Discover Cost-Effective Solutions: PV Panels China (2025)

Introduction: Navigating the Global Market for pv panels china

As the global demand for renewable energy sources continues to rise, international B2B buyers face the pressing challenge of sourcing high-quality photovoltaic (PV) panels from China. Navigating the complex landscape of suppliers, quality certifications, and pricing structures can be daunting, particularly for businesses in Africa, South America, the Middle East, and Europe. This guide aims to demystify the process by providing a comprehensive overview of the various types of PV panels available, their applications across different sectors, and the critical considerations for vetting suppliers effectively.

In this guide, you will discover essential insights into the latest technological advancements in PV panels, including monocrystalline and polycrystalline options, which can significantly impact efficiency and long-term performance. We will also delve into the nuances of cost analysis, helping you understand the total cost of ownership, including installation and maintenance, to make informed financial decisions. Furthermore, we will outline key strategies for assessing supplier reliability, including certifications and customer reviews, ensuring that you engage with reputable manufacturers.

By equipping you with this knowledge, this guide empowers international B2B buyers to make confident purchasing decisions that align with their business goals and sustainability initiatives. Whether you are a company in the UK seeking to enhance your energy portfolio or a Nigerian business looking to invest in solar technology, this guide serves as your essential resource in the dynamic market for PV panels from China.

Understanding pv panels china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Monocrystalline Panels | High efficiency, long lifespan, space-efficient design | Utility-scale projects, commercial installations | Pros: Best efficiency, space-saving. Cons: Higher cost. |

| Polycrystalline Panels | Cost-effective, good performance, slightly lower efficiency | Residential, small commercial projects | Pros: Lower initial cost. Cons: Larger space requirement, slightly lower efficiency. |

| Bifacial Panels | Dual-sided energy generation, enhanced performance in reflective environments | Large-scale solar farms, commercial rooftops | Pros: Increased energy output, versatile. Cons: Higher installation complexity. |

| Thin-Film Panels | Lightweight, flexible, lower efficiency | Building-integrated photovoltaics (BIPV), portable applications | Pros: Flexible, lightweight. Cons: Requires more space for same output. |

| Building-Integrated PV | Aesthetic integration with building materials | Urban developments, architectural projects | Pros: Aesthetic appeal, dual function. Cons: Higher upfront cost, complex installation. |

What Are the Characteristics of Monocrystalline Panels?

Monocrystalline panels are known for their high efficiency rates, typically ranging from 15% to 22%. Made from single-crystal silicon, these panels require less space to produce the same amount of energy compared to other types. They are ideal for utility-scale projects and commercial installations where space is limited. B2B buyers should consider the higher initial costs against the long-term energy savings and lifespan, which can exceed 25 years.

How Do Polycrystalline Panels Differ in Performance?

Polycrystalline panels are created from multiple silicon crystals and generally offer a lower efficiency of about 13% to 16%. They are more cost-effective than monocrystalline panels, making them a popular choice for residential and small commercial projects. Buyers should weigh the lower upfront costs against the slightly larger space requirements and reduced efficiency, especially in areas where roof space is at a premium.

What Benefits Do Bifacial Panels Provide for Large-Scale Projects?

Bifacial panels generate electricity from both sides, which can lead to an increase in energy production, especially in reflective environments. These panels are particularly suited for large-scale solar farms and commercial rooftops where maximizing output is essential. B2B buyers should consider the installation complexity and potential for higher initial costs, but the long-term benefits can justify the investment.

In What Situations Are Thin-Film Panels Most Effective?

Thin-film panels are lightweight and flexible, making them suitable for building-integrated photovoltaics (BIPV) and portable solar applications. While they have a lower efficiency rate (around 10% to 12%), they can be installed on surfaces where traditional panels may not fit. Buyers should consider their specific energy needs and available space, as these panels require a larger area to generate the same output as crystalline options.

Why Choose Building-Integrated PV for Urban Developments?

Building-integrated photovoltaics (BIPV) combine solar energy generation with architectural design, making them ideal for urban developments. These systems can enhance building aesthetics while providing energy savings. However, B2B buyers must account for the higher upfront costs and the complexity of installation, which may require specialized expertise. The dual functionality of BIPV can make it a worthwhile investment in the long run.

Related Video: Different Types of Solar Panels and Their Advantages

Key Industrial Applications of pv panels china

| Industry/Sector | Specific Application of pv panels china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Solar-powered irrigation systems | Reduces energy costs and enhances water accessibility | Quality of panels, compatibility with local systems, warranty terms |

| Construction | Building-integrated photovoltaics (BIPV) | Increases energy efficiency and sustainability ratings | Aesthetic design, local regulations, installation support |

| Manufacturing | Solar energy for production facilities | Lowers operational costs and carbon footprint | Panel efficiency, scalability, and maintenance services |

| Telecommunications | Off-grid solar power for remote towers | Ensures reliable connectivity in underserved areas | Durability, installation logistics, and local support |

| Mining | Solar-powered equipment for remote sites | Reduces reliance on diesel generators and costs | Panel durability, energy output under harsh conditions, and logistics support |

How Are PV Panels from China Used in Agriculture?

