Discover Cost-Saving Benefits of Ceramic Tile China (2025)

Introduction: Navigating the Global Market for ceramic tile china

In the dynamic landscape of international trade, sourcing ceramic tiles from China presents both opportunities and challenges for B2B buyers. With the growing demand for high-quality ceramic tiles across diverse markets, including Africa, South America, the Middle East, and Europe, navigating this global market can often feel overwhelming. Buyers face critical issues such as identifying reliable suppliers, understanding product specifications, and managing costs effectively. This guide serves as a comprehensive resource, designed to equip international buyers with the insights needed to make informed purchasing decisions.

Throughout this guide, we delve into various aspects of the ceramic tile industry, including types of tiles, their applications in residential and commercial settings, and essential tips for supplier vetting. We also explore pricing structures, shipping logistics, and quality assurance measures that are vital for successful transactions. By addressing common concerns and providing actionable strategies, this guide empowers B2B buyers from regions such as Colombia and France to streamline their sourcing processes and mitigate risks.

Understanding the intricacies of the ceramic tile market in China is crucial for establishing successful partnerships and achieving competitive advantages. Whether you are looking to enhance your product offerings or seeking cost-effective solutions for your projects, this guide will provide the knowledge and tools necessary to thrive in the global marketplace.

Understanding ceramic tile china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Glazed Ceramic Tiles | Smooth, glossy finish; water-resistant | Retail spaces, kitchens, bathrooms | Pros: Easy maintenance, aesthetic appeal. Cons: Can be slippery when wet. |

| Porcelain Tiles | Dense, durable, low water absorption | High-traffic areas, outdoor use | Pros: Highly durable, frost-resistant. Cons: Heavier, may require specialized installation. |

| Terracotta Tiles | Rustic appearance; unglazed or semi-glazed | Traditional homes, outdoor patios | Pros: Unique aesthetics, good thermal properties. Cons: Requires sealing, less durable than other types. |

| Mosaic Tiles | Small pieces arranged in patterns | Decorative applications, feature walls | Pros: Versatile design options, customizable. Cons: More labor-intensive to install. |

| Digital Printed Tiles | Customizable designs; realistic patterns | Commercial spaces, artistic installations | Pros: High design flexibility, can mimic natural materials. Cons: May fade over time if not properly sealed. |

What are Glazed Ceramic Tiles and Their B2B Suitability?

Glazed ceramic tiles are characterized by their smooth, glossy surface that is coated with a glass-like finish. This type is highly water-resistant, making it ideal for environments such as kitchens and bathrooms where moisture is prevalent. B2B buyers should consider glazed tiles for retail spaces that require easy maintenance and aesthetic appeal. However, the slippery surface may pose safety concerns in certain applications, particularly in wet areas.

How Do Porcelain Tiles Stand Out in the Market?

Porcelain tiles are known for their dense composition and low water absorption, making them exceptionally durable. They are suitable for high-traffic areas and outdoor applications, which is crucial for B2B buyers looking for longevity in their flooring solutions. While porcelain tiles offer frost resistance and a robust surface, their weight may necessitate specialized installation techniques, which could increase overall project costs.

What Makes Terracotta Tiles a Unique Choice?

Terracotta tiles provide a rustic charm that appeals to buyers interested in traditional aesthetics. Typically available in unglazed or semi-glazed finishes, they are ideal for outdoor patios and traditional homes. While they offer good thermal properties, it’s essential for B2B buyers to understand that terracotta requires sealing to prevent staining and may not be as durable as other tile types, which can impact long-term maintenance costs.

How Can Mosaic Tiles Enhance Design Flexibility?

Mosaic tiles consist of small pieces arranged to create intricate patterns, allowing for significant design versatility. They are commonly used in decorative applications and feature walls, providing a unique opportunity for businesses to showcase creativity. However, the installation of mosaic tiles can be labor-intensive, which may increase project timelines and costs. B2B buyers should weigh the artistic benefits against the potential for higher labor expenses.

What Are the Advantages of Digital Printed Tiles?

Digital printed tiles are revolutionizing the ceramic tile market by offering customizable designs that can realistically mimic natural materials. This type is particularly advantageous for commercial spaces and artistic installations, as it allows businesses to create unique environments tailored to their brand identity. While digital printed tiles provide high design flexibility, buyers should be aware that these tiles may fade over time if not properly sealed, necessitating careful consideration of long-term maintenance strategies.

Related Video: Basics of Ceramic Glazing: Types & Techniques

Key Industrial Applications of ceramic tile china

| Industry/Sector | Specific Application of ceramic tile china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Flooring and Wall Cladding | Enhanced durability, aesthetic appeal, and moisture resistance | Assessing local regulations, transportation logistics, and supplier reliability |

| Hospitality | Decorative Wall Tiles | Creates a luxurious ambiance and improves guest experience | Focus on design trends, customization options, and lead times |

| Healthcare | Antimicrobial Tiles | Reduces the risk of infection, easy maintenance | Certification standards for antimicrobial properties and compliance with health regulations |

| Retail | Point-of-Sale Displays | Increases customer engagement and enhances product visibility | Evaluating design flexibility, durability, and ease of installation |

| Food & Beverage | Kitchen and Bar Surfaces | Provides sanitary, easy-to-clean surfaces, and withstands heavy use | Sourcing for food-safe materials, slip resistance, and aesthetic compatibility |

How is Ceramic Tile China Used in the Construction Industry?

