Discover Cost-Effective Sourcing: Copper Wire China Guide (2025)

Introduction: Navigating the Global Market for copper wire china

In the complex landscape of international trade, sourcing copper wire from China presents both opportunities and challenges for B2B buyers. As industries across Africa, South America, the Middle East, and Europe increasingly rely on high-quality copper wire for electrical applications, navigating the myriad of suppliers, product types, and pricing structures can be daunting. This guide is designed to empower you with the knowledge and tools necessary to make informed purchasing decisions, ensuring that your sourcing strategy aligns with your business objectives.

This comprehensive resource covers essential aspects of the copper wire market, including the various types of copper wire available, their applications in different sectors, and the critical steps for vetting suppliers effectively. We will delve into cost considerations, helping you understand pricing trends and how to negotiate favorable terms. Additionally, we will address common challenges faced by international buyers, such as quality assurance and logistics, providing actionable insights to mitigate these risks.

Whether you are a buyer from Kenya looking to enhance your electrical infrastructure or an Italian manufacturer seeking reliable raw materials, this guide serves as your roadmap to navigating the global market for copper wire from China. By leveraging the information within, you can establish a robust supply chain that meets your quality standards while optimizing costs, ultimately driving your business forward in a competitive landscape.

Understanding copper wire china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

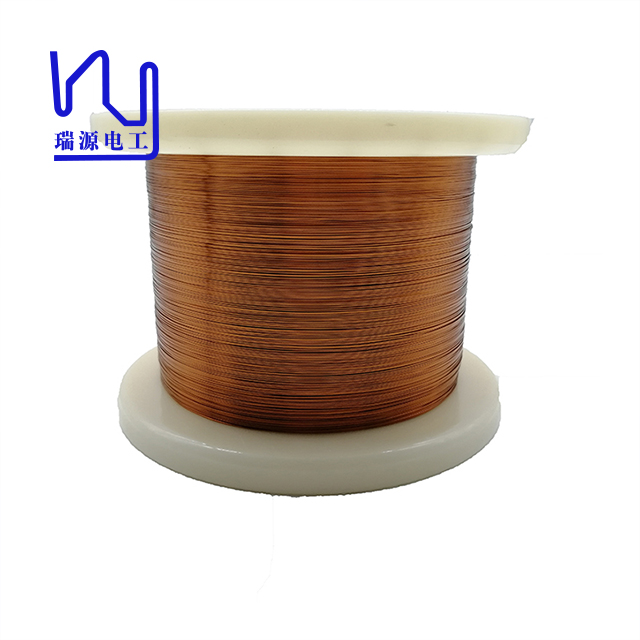

| Enamelled Copper Wire | Thin insulation layer, flexible, high conductivity | Motor windings, transformers, electronics | Pros: Excellent heat resistance, lightweight. Cons: More expensive than non-enamelled. |

| Bare Copper Wire | No insulation, high purity copper | Electrical connections, grounding, cabling | Pros: Low cost, high conductivity. Cons: Prone to oxidation, limited applications. |

| Tinned Copper Wire | Coated with tin for corrosion resistance | Marine applications, outdoor installations | Pros: Enhanced durability, prevents corrosion. Cons: Slightly higher cost than bare wire. |

| Stranded Copper Wire | Composed of multiple small wires, flexible and durable | Power transmission, flexible connections | Pros: Greater flexibility, easier to handle. Cons: Slightly lower conductivity than solid wire. |

| Copper Wire Rod | Raw form, used for manufacturing various copper products | Wire drawing, cable production | Pros: Versatile, suitable for various processes. Cons: Requires further processing. |

What are the characteristics of Enamelled Copper Wire and its B2B suitability?

Enamelled copper wire is characterized by its thin layer of insulation, which allows for high conductivity while maintaining flexibility. It is particularly suitable for applications in motor windings and transformers, where heat resistance is crucial. B2B buyers should consider the increased cost associated with enamelled wire, balanced against its performance advantages in high-temperature environments.

How does Bare Copper Wire fit into B2B applications?

Bare copper wire is notable for its high purity and lack of insulation, making it ideal for electrical connections and grounding. Its low cost is attractive for bulk purchases, particularly for projects with a high volume of wiring. However, buyers must be aware of its susceptibility to oxidation, which can affect performance over time, especially in outdoor settings.

Why choose Tinned Copper Wire for specific applications?

Tinned copper wire is coated with a layer of tin, providing enhanced corrosion resistance, making it suitable for marine and outdoor applications. This type of wire is particularly beneficial for B2B buyers in environments where moisture and salt exposure are concerns. While the cost is higher than bare copper, the longevity and durability often justify the investment.

What are the advantages of using Stranded Copper Wire in B2B contexts?

Stranded copper wire consists of multiple smaller wires twisted together, offering flexibility and durability. It is commonly used in power transmission and flexible connections, making it easier to work with in tight spaces. B2B buyers should consider the trade-off between flexibility and conductivity, as stranded wire may have slightly lower conductivity compared to solid wire.

How does Copper Wire Rod serve the manufacturing sector?

