Discover Cost-Effective Solutions: Gas Generator China (2025)

Introduction: Navigating the Global Market for gas generator china

In an era of increasing energy demands and the push for sustainable solutions, sourcing reliable gas generators from China presents both opportunities and challenges for international B2B buyers. Navigating the complexities of this global market can be daunting, especially for businesses in Africa, South America, the Middle East, and Europe, where regional energy needs and economic conditions vary significantly. This comprehensive guide aims to empower you with the knowledge necessary to make informed purchasing decisions that align with your operational requirements.

Throughout this guide, we will delve into various types of gas generators available in the Chinese market, highlighting their specific applications, from industrial use to backup power solutions for commercial enterprises. Additionally, we will provide actionable insights into the supplier vetting process, ensuring you can identify reliable manufacturers that meet international quality standards. Understanding the cost implications and potential financing options will also be covered, equipping you with the tools to negotiate effectively and secure the best deals.

By addressing common concerns such as regulatory compliance, logistics, and after-sales support, this guide is designed to facilitate a smooth procurement experience. Whether you’re in Nigeria seeking robust solutions for energy reliability, or in Turkey aiming to enhance your power infrastructure, our insights will help you navigate the complexities of sourcing gas generators from China with confidence and clarity.

Understanding gas generator china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Natural Gas Generators | Utilizes natural gas as fuel; high efficiency. | Power generation for industries and utilities. | Pros: Lower emissions, cost-effective. Cons: Availability of natural gas supply can vary. |

| Biogas Generators | Operates on organic waste; eco-friendly. | Waste management and energy production. | Pros: Sustainable, reduces waste. Cons: Initial setup cost can be high. |

| LPG Generators | Uses liquefied petroleum gas; portable options. | Remote power supply, construction sites. | Pros: High energy density, easy to transport. Cons: Safety concerns with handling gas. |

| Diesel Gas Generators | Combines diesel and gas for flexibility. | Backup power for critical applications. | Pros: Versatile fuel options, reliable. Cons: Higher emissions compared to natural gas. |

| Dual-Fuel Generators | Capable of running on both gas and diesel. | Versatile applications in various sectors. | Pros: Flexibility in fuel choice, efficient. Cons: More complex maintenance requirements. |

What Are the Key Characteristics of Natural Gas Generators?

Natural gas generators are known for their high efficiency and lower emissions compared to other fossil fuels. They are ideal for industrial power generation and utility applications, particularly in regions with a stable supply of natural gas. B2B buyers should consider the availability of natural gas in their area, as this can significantly impact operational costs. Furthermore, these generators are often quieter and require less maintenance, making them suitable for urban environments.

Why Choose Biogas Generators for Sustainable Solutions?

Biogas generators leverage organic waste to produce energy, making them an eco-friendly choice for businesses focused on sustainability. They are particularly beneficial for agricultural operations and facilities that generate substantial organic waste. B2B buyers should assess the initial investment required for setup, as it can be higher than traditional generators. However, the long-term savings and environmental benefits often outweigh these costs, making biogas an attractive option for responsible businesses.

How Do LPG Generators Provide Flexibility for Remote Applications?

LPG generators are valued for their portability and high energy density, making them an excellent choice for remote power supply needs, such as construction sites or outdoor events. They can be easily transported and set up in locations where traditional power sources are unavailable. Buyers should note the safety protocols required for handling LPG, as improper use can lead to hazardous situations. However, their efficiency and ease of use make them a practical solution for temporary power needs.

What Advantages Do Diesel Gas Generators Offer for Backup Power?

Diesel gas generators are designed to combine diesel fuel with gas, providing flexibility for businesses that require reliable backup power. They are particularly suited for critical applications, such as hospitals or data centers, where consistent power is essential. B2B buyers should consider the emissions associated with diesel use, as they can be higher than natural gas. Nonetheless, the versatility and reliability of diesel generators make them a strong choice for many enterprises.

Why Opt for Dual-Fuel Generators for Versatile Energy Needs?

Dual-fuel generators are capable of operating on both gas and diesel, offering flexibility for businesses that may face fuel supply fluctuations. This adaptability is especially beneficial in regions where fuel availability can vary. B2B buyers should be aware that while dual-fuel generators provide cost-saving opportunities, they may require more complex maintenance and monitoring systems. Overall, their versatility makes them a valuable investment for businesses looking to optimize their energy solutions.

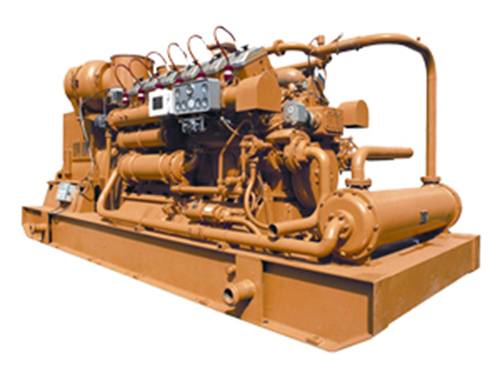

A stock image related to gas generator china.