In the construction sector, ceramic tile china is widely utilized for flooring and wall cladding. Its exceptional durability and moisture resistance make it ideal for both residential and commercial buildings. Buyers should consider local regulations that may dictate specific materials and installation practices, as well as the logistics of transporting heavy tiles. Additionally, international buyers must ensure that the tile designs align with regional aesthetic preferences and building codes.

What are the Benefits of Using Decorative Wall Tiles in Hospitality?

In the hospitality industry, decorative wall tiles made from ceramic tile china are employed to create visually striking environments in hotels and restaurants. These tiles not only enhance the aesthetic appeal but also contribute to a luxurious ambiance that can elevate the guest experience. B2B buyers in this sector should focus on current design trends, customization capabilities, and the lead times for delivery, which can significantly impact project timelines.

How Do Antimicrobial Tiles Benefit Healthcare Facilities?

Healthcare facilities utilize antimicrobial ceramic tiles to minimize the risk of infections. These tiles are specifically designed to inhibit bacterial growth, making them easier to maintain and clean. For B2B buyers in this sector, it is crucial to verify that the tiles meet certification standards for antimicrobial properties and comply with health regulations. This ensures that the materials used contribute effectively to patient safety and hygiene.

Why Are Point-of-Sale Displays Important in Retail?

In the retail sector, ceramic tile china is often used for point-of-sale displays, providing a visually appealing platform for product promotion. The durability and versatility of these tiles increase customer engagement and enhance product visibility. Buyers should evaluate the design flexibility and ease of installation of the tiles to ensure they meet specific retail needs. Additionally, understanding the overall cost-effectiveness of the displays can help businesses maximize their return on investment.

How Can Kitchen and Bar Surfaces Benefit from Ceramic Tile China?

Ceramic tile china is an excellent choice for kitchen and bar surfaces in the food and beverage industry due to its sanitary properties and ease of cleaning. These tiles can withstand heavy use while maintaining their aesthetic appeal, which is crucial in high-traffic areas. B2B buyers should prioritize sourcing tiles that are food-safe, slip-resistant, and compatible with the overall design of the establishment. This consideration not only enhances safety but also contributes to the establishment’s brand image.

Related Video: Amazing Modern Ceramic Tile Manufacturing Process With Advance Technology And Creative Workers

3 Common User Pain Points for ‘ceramic tile china’ & Their Solutions

Scenario 1: Navigating Quality Assurance in Bulk Orders

The Problem:

B2B buyers often face challenges when sourcing ceramic tiles from China, particularly concerning quality consistency. This issue can arise when placing large orders, where discrepancies in color, texture, and finish can lead to significant losses. Buyers in regions like Africa and South America may find themselves dealing with tiles that do not match their specifications, leading to delays in projects and increased costs for replacements or adjustments.

The Solution:

To ensure quality assurance in bulk orders, buyers should implement a robust quality control process. Start by requesting samples from potential suppliers, ensuring they meet your specific requirements. Once a supplier is selected, consider establishing a detailed quality assurance protocol, including on-site inspections during production. It can also be beneficial to collaborate with third-party inspection services familiar with ceramic tile production. This proactive approach can help mitigate risks associated with quality inconsistencies and ensure that the tiles delivered match the agreed-upon specifications.

Scenario 2: Overcoming Logistics and Shipping Challenges

The Problem:

International shipping can be a significant hurdle for B2B buyers dealing with ceramic tiles from China. Issues such as unexpected delays, customs clearance problems, and high freight costs can disrupt timelines and budget forecasts. Buyers from Europe and the Middle East may experience additional complications due to differing regulations and import duties, leading to further financial strain and project delays.

The Solution:

To navigate logistics challenges effectively, buyers should engage with logistics experts who specialize in international shipping for construction materials. Establishing a clear shipping timeline and understanding the local customs regulations of the destination country is crucial. Additionally, consider utilizing freight forwarders who can provide insights on the most efficient shipping routes and methods. Negotiating contracts with suppliers that include shipping terms can also help manage expectations and reduce unforeseen costs. Building a relationship with a reliable logistics partner can streamline the shipping process and ensure that deliveries arrive on time.

Scenario 3: Managing Design and Aesthetic Expectations

The Problem:

Design expectations can often lead to dissatisfaction among B2B buyers, especially when the ceramic tiles do not align with the envisioned aesthetic. Buyers from diverse markets, such as South America and Europe, may have unique design requirements influenced by cultural preferences. When tiles do not meet these aesthetic standards, it can lead to costly rework and a tarnished reputation among clients.

