Discover Cost-Saving Strategies with a Network Cable Supplier (2025)

Introduction: Navigating the Global Market for network cable supplier

Navigating the complexities of the global market for network cable suppliers can be a daunting challenge for B2B buyers, particularly those from emerging markets in Africa, South America, the Middle East, and established regions like Europe. As businesses increasingly rely on robust network infrastructure to enhance connectivity and operational efficiency, sourcing the right network cables becomes critical. This guide is designed to equip international buyers with the essential knowledge needed to make informed purchasing decisions.

In this comprehensive resource, we will explore various types of network cables, their applications across different industries, and effective strategies for supplier vetting. Buyers will gain insights into evaluating supplier reliability, understanding cost structures, and recognizing quality standards. Additionally, we will address regional considerations that impact procurement, ensuring that buyers can navigate cultural and regulatory landscapes effectively.

By leveraging the information presented in this guide, B2B buyers will be empowered to confidently select network cable suppliers that align with their organizational needs and budget constraints. Whether you’re based in Vietnam, Germany, or elsewhere, this guide aims to streamline your sourcing process, enabling you to build a reliable network infrastructure that supports your business goals.

Understanding network cable supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Copper Cable Suppliers | Utilizes copper wiring; cost-effective; supports lower frequencies. | Local area networks (LAN), telephone systems. | Pros: Low cost, widely available. Cons: Limited distance and speed compared to fiber. |

| Fiber Optic Cable Suppliers | Uses light signals for data transmission; higher bandwidth; longer distances. | Data centers, high-speed internet, telecommunications. | Pros: High speed, long-distance, immune to electromagnetic interference. Cons: Higher initial cost, fragile. |

| Coaxial Cable Suppliers | Features a central conductor, insulation, and an outer shield; robust against interference. | Cable television, broadband internet. | Pros: Durable, good for video signals. Cons: Bulkier, limited data capacity compared to fiber. |

| Network Cable Assemblers | Custom builds cables to specific requirements; can include various connectors. | Specialized networking setups, custom installations. | Pros: Tailored solutions, flexibility in design. Cons: Potentially higher costs and longer lead times. |

| Cable Management Suppliers | Offers accessories for organizing and protecting network cables; includes racks, ties, and trays. | Data centers, office environments. | Pros: Enhances organization, reduces wear and tear on cables. Cons: Often overlooked in budget planning. |

What Are the Key Characteristics of Copper Cable Suppliers?

Copper cable suppliers focus on providing twisted pair or coaxial cables, which are ideal for short-distance applications. These cables are cost-effective and widely used in local area networks (LANs) and telephone systems. When purchasing, buyers should consider the cable’s category (e.g., Cat 5e, Cat 6) to ensure it meets their speed and distance requirements. While copper cables are less expensive, they can experience signal degradation over longer distances.

How Do Fiber Optic Cable Suppliers Differ?

Fiber optic cable suppliers offer cables that transmit data using light signals, enabling higher speeds and greater bandwidth compared to copper options. These cables are particularly suitable for data centers and telecommunications, where high-speed internet and long-distance transmission are crucial. B2B buyers should evaluate the type of fiber (single-mode vs. multi-mode) based on their specific application needs. While the initial investment is higher, the long-term benefits in performance and reliability can justify the cost.

What Are the Advantages of Coaxial Cable Suppliers?

Coaxial cable suppliers provide cables that are robust and resistant to electromagnetic interference, making them suitable for cable television and broadband internet applications. Their design includes a central conductor, insulation, and an outer shield, providing durability. Buyers should consider coaxial cables for environments where physical protection and signal quality are priorities. However, they may not offer the same data capacity as fiber optic solutions, which could be a limitation in data-intensive applications.

Why Choose Network Cable Assemblers?

Network cable assemblers specialize in creating custom cable solutions tailored to specific business needs. They can provide various connectors and lengths, making them ideal for specialized networking setups. B2B buyers should consider the benefits of having a tailored solution that fits their unique requirements, although they may face higher costs and longer lead times. Customization ensures compatibility and optimal performance for specialized applications.

How Do Cable Management Suppliers Support B2B Networking?

Cable management suppliers provide essential accessories to organize and protect network cables, such as racks, ties, and trays. This is crucial for maintaining a tidy and efficient workspace, particularly in data centers and office environments. B2B buyers should recognize the importance of investing in cable management to enhance organization and reduce wear and tear on cables. Although often overlooked in budgeting, effective cable management can lead to long-term operational benefits.

Related Video: What Ethernet Cable to Use? Cat5? Cat6? Cat7?

Key Industrial Applications of network cable supplier

| Industry/Sector | Specific Application of Network Cable Supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | High-speed data transmission in telecom networks | Enhanced connectivity and bandwidth for services | Compliance with regional standards, durability, and scalability |

| Manufacturing | Automation and control systems connectivity | Improved operational efficiency and reduced downtime | Compatibility with existing systems, cable length, and shielding |

| Healthcare | Networking for medical devices and patient records | Secure and reliable data transfer for patient care | Compliance with health regulations, data security, and reliability |

| Smart Cities | Infrastructure for IoT devices and smart technologies | Enhanced city management and real-time data access | Scalability, environmental resistance, and integration capabilities |

| Education | Networking for educational institutions and e-learning | Improved access to digital resources and learning platforms | Cost-effectiveness, bandwidth requirements, and installation support |

How is Network Cable Supplier Used in Telecommunications?