Related Video: The Siemens SGT-800 A 50-MW-class industrial gas turbine

Key Industrial Applications of gas generator china

| Industry/Sector | Specific Application of gas generator china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Backup Power Supply for Production Lines | Ensures continuous operations during power outages | Reliability of supply, maintenance support, fuel type |

| Agriculture | Powering Irrigation Systems | Facilitates year-round crop production | Fuel efficiency, emissions standards, size and capacity |

| Telecommunications | Power for Cell Towers and Communication Networks | Maintains connectivity in remote areas | Noise levels, portability, and ease of installation |

| Mining | Power Generation for Remote Mining Operations | Reduces dependency on local grids | Durability, fuel availability, and operational costs |

| Healthcare | Emergency Power for Hospitals | Critical for life-saving equipment operation | Compliance with health regulations, service agreements |

How is Gas Generator China Used in Manufacturing?

In the manufacturing sector, gas generators from China serve as backup power supplies for production lines. These generators are critical during power outages, ensuring that operations remain uninterrupted. This reliability not only minimizes downtime but also protects the integrity of production schedules. For international buyers, especially from regions like Africa and South America, it is essential to consider the reliability of supply chains, the availability of maintenance support, and the specific fuel types that align with local energy policies.

What Role Do Gas Generators Play in Agriculture?

A stock image related to gas generator china.

Gas generators are increasingly used to power irrigation systems in agriculture, particularly in regions with inconsistent electricity supply. By providing a reliable energy source, these generators facilitate year-round crop production, thereby enhancing food security. Buyers should focus on fuel efficiency and emissions standards to ensure compliance with local regulations. Furthermore, understanding the size and capacity requirements for specific agricultural operations is crucial to making informed purchasing decisions.

How Do Gas Generators Support Telecommunications?

In the telecommunications sector, gas generators are vital for powering cell towers and communication networks, especially in remote areas where grid access is limited. They help maintain connectivity, which is essential for both business operations and emergency services. International B2B buyers should prioritize noise levels, portability, and ease of installation when sourcing these generators, as these factors can significantly impact operational efficiency in diverse environments.

What Are the Benefits of Gas Generators in Mining?

Gas generators are used extensively in mining operations, particularly in remote locations where traditional power sources are unreliable. These generators reduce dependency on local grids, enabling continuous operations and minimizing delays in production. Buyers in the mining sector should evaluate the durability of the generators, the availability of fuel, and the overall operational costs to ensure they are making a cost-effective investment.

How Are Gas Generators Essential for Healthcare Facilities?

In healthcare, gas generators provide emergency power for hospitals, ensuring that life-saving equipment remains operational during outages. This reliability is critical for patient safety and operational continuity. When sourcing gas generators, international buyers must consider compliance with health regulations and ensure that service agreements are in place for maintenance and support, especially in regions with less established infrastructure.

3 Common User Pain Points for ‘gas generator china’ & Their Solutions

Scenario 1: Navigating Quality Concerns in Gas Generators from China

The Problem: One of the most significant challenges B2B buyers face when sourcing gas generators from China is the inconsistency in product quality. Buyers often report receiving generators that do not meet their operational specifications or are prone to frequent breakdowns. This issue can lead to costly downtime, especially for businesses in sectors like construction or energy production, where reliable power sources are critical.

The Solution: To mitigate quality concerns, buyers should implement a comprehensive sourcing strategy. Start by conducting thorough due diligence on manufacturers. Utilize platforms like Alibaba or Global Sources to identify potential suppliers, but don’t stop there. Request samples and arrange factory visits, if possible, to assess production processes and quality control measures firsthand. Additionally, consider engaging third-party inspection services before shipment to ensure the generators meet specified standards and certifications. Establish clear performance criteria and request documentation that validates compliance with international standards, such as ISO certifications. By taking these steps, buyers can significantly reduce the risk of receiving subpar products.

Scenario 2: Overcoming Language Barriers and Communication Issues

The Problem: Language barriers can pose substantial challenges when negotiating with Chinese manufacturers, leading to misunderstandings about product specifications, pricing, and delivery schedules. This often results in delays and frustration for B2B buyers who rely on timely delivery of gas generators for their projects.

The Solution: To enhance communication, buyers should consider working with local intermediaries or agents who are fluent in both English and Mandarin. These professionals can facilitate clearer discussions and help bridge cultural gaps. Additionally, utilize technology—video conferencing tools and translation apps can be invaluable for real-time communication. When drafting contracts, ensure that all terms are clearly defined and consider having bilingual agreements to prevent misinterpretations. Regular check-ins throughout the manufacturing process can also help maintain alignment on expectations and timelines, ultimately leading to smoother transactions and fewer surprises.

