Discover Cost-Saving Benefits of Glass Fiber China (2025)

Introduction: Navigating the Global Market for glass fiber china

Navigating the global market for glass fiber China presents a significant challenge for international B2B buyers seeking quality, reliability, and cost-effectiveness. As industries increasingly demand lightweight, durable materials, sourcing high-performance glass fiber can be complex. This guide provides a thorough exploration of the various types of glass fiber available, their applications across different sectors, and the criteria for vetting suppliers effectively.

Buyers will gain insights into the manufacturing processes, environmental considerations, and the cost comparisons of different glass fiber types, enabling them to make informed purchasing decisions. Additionally, the guide highlights key trends influencing the market, including technological advancements and sustainability practices, which are crucial for buyers from Africa, South America, the Middle East, and Europe, including countries like Germany and Australia.

By equipping B2B buyers with comprehensive knowledge and actionable insights, this guide aims to empower businesses to navigate the complexities of sourcing glass fiber China successfully. Whether you are looking to enhance product performance or reduce manufacturing costs, understanding the nuances of this material will position your business for success in the competitive global marketplace.

Understanding glass fiber china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| E-Glass Fiber | High electrical resistance, cost-effective | Electrical insulation, automotive parts | Pros: Affordable, versatile; Cons: Lower mechanical strength compared to other types. |

| S-Glass Fiber | Superior tensile strength, high thermal stability | Aerospace, military applications | Pros: Exceptional performance; Cons: Higher cost, less availability. |

| C-Glass Fiber | Good corrosion resistance, moderate strength | Marine applications, chemical tanks | Pros: Cost-effective for corrosive environments; Cons: Lower tensile strength. |

| AR-Glass Fiber | Alkali-resistant, high durability | Concrete reinforcement, construction materials | Pros: Long lifespan in harsh conditions; Cons: More expensive than E-glass. |

| Hybrid Glass Fiber | Combination of different glass types | Specialized applications requiring unique properties | Pros: Tailored properties; Cons: Complexity in sourcing and specifications. |

What are the characteristics of E-Glass Fiber?

E-Glass Fiber is widely recognized for its excellent electrical insulation properties and cost-effectiveness. It consists primarily of silica, making it suitable for applications in the electrical and automotive industries. When considering E-Glass, B2B buyers should focus on its affordability and versatility, but also be aware that it offers lower mechanical strength compared to other glass fiber types, which may limit its use in high-stress environments.

Why choose S-Glass Fiber for demanding applications?

S-Glass Fiber is known for its superior tensile strength and thermal stability, making it ideal for aerospace and military applications where performance is critical. The enhanced strength allows for lighter designs without compromising durability. However, buyers should consider the higher cost and potentially limited availability when sourcing S-Glass, as it is often more expensive than E-Glass options.

How does C-Glass Fiber perform in corrosive environments?

C-Glass Fiber is characterized by its good corrosion resistance and moderate strength, making it an excellent choice for marine applications and chemical tanks. It provides a cost-effective solution for environments that require durability against corrosive substances. Buyers should note that while C-Glass is economical, it does not offer the same tensile strength as E- or S-Glass, which may be a consideration depending on the application.

What are the advantages of using AR-Glass Fiber?

AR-Glass Fiber, or alkali-resistant glass fiber, boasts high durability and is specifically designed for concrete reinforcement in construction materials. Its resistance to alkali makes it suitable for harsh environmental conditions, extending the lifespan of structures. Although it is generally more expensive than E-Glass, buyers will find that the investment pays off in longevity and reduced maintenance costs.

What makes Hybrid Glass Fiber unique?

Hybrid Glass Fiber combines various types of glass fibers to achieve tailored properties for specialized applications. This flexibility allows manufacturers to create materials that meet specific performance criteria, such as weight reduction or enhanced thermal resistance. However, buyers should be cautious of the complexities involved in sourcing and specifying hybrid fibers, as they may require a more detailed understanding of material properties and performance standards.

Related Video: The Trillion-Dollar Battle for Fiber-Optic Supremacy | WSJ U.S. vs. China

Key Industrial Applications of glass fiber china

| Industry/Sector | Specific Application of glass fiber china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Reinforcement in concrete and composite materials | Increases strength and durability of structures, reducing maintenance costs | Assess local regulations, material certifications, and compatibility with existing materials |

| Automotive | Lightweight components for vehicles | Enhances fuel efficiency and performance through weight reduction | Focus on compliance with automotive standards and testing requirements |

| Aerospace | Structural components and interiors | Improves performance and reduces weight, leading to fuel savings | Prioritize suppliers with aerospace certifications and advanced composite technologies |

| Marine | Hulls and components for boats | Provides corrosion resistance and lightweight solutions for better performance | Evaluate resistance to harsh marine environments and long-term durability |

| Electronics | Insulating materials in circuit boards | Enhances electrical performance and thermal stability | Ensure compatibility with specific electronic applications and certifications for safety |

How Is Glass Fiber China Used in the Construction Industry?

