Discover Cost-Saving Benefits of a Dog Tag Manufacturer (2025)

Introduction: Navigating the Global Market for dog tag manufacturer

In the fast-paced world of international trade, sourcing high-quality dog tag manufacturers poses a unique challenge for B2B buyers across diverse markets. Whether you’re a distributor in South Africa, a retailer in Argentina, or a procurement officer in the Middle East, understanding the nuances of dog tag production is essential for ensuring product quality, compliance, and cost-effectiveness. This guide aims to demystify the global landscape of dog tag manufacturing, offering insights into various types of tags, their applications, and the critical factors to consider when selecting suppliers.

From military use to pet identification and promotional items, dog tags serve myriad purposes across industries. This comprehensive resource covers essential topics such as the types of materials used, customization options, and the latest manufacturing technologies. It also delves into the crucial process of supplier vetting, highlighting best practices for assessing potential partners based on quality certifications, production capabilities, and ethical standards.

Moreover, understanding cost structures and price negotiation strategies will empower B2B buyers to make informed decisions, ultimately leading to successful procurement outcomes. By equipping yourself with the knowledge provided in this guide, you will be better positioned to navigate the complexities of the global market and establish fruitful partnerships with reliable dog tag manufacturers. Together, we will explore the pathways to streamline your sourcing process and enhance your competitive edge in the market.

Understanding dog tag manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Metal Dog Tag Manufacturers | Durable materials like stainless steel or aluminum | Military, pet identification, outdoor gear | Pros: High durability, custom engraving. Cons: Heavier, may be costlier. |

| Plastic Dog Tag Manufacturers | Lightweight, customizable colors and shapes | Promotional products, events, pet tags | Pros: Cost-effective, versatile designs. Cons: Less durable than metal. |

| Engraved Dog Tag Manufacturers | Precision engraving for detailed information | Identification, awards, commemorative items | Pros: High-quality finish, long-lasting. Cons: Limited material options. |

| Printed Dog Tag Manufacturers | Full-color printing capabilities | Marketing, branding, events | Pros: Eye-catching designs, quick production. Cons: Less durable, may fade. |

| Specialty Dog Tag Manufacturers | Unique features like RFID or QR codes | Security, asset tracking, veterinary uses | Pros: Innovative technology, enhanced functionality. Cons: Higher price point. |

What are the Characteristics of Metal Dog Tag Manufacturers?

Metal dog tag manufacturers typically utilize materials such as stainless steel or aluminum, known for their durability and resistance to wear and tear. This type is ideal for military applications, pet identification, and outdoor gear, where tags are exposed to harsh conditions. When considering metal tags, buyers should assess the weight and potential for custom engraving, as these features can enhance both functionality and branding opportunities.

How Do Plastic Dog Tag Manufacturers Differ?

Plastic dog tag manufacturers focus on lightweight, versatile products that can be easily customized in various colors and shapes. They are commonly used for promotional products, events, and pet tags. Buyers should consider the cost-effectiveness of plastic tags, especially for large orders. However, it is crucial to note that while they offer a wide range of design options, plastic tags may not withstand harsh conditions as well as their metal counterparts.

What Should Buyers Know About Engraved Dog Tag Manufacturers?

Engraved dog tag manufacturers specialize in producing tags with precision engraving, allowing for detailed information to be clearly displayed. These tags are popular for identification purposes, awards, and commemorative items. Buyers looking for high-quality finishes and long-lasting products should consider this option, but they should also be aware of the limited material choices available, which may restrict design flexibility.

What Are the Advantages of Printed Dog Tag Manufacturers?

Printed dog tag manufacturers offer the ability to create full-color designs that are visually striking, making them ideal for marketing and branding purposes. They are often used for events and promotional giveaways. While they can be produced quickly, buyers should weigh the aesthetic benefits against the potential for reduced durability, as printed designs may fade over time, especially when exposed to outdoor elements.

How Do Specialty Dog Tag Manufacturers Stand Out?

Specialty dog tag manufacturers provide unique features such as RFID or QR codes, which add enhanced functionality for security, asset tracking, and veterinary uses. This innovative technology is increasingly appealing to businesses looking for advanced solutions. Buyers should consider the higher price point associated with specialty tags, but the added benefits of improved tracking and identification can justify the investment in many B2B contexts.

Related Video: Pitbull Colors: 23 Coat Color Variations Explained (With Pictures)

Key Industrial Applications of dog tag manufacturer

| Industry/Sector | Specific Application of dog tag manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Military and Defense | Identification tags for personnel and equipment | Enhances security and accountability | Compliance with military standards and durability requirements |

| Healthcare | Patient identification and tracking | Improves patient safety and care efficiency | Biocompatibility and customization options for specific needs |

| Hospitality and Events | Guest identification and access control | Streamlines event management and enhances security | Branding options and durability for outdoor events |

| Pet Care | Animal identification tags | Reduces loss of pets and facilitates reunification | Customization for different animal sizes and materials used |

| Retail and E-commerce | Product tagging and inventory management | Improves inventory accuracy and reduces theft | Scalability and integration with existing inventory systems |

How Are Dog Tags Used in the Military and Defense Sector?