Scenario 3: Understanding Regulatory Compliance for Gas Generators

The Problem: B2B buyers often face confusion regarding the regulatory compliance of gas generators, especially when importing equipment from China to regions like Africa or Europe, where regulations can vary significantly. Non-compliance can lead to hefty fines, operational disruptions, or even the inability to sell products in certain markets.

The Solution: To navigate regulatory complexities, buyers should conduct comprehensive research on the specific compliance requirements in their target markets. This includes understanding emissions standards, safety regulations, and import tariffs that may apply to gas generators. Engaging with local regulatory bodies or consulting firms can provide valuable insights into compliance requirements. Additionally, ensure that the manufacturer provides all necessary certifications and documentation, such as CE marks for Europe or other regional approvals. Staying informed about changes in regulations can also help buyers adjust their sourcing strategies proactively, ensuring that the gas generators they procure meet all necessary compliance standards without incurring delays or fines.

Strategic Material Selection Guide for gas generator china

When selecting materials for gas generators manufactured in China, international B2B buyers must consider a variety of factors that influence performance, durability, and compliance with regional standards. Below is an analysis of several common materials used in gas generator construction, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

What are the Key Properties of Steel in Gas Generators?

Steel is a widely used material in gas generators due to its excellent mechanical properties and versatility. It typically offers high strength, good fatigue resistance, and can withstand significant temperature and pressure variations. Corrosion resistance can be enhanced through galvanization or alloying with chromium, leading to stainless steel variants.

Pros & Cons: Steel’s durability makes it suitable for demanding applications, but it can be heavy and may require additional protective coatings to prevent rust, especially in humid or corrosive environments. The manufacturing complexity can vary depending on the steel grade and treatment processes, impacting overall costs.

Impact on Application: Steel is compatible with various gases, including natural gas and biogas, making it a reliable choice for diverse applications.

Considerations for Buyers: Buyers in regions such as Nigeria and Turkey should ensure compliance with local standards like ASTM or DIN for steel grades. Additionally, understanding the local availability of specific steel types can influence procurement strategies.

How Does Aluminum Benefit Gas Generator Design?

Aluminum is increasingly favored in gas generator applications due to its lightweight nature and excellent corrosion resistance. It is particularly effective in reducing the overall weight of the generator, which can enhance transportability and installation efficiency.

Pros & Cons: The primary advantage of aluminum is its resistance to oxidation, which minimizes maintenance needs. However, it has lower strength compared to steel, which may limit its use in high-pressure applications. Manufacturing processes for aluminum can be more complex and costly, particularly for high-performance alloys.

Impact on Application: Aluminum is suitable for applications where weight savings are crucial, such as portable generators. Its compatibility with various fuels makes it versatile.

Considerations for Buyers: Buyers from South America and the Middle East should be aware of the availability of aluminum alloys that meet specific performance requirements and ensure compliance with relevant standards.

What Role Does Composite Material Play in Gas Generators?

Composite materials, particularly fiber-reinforced polymers, are gaining traction in gas generator manufacturing due to their high strength-to-weight ratio and resistance to corrosion. These materials can be tailored to meet specific performance criteria, making them suitable for various components within the generator.

Pros & Cons: The primary advantage of composites is their lightweight nature, which can lead to significant reductions in overall system weight. However, they can be more expensive to produce and may require specialized manufacturing processes, which could complicate supply chains.

Impact on Application: Composites are ideal for non-structural components that require high performance with minimal weight, such as enclosures or housing.

Considerations for Buyers: International buyers should evaluate the availability of composite materials that meet regional standards and consider the implications of sourcing these materials on lead times and costs.

How Does Copper Contribute to Gas Generator Efficiency?

Copper is often used in electrical components of gas generators due to its excellent electrical conductivity and thermal properties. It plays a crucial role in ensuring efficient energy transfer and heat dissipation, which are vital for optimal generator performance.

Pros & Cons: The key advantage of copper is its superior conductivity, leading to enhanced efficiency. However, copper can be more expensive than alternatives like aluminum, and it is susceptible to corrosion if not properly treated.

Impact on Application: Copper is essential for wiring and electrical connections within gas generators, making it critical for reliable operation.

Considerations for Buyers: Buyers in Europe and Africa should be mindful of copper pricing fluctuations and ensure compliance with electrical standards relevant to their markets.

Summary Table of Material Selection for Gas Generators

| Material | Typical Use Case for gas generator china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components | High strength and durability | Heavy and may require protective coatings | Medium |

| Aluminum | Lightweight components | Excellent corrosion resistance | Lower strength than steel | High |

| Composite | Non-structural components | High strength-to-weight ratio | More expensive and complex to manufacture | High |

| Copper | Electrical wiring and connections | Superior electrical conductivity | Susceptible to corrosion | Medium |

In conclusion, understanding the properties, advantages, and limitations of various materials is crucial for international B2B buyers when selecting gas generators from China. By considering these factors, buyers can make informed decisions that align with their operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for gas generator china

What Are the Main Stages of Manufacturing Gas Generators in China?