The Solution:

To manage design and aesthetic expectations effectively, clear communication is key. Buyers should provide comprehensive design briefs, including mood boards, color palettes, and examples of desired textures. It is also advisable to leverage digital tools such as 3D modeling software to visualize how the tiles will fit within the overall design. Consider visiting tile exhibitions or trade shows in China to see the products in person before making a purchase. Establishing a close collaboration with the supplier can also facilitate adjustments based on design feedback, ensuring the final product meets the buyer’s aesthetic standards. By prioritizing design alignment from the outset, buyers can avoid potential pitfalls and achieve a successful outcome for their projects.

Strategic Material Selection Guide for ceramic tile china

When selecting materials for ceramic tiles sourced from China, international B2B buyers must consider various factors that influence performance, cost, and compliance with regional standards. Here, we analyze four common materials used in ceramic tile production: porcelain, stoneware, earthenware, and terracotta. Each material has unique properties and implications for specific applications, especially in diverse markets such as Africa, South America, the Middle East, and Europe.

What are the Key Properties of Porcelain Tiles?

Porcelain tiles are made from a refined clay mixture that is fired at high temperatures, resulting in a dense and durable product. Key properties include high temperature resistance, low water absorption (less than 0.5%), and excellent durability against wear and tear. This makes porcelain tiles suitable for both indoor and outdoor applications, including high-traffic areas.

Pros: Porcelain tiles are highly durable, resistant to moisture, and can withstand heavy loads. They are also available in various finishes, making them versatile for aesthetic applications.

Cons: The manufacturing process can be complex and costly, which may lead to higher prices compared to other materials. Additionally, the hardness of porcelain can make cutting and installation more challenging.

Impact on Application: Porcelain tiles are ideal for environments that require high durability and moisture resistance, such as commercial kitchens and bathrooms. They are compatible with most adhesives and grout.

Considerations for Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as EN 14411 for ceramic tiles. Understanding local preferences for aesthetics and functionality is also crucial.

How Does Stoneware Compare to Other Ceramic Tile Materials?

Stoneware is made from a mixture of clay and other materials, fired at high temperatures to achieve a dense, non-porous finish. It is known for its strength and resistance to chipping.

Pros: Stoneware tiles are durable and have a unique aesthetic appeal, often resembling natural stone. They are also suitable for both indoor and outdoor use.

Cons: While stoneware is strong, it can be more expensive than earthenware and may require sealing to prevent staining.

Impact on Application: Stoneware is often used in residential and commercial spaces where aesthetics and durability are important, such as living rooms and dining areas.

Considerations for Buyers: Buyers should check for compliance with ASTM standards, especially in regions like South America where local regulations may differ. Understanding the market demand for natural aesthetics can influence purchasing decisions.

What Are the Benefits and Limitations of Earthenware Tiles?

Earthenware tiles are made from red or brown clay and fired at lower temperatures, making them more porous than porcelain or stoneware.

Pros: Earthenware is generally less expensive and offers a rustic, traditional look that appeals to many buyers. It is easy to cut and install, making it a popular choice for DIY projects.

Cons: The porosity of earthenware makes it less suitable for wet environments unless glazed. Its durability is also lower compared to porcelain and stoneware.

Impact on Application: Earthenware is often used in decorative applications, such as wall tiles or backsplashes, where moisture exposure is minimal.

Considerations for Buyers: Buyers should be aware of local climate conditions that may affect the longevity of earthenware tiles. Compliance with regional standards like JIS in Japan or DIN in Germany is essential for quality assurance.

Why Choose Terracotta Tiles for Specific Applications?

Terracotta tiles are made from natural clay and are known for their distinctive reddish-brown color. They are typically unglazed and porous.

Pros: Terracotta tiles are environmentally friendly and offer a warm, rustic appearance. They are also relatively inexpensive and easy to work with.

Cons: The porous nature of terracotta makes it susceptible to staining and damage from moisture, requiring regular sealing.

Impact on Application: Terracotta is best suited for indoor applications in dry climates, such as kitchens and living areas.

Considerations for Buyers: Buyers should consider the sealing requirements and maintenance needs of terracotta. Compliance with local environmental regulations regarding material sourcing is also important, especially in Europe.

Summary Table of Material Selection for Ceramic Tile China

| Material | Typical Use Case for ceramic tile china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Porcelain | High-traffic commercial areas | High durability and low water absorption | Higher manufacturing complexity | High |

| Stoneware | Residential and commercial spaces | Unique aesthetics and strength | Requires sealing to prevent staining | Med |

| Earthenware | Decorative applications | Cost-effective and easy to install | Lower durability and porosity | Low |

| Terracotta | Indoor applications in dry climates | Environmentally friendly and rustic look | Susceptible to moisture damage | Low |

This guide provides actionable insights for international B2B buyers, enabling them to make informed decisions based on material properties, application suitability, and compliance with regional standards. Understanding these factors is crucial for optimizing procurement strategies in the ceramic tile market.

In-depth Look: Manufacturing Processes and Quality Assurance for ceramic tile china

What Are the Key Stages in the Manufacturing Process of Ceramic Tiles in China?

The manufacturing of ceramic tiles in China involves several critical stages, ensuring that the end products meet high standards of quality and durability. Understanding these processes is essential for international B2B buyers to make informed purchasing decisions.

Material Preparation: What Goes Into Ceramic Tile Production?

