Discover Cost-Saving Benefits of Aluminum Composite Panel China (2025)

Introduction: Navigating the Global Market for aluminum composite panel china

Navigating the global market for aluminum composite panels from China can be a daunting task for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. With a multitude of suppliers, varying product specifications, and fluctuating prices, finding the right aluminum composite panel that meets quality and budget requirements is a significant challenge. This guide aims to streamline your sourcing process by providing comprehensive insights into the types of aluminum composite panels available, their diverse applications, and effective strategies for vetting suppliers.

In this guide, we delve into the key factors influencing the decision-making process, including material properties, manufacturing standards, and cost considerations. We also explore the latest trends in the industry, helping you stay ahead of the curve. Whether you are looking to invest in durable building materials for construction projects or aesthetic solutions for interior design, our guide equips you with the knowledge needed to make informed purchasing decisions.

By offering actionable insights and a structured approach to sourcing, this resource is tailored to empower international B2B buyers to navigate the complexities of the aluminum composite panel market in China with confidence. Understanding the nuances of this sector will not only enhance your procurement strategy but also ensure that you secure high-quality products that align with your business objectives.

Understanding aluminum composite panel china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Aluminum Composite Panel | Lightweight with a polyethylene core | Building facades, signage, interior applications | Pros: Cost-effective, versatile; Cons: Limited fire resistance. |

| Fire-Resistant Aluminum Composite Panel | Enhanced fire-retardant core material | High-rise buildings, public spaces | Pros: Meets safety regulations; Cons: Higher cost than standard panels. |

| Anti-Graffiti Aluminum Composite Panel | Special coating to resist stains and marks | Urban environments, transport hubs | Pros: Easy maintenance, long-lasting appearance; Cons: Initial higher investment. |

| Reflective Aluminum Composite Panel | Highly reflective surface for energy efficiency | Architectural designs, solar applications | Pros: Energy savings, aesthetic appeal; Cons: May require special installation. |

| Acoustic Aluminum Composite Panel | Sound-insulating properties | Auditoriums, conference rooms | Pros: Improves sound quality; Cons: Heavier than standard options. |

What are the Characteristics and Suitability of Standard Aluminum Composite Panels?

Standard aluminum composite panels (ACPs) feature a lightweight polyethylene core, making them easy to install and handle. These panels are widely used in building facades and interior applications due to their cost-effectiveness and versatility. However, international buyers should consider their limited fire resistance, which may not meet the safety standards required in certain regions, particularly in high-risk environments.

How Do Fire-Resistant Aluminum Composite Panels Enhance Safety?

Fire-resistant aluminum composite panels are designed with a specialized core material that significantly improves their fire-retardant properties. These panels are ideal for high-rise buildings and public spaces where safety regulations are stringent. While they offer enhanced safety, buyers must be prepared for a higher upfront cost compared to standard ACPs, making it crucial to assess the long-term benefits against the initial investment.

Why Choose Anti-Graffiti Aluminum Composite Panels for Urban Environments?

Anti-graffiti aluminum composite panels come with a special coating that makes them resistant to stains and marks, making them particularly suitable for urban environments and transport hubs. These panels are easy to maintain and help maintain a long-lasting aesthetic appeal. However, the initial investment may be higher than that of standard panels, which buyers should factor into their budget.

What Benefits Do Reflective Aluminum Composite Panels Offer?

Reflective aluminum composite panels are characterized by their highly reflective surfaces, which enhance energy efficiency in buildings by reducing heat absorption. These panels find applications in architectural designs and solar energy systems. While they provide significant energy savings and aesthetic appeal, buyers should be aware that installation may require specialized techniques, potentially increasing project costs.

How Do Acoustic Aluminum Composite Panels Improve Sound Quality?

Acoustic aluminum composite panels are engineered to provide sound insulation, making them an excellent choice for auditoriums and conference rooms. Their sound-absorbing properties improve sound quality in spaces where acoustics are critical. However, these panels tend to be heavier than standard options, which could impact installation logistics and costs. Buyers should evaluate their specific needs for sound management when considering this type of panel.

Related Video: Aluminum Composite panel fabrication and installation.

Key Industrial Applications of aluminum composite panel china

| Industry/Sector | Specific Application of aluminum composite panel china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Architecture | Facade cladding for commercial buildings | Enhances aesthetic appeal, improves insulation, and reduces maintenance costs. | Quality certification, fire resistance ratings, and design customization options. |

| Transportation | Interior panels for buses and trains | Lightweight construction improves fuel efficiency and reduces wear on structural elements. | Compliance with safety standards, durability under high-traffic conditions, and ease of installation. |

| Retail & Advertising | Signage and display systems | High visual impact due to reflective surfaces, customizable designs for brand enhancement. | Material thickness options, color fastness, and ease of fabrication. |

| Aerospace & Automotive | Lightweight panels for aircraft interiors and vehicle bodies | Reduces overall weight, enhancing performance and fuel efficiency. | Aerospace-grade materials, adherence to international safety standards, and corrosion resistance. |

| Electronics & Technology | Housing for electronic devices and appliances | Provides protection while being lightweight and aesthetically pleasing. | Thermal conductivity, electromagnetic interference shielding, and compatibility with various manufacturing processes. |

How is Aluminum Composite Panel China Used in Construction and Architecture?