In the telecommunications sector, network cable suppliers provide high-quality cables essential for data transmission across various platforms. These cables enable enhanced connectivity and support high bandwidth requirements, crucial for delivering reliable services to customers. For international buyers, especially from regions like Africa and South America, it is vital to ensure compliance with local telecom standards and regulations. Selecting cables that offer durability and scalability can significantly impact the performance and longevity of telecom networks.

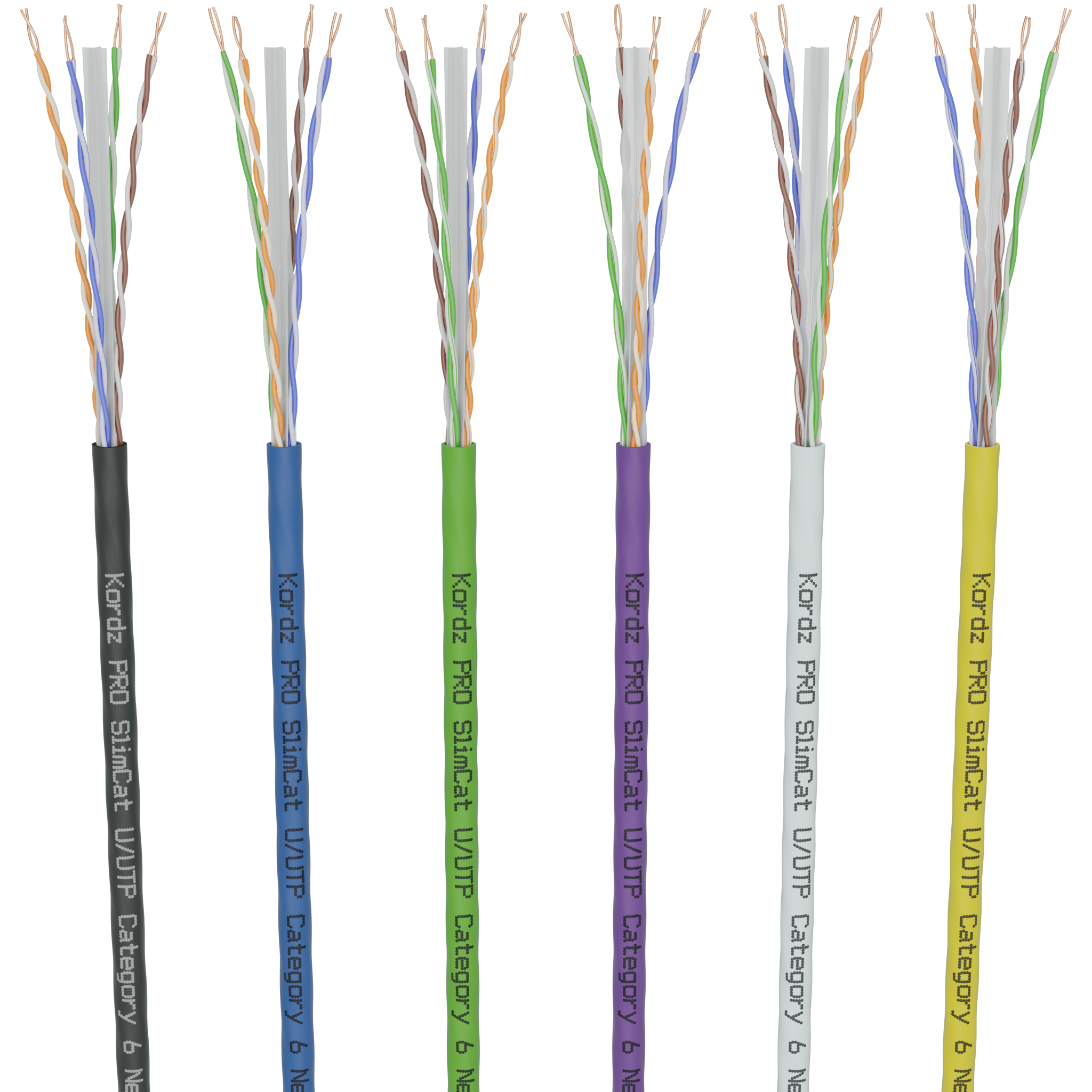

A stock image related to network cable supplier.

What are the Applications of Network Cables in Manufacturing?

In manufacturing, network cables play a pivotal role in connecting automation and control systems. They facilitate real-time communication between machines, sensors, and control units, leading to improved operational efficiency and reduced downtime. Buyers in this sector should focus on sourcing cables that are compatible with existing systems and capable of handling the specific environmental conditions of manufacturing plants. Additionally, considerations regarding cable length and shielding against electromagnetic interference are crucial for optimal performance.

How is Network Cable Supplier Utilized in Healthcare?

In the healthcare industry, network cables are vital for connecting medical devices and ensuring the secure transfer of patient records. These cables support the infrastructure needed for electronic health records (EHR) systems, enabling healthcare providers to access and share critical information efficiently. International buyers must prioritize compliance with health regulations and data security standards when sourcing network cables. Reliability and performance are essential, as any disruption can directly affect patient care.

What Role Do Network Cables Play in Smart Cities?

For smart cities, network cables are the backbone of IoT infrastructure, connecting various devices and systems that enhance urban management. These cables enable real-time data collection and analysis, improving traffic management, waste management, and public safety services. Buyers should consider the scalability of the network cables and their resistance to environmental factors, ensuring they can support the growing number of connected devices in urban areas. Integration capabilities with existing infrastructure are also crucial for seamless implementation.