In the construction sector, glass fiber china is utilized as a reinforcement material in concrete and composite structures. Its high tensile strength contributes to the overall durability of buildings and infrastructure, minimizing the risk of cracks and extending the lifespan of constructions. For international buyers, particularly from regions like Africa and South America, it is crucial to consider local building codes, material certifications, and compatibility with existing construction methods to ensure compliance and performance.

What Are the Benefits of Glass Fiber China in the Automotive Sector?

In the automotive industry, glass fiber china is employed to manufacture lightweight components, such as body panels and structural parts. The integration of glass fiber into vehicle designs helps reduce overall weight, which directly enhances fuel efficiency and performance. B2B buyers from Europe, including Germany, should focus on suppliers that meet stringent automotive standards and can provide testing data to ensure the materials’ reliability and safety.

How Does Glass Fiber China Enhance Aerospace Applications?

Aerospace applications leverage glass fiber china for structural components and interior fittings. The material’s lightweight nature combined with its strength allows for significant weight reductions, which translates into fuel savings and improved performance. Buyers in the Middle East and Europe should prioritize sourcing from manufacturers with aerospace certifications and proven experience in advanced composite technologies to ensure compliance with industry regulations.

Why Is Glass Fiber China Important for Marine Applications?

In the marine sector, glass fiber china is commonly used in the construction of hulls and various boat components. Its inherent resistance to corrosion and lightweight properties make it an ideal choice for enhancing the performance of marine vessels. B2B buyers, particularly in coastal regions of Africa and South America, should evaluate the material’s resistance to harsh marine environments and long-term durability to ensure optimal performance and safety.

How Is Glass Fiber China Applied in Electronics?

In electronics, glass fiber china serves as an essential insulating material in circuit boards. Its excellent electrical and thermal stability enhances the performance of electronic devices, making them more reliable. International buyers from Europe and South America must ensure that the sourcing of glass fiber aligns with specific electronic applications and meets safety certifications to avoid compliance issues and ensure product longevity.

Related Video: Fiber Optic Splicing Guide & Demo

3 Common User Pain Points for ‘glass fiber china’ & Their Solutions

Scenario 1: Navigating Quality Assurance in Glass Fiber China Purchases

The Problem: B2B buyers often face significant challenges in ensuring the quality of glass fiber products sourced from China. With varying standards and regulations, it can be difficult to ascertain whether the products will meet the required specifications. Issues such as inconsistent material properties, improper handling, and lack of certifications can lead to product failures or safety hazards, which are especially critical in industries like construction and aerospace.

The Solution: To mitigate quality concerns, buyers should implement a multi-step quality assurance process. First, conduct thorough research on potential suppliers, focusing on their certifications (such as ISO 9001) and previous client reviews. Establish clear specifications for the glass fiber products, including tensile strength, thermal resistance, and chemical composition. Second, consider visiting the manufacturing facility to perform on-site inspections or hiring third-party inspection services to verify production quality. Finally, incorporate a comprehensive testing plan upon receipt of goods to ensure they meet the specified standards before integration into production. This proactive approach will significantly reduce risks and ensure the reliability of the materials used.

Scenario 2: Overcoming Supply Chain Disruptions in Sourcing Glass Fiber China

The Problem: International B2B buyers frequently encounter supply chain disruptions when importing glass fiber products from China. Factors such as geopolitical tensions, natural disasters, or logistics delays can lead to unexpected lead times and increased costs. These disruptions can jeopardize project timelines and affect overall business operations, causing frustration and financial losses.

The Solution: To address supply chain vulnerabilities, it’s essential to develop a diversified sourcing strategy. Buyers should not rely solely on a single supplier or region; instead, consider establishing relationships with multiple manufacturers in different geographic locations. This redundancy allows for flexibility if one supplier faces disruptions. Additionally, leveraging advanced supply chain management software can enhance visibility and predict potential delays. Regularly communicating with suppliers about their capacities and challenges can also facilitate better planning. Finally, incorporating buffer stock into inventory strategies can help mitigate the impact of unforeseen delays, ensuring smoother operations and project continuity.

Scenario 3: Ensuring Regulatory Compliance When Importing Glass Fiber China

The Problem: B2B buyers must navigate a complex landscape of regulatory compliance when importing glass fiber products from China. Different countries have varying standards and regulations regarding material safety, environmental impact, and import tariffs. Failure to comply can result in costly fines, delays, or even product recalls, putting businesses at risk.

The Solution: To ensure compliance, buyers should engage with legal experts or consultants who specialize in international trade regulations specific to glass fiber materials. Familiarize yourself with the regulatory landscape of both the exporting (China) and importing (your country) regions, focusing on standards such as REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) in Europe or similar regulations elsewhere. It is also advisable to request documentation from suppliers that verify compliance with relevant safety and environmental standards. Additionally, consider joining industry associations that can provide resources and updates on regulatory changes. By proactively addressing compliance issues, B2B buyers can avoid pitfalls and streamline their import processes, ensuring smoother transactions and operational integrity.

Strategic Material Selection Guide for glass fiber china

What Are the Key Materials Used in Glass Fiber China?

