Discover Cost-Saving Solutions with Wire Mesh China (2025)

Introduction: Navigating the Global Market for wire mesh china

Navigating the global market for wire mesh from China can be a daunting task for international B2B buyers, particularly for those based in Africa, South America, the Middle East, and Europe. One of the key challenges faced by these buyers is identifying reliable suppliers who can provide high-quality products at competitive prices. This guide aims to demystify the complexities of sourcing wire mesh from China, offering an in-depth exploration of various types, applications, and industry standards that are crucial for informed decision-making.

In this comprehensive resource, we will cover essential aspects of wire mesh procurement, including the different types of wire mesh available, their specific applications across industries, and the best practices for vetting suppliers. Additionally, we will delve into cost considerations, shipping logistics, and quality assurance measures that can significantly impact your purchasing decisions.

By equipping B2B buyers with actionable insights and strategic advice, this guide empowers you to make informed choices that align with your business needs. Whether you are looking to enhance your production capabilities or fulfill specific project requirements, understanding the nuances of the wire mesh market in China can lead to successful procurement outcomes. As we explore these critical areas, you will gain the knowledge necessary to navigate this dynamic landscape effectively, ensuring your investments yield optimal returns.

Understanding wire mesh china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Stainless Steel Wire Mesh | Corrosion-resistant, durable, non-magnetic | Food processing, pharmaceuticals, architecture | Pros: Long lifespan, hygienic; Cons: Higher initial cost. |

| Galvanized Wire Mesh | Coated with zinc for rust resistance | Construction, fencing, agricultural uses | Pros: Cost-effective, good durability; Cons: Can corrode over time if scratched. |

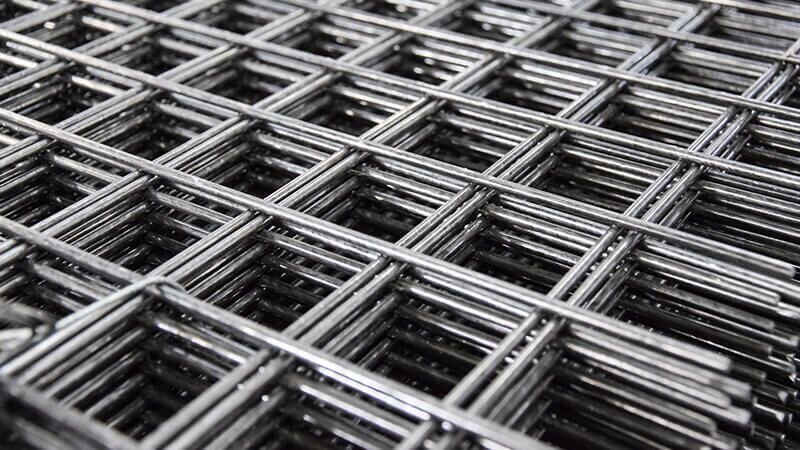

| Welded Wire Mesh | Made by welding intersecting wires | Industrial shelving, security fencing | Pros: Strong and stable; Cons: Limited flexibility in design. |

| Chain Link Fencing | Interwoven wire creating a diamond pattern | Perimeter security, sports fields | Pros: Affordable, easy to install; Cons: Less privacy and aesthetic appeal. |

| Expanded Metal Mesh | Created by stretching metal sheets | Grating, walkways, and decorative panels | Pros: Lightweight, versatile; Cons: Can be less durable under heavy loads. |

What are the Characteristics of Stainless Steel Wire Mesh?

Stainless steel wire mesh is known for its exceptional resistance to corrosion and oxidation, making it ideal for industries such as food processing and pharmaceuticals where hygiene is paramount. The mesh is typically non-magnetic, which is a significant advantage in applications where magnetic interference could be problematic. When considering purchasing, B2B buyers should evaluate the initial cost against the long-term benefits of durability and reduced maintenance.

Why is Galvanized Wire Mesh Popular in Construction?

Galvanized wire mesh is coated with zinc to provide excellent rust resistance, making it a popular choice for construction and agricultural applications. Its affordability and decent durability make it attractive for large-scale projects. However, B2B buyers should be aware that while galvanized mesh is cost-effective, it can corrode if the protective coating is damaged. Therefore, assessing the environment in which the mesh will be used is crucial.

What are the Advantages of Welded Wire Mesh in Industrial Applications?

Welded wire mesh consists of wires that are welded at their intersections, providing a strong and stable structure. This type of mesh is commonly used for industrial shelving and security fencing due to its robustness. Buyers should consider the limited flexibility of design options when choosing welded wire mesh, as it may not suit every application requiring custom shapes or sizes.

How Does Chain Link Fencing Provide Security and Affordability?

Chain link fencing is constructed from interwoven wires that create a diamond pattern, offering an effective and economical solution for perimeter security. It is widely used in sports fields and industrial settings. While it is easy to install and maintain, B2B buyers should consider the lack of privacy and aesthetic appeal, which may be a drawback for certain applications.

What Makes Expanded Metal Mesh Versatile for Various Applications?

Expanded metal mesh is made by stretching metal sheets, creating a lightweight and versatile product suitable for grating, walkways, and decorative panels. Its design allows for good airflow and visibility, making it ideal for applications that require both functionality and aesthetics. However, B2B buyers should note that while expanded metal mesh is versatile, it may not withstand heavy loads as effectively as other types of wire mesh.