In the agricultural sector, solar-powered irrigation systems leverage PV panels from China to provide a sustainable energy source for water pumps. This application addresses the challenge of energy costs in regions where electricity supply is inconsistent or expensive. International buyers, particularly from Africa and South America, should consider the quality and efficiency of the panels, ensuring they can withstand local environmental conditions. Additionally, compatibility with existing irrigation systems and favorable warranty terms are crucial for long-term investment security.

What Are the Benefits of Building-Integrated PV Panels in Construction?

Building-integrated photovoltaics (BIPV) are increasingly utilized in the construction industry, allowing buildings to generate their own energy. This application not only enhances energy efficiency but also improves sustainability ratings, which can be a significant selling point in the European and Middle Eastern markets. Buyers should focus on the aesthetic design of the panels to ensure they align with architectural requirements, alongside understanding local regulations regarding energy production. Installation support is another critical factor, as it can affect the overall project timeline and costs.

How Do Manufacturing Facilities Benefit from Solar Energy?

In manufacturing, solar energy sourced from Chinese PV panels can power production facilities, significantly lowering operational costs and reducing the carbon footprint. This application is particularly relevant for businesses looking to enhance their sustainability practices while maintaining profitability. International buyers need to evaluate the efficiency of the panels and their scalability to meet increasing energy demands. Maintenance services should also be considered, as ongoing support is vital for maximizing the return on investment.

Why Is Off-Grid Solar Power Important for Telecommunications?

Telecommunications companies are increasingly turning to off-grid solar power solutions for remote towers, especially in underserved regions. This application ensures reliable connectivity by providing a consistent power supply, which is critical for maintaining service quality. Buyers from Africa and the Middle East must consider the durability of the panels, ensuring they can withstand harsh environmental conditions. Furthermore, logistics for installation and local support services play a significant role in the successful implementation of these systems.

How Are PV Panels Used in Mining Operations?

In the mining industry, solar-powered equipment is becoming a viable alternative to diesel generators, reducing both operational costs and environmental impact. This application is particularly beneficial in remote mining sites where traditional power sources are not feasible. International buyers should prioritize the durability of the panels to withstand the rugged mining environment and assess the energy output capabilities to ensure they meet operational demands. Additionally, logistics support for installation and maintenance is essential to ensure uninterrupted operations.

Related Video: Solar Panels Plus Farming? Agrivoltaics Explained

3 Common User Pain Points for ‘pv panels china’ & Their Solutions

Scenario 1: Challenges in Quality Assurance for ‘PV Panels from China’

The Problem: Many international B2B buyers, especially from regions like Africa and South America, face significant challenges in ensuring the quality of PV panels sourced from China. These buyers often receive products that do not meet their specifications or industry standards, leading to potential project delays and financial losses. The lack of transparency in the manufacturing process and insufficient quality control measures can exacerbate these issues, leaving buyers uncertain about the reliability of their suppliers.

The Solution: To overcome quality assurance challenges, B2B buyers should implement a robust supplier evaluation process. Start by researching potential suppliers through industry-specific trade fairs, online directories, and customer reviews. Once potential suppliers are identified, request samples and conduct on-site inspections whenever possible. Establish clear specifications and quality standards that must be met before placing bulk orders. Additionally, consider engaging third-party quality assurance firms to perform factory audits and product testing. This proactive approach not only ensures that the panels meet the required quality standards but also builds a long-term partnership based on trust and reliability.

Scenario 2: Navigating Import Regulations and Tariffs for PV Panels

The Problem: Importing PV panels from China can be fraught with regulatory challenges, including tariffs, customs duties, and varying import regulations depending on the buyer’s country. B2B buyers in Europe and the Middle East, for instance, often struggle to understand these regulations, which can lead to unexpected costs and delays in receiving their shipments. The complexity of international trade laws can create significant barriers for companies looking to adopt solar technologies.

The Solution: To effectively navigate import regulations, B2B buyers should invest time in understanding the specific import requirements of their country. This includes researching tariff classifications, potential trade agreements, and any anti-dumping measures that might apply. Consulting with a customs broker or a trade compliance specialist can provide invaluable insights into the regulatory landscape. Moreover, buyers should maintain open communication with their suppliers to ensure that all necessary documentation is in order before shipment. By proactively addressing these regulatory challenges, buyers can streamline their import processes and avoid costly delays.

Scenario 3: Misalignment of Technical Specifications and Local Needs

The Problem: A common pain point for B2B buyers sourcing PV panels from China is the misalignment between the technical specifications of the panels and the local requirements of their market. For example, buyers in hot climates may require panels that perform optimally under high temperatures, while those in colder regions might prioritize panels with excellent low-light performance. This mismatch can lead to underperformance and dissatisfaction with the purchased products.

The Solution: To mitigate issues related to technical specifications, buyers should conduct thorough market research to understand the specific needs of their local environments. This research should include factors such as climate conditions, energy consumption patterns, and local regulations. Armed with this knowledge, buyers can communicate their needs clearly to suppliers in China. It is advisable to collaborate with engineers or technical experts who can help draft precise specifications that take local conditions into account. Furthermore, buyers should seek suppliers that offer customizable solutions or a range of products designed for different environments. This strategic alignment ensures that the PV panels not only meet buyer expectations but also maximize energy output and efficiency in their specific context.