In the construction and architecture sector, aluminum composite panels (ACPs) are primarily utilized for facade cladding of commercial buildings. They offer a modern aesthetic while enhancing insulation and reducing the need for maintenance. B2B buyers should focus on sourcing panels that meet quality certifications and fire resistance ratings, as these are crucial for safety and compliance in various regions, especially in urban developments across Africa and Europe.

What Are the Benefits of Aluminum Composite Panels in Transportation?

In the transportation industry, aluminum composite panels are employed in the interiors of buses and trains, contributing to lightweight construction. This reduction in weight leads to improved fuel efficiency and less wear on structural components. International buyers should ensure that the panels comply with safety standards and possess durability characteristics suitable for high-traffic environments, particularly in the Middle East and South America, where public transportation is expanding rapidly.

How Do Retail and Advertising Utilize Aluminum Composite Panels?

Retail and advertising sectors leverage aluminum composite panels for signage and display systems due to their high visual impact and customizable designs. These panels reflect light effectively, drawing attention to brands and enhancing customer engagement. Buyers should consider material thickness, color fastness, and the ease of fabrication when sourcing ACPs, ensuring that the products can withstand various environmental conditions, particularly in outdoor applications in Europe and Africa.

What Role Do Aluminum Composite Panels Play in Aerospace and Automotive Industries?

In the aerospace and automotive industries, aluminum composite panels are critical for lightweight construction in aircraft interiors and vehicle bodies. Their use leads to significant weight reductions, which enhance overall performance and fuel efficiency. When sourcing for these applications, B2B buyers must prioritize aerospace-grade materials that adhere to international safety standards and demonstrate excellent corrosion resistance, especially relevant for manufacturers in Turkey and the UAE.

How Are Aluminum Composite Panels Used in Electronics and Technology?

Aluminum composite panels find their application in the electronics and technology sector as housing for devices and appliances. They provide protection while remaining lightweight and visually appealing. Buyers should focus on sourcing panels with good thermal conductivity and electromagnetic interference shielding, ensuring compatibility with various manufacturing processes, which is essential for firms operating in competitive markets across South America and Europe.

Related Video: aluminum composite panel installation toturial

3 Common User Pain Points for ‘aluminum composite panel china’ & Their Solutions

Scenario 1: Navigating Quality Control Issues with Aluminum Composite Panels from China

The Problem: B2B buyers often encounter challenges regarding the quality of aluminum composite panels sourced from China. Many have experienced inconsistent product quality, which can lead to project delays, increased costs, and reputational damage. The lack of standardized quality control measures in manufacturing can result in panels that do not meet the required specifications or safety standards. This is particularly concerning for buyers in regions like Africa or the Middle East, where strict regulations may apply, and compliance is critical.

The Solution: To mitigate quality control issues, buyers should implement a rigorous supplier vetting process. This includes requesting certifications such as ISO 9001, which indicates adherence to quality management systems. Additionally, conducting factory audits or utilizing third-party inspection services before placing large orders can ensure that the manufacturing processes meet international standards. Establishing a clear set of specifications and expectations in the contract can also help maintain quality. Consider collaborating with suppliers who have a proven track record of servicing international markets, as they are more likely to understand and comply with specific quality requirements.

Scenario 2: Overcoming Communication Barriers in Sourcing Aluminum Composite Panels

The Problem: Many international buyers face significant communication barriers when sourcing aluminum composite panels from Chinese manufacturers. Misunderstandings can occur due to language differences, cultural nuances, or varying business practices. This can lead to errors in product specifications, order quantities, and delivery timelines, causing frustration and potential financial loss.

The Solution: To enhance communication effectiveness, B2B buyers should consider hiring a local sourcing agent or representative fluent in both the buyer’s and supplier’s languages. This intermediary can facilitate clearer discussions, ensuring that all technical details and requirements are accurately conveyed. Additionally, utilizing technology, such as video conferencing tools and collaborative platforms, can help bridge the gap. It’s also beneficial to create visual aids, such as diagrams or prototypes, to clarify specifications. Establishing regular check-ins during the sourcing process can help catch any issues early and maintain alignment between parties.

Scenario 3: Addressing Supply Chain Disruptions When Importing Aluminum Composite Panels

The Problem: Supply chain disruptions have become a pressing concern for B2B buyers, especially when sourcing aluminum composite panels from China. Factors like shipping delays, customs regulations, or geopolitical tensions can lead to unexpected interruptions. Buyers in South America and Europe often find themselves in a bind when they cannot meet project deadlines due to these delays, risking contracts and client satisfaction.

The Solution: To counteract supply chain vulnerabilities, buyers should diversify their sourcing strategies. This involves working with multiple suppliers across different regions to avoid reliance on a single source. Implementing just-in-time inventory practices can also help manage stock levels more effectively, reducing the risk of overstocking or stockouts. Additionally, buyers should stay informed about global shipping conditions and potential disruptions by subscribing to industry news updates or working with logistics professionals. Developing contingency plans, such as identifying alternative shipping routes or local suppliers, will also prepare buyers to respond swiftly to unforeseen challenges, ensuring continuity in their operations.