Related Video: How to Inspect a Metal / Wire Mesh Sling to OSHA and ASME Standards | L-6

Key Industrial Applications of wire mesh china

| Industry/Sector | Specific Application of wire mesh china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Building | Reinforcement in concrete structures | Enhances structural integrity and durability | Ensure compliance with local building codes and standards. |

| Agriculture & Farming | Pest control and crop protection | Reduces crop loss and increases yield | Look for corrosion-resistant materials suitable for outdoor use. |

| Water Treatment | Filtration and separation processes | Improves water quality and meets regulatory standards | Verify mesh size and material compatibility with specific treatment processes. |

| Mining & Mineral Processing | Sifting and sorting of materials | Increases efficiency in material handling | Evaluate mesh strength and durability under heavy loads. |

| Automotive & Aerospace | Component manufacturing and assembly | Ensures precision and quality in production | Consider certifications for safety and quality standards in manufacturing. |

How is Wire Mesh China Used in Construction and Building?

Wire mesh from China is primarily used as reinforcement in concrete structures, enhancing their strength and durability. By integrating wire mesh into concrete, builders can reduce the risk of cracking and structural failure, which is critical in regions prone to seismic activity or extreme weather conditions. International buyers should consider sourcing wire mesh that meets local building codes and standards to ensure compliance and safety in their construction projects.

What Role Does Wire Mesh Play in Agriculture and Farming?

In the agricultural sector, wire mesh serves as an effective solution for pest control and crop protection. By creating barriers against pests while allowing sunlight and moisture to reach plants, wire mesh significantly reduces crop loss and boosts yield. Buyers from regions such as Africa and South America should prioritize materials that are corrosion-resistant and suitable for outdoor conditions, ensuring longevity and effectiveness in their farming practices.

How is Wire Mesh Applied in Water Treatment?

In water treatment facilities, wire mesh is utilized for filtration and separation processes, helping to improve water quality by effectively removing contaminants. This application is essential for meeting regulatory standards in various countries. International B2B buyers should focus on verifying the mesh size and material compatibility with their specific water treatment processes to ensure optimal performance and compliance with health standards.

What Benefits Does Wire Mesh Offer in Mining and Mineral Processing?

In the mining and mineral processing industries, wire mesh is crucial for sifting and sorting materials, enhancing operational efficiency. By using durable wire mesh, companies can handle heavy loads and separate materials effectively, which is vital in maximizing productivity. Buyers should evaluate the mesh’s strength and durability to ensure it can withstand the rigors of mining operations, particularly in harsh environments.

How is Wire Mesh Used in Automotive and Aerospace Manufacturing?

Wire mesh is integral to the manufacturing and assembly processes in the automotive and aerospace sectors, where precision and quality are paramount. It is used in various components, ensuring they meet strict safety and performance standards. B2B buyers should consider sourcing wire mesh that comes with the necessary certifications, ensuring compliance with industry regulations and enhancing the overall quality of their production lines.

Related Video: Parametric Wire Mesh Fence in Revit

3 Common User Pain Points for ‘wire mesh china’ & Their Solutions

Scenario 1: Quality Assurance Challenges in Wire Mesh Sourcing

The Problem:

B2B buyers often face significant challenges when sourcing wire mesh from China due to varying quality standards. Many suppliers may promise high-quality products, but without proper due diligence, buyers risk receiving subpar materials that fail to meet project specifications. This situation can lead to project delays, increased costs for replacements, and damage to a company’s reputation. Buyers in regions like Africa and South America, where local standards may differ from international norms, are particularly susceptible to this issue.

The Solution:

To mitigate quality assurance challenges, B2B buyers should prioritize establishing strong relationships with reputable suppliers. This involves conducting thorough research on potential suppliers, including reviewing their certifications, production processes, and client testimonials. Utilizing third-party inspection services can also be beneficial. Before finalizing any orders, request samples to assess quality firsthand. Implementing a clear specification document outlining the required standards will ensure both parties have a mutual understanding of expectations. Additionally, consider utilizing platforms that provide ratings and reviews of suppliers to make informed decisions.

Scenario 2: Navigating Import Regulations for Wire Mesh

The Problem:

Importing wire mesh from China can be fraught with regulatory challenges, particularly for buyers in the Middle East and Europe. Each country has its own set of import regulations, tariffs, and compliance requirements, which can create confusion and lead to delays in shipment clearance. Buyers may find themselves facing unexpected costs or legal issues if they are not fully aware of the regulations governing their imports.

The Solution:

To navigate these import regulations effectively, it’s crucial for buyers to conduct comprehensive research on the specific requirements of their target market. This includes understanding tariff codes, import duties, and compliance standards related to wire mesh products. Engaging a local customs broker can provide invaluable insights and streamline the import process, ensuring all necessary paperwork is completed accurately. Additionally, staying updated on changes in trade agreements or regulations is essential, as these can impact costs and processes. Joining industry associations or trade groups can also facilitate access to valuable resources and networks that keep buyers informed about regulatory updates.

Scenario 3: Communication Barriers with Chinese Suppliers

The Problem:

Effective communication with suppliers in China can be a significant barrier for international B2B buyers, particularly for those in regions like South America and Africa. Language differences, cultural misunderstandings, and time zone discrepancies can lead to misinterpretations of order specifications, delivery timelines, and pricing structures. This can result in costly errors and frustration on both sides, ultimately impacting project timelines and relationships.

