial invoices and packing lists, ready for customs clearance. Also, consider the lead times for shipping and factor them into your project timelines to avoid delays. -

What are the common applications for carbon fiber tubes in various industries?

Carbon fiber tubes are widely used in industries such as aerospace, automotive, sports equipment, and construction due to their high strength-to-weight ratio and durability. They are ideal for applications requiring lightweight components that can withstand significant stress, such as frames for bicycles, drone arms, and structural supports in buildings. Understanding the specific application requirements will help you select the right type of carbon fiber tube for your projects. -

What are the risks involved in sourcing carbon fiber tubes from China, and how can I mitigate them?

Risks associated with sourcing carbon fiber tubes from China include quality inconsistencies, communication barriers, and potential delays in delivery. To mitigate these risks, conduct thorough research on suppliers, seek recommendations, and utilize platforms that offer buyer protection. Establish clear contracts outlining quality expectations, delivery schedules, and dispute resolution processes. Maintaining open communication with your supplier throughout the sourcing process can also help address issues before they escalate.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for carbon fiber tubes china

In today’s competitive landscape, international B2B buyers must prioritize strategic sourcing when considering carbon fiber tubes from China. The unique properties of carbon fiber, including its lightweight and high-strength characteristics, make it an essential material across various industries, from automotive to aerospace. By understanding the nuances of the Chinese market, buyers can leverage cost advantages while ensuring quality and compliance with international standards.

What are the key advantages of sourcing carbon fiber tubes from China? Establishing relationships with reliable suppliers can lead to improved negotiation power, optimized supply chain logistics, and access to innovative technologies. Buyers should focus on thorough supplier evaluations and consider certifications that reflect adherence to quality and environmental standards, which are increasingly important in today’s global market.

Looking ahead, the demand for carbon fiber tubes is expected to grow, driven by advancements in technology and increasing sustainability initiatives. International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should seize this opportunity to enhance their product offerings and competitive edge. Engage proactively with suppliers, invest in understanding market trends, and integrate strategic sourcing practices to ensure long-term success in the dynamic landscape of carbon fiber materials.