Discover Cost-Saving Benefits of Freightliner Argosy Custom (2025)

Introduction: Navigating the Global Market for freightliner argosy custom

The global market for the Freightliner Argosy Custom presents a unique challenge for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. Sourcing the right heavy-duty truck that meets both operational demands and regulatory requirements can be daunting. This guide aims to demystify the complexities surrounding the Freightliner Argosy Custom, providing an in-depth look at various models, their specific applications, and the benefits they offer to businesses engaged in logistics and transportation.

Within these pages, you will find comprehensive insights on the different configurations of the Argosy Custom, including their performance capabilities and customization options. We will explore essential factors such as supplier vetting processes, maintenance considerations, and cost analysis to help you make informed decisions. By understanding the nuances of sourcing the Freightliner Argosy Custom, you can better navigate the marketplace and select a truck that not only enhances your fleet’s efficiency but also aligns with your business goals.

This guide empowers international B2B buyers, especially those from regions like Argentina and Turkey, to leverage data-driven insights and expert recommendations. As you navigate the global market for the Freightliner Argosy Custom, our goal is to equip you with the knowledge necessary to optimize your purchasing strategy and ensure long-term success in your operations.

Understanding freightliner argosy custom Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Freightliner Argosy 580 | High cab, aerodynamic design, spacious interior | Long-haul transportation | Pros: Fuel-efficient, comfortable for long drives. Cons: Higher initial investment. |

| Freightliner Argosy 600 | Enhanced powertrain options, customizable features | Heavy-duty hauling, construction | Pros: Versatile configurations, robust performance. Cons: Maintenance costs can be higher. |

| Freightliner Argosy 700 | Advanced safety features, optimized for stability | Freight logistics, intermodal transport | Pros: Improved safety, reliability. Cons: Limited availability in some regions. |

| Freightliner Argosy 900 | Superior cargo capacity, multi-axle configurations | Bulk transport, heavy freight | Pros: High payload capacity, customizable specs. Cons: Larger size may limit maneuverability. |

| Freightliner Argosy Electric | Eco-friendly, electric powertrain, reduced emissions | Urban deliveries, sustainable logistics | Pros: Lower operating costs, sustainability. Cons: Limited range compared to diesel models. |

What Are the Key Characteristics of the Freightliner Argosy 580?

The Freightliner Argosy 580 is known for its high cab design and aerodynamic shape, which enhances fuel efficiency while providing a spacious interior for drivers. This model is particularly suitable for long-haul transportation, where comfort and fuel economy are paramount. B2B buyers should consider the initial investment against long-term savings on fuel costs, making it a valuable asset for companies focused on logistics efficiency.

How Does the Freightliner Argosy 600 Stand Out in Heavy-Duty Applications?

The Argosy 600 offers a range of powerful engine options and customizable features tailored for heavy-duty applications. It excels in construction and heavy hauling due to its robust performance and adaptability. B2B buyers should evaluate the specific needs of their operations, as the versatility of this model can align well with varying transport requirements, although it may incur higher maintenance costs.

What Safety Features Are Available in the Freightliner Argosy 700?

The Freightliner Argosy 700 is equipped with advanced safety features that enhance stability and driver confidence. This model is ideal for freight logistics and intermodal transport, where reliability is critical. B2B buyers should prioritize safety when selecting a vehicle, and the Argosy 700’s reputation for reliability makes it a strong contender, even if its availability may be limited in certain markets.

Why Choose the Freightliner Argosy 900 for Bulk Transport?

The Argosy 900 is designed for superior cargo capacity, featuring multi-axle configurations that allow it to handle heavy freight efficiently. This model is particularly beneficial for companies engaged in bulk transport, as it offers high payload capabilities and customizable specifications. However, B2B buyers should also consider the potential challenges of maneuverability due to its larger size, which can impact urban logistics.

What Are the Advantages of the Freightliner Argosy Electric for Sustainable Logistics?

The Freightliner Argosy Electric represents a significant shift towards eco-friendly transportation solutions, featuring an electric powertrain that reduces emissions. This model is well-suited for urban deliveries and companies prioritizing sustainability in their logistics operations. While it offers lower operating costs and aligns with green initiatives, B2B buyers should be aware of its limited range compared to traditional diesel models, necessitating careful planning for routes and charging infrastructure.

Related Video: 32-Foot Freightliner!! Andy Babiak’s Custom Argosy Truck Tour

Key Industrial Applications of freightliner argosy custom

| Industry/Sector | Specific Application of freightliner argosy custom | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics and Freight | Long-haul transportation of goods | Enhanced fuel efficiency and payload capacity | Local regulations, engine specifications, and service support availability |

| Construction | Heavy equipment transportation | Robust design for handling rugged terrains and loads | Availability of parts, maintenance services, and dealer network in the region |

| Agriculture | Transporting agricultural products | Reliable delivery for perishable goods | Temperature control options and adaptability to local road conditions |

| Mining | Hauling minerals and raw materials | High durability and low operating costs | Compliance with local mining regulations and terrain adaptability |

| Waste Management | Collection and transport of waste | Improved efficiency in urban waste collection | Local waste management regulations and vehicle emissions standards |

How is the Freightliner Argosy Custom Used in Logistics and Freight?