Copper wire rod is the raw form of copper used in the production of various copper products, including different types of wire. Its versatility makes it a staple in manufacturing, especially for wire drawing and cable production. Buyers in the manufacturing sector should evaluate the processing capabilities of their suppliers, as the quality of wire rod directly impacts the end products.

Related Video: Enameled Copper Wire Production Process-zhengzhou lp industry co,.ltd

Key Industrial Applications of copper wire china

| Industry/Sector | Specific Application of copper wire china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electrical Manufacturing | Power Cables and Wiring | High conductivity ensures efficient energy transfer | Compliance with international standards and certifications |

| Construction | Electrical Wiring in Buildings | Safety and reliability in electrical installations | Sourcing durable and corrosion-resistant materials |

| Telecommunications | Data Transmission Cables | Enhanced signal quality and reduced transmission loss | Consideration of cable flexibility and insulation types |

| Automotive | Wiring Harnesses | Improved safety and performance in vehicle electronics | Need for heat-resistant and durable wire materials |

| Renewable Energy | Solar Panel Connections | Optimized energy collection and conversion efficiency | Focus on environmentally friendly sourcing practices |

How is Copper Wire Used in Electrical Manufacturing?

In the electrical manufacturing sector, copper wire from China is primarily utilized in the production of power cables and wiring. Its exceptional electrical conductivity makes it indispensable for efficient energy transfer, reducing energy loss during transmission. International buyers, especially from regions like Africa and Europe, must ensure that the copper wire sourced meets global standards and certifications. This guarantees both quality and safety, which are critical in high-voltage applications.

What Role Does Copper Wire Play in Construction?

Copper wire is essential in the construction industry, particularly for electrical wiring in buildings. It provides a reliable and safe means of conducting electricity, which is crucial for both residential and commercial projects. Buyers should prioritize sourcing copper wire that is durable and resistant to corrosion, as these factors significantly enhance the longevity of electrical installations. In regions like South America and the Middle East, where climatic conditions can be challenging, this durability becomes even more critical.

How Does Copper Wire Enhance Telecommunications?

In telecommunications, copper wire is used in data transmission cables that facilitate communication networks. The high conductivity of copper ensures enhanced signal quality and minimizes transmission loss, which is vital for maintaining efficient communication systems. Buyers should consider the flexibility of copper wire and the types of insulation used, as these factors can affect installation ease and long-term performance. European buyers, in particular, should also be aware of the environmental regulations that may influence sourcing decisions.

Why is Copper Wire Important for Automotive Applications?

Copper wire is a key component in automotive wiring harnesses, which are crucial for connecting various electrical systems within vehicles. The use of high-quality copper wire enhances safety and performance in vehicle electronics, ensuring reliable operation of critical systems. International buyers, especially from regions like Africa and the Middle East, should focus on sourcing heat-resistant and durable wire materials to withstand the demanding conditions of automotive applications. This is essential for compliance with automotive industry standards.

How Does Copper Wire Contribute to Renewable Energy Solutions?

In the renewable energy sector, copper wire is vital for connecting solar panels and other energy collection systems. Its excellent conductivity optimizes energy collection and conversion efficiency, making it a preferred choice for solar installations. Buyers should emphasize environmentally friendly sourcing practices when procuring copper wire for renewable energy projects, aligning with global sustainability goals. This is particularly relevant for buyers in Europe, where there is a strong push towards green energy solutions.

Related Video: Amazing Process Of Mining Copper Ore To Produce Copper And Copper Products

3 Common User Pain Points for ‘copper wire china’ & Their Solutions

Scenario 1: Navigating Quality Assurance for Copper Wire from China

The Problem: Many B2B buyers experience significant anxiety when sourcing copper wire from China due to concerns about quality and compliance with international standards. This is particularly pressing for buyers in regions like Africa and the Middle East, where local regulations can be stringent. A buyer may order a large shipment, only to discover upon arrival that the wire does not meet their specified requirements or fails to pass local quality checks, leading to costly returns and project delays.

The Solution: To mitigate these risks, buyers should implement a rigorous supplier evaluation process before placing orders. This includes requesting detailed product specifications and certifications, such as ISO 9001 for quality management systems or specific electrical standards relevant to their industry. Conducting virtual audits or hiring third-party inspection services in China can help ensure that the manufacturing processes meet your quality expectations. Establishing a clear communication channel with the supplier for ongoing quality updates during production can further enhance trust and reliability.

Scenario 2: Overcoming Logistics and Supply Chain Challenges with Copper Wire from China

The Problem: International B2B buyers often face logistical nightmares when importing copper wire from China, especially due to complex customs regulations and unpredictable shipping timelines. For instance, a buyer in South America might place an order only to find that delays at customs result in missed project deadlines, incurring additional costs and damaging client relationships.