Strategic Material Selection Guide for pv panels china

What Are the Key Materials Used in PV Panels from China?

When selecting photovoltaic (PV) panels, the choice of materials significantly influences performance, durability, and cost. Here, we analyze four common materials used in PV panels manufactured in China, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Silicon Impact the Performance of PV Panels?

Key Properties: Silicon is the most widely used material in PV panels. It has excellent temperature stability, with a temperature coefficient of around -0.3% per °C, which indicates good performance in varying climates. Silicon also exhibits high corrosion resistance, making it suitable for outdoor applications.

Pros & Cons: The primary advantage of silicon is its efficiency and longevity, often exceeding 25 years of operational life. However, the manufacturing process can be complex and costly, particularly for high-purity silicon. This complexity can lead to higher initial costs, which may be a consideration for buyers in developing regions.

Impact on Application: Silicon panels are compatible with a wide range of applications, from residential rooftops to large-scale solar farms. However, they may require specific inverters and mounting systems that can add to overall project costs.

Considerations for International Buyers: Buyers should ensure that the silicon used complies with international standards such as ASTM and IEC. In regions like Africa and South America, where solar energy adoption is growing, understanding local regulations regarding silicon sourcing and recycling is crucial.

What Role Does Cadmium Telluride Play in PV Technology?

Key Properties: Cadmium telluride (CdTe) is a thin-film material that offers lower production costs and a smaller carbon footprint compared to crystalline silicon. It performs well in low-light conditions, making it suitable for various climates.

Pros & Cons: The main advantage of CdTe is its lower manufacturing cost, which can lead to cheaper PV panels. However, concerns about cadmium’s toxicity and environmental impact can pose challenges for regulatory compliance and public acceptance.

Impact on Application: CdTe panels are often used in utility-scale solar installations due to their cost-effectiveness and efficiency in large arrays. However, they may not be suitable for residential applications where aesthetic concerns are paramount.

Considerations for International Buyers: Buyers should be aware of the environmental regulations surrounding cadmium use in their regions. Compliance with standards such as RoHS (Restriction of Hazardous Substances) is essential, particularly in Europe and parts of the Middle East.

How Does Bifacial Glass Enhance PV Panel Efficiency?

Key Properties: Bifacial glass is used in the construction of PV panels to allow light to penetrate from both sides, enhancing overall efficiency. It has high durability and excellent weather resistance, withstanding harsh environmental conditions.

Pros & Cons: The key advantage of bifacial glass is its ability to capture reflected light, which can increase energy output by 10-20%. However, the initial investment is higher compared to traditional glass, potentially deterring some buyers.

Impact on Application: Bifacial panels are particularly effective in installations with reflective surfaces, such as white rooftops or sandy areas. They are increasingly popular in large-scale solar farms.

Considerations for International Buyers: Buyers should consider the installation environment when selecting bifacial panels. Moreover, understanding local market preferences and compliance with standards such as JIS and DIN can aid in making informed purchasing decisions.

What Is the Significance of Aluminum Frames in PV Panel Durability?

Key Properties: Aluminum frames provide structural support and protection for PV panels. They are lightweight, corrosion-resistant, and can endure high-pressure conditions.

Pros & Cons: The primary advantage of aluminum frames is their durability and ease of installation. However, they can add to the overall weight of the panels, which may require additional structural support in certain applications.

Impact on Application: Aluminum frames are suitable for a variety of installations, from residential to commercial. Their robustness is especially beneficial in areas prone to extreme weather conditions.

Considerations for International Buyers: Buyers should ensure that aluminum frames meet local standards for strength and corrosion resistance. In regions like Europe and the Middle East, understanding the implications of aluminum sourcing and recycling can be beneficial.

Summary Table of Material Selection for PV Panels

| Material | Typical Use Case for PV Panels China | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon | Residential and commercial solar arrays | High efficiency and longevity | Complex manufacturing process | High |

| Cadmium Telluride | Utility-scale solar installations | Lower production costs | Environmental and toxicity concerns | Medium |

| Bifacial Glass | Large-scale solar farms | Increased energy output | Higher initial investment | High |

| Aluminum Frames | Various installations | Durability and corrosion resistance | Potential added weight | Medium |

This analysis provides international B2B buyers with insights into the materials used in PV panels from China, helping them make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for pv panels china

What Are the Main Stages in the Manufacturing Process of PV Panels in China?

The manufacturing process of photovoltaic (PV) panels in China is a complex and multi-stage operation that ensures high-quality solar products. Understanding these stages is crucial for international B2B buyers seeking reliable suppliers.