In the logistics and freight sector, the Freightliner Argosy Custom is primarily employed for long-haul transportation of goods across vast distances. Its enhanced fuel efficiency and high payload capacity make it ideal for businesses looking to optimize operational costs while meeting delivery timelines. International B2B buyers in this sector must consider local regulations regarding weight limits and emissions standards to ensure compliance and avoid penalties.

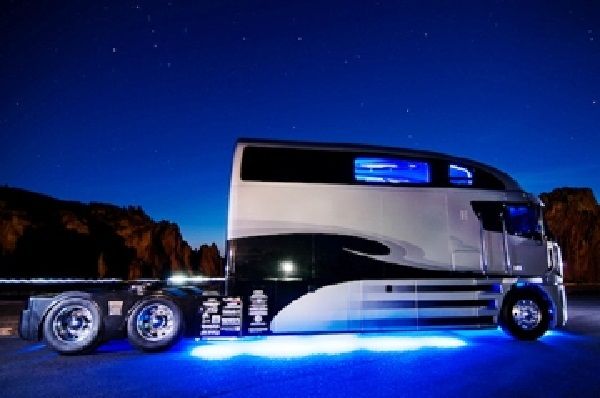

A stock image related to freightliner argosy custom.

What Role Does the Freightliner Argosy Custom Play in Construction?

The construction industry benefits from the Freightliner Argosy Custom’s capability to transport heavy equipment and materials to job sites. Its robust design allows it to navigate rugged terrains, making it suitable for challenging construction environments. Buyers should prioritize sourcing options that offer strong after-sales support, including parts availability and maintenance services, particularly in remote areas of Africa and South America.

How Does the Freightliner Argosy Custom Support Agriculture?

A stock image related to freightliner argosy custom.

In agriculture, the Freightliner Argosy Custom is utilized to transport agricultural products, including crops and livestock. Its reliability is crucial for ensuring timely deliveries, especially for perishable goods that require quick transport to market. Buyers should consider temperature control options and the vehicle’s adaptability to local road conditions, which can vary significantly across regions in the Middle East and Europe.

What Advantages Does the Freightliner Argosy Custom Offer in Mining Applications?

The mining industry relies on the Freightliner Argosy Custom for hauling minerals and raw materials from extraction sites to processing facilities. Its high durability and low operating costs make it an attractive option for companies operating in harsh environments. Buyers must ensure that the vehicle complies with local mining regulations and can handle the specific terrain challenges they face in countries like Turkey and Argentina.

How is the Freightliner Argosy Custom Used in Waste Management?

In waste management, the Freightliner Argosy Custom is effective for the collection and transport of waste. Its design enhances efficiency in urban waste collection processes, helping municipalities manage waste more effectively. International buyers should pay attention to local waste management regulations and vehicle emissions standards to ensure compliance and minimize environmental impact.

3 Common User Pain Points for ‘freightliner argosy custom’ & Their Solutions

Scenario 1: Difficulty in Sourcing Replacement Parts for Freightliner Argosy Custom

The Problem:

One of the most significant challenges faced by international B2B buyers of the Freightliner Argosy Custom is the sourcing of replacement parts, particularly in regions like Africa and South America, where supply chains may be less robust. When a vehicle requires maintenance or repairs, delays in obtaining the necessary parts can lead to costly downtimes. This not only affects operational efficiency but can also result in lost contracts or customer dissatisfaction.

The Solution:

To effectively address this issue, B2B buyers should establish relationships with reputable Freightliner dealers and distributors in their region. Utilizing the Freightliner dealer locator tool can help identify authorized dealers who stock genuine parts. Additionally, buyers should consider investing in a local parts inventory management system to track and order essential parts proactively. By building a reliable network of suppliers and maintaining a small stock of frequently needed parts, businesses can mitigate downtime and enhance operational continuity. Furthermore, consider leveraging online platforms or forums where other Freightliner Argosy Custom owners share insights about reliable suppliers and alternative parts options.

Scenario 2: Navigating Compliance and Regulatory Issues with Freightliner Argosy Custom

The Problem:

International buyers often struggle with compliance regarding vehicle specifications and emissions standards, which vary significantly across regions such as the Middle East and Europe. Failure to comply with these regulations can lead to fines, vehicle impoundment, or the inability to transport goods, severely impacting business operations.