How are Network Cables Used in Educational Institutions?

In educational settings, network cables are essential for creating robust networks that support e-learning and digital resources. They enable reliable internet access for students and faculty, facilitating the use of online learning platforms and digital tools. B2B buyers in this sector should seek cost-effective solutions that meet bandwidth requirements while ensuring ease of installation and maintenance. The ability to support a growing number of devices in classrooms and campuses is also a significant consideration for educational institutions.

Related Video: Learn Network Cable Management Inside Rack From Scratch

3 Common User Pain Points for ‘network cable supplier’ & Their Solutions

Scenario 1: The Dilemma of Compatibility with Existing Infrastructure

The Problem:

B2B buyers often face significant challenges when sourcing network cables that are compatible with their existing infrastructure. This issue is particularly prevalent in regions with rapidly evolving technology, such as Africa and South America, where businesses may be using older equipment. For instance, a company may find that their newly purchased cables do not fit the connectors of their legacy switches or routers. This incompatibility not only leads to wasted time and financial resources but also disrupts operations, causing frustration among teams that depend on seamless connectivity.

The Solution:

To overcome compatibility issues, buyers should conduct a thorough inventory of their existing network equipment before purchasing network cables. This includes checking the specifications of connectors, supported standards (like Cat5e, Cat6, or fiber optics), and even the length requirements based on the layout of the office or facility. Engaging directly with suppliers who offer customizable solutions can also be beneficial. For example, suppliers that provide a variety of cable types and lengths can help buyers find the exact match for their needs. Additionally, consider investing in cables that are backward compatible, which can provide flexibility in future upgrades without needing to replace existing infrastructure.

Scenario 2: The Challenge of Sourcing Quality Cables at Competitive Prices

The Problem:

Another common pain point for B2B buyers is sourcing high-quality network cables at competitive prices. With a plethora of suppliers, especially in emerging markets, companies may be tempted to opt for cheaper options that compromise quality. This can lead to frequent failures, increased downtime, and ultimately, a loss of productivity. For instance, a business in the Middle East may choose a low-cost supplier that does not adhere to industry standards, resulting in frequent network disruptions and costly repairs.

The Solution:

To ensure the procurement of quality network cables without exceeding budget constraints, buyers should implement a rigorous supplier evaluation process. This includes reviewing certifications such as ISO or RoHS compliance, which can indicate adherence to quality and safety standards. Additionally, establishing long-term relationships with reputable suppliers can result in better pricing models and reliability. Buyers can also leverage bulk purchasing agreements, which may offer discounts while ensuring a steady supply of high-quality cables. Furthermore, investing in cables with extended warranties can provide peace of mind, as it covers potential defects or performance issues, thus safeguarding the company’s investment.

Scenario 3: The Complexity of Installation and Maintenance

The Problem:

The installation and maintenance of network cables can often be a daunting task for B2B buyers, particularly for organizations that lack in-house IT expertise. In regions like Europe, where regulations around data handling and connectivity standards are stringent, improper installation can lead to compliance issues and costly penalties. A common scenario includes a company that hires a contractor with limited experience, leading to suboptimal cable management, which causes signal interference and reduces network performance.

The Solution:

To mitigate installation and maintenance challenges, companies should consider working with certified professionals who specialize in network infrastructure. Prior to installation, conducting a site survey can help identify potential issues, such as electromagnetic interference from nearby equipment. Buyers should also opt for structured cabling solutions, which simplify maintenance and future upgrades. Additionally, providing training for internal IT staff on best practices for cable management can empower them to handle basic maintenance, reducing reliance on external contractors. Regular audits and assessments of the cabling system can also help ensure compliance with industry standards and preemptively identify potential issues before they escalate.

Strategic Material Selection Guide for network cable supplier

When selecting materials for network cables, international B2B buyers must consider various factors that influence performance, durability, and compliance with regional standards. Below is an analysis of four common materials used in the production of network cables, focusing on their properties, advantages, limitations, and implications for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Copper in Network Cables?

Copper is the most widely used material for network cables, particularly in Ethernet cables. Its key properties include excellent electrical conductivity, which allows for high-speed data transmission, and flexibility, making it easier to work with during installation. Copper cables typically have good temperature ratings, allowing them to operate efficiently in a range of environments.

Pros & Cons: The primary advantage of copper is its superior conductivity, which enhances performance. However, it is susceptible to corrosion and can be more expensive than alternative materials like aluminum. Additionally, the manufacturing process for copper cables can be complex, impacting production timelines.

Impact on Application: Copper cables are compatible with various media types, including voice, video, and data. They are essential for applications requiring high bandwidth and low latency, such as data centers and enterprise networks.

Considerations for International Buyers: Buyers must ensure compliance with international standards such as ASTM and IEC. In regions like Europe, adherence to RoHS regulations concerning hazardous substances is also crucial.

How Does Fiber Optic Cable Material Compare?

Fiber optic cables utilize glass or plastic fibers to transmit data as light signals, offering significant advantages in terms of speed and bandwidth. The key properties of fiber optic materials include high tensile strength and resistance to electromagnetic interference, making them ideal for high-performance applications.

Pros & Cons: The primary advantage of fiber optic cables is their ability to transmit data over long distances without loss of quality. However, they are more fragile than copper cables, which can complicate installation and increase costs. The manufacturing process is also more complex, requiring specialized equipment.