The Solution:

To overcome communication barriers, B2B buyers should consider employing bilingual staff or using professional translation services to facilitate clearer dialogue with suppliers. Setting up regular video calls can help build rapport and ensure that both parties are aligned on expectations. Additionally, utilizing project management tools that offer collaborative features can enhance communication and track progress in real-time. It’s also advisable to create a detailed communication plan that outlines key contacts, preferred communication methods, and regular check-in intervals. This structured approach can significantly reduce misunderstandings and foster a more productive partnership.

Strategic Material Selection Guide for wire mesh china

When selecting wire mesh from China for international B2B applications, understanding the properties and implications of different materials is crucial. This guide will analyze four common materials used in wire mesh production, focusing on their performance characteristics, advantages and disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Stainless Steel Wire Mesh?

Stainless Steel is one of the most popular materials for wire mesh due to its excellent corrosion resistance and durability. Typically, stainless steel wire mesh can withstand high temperatures and pressures, making it suitable for various applications, including filtration and architectural uses. The most common grades used are 304 and 316, with 316 offering superior resistance to chlorides and other corrosive environments.

Pros & Cons: The primary advantage of stainless steel wire mesh is its longevity and maintenance-free nature, which can lead to lower lifecycle costs. However, it is generally more expensive than other materials, which can be a significant factor for budget-conscious buyers. Additionally, the manufacturing process can be complex, requiring specialized equipment and expertise.

Impact on Application: Stainless steel wire mesh is compatible with a wide range of media, including liquids, gases, and solids. Its use is prevalent in food and beverage processing, chemical industries, and construction.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and DIN. Additionally, understanding local preferences for specific grades can impact procurement decisions.

How Does Galvanized Steel Wire Mesh Compare?

Galvanized Steel wire mesh is coated with zinc to enhance its corrosion resistance. This material is often used in applications where exposure to moisture is a concern, such as in agricultural and outdoor settings.

Pros & Cons: The key advantage of galvanized steel is its cost-effectiveness compared to stainless steel, making it an attractive option for projects with tight budgets. However, the zinc coating can wear off over time, especially in harsh environments, leading to potential rust issues. The manufacturing process is less complex, which can result in lower production costs.

Impact on Application: Galvanized wire mesh is commonly used in fencing, drainage, and construction applications. It is suitable for environments where aesthetic considerations are less critical.

Considerations for International Buyers: Buyers should be aware of the standards for galvanization, such as ASTM A123, and consider the environmental impact of using galvanized materials in their regions.

What Are the Benefits of PVC Coated Wire Mesh?

PVC Coated Wire Mesh offers a protective layer of polyvinyl chloride, enhancing the wire mesh’s durability and corrosion resistance. This material is particularly popular in applications requiring additional protection from environmental factors.

Pros & Cons: The primary advantage of PVC-coated wire mesh is its aesthetic appeal and additional protection against corrosion and wear. However, it may not withstand extreme temperatures as effectively as stainless steel or galvanized options. The production process can also be more complex due to the coating application.

Impact on Application: PVC-coated wire mesh is ideal for decorative fencing, animal enclosures, and landscaping applications, where visual appeal is important.

Considerations for International Buyers: Buyers should check for compliance with local standards regarding the use of PVC materials, especially in regions with stringent environmental regulations.

Why Choose Aluminum Wire Mesh for Lightweight Applications?

Aluminum Wire Mesh is known for its lightweight properties and resistance to corrosion. It is often used in applications where weight is a critical factor, such as in aerospace and automotive industries.

Pros & Cons: The main advantage of aluminum wire mesh is its lightweight nature, which can reduce overall project weight and costs. However, it is generally less durable than stainless steel or galvanized options, making it unsuitable for heavy-duty applications. The manufacturing process is relatively straightforward, contributing to lower costs.

Impact on Application: Aluminum wire mesh is commonly used in applications such as HVAC systems, filtration, and decorative elements.

Considerations for International Buyers: Buyers should ensure that the aluminum wire mesh meets relevant standards, such as ASTM B221, to ensure quality and performance.

Summary Table of Wire Mesh Materials

| Material | Typical Use Case for wire mesh china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Filtration, construction, food processing | Excellent corrosion resistance | Higher cost, complex manufacturing | High |

| Galvanized Steel | Fencing, drainage, construction | Cost-effective, good moisture resistance | Zinc coating can wear off | Medium |

| PVC Coated Wire Mesh | Decorative fencing, landscaping | Aesthetic appeal, additional protection | Limited temperature resistance | Medium |

| Aluminum Wire Mesh | HVAC, filtration, lightweight applications | Lightweight, corrosion-resistant | Less durable than other materials | Low |

This strategic material selection guide provides valuable insights for international B2B buyers looking to procure wire mesh from China. By understanding the properties, advantages, and limitations of each material, buyers can make informed decisions that align with their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for wire mesh china

What Are the Main Stages of Manufacturing Wire Mesh in China?

The manufacturing of wire mesh in China involves several critical stages, each designed to ensure the product meets international quality standards. Understanding these stages is essential for B2B buyers looking to source wire mesh effectively.

Material Preparation: What Materials Are Used for Wire Mesh?