The Solution:

To navigate these complexities, buyers should conduct thorough research on the specific regulations in their operational regions. Consulting with local regulatory bodies and logistics experts can provide valuable insights into compliance requirements for the Freightliner Argosy Custom. Additionally, it is advisable to work closely with Freightliner’s technical support team, which can offer guidance on vehicle configurations that meet local standards. Buyers should also consider enrolling in training programs or workshops focusing on compliance for commercial vehicles. This proactive approach not only minimizes legal risks but also positions the company as a responsible and compliant operator in the logistics space.

Scenario 3: Ensuring Optimal Performance and Fuel Efficiency of Freightliner Argosy Custom

The Problem:

Another prevalent pain point for B2B buyers is the challenge of maintaining optimal performance and fuel efficiency of the Freightliner Argosy Custom, especially in demanding environments typical in regions like Turkey and parts of Africa. Poor fuel efficiency can lead to inflated operational costs, affecting overall profitability.

The Solution:

To enhance the performance and fuel efficiency of their Freightliner Argosy Custom trucks, buyers should implement a comprehensive maintenance schedule that includes regular engine checks, tire rotations, and air filter replacements. Utilizing telematics solutions can provide real-time data on vehicle performance and fuel consumption, allowing for data-driven decisions to improve efficiency. Additionally, buyers should invest in driver training programs that emphasize eco-driving techniques, such as maintaining steady speeds and minimizing idling times. By fostering a culture of efficiency and leveraging technology, businesses can significantly reduce fuel costs and improve their bottom line, while also extending the lifespan of their vehicles.

Strategic Material Selection Guide for freightliner argosy custom

When selecting materials for the Freightliner Argosy Custom, understanding the properties, advantages, and limitations of each material is crucial for ensuring optimal performance and compliance with international standards. Below, we analyze four common materials used in the construction of the Freightliner Argosy Custom, focusing on their key properties, pros and cons, and specific considerations for international B2B buyers.

What Are the Key Properties of Steel in Freightliner Argosy Custom?

Steel is a primary material used in the Freightliner Argosy Custom due to its strength and durability. Key properties include high tensile strength, excellent temperature resistance, and good weldability. Steel can withstand high pressures, making it suitable for structural components and chassis.

Pros:

– Durability: Steel’s robust nature ensures long-lasting performance, even in harsh environments.

– Cost-Effectiveness: Generally, steel is more affordable compared to other materials, making it a popular choice.

– Manufacturing Flexibility: It can be easily shaped and welded, allowing for complex designs.

Cons:

– Corrosion Susceptibility: Without proper treatment, steel can rust, especially in humid climates.

– Weight: Steel is heavier than alternative materials, which may affect fuel efficiency.

Impact on Application: Steel’s compatibility with various media, including oils and fuels, makes it ideal for truck applications. However, corrosion-resistant coatings may be necessary in coastal regions.

How Does Aluminum Benefit the Freightliner Argosy Custom?

Aluminum is increasingly used in the Freightliner Argosy Custom for components that require a lightweight yet strong material. Key properties include excellent corrosion resistance, low density, and good thermal conductivity.

Pros:

– Lightweight: Reduces overall vehicle weight, enhancing fuel efficiency and payload capacity.

– Corrosion Resistance: Naturally resistant to corrosion, making it suitable for various environmental conditions.

– Recyclability: Aluminum is highly recyclable, appealing to environmentally conscious buyers.

Cons:

– Higher Cost: Aluminum is typically more expensive than steel, which may affect budget considerations.

– Manufacturing Complexity: Requires specialized techniques for welding and joining.

Impact on Application: Aluminum’s compatibility with various media makes it suitable for fuel tanks and body panels, but care must be taken to ensure proper bonding with other materials.

What Are the Advantages of Composite Materials in Freightliner Argosy Custom?

Composite materials, such as fiberglass or carbon fiber, are becoming popular in the automotive industry, including in the Freightliner Argosy Custom. They offer unique properties like high strength-to-weight ratios and excellent resistance to environmental factors.

Pros:

– High Strength-to-Weight Ratio: Provides structural integrity while minimizing weight.

– Corrosion and Chemical Resistance: Ideal for parts exposed to harsh chemicals and weather conditions.

– Design Flexibility: Can be molded into complex shapes, allowing for innovative designs.

Cons:

– Cost: Composites can be significantly more expensive than traditional materials.

– Repair Complexity: Damage to composite materials can be more challenging to repair compared to metals.

Impact on Application: Composites are suitable for non-structural components and interior fittings, but their cost may limit widespread use in budget-sensitive markets.

Why Is Rubber Important for Freightliner Argosy Custom?

Rubber is essential for various components, particularly in suspension and sealing applications. Key properties include excellent elasticity, vibration dampening, and resistance to wear.

Pros:

– Vibration Absorption: Reduces noise and enhances ride comfort.

– Weather Resistance: Performs well in diverse climates, providing reliable sealing and protection.