The Solution: To navigate these logistical challenges, buyers should engage with experienced freight forwarders who specialize in importing electrical materials from China. These professionals can provide insights into customs regulations and help streamline the shipping process. It’s also advisable to establish a buffer period in project timelines to accommodate potential delays. Additionally, consider utilizing air freight for urgent orders, despite the higher costs, to ensure timely delivery. Building a strong relationship with your supplier can also lead to better shipping terms and improved responsiveness to any logistical issues that arise.

Scenario 3: Addressing Price Volatility in the Copper Market

The Problem: Price volatility in the copper market can create significant budgeting challenges for B2B buyers. For example, a company in Italy may secure a contract based on a specific copper price, only to find that market fluctuations have dramatically increased costs by the time they are ready to place an order. This unpredictability can lead to either increased project costs or the need to renegotiate contracts, straining client relationships.

The Solution: To combat price volatility, B2B buyers should consider establishing long-term contracts with fixed pricing or pricing formulas that account for fluctuations in the copper market. This can be done by negotiating with suppliers for a set price for a specific period or by agreeing to a price linked to a recognized index. Another strategy is to explore options for hedging against price increases through financial instruments or forward contracts. Maintaining open communication with suppliers about market conditions can also provide timely insights, allowing buyers to make informed decisions and adjust their purchasing strategies accordingly.

Strategic Material Selection Guide for copper wire china

When selecting materials for copper wire manufacturing in China, international B2B buyers must consider various factors that influence performance, cost, and compliance with regional standards. Below, we analyze four common materials used in the production of copper wire, highlighting their properties, advantages, disadvantages, and implications for specific applications.

What are the Key Properties of Copper Wire Materials?

1. Bare Copper

Bare copper is the most common material used in copper wire applications due to its excellent conductivity and malleability.

- Key Properties: It has a high electrical conductivity rating (around 97% IACS), making it ideal for electrical applications. It also exhibits good thermal conductivity and can withstand moderate temperatures without degrading.

- Pros & Cons: The primary advantage of bare copper is its superior conductivity, which enhances performance in electrical systems. However, it is prone to corrosion, particularly in humid or acidic environments, which can limit its durability.

- Impact on Application: Bare copper is suitable for applications requiring high conductivity, such as power transmission and residential wiring. However, it may not be suitable for outdoor or corrosive environments without additional protective coatings.

- Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local electrical standards (e.g., IEC standards) and consider protective coatings to enhance durability in humid climates.

2. Tinned Copper

Tinned copper wire is coated with a thin layer of tin, providing enhanced corrosion resistance.

- Key Properties: Tinned copper maintains good electrical conductivity while offering better protection against oxidation and corrosion compared to bare copper.

- Pros & Cons: The key advantage is its longevity in harsh environments, making it suitable for marine and outdoor applications. However, the tin coating can slightly reduce electrical conductivity compared to bare copper.

- Impact on Application: Tinned copper is ideal for applications exposed to moisture or corrosive elements, such as in coastal regions or industrial settings. Its performance in high-temperature applications is also commendable.

- Considerations for International Buyers: Buyers in the Middle East and Europe should verify compliance with ASTM B33 standards for tinned copper wire and consider the specific environmental conditions of their applications.

3. Copper Alloy

Copper alloys, such as bronze or brass, are sometimes used in specialized wire applications.

- Key Properties: These alloys offer enhanced strength and resistance to wear and fatigue, making them suitable for mechanical applications.

- Pros & Cons: The primary advantage is improved durability and resistance to deformation under stress. However, the cost of copper alloys is generally higher than that of pure copper or tinned copper, which can impact budget considerations.

- Impact on Application: Copper alloys are suitable for applications that require both electrical conductivity and mechanical strength, such as in automotive and aerospace industries.

- Considerations for International Buyers: Buyers should be aware of the specific alloy compositions and their compliance with international standards like JIS H3250 for copper alloys, especially in Europe and Japan.

4. Copper-Clad Aluminum (CCA)

Copper-clad aluminum combines the conductivity of copper with the lightweight properties of aluminum.

- Key Properties: CCA wire features a copper outer layer that provides good conductivity while the aluminum core reduces overall weight.

- Pros & Cons: The main advantage is cost-effectiveness and reduced weight, making it easier to handle and install. However, CCA has lower conductivity compared to pure copper, which can affect performance in high-demand applications.

- Impact on Application: CCA is often used in telecommunications and low-voltage applications where weight and cost are significant factors.

- Considerations for International Buyers: Buyers in regions like Africa and South America should ensure that CCA meets local electrical standards and consider the implications of reduced conductivity in their specific applications.

Summary Table of Material Selection for Copper Wire

| Material | Typical Use Case for copper wire china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Bare Copper | Electrical wiring and power transmission | Superior conductivity | Prone to corrosion | Medium |

| Tinned Copper | Marine and outdoor applications | Enhanced corrosion resistance | Slightly lower conductivity | Medium |

| Copper Alloy | Automotive and aerospace applications | Improved strength and durability | Higher cost than pure copper | High |

| Copper-Clad Aluminum | Telecommunications and low-voltage wiring | Lightweight and cost-effective | Lower conductivity than pure copper | Low |

This strategic material selection guide provides international B2B buyers with essential insights into the various materials used in copper wire production in China, enabling informed decisions that align with their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for copper wire china

What Are the Main Stages in the Manufacturing Process of Copper Wire in China?