When selecting materials for glass fiber china, it is essential to understand the properties, advantages, and limitations of each material. This knowledge will help international B2B buyers make informed decisions that align with their specific needs and compliance standards.

What Are the Key Properties of E-Glass Fiber?

E-glass fiber is one of the most commonly used materials in glass fiber china. It offers excellent electrical insulation properties, making it suitable for applications in the electrical and electronics sectors. E-glass fibers can withstand temperatures up to 300°C and have good corrosion resistance against various chemicals.

Pros: E-glass fiber is relatively low-cost and widely available, making it an economical choice for many applications. Its lightweight nature and high strength-to-weight ratio enhance product performance.

Cons: However, E-glass fibers have limited resistance to high temperatures compared to other types of glass fibers, which may restrict their use in extreme environments.

Impact on Application: E-glass fiber is ideal for applications requiring electrical insulation and moderate mechanical strength, such as in automotive and construction sectors.

Considerations for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should ensure that E-glass products meet local standards such as ASTM or DIN. Understanding the supply chain and sourcing from reputable manufacturers can mitigate risks associated with material quality.

How Does S-Glass Fiber Compare?

S-glass fiber is another popular choice, known for its superior mechanical properties and higher tensile strength than E-glass. It can withstand temperatures up to 600°C and offers excellent resistance to chemical corrosion.

Pros: The high strength and thermal stability of S-glass make it suitable for demanding applications, including aerospace and military sectors.

Cons: The primary downside is its higher cost compared to E-glass, which may not be suitable for budget-sensitive projects.

Impact on Application: S-glass fiber is particularly effective in applications requiring high-performance materials, such as high-stress components in aerospace and automotive industries.

Considerations for International Buyers: Buyers should be aware of the specific certifications required for S-glass applications, especially in regulated industries. Compliance with international standards is crucial for market acceptance.

What Are the Benefits of C-Glass Fiber?

C-glass fiber is often used in applications requiring high corrosion resistance, particularly in chemical processing industries. It offers good mechanical properties and can withstand temperatures up to 250°C.

Pros: C-glass is relatively cost-effective and provides excellent durability in corrosive environments, making it suitable for a range of applications.

Cons: However, C-glass fibers may not have the same mechanical strength as E-glass or S-glass, which can limit their use in high-stress applications.

Impact on Application: C-glass is widely used in the production of tanks, pipes, and other components in the chemical and wastewater treatment industries.

Considerations for International Buyers: Buyers should ensure compliance with local environmental regulations and industry standards. Understanding the specific needs of the local market can enhance product acceptance.

What Role Does Vinyl Ester Resin Play?

Vinyl ester resin is often used in conjunction with glass fibers to enhance the overall performance of glass fiber china. It offers excellent resistance to corrosion and heat, making it suitable for various applications.

Pros: The combination of vinyl ester resin with glass fibers results in a composite material that is strong, durable, and resistant to harsh environments.

Cons: The manufacturing process can be more complex and costly, which may affect the overall price of the final product.

Impact on Application: Vinyl ester resin is commonly used in marine, automotive, and industrial applications where high performance and durability are required.

Considerations for International Buyers: Buyers should be aware of the specific certifications needed for vinyl ester applications and ensure that their suppliers comply with international standards.

Summary Table of Material Properties

| Material | Typical Use Case for Glass Fiber China | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| E-Glass Fiber | Electrical insulation in automotive and construction | Economical and widely available | Limited high-temperature resistance | Low |

| S-Glass Fiber | High-performance aerospace and military components | Superior strength and thermal stability | Higher cost compared to E-glass | High |

| C-Glass Fiber | Chemical processing tanks and pipes | Excellent corrosion resistance | Lower mechanical strength | Medium |

| Vinyl Ester Resin | Marine and industrial applications | Strong and durable composite material | Complex manufacturing process | Medium |

This analysis provides international B2B buyers with a strategic overview of the materials used in glass fiber china, enabling them to make informed decisions based on their specific needs and market requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for glass fiber china

What Are the Key Stages in the Manufacturing Process of Glass Fiber China?

The manufacturing of glass fiber products involves several critical stages, each contributing to the overall quality and performance of the final product. Understanding these stages is essential for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, who are looking to source high-quality glass fiber materials.

1. Material Preparation: What Raw Materials Are Used?

The first stage in glass fiber manufacturing is the preparation of raw materials. The primary components include silica sand, alumina, and various additives such as limestone and magnesia. These materials are carefully selected to ensure the desired properties of the glass fiber, such as strength and thermal resistance.

Once the materials are sourced, they undergo a thorough mixing process to achieve a homogeneous blend. This mixture is then melted in a furnace at high temperatures, typically around 1,400 to 1,600 degrees Celsius. The choice of raw materials and the precision of this process significantly influence the quality of the glass fiber produced.

2. Forming: How Is Glass Fiber Shaped?

After the raw materials are melted, the next step is forming the glass fiber. This process typically involves the use of a fiberizing machine, which extrudes the molten glass through fine orifices to create continuous strands of fiber. The fiber diameter can be controlled based on the intended application, with typical diameters ranging from 5 to 30 micrometers.