Strategic Material Selection Guide for aluminum composite panel china

When selecting materials for aluminum composite panels (ACP) sourced from China, international B2B buyers must consider several key materials commonly used in their production. Each material has distinct properties, advantages, and limitations that can significantly impact product performance and suitability for specific applications.

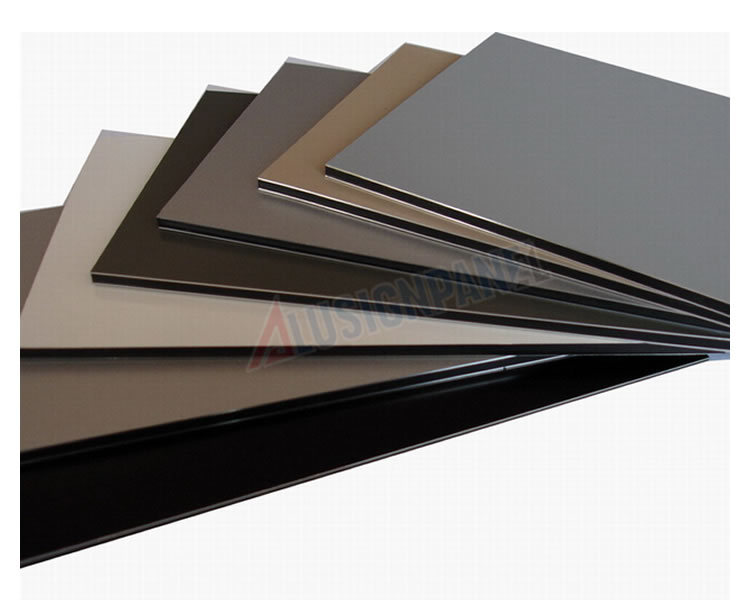

A stock image related to aluminum composite panel china.

What Are the Key Materials for Aluminum Composite Panels?

1. Aluminum Alloy (AA3003)

Key Properties: Aluminum Alloy 3003 is known for its excellent corrosion resistance, good weldability, and moderate strength. It performs well in temperatures up to 150°C (302°F) and has a pressure rating suitable for most architectural applications.

Pros & Cons: The primary advantage of AA3003 is its lightweight nature combined with good formability, making it ideal for intricate designs. However, its moderate strength may not be suitable for high-stress applications, and it can be more expensive than lower-grade alloys.

Impact on Application: This alloy is particularly suitable for applications requiring good thermal insulation and aesthetic appeal, such as building facades and interior cladding.

Considerations for International Buyers: Compliance with international standards like ASTM and EN is crucial. Buyers from regions like the Middle East and Europe often prefer materials with established certifications for durability and safety.

2. Polyethylene Core

Key Properties: Polyethylene (PE) cores are lightweight, with a density of around 0.94 g/cm³, and offer good thermal insulation properties. They can withstand temperatures up to 80°C (176°F) and are resistant to moisture.

Pros & Cons: The major advantage of PE cores is their cost-effectiveness and ease of manufacturing. However, they are less fire-resistant compared to mineral-filled cores, which can be a significant drawback in fire-sensitive applications.

Impact on Application: PE cores are commonly used in interior applications and signage, where fire safety is less of a concern.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure that the materials meet local fire safety regulations and standards, which may differ significantly from European requirements.

3. Mineral-Filled Core

Key Properties: Mineral-filled cores provide enhanced fire resistance, rated up to Class A. They can withstand higher temperatures than PE cores, making them suitable for a wider range of applications.

Pros & Cons: The primary advantage is their fire safety performance, making them suitable for high-rise buildings and public spaces. However, they tend to be heavier and more expensive than PE cores, which may affect shipping costs and installation.

Impact on Application: These cores are ideal for applications where fire safety is paramount, such as in urban environments with strict building codes.

Considerations for International Buyers: Compliance with fire safety regulations, such as those set by the NFPA in the U.S. or local standards in the UAE, is essential. Buyers must also consider the implications of increased weight on structural support.

4. Aluminum Composite Material (ACM)

Key Properties: ACM typically consists of two aluminum sheets enclosing a non-aluminum core, often made from polyethylene or mineral-filled materials. This combination provides excellent durability, aesthetic versatility, and weather resistance.

Pros & Cons: ACM is highly durable and available in a wide range of finishes, making it suitable for various architectural applications. However, the manufacturing process can be complex and may lead to higher costs.

Impact on Application: ACM is widely used in exterior cladding, signage, and interior applications due to its aesthetic appeal and durability.

Considerations for International Buyers: Buyers should ensure that ACM products comply with local building codes and standards, particularly concerning fire safety and environmental impact.