The manufacturing process for copper wire in China is a multi-stage operation that emphasizes efficiency and quality. Understanding these stages can help international B2B buyers make informed decisions when sourcing copper wire.

Material Preparation

The first stage involves sourcing high-quality copper, often in the form of cathodes or billets. This raw material is critical, as the quality of copper directly impacts the electrical conductivity and durability of the final product. Suppliers in China typically source copper from both local mines and international markets. The material undergoes initial inspections to ensure compliance with relevant specifications.

Once the copper is sourced, it is melted in a furnace, and impurities are removed through a process called refining. This refined copper is then cast into rods, which serve as the basis for wire production.

Forming: How Is Copper Wire Shaped?

After material preparation, the next stage is forming. This process involves drawing the copper rods into wires through a series of dies that progressively reduce the diameter. The drawing process can be cold or hot, depending on the desired properties of the final wire. Cold drawing is commonly preferred for its ability to enhance tensile strength and improve surface finish.

In addition to drawing, other techniques such as extrusion may be employed for specific applications. This involves forcing heated copper through a die to create various shapes. Understanding these techniques allows B2B buyers to select suppliers that align with their specific application needs.

Assembly: What Are the Key Steps in Assembly?

While copper wire may not have a complex assembly stage like other products, it can still involve several processes, such as twisting or bundling wires for specific applications. For instance, multi-stranded wire requires careful assembly to ensure that the strands are tightly wound together, enhancing flexibility and conductivity.

This stage is crucial for ensuring that the wire meets the necessary specifications for various applications, such as electrical wiring, telecommunications, or industrial use. Buyers should inquire about the assembly capabilities of their suppliers to ensure they can deliver the required specifications.

Finishing: How Is Quality Enhanced During This Stage?

The finishing stage involves several processes aimed at enhancing the properties of the copper wire. This may include annealing, a heat treatment that improves ductility and electrical conductivity. Additionally, surface treatments like tinning or coating may be applied to enhance corrosion resistance.

Finishing is vital for ensuring that the wire performs well in its intended application. Buyers should ask potential suppliers about their finishing techniques and how they align with industry standards.

What International Standards Govern Quality Assurance for Copper Wire?

Quality assurance is a critical aspect of the manufacturing process, especially for international B2B buyers. Various international standards help ensure that copper wire products meet specific quality benchmarks.

ISO 9001: What Does It Mean for Quality Management?

ISO 9001 is one of the most recognized international standards for quality management systems. Suppliers who are ISO 9001 certified have demonstrated their ability to consistently provide products that meet customer and regulatory requirements. For B2B buyers, sourcing from ISO-certified suppliers can significantly reduce the risk of quality issues.

CE Marking: What Is Its Importance for European Buyers?

For buyers in Europe, the CE marking indicates that a product complies with EU safety, health, and environmental protection standards. This is particularly important for electrical applications, where safety is paramount. B2B buyers should ensure that their suppliers can provide CE certification for their copper wire products.

API Standards: Are They Relevant for the Copper Wire Industry?

The American Petroleum Institute (API) has specific standards that may apply if the copper wire is intended for use in oil and gas applications. Buyers in industries requiring API compliance should verify that their suppliers can meet these standards.

What Are the Key Quality Control Checkpoints in Copper Wire Manufacturing?

Quality control (QC) is integral to the manufacturing process, ensuring that the final product meets the required specifications. Key QC checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival at the facility. B2B buyers should confirm that their suppliers have robust IQC processes in place to catch any defects early.

-

In-Process Quality Control (IPQC): During manufacturing, continuous checks are performed to monitor the quality of the wire at various stages. This might include measuring the diameter, checking tensile strength, and evaluating surface quality.

-

Final Quality Control (FQC): After the manufacturing process, the finished products undergo rigorous testing to ensure compliance with specifications. This often includes electrical tests, dimensional checks, and visual inspections.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control processes of suppliers is crucial. Here are several actionable strategies:

Conducting Audits: What Should Buyers Look For?

Buyers should consider conducting on-site audits of potential suppliers. This allows them to evaluate the manufacturing processes, quality control measures, and overall operational capabilities. During an audit, buyers should check for adherence to international standards and the presence of necessary certifications.

Requesting Quality Reports: What Information Should Be Included?

Buyers should ask suppliers for detailed quality reports that outline testing methods, results, and compliance with relevant standards. These reports should provide insights into the supplier’s quality management practices and product reliability.

Utilizing Third-Party Inspections: How Can They Help?

Engaging third-party inspection services can provide an objective assessment of a supplier’s quality control processes. These services can conduct random inspections during manufacturing and before shipment, ensuring that the products meet the required specifications.

What Are the QC and Certification Nuances for International B2B Buyers?

For buyers from Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification can be complex. It’s essential to consider regional regulations and standards that may impact product quality and compliance.