The formed fibers are then collected on a rotating drum or conveyor belt. During this stage, additives such as sizing agents may be applied to enhance the fibers’ properties, including adhesion, flexibility, and moisture resistance. This is a critical step, as the application of sizing can affect the compatibility of the fibers with resins and other materials in composite applications.

3. Assembly: How Are Glass Fibers Processed for End Products?

Once the fibers are formed, they can be assembled into various products. This stage may involve weaving the fibers into mats, fabrics, or other structures, depending on the intended application. For example, woven glass fiber fabrics are commonly used in the automotive and aerospace industries due to their lightweight and high-strength properties.

In some cases, the fibers are combined with other materials, such as resins, to create composite materials. The assembly process is crucial as it determines the product’s final characteristics, including strength, flexibility, and durability.

4. Finishing: What Treatments Enhance Glass Fiber Products?

The finishing stage involves various treatments to improve the glass fiber’s performance and appearance. This may include cutting, coating, or additional thermal treatments. Some manufacturers may apply specialized coatings to enhance resistance to chemicals or UV exposure, making the products suitable for specific environments.

Quality control measures are also integrated into the finishing process to ensure that the final products meet industry standards. This is particularly important for international buyers who need to ensure compliance with regional regulations and standards.

What Are the Key Quality Assurance Practices in Glass Fiber Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process for glass fiber products. Implementing robust QA practices ensures that products meet the required specifications and standards, providing confidence to B2B buyers.

International Standards: What Certifications Should Buyers Look For?

Internationally recognized quality standards, such as ISO 9001, are vital for manufacturers of glass fiber products. ISO 9001 focuses on quality management systems, emphasizing continuous improvement and customer satisfaction. Compliance with this standard indicates that the manufacturer has established processes to ensure product quality.

In addition to ISO certifications, other industry-specific standards may apply. For example, CE marking is essential for products sold within the European Union, indicating compliance with health, safety, and environmental protection standards. Similarly, the American Petroleum Institute (API) certification is crucial for manufacturers supplying products to the oil and gas industry.

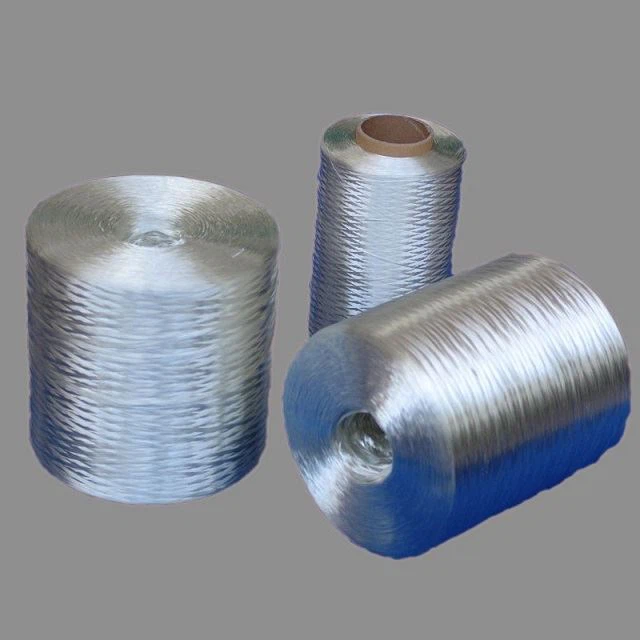

A stock image related to glass fiber china.

QC Checkpoints: How Are Quality Controls Implemented?

Quality control checkpoints are established throughout the manufacturing process to monitor and ensure product quality. These checkpoints typically include:

-

Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards before entering the production process.

-

In-Process Quality Control (IPQC): During the manufacturing stages, random samples of the product are tested for adherence to quality standards. This includes measuring fiber diameter, tensile strength, and other critical properties.

-

Final Quality Control (FQC): Finished products undergo comprehensive testing to verify they meet all specifications before shipping. This may include visual inspections, mechanical testing, and compliance checks against relevant standards.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential to ensure product reliability and compliance with required standards. Here are some effective strategies:

-

Conduct Supplier Audits: Periodic audits of the manufacturing facility can provide insights into the supplier’s quality management practices. Audits can help assess compliance with international standards and identify potential areas for improvement.

-

Request Quality Control Reports: Suppliers should be able to provide documentation of their quality control processes, including test results and certifications. This transparency allows buyers to verify that the products meet the required standards.

-

Engage Third-Party Inspectors: For additional assurance, buyers can hire third-party inspection services to evaluate the manufacturing processes and product quality. These independent assessments can provide an unbiased evaluation of the supplier’s capabilities.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers from diverse regions must be aware of specific quality control nuances when sourcing glass fiber products. For instance, cultural differences may affect communication and expectations regarding quality standards. Buyers should ensure they clearly articulate their requirements and expectations during the procurement process.