The manufacturing process of gas generators in China involves several crucial stages, each designed to ensure efficiency and high-quality output. Understanding these stages is essential for B2B buyers looking to source reliable products.

-

Material Preparation: The first step in the manufacturing process is material preparation. High-quality raw materials, such as steel, copper, and aluminum, are sourced from reputable suppliers. These materials undergo rigorous quality checks to ensure they meet international standards, which is critical for the performance and longevity of the gas generators.

-

Forming: The forming stage involves shaping the raw materials into components that will make up the gas generator. Techniques such as stamping, bending, and welding are commonly used. Advanced CNC (Computer Numerical Control) machines are often employed to achieve precision in cutting and shaping, ensuring that parts fit together seamlessly.

-

Assembly: Once the components are formed, they are assembled into the final product. This stage typically involves a combination of manual labor and automated processes. Skilled technicians carefully assemble the generator, integrating the engine, electrical systems, and control panels. Quality control measures are implemented throughout the assembly process to detect any defects early.

-

Finishing: The finishing stage includes painting, coating, and other surface treatments to enhance durability and aesthetics. This step not only protects the gas generator from environmental factors but also contributes to its overall efficiency. Finishing processes often adhere to specific industry standards to ensure compliance with international regulations.

How Is Quality Assurance Integrated into Gas Generator Manufacturing?

Quality assurance (QA) is a fundamental aspect of the gas generator manufacturing process in China. It ensures that the final product meets both domestic and international standards, providing peace of mind for B2B buyers.

-

International Standards Compliance: Many manufacturers in China adhere to international quality management standards such as ISO 9001. This certification indicates that the company has implemented a systematic approach to managing quality and continuous improvement.

-

Industry-Specific Standards: In addition to ISO certifications, gas generators may need to comply with industry-specific standards such as CE marking for the European market and API (American Petroleum Institute) standards for the oil and gas sector. Compliance with these standards ensures that the products meet safety and performance requirements.

What Are the Key Quality Control Checkpoints in Gas Generator Manufacturing?

Quality control (QC) is integrated into various stages of the manufacturing process, with key checkpoints established to ensure the reliability of the final product.

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival at the manufacturing facility. Materials are assessed for compliance with specifications and standards before they are approved for use in production.

-

In-Process Quality Control (IPQC): During the manufacturing process, IPQC checks are performed at critical stages, such as during forming and assembly. This ensures that any defects are identified and rectified immediately, reducing the likelihood of issues in the final product.

-

Final Quality Control (FQC): Once the gas generators are fully assembled, a final inspection is conducted. This includes testing the functionality of the unit, checking for leaks, and verifying that all components work as intended. Detailed reports are generated to document the findings.

What Common Testing Methods Are Used in Gas Generator Quality Control?

Testing methods play a crucial role in ensuring the performance and safety of gas generators. Common testing techniques include:

-

Functional Testing: This assesses the operational capabilities of the gas generator under various load conditions. It verifies that the generator performs as expected in real-world scenarios.

-

Load Testing: Load tests are conducted to evaluate the generator’s performance under maximum load conditions. This helps to identify any potential weaknesses in the system.

-

Vibration Testing: This method assesses the generator’s ability to withstand vibrations during operation. It is essential for ensuring the longevity and reliability of the unit.

-

Noise Level Testing: This ensures that the gas generator operates within acceptable noise limits, which is particularly important for applications in urban or residential areas.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial for building trust and ensuring product reliability.

-

Supplier Audits: Conducting audits of the manufacturing facilities can provide valuable insights into the supplier’s quality management practices. These audits can be performed by the buyer’s quality assurance team or through third-party inspection services.

-

Requesting Quality Reports: Buyers should request detailed quality assurance reports from suppliers. These documents should outline the testing methods used, results obtained, and any corrective actions taken in case of discrepancies.

-

Third-Party Inspections: Engaging independent third-party inspection agencies can add an extra layer of assurance. These agencies can perform random checks and audits to verify that the supplier meets international quality standards.

What Are the Quality Control and Certification Nuances for International Buyers?

International buyers must navigate several nuances related to quality control and certification when sourcing gas generators from China.

-

Understanding Certification Requirements: Different regions have specific certification requirements. For example, CE marking is mandatory for products sold in the European Union, while UL certification may be needed for the North American market. Buyers should clarify these requirements with suppliers before making purchases.

-

Language and Documentation Barriers: Communication barriers can pose challenges in understanding quality reports and certifications. Buyers should ensure that all documentation is available in a language they understand, preferably with clear explanations of technical terms.