Impact on Application: Fiber optics are particularly suited for high-speed internet connections and telecommunications. They are increasingly used in urban areas and industrial applications where high data rates are essential.

Considerations for International Buyers: Buyers should be aware of the varying standards for fiber optic cables in different regions. Compliance with standards such as ISO/IEC 11801 is essential, especially in Europe and the Middle East.

What Are the Benefits of Aluminum in Network Cables?

Aluminum is often used as a cost-effective alternative to copper in network cables. Its key properties include lightweight characteristics and decent conductivity, though not as high as copper.

Pros & Cons: The main advantage of aluminum is its lower cost, making it an attractive option for budget-conscious projects. However, aluminum is less durable and more prone to corrosion, which can limit its application in harsh environments. Its conductivity is also inferior, which may affect performance in high-demand scenarios.

Impact on Application: Aluminum cables are suitable for applications where budget constraints are a significant factor, such as residential networking or temporary installations.

Considerations for International Buyers: Buyers should ensure that aluminum cables meet relevant safety and performance standards, such as those set by ANSI or IEEE, particularly in regions with stringent regulations.

What Role Does Polyethylene Play in Network Cable Insulation?

Polyethylene (PE) is commonly used as insulation material for network cables. Its key properties include excellent dielectric strength and resistance to moisture and chemicals.

Pros & Cons: The primary advantage of polyethylene is its ability to protect cables from environmental factors, enhancing durability. However, it has a lower temperature rating compared to other insulation materials like PVC, which can limit its use in high-temperature applications.

Impact on Application: PE is suitable for outdoor applications and environments where exposure to moisture is a concern, such as in telecommunications and data centers.

Considerations for International Buyers: Compliance with environmental standards is crucial, particularly in Europe, where regulations on materials used in cable insulation can be stringent.

Summary Table of Material Selection for Network Cables

| Material | Typical Use Case for network cable supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Ethernet cables, data centers | Superior conductivity | Susceptible to corrosion, higher cost | High |

| Fiber Optic | Telecommunications, high-speed internet | Long-distance data transmission | Fragile, complex manufacturing | High |

| Aluminum | Residential networking, temporary installs | Cost-effective | Lower conductivity, prone to corrosion | Low |

| Polyethylene | Outdoor applications, moisture-prone areas | Excellent moisture resistance | Lower temperature rating | Medium |

This guide provides international B2B buyers with a comprehensive overview of material options for network cables, helping them make informed decisions that align with their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for network cable supplier

What Are the Key Stages of Manufacturing Network Cables?

The manufacturing process for network cables involves several critical stages that ensure the final product meets both performance and quality standards. Understanding these stages is essential for international B2B buyers who are looking to partner with reliable suppliers.

-

Material Preparation

The first step in the manufacturing of network cables is the selection and preparation of raw materials. This includes copper or fiber optics for the core, insulation materials (like PVC or LSZH), and an outer jacket. Suppliers should ensure that these materials comply with international standards to guarantee conductivity and durability. Buyers should inquire about the sourcing of materials to ensure they are from reputable suppliers. -

Forming

In this stage, the prepared materials are formed into the desired shapes. For copper cables, this typically involves drawing the copper into fine wires. For fiber optics, the glass fibers are drawn from preforms. The precision in this process is crucial, as any deviation can affect the cable’s performance. B2B buyers should verify that the suppliers utilize advanced machinery and techniques to ensure consistent quality during forming. -

Assembly

After forming, the next stage is assembly. This involves twisting pairs of wires together for twisted pair cables or arranging fibers in the correct configuration for fiber optic cables. The assembly process can vary based on the cable type—e.g., Cat5e, Cat6, or fiber optic. Buyers should inquire about the assembly techniques used, as automated systems often yield higher consistency and lower defect rates. -

Finishing

The final stage involves applying protective coatings, labeling, and testing the cables. This may also include the application of additional shielding for enhanced performance in electromagnetic interference (EMI) environments. B2B buyers should request information on the finishing processes, as proper finishing can significantly impact the cable’s lifespan and performance.

How Is Quality Assurance Integrated into Network Cable Manufacturing?

A stock image related to network cable supplier.

Quality assurance (QA) is a vital component of the manufacturing process, ensuring that each batch of network cables meets international and industry-specific standards. Here’s how suppliers typically implement QA measures:

-

International Standards

Suppliers often adhere to international quality management standards such as ISO 9001, which outlines criteria for a quality management system. Additionally, compliance with industry-specific standards like CE (Conformité Européenne) for European markets or API (American Petroleum Institute) standards can be crucial for specific applications. Buyers should confirm that their suppliers maintain these certifications. -

Quality Control Checkpoints

The quality control (QC) process is generally segmented into three main checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During manufacturing, random samples are tested at various stages to detect any defects or deviations from quality standards.

– Final Quality Control (FQC): After finishing, a comprehensive inspection and testing of the final product ensure that it adheres to all performance specifications. -

Common Testing Methods

Various testing methods are employed throughout the manufacturing process, including:

– Electrical Testing: Measures parameters such as resistance and capacitance to ensure optimal performance.

– Mechanical Testing: Assesses the tensile strength and flexibility of the cables.