-

Material Preparation

The first stage involves sourcing and preparing raw materials. Silicon is the primary component of most PV panels, and its purity significantly affects the efficiency of the final product. Manufacturers typically use high-purity silicon, which is refined through processes such as the Siemens process. Other materials, such as glass, backsheet, and encapsulants, are also sourced at this stage. -

Forming

In this stage, the purified silicon is melted and formed into wafers. These wafers are then cut into specific dimensions, typically 156 mm x 156 mm or 158 mm x 158 mm, depending on the desired panel size. Various techniques, such as the Czochralski method or the casting method, are employed to create high-quality silicon wafers. -

Assembly

The assembly stage is where the individual solar cells are interconnected to form a module. This involves placing the cells on a substrate and connecting them with conductive materials. The assembly process also includes the application of protective layers, such as glass on the front and a backsheet, to enhance durability and efficiency. Automation plays a significant role in this stage to ensure consistency and speed. -

Finishing

The final stage involves testing and packaging the completed panels. Panels undergo a series of tests to ensure they meet performance and safety standards. This includes visual inspections, electrical performance testing, and stress testing to simulate environmental conditions.

How Is Quality Assurance Implemented in the PV Panel Manufacturing Process?

Quality assurance (QA) is integral to the manufacturing of PV panels, ensuring that products meet international standards and buyer expectations.

-

International Standards and Certifications

Adhering to internationally recognized standards is essential for manufacturers targeting global markets. Key certifications include:

– ISO 9001: This standard focuses on quality management systems, ensuring consistent quality in products and services.

– CE Marking: Required for products sold in the European Economic Area, it signifies compliance with health, safety, and environmental protection standards.

– IEC 61215 and IEC 61730: These are specific to PV modules, covering performance and safety testing. -

Quality Control Checkpoints

Manufacturers implement multiple quality control checkpoints throughout the production process:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specifications.

– In-Process Quality Control (IPQC): Continuous monitoring occurs during the manufacturing stages to catch defects early.

– Final Quality Control (FQC): The finished products are subjected to rigorous testing before shipment to ensure they meet all specified criteria. -

Common Testing Methods

Various testing methods are employed to validate the quality of PV panels:

– Electroluminescence Testing: This method identifies micro-cracks in solar cells.

– Thermal Imaging: Used to detect hot spots and assess the overall health of solar modules.

– Mechanical Load Testing: Ensures that panels can withstand environmental stresses such as wind and snow.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, verifying the quality control practices of Chinese suppliers is essential to mitigate risks. Here are actionable steps to ensure supplier reliability:

-

Conduct Supplier Audits

Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. Buyers should consider scheduling on-site visits to assess the facilities firsthand and evaluate the adherence to quality standards. -

Request Quality Reports

Suppliers should be able to provide detailed quality reports that outline testing results, compliance with standards, and any corrective actions taken in case of non-conformities. These documents are crucial for transparency and accountability. -

Engage Third-Party Inspectors

Utilizing independent third-party inspection services can provide an unbiased evaluation of the supplier’s quality control processes. These inspectors can conduct random checks and validate the quality of products before shipment.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

Navigating the quality control landscape as an international buyer requires an understanding of specific nuances that may impact sourcing decisions:

-

Regional Standards and Compliance

Different regions may have varying standards for PV panels. For example, while CE marking is crucial for European buyers, buyers in Africa or South America may prioritize different certifications. Understanding these nuances helps buyers ensure compliance with local regulations. -

Cultural Differences in Quality Expectations

Cultural perceptions of quality can differ across regions. Buyers should communicate clearly with suppliers about their quality expectations and ensure that these align with the supplier’s capabilities. -

Long-term Relationships with Suppliers

Establishing long-term partnerships with suppliers can facilitate better quality assurance practices. Engaging in regular communication, feedback, and collaborative improvements can enhance the reliability of the products supplied.

Conclusion

Understanding the manufacturing processes and quality assurance practices for PV panels in China is vital for international B2B buyers. By familiarizing themselves with the stages of production, relevant quality standards, and methods of supplier verification, buyers can make informed decisions that ensure the procurement of high-quality solar products. This knowledge is particularly beneficial for buyers in Africa, South America, the Middle East, and Europe, where the demand for renewable energy solutions is rapidly growing.