-

Cultural Differences in Quality Standards: Cultural perceptions of quality can vary significantly. Buyers should establish clear expectations regarding quality standards and ensure that suppliers are aligned with these expectations.

By understanding the manufacturing processes, quality control checkpoints, and verification methods, B2B buyers can make informed decisions when sourcing gas generators from China. This knowledge empowers them to build strong partnerships with suppliers, ultimately leading to successful procurement outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘gas generator china’

Introduction

Sourcing a gas generator from China can be a strategic move for international B2B buyers looking to enhance their operational efficiency. This guide provides a comprehensive checklist to streamline the procurement process, ensuring you make informed decisions while navigating the complexities of international trade. Each step is crafted to help you mitigate risks and maximize value in your purchasing journey.

Step 1: Define Your Technical Specifications

Before engaging suppliers, it is essential to clarify your technical requirements. Specify the generator’s capacity, fuel type, emission standards, and intended application.

- Capacity Requirements: Determine the power output needed for your operations.

- Compliance Standards: Identify any regional regulations your generator must meet, particularly regarding emissions.

Step 2: Research the Market Landscape

Understanding the market landscape is crucial for identifying potential suppliers. Conduct thorough research on the current trends in gas generator production in China.

- Supplier Reputation: Look for industry reviews and rankings to gauge the reliability of different manufacturers.

- Market Trends: Stay updated on innovations in gas generator technology that could benefit your operations.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers before making a commitment. Request company profiles, case studies, and references from other businesses that have procured similar products.

- Quality Assurance: Inquire about quality control processes to ensure the generators meet international standards.

- Past Performance: Ask for testimonials from clients in your industry or region to assess supplier credibility.

Step 4: ✅ Verify Supplier Certifications

Confirm that suppliers possess relevant certifications, which can indicate their adherence to quality and safety standards.

- ISO Certifications: Look for ISO 9001 (Quality Management) and ISO 14001 (Environmental Management) to ensure compliance.

- Local Certifications: Check for certifications specific to your region, as these can affect product acceptance.

Step 5: Request Detailed Quotations

Once you have shortlisted suppliers, request detailed quotations. This should include pricing, delivery timelines, and warranty terms.

- Breakdown of Costs: Ensure that the quotation outlines all costs, including shipping, taxes, and any additional fees.

- Warranty and Support: Clarify the warranty period and what support is offered after the sale.

Step 6: Conduct a Factory Visit or Virtual Tour

If possible, arrange a factory visit or a virtual tour to assess the supplier’s production capabilities.

- Production Capacity: Observe the manufacturing process to ensure they can meet your order volume.

- Quality Control Measures: Evaluate how they manage quality assurance throughout production.

Step 7: Establish Clear Payment Terms

Before finalizing the purchase, negotiate payment terms that protect your investment.

- Payment Structure: Discuss whether to use an upfront payment, milestones, or a letter of credit.

- Currency and Exchange Rates: Be aware of potential fluctuations in currency that could affect your total cost.

By following these steps, international B2B buyers can effectively navigate the procurement process for gas generators from China, ensuring a successful and profitable investment.

Comprehensive Cost and Pricing Analysis for gas generator china Sourcing

What Are the Key Cost Components in Sourcing Gas Generators from China?

When sourcing gas generators from China, understanding the cost structure is vital for making informed purchasing decisions. The main components influencing the total cost include:

-

Materials: The quality and type of materials used in the production of gas generators significantly impact costs. High-quality steel, copper, and advanced electronics can lead to higher upfront costs but often yield better performance and longevity.

-

Labor: Labor costs in China are generally lower than in many Western countries, but they can vary by region and the complexity of the manufacturing process. Skilled labor may demand higher wages, which could influence the overall cost of production.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can minimize overhead, making it crucial to assess a supplier’s operational efficiency.

-

Tooling: Custom tooling for specific generator designs can be a significant expense. If you require unique specifications, be prepared for an additional investment in tooling that may not be necessary for standard models.

-

Quality Control (QC): Ensuring that the products meet international standards involves thorough quality control processes. Suppliers may charge extra for rigorous testing and certification, which is essential to guarantee reliability and compliance.

-

Logistics: Shipping costs can vary widely based on the volume of goods, shipping methods, and destination. International shipping from China may involve tariffs, insurance, and handling fees, all of which should be factored into the total cost.

-

Margin: Suppliers will typically add a profit margin to cover their costs and ensure profitability. Understanding the market and negotiating effectively can help secure a better deal.

How Do Price Influencers Affect Gas Generator Costs?

Several factors can influence the pricing of gas generators from China, making it essential for buyers to consider these elements:

-

Volume/MOQ: Purchasing in larger quantities can significantly reduce the unit price. Suppliers often have a minimum order quantity (MOQ), and negotiating for larger orders can lead to better pricing.