The first step in the manufacturing process is material preparation. This involves sourcing high-quality raw materials, primarily clay, feldspar, and quartz. Suppliers often source these materials locally to reduce costs and ensure freshness. The materials are then processed to remove impurities, which may include grinding them into a fine powder. This powder is often mixed with water to achieve the desired consistency.

How Are Ceramic Tiles Formed?

Once the materials are prepared, the next step is forming. There are several techniques used in this stage, including:

- Pressing: This is the most common method, where the mixed powder is pressed into molds under high pressure. This technique ensures uniform density and strength.

- Extrusion: In this method, the material is forced through a die to create long strips, which can be cut into tiles. This is often used for producing tiles with specific shapes and designs.

- Casting: This involves pouring the liquid clay mixture into molds. It’s less common but allows for intricate designs and shapes.

Each method has its advantages, and the choice often depends on the desired tile specifications.

What Finishing Processes Enhance Ceramic Tile Quality?

After forming, the tiles undergo various finishing processes, which include:

- Drying: Tiles are dried to remove excess moisture. This is a critical step to prevent cracking during firing.

- Firing: Tiles are then fired in kilns at high temperatures (around 1,200°C). This process vitrifies the clay, making the tiles hard and durable.

- Glazing: A glaze is applied to the surface of the tiles, which can enhance aesthetics and provide a waterproof layer. The tiles are then fired again to set the glaze.

These finishing processes significantly impact the tile’s final appearance, durability, and functionality.

How Is Quality Assurance Implemented in Ceramic Tile Manufacturing?

Quality assurance (QA) is a vital aspect of the ceramic tile manufacturing process, ensuring that products meet international standards and customer expectations. For international B2B buyers, understanding these QA processes can provide insights into supplier reliability and product quality.

Which International Standards Are Relevant for Ceramic Tiles?

Manufacturers often comply with various international quality standards, such as:

- ISO 9001: This standard focuses on quality management systems, ensuring consistent quality in products and services.

- CE Marking: Particularly relevant in Europe, this certification indicates that the tiles meet health, safety, and environmental protection standards.

- API Standards: While more common in oil and gas, some ceramic products used in industrial applications may adhere to these specifications.

B2B buyers should request documentation proving compliance with these standards to ensure the quality and safety of their purchases.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is implemented through various checkpoints during the manufacturing process:

- Incoming Quality Control (IQC): This initial stage checks the quality of raw materials upon receipt. It ensures that only high-quality materials enter the production line.

- In-Process Quality Control (IPQC): During the forming and finishing stages, samples are taken at regular intervals to monitor quality. This helps identify issues early in the process.

- Final Quality Control (FQC): After the tiles are finished, a final inspection is conducted to assess the overall quality and ensure that they meet design specifications.

These checkpoints help maintain high standards and reduce the risk of defective products reaching the market.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying supplier QC practices is crucial. Here are some actionable steps:

- Conduct Supplier Audits: Regular audits can provide insights into a manufacturer’s QC practices. Buyers should consider scheduling visits to the manufacturing facility to observe processes firsthand.

- Request Quality Control Reports: Suppliers should be willing to provide detailed QC reports, including test results and compliance certificates. This documentation serves as proof of their commitment to quality.

- Utilize Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s QC practices. These services can conduct random inspections and provide reports on product quality.

What Common Testing Methods Are Used for Quality Assurance?

To ensure the quality of ceramic tiles, manufacturers employ various testing methods, including:

- Water Absorption Tests: This determines the porosity of the tiles, which is critical for assessing durability and suitability for different applications.

- Breaking Strength Tests: This evaluates the strength of the tiles under pressure, ensuring they can withstand typical use conditions.

- Color and Glaze Consistency Tests: These tests ensure that the aesthetic qualities of the tiles meet specified standards.

Buyers should inquire about the specific testing methods used by suppliers and request access to test results to validate the quality of their products.

What Are the Quality Control Nuances for International Buyers?

B2B buyers from different regions may face unique challenges regarding quality control. For instance:

- Cultural Differences: Understanding local manufacturing practices and quality expectations can aid in aligning supplier capabilities with buyer requirements.

- Regulatory Compliance: Buyers must be aware of the specific regulations in their countries regarding imported ceramic tiles. This knowledge can help in selecting suppliers who meet these standards.

- Language Barriers: Communication can sometimes hinder quality assurance efforts. Buyers should consider working with suppliers who have proficient English language capabilities or engage local intermediaries.

By being proactive in understanding and verifying the manufacturing processes and quality assurance measures of ceramic tile suppliers in China, B2B buyers can mitigate risks and ensure that they are sourcing high-quality products that meet their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ceramic tile china’

In the competitive landscape of international B2B trade, sourcing ceramic tiles from China can present both opportunities and challenges. This practical sourcing guide aims to equip buyers from regions such as Africa, South America, the Middle East, and Europe with a clear, actionable checklist to streamline the procurement process.

Step 1: Define Your Technical Specifications

Begin by outlining the specific requirements for your ceramic tiles. This includes dimensions, design, color, and finish. Having clear specifications helps in communicating effectively with suppliers and ensures that the products meet your quality standards.