The first step in the manufacturing process is material preparation, which typically involves selecting high-quality wire. Common materials include stainless steel, carbon steel, and galvanized wire, each chosen based on the intended application of the wire mesh. The wire is sourced from reputable suppliers, and before use, it undergoes rigorous inspection to ensure it meets the required specifications.

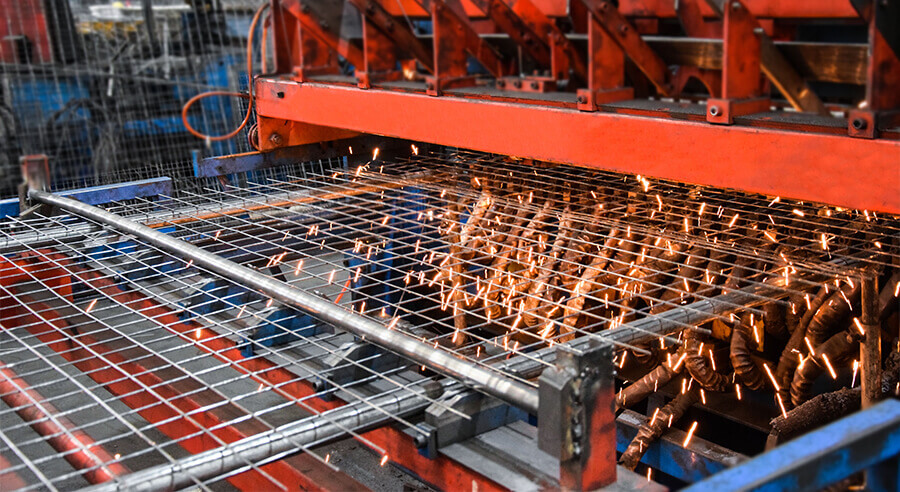

How Is Wire Mesh Formed?

Once the materials are prepared, the next stage is forming. This process involves several techniques, including weaving, welding, and knitting.

-

Weaving: This traditional method uses various weaving techniques, such as plain weave or twill weave, to create mesh with different properties and applications.

-

Welding: Used for more robust applications, welding techniques such as spot welding or resistance welding are employed to create a strong bond between intersecting wires.

-

Knitting: This technique is often used for producing flexible wire mesh products, suitable for applications like filtration.

The chosen method impacts the wire mesh’s strength, flexibility, and overall performance, making it vital for buyers to specify their requirements clearly.

What Does the Assembly Process Involve?

After forming, the assembly process takes place. This stage involves cutting the wire mesh to specified dimensions and shapes, which may include rolls, sheets, or custom shapes based on client specifications. This is often followed by additional processes like coating or treating the mesh to enhance its durability and resistance to environmental factors.

What Are the Finishing Techniques for Wire Mesh?

Finishing is the final stage of manufacturing wire mesh, where products undergo processes such as galvanizing, powder coating, or painting.

-

Galvanizing: This method involves applying a protective zinc coating to prevent rust and corrosion, making the wire mesh suitable for outdoor applications.

-

Powder Coating: This technique adds a layer of color and protection, enhancing aesthetic appeal and durability.

-

Electroplating: A process used primarily for stainless steel mesh, it provides additional corrosion resistance and a sleek finish.

Choosing the right finishing technique can significantly affect the longevity and performance of wire mesh, making it essential for buyers to communicate their specific needs.

How Is Quality Assurance Implemented in Wire Mesh Manufacturing?

Quality assurance (QA) is a critical component of the manufacturing process, ensuring that the final products meet both international and industry-specific standards.

What International Standards Apply to Wire Mesh Manufacturing?

One of the primary international standards relevant to wire mesh manufacturing is ISO 9001, which focuses on quality management systems. Adherence to this standard ensures that manufacturers have systematic processes in place to monitor and improve quality.

In addition to ISO standards, industry-specific certifications such as CE marking for European markets and API (American Petroleum Institute) standards for oil and gas applications may also apply. These certifications provide additional assurance regarding the safety and reliability of the wire mesh products.

What Are the Key Quality Control Checkpoints?

Quality control (QC) in wire mesh manufacturing typically includes several checkpoints throughout the production process:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

-

In-Process Quality Control (IPQC): During manufacturing, periodic inspections are conducted to monitor the production process and ensure compliance with quality standards.

-

Final Quality Control (FQC): After manufacturing, a final inspection is carried out to verify that the wire mesh products meet all specifications and quality requirements.

These checkpoints help identify and rectify any defects early in the process, reducing waste and ensuring high-quality products.

What Common Testing Methods Are Used for Wire Mesh?

Several testing methods are commonly employed to verify the quality and performance of wire mesh:

-

Tensile Testing: This assesses the strength of the wire mesh by measuring how much it can stretch before breaking.

-

Corrosion Testing: Evaluates the resistance of wire mesh to rust and corrosion, particularly for products intended for outdoor use.

-

Dimensional Inspection: Ensures that the wire mesh meets specified dimensions and tolerances.

By understanding these testing methods, B2B buyers can better assess the quality of the wire mesh they intend to purchase.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are some actionable steps:

-

Conduct Supplier Audits: Regular audits of the manufacturing facility can provide insights into their quality management systems and adherence to standards.

-

Request Quality Assurance Reports: Suppliers should be willing to provide documentation detailing their quality control processes, results from testing, and certifications.