In the military and defense sector, dog tags serve as essential identification tools for personnel and equipment. They help maintain accountability and security, especially in combat situations where quick identification is critical. Buyers from this sector need to ensure that the tags meet specific military standards for durability and resistance to environmental factors. Additionally, manufacturers must offer customization options to include vital information such as blood type and emergency contacts.

What Role Do Dog Tags Play in Healthcare?

In healthcare settings, dog tags are increasingly utilized for patient identification and tracking. These tags are crucial in preventing medical errors and ensuring that patients receive the correct treatments. International buyers in the healthcare industry must consider the biocompatibility of materials used in manufacturing dog tags, especially for patients with allergies. Customization options, such as barcodes or RFID technology, can further enhance tracking capabilities and improve overall patient care.

How Are Dog Tags Beneficial in Hospitality and Events?

In the hospitality and events industry, dog tags are used for guest identification and access control. They facilitate streamlined event management by allowing staff to easily identify guests and grant them appropriate access. For international buyers, sourcing tags that offer branding options is essential for enhancing the event’s theme. Durability is also a key consideration, particularly for outdoor events where tags may be exposed to various weather conditions.

Why Are Dog Tags Important in Pet Care?

Dog tags play a vital role in the pet care industry by providing identification for animals. These tags significantly reduce the chances of pets getting lost and aid in their swift reunification with owners. Buyers in this sector should prioritize customization options that cater to different animal sizes and ensure that the materials used are safe and comfortable for pets. The ability to incorporate features such as QR codes can further enhance the functionality of these identification tags.

How Do Dog Tags Enhance Retail and E-commerce Operations?

In retail and e-commerce, dog tags are instrumental in product tagging and inventory management. They help businesses improve inventory accuracy and reduce theft, thereby enhancing operational efficiency. International buyers should look for manufacturers who can provide scalable solutions that integrate seamlessly with existing inventory systems. Customization options for branding and unique product identifiers can also add significant value to retail operations.

3 Common User Pain Points for ‘dog tag manufacturer’ & Their Solutions

Scenario 1: Inconsistent Quality and Durability of Dog Tags

The Problem: Many B2B buyers face the challenge of inconsistent quality when sourcing dog tags from manufacturers. This inconsistency can lead to tags that wear out quickly or fail to meet required specifications, resulting in additional costs and reputational damage. For businesses in sectors like the military, pet services, or event management, the reliability and durability of dog tags are critical. A buyer from South Africa, for example, may experience frustration when tags that were promised to last a year start fading within months.

The Solution: To ensure consistent quality, buyers should establish stringent quality assurance criteria before engaging with a dog tag manufacturer. Request samples to evaluate the material and print quality, and consider manufacturers who provide warranties or guarantees on their products. It is also beneficial to inquire about the manufacturing process, including the materials used (such as stainless steel versus aluminum) and the printing techniques (laser engraving vs. printing). Establishing a clear set of expectations and maintaining open lines of communication throughout the manufacturing process can help mitigate these quality issues.

Scenario 2: Complicated Customization Processes for Dog Tags

The Problem: Customization is a key requirement for many B2B buyers, but the process can often be convoluted and time-consuming. For instance, a buyer in Argentina looking to create unique dog tags for a promotional campaign may find that many manufacturers have rigid templates or limited options for customization. This can lead to delays and ultimately affect the marketing strategy due to a lack of tailored products.

The Solution: Buyers should prioritize manufacturers who specialize in flexible customization options. Look for companies that offer a user-friendly online design tool that allows you to visualize your custom tags in real-time. Additionally, establish a clear timeline for customization and request a detailed outline of the steps involved. Engaging in a dialogue with the manufacturer to understand their capabilities and limitations can also help streamline the process. Furthermore, consider partnering with manufacturers who have a proven track record in producing custom tags for similar industries.

Scenario 3: High Minimum Order Quantities Leading to Excess Inventory

The Problem: Many dog tag manufacturers impose high minimum order quantities (MOQs), which can be a significant barrier for small to medium-sized enterprises (SMEs) or startups. A buyer from the Middle East may find that ordering 500 tags is excessive for their initial needs, resulting in excess inventory that ties up capital and storage space. This situation can be particularly problematic for seasonal or event-based sales strategies.

The Solution: To navigate high MOQs, buyers should seek out manufacturers who offer flexible order quantities or tiered pricing structures. Some manufacturers may be willing to negotiate on MOQs for first-time orders or for long-term contracts. Additionally, consider forming a purchasing consortium with other businesses in your region to collectively meet MOQ requirements. This collaborative approach not only reduces costs but also fosters community partnerships. Researching manufacturers that cater specifically to SMEs can also lead to better pricing and order flexibility, ultimately allowing for a more manageable inventory strategy.