For example, buyers in Africa may face challenges related to local infrastructure and regulatory frameworks. Engaging with suppliers who understand these challenges can lead to more reliable partnerships. Similarly, buyers in Europe must navigate stringent EU regulations, making it vital to work with suppliers who are well-versed in compliance.

By focusing on these aspects, international B2B buyers can make informed decisions when sourcing copper wire from China, ensuring that they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘copper wire china’

To successfully source copper wire from China, international B2B buyers must navigate a complex landscape of suppliers, certifications, and quality standards. This guide provides a clear, actionable checklist to ensure a smooth procurement process, helping you make informed decisions.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the copper wire you need, including gauge, insulation type, and conductivity. This step is crucial because it sets the foundation for your sourcing process and ensures that suppliers can meet your specific needs.

- Considerations:

- Identify the standards and certifications that are relevant to your industry.

- Be specific about the quantity and delivery timelines required.

Step 2: Conduct Market Research

Research the current market trends for copper wire in China, including pricing, demand, and supplier reputation. Understanding the market will help you make informed decisions and negotiate better prices.

- Key Points:

- Utilize platforms like Alibaba, Made-in-China, and Global Sources to gather information.

- Look for industry reports or market analyses that highlight emerging trends.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website.

- What to Assess:

- Verify the supplier’s history and experience in manufacturing copper wire.

- Look for third-party reviews and testimonials to gauge reliability.

Step 4: Verify Supplier Certifications

Ensure that the suppliers you are considering hold relevant certifications, such as ISO 9001 for quality management and RoHS compliance for environmental standards. This step is vital for ensuring product quality and compliance with international regulations.

- Certification Details:

- Ask for documentation proving certifications.

- Check if the certifications are up-to-date and relevant to your market.

Step 5: Request Samples

Before placing a bulk order, request samples of the copper wire to evaluate quality. This allows you to assess the material and craftsmanship, ensuring it meets your specifications.

- Sample Evaluation:

- Inspect the samples for conductivity, insulation quality, and overall finish.

- Conduct necessary tests to confirm that the wire meets industry standards.

Step 6: Negotiate Terms and Pricing

Once you have identified a suitable supplier, enter negotiations regarding pricing, payment terms, and delivery schedules. This is a critical step to ensure that you are receiving the best value for your investment.

- Negotiation Tips:

- Be clear about your budget constraints and expected timelines.

- Explore options for bulk discounts or long-term partnership agreements.

Step 7: Establish a Communication Plan

Develop a clear communication plan with the supplier to ensure transparency throughout the sourcing process. Regular updates and check-ins can prevent misunderstandings and keep the project on track.

- Effective Communication:

- Set expectations regarding response times and preferred communication channels.

- Establish a point of contact on both sides to streamline discussions.

By following this checklist, B2B buyers can effectively navigate the sourcing process for copper wire from China, ensuring they secure quality products that meet their specific needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for copper wire china Sourcing

What Are the Key Cost Components for Sourcing Copper Wire from China?

When sourcing copper wire from China, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The price of copper fluctuates based on global market conditions. Buyers should keep an eye on commodity prices and consider how they impact overall costs.

-

Labor: Labor costs in China are generally lower than in many Western countries, but there can be significant variations based on region and the complexity of the manufacturing process. Skilled labor may command higher wages, impacting overall pricing.

-

Manufacturing Overhead: This encompasses utilities, rent, and administrative costs associated with production. Manufacturers in China often have streamlined operations, but overhead can vary based on the facility’s location and scale.

-

Tooling: Initial costs for molds and tools can be significant, especially for customized wire specifications. These costs are typically amortized over larger production runs.

-

Quality Control (QC): Implementing robust QC measures can add to costs but is essential for ensuring product reliability. Third-party inspections may also be necessary, which can further increase expenses.

-

Logistics: Freight costs can vary widely depending on shipping methods (air vs. sea), distance, and current global shipping rates. Incoterms also play a vital role in defining who bears these costs.

-

Margin: Suppliers will typically mark up their prices to include profit margins, which can vary based on competition and market demand.

What Influences the Pricing of Copper Wire Sourced from China?

Several factors can affect the pricing of copper wire, making it essential for buyers to navigate these influences wisely:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs. Buyers should negotiate MOQs that align with their needs while maximizing savings.

-

Specifications and Customization: Unique specifications or custom requirements can drive up costs. Buyers should assess whether standard products meet their needs to avoid unnecessary expenses.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., ISO, RoHS) often come at a premium. Buyers should weigh the importance of these factors against their budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but offer greater assurance of quality and service.

-

Incoterms: Understanding the Incoterms agreed upon in the contract is critical. They define responsibilities and can significantly impact the total landed cost of goods.

How Can International B2B Buyers Optimize Costs When Sourcing Copper Wire?

For buyers in Africa, South America, the Middle East, and Europe, optimizing costs involves strategic planning and negotiation:

-

Negotiate Effectively: Build relationships with suppliers and be clear about your expectations. Leverage your volume needs to negotiate better pricing and terms.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider logistics, potential tariffs, and the costs associated with quality issues when calculating TCO.