-

Engage Third-Party Inspection Services: Utilizing independent inspection agencies can provide an unbiased evaluation of the wire mesh quality before shipment.

What Are the Quality Control and Certification Nuances for International Buyers?

International B2B buyers must navigate various quality control and certification nuances specific to their regions. For example, while CE marking is crucial for products entering the European market, other regions may have different requirements.

Understanding these nuances is essential for ensuring compliance and avoiding costly delays in shipping or customs clearance. Buyers should engage with their suppliers early in the negotiation process to clarify certification requirements and ensure that products are compliant with local regulations.

By grasping the intricacies of manufacturing processes and quality assurance in wire mesh production, international B2B buyers can make informed decisions and foster successful partnerships with suppliers in China.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘wire mesh china’

Introduction

In today’s competitive global market, sourcing wire mesh from China can be a strategic move for international B2B buyers. This practical sourcing guide offers a step-by-step checklist designed to streamline your procurement process, ensuring that you select the right suppliers and products that meet your specific needs.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is essential before starting the sourcing process. Determine the type of wire mesh you need, including materials, dimensions, and intended applications. This clarity will help you communicate effectively with potential suppliers and avoid misunderstandings that could lead to costly errors.

- Material Types: Identify whether you require stainless steel, galvanized, or another material based on durability and application.

- Mesh Size and Opening: Specify the mesh size, as this impacts both functionality and pricing.

Step 2: Conduct Market Research for Reliable Suppliers

Engage in thorough market research to identify reputable suppliers in China. Utilize platforms like Alibaba, Made-in-China, or trade directories that specialize in industrial products. This step is crucial to ensure you are dealing with established players who have a track record of quality and reliability.

- Check Supplier Ratings: Look for suppliers with high ratings and positive reviews from previous buyers.

- Seek Local Recommendations: If possible, connect with other businesses in your region that have sourced wire mesh from China.

Step 3: Evaluate Potential Suppliers

Before making any commitments, conduct a comprehensive evaluation of potential suppliers. Request detailed company profiles, including their manufacturing capabilities, quality control processes, and case studies showcasing past projects. This diligence will help you gauge their reliability and capacity to meet your needs.

- Request References: Ask for contact information of previous clients to get firsthand insights about their experiences.

- Assess Production Capacity: Ensure that the supplier can handle your order volume and timeline.

Step 4: Verify Supplier Certifications

It’s vital to confirm that your chosen suppliers have the necessary certifications and quality standards in place. Compliance with international standards, such as ISO certification, ensures that the products meet safety and quality benchmarks.

- Quality Assurance Processes: Inquire about their quality control procedures to ensure consistent product quality.

- Environmental Compliance: Check if the supplier adheres to environmental regulations, particularly if you have sustainability goals.

Step 5: Request Samples for Quality Assessment

Before placing a bulk order, request samples of the wire mesh. This step allows you to evaluate the quality, gauge the material’s suitability, and ensure it meets your specifications.

- Inspect Samples Thoroughly: Examine the samples for durability, finish, and any defects.

- Test Functionalities: If possible, conduct tests to see if the wire mesh performs as required in your applications.

Step 6: Negotiate Terms and Pricing

Once you have selected a supplier, proceed to negotiate pricing, payment terms, and delivery schedules. This step is critical to ensure that you achieve a favorable deal without compromising on quality or service.

- Discuss Payment Methods: Consider secure payment options that protect your investment.

- Clarify Delivery Timelines: Ensure that the supplier can meet your deadlines and discuss penalties for delays.

Step 7: Establish a Communication Plan

Effective communication is key to a successful sourcing experience. Establish a clear communication plan with your supplier to facilitate ongoing dialogue throughout the procurement process.

- Set Regular Check-Ins: Schedule updates to discuss production progress and address any potential issues.

- Use Technology for Transparency: Utilize platforms that allow for real-time tracking of your order status.

By following this comprehensive checklist, B2B buyers can navigate the complexities of sourcing wire mesh from China with confidence, ultimately leading to successful procurement outcomes.

Comprehensive Cost and Pricing Analysis for wire mesh china Sourcing

What Are the Key Cost Components in Wire Mesh Sourcing from China?

When sourcing wire mesh from China, understanding the cost structure is crucial for international B2B buyers. The primary components influencing costs include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The cost of raw materials, such as steel or aluminum, can fluctuate based on global market trends. Buyers should monitor commodity prices to anticipate changes in their sourcing costs.

-

Labor: Labor costs in China are relatively lower compared to many Western countries. However, wages can vary significantly based on the region and the complexity of manufacturing processes. For specialized wire mesh products, skilled labor may command higher rates.

-

Manufacturing Overhead: This includes factory expenses such as utilities, equipment depreciation, and administrative costs. Understanding how these costs are allocated can help buyers gauge the pricing strategies of potential suppliers.

-

Tooling: Custom tooling may be necessary for specialized wire mesh designs, adding to the initial costs. Buyers should factor in these expenses when evaluating quotes, especially for customized orders.

-

Quality Control: Investing in QC processes is essential to ensure product quality. Suppliers that prioritize QC may charge higher prices, but this can lead to reduced defects and returns, ultimately saving costs for the buyer.

-

Logistics: Shipping costs can vary widely based on the destination, shipping method, and order volume. It’s crucial to understand the implications of Incoterms on logistics expenses, which can affect overall pricing.