– Environmental Testing: Evaluates performance under various conditions, including temperature and humidity.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial. Here are actionable steps to ensure the reliability of potential partners:

-

Conduct Supplier Audits

Periodic audits of suppliers can provide valuable insights into their manufacturing processes and quality control measures. Buyers should develop an audit checklist based on relevant industry standards to assess compliance. -

Request Quality Assurance Reports

Suppliers should be willing to share QA reports, including results from IQC, IPQC, and FQC. These documents can help buyers evaluate the consistency and reliability of the supplier’s products. -

Engage Third-Party Inspection Services

Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. This is particularly beneficial for buyers in regions where regulatory compliance is critical. -

Understand Certification Nuances

Different regions may have specific certification requirements. Buyers should familiarize themselves with the certifications that are relevant to their local markets and ensure that their suppliers comply. This is especially important for buyers from Europe, where CE certification is mandatory for many products.

What Are the Challenges in Quality Assurance for International B2B Buyers?

International B2B buyers face unique challenges when it comes to quality assurance in network cable manufacturing. Understanding these challenges can help buyers make informed decisions.

-

Cultural Differences in Quality Standards

Variations in quality expectations and manufacturing practices across regions can lead to misunderstandings. Buyers should ensure clear communication regarding quality expectations and requirements. -

Logistical Issues

Shipping cables internationally can pose risks to product integrity. Buyers should work with suppliers who have robust logistical practices to mitigate risks during transportation. -

Regulatory Compliance

Different countries have varying regulations regarding cable specifications and safety. Buyers must stay informed about these regulations to avoid compliance issues that could arise from importing non-compliant products.

Conclusion

For international B2B buyers seeking network cable suppliers, understanding the manufacturing processes and quality assurance measures is essential for ensuring product reliability and performance. By focusing on material preparation, forming, assembly, and finishing, as well as implementing robust quality control practices, suppliers can meet the high standards expected by buyers across diverse markets. Engaging in thorough verification processes and understanding the nuances of international quality standards will further empower buyers to make informed sourcing decisions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘network cable supplier’

When sourcing network cable suppliers, international B2B buyers must navigate a complex landscape of options and requirements. This guide provides a structured checklist to ensure a successful procurement process, particularly for buyers from Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Before approaching suppliers, clearly outline the technical specifications of the network cables you require. Consider factors such as cable type (e.g., CAT5e, CAT6, fiber optic), length, performance standards, and environmental ratings. This step is crucial to ensure compatibility with your existing infrastructure and to communicate your needs effectively to potential suppliers.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential network cable suppliers. Utilize online directories, trade associations, and industry-specific platforms to compile a list. Look for suppliers with a strong reputation in the market, particularly those with experience serving clients in your region or industry. A well-researched supplier list will provide a solid foundation for your sourcing process.

Step 3: Verify Supplier Certifications

It is essential to confirm that your chosen suppliers hold the necessary certifications and compliance with international standards. Look for certifications such as ISO 9001 for quality management and UL or CE marks for safety. Verifying these credentials ensures that the supplier adheres to quality standards and regulatory requirements, which can mitigate risks in your procurement process.

Step 4: Request Samples and Product Specifications

Before making a bulk purchase, request samples of the network cables. This allows you to assess the quality, durability, and performance of the products firsthand. Additionally, ask for detailed product specifications, including technical data sheets and installation guidelines. Evaluating samples helps you make informed decisions and ensures that the products meet your requirements.

Step 5: Evaluate Supplier Capabilities and Experience

Assess the capabilities and experience of potential suppliers. Inquire about their production capacity, lead times, and past projects. A supplier with a proven track record in delivering to businesses similar to yours can provide confidence in their ability to meet your demands. Don’t hesitate to ask for case studies or references from previous clients.

Step 6: Negotiate Terms and Pricing

Once you’ve narrowed down your options, engage in negotiations regarding pricing, payment terms, and delivery schedules. Be transparent about your budget and expectations while remaining open to discussion. A good negotiation can lead to favorable terms that benefit both parties, enhancing the overall value of your procurement process.

Step 7: Establish Communication and Support Channels

Effective communication is vital throughout the sourcing process. Establish clear lines of communication with your chosen supplier, including who to contact for technical support, order tracking, and post-purchase assistance. Good communication can help resolve issues quickly and foster a positive long-term relationship with your supplier.

By following these steps, international B2B buyers can systematically approach the sourcing of network cable suppliers, ensuring they select a partner that meets their technical needs and business objectives.

Comprehensive Cost and Pricing Analysis for network cable supplier Sourcing

Understanding the cost structure and pricing analysis for network cable suppliers is crucial for international B2B buyers aiming to make informed purchasing decisions. This section delves into the various cost components, price influencers, and practical tips for negotiating favorable deals, especially for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Network Cable Sourcing?

When sourcing network cables, several cost components contribute to the overall pricing structure:

-

Materials: The type of materials used significantly impacts cost. High-quality copper or fiber optics can be more expensive but may offer better performance and durability. Buyers should assess the material specifications to ensure they meet their operational needs.

-

Labor: Labor costs vary by region and the complexity of the manufacturing process. In regions with lower labor costs, such as parts of Asia, buyers may find more competitive pricing. However, this can come at the expense of quality or compliance with international standards.

-

Manufacturing Overhead: This includes costs associated with utilities, rent, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs, which can be passed on to buyers.

-

Tooling: Custom tooling for specific cable designs or specifications can add to upfront costs. Buyers should consider whether custom designs are necessary or if standard products will suffice.

-

Quality Control (QC): Implementing stringent QC processes can increase costs but is essential for ensuring product reliability. Certifications such as ISO or UL can also affect pricing, as they require compliance with specific standards.