-

Specifications/Customization: Customized products usually come at a premium. Clearly defining your requirements can help in obtaining accurate quotes and avoiding unexpected costs.

-

Materials: The choice of materials directly affects the cost. Opting for premium components may enhance performance but will increase initial expenses.

-

Quality and Certifications: Generators that meet international standards often have a higher price tag. Certifications can provide assurance of quality but might also add to the cost.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more but often provide better quality assurance and after-sales support.

-

Incoterms: The agreed terms of shipping (Incoterms) can greatly influence the final price. Understanding whether costs include freight, insurance, and duties is critical for budget planning.

What Are the Best Buyer Tips for Cost-Efficiency in Gas Generator Sourcing?

To maximize cost-efficiency when sourcing gas generators from China, international B2B buyers should consider the following strategies:

-

Negotiate Effectively: Build a strong relationship with suppliers and negotiate terms that benefit both parties. Being well-informed about market prices and competitor offerings can strengthen your bargaining position.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors such as maintenance, fuel efficiency, and lifespan when calculating TCO. A higher upfront cost might result in lower operational costs over time.

-

Understand Pricing Nuances: Be aware of seasonal fluctuations in pricing and demand. Certain periods may yield better pricing opportunities, so timing your purchase can be advantageous.

-

Conduct Supplier Audits: Assess potential suppliers’ capabilities, certifications, and past performance. This due diligence can help mitigate risks associated with quality and reliability, ultimately saving costs related to failures or warranty claims.

-

Explore Local Partnerships: Engaging local agents or distributors familiar with the Chinese market can provide insights and help navigate logistics and regulatory challenges, leading to more favorable pricing.

Disclaimer

Prices for gas generators sourced from China can vary widely based on the aforementioned factors and may change over time. It is advisable to conduct thorough market research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing gas generator china With Other Solutions

Understanding the Importance of Alternatives in Power Solutions

In the realm of energy solutions, particularly for international B2B buyers, evaluating alternatives to gas generators from China is crucial for informed decision-making. The right choice can significantly impact operational efficiency, cost-effectiveness, and overall business performance. This section will delve into viable alternatives, providing a comprehensive comparison to help buyers assess their options effectively.

Comparison Table of Gas Generator China and Alternatives

| Comparison Aspect | Gas Generator China | Solar Power Solutions | Diesel Generators |

|---|---|---|---|

| Performance | High efficiency; reliable under various loads | Depends on sunlight; lower efficiency in cloudy conditions | Consistent power output; robust in diverse environments |

| Cost | Moderate initial investment; lower operational costs | Higher upfront investment; long-term savings on fuel | Lower initial cost; higher fuel and maintenance costs |

| Ease of Implementation | Requires trained personnel for setup | Installation can be complex; permits may be needed | Straightforward setup; widely available |

| Maintenance | Requires regular maintenance; parts may be sourced from China | Minimal maintenance; occasional cleaning required | Regular maintenance needed; fuel system checks essential |

| Best Use Case | Industrial applications; remote areas with gas supply | Renewable energy projects; areas with high solar exposure | Backup power; construction sites; remote operations |

Analyzing Solar Power Solutions as an Alternative

Solar power solutions utilize photovoltaic panels to convert sunlight into electricity. The primary advantage of solar systems lies in their sustainability and low operational costs after installation. However, they require a significant upfront investment and can be less effective in regions with limited sunlight. For international buyers in Africa or South America, where solar exposure is higher, this could be a viable long-term investment despite the initial costs.

Evaluating Diesel Generators as an Alternative

Diesel generators are a traditional power source known for their reliability and performance in various conditions. They are relatively easy to set up and often have lower initial costs compared to gas generators. However, the ongoing fuel costs and maintenance can add up over time, making them less appealing for long-term use. For buyers in the Middle East or Europe, where diesel fuel is readily available, these generators can serve as dependable backup solutions, particularly in construction or remote site applications.

Conclusion: How to Choose the Right Power Solution for Your Needs

When selecting the appropriate power solution, international B2B buyers must consider their specific operational requirements, budget constraints, and long-term energy goals. While gas generators from China offer a balance of performance and cost-effectiveness, alternatives like solar power and diesel generators each present unique advantages and disadvantages. By thoroughly evaluating these options against their business needs, buyers can make informed decisions that align with their operational goals and contribute to sustainable growth.

Essential Technical Properties and Trade Terminology for gas generator china

What Are the Key Technical Properties of Gas Generators from China?