– Cost-Effective: Generally lower in cost compared to advanced materials like composites.

Cons:

– Degradation Over Time: Rubber can degrade due to UV exposure and extreme temperatures.

– Limited Structural Use: Not suitable for load-bearing applications.

Impact on Application: Rubber’s compatibility with oils and fuels makes it ideal for seals and gaskets, but buyers should consider the environmental conditions to ensure longevity.

Summary Table of Material Selection for Freightliner Argosy Custom

| Material | Typical Use Case for freightliner argosy custom | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Chassis and structural components | High durability and cost-effective | Corrosion susceptibility | Medium |

| Aluminum | Body panels and fuel tanks | Lightweight and corrosion-resistant | Higher cost and complexity | High |

| Composite | Non-structural components | High strength-to-weight ratio | Expensive and complex repairs | High |

| Rubber | Seals and suspension components | Excellent vibration absorption | Degrades over time | Low |

This strategic material selection guide aims to provide international B2B buyers with actionable insights, enabling informed decisions that align with performance requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for freightliner argosy custom

What Are the Key Stages in the Manufacturing Process of the Freightliner Argosy Custom?

The manufacturing process of the Freightliner Argosy Custom involves several critical stages that ensure the production of high-quality, durable trucks tailored for various applications. Understanding these stages can help international B2B buyers evaluate suppliers effectively.

1. Material Preparation

The first stage involves sourcing and preparing raw materials. Freightliner emphasizes using high-grade steel and lightweight aluminum to enhance durability and fuel efficiency. The materials undergo rigorous quality checks to ensure compliance with industry standards. Buyers should inquire about the types of materials used and their sourcing to ensure that they meet local regulations and performance expectations.

2. Forming

In this stage, materials are shaped into components using advanced techniques such as stamping, bending, and machining. Computer Numerical Control (CNC) machines are often employed for precision in shaping parts like chassis and frames. For B2B buyers, understanding the forming technologies used is essential, as these directly impact the truck’s performance and longevity.

3. Assembly

The assembly process is where all the formed components come together. Automated assembly lines are common, utilizing robotics for tasks that require high precision and efficiency. This stage includes installing the drivetrain, electrical systems, and interior features. Buyers should assess how assembly is managed and whether it allows for customization, which can be crucial for meeting specific regional needs.

4. Finishing

Finally, the finishing stage involves painting and applying protective coatings to enhance the truck’s aesthetics and durability. This stage also includes quality checks to ensure that the finishing meets the desired standards. B2B buyers should confirm the types of finishes used, as these can affect maintenance needs and the truck’s overall lifespan.

How Is Quality Assurance Implemented in the Manufacturing of Freightliner Argosy Custom?

Quality assurance is a critical aspect of the manufacturing process, ensuring that each truck meets stringent safety and performance standards. For international buyers, understanding these quality assurance mechanisms can aid in supplier evaluation.

International Standards and Certifications

Freightliner adheres to various international standards, including ISO 9001, which outlines requirements for a quality management system. Compliance with ISO standards indicates that the manufacturer has processes in place to ensure consistent quality. Additionally, certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for specific components are crucial for B2B buyers. Understanding these certifications can guide buyers in assessing a supplier’s credibility.

What Are the Key Quality Control Checkpoints During Production?

Quality control (QC) is implemented at several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon delivery to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): Throughout the manufacturing stages, regular checks are conducted to monitor processes and identify any deviations from quality standards.

-

Final Quality Control (FQC): After assembly, each truck undergoes comprehensive testing to verify functionality and safety before it is released for sale.

B2B buyers should inquire about the frequency and types of inspections conducted at these checkpoints to ensure thorough quality management.

What Common Testing Methods Are Used to Ensure Quality?

Testing methods employed include:

-

Dynamic Testing: Evaluating the truck’s performance under various load conditions to ensure it meets design specifications.

-

Durability Testing: Subjecting the vehicle to stress tests that mimic real-world conditions to assess its resilience.

-

Safety Testing: Ensuring compliance with safety standards through crash tests and assessments of safety features.

Buyers can request detailed testing reports to verify compliance with these methods.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, verifying the quality control measures of suppliers is essential to mitigate risks associated with procurement.

Supplier Audits and Reports

Conducting supplier audits is one of the most effective ways to verify quality control practices. During an audit, buyers can assess the manufacturing processes, quality management systems, and compliance with international standards. Requesting regular quality reports can also provide insights into the supplier’s performance over time.

Utilizing Third-Party Inspections

Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality assurance processes. These inspections can be particularly valuable for buyers in regions such as Africa and South America, where establishing trust with local suppliers may be challenging.

What Are the Quality Control Nuances for International B2B Buyers?