- Considerations: Think about the intended use—residential, commercial, or industrial. This will influence the durability and aesthetic requirements of the tiles.

Step 2: Conduct Market Research

Understanding market dynamics is essential for informed decision-making. Research current trends in ceramic tile design and pricing, particularly in your target market.

- Action Items:

- Analyze local competitors to see what styles and prices are popular.

- Look into the demand for eco-friendly or sustainable tiles, as this is an emerging trend in many regions.

Step 3: Identify Potential Suppliers

Compile a list of potential suppliers from China. Utilize online platforms such as Alibaba, Global Sources, and trade fairs to discover manufacturers that specialize in ceramic tiles.

- Best Practices: Focus on suppliers with a solid track record and positive reviews. Check their production capabilities and ensure they can meet your volume needs.

Step 4: Verify Supplier Certifications

Before moving forward, it’s crucial to verify that your selected suppliers hold the necessary certifications. Look for ISO certifications and compliance with international quality standards.

- Why This Matters: Certifications can indicate a supplier’s commitment to quality and safety, which is particularly important when importing goods.

Step 5: Request Samples

Always request samples before placing a bulk order. This allows you to assess the quality, color accuracy, and finish of the tiles firsthand.

- Things to Check:

- Ensure that the samples reflect the specifications you require.

- Evaluate the packaging and delivery times to gauge the supplier’s reliability.

Step 6: Negotiate Terms and Pricing

Engage in negotiations to secure favorable terms and pricing. Be clear about your budget, payment terms, and lead times.

- Tips:

- Explore bulk purchase discounts and payment methods that provide some level of buyer protection.

- Discuss potential for long-term partnership agreements, which may yield better pricing over time.

Step 7: Establish a Logistics Plan

Finally, develop a logistics plan for shipping and handling your order. Consider the shipping methods, customs regulations, and timelines involved.

- Key Considerations:

- Collaborate with a freight forwarder familiar with importing ceramic tiles.

- Factor in potential delays due to customs inspections or shipping disruptions.

By following this step-by-step checklist, international B2B buyers can navigate the complexities of sourcing ceramic tiles from China more effectively, ensuring a successful procurement process.

Comprehensive Cost and Pricing Analysis for ceramic tile china Sourcing

What Are the Key Cost Components in Sourcing Ceramic Tiles from China?

When sourcing ceramic tiles from China, understanding the cost structure is vital for effective budgeting and financial planning. The primary components that influence the overall cost include:

-

Materials: The quality and type of raw materials used in ceramic tile production significantly affect pricing. High-quality clays, glazes, and additives contribute to better durability and aesthetics but may increase costs.

-

Labor: Labor costs in China are generally lower than in many Western countries, which can reduce the overall price of ceramic tiles. However, skilled labor for quality control and specialized manufacturing processes can increase costs.

-

Manufacturing Overhead: This includes utilities, facility maintenance, and administrative expenses. Efficient production processes can help keep overhead costs down.

-

Tooling: Initial investment in molds and tools can be substantial, particularly for custom designs. Understanding these costs upfront is essential for accurate pricing.

-

Quality Control (QC): Implementing stringent QC measures ensures product consistency and reduces returns. This can add to the cost but is necessary for maintaining a good reputation and minimizing defects.

-

Logistics: Shipping costs, including freight and insurance, can vary widely based on destination and shipping method. It’s important to factor in these costs when calculating total expenses.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary based on market conditions and competition.

How Do Price Influencers Impact the Sourcing of Ceramic Tiles?

Several factors can influence the pricing of ceramic tiles, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Ordering in bulk can significantly reduce per-unit costs. Buyers should negotiate MOQ terms to achieve better pricing.

-

Specifications and Customization: Customized tiles may incur additional costs due to unique molds or materials. Clearly defining specifications upfront can help manage expectations and budget.

-

Materials and Quality Certifications: Tiles that meet international quality standards or possess certifications (like ISO or CE) often command higher prices. Understanding the importance of these certifications can guide purchasing decisions.

-

Supplier Factors: The supplier’s reputation, reliability, and production capacity can influence pricing. Established suppliers may charge more due to their experience and quality assurance practices.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can significantly affect the final cost. Terms like FOB (Free On Board) and CIF (Cost, Insurance, and Freight) determine who is responsible for shipping and insurance, impacting overall costs.

What Tips Can Help Buyers Negotiate Better Prices for Ceramic Tiles?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, implementing effective negotiation strategies can lead to significant savings:

-

Conduct Market Research: Understanding the market rates and competitor offerings can provide leverage during negotiations. Knowledge of current trends can also help in assessing whether a supplier’s pricing is fair.

-

Emphasize Long-Term Relationships: Building a solid relationship with suppliers can lead to better pricing and terms. Suppliers are often willing to negotiate for repeat business.

-

Evaluate Total Cost of Ownership (TCO): Beyond initial pricing, consider factors such as durability, maintenance costs, and potential wastage. A slightly higher upfront cost for quality tiles may lead to lower long-term expenses.

-

Be Flexible with Payment Terms: Offering upfront payments or flexible payment terms can incentivize suppliers to provide better pricing.