Summary Table of Material Selection for Aluminum Composite Panels

| Material | Typical Use Case for aluminum composite panel china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloy (AA3003) | Building facades, interior cladding | Lightweight, good corrosion resistance | Moderate strength, higher cost | Medium |

| Polyethylene Core | Interior applications, signage | Cost-effective, easy to manufacture | Less fire-resistant | Low |

| Mineral-Filled Core | High-rise buildings, public spaces | Excellent fire resistance | Heavier, more expensive | High |

| Aluminum Composite Material (ACM) | Exterior cladding, signage | Durable, aesthetic versatility | Complex manufacturing, potentially higher cost | Medium |

This material selection guide provides a foundational understanding for international B2B buyers looking to source aluminum composite panels from China, ensuring they make informed decisions based on specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for aluminum composite panel china

What Are the Key Manufacturing Processes for Aluminum Composite Panels in China?

Manufacturing aluminum composite panels (ACP) involves several critical stages, each contributing to the final product’s quality and performance. Understanding these processes is essential for international B2B buyers looking to source high-quality ACPs from China.

1. Material Preparation: What Materials Are Used in ACP Manufacturing?

The primary materials used in ACP manufacturing include two aluminum sheets and a non-aluminum core, typically made from polyethylene or mineral-based materials. The aluminum sheets are usually coated with a protective film to prevent scratches during manufacturing. Sourcing high-grade aluminum is crucial, as the strength and durability of the final product depend on the quality of these materials.

In China, suppliers often employ advanced techniques for material preparation, such as chemical cleaning and surface treatment, which enhance adhesion and corrosion resistance. Buyers should ensure that their suppliers utilize high-quality materials that meet international standards.

2. How Are Aluminum Composite Panels Formed?

The forming process involves several key techniques, including:

- Cutting: Aluminum sheets are cut to specified dimensions using CNC machines for precision.

- Bonding: The core material is bonded between the two aluminum sheets using a strong adhesive. This is often done through a continuous lamination process under heat and pressure, ensuring a solid bond.

- Shaping: Panels may be shaped into specific forms or profiles based on application needs, such as curves or angles.

Understanding these processes helps buyers evaluate suppliers’ capabilities and the potential for customization based on project requirements.

3. What Assembly Techniques Are Used in ACP Manufacturing?

After forming, the panels undergo an assembly process that may include:

- Edge Treatment: Edges of the panels are treated to prevent corrosion and enhance aesthetics.

- Drilling and Punching: Holes may be drilled or punched for installation purposes, ensuring that they meet specific architectural requirements.

These assembly techniques are crucial for ensuring the panels are ready for installation and meet the design specifications required by clients.

4. What Finishing Processes Are Essential for ACP Quality?

Finishing processes significantly impact the aesthetic appeal and durability of aluminum composite panels. Key finishing techniques include:

- Coating: Panels are often coated with protective paints or finishes, such as PVDF (polyvinylidene fluoride) or PE (polyester), providing UV protection and color stability.

- Quality Control: After finishing, panels undergo rigorous quality checks to ensure uniformity in color and texture.

These finishing processes not only enhance the visual appeal of the panels but also contribute to their longevity in various environmental conditions.

How Is Quality Assurance Implemented in ACP Manufacturing?

Quality assurance (QA) is a critical component of the manufacturing process, ensuring that the final product meets both international standards and customer expectations.

1. What International Standards Are Relevant for ACP Quality?

Many manufacturers in China adhere to international quality standards, such as:

- ISO 9001: This standard focuses on quality management systems, ensuring consistency in processes and products.

- CE Marking: This certification indicates that products comply with EU safety, health, and environmental protection standards.

For buyers from regions like Africa, South America, the Middle East, and Europe, verifying these certifications can provide confidence in the quality and safety of the products.

2. What Are the Key Quality Control Checkpoints?

Quality control is integrated into various stages of manufacturing, with key checkpoints including:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during production helps identify any defects early in the process.

- Final Quality Control (FQC): A thorough inspection of the finished panels is conducted to ensure they meet all specifications before shipping.

These checkpoints are vital for minimizing defects and ensuring that the panels are manufactured to the highest standards.

3. What Testing Methods Are Commonly Used for ACPs?

Several testing methods are employed to evaluate the quality of aluminum composite panels, including:

- Adhesion Testing: Assesses the bond strength between the aluminum sheets and core material.

- Fire Resistance Testing: Determines how well the panels withstand fire, which is crucial for safety compliance.

- Weather Resistance Testing: Evaluates how panels perform under extreme weather conditions, ensuring longevity.

B2B buyers should inquire about the specific testing methods used by suppliers to guarantee that their products meet necessary safety and performance standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verifying the quality control practices of suppliers is essential for international buyers to ensure they receive high-quality products. Here are some actionable strategies:

1. Conduct Supplier Audits

Regular audits of manufacturing facilities can provide insight into the operational standards and quality control practices of suppliers. During these audits, buyers can assess the adherence to international standards and the effectiveness of quality checkpoints.

2. Request Quality Control Reports

Buyers should request detailed QC reports from suppliers, which should outline the testing methods used, results obtained, and any corrective actions taken for non-conformance. This transparency fosters trust and confidence in the supplier’s commitment to quality.