Strategic Material Selection Guide for dog tag manufacturer

When selecting materials for dog tags, manufacturers must consider various factors that influence product performance, durability, and cost. Below is an analysis of four common materials used in dog tag manufacturing, tailored to meet the needs of international B2B buyers from regions such as Africa, South America, the Middle East, and Europe.

What are the Key Properties of Aluminum for Dog Tags?

Aluminum is a popular choice for dog tags due to its lightweight nature and corrosion resistance. It typically performs well under a range of temperatures and pressures, making it suitable for various environments. Aluminum is also non-magnetic, which is advantageous for military and security applications.

Pros & Cons:

The main advantage of aluminum is its cost-effectiveness and ease of manufacturing. It can be easily anodized for additional durability and aesthetic appeal. However, aluminum is less durable than other metals and can be prone to scratching and bending, which may not be ideal for high-impact environments.

Impact on Application:

Aluminum dog tags are suitable for general use, including identification for pets and personnel. However, they may not withstand extreme conditions, such as high heat or exposure to harsh chemicals.

Considerations for International Buyers:

When sourcing aluminum dog tags, buyers should ensure compliance with relevant standards such as ASTM B209 for aluminum sheet and plate. Additionally, understanding local regulations regarding recycling and material sourcing is essential, especially in regions like South Africa and Argentina.

How Does Stainless Steel Compare as a Material for Dog Tags?

Stainless steel is renowned for its strength and corrosion resistance, making it an excellent choice for dog tags intended for rugged use. It can withstand high temperatures and is resistant to tarnishing, which is critical for maintaining the tag’s appearance over time.

Pros & Cons:

The key advantage of stainless steel is its durability, making it suitable for military, industrial, and outdoor applications. However, the manufacturing process can be more complex and costly compared to aluminum. Additionally, stainless steel is heavier, which may be a consideration for some applications.

Impact on Application:

Stainless steel dog tags are ideal for environments where durability is paramount, such as in military or adventure sports. They are compatible with a wide range of media, including water and various chemicals, without degrading.

Considerations for International Buyers:

Buyers should look for compliance with standards such as ASTM A240 for stainless steel sheets. Understanding the specific grades of stainless steel used (e.g., 304 vs. 316) is crucial for ensuring the right balance of cost and performance.

What Are the Advantages of Using Plastic for Dog Tags?

Plastic dog tags are lightweight, flexible, and can be produced in various colors and designs. They are often used in applications where cost is a significant factor, such as promotional items or temporary identification tags.

Pros & Cons:

The primary advantage of plastic is its low cost and ease of customization. However, plastic is generally less durable than metal and may not withstand extreme environmental conditions. It can also be susceptible to fading and cracking over time.

Impact on Application:

Plastic dog tags are suitable for short-term use or promotional events but may not be appropriate for long-term identification needs in harsh environments.

Considerations for International Buyers:

Buyers should be aware of the environmental impact of plastic and consider sourcing biodegradable options. Compliance with local regulations regarding plastic use and disposal is also essential, especially in regions with strict environmental laws.

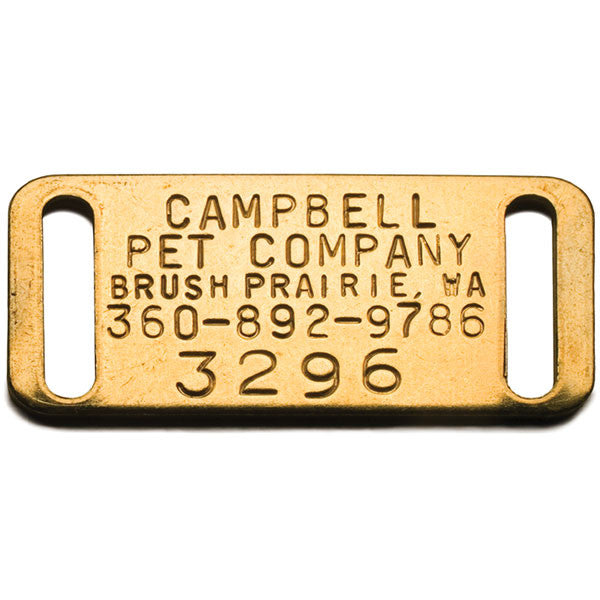

How Does Brass Fit into the Material Selection for Dog Tags?

Brass offers a unique aesthetic appeal with its gold-like appearance, making it a popular choice for decorative dog tags. It has good corrosion resistance and can be easily engraved.

Pros & Cons:

The aesthetic quality of brass is its key advantage, appealing to consumers looking for stylish identification solutions. However, brass can tarnish over time and may require regular maintenance to keep its appearance. Additionally, it is generally more expensive than aluminum and plastic.

Impact on Application:

Brass dog tags are often used in fashion accessories or as commemorative items. They are not typically suited for high-stress environments due to their susceptibility to wear and tarnish.