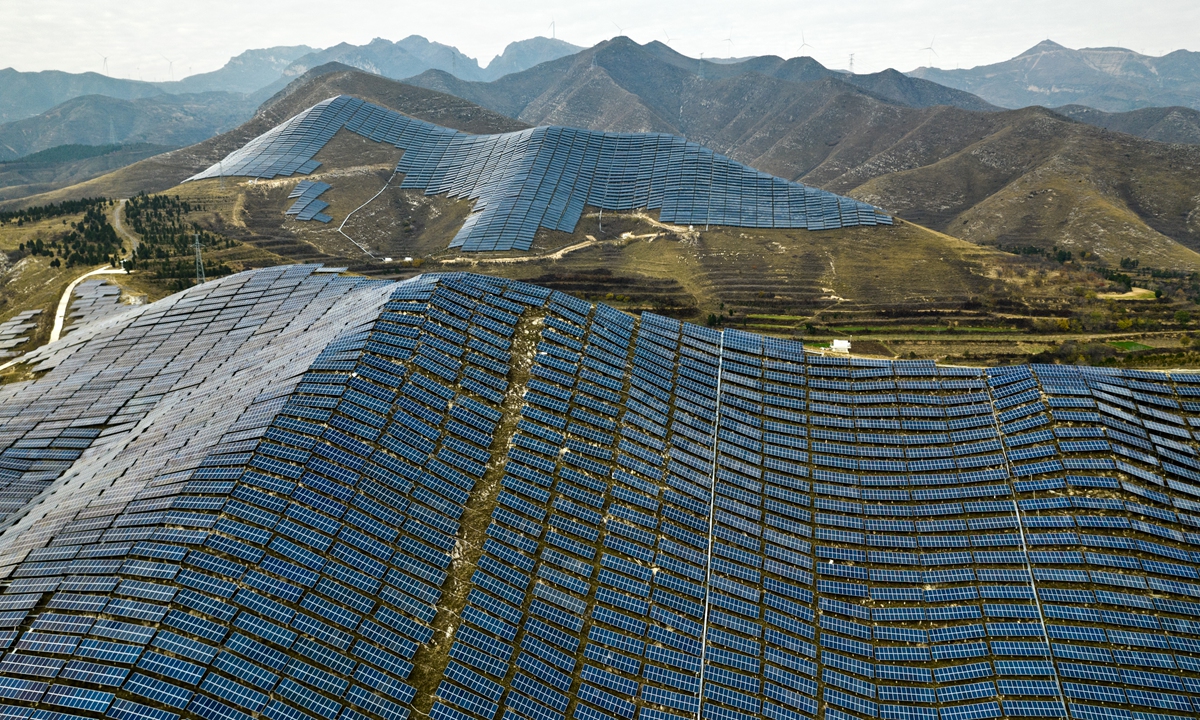

A stock image related to pv panels china.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pv panels china’

A stock image related to pv panels china.

In the competitive landscape of renewable energy, sourcing photovoltaic (PV) panels from China requires a strategic approach. This guide outlines essential steps that B2B buyers should follow to ensure a successful procurement process, minimizing risks and maximizing value.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial before engaging with suppliers. This includes determining the type of PV panels you need, such as monocrystalline or polycrystalline, as well as the desired wattage, efficiency ratings, and dimensions. Having precise specifications helps avoid misunderstandings and ensures that the products meet your project requirements.

Step 2: Conduct Market Research on Suppliers

Research potential suppliers to understand the landscape of the PV panel market in China. Look for manufacturers with a solid reputation, positive reviews, and a track record of delivering quality products. Utilize platforms like Alibaba, Global Sources, or industry-specific trade shows to gather information about various suppliers.

Step 3: ✅ Verify Supplier Certifications

Before proceeding with any supplier, it’s essential to verify their certifications and compliance with international standards. Look for certifications such as ISO 9001 for quality management and IEC 61215 for solar panel performance. These certifications indicate that the supplier adheres to industry standards, which can significantly impact product reliability and safety.

Step 4: Request Samples for Quality Assessment

Request samples of the PV panels to conduct a quality assessment. This step allows you to evaluate the panels’ physical characteristics, such as build quality and performance metrics. Testing samples can help you confirm that the products meet your specifications and expectations before making a larger order.

Step 5: Evaluate Pricing and Payment Terms

Analyze the pricing structures offered by different suppliers, considering not just the unit price but also shipping costs, taxes, and potential tariffs. Additionally, discuss payment terms to find a mutually agreeable arrangement that protects both parties. Payment options like letters of credit can offer security in transactions.

Step 6: Negotiate Contracts and Delivery Terms

Once you’ve selected a supplier, negotiate the contract terms, including delivery timelines, warranties, and after-sales support. Ensure that the contract clearly outlines the responsibilities of both parties to avoid disputes later. Pay attention to logistics and shipping arrangements, especially if sourcing from regions with complex trade regulations.

Step 7: Establish a Communication Plan

Maintaining clear communication with your supplier throughout the sourcing process is vital. Set up a communication plan that includes regular updates on production timelines, shipping schedules, and any potential issues. This proactive approach fosters a good relationship and can lead to better service and support in the future.

By following these steps, B2B buyers can navigate the complexities of sourcing PV panels from China effectively, ensuring they make informed decisions that align with their business goals.

Comprehensive Cost and Pricing Analysis for pv panels china Sourcing

What Are the Key Cost Components in Sourcing PV Panels from China?

When sourcing photovoltaic (PV) panels from China, understanding the various cost components is crucial for international B2B buyers. The primary cost components include:

-

Materials: The type of materials used in manufacturing PV panels significantly impacts the cost. High-quality silicon, glass, and backsheet materials will elevate the price but often enhance the durability and efficiency of the panels.

-

Labor: Labor costs in China are generally lower than in Europe or the Americas. However, the skill level of the workforce can influence production quality and efficiency.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and indirect labor. Efficient manufacturing processes can help reduce overhead costs, making it essential to assess a supplier’s operational efficiency.

-

Tooling: Custom tooling for specific panel designs can add to the initial investment. Buyers should consider whether the tooling costs can be amortized over large production runs.

-

Quality Control (QC): Implementing robust QC measures ensures that the panels meet international standards. The costs associated with QC processes should be factored into the overall pricing.

-

Logistics: Transportation costs from China to the buyer’s location can vary based on distance, shipping method, and freight rates. It’s essential to consider these costs in the total purchase price.