-

Leverage Technology: Utilize online platforms and trade shows to compare different suppliers and negotiate better deals. Digital tools can facilitate communication and streamline the procurement process.

Final Considerations for B2B Buyers

While the information provided offers a comprehensive overview of the cost and pricing dynamics associated with sourcing ceramic tiles from China, it is important to note that prices can fluctuate based on market conditions and other external factors. Therefore, buyers should always seek multiple quotes and remain adaptable to changes in the supply chain landscape.

Alternatives Analysis: Comparing ceramic tile china With Other Solutions

Understanding Alternative Solutions to Ceramic Tile China

As international B2B buyers explore flooring and tiling options, it’s crucial to consider a range of alternatives to ceramic tile from China. This analysis will compare ceramic tile with vinyl flooring and natural stone, two popular alternatives, to help buyers make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Ceramic Tile China | Vinyl Flooring | Natural Stone |

|---|---|---|---|

| Performance | High durability, water-resistant | Moderate durability, water-resistant but less than tile | Extremely durable, but porous; requires sealing |

| Cost | Moderate to high | Low to moderate | High |

| Ease of Implementation | Requires skilled labor for installation | DIY-friendly; easy to install | Requires skilled labor; heavy materials |

| Maintenance | Low maintenance; easy to clean | Moderate; needs replacement over time | High; requires regular sealing and maintenance |

| Best Use Case | Residential and commercial spaces | Residential, especially in low-traffic areas | High-end residential and commercial spaces |

What Are the Benefits and Drawbacks of Vinyl Flooring as an Alternative?

Vinyl flooring offers a cost-effective solution that is appealing for its ease of installation and maintenance. It is particularly suitable for residential spaces or low-traffic commercial areas due to its moderate durability. However, it may not withstand heavy foot traffic or extreme conditions as well as ceramic tile, making it less ideal for high-traffic commercial environments. Moreover, while vinyl is water-resistant, it is not completely waterproof, which can lead to issues in areas prone to moisture.

How Does Natural Stone Compare to Ceramic Tile China?

Natural stone, such as granite or marble, is renowned for its aesthetic appeal and exceptional durability. It works well in high-end residential and commercial spaces, offering a luxurious finish. However, the high cost and the need for regular sealing can be significant drawbacks. Installation also requires skilled labor due to the weight and handling of the stone. Unlike ceramic tile, natural stone is porous, which can lead to staining if not properly maintained, making it less suitable for all applications.

Conclusion: How Can B2B Buyers Select the Right Flooring Solution?

When choosing between ceramic tile from China, vinyl flooring, and natural stone, B2B buyers should consider their specific needs, including budget, the environment where the flooring will be installed, and the desired aesthetics. Ceramic tile offers a robust solution for both residential and commercial applications, while vinyl flooring serves as a budget-friendly option for low-traffic areas. Natural stone, though more expensive, can elevate the design of high-end spaces but requires more maintenance. By assessing these factors, buyers can select the most appropriate flooring solution tailored to their unique requirements.

Essential Technical Properties and Trade Terminology for ceramic tile china

What Are the Key Technical Properties of Ceramic Tiles from China?

When sourcing ceramic tiles from China, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications to consider:

1. Material Grade

Material grade indicates the quality and durability of the ceramic tile. Common grades include standard, premium, and ultra-premium, which reflect variations in raw materials and manufacturing processes. Higher-grade tiles typically offer enhanced strength, aesthetics, and longevity, making them ideal for high-traffic areas. B2B buyers should assess their project requirements to select the appropriate material grade that balances cost and performance.

2. Water Absorption Rate

The water absorption rate measures how much water a tile can absorb over a specified period. It is a critical factor for determining a tile’s suitability for wet areas, such as bathrooms and kitchens. Tiles with a lower absorption rate (below 0.5%) are generally more resistant to stains and moisture, making them ideal for both residential and commercial applications. Buyers should prioritize low-absorption tiles for environments exposed to water.

3. PEI Rating (Porcelain Enamel Institute)

The PEI rating assesses the wear resistance of ceramic tiles, categorizing them from 1 to 5. A higher PEI rating indicates greater durability and suitability for various applications, including heavy foot traffic areas. For B2B buyers, understanding PEI ratings can guide their selection process based on expected usage and foot traffic levels.

4. Surface Finish

Ceramic tiles come with various surface finishes, such as glazed, matte, or polished. Each finish affects aesthetics, slip resistance, and ease of maintenance. For example, glazed tiles are easier to clean but may be slippery when wet. Understanding these finishes helps buyers choose tiles that meet both functional and design requirements for their projects.

5. Dimensions and Tolerance

Tile dimensions and tolerance refer to the size and precision of each tile. Standard sizes include 12×12 inches or 24×24 inches, but custom sizes are also available. Tolerance is crucial for ensuring uniformity and fit during installation. Buyers should consider these factors to avoid complications during the installation process, particularly in large-scale projects.

What Are Common Trade Terms in the Ceramic Tile Industry?