When considering gas generators from China, understanding their technical specifications is crucial for making informed purchasing decisions. Here are several key properties that international B2B buyers should evaluate:

-

Material Grade

– The material grade of a gas generator significantly impacts its durability and efficiency. High-grade materials, such as stainless steel or specific alloys, resist corrosion and wear, enhancing the generator’s lifespan. Buyers should prioritize suppliers that provide clear information on material specifications to ensure the product meets operational demands. -

Fuel Type Compatibility

– Gas generators can operate on various fuel types, including natural gas, propane, and biogas. Knowing the compatibility of a generator with specific fuels is essential for ensuring operational efficiency and cost-effectiveness. Buyers in regions with limited fuel availability should confirm that the generator can be adapted to local fuel sources. -

Power Output and Capacity Ratings

– Power output is a critical specification, usually measured in kilowatts (kW) or megawatts (MW). Understanding the generator’s capacity helps buyers match it with their energy requirements. It is advisable to assess whether the generator can handle peak loads and if it can operate continuously or intermittently, depending on the application. -

Noise Level

– Noise level, often measured in decibels (dB), is an important consideration, especially in urban settings or residential areas. Buyers should look for generators with soundproofing features or those designed to operate quietly to comply with local regulations and minimize disturbances. -

Efficiency Rating

– Efficiency ratings indicate how effectively a generator converts fuel into energy. Higher efficiency means lower fuel costs and reduced emissions. B2B buyers should seek generators with favorable efficiency ratings to align with sustainability goals and operational cost savings. -

Control Systems and Automation

– Advanced control systems enhance the functionality of gas generators, allowing for automated operation, remote monitoring, and diagnostics. Buyers should evaluate the sophistication of the control systems offered and consider how these features can improve operational reliability and reduce maintenance needs.

What Are Common Trade Terms for Gas Generators from China?

Understanding industry jargon is vital for effective communication and negotiation in B2B transactions. Here are essential terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

– An OEM produces parts or equipment that may be marketed by another company under its brand. In the context of gas generators, working with an OEM can offer customization options and ensure that the equipment meets specific industry standards. -

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory levels and cash flow. Understanding MOQ helps businesses plan their procurement strategies effectively. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to request pricing for specific products or services. It is an important step in the sourcing process that allows buyers to compare costs and negotiate terms. A well-structured RFQ can lead to better deals and stronger supplier relationships. -

Incoterms (International Commercial Terms)

– Incoterms are a set of predefined trade terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping costs, risks, and delivery obligations, facilitating smoother cross-border trade. -

Lead Time

– Lead time refers to the time taken from placing an order to receiving the goods. It is a critical factor in supply chain management and can impact project timelines. Buyers should discuss lead times upfront to align their operational needs with supplier capabilities. -

Warranty and Service Agreements

– Warranties and service agreements outline the terms of support and maintenance provided by the manufacturer. These documents are vital for ensuring product reliability and longevity. Buyers should carefully review warranty terms to understand coverage limits and service options available post-purchase.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions when sourcing gas generators from China, ensuring they select the right products for their needs while navigating the complexities of global trade.

Navigating Market Dynamics and Sourcing Trends in the gas generator china Sector

What Are the Key Market Dynamics Impacting the Gas Generator Sector in China?

The gas generator market in China is characterized by rapid growth, driven by increasing energy demands and a shift towards cleaner energy sources. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of several key trends. First, the rise of renewable energy integration is compelling manufacturers to innovate and produce hybrid systems that combine gas generators with solar or wind technologies. This trend not only enhances efficiency but also aligns with global sustainability goals.

Additionally, digital transformation in the gas generator sector is becoming prevalent. Technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) are being used for predictive maintenance, enabling businesses to optimize their operations. B2B buyers should consider suppliers that leverage these technologies for better reliability and lower operational costs.

Moreover, the geopolitical landscape is influencing sourcing strategies. With the ongoing changes in trade policies and tariffs, buyers need to evaluate the risks associated with sourcing from China. Establishing relationships with local suppliers can mitigate some of these risks while also providing insights into market fluctuations.

How Can B2B Buyers Ensure Sustainable and Ethical Sourcing of Gas Generators from China?

The importance of sustainability in sourcing practices cannot be overstated. For international B2B buyers, particularly those in Africa and South America, understanding the environmental impact of gas generators is crucial. The production and operation of these generators contribute to greenhouse gas emissions, hence the need for manufacturers to adopt greener practices.

Buyers should prioritize suppliers who are committed to ethical supply chains. This includes sourcing raw materials responsibly and ensuring that labor practices meet international standards. Certifications such as ISO 14001 for environmental management and ISO 9001 for quality management can serve as indicators of a manufacturer’s commitment to sustainability.

Furthermore, the trend toward “green” certifications is gaining traction. Buyers should look for products that utilize eco-friendly materials and technologies that reduce emissions, such as low-NOx engines. Engaging with suppliers that have a clear sustainability agenda not only enhances brand reputation but also aligns with the increasing regulatory pressures across Europe and beyond.

How Has the Gas Generator Market in China Evolved Over Time?