-

Margin: Suppliers often mark up prices to ensure profitability. Understanding the typical margin in the PV panel industry can help buyers gauge whether a quote is reasonable.

How Do Price Influencers Affect Sourcing PV Panels?

Several factors can influence the pricing of PV panels sourced from China:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often yield better pricing. Understanding a supplier’s MOQ can help buyers negotiate favorable terms.

-

Specifications and Customization: Customized panels to meet specific energy needs may incur additional costs. Buyers should evaluate the trade-off between customization and price.

-

Materials and Quality Certifications: Higher-quality materials and certifications (like ISO or IEC) can lead to increased prices. Buyers need to assess the value these certifications add to their projects.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more but offer better quality assurance and support.

-

Incoterms: The chosen Incoterm (e.g., FOB, CIF) significantly impacts the total cost. Buyers should clarify the responsibilities for shipping, insurance, and tariffs to avoid unexpected costs.

What Are the Best Negotiation Strategies for International Buyers?

For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to better pricing and terms:

-

Conduct Market Research: Understanding the average prices and market conditions can empower buyers during negotiations.

-

Leverage Volume Discounts: If possible, consolidate purchases to increase order sizes and negotiate better prices.

-

Clarify Payment Terms: Discuss payment terms upfront. Flexible terms can provide cash flow benefits and reduce financial strain.

-

Emphasize Long-Term Relationships: Building a long-term partnership with suppliers can lead to better pricing and service.

How to Calculate Total Cost of Ownership for PV Panels?

Calculating the Total Cost of Ownership (TCO) is vital for understanding the long-term financial implications of purchasing PV panels:

-

Initial Purchase Price: Include all costs associated with purchasing the panels, including shipping and tariffs.

-

Installation Costs: Factor in the costs associated with installing the panels, which can vary based on location and installation complexity.

-

Maintenance Costs: Regular maintenance is crucial for panel longevity. Estimate these costs over the expected lifespan of the panels.

-

Energy Savings: Calculate potential savings from reduced energy costs, which can offset initial investments.

-

Resale Value: Consider the potential resale value of the panels at the end of their lifecycle.

Conclusion: Why Understanding Pricing Nuances is Essential for B2B Buyers

International B2B buyers must navigate a complex landscape of costs and pricing when sourcing PV panels from China. By comprehensively understanding the cost components, price influencers, and effective negotiation strategies, buyers can make informed purchasing decisions that align with their financial objectives. Always remember that prices can vary widely, and it’s advisable to obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing pv panels china With Other Solutions

When evaluating renewable energy solutions, especially in the context of solar energy, international B2B buyers must consider various alternatives to ‘pv panels china’. This section provides a comprehensive comparison of Chinese photovoltaic (PV) panels with two viable alternatives: Thin-Film Solar Technology and Concentrated Solar Power (CSP). Each option presents unique advantages and challenges, influencing the decision-making process for businesses looking to invest in solar energy solutions.

Comparison Table

| Comparison Aspect | Pv Panels China | Thin-Film Solar Technology | Concentrated Solar Power (CSP) |

|---|---|---|---|

| Performance | High efficiency (15-22%) | Lower efficiency (10-12%) | Very high efficiency (up to 25%) |

| Cost | Competitive pricing | Lower initial cost | Higher initial investment |

| Ease of Implementation | Established supply chains | Flexible installation | Requires large land areas |

| Maintenance | Low maintenance | Moderate maintenance | Higher maintenance |

| Best Use Case | Large-scale solar farms | Residential and commercial | Utility-scale projects |

What Are the Pros and Cons of Thin-Film Solar Technology?

Thin-film solar technology utilizes a variety of materials, including cadmium telluride and amorphous silicon, to create lightweight and flexible solar panels. One of its primary advantages is the lower initial cost, making it accessible for smaller projects or residential installations. Its lightweight nature allows for easier installation on various surfaces. However, thin-film panels generally have lower efficiency compared to traditional silicon panels, which may require more space to generate the same amount of energy. Additionally, while maintenance is moderate, the lifespan of thin-film panels can be shorter, impacting long-term investment returns.

How Does Concentrated Solar Power (CSP) Compare to PV Panels from China?

Concentrated Solar Power (CSP) systems use mirrors or lenses to focus sunlight onto a small area, generating heat that is then converted into electricity. CSP boasts very high efficiency rates, often exceeding 25%, which can yield substantial energy output for utility-scale projects. However, the technology requires significant initial investment and is dependent on large land areas, making it less suitable for urban settings. CSP systems also tend to have higher maintenance needs due to their mechanical components. While they can provide a reliable energy source, the infrastructure costs and land requirements can be a barrier for some businesses.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the ideal solar energy solution, B2B buyers must assess their specific needs, including budget constraints, space availability, and energy requirements. For large-scale installations seeking cost-effective solutions, ‘pv panels china’ may be the most viable option, given their competitive pricing and established supply chains. However, for businesses focused on sustainability and efficiency, CSP could provide a more substantial long-term return on investment despite its higher upfront costs. Conversely, those with limited space or lower budgets may find thin-film technology to be a more practical choice. Ultimately, the decision should align with the company’s energy goals, financial capabilities, and operational context.