Familiarizing yourself with industry terminology can streamline communication and negotiations with suppliers. Here are some essential trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce goods based on specifications provided by another company, often a brand. In the ceramic tile industry, an OEM may create customized designs or specifications for a buyer’s brand. Understanding OEM relationships can help B2B buyers ensure quality and consistency in their product offerings.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is vital for B2B buyers to understand their purchasing limits and negotiate better deals. Knowing the MOQ helps buyers plan their inventory and budget effectively, especially when sourcing from international suppliers.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products. For ceramic tiles, an RFQ allows buyers to compare offers and negotiate terms effectively. Including precise specifications in an RFQ helps ensure accurate responses from suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for B2B buyers to understand their obligations and manage risks when importing ceramic tiles. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight).

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the products. Understanding lead times is essential for B2B buyers to manage project timelines effectively. Suppliers may have varying lead times based on production schedules, which can impact project planning and execution.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing ceramic tiles from China, ensuring quality and efficiency in their projects.

Navigating Market Dynamics and Sourcing Trends in the ceramic tile china Sector

What Are the Current Market Dynamics and Key Trends in the Ceramic Tile Sector?

The ceramic tile market is experiencing transformative growth, driven by several global factors that international B2B buyers need to consider. Demand for ceramic tiles is increasingly influenced by urbanization, particularly in developing regions such as Africa and South America. Urban expansion leads to a surge in construction and renovation activities, driving the need for durable and aesthetically pleasing flooring solutions. In Europe and the Middle East, trends towards luxury and custom designs are shaping buyer preferences, with a growing emphasis on high-quality materials and unique styles.

Emerging technologies are also reshaping the sourcing landscape. Digital platforms and B2B marketplaces are simplifying the procurement process, enabling buyers to access a wider range of suppliers and products from China. Innovations in manufacturing, such as 3D printing and advanced glazing techniques, are resulting in more versatile and sustainable product offerings. Buyers should leverage these technologies to enhance their sourcing strategies and stay competitive in their local markets.

Furthermore, the ceramic tile sector is becoming increasingly interconnected, with supply chains spanning multiple countries. This globalization presents both opportunities and challenges. International buyers must stay informed about trade policies, tariffs, and geopolitical factors that could impact sourcing decisions. By being proactive and adaptable, buyers can navigate these complexities and optimize their procurement processes.

How Does Sustainability and Ethical Sourcing Impact the Ceramic Tile Industry?

Sustainability is becoming a cornerstone of the ceramic tile industry, influencing both manufacturing practices and purchasing decisions. International B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to environmental stewardship. This includes the use of eco-friendly materials, such as recycled clay and natural pigments, as well as sustainable manufacturing processes that minimize waste and energy consumption.

Ethical sourcing is equally important, particularly for buyers in regions where social responsibility is a growing concern. Ensuring that suppliers adhere to fair labor practices and maintain transparency in their supply chains is essential for building trust and brand loyalty. Certifications such as LEED (Leadership in Energy and Environmental Design) and Greenguard can help buyers identify products that meet rigorous environmental standards.

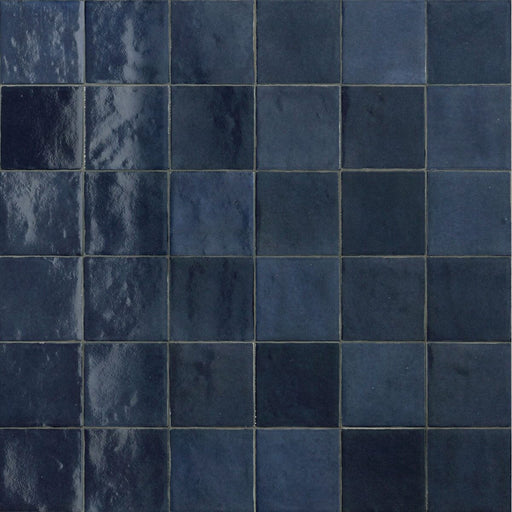

A stock image related to ceramic tile china.

Moreover, the demand for ‘green’ materials is on the rise, with consumers increasingly favoring products that contribute to healthier living environments. By aligning procurement strategies with sustainability goals, international B2B buyers can differentiate themselves in the marketplace and appeal to environmentally-conscious consumers.

What Is the Evolution of the Ceramic Tile Market?

The ceramic tile industry has undergone significant evolution over the past few decades. Initially dominated by traditional manufacturing techniques, the sector has embraced technological advancements that enhance production efficiency and product diversity. The rise of globalization has facilitated the expansion of ceramic tile exports from China, making it a major player in the global market.

As buyer preferences shift towards customization and sustainability, manufacturers are adapting their strategies to meet these demands. The integration of digital technologies in design and manufacturing processes is enabling the creation of innovative tile designs that cater to diverse aesthetic preferences. This evolution not only enhances product offerings but also positions the ceramic tile sector for continued growth in the global marketplace.

By understanding these dynamics, international B2B buyers can make informed decisions that align with market trends and consumer expectations, ensuring their long-term success in the ceramic tile industry.

Frequently Asked Questions (FAQs) for B2B Buyers of ceramic tile china

-

How do I choose the right ceramic tile supplier from China?