3. Utilize Third-Party Inspection Services

Engaging third-party inspection services can provide an unbiased assessment of the manufacturing processes and final products. This is particularly beneficial for international buyers who may not have the capacity to conduct thorough inspections themselves.

Conclusion: What Should B2B Buyers Look for in a Supplier?

When sourcing aluminum composite panels from China, international B2B buyers should focus on suppliers with robust manufacturing processes and stringent quality control practices. By understanding the key stages of production, relevant international standards, and effective verification methods, buyers can make informed decisions that lead to successful partnerships and high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘aluminum composite panel china’

The following guide outlines a practical checklist for international B2B buyers looking to procure aluminum composite panels from China. This step-by-step approach is designed to ensure that you make informed decisions throughout the sourcing process, ultimately leading to successful procurement.

Step 1: Define Your Technical Specifications

Clearly outline the technical specifications for the aluminum composite panels you need. This includes dimensions, thickness, color, and any specific fire ratings or certifications required for your project. Defining these specifications upfront helps streamline the sourcing process and ensures that suppliers can meet your needs effectively.

- Consider application requirements: Understand the environmental conditions where the panels will be used, such as weather exposure and load-bearing needs.

- Identify industry standards: Familiarize yourself with relevant building codes and standards in your region to ensure compliance.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers in China. Utilize online platforms like Alibaba, Made-in-China, and global trade directories to compile a list of manufacturers.

- Check company backgrounds: Look for supplier history, production capacity, and areas of expertise.

- Read reviews and testimonials: Seek feedback from previous clients to gauge reliability and product quality.

Step 3: Evaluate Supplier Certifications

Before proceeding with any supplier, verify their certifications and compliance with international standards. This is crucial for ensuring product quality and safety.

- Request documentation: Ask for ISO certifications, quality management system certifications, and compliance with specific industry standards (e.g., ASTM, EN).

- Assess factory audits: If possible, conduct or request third-party audits of the manufacturing facilities to confirm their capabilities.

Step 4: Request Samples

Always request samples before placing a large order. This step allows you to assess the quality of the aluminum composite panels first-hand.

- Evaluate physical properties: Check for color accuracy, surface finish, and structural integrity.

- Test performance: If applicable, perform tests related to fire resistance or weatherproofing to ensure they meet your project’s requirements.

Step 5: Negotiate Terms and Pricing

Once you have selected a supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Effective negotiation can lead to better pricing and favorable terms.

- Discuss payment options: Consider using secure payment methods such as letter of credit or escrow services for larger orders.

- Clarify delivery timelines: Ensure that both parties agree on delivery dates and logistics to avoid delays.

Step 6: Establish Communication Protocols

Maintain clear and consistent communication with your supplier throughout the sourcing process. Establishing a communication protocol can help manage expectations and resolve issues quickly.

- Set regular check-ins: Schedule periodic updates to discuss production progress and address any concerns.

- Use project management tools: Consider utilizing tools like Slack or Trello for real-time collaboration and tracking.

Step 7: Plan for Quality Control

Implement a quality control plan to monitor the production process and ensure that the final products meet your specifications.

- Define inspection criteria: Establish what will be inspected, including dimensions, surface quality, and packaging.

- Consider third-party inspections: Hire a quality inspection service to perform checks before shipment, reducing the risk of receiving defective products.

By following this checklist, B2B buyers can navigate the complexities of sourcing aluminum composite panels from China with greater confidence and efficiency.

Comprehensive Cost and Pricing Analysis for aluminum composite panel china Sourcing

What Are the Key Cost Components for Sourcing Aluminum Composite Panels from China?

Understanding the cost structure is critical for international B2B buyers looking to source aluminum composite panels (ACP) from China. The primary components of the cost structure include:

-

Materials: The cost of raw materials, primarily aluminum sheets and the core material (usually polyethylene or fire-resistant material), significantly impacts the final price. Prices can fluctuate based on global aluminum market trends, which are influenced by supply chain issues and demand from various industries.

-

Labor: Labor costs in China are relatively lower compared to many Western countries. However, the skill level required for manufacturing high-quality ACP can influence labor costs. Skilled workers may demand higher wages, particularly in regions with a strong manufacturing base.

-

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities, maintenance, and administrative expenses. Efficient factories may have lower overhead costs, which can be passed on to buyers.

-

Tooling: Custom tooling for specific panel designs can add to the upfront costs. Buyers should consider whether standard tooling can meet their needs to avoid unnecessary expenses.

-

Quality Control (QC): Implementing robust QC processes ensures that the panels meet international standards and certifications. This step is crucial for buyers in regions with stringent building codes, and it can slightly increase costs.

-

Logistics: Shipping costs, including freight, insurance, and customs duties, vary significantly depending on the destination. Incoterms also play a vital role in determining who bears the cost and risk during transit.

-

Margin: Suppliers typically include a profit margin in their pricing, which varies based on competition, demand, and the supplier’s positioning in the market.

How Do Price Influencers Affect Sourcing Decisions for Aluminum Composite Panels?