When engaging with suppliers from different regions, B2B buyers must be aware of potential quality control nuances:

-

Regulatory Compliance: Different regions may have varying regulatory requirements. Buyers must ensure that their suppliers meet local standards in addition to international ones.

-

Cultural Differences: Understanding the manufacturing culture in regions like Turkey or South America can provide insights into potential challenges or advantages in quality control practices.

-

Supply Chain Transparency: Buyers should seek suppliers who can provide transparency in their supply chain, ensuring that all components meet the required quality standards.

In conclusion, understanding the manufacturing processes and quality assurance measures for the Freightliner Argosy Custom is crucial for international B2B buyers. By focusing on material preparation, forming, assembly, and finishing stages, alongside robust quality control practices, buyers can make informed decisions that align with their operational needs and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘freightliner argosy custom’

In the competitive landscape of B2B procurement, acquiring a Freightliner Argosy Custom demands a strategic approach. This guide provides a practical checklist to facilitate the sourcing process, ensuring that buyers from Africa, South America, the Middle East, and Europe can make informed decisions.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s essential to clearly outline your technical requirements. This includes engine specifications, chassis type, load capacity, and any custom features you may need. Having detailed specifications helps suppliers understand your needs and ensures that you receive accurate quotes.

- Key Considerations:

- Identify the primary use of the vehicle (e.g., long-haul transportation, local deliveries).

- Consider compliance with local regulations regarding emissions and safety standards.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of the Freightliner Argosy Custom. Look for companies with a strong presence in your target markets and those that specialize in heavy-duty vehicles.

- Actions to Take:

- Utilize online directories and trade associations to compile a list of potential suppliers.

- Read reviews and testimonials to gauge customer satisfaction and reliability.

Step 3: Evaluate Supplier Certifications and Reputation

Before engaging with suppliers, verify their certifications and industry reputation. This step is vital to ensure that you are dealing with legitimate businesses that adhere to quality standards.

- Important Aspects:

- Check for ISO certifications or other relevant industry standards.

- Request references from previous clients to assess their experience with the supplier.

Step 4: Request Detailed Quotes

Once you have shortlisted potential suppliers, request detailed quotes that include pricing, delivery timelines, and warranty information. This transparency allows for better comparisons and informed decision-making.

- Key Elements to Look For:

- Breakdown of costs (vehicle price, shipping, customs duties).

- Clear warranty terms and after-sales support options.

Step 5: Conduct Site Visits or Virtual Tours

If feasible, visit the supplier’s facility or request a virtual tour. This firsthand experience can provide insights into their operational capabilities and quality control processes.

- Benefits of Site Visits:

- Observe the manufacturing process and quality assurance measures.

- Meet key personnel to discuss your requirements in detail.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, engage in negotiations to establish favorable terms. This includes payment methods, delivery schedules, and service agreements.

- Negotiation Tips:

- Be clear about your expectations regarding delivery times and service levels.

- Consider offering bulk orders for discounts or better terms.

Step 7: Finalize the Purchase Agreement

After reaching an agreement, ensure that all terms are documented in a formal purchase agreement. This contract should outline all agreed-upon terms, including payment schedules, delivery expectations, and penalties for non-compliance.

- Critical Components:

- Ensure clarity on warranties and after-sales support.

- Include clauses for dispute resolution to protect your interests.

By following this checklist, international B2B buyers can effectively navigate the procurement process for the Freightliner Argosy Custom, minimizing risks and ensuring a successful purchase.

Comprehensive Cost and Pricing Analysis for freightliner argosy custom Sourcing

What Are the Key Cost Components for Sourcing Freightliner Argosy Custom Trucks?

When analyzing the cost structure for sourcing Freightliner Argosy custom trucks, several critical components must be considered:

-

Materials: The quality and type of materials used in the manufacturing process significantly impact costs. High-grade steel and advanced composites may enhance durability and performance but come at a higher price.

-

Labor: Labor costs vary by region and can be influenced by local wage standards. Countries with a skilled workforce, such as those in Europe, may have higher labor costs compared to regions in Africa or South America.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient manufacturing practices can reduce overhead, making the final product more competitive in pricing.

-

Tooling: Customization often requires specific tooling, which can be a significant upfront cost. Buyers should assess whether these costs are amortized over large orders or absorbed in smaller quantities.

-

Quality Control (QC): Investments in quality assurance processes ensure that the trucks meet regulatory and safety standards. While this adds to the initial costs, it can prevent costly recalls or repairs later.

-

Logistics: Shipping and handling costs are particularly relevant for international buyers. Factors such as distance, shipping method, and freight rates can vary widely, influencing the total cost.

-

Margin: Supplier profit margins will vary depending on market conditions and competition. Understanding these margins can help in negotiations.

How Do Price Influencers Affect the Cost of Freightliner Argosy Custom Trucks?