Additionally, understanding local regulations and standards is crucial. For example, buyers from Europe may need to navigate stricter environmental regulations compared to those in other regions. Collaborating with suppliers who have experience in international markets can help mitigate these challenges and ensure compliance with local laws.

In summary, a thorough understanding of the manufacturing processes and quality assurance practices for glass fiber products is vital for international B2B buyers. By focusing on these aspects, buyers can make informed decisions, ensuring they source high-quality materials that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘glass fiber china’

In the competitive world of international sourcing, particularly for materials like glass fiber china, it is crucial for B2B buyers to follow a structured approach. This guide outlines a checklist that can streamline the procurement process, ensuring that buyers from Africa, South America, the Middle East, and Europe make informed decisions.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential for sourcing glass fiber china. This includes determining the required strength, weight, thickness, and finish of the product. By outlining these criteria, you can more effectively communicate your needs to suppliers and ensure that the materials meet your project requirements.

- Consider Applications: Different applications may require different specifications; for example, aerospace components may need higher strength standards than consumer goods.

- Regulatory Compliance: Ensure that your specifications comply with local regulations and industry standards, as this can impact safety and performance.

Step 2: Conduct Market Research

Research the current market for glass fiber china to understand pricing, availability, and trends. This step is vital for making informed purchasing decisions and for negotiating effectively with suppliers.

- Analyze Competitors: Look into what similar companies are using and their sourcing strategies.

- Identify Key Players: Make a list of reputable manufacturers and distributors in the regions of interest.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it is crucial to conduct thorough evaluations. Request company profiles, product samples, and references from existing clients to assess their credibility and reliability.

- Check Certifications: Ensure that suppliers hold necessary certifications, such as ISO or ASTM standards, which can indicate a commitment to quality.

- Assess Production Capabilities: Understanding their production capacity can help you gauge if they can meet your volume needs, especially for large orders.

Step 4: Request Quotes and Proposals

Once you have shortlisted potential suppliers, request detailed quotes and proposals. This step allows you to compare pricing, lead times, and payment terms across different suppliers.

- Be Specific: Provide suppliers with your technical specifications to receive accurate quotes.

- Include Shipping Costs: Don’t forget to factor in shipping and handling, as these can significantly affect the overall cost.

Step 5: Verify Supplier Certifications

Supplier certifications can offer peace of mind regarding quality and compliance. Make it a priority to verify any claimed certifications.

- Cross-Check with Regulatory Bodies: Use external resources to confirm that certifications are valid and up-to-date.

- Assess Quality Control Processes: A supplier’s quality control procedures can impact the end product’s performance and reliability.

Step 6: Conduct a Site Visit or Audit

If feasible, conduct a site visit to the supplier’s manufacturing facility. This step provides firsthand insight into their operations and quality assurance processes.

- Observe Production Practices: Look for adherence to safety protocols and manufacturing standards.

- Meet the Team: Engaging with the management and production team can build rapport and facilitate better communication.

Step 7: Negotiate Terms and Establish Contracts

Once you have selected a supplier, it is important to negotiate favorable terms and establish a clear contract. This should outline payment terms, delivery schedules, and responsibilities.

- Clarify Terms: Ensure that all aspects of the agreement are clear, including warranties and return policies.

- Include Contingencies: Plan for potential disruptions by including clauses that address delays or quality issues.

By following this checklist, B2B buyers can effectively source glass fiber china, minimizing risks and ensuring that they receive high-quality materials that meet their specific needs.

Comprehensive Cost and Pricing Analysis for glass fiber china Sourcing

When sourcing glass fiber products from China, international B2B buyers must navigate a complex cost structure and pricing landscape. Understanding the various components that contribute to the total cost can lead to better negotiation outcomes and more informed purchasing decisions.

What are the Key Cost Components in Glass Fiber Sourcing?

-

Materials: The primary raw material for glass fiber is silica sand, along with additives like alumina and calcium oxide. The quality and source of these materials significantly impact pricing. Higher-grade materials can lead to better product performance but will also increase costs.

-

Labor Costs: Labor expenses in China are generally lower than in Europe or North America, but they can vary by region and the complexity of the manufacturing process. Skilled labor for specialized tasks, such as quality control (QC) or technical fabrication, may command higher wages.

-

Manufacturing Overhead: This includes utilities, maintenance, and factory management costs. Efficient manufacturing processes can minimize overhead, which is reflected in the pricing of the final product.

-

Tooling: Custom molds and tools required for specific glass fiber products can represent a significant initial investment. Buyers should consider these costs when requesting customized products, as they can be amortized over larger production runs.

-

Quality Control (QC): Implementing robust QC measures to ensure product consistency and compliance with international standards adds to the overall cost. Certifications such as ISO 9001 can enhance product credibility but may also increase the price.

-

Logistics: Shipping costs can vary widely based on the Incoterms agreed upon in the contract. Factors such as distance, shipping method (air vs. sea), and any tariffs or duties applicable to the destination country must be factored into the total cost.

-

Margin: Suppliers typically apply a markup to cover their costs and achieve profit goals. This margin can fluctuate based on market demand, competition, and supplier capabilities.