-

Logistics: Shipping costs, including freight and insurance, can vary significantly based on distance and mode of transport. Understanding Incoterms is crucial for determining who bears these costs.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary based on market conditions and the competitive landscape.

How Do Price Influencers Affect Network Cable Pricing?

Several factors can influence the final price of network cables:

-

Volume/MOQ: The minimum order quantity (MOQ) often dictates pricing. Larger orders typically yield better pricing due to economies of scale. Buyers should consider consolidating orders to meet MOQs and reduce unit costs.

-

Specifications and Customization: Customized cables with specific features or certifications will generally cost more. Buyers should evaluate whether the added features justify the higher cost or if off-the-shelf solutions suffice.

-

Material Quality and Certifications: Higher-quality materials and certifications can lead to increased pricing but may offer long-term savings through enhanced performance and lower failure rates.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge a premium for their products due to perceived quality and service reliability.

-

Incoterms: Understanding the implications of different Incoterms can help buyers manage costs effectively. Terms like FOB (Free on Board) or CIF (Cost Insurance and Freight) dictate who is responsible for shipping and associated costs.

What Are Effective Buyer Tips for Cost-Efficiency in Network Cable Sourcing?

-

Negotiate Terms: Always negotiate terms with suppliers. Discuss volume discounts, payment terms, and delivery schedules to find mutually beneficial arrangements.

-

Consider Total Cost of Ownership (TCO): Evaluate the TCO, which includes not just the purchase price but also installation, maintenance, and potential downtime. Investing in higher-quality cables may reduce long-term costs.

-

Research Market Trends: Stay informed about market trends and fluctuations in material costs. This knowledge can provide leverage during negotiations.

-

Leverage Supplier Relationships: Building strong relationships with suppliers can lead to better pricing and service. Regular communication can help ensure that buyers are informed about new products or changes in pricing.

- Be Mindful of Pricing Nuances for International Transactions: Currency fluctuations, import duties, and regional pricing differences can all affect the final cost. Buyers should factor these elements into their budgeting and purchasing strategies.

Conclusion

By understanding the cost components and price influencers in network cable sourcing, international B2B buyers can make more informed decisions. Utilizing strategic negotiation tactics and considering the total cost of ownership will help secure the best value, ensuring that investments in network infrastructure yield optimal returns.

Alternatives Analysis: Comparing network cable supplier With Other Solutions

Understanding the Importance of Evaluating Alternatives

When considering a network cable supplier, it’s essential to explore various alternatives that can fulfill similar requirements. This not only helps in assessing the best fit for your specific needs but also provides insights into potential cost savings, performance enhancements, and implementation challenges. By evaluating different options, B2B buyers from regions such as Africa, South America, the Middle East, and Europe can make informed decisions that align with their operational goals.

Comparison Table of Network Cable Supplier and Alternatives

| Comparison Aspect | Network Cable Supplier | Fiber Optic Solutions | Wireless Networking Solutions |

|---|---|---|---|

| Performance | High bandwidth, low latency | Very high bandwidth, minimal latency | Moderate bandwidth, variable latency |

| Cost | Moderate initial investment, ongoing maintenance costs | Higher initial costs, lower maintenance | Low initial costs, potential hidden costs for scaling |

| Ease of Implementation | Requires skilled labor for installation | Complex installation, needs specialized knowledge | Quick setup, minimal technical expertise required |

| Maintenance | Regular inspections needed | Low maintenance, durable | Varies, can require frequent updates |

| Best Use Case | Reliable for fixed installations, high data traffic | Ideal for high-speed internet, long-distance communication | Suitable for mobile access, temporary setups |

In-Depth Analysis of Alternative Solutions

Fiber Optic Solutions: Are They Worth the Investment?

Fiber optic cables offer significantly higher bandwidth capabilities than traditional copper cables, making them an excellent choice for businesses that require fast and reliable data transfer over long distances. The durability of fiber optics also means lower maintenance costs over time. However, the initial investment can be steep, and installation often requires specialized technicians. This makes fiber optics particularly suitable for large enterprises in urban areas where data demands are high, but may be less feasible for smaller companies or those in remote locations.

Wireless Networking Solutions: Convenience vs. Performance

Wireless networking solutions have become increasingly popular due to their ease of setup and flexibility. They are ideal for businesses that need quick deployment or have mobile workforce needs. However, performance can be inconsistent, especially in areas with heavy interference or high user demand. While initial costs are generally lower than wired solutions, wireless networks may incur hidden costs associated with ongoing security updates and infrastructure upgrades. This makes them a good fit for small to medium-sized businesses or temporary setups, but less ideal for operations that require a stable and high-speed connection.

Conclusion: How to Choose the Right Solution for Your Business Needs

Choosing the right network infrastructure is crucial for the success of any B2B operation. Buyers should assess their specific needs, including performance requirements, budget constraints, and the technical expertise available within their organization. For those needing high-speed, reliable connections, a network cable supplier may be the best option, while businesses focused on flexibility and lower initial costs might consider wireless solutions. Ultimately, understanding the pros and cons of each alternative enables B2B buyers to make strategic choices that enhance operational efficiency and support long-term growth.

Essential Technical Properties and Trade Terminology for network cable supplier

What Are the Essential Technical Properties of Network Cables?

Understanding the technical specifications of network cables is crucial for B2B buyers to make informed purchasing decisions. Here are some key properties to consider:

1. Material Grade: What Type of Copper or Fiber Optics Should You Choose?

The material used in network cables significantly affects their performance. Most Ethernet cables use copper, while fiber optic cables utilize glass or plastic fibers. Buyers should prioritize high-quality copper with a minimum of 99.9% purity for optimal conductivity. Fiber optics, on the other hand, should be chosen based on the intended bandwidth and distance requirements.