Several factors influence the pricing of aluminum composite panels, making it essential for buyers to understand these elements:

-

Volume/MOQ: Minimum order quantities (MOQs) can affect pricing. Higher volumes generally result in lower per-unit costs due to economies of scale.

-

Specifications and Customization: Custom designs, finishes, or specific certifications can lead to increased costs. Buyers should assess whether custom features are necessary for their projects.

-

Quality and Certifications: Panels with higher quality ratings or specific certifications (such as fire resistance) typically command higher prices. It is crucial for buyers to balance cost with compliance to local regulations.

-

Supplier Factors: The reputation, reliability, and financial stability of suppliers can impact pricing. Established suppliers may charge a premium but often provide more consistent quality and service.

-

Incoterms: The choice of Incoterms affects the total landed cost. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can help buyers manage their logistics costs effectively.

What Tips Can International B2B Buyers Use to Optimize Costs When Sourcing from China?

To maximize cost-efficiency when sourcing aluminum composite panels from China, buyers should consider the following strategies:

-

Negotiate Terms: Always negotiate pricing and payment terms. Suppliers may be willing to offer discounts for larger orders or prompt payments.

-

Focus on Total Cost of Ownership (TCO): Analyze the TCO, which includes initial purchase price, shipping, taxes, and potential costs related to quality issues. A lower upfront price may lead to higher long-term costs if quality is compromised.

-

Evaluate Multiple Suppliers: Obtaining quotes from various suppliers not only provides a benchmark for pricing but also helps in understanding the market landscape.

-

Consider Long-Term Relationships: Building relationships with suppliers can lead to better pricing and terms over time. Loyal buyers often receive preferential treatment in terms of pricing and service.

-

Stay Updated on Market Trends: Keep an eye on global aluminum prices and trade policies, as these factors can influence sourcing costs.

Disclaimer on Indicative Prices

Prices for aluminum composite panels can vary widely based on the factors discussed. It is advisable for buyers to conduct thorough market research and obtain current quotes from multiple suppliers to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing aluminum composite panel china With Other Solutions

When evaluating materials for construction and architectural applications, it’s essential to consider various alternatives to aluminum composite panels from China. While these panels are known for their durability and aesthetic appeal, several other solutions can meet similar needs. This section will compare aluminum composite panels with two viable alternatives: fiberglass reinforced panels (FRP) and polycarbonate sheets.

Comparison Table of Aluminum Composite Panel China and Alternatives

| Comparison Aspect | Aluminum Composite Panel China | Fiberglass Reinforced Panels (FRP) | Polycarbonate Sheets |

|---|---|---|---|

| Performance | High strength-to-weight ratio, excellent thermal insulation | Good impact resistance, moderate thermal insulation | High impact resistance, UV protection |

| Cost | Moderate initial cost, long-term savings due to durability | Generally lower cost but shorter lifespan | Higher initial cost, cost-effective over time |

| Ease of Implementation | Requires professional installation, easy to handle | Lightweight and easy to install | Simple installation, often DIY-friendly |

| Maintenance | Low maintenance, resistant to corrosion | Requires regular maintenance to prevent degradation | Low maintenance, but prone to scratching |

| Best Use Case | High-rise buildings, facades, and signage | Industrial applications, wall panels, and ceilings | Skylights, greenhouses, and protective barriers |

What Are the Advantages and Disadvantages of Fiberglass Reinforced Panels (FRP)?

Fiberglass reinforced panels are a cost-effective alternative to aluminum composite panels. They boast good impact resistance and are lightweight, making them suitable for various applications, particularly in industrial settings. However, while they are less expensive upfront, FRPs can have a shorter lifespan, requiring more frequent replacements. Additionally, they may need regular maintenance to prevent degradation from environmental factors, which can incur additional costs over time.

How Do Polycarbonate Sheets Compare to Aluminum Composite Panels?

Polycarbonate sheets are recognized for their exceptional impact resistance and UV protection, making them ideal for applications such as skylights and greenhouses. They are relatively easy to install and can often be handled by DIY enthusiasts, which can reduce labor costs. However, polycarbonate sheets typically have a higher initial cost compared to aluminum composite panels. While they require minimal maintenance, they can be prone to scratching, which may affect their visual appeal over time.

Conclusion: Which Material Should B2B Buyers Choose?

Selecting the right material for construction projects requires careful consideration of various factors, including performance, cost, and maintenance. B2B buyers should assess their specific needs, such as the intended application and environmental conditions. For projects requiring high durability and aesthetic appeal, aluminum composite panels may be the best choice. Conversely, for budget-conscious projects or where ease of installation is paramount, fiberglass reinforced panels or polycarbonate sheets could be more suitable. Ultimately, understanding the unique advantages and limitations of each option will empower buyers to make informed decisions that align with their project goals.

Essential Technical Properties and Trade Terminology for aluminum composite panel china

What Are the Key Technical Properties of Aluminum Composite Panels?