Considerations for International Buyers:

When sourcing brass dog tags, buyers should consider compliance with standards such as ASTM B36 for brass. Understanding the alloy composition is important, especially in regions where specific material properties are required for durability.

Summary Table of Material Selection for Dog Tags

| Material | Typical Use Case for dog tag manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | General identification tags | Lightweight and cost-effective | Less durable, prone to scratches | Low |

| Stainless Steel | Military and industrial applications | High durability and corrosion resistance | Heavier and more expensive | High |

| Plastic | Promotional and temporary tags | Low cost and easy customization | Less durable, can fade or crack | Low |

| Brass | Decorative and commemorative items | Aesthetic appeal | Can tarnish and requires maintenance | Medium |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, helping them make informed decisions based on their specific needs and regional considerations.

A stock image related to dog tag manufacturer.

In-depth Look: Manufacturing Processes and Quality Assurance for dog tag manufacturer

What Are the Main Stages of Manufacturing Dog Tags?

The manufacturing process for dog tags involves several key stages, each critical to ensuring the final product meets quality and durability standards. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation: What Materials Are Commonly Used for Dog Tags?

The first stage in the manufacturing process is material preparation. Dog tags are typically made from stainless steel, aluminum, or brass due to their durability and corrosion resistance. Suppliers often source these materials from certified vendors to ensure quality. Buyers should inquire about the material specifications and certifications, such as ASTM standards, to ensure they meet their requirements.

How Are Dog Tags Formed During Manufacturing?

The forming stage involves shaping the raw materials into the desired dog tag form. This process may include methods such as stamping, laser cutting, or CNC machining. Stamping is the most common method, as it allows for high-volume production and can achieve intricate designs. B2B buyers should consider the manufacturer‘s capabilities in these techniques, as they impact both the cost and the design flexibility of the final product.

What Is Involved in the Assembly Process of Dog Tags?

Once the individual components are formed, they move to the assembly stage. For dog tags, this typically includes adding features such as holes for chains or engraving. Manufacturers may utilize automated systems for assembly to enhance efficiency and consistency. Buyers should ask about the assembly process to ensure it aligns with their desired product features and quality standards.

How Is the Finishing Stage Critical for Dog Tag Quality?

The finishing stage is essential for enhancing the aesthetic appeal and durability of dog tags. This may involve processes such as polishing, anodizing, or applying protective coatings. The choice of finishing technique can affect the tag’s resistance to scratches and environmental factors. B2B buyers should discuss finishing options with manufacturers to ensure they meet their branding and durability needs.

What International Standards Govern Quality Assurance in Dog Tag Manufacturing?

Quality assurance is critical in the dog tag manufacturing process, ensuring that products meet both customer expectations and regulatory requirements. International standards like ISO 9001 provide a framework for quality management systems, helping manufacturers maintain consistent quality across production.

Which Industry-Specific Certifications Should Buyers Look For?

In addition to general standards, specific certifications may apply to dog tag manufacturing, such as CE marking in Europe and API specifications in the oil and gas industry. Buyers should verify that their suppliers hold relevant certifications, as this can impact market access and compliance with local regulations.

What Are the Key Quality Control Checkpoints in Dog Tag Manufacturing?

Quality control (QC) is an ongoing process that includes multiple checkpoints throughout the manufacturing stages. Common checkpoints include:

- Incoming Quality Control (IQC): Verification of raw materials upon receipt to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during production to identify defects early and minimize waste.

- Final Quality Control (FQC): Inspection of finished products to ensure they meet all specifications before shipment.

B2B buyers should inquire about the QC processes of potential suppliers to ensure rigorous standards are upheld.

What Common Testing Methods Are Used in Dog Tag Quality Assurance?

To validate the quality of dog tags, manufacturers may employ various testing methods, including:

- Mechanical Testing: Assessing tensile strength, hardness, and flexibility.

- Corrosion Resistance Testing: Evaluating how well the tags withstand environmental factors.

- Dimensional Inspection: Ensuring that the tags meet specified measurements and tolerances.

Buyers can request reports on these tests to verify compliance with their quality standards.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control practices of their suppliers. Here are some strategies:

- Conduct Audits: Schedule on-site audits to assess manufacturing processes and quality control systems directly.

- Request Quality Reports: Ask suppliers for documentation detailing their QC processes, including any testing results and certifications.

- Engage Third-Party Inspectors: Consider hiring independent inspection services to evaluate production quality before shipment.

What Are the Quality Control Nuances for International Buyers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential. Different markets may have specific regulations and standards that manufacturers must adhere to. For example, European buyers may require CE certification, while buyers in the Middle East might focus on compliance with local standards.

Additionally, cultural differences can influence communication and expectations regarding quality. Buyers should establish clear quality specifications and maintain open lines of communication with suppliers to mitigate any potential misunderstandings.