-

Stay Informed on Pricing Trends: Regularly monitor market conditions for copper and manufacturing costs. Being informed allows buyers to make timely decisions and negotiate from a position of strength.

-

Understand Pricing Nuances: Different regions may have varied pricing structures based on local economic factors. For example, buyers in Italy may face different tariffs compared to those in Kenya. Research these nuances to avoid surprises.

-

Consider Long-term Partnerships: Establishing long-term relationships with suppliers can lead to better pricing, priority service, and improved product offerings.

Disclaimer Regarding Indicative Prices

Prices for copper wire sourced from China can vary significantly based on the aforementioned factors. It is advisable for buyers to conduct thorough market research and request quotes from multiple suppliers to ensure competitive pricing and terms.

Alternatives Analysis: Comparing copper wire china With Other Solutions

Introduction to Alternative Solutions for Copper Wire in B2B Procurement

In the global market, international B2B buyers often seek alternatives to traditional products like copper wire from China. As companies aim to optimize performance, reduce costs, and enhance sustainability, exploring viable alternatives becomes essential. This section provides a comparative analysis of copper wire from China against two prominent alternatives: aluminum wire and fiber optic cables. By evaluating these options, buyers can make informed decisions that align with their operational needs and budget constraints.

| Comparison Aspect | Copper Wire China | Aluminum Wire | Fiber Optic Cables |

|---|---|---|---|

| Performance | High conductivity, durable | Lower conductivity, lightweight | Extremely high bandwidth, low signal loss |

| Cost | Moderate to high | Generally lower | Higher initial investment |

| Ease of Implementation | Widely available, standard sizes | Easy to handle, flexible | Requires specialized installation |

| Maintenance | Low maintenance | Corrosion resistance, moderate maintenance | Low maintenance, durable |

| Best Use Case | Electrical wiring, industrial applications | Power transmission, residential wiring | Telecommunications, high-speed data transfer |

What Are the Pros and Cons of Aluminum Wire as an Alternative?

Aluminum wire serves as a cost-effective alternative to copper wire. Its lower price point can significantly benefit projects with tight budgets, especially in developing regions like Africa and South America. Additionally, aluminum is lightweight, making it easier to handle and install, particularly in overhead power lines. However, aluminum has lower conductivity compared to copper, which may require larger wire gauges to achieve the same electrical performance. Furthermore, aluminum is more susceptible to corrosion, potentially leading to increased maintenance costs over time.

How Do Fiber Optic Cables Compare to Copper Wire?

Fiber optic cables represent a cutting-edge alternative that excels in high-speed data transmission. They offer significantly higher bandwidth than copper wire, making them ideal for telecommunications and data centers. While fiber optics have a higher initial cost and require specialized installation, their low maintenance and durability can lead to long-term savings. However, fiber optics are not suitable for all applications, particularly those requiring high power transmission, which limits their use in traditional electrical wiring contexts.

Conclusion: How Can B2B Buyers Choose the Right Solution?

When selecting between copper wire from China, aluminum wire, and fiber optic cables, B2B buyers must evaluate their specific needs and application contexts. Factors such as performance requirements, budget constraints, and installation capabilities should guide decision-making. For electrical wiring and industrial applications, copper wire remains a robust choice, while aluminum wire offers a budget-friendly alternative for power transmission. In contrast, fiber optic cables are optimal for high-speed data applications, albeit at a higher upfront investment. By carefully assessing these alternatives, international buyers can enhance their procurement strategies and align with their operational goals.

Essential Technical Properties and Trade Terminology for copper wire china

What Are the Key Technical Properties of Copper Wire from China?

When sourcing copper wire from China, understanding its essential technical properties is crucial for ensuring product quality and compliance with industry standards. Here are several critical specifications to consider:

-

Material Grade

– The material grade of copper wire, often denoted by standards such as ASTM or IEC, indicates the purity and quality of the copper used. Higher grades (e.g., C11000) contain 99.99% copper, which enhances conductivity and corrosion resistance. For B2B buyers, selecting the appropriate grade is vital to ensure that the wire meets the operational requirements of electrical applications. -

Conductor Resistance

– Measured in ohms per kilometer (Ω/km), conductor resistance determines how much electrical resistance the wire will present during operation. Lower resistance values are preferable, as they lead to improved energy efficiency and reduced heat generation. Buyers should consider this property to ensure optimal performance in their applications. -

Tolerance

– Tolerance refers to the permissible deviation in wire diameter, which can affect electrical performance and compatibility with connectors. Manufacturers usually specify tolerances in percentage terms. Understanding these tolerances helps buyers ensure that the wire will fit properly in their systems and maintain consistent performance. -

Stranding

– Stranding indicates how the wire is constructed, either as solid or stranded wire. Stranded wire is made up of multiple smaller wires twisted together, which offers flexibility and ease of installation, especially in applications requiring bending. Buyers should evaluate their specific needs to determine the appropriate stranding type. -

Insulation Type

– The insulation material surrounding the copper wire (e.g., PVC, XLPE, or rubber) affects its durability, thermal resistance, and suitability for specific environments. Selecting the correct insulation type is essential for ensuring long-term performance and safety in various applications.