When considering aluminum composite panels (ACP) from China, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications:

-

Material Grade

– Aluminum composite panels are typically made from various grades of aluminum, often categorized by their alloy composition. Common grades include 3003 and 5005, which offer different levels of strength, corrosion resistance, and weldability. Buyers should choose the grade based on specific project requirements, such as exposure to harsh environments or structural needs. -

Panel Thickness

– The thickness of ACP can range from 2mm to 6mm or more. Thicker panels provide enhanced durability and resistance to deformation, making them suitable for applications in high-traffic areas. B2B buyers need to consider the balance between weight and strength when selecting panel thickness for their projects. -

Fire Resistance Rating

– In many regions, compliance with fire safety regulations is mandatory. Aluminum composite panels may come with different fire ratings, such as Class A or B, determined by their core material. Understanding these ratings is essential for international buyers to ensure that their projects meet local building codes and safety standards. -

Surface Treatment

– The surface finish of ACP can significantly impact its aesthetic appeal and longevity. Common treatments include PVDF (polyvinylidene fluoride) and polyester coatings. PVDF offers superior UV resistance and durability, making it preferable for outdoor applications. Buyers should assess the surface treatment based on the intended use and environmental exposure. -

Tolerance Levels

– Tolerance refers to the permissible limit of variation in dimensions and physical properties of the panels. High tolerance levels ensure that panels fit seamlessly during installation, reducing waste and labor costs. Buyers should specify tolerance requirements in their orders to avoid costly adjustments on-site.

What Are Common Trade Terms Used in the Aluminum Composite Panel Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the procurement process. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce components or products that are used in another company’s end products. For B2B buyers, understanding whether a supplier operates as an OEM can influence sourcing decisions, especially when customization is required. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest number of units a supplier is willing to sell. This term is crucial for buyers, as it affects inventory management and cash flow. Understanding MOQ can help buyers plan their orders strategically to avoid overstocking or understocking. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers asking for pricing and terms for specific products. This process is vital for comparing offers and ensuring that buyers receive competitive pricing for aluminum composite panels. -

Incoterms (International Commercial Terms)

– These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Common Incoterms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight). Knowing these terms helps buyers understand shipping costs and liabilities, thus facilitating smoother transactions. -

Lead Time

– Lead time refers to the duration between placing an order and receiving the goods. In the context of aluminum composite panels, understanding lead times is essential for project planning and ensuring timely completion of construction or manufacturing projects. -

Certification Standards

– This term encompasses various quality and safety certifications that aluminum composite panels may possess, such as ISO, CE, or ASTM certifications. These standards assure buyers of the product’s quality and compliance with industry regulations, which is particularly important for international sourcing.

By grasping these technical specifications and trade terms, international B2B buyers can navigate the complexities of sourcing aluminum composite panels from China with greater confidence and efficiency.

Navigating Market Dynamics and Sourcing Trends in the aluminum composite panel china Sector

What Are the Key Trends Shaping the Aluminum Composite Panel Market in China?

The aluminum composite panel (ACP) market in China is experiencing significant growth, driven by various global factors. Firstly, rapid urbanization and infrastructural development in emerging markets such as Africa, South America, and the Middle East are leading to increased demand for lightweight, durable building materials. The construction industry’s shift towards energy-efficient materials is a crucial driver, as ACPs offer excellent insulation properties, contributing to reduced energy costs.

In addition, technological advancements are reshaping sourcing trends. The adoption of digital platforms for procurement is becoming prevalent, enabling international B2B buyers to connect with Chinese manufacturers more effectively. Innovations in manufacturing processes, including automated production lines, are enhancing the quality and consistency of ACPs, making them more appealing to global markets.

Furthermore, the increasing focus on sustainability is influencing market dynamics. Buyers are seeking suppliers who prioritize eco-friendly practices, such as utilizing recycled materials in their products. This trend is particularly relevant for buyers from Europe, where stringent regulations regarding sustainability are in place.

How Is Sustainability and Ethical Sourcing Important for B2B Buyers in the Aluminum Composite Panel Sector?

Sustainability has become a critical consideration for B2B buyers in the aluminum composite panel sector. The environmental impact of aluminum production is significant, with high energy consumption and carbon emissions associated with traditional manufacturing methods. As a result, buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing their carbon footprint through sustainable practices.

Ethical sourcing is equally important. International buyers are now more aware of supply chain transparency and the ethical implications of their purchases. Suppliers that can provide certifications for environmentally friendly practices or source materials responsibly will have a competitive edge in the market. Certifications like LEED (Leadership in Energy and Environmental Design) and ISO 14001 (Environmental Management Systems) are essential indicators of a supplier’s commitment to sustainability.

Moreover, using ‘green’ materials in aluminum composite panels not only meets regulatory requirements but also appeals to environmentally conscious consumers. Buyers from regions like the UAE and Turkey are particularly focused on sourcing products that align with their sustainability goals, thereby enhancing their brand image in the marketplace.

What Is the Evolution of the Aluminum Composite Panel Market in China?

The aluminum composite panel market in China has undergone a remarkable transformation over the past few decades. Initially emerging in the 1980s, ACPs were primarily used for signage and decorative purposes. However, as construction techniques evolved and demand for modern architectural designs increased, ACPs gained popularity in building facades and interior applications.