Conclusion: How to Make Informed Decisions in Dog Tag Procurement

In summary, understanding the manufacturing processes and quality assurance practices for dog tags is crucial for international B2B buyers. By familiarizing themselves with the stages of production, relevant standards, and effective verification methods, buyers can make more informed decisions. This not only enhances their supply chain reliability but also ensures that the final products meet their quality and branding requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dog tag manufacturer’

In the competitive landscape of international B2B procurement, sourcing a reliable dog tag manufacturer requires a strategic approach. This guide provides a comprehensive checklist to help buyers from Africa, South America, the Middle East, and Europe navigate the sourcing process effectively, ensuring they select a supplier that meets their technical and commercial needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first critical step in sourcing dog tags. Determine the materials, dimensions, and any specific features required, such as engraving or color options. This clarity helps in communicating your needs to potential suppliers and ensures that the products meet your standards.

Step 2: Conduct Market Research for Potential Suppliers

Before reaching out, conduct thorough market research to identify potential dog tag manufacturers. Utilize online platforms, trade shows, and industry networks to gather a list of suppliers. Pay attention to their geographical location, as sourcing from nearby regions can reduce shipping costs and lead times.

Step 3: Verify Supplier Certifications and Compliance

Compliance with industry standards is essential when selecting a manufacturer. Request certifications such as ISO 9001 for quality management and any relevant safety standards. This step ensures that the supplier adheres to best practices, which can significantly affect product quality and reliability.

Step 4: Evaluate Potential Suppliers’ Experience and Reputation

Review the experience and reputation of each potential supplier. Look for case studies, client testimonials, and references, particularly from businesses in similar industries or regions. A supplier with a proven track record is more likely to deliver quality products on time.

Step 5: Request and Analyze Samples

Before making a bulk order, request samples of the dog tags you intend to procure. Analyzing samples allows you to evaluate the quality, durability, and craftsmanship of the products. Ensure the samples reflect your specifications to avoid discrepancies in the final order.

Step 6: Discuss Pricing and Payment Terms

Engage in discussions regarding pricing structures and payment terms with shortlisted suppliers. Be transparent about your budget, and inquire about bulk order discounts, payment schedules, and any additional costs such as shipping or customs duties. Understanding these terms upfront can help you avoid unexpected expenses.

Step 7: Establish Clear Communication Channels

Effective communication is vital throughout the sourcing process. Establish clear channels for updates, queries, and feedback. Consider language barriers and time zone differences, especially when dealing with suppliers from diverse regions. This proactive approach fosters a collaborative relationship and minimizes misunderstandings.

By following this checklist, B2B buyers can streamline their sourcing process for dog tag manufacturers, ensuring they select a partner that aligns with their quality standards and business objectives.

Comprehensive Cost and Pricing Analysis for dog tag manufacturer Sourcing

What Are the Key Cost Components in Dog Tag Manufacturing?

Understanding the cost structure is crucial for B2B buyers sourcing dog tags. The primary cost components include:

-

Materials: The choice of materials—such as stainless steel, aluminum, or plastic—significantly impacts pricing. Higher-quality materials typically lead to increased durability and aesthetic appeal, but they also elevate costs. International buyers should consider local suppliers for raw materials to mitigate import duties and shipping costs.

-

Labor: Labor costs vary by region. In countries with lower wage standards, such as certain areas in Africa and South America, manufacturers may offer competitive pricing. However, the skill level of the workforce can also affect quality, which is vital for maintaining standards.

-

Manufacturing Overhead: This includes utilities, rent, and equipment maintenance. Buyers should inquire about the overhead rates to understand how they affect overall pricing. Efficient manufacturers often have lower overheads, which can translate to better prices for buyers.

-

Tooling: Custom tooling can be a significant upfront cost, especially for unique designs. Buyers should weigh the benefits of custom tooling against the potential for increased production costs and lead times.

-

Quality Control (QC): Investing in QC processes ensures that the final products meet specifications and standards. A robust QC system may add to initial costs but can save money in the long run by reducing defects and returns.

-

Logistics: Shipping costs and delivery times can vary widely based on the manufacturer’s location and the buyer’s destination. Understanding the logistics involved is crucial for budgeting and ensuring timely delivery.

-

Margin: Manufacturers typically add a profit margin to their pricing. This margin can vary based on competition, market demand, and the perceived value of the product.

How Do Price Influencers Affect Dog Tag Sourcing?

Several factors can influence the pricing of dog tags, which B2B buyers should carefully consider:

-

Volume and Minimum Order Quantity (MOQ): Ordering in bulk often leads to lower per-unit costs. Buyers should negotiate MOQs that align with their needs while maximizing cost efficiency.

-

Specifications and Customization: Custom designs or specifications may incur additional costs. Buyers should evaluate whether the added value justifies the extra expense.

-

Materials and Quality Certifications: The choice of materials and any relevant quality certifications can affect pricing. Ensure that the supplier complies with industry standards, which can also impact the final price.

-

Supplier Factors: The supplier’s reputation, experience, and production capabilities play a significant role in pricing. Reliable suppliers may charge more, but they often provide better quality and service.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for international buyers. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can influence pricing and risk allocation in shipping.