What Are Common Trade Terms Used in the Copper Wire Industry?

Understanding trade terminology is equally important for navigating the complexities of international B2B transactions. Here are some essential terms that buyers should be familiar with:

-

OEM (Original Equipment Manufacturer)

– OEM refers to companies that produce products that are sold under another company’s brand name. In the context of copper wire, buyers might work with OEMs to ensure that the wire meets specific design and performance standards required for their products. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory and budget effectively. Negotiating MOQs can lead to better pricing and terms, especially for larger purchases. -

RFQ (Request for Quotation)

– An RFQ is a formal document sent by a buyer to potential suppliers to request pricing and terms for specific products. Crafting a detailed RFQ can help buyers receive accurate quotes and compare offers effectively, ensuring they get the best value for their investments. -

Incoterms (International Commercial Terms)

– Incoterms define the responsibilities of buyers and sellers in international shipping. Familiarity with these terms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is vital for understanding who bears the costs and risks associated with transportation, which can significantly impact overall pricing. -

Lead Time

– Lead time refers to the amount of time it takes for a supplier to fulfill an order after it has been placed. Buyers should always inquire about lead times to manage their production schedules and ensure timely delivery of materials. -

Certification Standards

– Certification standards like ISO or RoHS indicate compliance with specific quality and safety regulations. Buyers should prioritize sourcing from manufacturers that adhere to these standards to ensure product reliability and safety in their applications.

By grasping these technical properties and trade terms, international B2B buyers can make informed purchasing decisions and foster successful supplier relationships in the copper wire market from China.

Navigating Market Dynamics and Sourcing Trends in the copper wire china Sector

What are the Current Market Dynamics and Key Trends in the Copper Wire Sector?

The copper wire market has been experiencing significant shifts driven by technological advancements and changing buyer preferences. One of the primary global drivers is the increasing demand for high-conductivity materials across various sectors, including renewable energy, telecommunications, and construction. Countries in Africa, South America, the Middle East, and Europe are witnessing robust growth in infrastructure projects, which fuels the demand for copper wire. For instance, nations like Kenya are investing heavily in energy and transportation projects, while Italy focuses on upgrading its electrical grid.

Emerging B2B technologies are also reshaping sourcing trends. The rise of digital marketplaces allows international buyers to connect directly with manufacturers in China, streamlining procurement processes. Additionally, the integration of AI and data analytics in supply chain management enables buyers to make informed decisions by predicting market fluctuations and optimizing inventory levels. This is particularly relevant for buyers from regions with fluctuating copper prices, as timely information can lead to cost savings.

Furthermore, sustainability is becoming a critical factor for B2B buyers. Companies are increasingly looking for suppliers who can demonstrate responsible sourcing practices and transparent supply chains. This trend is particularly prevalent in Europe, where regulatory frameworks are pushing for greater accountability in raw material sourcing.

How is Sustainability Impacting the Sourcing of Copper Wire in China?

Sustainability and ethical sourcing have become paramount in the copper wire industry, reflecting a broader shift towards environmental responsibility. The extraction and processing of copper have significant environmental impacts, including habitat destruction and high energy consumption. International B2B buyers are increasingly prioritizing suppliers that adhere to sustainable practices, which not only mitigates environmental harm but also enhances their own brand reputation.

The importance of ethical supply chains cannot be overstated. Buyers from regions like Africa and South America are particularly concerned about the social implications of sourcing copper wire, including labor practices and community impacts. By choosing suppliers with certifications such as ISO 14001 (Environmental Management) or the Responsible Minerals Initiative, companies can ensure that their procurement aligns with global sustainability standards.

Moreover, the demand for ‘green’ materials is rising. Buyers are seeking copper wire products that are either recycled or produced using renewable energy sources. This trend presents an opportunity for suppliers to differentiate themselves in a competitive market by offering sustainable alternatives that meet the evolving expectations of international buyers.

What is the Evolution of the Copper Wire Market in China?

The copper wire market in China has evolved significantly over the past few decades, transitioning from a predominantly domestic focus to becoming a global powerhouse in copper production and exportation. In the early 2000s, China began to ramp up its manufacturing capabilities, leveraging its vast labor force and investment in infrastructure. This expansion allowed Chinese manufacturers to dominate the global copper wire market, catering to diverse industries and international buyers.

As the market matured, so did the complexities of sourcing copper wire. Buyers began to demand higher quality and more reliable supply chains, prompting manufacturers to adopt advanced technologies and quality control measures. The shift towards sustainability and ethical sourcing has also influenced this evolution, with many manufacturers now prioritizing environmentally friendly practices to meet the demands of global buyers.

Today, China remains a crucial player in the copper wire sector, with ongoing innovations and adaptations that respond to global market dynamics. This evolution presents a wealth of opportunities for international B2B buyers seeking reliable, high-quality copper wire products while navigating the complexities of sustainability and ethical sourcing.