Essential Technical Properties and Trade Terminology for pv panels china

What Are the Key Technical Properties of PV Panels from China?

When sourcing photovoltaic (PV) panels from China, understanding the essential technical properties is crucial for making informed purchasing decisions. Here are some critical specifications to consider:

1. Material Grade

PV panels are typically made from silicon, either monocrystalline or polycrystalline. Monocrystalline panels are known for their higher efficiency and longevity, making them suitable for limited space applications. In contrast, polycrystalline panels are generally less expensive but offer lower efficiency. B2B buyers must assess their needs based on installation space, budget, and expected energy output.

2. Tolerance

Tolerance refers to the allowable variation in a panel’s output performance. For instance, a panel with a tolerance of ±5% will produce between 95% and 105% of its rated output. This specification is vital for buyers in ensuring that the panels will meet their energy requirements consistently. A lower tolerance is preferable for projects where energy generation needs to be predictable and reliable.

3. Efficiency Rating

The efficiency rating indicates how effectively a PV panel converts sunlight into electricity. Higher efficiency ratings (above 20%) are essential for projects where space is limited. B2B buyers should prioritize panels with higher efficiency for installations in urban areas or regions with less sunlight exposure.

4. Temperature Coefficient

This property measures how much a panel’s efficiency decreases as temperature increases. A lower temperature coefficient means better performance in hot climates, which is particularly relevant for buyers in regions such as Africa and the Middle East. Understanding this specification helps buyers select panels that will perform optimally in their specific climate conditions.

5. Warranty Period

The warranty period for PV panels typically ranges from 10 to 25 years. A longer warranty indicates greater manufacturer confidence in the product’s durability and performance. For B2B buyers, this is a critical factor in ensuring long-term investment protection and minimizing future costs associated with replacements or repairs.

Which Trade Terms Are Essential for Sourcing PV Panels?

Understanding trade terminology is equally important for B2B buyers when engaging with suppliers. Here are some common terms you should be familiar with:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of PV panels, many Chinese manufacturers operate as OEMs, allowing buyers to customize products under their brand. This is essential for businesses looking to establish a unique market presence.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is crucial for buyers, especially small businesses or startups, as it affects cash flow and inventory management. Negotiating MOQs can often lead to better pricing or terms.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and terms for specific products. B2B buyers should prepare detailed RFQs to ensure they receive accurate quotes that reflect their requirements. This process can streamline procurement and enhance supplier communication.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping. Common terms include FOB (Free On Board) and CIF (Cost, Insurance, and Freight). Understanding these terms helps buyers clarify shipping costs and risks, ensuring smoother transactions.

5. Lead Time

Lead time refers to the period between placing an order and receiving the goods. For PV panels, lead times can vary significantly based on manufacturing capacity and shipping logistics. Buyers should factor in lead times when planning installations to avoid delays in project timelines.

By familiarizing themselves with these essential technical properties and trade terms, B2B buyers can navigate the complexities of sourcing PV panels from China more effectively, ultimately leading to better purchasing decisions and successful project outcomes.

Navigating Market Dynamics and Sourcing Trends in the pv panels china Sector

What Are the Current Market Dynamics in the PV Panels China Sector?

The global solar energy market is experiencing significant growth, driven by increasing demand for renewable energy sources, government incentives, and technological advancements. In the context of China, which dominates the photovoltaic (PV) panel manufacturing sector, several key trends are emerging. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are witnessing a shift towards more competitive pricing and improved technology offerings from Chinese manufacturers. This is particularly relevant for buyers in developing regions where cost-effective solutions are essential for scaling renewable energy projects.

Additionally, the rise of smart technology integration, such as IoT-enabled PV systems, is changing the landscape. Buyers are increasingly looking for suppliers who can provide not just panels but also comprehensive solutions that include energy management systems. The push for higher efficiency rates in solar panels is also influencing procurement decisions, with many buyers prioritizing products that offer better performance in diverse environmental conditions.

Furthermore, geopolitical factors and trade policies are affecting sourcing strategies. Buyers must stay informed about tariffs and trade agreements that could impact the cost and availability of PV panels. As the market evolves, the emphasis on strategic partnerships with reliable suppliers who can navigate these dynamics will become increasingly critical.

How Important Is Sustainability and Ethical Sourcing in the PV Panels China Sector?

Sustainability has become a non-negotiable aspect of sourcing PV panels. International B2B buyers are not only concerned about the cost and efficiency of solar panels but also about their environmental impact. The demand for ethically sourced materials and sustainable manufacturing processes is rising, particularly in Europe and North America, where regulations are stringent.

Buyers should look for suppliers that provide transparency regarding their supply chains. Certifications such as ISO 14001 for environmental management and adherence to international labor standards can be indicators of a supplier’s commitment to sustainable practices. The use of recycled materials and responsible sourcing of raw materials, like silicon, are also increasingly important considerations.

Moreover, green certifications for PV panels, such as the Green Building Council’s LEED certification, can enhance the marketability of solar projects. Buyers from regions like Africa and South America, where sustainability can significantly impact community acceptance and regulatory approvals, should prioritize partnerships with manufacturers that share a commitment to ethical sourcing and environmental stewardship.