What Tips Can Help Buyers Negotiate Better Pricing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, employing effective negotiation strategies can lead to significant cost savings:

-

Research and Benchmarking: Conduct thorough market research to understand standard pricing. This knowledge will empower buyers during negotiations.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial price. Consider factors like durability, maintenance, and potential replacement costs to assess the true value of the investment.

-

Build Long-term Relationships: Establishing strong relationships with suppliers can lead to better pricing, terms, and priority service. Long-term partnerships often yield more favorable conditions.

-

Be Prepared to Walk Away: If the price does not meet your budget or expectations, be willing to explore other suppliers. This strategy can sometimes prompt suppliers to offer better deals.

Conclusion: Pricing Nuances for International B2B Buyers

In conclusion, sourcing dog tags involves navigating a complex landscape of costs and pricing influences. By understanding the various components and employing strategic negotiation tactics, international buyers can optimize their purchasing decisions. Keep in mind that prices can fluctuate due to market conditions, so always obtain updated quotes and maintain flexibility in your sourcing strategy.

Alternatives Analysis: Comparing dog tag manufacturer With Other Solutions

In today’s global marketplace, B2B buyers face a multitude of options when selecting solutions for identification and branding needs, such as dog tags. Understanding the alternatives available is essential for making informed decisions that align with specific business objectives. This section will explore how dog tag manufacturers compare to other viable solutions, including digital ID solutions and custom-printed labels.

Comparison Table: Evaluating Dog Tag Manufacturer Against Alternative Solutions

| Comparison Aspect | Dog Tag Manufacturer | Digital ID Solutions | Custom-Printed Labels |

|---|---|---|---|

| Performance | High durability and visibility | Flexible, can be updated easily | Variable durability based on materials |

| Cost | Moderate to high | Subscription-based or one-time fee | Generally low to moderate |

| Ease of Implementation | Requires setup and inventory | Quick setup, software dependent | Simple printing process |

| Maintenance | Low maintenance | Requires periodic updates | Low maintenance, depends on application |

| Best Use Case | Military, events, pet identification | Corporate ID, access control | Product labeling, events, promotional items |

What Are the Pros and Cons of Digital ID Solutions?

Digital ID solutions leverage technology to provide flexible and easily updatable identification methods. One of the primary advantages is their adaptability; companies can modify digital IDs to reflect changes in personnel or branding without incurring significant costs. Moreover, they often integrate with existing IT infrastructure, allowing for streamlined access control and tracking.

However, there are downsides. Digital IDs require ongoing management, including software updates and potentially higher long-term costs if subscription models are utilized. Additionally, reliance on technology can pose risks in areas with limited internet connectivity or in situations where physical access is required.

How Do Custom-Printed Labels Compare?

Custom-printed labels offer a cost-effective and straightforward solution for identification needs. They are particularly advantageous for businesses looking for a low-cost alternative that can be produced quickly and in bulk. Custom labels can be designed to fit various applications, from product packaging to event giveaways, making them versatile.

On the flip side, custom-printed labels may not provide the same level of durability as dog tags or digital IDs, especially in harsh environments. Their longevity can be affected by factors such as exposure to moisture or abrasion, which can lead to fading or wear over time. Consequently, businesses must consider the specific application and environmental conditions when opting for labels.

How Can B2B Buyers Choose the Right Solution?

When selecting between a dog tag manufacturer and alternative solutions, B2B buyers should carefully assess their unique needs and the context in which the identification solution will be used. Factors such as budget constraints, the intended lifespan of the product, and the need for adaptability should be prioritized. For instance, military organizations may prioritize the robustness of dog tags, while corporate environments might lean towards the flexibility of digital IDs. Ultimately, understanding the specific requirements will enable buyers to make a choice that enhances their operational efficiency and meets their branding objectives.

Essential Technical Properties and Trade Terminology for dog tag manufacturer

What Are the Key Technical Properties of Dog Tags?

Understanding the essential technical properties of dog tags is crucial for B2B buyers looking to make informed purchasing decisions. Here are some critical specifications that you should consider:

1. Material Grade

The choice of material significantly impacts the durability, aesthetic appeal, and overall functionality of dog tags. Common materials include stainless steel, aluminum, brass, and titanium. Each material has unique properties; for instance, stainless steel offers corrosion resistance and longevity, making it ideal for military or outdoor use. B2B buyers must specify the desired material grade to ensure the product meets their requirements for strength and appearance.

2. Tolerance

Tolerance refers to the allowable variation in dimensions and is critical for ensuring compatibility with other equipment or accessories. For instance, a tolerance of ±0.1 mm might be acceptable for standard dog tags, while military applications may require tighter tolerances. Understanding tolerances helps buyers evaluate the precision of the manufacturing process, which is vital for applications that demand high accuracy.

3. Finish

The finish of dog tags affects both aesthetics and functionality. Common finishes include brushed, polished, and anodized. A brushed finish may enhance grip and reduce glare, while anodized finishes can improve corrosion resistance and allow for vibrant colors. Buyers should consider the intended use when selecting a finish, as it can impact the tag’s visibility and durability.