2. Cable Category: Which Category Meets Your Network Needs?

Network cables are categorized (e.g., Cat5e, Cat6, Cat6a, Cat7) based on their transmission capabilities. For instance, Cat6 supports up to 10 Gbps over 55 meters, making it suitable for high-speed networks. Understanding these categories allows buyers to select cables that meet their specific bandwidth and distance needs, ensuring efficient network performance.

3. Attenuation: How Does Signal Loss Impact Performance?

Attenuation refers to the reduction in signal strength as it travels through a cable. It is measured in decibels (dB) per meter. Lower attenuation values indicate better performance, especially for long-distance applications. B2B buyers should look for cables with low attenuation to minimize signal loss and maintain data integrity.

4. Jacket Material: What Should You Consider for Environmental Resistance?

The outer jacket of a cable protects it from physical damage and environmental factors. Common materials include PVC (Polyvinyl Chloride) and LSZH (Low Smoke Zero Halogen). LSZH is preferred in environments where fire safety is a concern, as it emits minimal smoke and toxic fumes. Selecting the right jacket material is vital for ensuring durability and safety in various environments.

5. Length and Tolerance: How Do They Affect Installation?

The length of the cable impacts its performance, particularly in terms of attenuation and latency. Most standards recommend a maximum length of 100 meters for Ethernet cables. Tolerance refers to the allowable deviation from specified lengths. Understanding these specifications is crucial for ensuring proper installation and performance in network setups.

What Are Common Trade Terms in the Network Cable Industry?

Familiarity with industry jargon helps B2B buyers navigate negotiations and contracts effectively. Here are several key terms:

1. OEM (Original Equipment Manufacturer): What Does This Mean for Your Supply Chain?

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of network cables, OEM suppliers often provide customized solutions tailored to the specific needs of businesses, allowing for greater flexibility in product offerings.

2. MOQ (Minimum Order Quantity): How Does This Impact Your Purchasing Strategy?

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is essential for buyers, as it can affect budget planning and inventory management. Negotiating MOQs can lead to cost savings and better alignment with business needs.

3. RFQ (Request for Quotation): How to Get Accurate Pricing?

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. It typically includes detailed specifications, quantities, and terms. Using RFQs effectively ensures that buyers receive competitive pricing and understand the full scope of potential costs involved.

4. Incoterms (International Commercial Terms): How Do They Affect Your Shipping Agreements?

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is critical for B2B buyers, as they clarify who is responsible for shipping, insurance, and tariffs, ultimately influencing overall costs and logistical planning.

5. Lead Time: Why Is This Important for Your Supply Chain?

Lead time refers to the time it takes from placing an order to receiving the goods. This metric is crucial for project planning and inventory management. B2B buyers should always inquire about lead times to ensure that their supply chains remain efficient and responsive to changing demands.

By grasping these essential technical properties and trade terms, B2B buyers can make more informed decisions when sourcing network cables, ultimately leading to better outcomes for their businesses.

Navigating Market Dynamics and Sourcing Trends in the network cable supplier Sector

What are the Current Market Dynamics and Key Trends in the Network Cable Supplier Sector?

The network cable supplier sector is experiencing significant transformation driven by technological advancements and increasing global connectivity demands. Factors such as the rise of 5G networks, IoT proliferation, and the expansion of data centers are propelling growth in demand for high-quality network cables. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for strategic sourcing.

Emerging trends include a shift towards fiber optic cables due to their superior bandwidth and speed capabilities compared to traditional copper cables. Additionally, there is a growing emphasis on integrated solutions, where suppliers offer not just cables but complete network solutions that include installation and support services. The move towards smart cities and enhanced telecommunication infrastructure is further influencing sourcing decisions, pushing buyers to consider suppliers who can provide innovative products that meet future connectivity challenges.

Market dynamics are also shaped by geopolitical factors, including trade regulations and tariffs, which can affect the availability and pricing of network cables. Buyers must navigate these complexities by establishing relationships with suppliers who have a global reach and can offer competitive pricing without compromising quality.

How is Sustainability Impacting the Network Cable Supplier Sector?

Sustainability is becoming a cornerstone of sourcing strategies in the network cable supplier sector. Environmental considerations are prompting buyers to seek suppliers who prioritize eco-friendly practices and materials. The production of cables often involves significant energy consumption and the use of non-renewable resources, leading to a growing demand for sustainable alternatives.

International B2B buyers should pay attention to suppliers that have adopted ethical sourcing practices and can demonstrate compliance with environmental standards. Certifications such as RoHS (Restriction of Hazardous Substances) and ISO 14001 (Environmental Management Systems) are indicators of a supplier’s commitment to sustainability. Moreover, the use of recycled materials in cable production is gaining traction, enabling buyers to reduce their carbon footprint while still meeting quality requirements.

As corporate social responsibility (CSR) gains prominence, buyers can enhance their brand reputation by partnering with suppliers that uphold ethical labor practices and contribute positively to their communities. Emphasizing sustainability not only addresses regulatory pressures but also aligns with the values of increasingly environmentally-conscious consumers.

What is the Evolution of the Network Cable Supplier Sector?