Selecting the right ceramic tile supplier involves several key steps. First, conduct thorough research to identify reputable manufacturers with a proven track record in international trade. Look for suppliers who have experience exporting to your region and can provide references from other international buyers. Utilize platforms like Alibaba or Global Sources to verify their credibility. Additionally, request samples to assess product quality and ensure they meet your specific requirements. Finally, consider visiting the supplier’s facility if possible, as this can provide invaluable insights into their production capabilities and quality control processes. -

What certifications should I look for in Chinese ceramic tile suppliers?

When sourcing ceramic tiles from China, it’s essential to ensure that suppliers possess relevant certifications. Key certifications include ISO 9001 for quality management systems and CE marking for compliance with European standards. Additionally, check for certifications such as Green Label or FloorScore, which indicate low emissions and eco-friendliness. For buyers in Africa and the Middle East, it may also be important to verify compliance with local regulations. Request documentation to confirm these certifications before proceeding with orders to ensure product safety and quality. -

What are the common minimum order quantities (MOQ) for ceramic tiles?

Minimum order quantities (MOQ) for ceramic tiles can vary significantly depending on the supplier and the type of tiles. Typically, MOQs range from 100 to 1,000 square meters. However, some suppliers may offer lower MOQs for specific designs or during promotional periods. It’s advisable to communicate your needs clearly and negotiate MOQs, especially if you are a smaller buyer or testing a new product line. Understanding the supplier’s capacity and flexibility can help you plan your inventory and manage costs effectively. -

How can I customize ceramic tiles to fit my project needs?

Many Chinese ceramic tile suppliers offer customization options, allowing you to tailor designs, sizes, and colors to meet specific project requirements. Start by discussing your vision with potential suppliers and inquire about their customization capabilities. Be clear about your design specifications, including dimensions, finishes, and any patterns. Some manufacturers may require a minimum order for customized designs, so factor this into your decision-making process. Additionally, request visual mock-ups or prototypes to ensure the final product aligns with your expectations before placing a larger order. -

What payment terms are typically offered by Chinese ceramic tile suppliers?

Payment terms can vary widely among suppliers, but common options include a 30% deposit upfront with the balance due before shipment or upon receipt of shipping documents. Some suppliers may also accept letters of credit (LC) or PayPal for smaller transactions. It’s crucial to establish clear payment terms during negotiations to avoid misunderstandings later. Consider using escrow services for larger orders to protect your investment. Always ensure that the payment method aligns with your financial capabilities and risk tolerance. -

How do I ensure quality assurance for ceramic tiles sourced from China?

To ensure quality assurance when sourcing ceramic tiles, establish clear quality standards and inspection criteria with your supplier before production begins. Request that the supplier provides detailed product specifications and samples for your review. Consider hiring a third-party inspection service to conduct quality checks at various production stages and before shipment. This can help identify any defects or inconsistencies early in the process. Additionally, build a good relationship with your supplier to facilitate open communication regarding quality issues. -

What logistics considerations should I keep in mind when importing ceramic tiles?

Importing ceramic tiles involves several logistical considerations, including shipping methods, customs regulations, and lead times. Determine whether ocean freight or air freight is more suitable based on your budget and urgency. Ensure that you understand the customs duties and taxes applicable to your import, as these can significantly affect your overall costs. Collaborate with a freight forwarder experienced in handling ceramic tiles to streamline the shipping process and mitigate risks. Finally, factor in lead times for production and shipping to align your inventory needs with project timelines. -

How can I effectively communicate with Chinese suppliers?

Effective communication with Chinese suppliers is crucial for successful transactions. Use clear, concise language and avoid jargon to minimize misunderstandings. Consider utilizing translation services if necessary, especially for technical specifications. Establish a single point of contact to streamline communication and ensure consistency. Regular follow-ups can help maintain momentum throughout the negotiation and production process. Additionally, be culturally sensitive and patient, as building trust may take time, but it can lead to more fruitful long-term relationships.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for ceramic tile china

What Are the Key Takeaways for B2B Buyers in Ceramic Tile Sourcing?

In conclusion, international B2B buyers looking to source ceramic tiles from China should prioritize strategic sourcing to maximize value and minimize risks. Understanding the nuances of the Chinese market, including supplier reliability, production capabilities, and compliance with international standards, is essential. Establishing strong relationships with verified suppliers can lead to better pricing, quality assurance, and timely deliveries, which are crucial for maintaining competitive advantage in your local markets.

How Can Buyers Prepare for Future Trends in Ceramic Tile Sourcing?

As the global demand for ceramic tiles continues to evolve, buyers must stay informed about emerging trends such as sustainable materials, innovative designs, and digital procurement solutions. Engaging with local partners and leveraging technology can enhance your sourcing strategies, allowing you to respond swiftly to market changes and consumer preferences.

What Steps Should You Take Next in Your Sourcing Journey?

Now is the time to reassess your sourcing strategies and consider expanding your supplier network in China. By focusing on strategic partnerships and utilizing market intelligence, you can unlock new opportunities and drive growth for your business in Africa, South America, the Middle East, and Europe. Take proactive steps today to ensure your ceramic tile sourcing aligns with future trends and consumer demands, securing your position in the competitive landscape.