How Do Price Influencers Affect Glass Fiber Pricing?

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their needs while maximizing cost efficiency.

-

Specifications and Customization: Custom specifications can increase costs due to the additional complexity in production. Buyers should carefully assess whether the benefits of customization outweigh the additional costs.

-

Quality and Certifications: Higher quality materials and products often come with higher price tags. Buyers must evaluate the importance of certifications and quality assurance in their purchasing decisions.

-

Supplier Factors: Supplier reputation, reliability, and past performance can influence pricing. Working with established suppliers may offer assurance of quality but can also come at a premium.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF) affects who bears the costs and risks during shipping. Understanding these terms is crucial for accurate cost forecasting.

What Tips Can Help Buyers Optimize Costs in Glass Fiber Sourcing?

-

Negotiate Effectively: Engage suppliers in discussions about pricing structures and be transparent about your needs. This could lead to better terms, especially for long-term partnerships.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also ongoing costs such as maintenance, shipping, and potential rework. This comprehensive view can highlight the true cost of sourcing decisions.

-

Stay Informed About Market Trends: Regularly monitor the glass fiber market for shifts in demand, supply chain disruptions, and material prices. This knowledge can provide leverage during negotiations.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing, priority service, and insights into upcoming changes in the market.

Disclaimer on Indicative Prices

Prices for glass fiber products can vary significantly based on the factors discussed above. It is crucial for buyers to request quotes tailored to their specific needs and circumstances to ensure accurate budgeting and planning.

Alternatives Analysis: Comparing glass fiber china With Other Solutions

Understanding Alternatives to Glass Fiber China

In the world of industrial materials, glass fiber china offers unique advantages, particularly in applications requiring strength, durability, and lightweight characteristics. However, international B2B buyers should also consider alternative solutions that may better suit their specific needs. This section provides a comparative analysis of glass fiber china against two viable alternatives: carbon fiber composites and traditional ceramic materials.

Comparison Table of Glass Fiber China and Alternatives

| Comparison Aspect | Glass Fiber China | Carbon Fiber Composites | Traditional Ceramics |

|---|---|---|---|

| Performance | High tensile strength, lightweight, and good corrosion resistance | Superior strength-to-weight ratio, excellent fatigue resistance | Excellent heat and wear resistance, but brittle |

| Cost | Moderate cost, economical for large-scale applications | High initial cost, justified for performance-critical applications | Generally low to moderate cost, depending on material quality |

| Ease of Implementation | Easy to mold and shape; compatible with various manufacturing processes | Requires specialized processes for molding and curing | Well-established manufacturing processes, but limited design flexibility |

| Maintenance | Low maintenance, resistant to environmental factors | Low maintenance, but damage can be difficult to repair | Requires regular maintenance; prone to chipping and cracking |

| Best Use Case | Automotive, aerospace, and construction applications | High-performance sports equipment, aerospace, and automotive industries | Pottery, tiles, and industrial components requiring high thermal resistance |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of Carbon Fiber Composites?

Carbon fiber composites are renowned for their exceptional strength-to-weight ratio, making them ideal for applications where reducing weight is crucial without compromising structural integrity. Industries such as aerospace and high-performance automotive heavily utilize carbon fiber due to its superior performance in demanding conditions. However, the high cost of production and specialized manufacturing processes may deter some buyers, particularly in less performance-critical applications. For businesses in Africa and South America where cost considerations are paramount, carbon fiber may not always be the most feasible choice.

How Do Traditional Ceramics Compare to Glass Fiber China?

Traditional ceramics offer a strong alternative, especially in applications where heat and wear resistance are critical. They are commonly used in pottery, tiles, and industrial components. The advantages of ceramics include their generally lower cost and established manufacturing processes, making them accessible for a wide range of applications. However, ceramics are also known for being brittle, which can lead to potential failure under impact or stress. Businesses in the Middle East and Europe that focus on aesthetics and durability may find ceramics appealing, but they should weigh the trade-offs regarding fragility compared to glass fiber china’s resilience.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting the appropriate material for a specific application, B2B buyers must consider their unique requirements, including performance, cost, and ease of implementation. Glass fiber china provides a balanced option for many industries, particularly in automotive and construction, where a combination of strength and lightweight characteristics is essential. However, for applications demanding higher performance, carbon fiber composites may be worth the investment. Alternatively, traditional ceramics might be suitable for those focused on cost and aesthetic qualities but should be approached with caution due to their brittleness. Ultimately, a thorough evaluation of these factors will empower buyers to make informed decisions that align with their operational needs and budget constraints.

Essential Technical Properties and Trade Terminology for glass fiber china

What Are the Key Technical Properties of Glass Fiber China?

Understanding the essential technical properties of glass fiber is crucial for international B2B buyers, especially when sourcing materials for construction, automotive, or industrial applications. Here are some critical specifications to consider:

1. Material Grade

Material grade refers to the specific formulation and quality of the glass fiber. Common grades include E-glass (Electrical glass) and S-glass (Structural glass). E-glass offers excellent electrical insulation properties, while S-glass provides higher tensile strength and thermal resistance. Selecting the appropriate grade is vital for ensuring that the material meets performance requirements for specific applications.