The network cable supplier sector has evolved significantly over the past few decades. Initially dominated by copper-based cables, the industry witnessed a paradigm shift with the advent of fiber optics in the late 20th century. This transition was driven by the need for higher data transmission speeds and greater bandwidth, particularly with the rise of the internet and digital communication.

In the 21st century, the proliferation of digital technologies has further transformed the landscape. The emergence of cloud computing, big data analytics, and IoT devices has increased the demand for reliable and efficient network infrastructure. Suppliers have adapted by innovating their product offerings, focusing on not just performance but also sustainability and ethical sourcing.

Today, the market is characterized by a blend of traditional and cutting-edge technologies, with suppliers constantly evolving to meet the diverse needs of their B2B clients worldwide. This historical context is vital for international buyers, as it underscores the importance of selecting suppliers who can not only deliver quality products but also anticipate and respond to future industry trends.

Frequently Asked Questions (FAQs) for B2B Buyers of network cable supplier

-

How do I select the right network cable supplier for my business needs?

Selecting the right network cable supplier involves assessing your specific requirements, such as cable type (e.g., CAT5e, CAT6, fiber optic), volume, and customization options. Research potential suppliers by checking their industry reputation, certifications, and customer reviews. It’s also beneficial to request samples to evaluate product quality. Additionally, consider suppliers with local warehouses or distribution centers to ensure timely delivery and lower shipping costs, especially important for buyers in Africa, South America, the Middle East, and Europe. -

What are the key factors to consider when vetting a network cable supplier?

When vetting a network cable supplier, key factors include their manufacturing capabilities, quality assurance processes, and compliance with international standards (e.g., ISO, RoHS). Assess their production capacity to meet your order volume and timeline. It’s also crucial to evaluate their customer service and communication responsiveness. Request case studies or references from similar businesses to understand their reliability and performance in fulfilling orders. -

Can I customize network cables for my specific applications?

Yes, many network cable suppliers offer customization options tailored to specific applications. This may include variations in length, color, connector types, and shielding. When seeking customization, clearly communicate your requirements and ensure the supplier can accommodate them without compromising quality. Be prepared to discuss minimum order quantities (MOQ) and potential lead times for customized orders, as these can vary significantly between suppliers. -

What is the typical minimum order quantity (MOQ) for network cables?

The minimum order quantity (MOQ) for network cables can vary widely depending on the supplier and the type of cable. Commonly, MOQs range from 100 to 1,000 units. For customized cables, the MOQ may be higher due to the additional manufacturing processes involved. It’s advisable to inquire about MOQs during your initial discussions with suppliers to ensure they align with your purchasing capabilities and project needs. -

What payment terms should I expect from network cable suppliers?

Payment terms for network cable suppliers typically vary based on the supplier’s policies and your business relationship. Common terms include payment in advance, net 30, or net 60 days after invoice receipt. For new suppliers, expect to pay upfront or negotiate a deposit. Establishing a good credit history with your supplier may lead to more favorable payment terms over time. Always clarify payment methods accepted, such as bank transfers, letters of credit, or digital payment platforms. -

How do I ensure quality assurance in my network cable orders?

To ensure quality assurance in network cable orders, request documentation of the supplier’s quality control processes, including certifications and testing procedures. Ask for samples to test for compliance with your specifications before placing a large order. Consider suppliers who provide warranties or guarantees on their products, as this reflects confidence in their quality. Regular communication and feedback during the production process can also help maintain quality standards. -

What logistics considerations should I keep in mind when sourcing network cables internationally?

When sourcing network cables internationally, consider shipping costs, delivery times, and customs regulations. Work with suppliers that have experience in international shipping to avoid delays and additional fees. Ensure that your chosen supplier provides proper documentation for customs clearance. Additionally, evaluate shipping methods (air, sea, land) based on your urgency and budget, and consider using freight forwarders to simplify logistics management. -

How do I handle disputes with my network cable supplier?

Handling disputes with a network cable supplier requires clear communication and documentation of all transactions. Start by addressing the issue directly with the supplier, providing evidence of any discrepancies or quality concerns. If the issue remains unresolved, refer to the terms outlined in your purchase agreement regarding dispute resolution. Engaging a third-party mediator or arbitrator may be necessary if the dispute escalates. Maintaining a professional tone and seeking a mutually beneficial resolution is key to preserving the business relationship.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for network cable supplier

In today’s competitive landscape, strategic sourcing of network cables is essential for international B2B buyers. By prioritizing quality, cost-efficiency, and supplier reliability, businesses can secure a robust supply chain that meets their technological needs. Understanding the local market dynamics in regions such as Africa, South America, the Middle East, and Europe allows buyers to make informed decisions that align with their operational goals.

How Can Strategic Sourcing Enhance Your Supply Chain?

Investing in strategic sourcing not only reduces costs but also enhances product quality and supplier relationships. By leveraging a diverse supplier base, companies can mitigate risks associated with supply disruptions and ensure a steady flow of materials. Furthermore, the ability to negotiate favorable terms can lead to improved cash flow and overall financial health.

What’s Next for International B2B Buyers?

As the demand for high-quality network cables continues to rise, international buyers must stay ahead of trends and innovations in the market. Embrace digital tools and platforms for supplier evaluation and selection, and consider sustainability practices as part of your sourcing strategy. By taking these proactive steps, businesses can ensure they are not only prepared for current demands but also poised for future growth.

In conclusion, the path to successful sourcing is paved with strategic decisions that align with market trends and buyer needs. Engage with reliable suppliers and invest in long-term partnerships to secure your competitive advantage in the global marketplace.