Several factors influence pricing, which international buyers must consider:

-

Volume and Minimum Order Quantity (MOQ): Larger orders can often leverage discounts. Understanding a supplier’s MOQ policy is crucial for cost efficiency.

-

Specifications and Customization: Custom features or modifications can significantly affect pricing. Buyers should clearly define their needs to avoid unexpected costs.

-

Materials: Opting for premium materials can enhance performance but will increase costs. Buyers should evaluate the trade-off between price and quality.

-

Quality Certifications: Compliance with international standards may add to the cost but ensures reliability and safety, which is particularly important for buyers in regulated markets.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may command higher prices but offer better service and quality assurance.

-

Incoterms: Understanding shipping terms is essential. Different Incoterms can shift costs and risks, affecting the overall price structure.

What Are the Best Practices for Negotiating Freightliner Argosy Custom Truck Prices?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, here are some actionable negotiation tips:

-

Research and Benchmarking: Familiarize yourself with market prices and standards. Utilize industry reports and competitor pricing to strengthen your negotiation position.

-

Engage Multiple Suppliers: Request quotes from various suppliers to create competition. This can help in achieving better pricing and terms.

-

Focus on Total Cost of Ownership (TCO): Consider all costs associated with the truck, including maintenance, fuel efficiency, and resale value, rather than just the initial purchase price.

-

Leverage Volume Discounts: If planning to make large purchases, negotiate based on volume. Suppliers may offer significant discounts for bulk orders.

-

Clarify Terms Upfront: Ensure that all pricing components, including shipping and customs duties, are clearly defined in the agreement to avoid unexpected expenses later.

-

Be Aware of Pricing Nuances: Understand that international trade can involve fluctuations in currency and tariffs. Factor these into your budget and negotiations.

Disclaimer on Indicative Prices

Prices for Freightliner Argosy custom trucks can vary widely based on the factors discussed above. Buyers should seek quotes tailored to their specific needs and circumstances to ensure accuracy. Always consider the implications of regional market conditions and changes in the supply chain when planning your budget.

Alternatives Analysis: Comparing freightliner argosy custom With Other Solutions

In the competitive landscape of freight and logistics, international B2B buyers must evaluate various transport solutions to meet their specific operational needs. The Freightliner Argosy Custom is a notable option, but several alternatives may also suit your requirements. This analysis compares the Freightliner Argosy Custom with two prominent alternatives: the Scania R Series and the Volvo FH Series, focusing on key performance metrics and operational considerations.

Comparison Table: Freightliner Argosy Custom vs. Alternatives

| Comparison Aspect | Freightliner Argosy Custom | Scania R Series | Volvo FH Series |

|---|---|---|---|

| Performance | High torque, fuel-efficient | Strong engine options, versatile | Excellent aerodynamics, fuel-efficient |

| Cost | Moderate upfront cost | Higher upfront investment | Competitive pricing with leasing options |

| Ease of Implementation | Requires experienced drivers | Easy to adapt to various uses | User-friendly technology integration |

| Maintenance | Moderate, parts availability varies | Low maintenance costs due to robust design | Accessible service network, easy repairs |

| Best Use Case | Long-haul freight transport | Versatile applications, regional and long-haul | Ideal for heavy loads, long-distance transport |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of the Scania R Series?

The Scania R Series is renowned for its strong engine performance and versatility, making it suitable for a variety of applications, from regional distribution to long-haul transport. One of its significant advantages is the availability of multiple engine configurations that cater to different load requirements. However, the initial investment can be higher compared to the Freightliner Argosy Custom. Furthermore, while Scania’s parts and services are generally reliable, they may not be as widely available in remote regions of Africa and South America.

How Does the Volvo FH Series Compare in Terms of Performance and Cost?

The Volvo FH Series excels in aerodynamics and fuel efficiency, making it an excellent choice for long-distance transportation of heavy loads. Its user-friendly technology allows for easy integration into existing fleets, and it often comes with competitive leasing options, which can help manage cash flow for B2B buyers. However, the upfront cost can still be relatively high, and while maintenance is straightforward, it relies heavily on the availability of service centers, which may vary by region.

Conclusion: How to Choose the Right Freight Solution for Your Business?

When selecting the right freight solution, B2B buyers must consider their unique operational needs, including the types of loads transported, the regions serviced, and budget constraints. The Freightliner Argosy Custom offers a balanced approach for long-haul freight, while the Scania R Series provides versatility and engine options suited for various applications. In contrast, the Volvo FH Series stands out for its efficiency and user-friendly technology. Ultimately, understanding the strengths and weaknesses of each option will empower international buyers to make informed decisions that enhance their logistics capabilities and support their business goals.

Essential Technical Properties and Trade Terminology for freightliner argosy custom

What Are the Key Technical Properties of the Freightliner Argosy Custom?