Over time, advancements in manufacturing technologies have improved the performance and aesthetic appeal of ACPs. The introduction of high-quality coatings and the ability to produce panels in a wide range of colors and finishes have expanded their application in commercial and residential buildings. As the market continues to evolve, international B2B buyers can expect ongoing innovations that cater to both functional and aesthetic needs, reinforcing the relevance of aluminum composite panels in contemporary construction.

Frequently Asked Questions (FAQs) for B2B Buyers of aluminum composite panel china

-

How do I choose the right aluminum composite panel supplier in China?

Selecting the right supplier requires careful consideration of several factors. Start by researching potential suppliers and assessing their industry reputation through reviews and testimonials. Look for suppliers with experience in exporting to your region, as they will understand local regulations and logistics. Verify their certifications and quality standards, such as ISO 9001, to ensure they meet international manufacturing requirements. Lastly, request samples to evaluate the product quality before making a large order. -

What are the benefits of using aluminum composite panels in construction?

Aluminum composite panels (ACP) are favored in construction due to their lightweight, durability, and aesthetic appeal. They offer excellent weather resistance, thermal insulation, and soundproofing qualities, making them ideal for both indoor and outdoor applications. Additionally, ACP is easy to maintain and can be customized in various colors and finishes, allowing architects to achieve innovative designs. The recyclability of aluminum further enhances its appeal in sustainable building practices. -

What minimum order quantity (MOQ) should I expect when sourcing aluminum composite panels from China?

The MOQ for aluminum composite panels varies by supplier, but it typically ranges from 100 to 500 square meters. Factors influencing MOQ include the supplier’s production capacity, the specific panel specifications, and customization options. When negotiating with suppliers, it’s essential to clarify the MOQ upfront and explore potential flexibility, especially if you are testing a new market or product line. -

How can I ensure quality control when sourcing aluminum composite panels from China?

To ensure quality control, start by establishing clear specifications and standards for the panels you require. Request third-party inspections before shipment, which can help verify product quality and compliance with your standards. It’s also beneficial to develop a good relationship with your supplier, as this can facilitate better communication and responsiveness to any quality issues. Utilize contracts that include quality assurance clauses to protect your interests. -

What payment terms are typically offered by Chinese suppliers for aluminum composite panels?

Payment terms can vary, but many suppliers offer terms such as 30% advance payment and 70% upon delivery or before shipment. Some may provide more flexible terms based on your business relationship and order size. Utilizing secure payment methods like PayPal or letters of credit can also provide additional protection. Always ensure that the payment terms are clearly outlined in your purchase agreement to avoid misunderstandings. -

How do I handle logistics and shipping when importing aluminum composite panels from China?

When importing, consider partnering with a freight forwarder who specializes in international shipping. They can help navigate customs regulations and ensure timely delivery. Discuss shipping methods (air vs. sea) based on your urgency and budget. Additionally, confirm that your supplier is familiar with export procedures to minimize delays. It’s crucial to account for potential duties and tariffs in your total landed cost calculations. -

Can I customize aluminum composite panels to fit my specific needs?

Yes, many manufacturers offer customization options for aluminum composite panels, including size, color, and surface finish. When discussing your project requirements, provide detailed specifications to the supplier. Customization may affect the MOQ and lead time, so be prepared for potential adjustments in pricing and delivery schedules. Collaborating closely with the supplier during the design phase can ensure that the final product meets your exact needs. -

What are the key certifications to look for when sourcing aluminum composite panels from China?

When sourcing aluminum composite panels, look for certifications such as ISO 9001 for quality management systems and CE marking, which indicates compliance with European safety standards. Additional certifications like ASTM or UL ratings can signify that the products meet specific performance criteria, particularly for fire resistance and environmental standards. These certifications not only assure product quality but also facilitate smoother international trade.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for aluminum composite panel china

What Are the Key Takeaways for Strategic Sourcing of Aluminum Composite Panels from China?

In conclusion, strategic sourcing of aluminum composite panels from China presents a wealth of opportunities for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. By leveraging China’s robust manufacturing capabilities, buyers can access high-quality products at competitive prices, while also benefiting from the versatility and durability of aluminum materials. Understanding local market dynamics, regulatory requirements, and supplier capabilities is crucial for minimizing risks and maximizing returns.

How Can International Buyers Prepare for Future Trends?

As the demand for sustainable and energy-efficient building materials continues to rise, aluminum composite panels will play a pivotal role in modern construction. Buyers should stay informed about innovations in production techniques and emerging trends such as eco-friendly materials and advanced coatings. Engaging with suppliers who prioritize sustainability will not only align with global trends but also enhance brand reputation.

What Steps Should You Take Next?

To capitalize on these insights, international buyers are encouraged to conduct thorough market research and establish strong relationships with reputable Chinese manufacturers. Actively participating in trade shows and industry forums can further enhance sourcing strategies. As the market evolves, remain adaptable and proactive in sourcing decisions to ensure your business stays ahead in the competitive landscape of aluminum composite panels.