Frequently Asked Questions (FAQs) for B2B Buyers of copper wire china

-

How do I ensure the quality of copper wire sourced from China?

To ensure quality, request samples from potential suppliers before placing large orders. Look for certifications such as ISO 9001, which indicates adherence to international quality standards. Additionally, consider third-party quality inspections, especially if you are sourcing in bulk. Establishing clear specifications for the copper wire, including purity levels and gauge sizes, can also help prevent issues down the line. Engaging with suppliers who have a strong reputation and positive reviews in the industry can further ensure quality assurance. -

What are the key factors to consider when vetting copper wire suppliers in China?

When vetting suppliers, evaluate their production capabilities, industry experience, and financial stability. Check their compliance with international standards and certifications relevant to copper wire. It’s advisable to perform background checks, including visiting their manufacturing facilities if possible. Additionally, seek references from other international buyers who have worked with them to gain insights into their reliability and service levels. Transparency in communication and responsiveness to inquiries can also indicate a supplier’s professionalism. -

What is the typical minimum order quantity (MOQ) for copper wire from Chinese suppliers?

MOQs for copper wire can vary significantly among suppliers, typically ranging from 1,000 to 5,000 meters, depending on the type and specifications of the wire. Some manufacturers may offer lower MOQs for custom orders, but this can affect pricing. It’s beneficial to negotiate MOQs, especially if you are looking to test the market with smaller quantities first. Understanding your own demand and aligning it with the supplier’s capabilities can lead to better terms. -

What payment terms should I expect when sourcing copper wire from China?

Payment terms can vary widely among suppliers, but common practices include a 30% upfront deposit with the balance due before shipment. Some suppliers may offer more flexible terms, such as Letter of Credit (L/C) or PayPal for smaller transactions. Always clarify payment methods and terms before finalizing your order to avoid misunderstandings. It’s also advisable to use secure payment options that provide buyer protection to minimize risks. -

How can I customize copper wire orders to meet specific requirements?

To customize your copper wire orders, clearly define your specifications, including wire gauge, insulation type, and length. Engage with suppliers who have experience in custom orders and are willing to accommodate specific requests. Providing detailed drawings or samples can help suppliers understand your needs better. Discuss lead times for custom orders, as these can be longer than standard products, and ensure that both parties agree on the design and quality standards before production begins. -

What logistics considerations should I keep in mind when importing copper wire from China?

Logistics play a crucial role in international trade. Consider factors such as shipping methods (air freight vs. sea freight), lead times, and customs clearance processes. Work with a reliable freight forwarder familiar with importing copper wire to navigate tariffs and regulations. Also, factor in costs associated with insurance and storage, as well as the reliability of the supplier’s delivery schedules. Keeping open lines of communication with your logistics partner can help mitigate potential delays.

A stock image related to copper wire china.

-

What are the common challenges faced by international B2B buyers when sourcing copper wire?

Challenges may include fluctuating prices due to market demand, quality inconsistencies among suppliers, and navigating complex import regulations. Language barriers can also complicate communication, leading to misunderstandings. Additionally, ensuring timely delivery amidst global shipping disruptions can be challenging. To overcome these obstacles, establish strong relationships with suppliers, conduct thorough market research, and stay updated on industry trends. Having contingency plans for sourcing and logistics can also help manage risks effectively. -

How can I build long-term relationships with copper wire suppliers in China?

Building long-term relationships involves consistent communication, transparency, and mutual respect. Regularly engage with suppliers through updates on your business needs and market trends. Establish clear expectations regarding quality and delivery timelines, and provide feedback to help suppliers improve. Consider visiting their facilities periodically to strengthen your partnership. Offering loyalty incentives, such as larger orders or longer contracts, can also encourage suppliers to prioritize your business and foster a collaborative environment.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for copper wire china

In the competitive landscape of copper wire sourcing, international buyers must prioritize strategic sourcing to optimize their supply chain efficiency and cost-effectiveness. The insights provided throughout this guide highlight the critical factors influencing copper wire procurement from China, including the importance of supplier reliability, quality assurance, and market trends. By leveraging long-term partnerships with reputable Chinese manufacturers, companies from Africa, South America, the Middle East, and Europe can secure a consistent supply of high-quality copper wire, essential for various applications from construction to electronics.

How Can Strategic Sourcing Enhance Your Copper Wire Procurement?

Strategic sourcing not only reduces costs but also mitigates risks associated with supply chain disruptions. As global demand for copper wire continues to rise, international buyers must remain vigilant about market fluctuations and regulatory changes. Engaging with local experts and conducting thorough market research will provide a competitive edge in navigating these complexities.

What Should B2B Buyers Do Next?

Looking ahead, B2B buyers should actively explore opportunities for collaboration with Chinese suppliers, focusing on innovation and sustainability in sourcing practices. By adopting a proactive approach to sourcing, businesses can enhance their operational resilience and adaptability in an ever-changing market. Now is the time to take action—evaluate your sourcing strategy and align it with the insights shared in this guide to ensure your business thrives in the global copper wire market.