2. Tolerance

Tolerance defines the permissible limit of variation in dimensions and properties of glass fiber products. In B2B transactions, maintaining strict tolerances is essential for ensuring compatibility with other components and systems. For example, a tolerance of ±0.5 mm in thickness may be required for components used in precision machinery. High-quality suppliers should provide detailed tolerance specifications to meet industry standards.

3. Tensile Strength

Tensile strength measures the maximum amount of tensile (pulling) stress that a material can withstand before failure. For glass fiber, this property is crucial in applications where strength and durability are paramount, such as in aerospace or automotive components. Understanding the tensile strength helps buyers assess the suitability of the glass fiber for their specific use case, ensuring safety and reliability.

4. Moisture Absorption

Moisture absorption indicates how much water the glass fiber can absorb over time. This property is significant because excessive moisture can weaken the material and compromise its structural integrity. For applications in humid environments, selecting glass fiber with low moisture absorption is critical to maintaining performance standards.

5. Chemical Resistance

Chemical resistance refers to the material’s ability to withstand exposure to various chemicals without degrading. This property is especially important in industrial applications where glass fiber may come into contact with harsh substances. Buyers should inquire about chemical resistance ratings to ensure that the glass fiber will perform optimally in their specific operational environments.

What Trade Terms Should B2B Buyers Understand When Sourcing Glass Fiber China?

Navigating the world of international trade involves understanding key terms that can affect transactions and relationships with suppliers. Here are some essential trade terminologies:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that manufactures products that are sold under another company’s brand. In the context of glass fiber, an OEM supplier may produce specific glass fiber products that are then branded and sold by another company. Understanding OEM relationships can help buyers identify reputable suppliers and negotiate better pricing.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum quantity of products that a supplier is willing to sell. For glass fiber products, MOQs can vary significantly depending on the manufacturer and product type. B2B buyers should be aware of MOQs to ensure that they can meet their production needs without excessive inventory costs.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers use to solicit price quotes from suppliers for specific products or services. In the glass fiber industry, an RFQ should include detailed specifications, quantities, and delivery requirements. Submitting a well-structured RFQ can lead to more accurate quotes and better supplier responses.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in global trade. They cover aspects such as shipping costs, insurance, and delivery points. Familiarity with Incoterms can help B2B buyers clarify shipping responsibilities and avoid potential disputes during the procurement process.

5. Lead Time

Lead time is the amount of time it takes from placing an order to receiving the goods. Understanding lead times is crucial for project planning and inventory management. Buyers should discuss lead times with suppliers to ensure timely delivery and minimize disruptions in their supply chain.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing glass fiber from China, ensuring they select the right materials and negotiate effectively with suppliers.

Navigating Market Dynamics and Sourcing Trends in the glass fiber china Sector

What Are the Current Market Dynamics and Key Trends in the Glass Fiber China Sector?

The global glass fiber market is witnessing robust growth driven by increased demand across various sectors such as construction, automotive, and renewable energy. The Asia-Pacific region, particularly China, is a key player due to its advanced manufacturing capabilities and large-scale production. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial.

Emerging trends include the adoption of advanced manufacturing technologies such as automation and AI, which enhance production efficiency and reduce costs. Additionally, there is a shift towards lightweight materials that improve fuel efficiency in automotive applications. Buyers should be aware of the increasing use of glass fiber in wind turbine blades and other renewable energy applications, as this trend aligns with global sustainability goals.

Furthermore, fluctuating raw material prices and geopolitical factors are influencing sourcing strategies. Buyers should consider establishing long-term partnerships with suppliers in China to mitigate risks associated with price volatility and supply chain disruptions. Leveraging digital platforms for procurement can streamline sourcing processes and enhance transparency.

How Does Sustainability and Ethical Sourcing Impact the Glass Fiber China Sector?

Sustainability is becoming a pivotal consideration for B2B buyers in the glass fiber sector. The environmental impact of glass fiber production, including energy consumption and waste generation, necessitates a focus on sustainable practices. Ethical sourcing is increasingly important, as buyers seek to ensure that their supply chains are not only efficient but also socially responsible.

Certification programs, such as ISO 14001 for environmental management, are crucial for validating suppliers’ commitment to sustainability. Buyers should prioritize sourcing from manufacturers who utilize recycled materials and demonstrate compliance with green certifications. This not only enhances brand reputation but also aligns with the growing consumer demand for environmentally friendly products.

Moreover, the integration of eco-friendly materials and processes into the production of glass fiber can lead to reduced carbon footprints. Buyers should seek partnerships with suppliers who are investing in sustainable technologies, as this can provide a competitive advantage in the market.

What Is the Historical Context of Glass Fiber Production in China?

The evolution of glass fiber production in China dates back to the mid-20th century, with significant advancements made in the 1980s as the country opened its markets. Initially focused on meeting domestic demand, China’s glass fiber industry has since expanded to become a global leader in production capacity and innovation.