Understanding the technical specifications of the Freightliner Argosy Custom is essential for B2B buyers looking to make informed purchasing decisions. Here are some critical properties to consider:

1. Engine Specifications

The Freightliner Argosy Custom typically features a robust engine offering varying horsepower ratings. Buyers should pay attention to the engine’s torque, which is crucial for heavy-duty applications. A higher torque rating ensures better performance in challenging terrains, making it suitable for long-haul and vocational tasks.

2. Payload Capacity

The payload capacity of the Argosy Custom is a significant consideration. This truck can handle substantial loads, often exceeding 20,000 lbs, depending on the configuration. For international buyers, understanding local regulations regarding weight limits is vital to avoid penalties and ensure compliance.

3. Fuel Efficiency

Fuel efficiency is another critical property, especially for businesses focused on cost management. The Argosy Custom is designed with advanced aerodynamics and engine technology to optimize fuel consumption, offering potential savings over time. Evaluating the miles per gallon (MPG) rating can aid buyers in forecasting operational costs.

4. Chassis Design

The chassis design of the Argosy Custom affects its durability and performance. Constructed with high-strength materials, it provides better structural integrity and can withstand heavy-duty usage. Buyers should assess the chassis configuration to ensure it meets their operational needs, particularly for specific applications like towing or heavy lifting.

5. Safety Features

Safety is paramount in commercial trucking. The Argosy Custom comes equipped with several safety features, including advanced braking systems and electronic stability control. Understanding these features can help buyers minimize risks and enhance driver safety, which is critical for maintaining compliance with safety regulations.

What Trade Terms Should B2B Buyers of the Freightliner Argosy Custom Know?

Navigating the purchase process requires familiarity with industry jargon. Here are several essential terms that international B2B buyers should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to the company that produces the original parts and equipment used in the Freightliner Argosy Custom. For buyers, knowing whether parts are OEM or aftermarket can influence decisions on quality, warranty, and compatibility.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and upfront costs. Understanding the MOQ can help businesses plan their purchasing strategy effectively.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to solicit price quotes for specific products or services. For international buyers, submitting an RFQ can streamline the procurement process and ensure competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers in shipping and delivery. Familiarity with these terms helps B2B buyers understand their obligations regarding shipping costs, insurance, and risk transfer.

5. Lead Time

Lead time refers to the period between placing an order and receiving the goods. For businesses operating in tight timelines, understanding lead times can help in planning logistics and ensuring timely delivery of the Freightliner Argosy Custom.

Conclusion

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, understanding the technical properties and trade terminology associated with the Freightliner Argosy Custom is crucial for making informed purchasing decisions. By leveraging this knowledge, businesses can enhance operational efficiency and ensure compliance with local regulations.

Navigating Market Dynamics and Sourcing Trends in the freightliner argosy custom Sector

What Are the Key Market Dynamics Influencing the Freightliner Argosy Custom Sector?

The global freightliner argosy custom market is experiencing significant shifts driven by various factors including technology advancements, regulatory changes, and evolving customer expectations. In regions like Africa and South America, increasing demand for efficient logistics solutions is propelling the growth of heavy-duty trucks, particularly in urban areas where freight movement is paramount. The Middle East and Europe are witnessing a push towards more sustainable transport solutions, influenced by stringent emissions regulations and a growing emphasis on reducing carbon footprints.

Emerging B2B technologies, such as telematics and IoT, are enhancing fleet management capabilities, allowing buyers to optimize routes and reduce operational costs. Additionally, the rise of e-commerce is transforming the freight landscape, increasing the need for reliable and customizable transportation solutions. International buyers should stay informed about these trends to effectively navigate the complexities of the freightliner argosy custom market.

How Can Sustainability and Ethical Sourcing Impact Your B2B Operations?

Sustainability is becoming a critical consideration for B2B buyers in the freightliner argosy custom sector. The environmental impact of freight operations is under scrutiny, prompting companies to adopt more sustainable practices. Ethical sourcing is not just a compliance requirement but a competitive advantage that can enhance brand reputation and customer loyalty.

To align with sustainability goals, B2B buyers should prioritize suppliers who utilize ‘green’ certifications and materials. This includes sourcing from manufacturers that adhere to environmental regulations and implement energy-efficient technologies in their production processes. Additionally, transparency in the supply chain can help mitigate risks associated with unethical sourcing practices. By focusing on sustainability, buyers can contribute to a more responsible freight industry while also meeting the expectations of increasingly eco-conscious consumers.

What Is the Historical Context of the Freightliner Argosy Custom?

The Freightliner Argosy custom has a rich history that reflects the evolution of heavy-duty trucking. Launched in the late 1990s, the Argosy was designed to meet the diverse needs of the trucking industry, featuring a unique cab-over-engine design that maximizes cargo space while enhancing aerodynamics. Over the years, it has undergone numerous upgrades to improve safety, efficiency, and driver comfort, positioning itself as a preferred choice for international buyers.