4. Weight

Weight is another significant property that can influence user comfort, especially for tags meant to be worn for extended periods. Lightweight materials like aluminum are preferable for everyday wear, while heavier materials like stainless steel may be better suited for rugged environments. B2B buyers should assess the weight of the dog tag in relation to its intended application and user demographics.

5. Customization Options

A stock image related to dog tag manufacturer.

Customization capabilities, such as engraving or embossing, allow businesses to tailor dog tags to specific branding or identification needs. This property is particularly important for military and corporate clients who require unique identifiers. Understanding the available customization options can enhance the product’s value and relevance for the buyer.

What Are Common Trade Terms Used in the Dog Tag Manufacturing Industry?

Familiarity with industry terminology can greatly facilitate negotiations and transactions. Here are some key trade terms relevant to dog tag manufacturing:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of dog tags, an OEM might create tags based on specifications provided by a branding company. Understanding OEM relationships can help buyers ensure they are sourcing high-quality products that meet their standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to produce or sell. For dog tags, MOQs can vary widely depending on the manufacturer and material. Buyers should be aware of MOQs to avoid over-committing to quantities that exceed their needs, which can impact cash flow and inventory management.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request price quotes for specific products. When purchasing dog tags, submitting an RFQ allows buyers to compare pricing, lead times, and terms across multiple suppliers, ensuring they receive the best value for their investment.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. For dog tags, understanding Incoterms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can help clarify shipping responsibilities and costs, minimizing the risk of misunderstandings during international trade.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. In dog tag manufacturing, lead times can vary based on the complexity of the order and the manufacturer’s capacity. Buyers should inquire about lead times to ensure they can meet their project deadlines and avoid disruptions.

By grasping these essential properties and terms, international B2B buyers can navigate the complexities of sourcing dog tags more effectively, ensuring they make informed decisions that align with their business goals.

Navigating Market Dynamics and Sourcing Trends in the dog tag manufacturer Sector

What Are the Current Market Dynamics and Sourcing Trends in the Dog Tag Manufacturer Sector?

The global dog tag manufacturing sector is undergoing significant transformation, driven by various market dynamics and emerging B2B technology trends. As international buyers from regions such as Africa, South America, the Middle East, and Europe seek reliable suppliers, they must navigate these complexities effectively. One of the primary drivers is the increasing demand for personalized and custom dog tags, which has led manufacturers to adopt advanced technologies like 3D printing and laser engraving. These technologies not only enhance product customization but also improve production efficiency, allowing for quicker turnaround times—a crucial factor for B2B buyers requiring swift delivery.

Moreover, the rise of e-commerce platforms and digital marketplaces has streamlined sourcing processes, making it easier for buyers to connect with manufacturers across the globe. However, this convenience comes with challenges, including quality assurance and supply chain transparency. Buyers must conduct thorough due diligence when evaluating suppliers to ensure they meet specific quality standards and compliance regulations.

Additionally, the market is influenced by geopolitical factors, economic fluctuations, and trade policies, especially in regions like the Middle East and Europe. For instance, tariffs and trade agreements can significantly impact pricing and availability. Understanding these dynamics is crucial for B2B buyers to optimize their sourcing strategies and mitigate risks associated with international procurement.

How Does Sustainability and Ethical Sourcing Impact the Dog Tag Manufacturing Sector?

Sustainability and ethical sourcing are increasingly becoming priorities for B2B buyers in the dog tag manufacturing sector. The environmental impact of production processes is under scrutiny, with manufacturers encouraged to adopt greener practices. This includes using recycled materials and reducing waste during production. Buyers are now more inclined to partner with suppliers that prioritize sustainability, as this aligns with their corporate social responsibility (CSR) goals and appeals to environmentally conscious consumers.

Ethical supply chains are also crucial. Buyers should look for manufacturers that adhere to fair labor practices and demonstrate transparency in their sourcing processes. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can serve as indicators of a manufacturer’s commitment to sustainability and ethical practices. By prioritizing suppliers with these certifications, B2B buyers can ensure that their procurement not only meets quality standards but also contributes positively to the environment and society.

Furthermore, the demand for ‘green’ materials, such as biodegradable plastics or sustainably sourced metals, is on the rise. Buyers should actively seek manufacturers who can provide these eco-friendly options, as they not only enhance brand reputation but can also lead to cost savings in waste management and compliance with environmental regulations.

What Is the Evolution of the Dog Tag Manufacturing Industry?

The dog tag manufacturing industry has evolved significantly over the decades, transitioning from basic identification tags used primarily by military personnel to personalized accessories with a wide range of applications. Initially, dog tags were simple metal plates stamped with identification information; however, advancements in technology have transformed them into customizable products that cater to various markets, including pet owners, fashion enthusiasts, and corporate branding.