Chinese manufacturers have adopted cutting-edge technologies and practices, enabling them to produce high-quality glass fiber products that meet international standards. This historical context is essential for B2B buyers, as it highlights China’s commitment to enhancing its industrial capabilities and establishing itself as a reliable sourcing destination for glass fiber products.

In conclusion, understanding the market dynamics, sustainability considerations, and historical context of the glass fiber sector in China can empower international B2B buyers to make informed sourcing decisions that align with their strategic objectives.

Frequently Asked Questions (FAQs) for B2B Buyers of glass fiber china

-

How do I choose the right supplier for glass fiber china?

Choosing the right supplier for glass fiber china involves several key factors. Start by evaluating the supplier’s reputation and experience in the industry. Look for reviews, testimonials, and case studies that demonstrate their reliability. Ensure they have the necessary certifications and compliance with international standards. Additionally, request samples to assess the quality of their products. Finally, consider their responsiveness and willingness to communicate, as this will be crucial for a successful partnership. -

What are the common applications of glass fiber china?

Glass fiber china is widely used in various applications due to its strength and lightweight properties. Common uses include construction materials, automotive components, sporting goods, and consumer electronics. In the construction sector, it is often utilized for insulation and reinforcement in walls, roofs, and floors. Understanding the specific application you are targeting will help you select the appropriate type and grade of glass fiber china. -

What are the typical minimum order quantities (MOQ) for glass fiber china?

Minimum order quantities (MOQ) for glass fiber china can vary significantly between suppliers and product types. Generally, MOQs can range from 100 kilograms to several tons, depending on the complexity of the item and the manufacturer’s production capabilities. When negotiating with suppliers, inquire about flexibility in MOQs, especially if you are a smaller business or testing a new product line. Some suppliers may offer lower MOQs for trial orders or long-term partnerships. -

How can I ensure the quality of glass fiber china products?

To ensure the quality of glass fiber china products, implement a robust quality assurance (QA) process. Begin by requesting certifications that validate the supplier’s adherence to international standards, such as ISO 9001. Conduct regular audits of the supplier’s production facilities and request detailed product specifications. Additionally, consider third-party inspections or testing services to verify material properties before shipment. Establishing clear quality expectations and communication channels with your supplier is essential. -

What payment terms should I expect when sourcing glass fiber china?

Payment terms for glass fiber china can vary widely among suppliers. Common arrangements include a deposit of 30% upfront with the balance due upon shipment or delivery. Some suppliers may offer net payment terms, such as net 30 or net 60 days, especially for established relationships. Always clarify payment terms before finalizing orders, and consider using secure payment methods like letters of credit or escrow services to mitigate risks in international transactions. -

What logistics considerations should I keep in mind when importing glass fiber china?

When importing glass fiber china, logistics considerations include shipping methods, customs regulations, and freight forwarding. Choose a reliable freight forwarder experienced in handling glass products to ensure safe transportation. Be aware of the import duties and taxes applicable in your country, as these can affect your overall costs. Additionally, consider the potential for delays in customs clearance and plan accordingly by allowing sufficient time for delivery. -

How can I customize glass fiber china products to meet my specifications?

Customization of glass fiber china products typically involves discussing your specific requirements with the supplier. Many manufacturers offer options for varying dimensions, colors, and formulations to suit particular applications. It’s essential to provide detailed specifications and, if possible, prototypes to convey your needs accurately. Keep in mind that custom orders may have longer lead times and potentially higher costs, so plan your sourcing strategy accordingly. -

What are the environmental considerations when sourcing glass fiber china?

When sourcing glass fiber china, it’s important to consider the environmental impact of production and disposal. Look for suppliers who implement sustainable practices, such as recycling waste materials and using eco-friendly manufacturing processes. Inquire about the lifecycle of the products and whether they can be recycled after use. Additionally, understanding the environmental regulations in your region can help ensure compliance and support your organization’s sustainability goals.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for glass fiber china

The strategic sourcing of glass fiber from China presents a unique opportunity for international B2B buyers seeking high-quality materials for diverse applications. By understanding the intricacies of the glass fiber market—including production techniques, types, and their respective applications—buyers can make informed decisions that enhance their supply chain efficiency. The emphasis on quality control and sustainability in sourcing practices is paramount, especially as global demand for eco-friendly materials grows.

How Can Buyers Leverage Strategic Sourcing for Competitive Advantage?

Investing time in building relationships with reputable Chinese manufacturers can yield significant benefits, including cost savings and reliable supply chains. Engaging in thorough due diligence and leveraging data analytics can help identify the best suppliers who align with your quality and ethical standards.

Looking ahead, the glass fiber industry is poised for growth, driven by advancements in technology and increasing applications across various sectors. International buyers from Africa, South America, the Middle East, and Europe should proactively explore partnerships with Chinese suppliers to stay ahead of market trends. By embracing strategic sourcing, you not only secure quality materials but also position your business for long-term success in a competitive landscape.