The evolution of the gas generator market in China has been marked by significant technological advancements and shifting energy policies. Initially focused on traditional fossil fuel generators, the sector has progressively embraced cleaner technologies in response to both domestic and international environmental pressures.

The Chinese government has implemented various initiatives to promote cleaner energy production, leading to the development of more efficient and environmentally friendly gas generators. This shift has opened up new opportunities for international B2B buyers, as the market now offers a range of innovative products that cater to diverse energy needs.

As the landscape continues to evolve, it is essential for buyers to stay informed about emerging technologies and regulatory changes that could impact sourcing decisions. Engaging with forward-thinking manufacturers who are at the forefront of these trends will be critical for securing a competitive advantage in the global market.

Frequently Asked Questions (FAQs) for B2B Buyers of gas generator china

-

How do I choose the right gas generator from China for my business needs?

Selecting the right gas generator involves understanding your specific requirements, including power output, fuel type, and operational environment. Conduct a thorough assessment of your energy needs, considering factors like load capacity and runtime. Research various manufacturers in China, focusing on their product specifications, customer reviews, and industry certifications. Engaging with suppliers for detailed product information and possibly requesting samples can also assist in making an informed decision. -

What are the common payment terms for purchasing gas generators from China?

Payment terms can vary significantly among suppliers. Common arrangements include a 30% deposit upfront with the balance due before shipment, or a letter of credit (LC) that offers security for both parties. It’s crucial to negotiate terms that are favorable to your cash flow while ensuring the supplier’s reliability. Be cautious of any supplier requesting full payment in advance and ensure that you have a solid agreement in place regarding quality and delivery timelines. -

What are the minimum order quantities (MOQs) for gas generators from Chinese suppliers?

MOQs can differ widely based on the manufacturer and the type of gas generator. Typically, MOQs can range from one unit for smaller suppliers to several units for larger manufacturers. If you are a smaller business or just starting, inquire whether the supplier can accommodate lower quantities or if they offer flexibility in the MOQ. Establishing a good relationship with the supplier may also help in negotiating more favorable terms. -

How can I verify the credibility of a gas generator supplier in China?

To verify a supplier’s credibility, consider conducting background checks through platforms like Alibaba or Global Sources, where you can see ratings, reviews, and transaction history. Request references from previous clients and inquire about their experiences. Additionally, consider visiting the supplier’s facility if feasible, or hiring third-party inspection services to assess the quality of their products and adherence to international standards. -

What customization options are available for gas generators from Chinese manufacturers?

Many Chinese manufacturers offer customization options tailored to your specific needs, such as modifications to power output, fuel types, and design features. When discussing customization, clearly communicate your requirements and ensure that the supplier has the capability to meet those needs. Request detailed specifications and prototypes where possible to confirm that the final product aligns with your expectations. -

What quality assurance measures should I expect from Chinese gas generator suppliers?

Quality assurance measures can include adherence to international standards such as ISO certifications, product testing protocols, and warranty policies. Ask suppliers about their quality control processes, including how they test their products before shipment. Additionally, consider requesting certifications and test reports to ensure that the gas generators meet your region’s regulatory requirements and safety standards. -

What logistics considerations should I be aware of when importing gas generators from China?

Logistics considerations include choosing the right shipping method, understanding import duties, and ensuring compliance with local regulations. Depending on the size and weight of the gas generators, options may range from air freight for faster delivery to sea freight for cost-effectiveness. Work with a reliable freight forwarder who can navigate customs clearance and provide insights on the best practices for importing machinery into your country. -

How can I ensure timely delivery of gas generators sourced from China?

To ensure timely delivery, establish clear timelines and milestones with your supplier during the negotiation phase. Regularly communicate with the supplier throughout the production process and request updates on progress. Additionally, factor in potential delays such as customs clearance and transportation logistics by building extra time into your project timeline. Having a contingency plan can also help mitigate risks associated with unexpected delays.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for gas generator china

In the evolving landscape of energy solutions, strategic sourcing of gas generators from China presents a myriad of opportunities for international B2B buyers. By leveraging China’s manufacturing prowess and competitive pricing, businesses in Africa, South America, the Middle East, and Europe can optimize their energy supply chains. Key takeaways emphasize the importance of thorough supplier vetting, understanding regulatory compliance, and assessing the total cost of ownership, which includes not just purchase price but also maintenance and operational efficiency.

How can strategic sourcing enhance your energy reliability? The right partnerships can lead to improved energy resilience, especially in regions facing infrastructure challenges. Engaging with credible Chinese manufacturers not only ensures high-quality products but also fosters innovation through access to advanced technologies.

As you look to the future, consider the growing demand for sustainable and efficient energy solutions. By prioritizing strategic sourcing, you position your business to navigate market fluctuations and enhance operational stability. Now is the time to act—explore partnerships with reputable Chinese gas generator suppliers to secure your energy needs and drive your business forward in an increasingly competitive global market.