-

Margin: Supplier margins can vary depending on market competition and the supplier’s position. Understanding the typical margin range in the industry can aid in identifying reasonable pricing.

How Do Price Influencers Affect Wire Mesh Sourcing?

Several factors can influence the pricing of wire mesh sourced from China:

-

Volume and Minimum Order Quantity (MOQ): Generally, larger orders lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their purchasing capacity.

-

Specifications and Customization: Custom designs and specifications can significantly increase costs. Buyers should clearly communicate their requirements to avoid unexpected expenses.

-

Material Choices: The choice of material directly impacts price. For instance, galvanized wire mesh may be more expensive than plain steel due to additional processing.

-

Quality and Certifications: Products meeting international quality standards or certifications may carry a premium price. Buyers should weigh the benefits of compliance against the potential cost increase.

-

Supplier Factors: The supplier’s reputation, production capabilities, and location can also influence pricing. Established suppliers may charge more for their reliability and service.

-

Incoterms: Understanding Incoterms is vital, as they dictate the responsibilities of buyers and sellers during shipping. This can directly affect the total landed cost of wire mesh.

What Are the Best Buyer Tips for Cost-Efficiency?

To maximize cost-efficiency when sourcing wire mesh from China, international B2B buyers should consider the following strategies:

-

Negotiate Effectively: Develop strong negotiation skills and be prepared to discuss price, terms, and conditions. Building a rapport with suppliers can lead to better deals.

-

Assess Total Cost of Ownership (TCO): Look beyond initial prices to understand the TCO, which includes shipping, duties, and potential returns. This holistic view can prevent underestimating costs.

-

Leverage Volume Discounts: If feasible, consolidate orders across multiple products or projects to meet higher MOQs, which can unlock volume discounts.

-

Evaluate Supplier Options: Don’t settle for the first quote. Compare multiple suppliers and their offerings, taking into consideration quality, service, and reliability alongside price.

-

Stay Informed on Market Trends: Regularly monitor market conditions and material prices. Awareness of trends can help buyers time their purchases effectively, potentially leading to cost savings.

Disclaimer on Indicative Prices

Prices for wire mesh sourced from China can vary widely based on the factors discussed. It is advisable for buyers to seek multiple quotes and conduct thorough due diligence before making purchasing decisions to ensure they receive competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing wire mesh china With Other Solutions

Understanding the Importance of Comparing Alternatives

When considering wire mesh solutions, it is essential for B2B buyers to evaluate alternatives that might meet their needs in terms of performance, cost, and application. The right choice can significantly impact operational efficiency, safety, and overall project success. This section analyzes wire mesh china against two viable alternatives: welded wire fencing and expanded metal mesh. By comparing these options, buyers can make informed decisions tailored to their specific requirements.

Comparison Table of Wire Mesh China and Alternatives

| Comparison Aspect | Wire Mesh China | Welded Wire Fencing | Expanded Metal Mesh |

|---|---|---|---|

| Performance | High durability | Moderate durability | High strength |

| Cost | Competitive pricing | Moderate cost | Higher cost |

| Ease of Implementation | Easy to install | Moderate installation | More complex installation |

| Maintenance | Low maintenance | Moderate maintenance | Low maintenance |

| Best Use Case | General applications | Security and perimeter | Heavy-duty applications |

What Are the Pros and Cons of Welded Wire Fencing?

Welded wire fencing is a popular choice among B2B buyers seeking a balance between cost and performance. It provides moderate durability, making it suitable for security and perimeter applications. One of the significant advantages of welded wire fencing is its ease of customization, allowing buyers to tailor the height and gauge according to specific security needs. However, its moderate durability may not withstand extreme conditions as effectively as wire mesh china or expanded metal. Additionally, while the initial cost is reasonable, maintenance can become a factor over time, especially in harsh environments.

How Does Expanded Metal Mesh Compare to Wire Mesh China?

Expanded metal mesh offers exceptional strength and durability, making it an ideal solution for heavy-duty applications such as industrial flooring and security barriers. Its unique design provides high rigidity and resistance to bending, which can be advantageous in demanding environments. However, the cost of expanded metal mesh is typically higher than that of wire mesh china, which may not be feasible for all projects, particularly for businesses operating on tight budgets. Furthermore, the installation process can be more complex, requiring specialized tools and skills, which can increase labor costs and time.

How Can B2B Buyers Choose the Right Solution?

Selecting the right mesh solution requires a thorough assessment of specific project needs, budget constraints, and long-term operational goals. Buyers should consider the environment in which the product will be used, the level of security required, and the potential for wear and tear. For instance, if the application demands high strength and durability, expanded metal mesh may be the best choice despite its higher cost. Conversely, for general applications with moderate security needs, wire mesh china or welded wire fencing may offer a more economical solution. Ultimately, understanding the unique advantages and limitations of each option will empower B2B buyers to make choices that align with their strategic objectives.

Essential Technical Properties and Trade Terminology for wire mesh china

What Are the Key Technical Properties of Wire Mesh from China?