In recent years, the integration of digital technology into manufacturing processes has further revolutionized the industry. The introduction of computer-aided design (CAD) and advanced engraving techniques has allowed for intricate designs and personalization options, meeting the growing consumer demand for unique products. This evolution has positioned dog tags not just as functional items but also as fashionable accessories, enabling manufacturers to explore new markets and expand their customer base.

As the industry continues to adapt to changing consumer preferences and technological advancements, international B2B buyers must stay informed about these trends to make strategic sourcing decisions that align with market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of dog tag manufacturer

-

How do I select a reliable dog tag manufacturer for my business needs?

To select a reliable dog tag manufacturer, start by researching potential suppliers through industry directories, trade shows, and online platforms. Look for manufacturers with positive reviews and established experience in the dog tag sector. Assess their production capabilities, certifications, and quality control measures. Request samples to evaluate material quality and craftsmanship. Finally, communicate directly with the manufacturer to gauge responsiveness and willingness to accommodate your specific requirements. -

What customization options are available when ordering dog tags?

Most dog tag manufacturers offer a variety of customization options, including material choice (e.g., stainless steel, aluminum), size, shape, color, and engraving techniques. You can often personalize tags with logos, text, or images, which is essential for branding. Ensure you discuss your specific design needs with the manufacturer and review their capabilities to guarantee they can deliver your desired specifications. -

What are the typical minimum order quantities (MOQ) for dog tags?

Minimum order quantities for dog tags can vary significantly by manufacturer and the complexity of the order. Generally, MOQs range from 100 to 1,000 pieces, but some manufacturers may accommodate smaller orders, especially for custom designs. It’s advisable to inquire about MOQs early in the negotiation process to align your purchasing plans with the manufacturer’s requirements, particularly if you’re a startup or entering a new market. -

What payment terms should I expect when sourcing dog tags internationally?

Payment terms can vary widely among international dog tag manufacturers. Common arrangements include upfront payments, partial payments, or payment upon delivery. Some manufacturers may accept credit cards, while others prefer bank transfers or letters of credit. Always clarify payment terms before finalizing your order and consider using secure payment methods to protect your investment, especially in cross-border transactions. -

How can I ensure quality assurance for my dog tag order?

To ensure quality assurance, request detailed information on the manufacturer’s quality control processes. This may include inspections during production, testing of materials, and compliance with international standards. Ask for certifications such as ISO or ASTM, which demonstrate adherence to quality benchmarks. You can also consider hiring a third-party inspection service to verify quality before shipment, especially for large orders. -

What logistics and shipping considerations should I keep in mind when ordering dog tags?

When ordering dog tags internationally, consider shipping methods, lead times, and customs clearance processes. Discuss logistics with your manufacturer to understand their shipping options and associated costs. Factor in potential delays at customs, especially if importing to countries with strict regulations. It’s also prudent to choose a reliable freight forwarder who can handle the complexities of international shipping, ensuring timely delivery. -

How can I effectively communicate my design requirements to a dog tag manufacturer?

Clear communication is crucial when conveying design requirements to a dog tag manufacturer. Prepare detailed specifications, including sketches, dimensions, materials, and any text or logos to be included. Utilize visual aids like mockups or reference images to illustrate your vision. Establish a direct line of communication, whether via email or video calls, to discuss feedback and adjustments promptly throughout the design process. -

What are the common challenges faced when sourcing dog tags internationally, and how can I overcome them?

Common challenges include language barriers, differing quality standards, and logistical issues. To overcome these, conduct thorough research on potential manufacturers, utilize translation services if necessary, and establish clear expectations from the outset. Building a strong relationship with your supplier can also help mitigate misunderstandings. Additionally, stay informed about trade regulations in both your country and the manufacturer’s location to navigate potential barriers effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for dog tag manufacturer

What Are the Key Takeaways for B2B Buyers in Dog Tag Manufacturing?

In conclusion, strategic sourcing in the dog tag manufacturing sector offers substantial benefits for international B2B buyers. By prioritizing supplier relationships, understanding regional market dynamics, and leveraging technology, businesses can enhance operational efficiency and reduce costs. Buyers from regions such as Africa, South America, the Middle East, and Europe should be particularly mindful of local regulations, cultural nuances, and logistical considerations when selecting suppliers.

How Can Strategic Sourcing Elevate Your Competitive Edge?

Engaging in a well-structured sourcing strategy not only streamlines procurement processes but also fosters innovation and responsiveness to market demands. This is essential in a competitive landscape where agility can determine market leadership. As you evaluate potential suppliers, consider their ability to adapt to changing consumer preferences and their commitment to sustainability practices, which are increasingly important to global buyers.

What Does the Future Hold for Dog Tag Manufacturing?

Looking ahead, the dog tag manufacturing industry is poised for growth driven by technological advancements and rising demand for personalized products. Buyers are encouraged to explore partnerships that emphasize flexibility and innovation. By doing so, you can position your business for success in an evolving market landscape. Take proactive steps today to secure a competitive advantage in this dynamic sector.