In recent years, the focus has shifted towards integrating advanced technologies that support sustainable operations, such as alternative fuel options and telematics systems. This evolution underscores the adaptability of the Freightliner Argosy custom in meeting the changing demands of the global market, making it an attractive option for B2B buyers looking to invest in reliable and innovative freight solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of freightliner argosy custom

-

How can I customize a Freightliner Argosy to meet my specific needs?

Customization options for the Freightliner Argosy include engine specifications, transmission types, and cabin configurations. Buyers can work directly with Freightliner dealerships or authorized custom builders to specify features such as additional storage, specialized seating, and technological enhancements. It’s advisable to provide detailed requirements upfront to ensure the vehicle is tailored to your operational needs. Researching local regulations and market preferences in your region can also guide your customization choices. -

What are the key factors to consider when sourcing a Freightliner Argosy for international shipment?

When sourcing a Freightliner Argosy for international shipment, consider the following factors: compliance with local regulations in your country, shipping logistics, and potential tariffs. Verify that the vehicle meets safety and emissions standards applicable in your region. Additionally, assess the reliability of your supplier, their shipping capabilities, and after-sales support to ensure a seamless acquisition process. -

What are the minimum order quantities (MOQ) when purchasing Freightliner Argosy trucks?

Minimum order quantities can vary based on the supplier and the specific configurations requested. Typically, manufacturers like Freightliner may have MOQs for custom orders, especially for fleet purchases. It’s advisable to discuss your requirements directly with your dealer or manufacturer representative to understand the MOQ and any potential flexibility based on your purchasing plans. -

What payment terms should I negotiate when buying Freightliner Argosy trucks?

Negotiating payment terms is crucial to manage cash flow effectively. Common terms include upfront deposits followed by balance payments upon delivery or financing options that allow for installment payments. Always clarify the payment schedule, interest rates (if applicable), and any penalties for late payments. Understanding local banking options and currency exchange rates can also aid in negotiating favorable terms. -

How do I vet suppliers when sourcing Freightliner Argosy trucks internationally?

To vet suppliers, conduct thorough research including checking their reputation, customer reviews, and industry certifications. Request references from other B2B buyers, and assess their experience with international trade. Visiting the supplier’s facilities or attending trade shows can provide insights into their operational capabilities. Establish clear communication regarding your expectations and assess their responsiveness and professionalism during initial interactions. -

What quality assurance measures should I expect when purchasing Freightliner Argosy trucks?

Quality assurance measures typically include pre-delivery inspections, compliance with manufacturing standards, and warranty provisions. Ensure that your supplier provides documentation of quality checks and certifications. Inquire about their return policy and support for warranty claims, as these factors significantly impact the long-term reliability of the vehicles you purchase. -

What logistics considerations should I keep in mind when importing Freightliner Argosy trucks?

Logistics considerations include understanding shipping routes, customs regulations, and import duties in your country. Coordinate with freight forwarders to manage the logistics of transporting the vehicles from the supplier to your location. Additionally, plan for potential delays in customs clearance and ensure that you have all necessary documentation, including bills of lading and import permits, to facilitate smooth transit.

- How can I ensure the Freightliner Argosy I purchase is compliant with local regulations?

To ensure compliance, research the specific regulations governing vehicle emissions, safety standards, and operational requirements in your region. Consult with local transport authorities or industry associations for guidelines. Engaging a local legal advisor or customs broker can also help navigate the complexities of import regulations and ensure that your Freightliner Argosy meets all necessary criteria before it enters your market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for freightliner argosy custom

Why Is Strategic Sourcing Essential for International Buyers of Freightliner Argosy Custom?

In conclusion, effective strategic sourcing of the Freightliner Argosy Custom offers international B2B buyers a pathway to enhanced operational efficiency and profitability. By leveraging the truck’s superior design, fuel efficiency, and advanced safety features, businesses can optimize their logistics and distribution networks, particularly in diverse markets like Africa, South America, the Middle East, and Europe.

Buyers should prioritize establishing relationships with authorized Freightliner dealers, ensuring access to genuine parts, expert service, and comprehensive support. This approach not only enhances vehicle longevity but also minimizes downtime, a critical factor in maintaining competitive advantage in the logistics sector.

What Does the Future Hold for Freightliner Argosy Custom Buyers?

Looking ahead, the Freightliner Argosy Custom stands poised to adapt to evolving market demands, including the increasing emphasis on sustainability and technological innovation. As the industry shifts towards greener practices, exploring electric and alternative fuel options could further bolster operational effectiveness.

International B2B buyers are encouraged to stay informed about emerging trends and innovations related to the Freightliner Argosy Custom. By aligning their sourcing strategies with these developments, businesses can ensure they remain at the forefront of the transportation sector. Take proactive steps today to secure your fleet’s future success.