When sourcing wire mesh from China, understanding its technical properties is crucial for making informed purchasing decisions. Here are several key specifications to consider:

-

Material Grade

– Wire mesh is typically made from various materials, including stainless steel, carbon steel, and galvanized wire. The material grade affects durability, corrosion resistance, and overall performance. For instance, 304 stainless steel is commonly used for its excellent corrosion resistance, making it suitable for outdoor or marine applications. Selecting the appropriate material grade ensures that the wire mesh meets the specific needs of your project. -

Wire Diameter

– The diameter of the wire used in the mesh directly impacts its strength and application. Thicker wires provide greater strength and load-bearing capacity, while thinner wires offer flexibility and ease of installation. For B2B buyers, selecting the right wire diameter is essential for ensuring that the mesh can withstand operational stresses in its intended environment. -

Mesh Opening Size

– Mesh opening size is critical in determining the wire mesh’s functionality. It affects factors such as airflow, visibility, and material retention. For example, a finer mesh is ideal for filtering applications, while a larger opening is suitable for security fencing. Buyers must understand the specifications required for their specific applications to ensure optimal performance. -

Tolerance

– Tolerance refers to the allowable deviation from specified dimensions. High tolerance levels ensure that the wire mesh fits seamlessly into the intended application, reducing the likelihood of installation issues. In sectors like construction and manufacturing, precise tolerances are crucial for maintaining structural integrity and operational efficiency. -

Finish Type

– The finish of the wire mesh can significantly influence its durability and aesthetic appeal. Common finishes include galvanized, PVC-coated, and powder-coated options. Each finish offers different levels of corrosion resistance and maintenance requirements. B2B buyers should assess the environmental conditions where the mesh will be used to choose the most appropriate finish.

What Are Common Trade Terms for Wire Mesh Transactions?

Understanding industry terminology is vital for navigating international trade in wire mesh. Here are several commonly used terms that B2B buyers should familiarize themselves with:

-

OEM (Original Equipment Manufacturer)

– OEM refers to a company that manufactures products that are sold under another company’s brand. In wire mesh transactions, you might encounter OEM suppliers who produce customized products per your specifications. Knowing how to leverage OEM relationships can help you secure unique solutions tailored to your needs. -

MOQ (Minimum Order Quantity)

– MOQ is the minimum quantity of products that a supplier is willing to sell. Understanding MOQ is essential for buyers, as it can affect budget and inventory management. Buyers from Africa, South America, and other regions should negotiate MOQs that align with their project requirements and financial capabilities. -

RFQ (Request for Quotation)

– An RFQ is a formal document sent to suppliers requesting price quotes for specified products. This process is crucial for comparing prices and terms across different suppliers. Providing detailed specifications in your RFQ can lead to more accurate quotes and better negotiation outcomes. -

Incoterms (International Commercial Terms)

– Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) helps buyers understand their liabilities and rights in the shipping process, which is critical for international transactions. -

Lead Time

– Lead time refers to the time taken from placing an order to delivery. In wire mesh sourcing, lead times can vary significantly based on production schedules and shipping methods. Understanding lead times is vital for project planning and ensuring that materials arrive when needed. -

Certifications

– Certifications, such as ISO or CE marks, indicate that products meet specific quality and safety standards. Buyers should verify the certifications of their suppliers to ensure compliance with international standards, which can enhance product credibility and reduce risk.

By grasping these essential technical properties and trade terms, B2B buyers can navigate the complexities of sourcing wire mesh from China more effectively, ensuring they make informed decisions that align with their business objectives.

Navigating Market Dynamics and Sourcing Trends in the wire mesh china Sector

What are the Current Market Dynamics in the Wire Mesh Sector?

The wire mesh market, particularly in China, has witnessed significant growth driven by various global factors. One primary driver is the increasing demand for construction and infrastructure development across Africa, South America, the Middle East, and Europe. The construction sector alone accounts for a large portion of wire mesh consumption, as it is vital for reinforcing concrete and providing structural integrity. Additionally, advancements in technology are reshaping sourcing strategies. B2B buyers are increasingly leveraging digital platforms for supplier discovery and procurement, enhancing transparency and efficiency in the sourcing process.

A stock image related to wire mesh china.

Emerging trends also highlight the rise of automation and smart manufacturing techniques, which are streamlining production processes and improving quality control. International B2B buyers are encouraged to stay informed about these technological advancements to ensure they partner with suppliers that adopt best practices. Furthermore, the ongoing global emphasis on sustainability is influencing sourcing decisions, prompting buyers to seek out suppliers who prioritize eco-friendly practices and materials.

How Can Sustainability and Ethical Sourcing Impact Your Supply Chain?

Sustainability and ethical sourcing are critical considerations for B2B buyers in the wire mesh sector. The environmental impact of wire mesh production is considerable, primarily due to energy consumption and waste generation. Therefore, buyers should prioritize suppliers who implement sustainable practices such as energy-efficient manufacturing processes and responsible sourcing of raw materials.

The importance of ethical supply chains cannot be overstated, particularly in regions where labor practices may vary. Buyers should seek suppliers that are transparent about their labor practices and comply with international labor standards. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

Moreover, the growing consumer demand for ‘green’ materials is reshaping product offerings in the wire mesh market. Buyers should inquire about the availability of recycled wire mesh options and assess suppliers’ capabilities in providing products that meet green certifications. By aligning with sustainable and ethical suppliers, businesses can enhance their brand reputation and meet the growing expectations of environmentally-conscious stakeholders.

How Has the Wire Mesh Market Evolved Over Time?