What Is the Evolution of the PV Panels China Sector and Its Significance for B2B Buyers?

The evolution of the PV panels sector in China has been marked by rapid technological advancements and significant investment in research and development. Initially, the industry was characterized by low-cost, low-efficiency products; however, over the past decade, there has been a substantial shift towards higher efficiency panels and innovative solar technologies.

China’s government policies, such as subsidies for solar installations and ambitious renewable energy targets, have propelled the sector’s growth. This evolution has positioned China as a leader in solar technology, making it a critical sourcing destination for international buyers. Understanding this historical context can help B2B buyers appreciate the competitive landscape and the potential for future innovations.

As the market continues to mature, buyers should remain vigilant about emerging technologies and trends that could influence their sourcing strategies. The ongoing development of bifacial panels and advancements in energy storage solutions are examples of innovations that could reshape procurement decisions in the near future. By aligning with forward-thinking manufacturers, international B2B buyers can secure a competitive advantage in the growing renewable energy landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of pv panels china

-

How can I verify the quality of PV panels from Chinese suppliers?

To ensure the quality of PV panels, request certifications such as IEC 61215 and IEC 61730, which indicate compliance with international standards. Additionally, consider conducting factory audits or utilizing third-party inspection services to evaluate production processes and materials used. Request samples for testing under local conditions to assess performance and durability. Building relationships with suppliers through communication and transparency can also enhance trust in product quality. -

What is the average lead time for purchasing PV panels from China?

The lead time for PV panels typically ranges from 4 to 12 weeks, depending on the manufacturer’s production capacity and your order size. Factors such as customization, shipping method, and local regulations can also impact delivery times. It’s advisable to discuss timelines with suppliers upfront and factor in potential delays due to customs or logistical issues when planning your project schedule. -

What are the minimum order quantities (MOQs) for PV panels from Chinese manufacturers?

Minimum order quantities can vary significantly among suppliers, often ranging from 100 to 1,000 panels or more. MOQs may be influenced by the panel type, customization requirements, and the supplier’s operational capacity. When negotiating, consider your project needs and ask suppliers if they offer flexibility in order size or discounts for larger purchases, which can help optimize your budget and inventory management. -

What payment terms should I expect when sourcing PV panels from China?

Payment terms can vary, but common practices include a 30% deposit upfront with the balance due before shipment or upon delivery. Some suppliers may accept letters of credit or escrow services for added security. Always clarify payment conditions and negotiate terms that protect both parties. Being informed about local banking regulations and currency exchange rates can also aid in smoother transactions. -

How can I ensure compliance with local regulations when importing PV panels?

To ensure compliance, familiarize yourself with your country’s import regulations, safety standards, and certification requirements for solar products. Collaborate with your supplier to obtain necessary documentation, such as certificates of origin and compliance. Consulting with local customs brokers or legal experts can also help navigate the complexities of importing PV panels while avoiding potential fines or delays. -

What customization options are available for PV panels from Chinese suppliers?

Many manufacturers offer customization options, including panel size, power output, and frame materials. Some suppliers may also provide branding options for your company logo. Discuss your specific requirements with potential suppliers to understand their capabilities and limitations. Ensure that any customizations meet both your project specifications and regulatory standards to avoid complications during installation. -

How do logistics and shipping impact my sourcing of PV panels from China?

Logistics and shipping play a crucial role in the sourcing process, affecting costs, delivery times, and product condition upon arrival. Choose a reliable shipping method based on your budget and urgency, with options ranging from air freight for faster delivery to sea freight for cost savings. Collaborate with logistics providers experienced in international trade to ensure proper handling and documentation, minimizing risks of damage or delays. -

What should I include in my supplier vetting process for PV panels?

When vetting suppliers, consider their industry experience, financial stability, production capacity, and customer reviews. Request references from previous clients and assess their responsiveness to inquiries. Additionally, evaluate their quality control processes and certifications. Conducting on-site visits or audits can further enhance your understanding of their operations and commitment to quality, which is essential for long-term partnerships.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for pv panels china

In the evolving landscape of solar energy, strategic sourcing of PV panels from China offers significant advantages for international B2B buyers. By leveraging China’s robust manufacturing capabilities, businesses can access high-quality panels at competitive prices, thus enhancing their sustainability initiatives while maximizing ROI. It is essential to conduct thorough market research and supplier evaluations, ensuring that chosen partners align with long-term business goals and compliance standards.

What Are the Key Takeaways for International Buyers?

Buyers should focus on establishing strong relationships with reliable suppliers, understanding the full lifecycle costs of PV panels, and staying informed about technological advancements and regulatory changes. Strategic sourcing is not just about cost reduction; it’s about fostering innovation and ensuring supply chain resilience.

What Does the Future Hold for PV Panels Sourcing?

As global demand for renewable energy continues to rise, the opportunity for growth in the solar sector is immense. Buyers from Africa, South America, the Middle East, and Europe are encouraged to seize this moment to invest in sustainable energy solutions. By prioritizing strategic sourcing of PV panels, businesses can position themselves as leaders in the green energy transition, ultimately contributing to a more sustainable future.