The wire mesh industry has evolved significantly over the last few decades, driven by technological advancements and changing market demands. Initially, wire mesh was primarily used in construction; however, its applications have expanded to include agriculture, mining, and security sectors. This diversification has opened new avenues for international B2B buyers, allowing them to explore various uses of wire mesh beyond traditional construction applications.

The rise of globalization has also played a crucial role in shaping the wire mesh market. Chinese manufacturers have emerged as key players, offering competitive pricing and a wide range of products. This shift has encouraged international buyers to explore sourcing options in China, leading to increased collaboration and partnerships across borders. As the market continues to grow, understanding these historical dynamics will help B2B buyers make informed decisions and adapt to the evolving landscape of the wire mesh sector.

Frequently Asked Questions (FAQs) for B2B Buyers of wire mesh china

-

How do I solve quality issues when sourcing wire mesh from China?

To address quality concerns, it’s essential to conduct thorough supplier vetting. Start by requesting samples to evaluate material quality and craftsmanship. Utilize third-party inspection services to verify manufacturing standards before shipment. Establish clear quality assurance protocols and communicate your specific requirements to the supplier. Regularly visit manufacturing sites if possible, or engage with local agents who can help oversee production. This proactive approach minimizes risks and ensures the products meet your expectations. -

What is the best way to negotiate payment terms with wire mesh suppliers in China?

Negotiating favorable payment terms involves clear communication and understanding of industry practices. Start by proposing a payment structure that aligns with your cash flow, such as a 30% upfront deposit with the remaining balance upon shipment. Be open to discussing alternatives like letters of credit or escrow services to enhance trust. Research the supplier’s payment preferences and be prepared to compromise. Establishing a good relationship can lead to more flexible terms in future transactions. -

What customization options are available for wire mesh products sourced from China?

Many Chinese suppliers offer extensive customization options, including size, material, and weave type. To ensure your specifications are met, provide detailed drawings and descriptions of your requirements. Inquire about minimum order quantities (MOQs) for custom products, as these can vary significantly among suppliers. Additionally, request information about lead times for customized orders to align with your project timelines. Clear communication about your needs will facilitate a smoother production process. -

How can I ensure timely delivery of wire mesh shipments from China?

To guarantee timely delivery, select suppliers with a proven track record of on-time shipments. Discuss shipping methods upfront and choose reliable logistics partners. Establish a clear timeline for production and shipping, and include penalties for delays in your contract. Use freight forwarders who can provide real-time tracking and updates on your shipment status. Planning ahead for potential customs delays is also critical, especially for international shipments to regions like Africa or South America. -

What should I consider when vetting wire mesh suppliers in China?

When vetting suppliers, evaluate their production capabilities, quality certifications (like ISO), and customer reviews. Request references from previous clients, especially those in your industry or region. It’s beneficial to check if they comply with international standards relevant to your market, such as environmental regulations. If possible, conduct a factory audit or enlist a third-party inspection agency to assess their operations and quality control processes. Building a reliable supplier relationship is vital for long-term success. -

What are the minimum order quantities (MOQs) for wire mesh products in China?

MOQs for wire mesh can vary significantly depending on the supplier and product type. Generally, standard products may have lower MOQs, while customized items will require larger orders. It’s essential to discuss these terms upfront during negotiations. If MOQs are higher than your needs, consider collaborating with other buyers to meet the minimum requirement or negotiate a trial order to establish a relationship before committing to larger quantities. -

What are the common logistics challenges when importing wire mesh from China?

Logistics challenges can include customs clearance delays, shipping costs, and damage during transit. To mitigate these risks, choose experienced freight forwarders familiar with your destination country’s regulations. Properly labeling and packaging products will reduce the likelihood of damage. Additionally, familiarize yourself with import tariffs and duties specific to wire mesh in your region to avoid unexpected costs. Planning for contingencies can help ensure smooth logistics operations.

A stock image related to wire mesh china.

- How can I ensure compliance with international trade regulations when buying wire mesh from China?

Understanding and complying with international trade regulations is crucial. Start by researching import regulations specific to your country, including necessary documentation like import licenses and customs declarations. Work with a customs broker to navigate complex regulations and ensure all paperwork is in order. Additionally, verify that your supplier adheres to international standards and certifications to prevent compliance issues. Staying informed about trade agreements can also provide insights into potential tariff reductions or exemptions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for wire mesh china

In navigating the complexities of sourcing wire mesh from China, international B2B buyers must prioritize strategic sourcing as a fundamental approach to procurement. By understanding local regulations, market dynamics, and supplier capabilities, companies from Africa, South America, the Middle East, and Europe can enhance their supply chain resilience. Key takeaways include the importance of establishing strong relationships with reliable suppliers, leveraging technology for supply chain transparency, and conducting thorough market research to identify cost-effective solutions.

What steps can B2B buyers take to optimize their sourcing strategies? Engaging with local trade experts and participating in industry exhibitions can provide valuable insights into trends and innovations within the wire mesh sector. Additionally, diversifying supplier bases can mitigate risks associated with geopolitical tensions and economic fluctuations.

Looking ahead, the demand for wire mesh is poised to grow as infrastructure projects expand globally. B2B buyers are encouraged to adopt a proactive stance, continuously reassessing their sourcing strategies to capitalize on emerging opportunities. By making informed decisions now, businesses can position themselves for long-term success in an increasingly competitive landscape. Embrace the potential of strategic sourcing and seize the opportunities that the wire mesh market in China has to offer.