Discover Cost-Saving Tips from a Top Carbide Inserts Supplier (2025)

Introduction: Navigating the Global Market for carbide inserts supplier

Navigating the global market for carbide inserts suppliers can be a daunting task for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, including countries like Turkey and the UK. Sourcing high-quality carbide inserts that meet specific industrial needs while ensuring cost-effectiveness is essential for maintaining competitive advantage. This guide aims to demystify the complexities involved in selecting the right suppliers by providing a comprehensive overview of the types of carbide inserts available, their diverse applications across various industries, and critical factors to consider when vetting suppliers.

Understanding the nuances of the carbide inserts market is crucial for making informed purchasing decisions. This guide offers actionable insights into evaluating supplier reliability, assessing product quality, and navigating pricing structures. By breaking down the essential elements of supplier selection—such as certifications, customer reviews, and logistical considerations—B2B buyers will be better equipped to mitigate risks and enhance their procurement strategies.

In a landscape marked by rapid technological advancements and evolving market demands, this guide empowers you with the knowledge needed to confidently engage with suppliers, ensuring that your business remains at the forefront of innovation and efficiency. Whether you are looking to optimize your machining processes or seeking to expand your supplier network, the insights provided here will serve as a valuable resource for your sourcing journey.

Understanding carbide inserts supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Carbide Inserts | Widely used, general-purpose inserts; available in various shapes and sizes | Turning, milling, drilling | Pros: Versatile, cost-effective. Cons: Limited performance in specialized applications. |

| Coated Carbide Inserts | Features a thin layer of coating (e.g., TiN, TiAlN) for enhanced performance | High-speed machining, tough materials | Pros: Improved wear resistance. Cons: Higher cost, may require special handling. |

| Cermet Inserts | Composite of ceramic and metal; offers superior hardness and wear resistance | Precision machining, finishing | Pros: Excellent surface finish. Cons: Brittle, less impact resistance. |

| Insert Grades | Different grades for specific materials and applications (e.g., steel, aluminum) | Material-specific machining processes | Pros: Optimized performance for material. Cons: Complexity in selection. |

| Custom Carbide Inserts | Tailored designs for specific machining needs; often produced in lower quantities | Specialized applications, unique geometries | Pros: Perfect fit for unique tasks. Cons: Higher costs and longer lead times. |

What Are Standard Carbide Inserts and Their B2B Relevance?

Standard carbide inserts are the backbone of the machining industry, providing a reliable solution for general-purpose cutting applications. These inserts come in various shapes, such as round, square, and triangular, making them suitable for turning, milling, and drilling tasks. For B2B buyers, their versatility and cost-effectiveness make them an attractive option, especially for businesses with diverse machining needs. However, they may not perform as well in specialized applications, necessitating a careful evaluation of specific project requirements.

How Do Coated Carbide Inserts Enhance Performance?

Coated carbide inserts feature a thin layer of specialized coatings, such as Titanium Nitride (TiN) or Titanium Aluminum Nitride (TiAlN), which significantly enhance their performance. These coatings improve wear resistance and reduce friction, making them ideal for high-speed machining and tough materials. For B2B buyers, while the initial investment is higher, the long-term benefits of reduced tool wear and improved efficiency can justify the cost. However, buyers must consider that these inserts may require special handling due to their coatings.

What Are Cermet Inserts and Their Advantages?

Cermet inserts, composed of a blend of ceramic and metal, are known for their exceptional hardness and wear resistance. They are particularly effective in precision machining and finishing processes, yielding superior surface finishes. For B2B buyers, cermet inserts offer a compelling advantage for applications requiring high precision; however, their brittleness can be a drawback in high-impact scenarios. Companies should assess their specific machining environments to determine if cermet inserts are a suitable choice.

How Do Insert Grades Affect Machining Processes?

Insert grades refer to the specific material compositions and treatments of carbide inserts designed for particular applications, such as machining steel or aluminum. Each grade is optimized for performance in specific environments, making it crucial for B2B buyers to understand the nuances of each grade. While selecting the appropriate grade can lead to improved efficiency and tool life, the complexity involved in making the right choice can be a challenge. Buyers must consider their material types and machining conditions when selecting insert grades.

Why Consider Custom Carbide Inserts for Specialized Applications?

Custom carbide inserts are designed to meet unique machining requirements, providing tailored solutions for specialized applications. These inserts can be produced in lower quantities and may feature unique geometries that standard inserts cannot accommodate. For B2B buyers, the primary advantage is achieving a perfect fit for specific tasks, enhancing productivity and precision. However, the costs associated with custom inserts and longer lead times can be a deterrent, prompting businesses to weigh the benefits against potential delays and expenses.

Related Video: Intro of carbide insert types and thier uses And sell your old carbide inserts to us directly

Key Industrial Applications of carbide inserts supplier

| Industry/Sector | Specific Application of carbide inserts supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision machining of turbine components | Enhanced durability and precision machining | Certification standards, material specifications, lead times |

| Automotive | Engine block and cylinder head machining | Improved surface finish and reduced cycle time | Compatibility with existing machinery, supplier reliability, cost-effectiveness |

| Oil and Gas | Drilling and milling operations | Increased tool life and reduced downtime | Local regulations, environmental compliance, availability of technical support |

| Metal Fabrication | Tooling for stamping and cutting operations | Higher productivity and reduced material waste | Customization options, bulk purchasing, delivery schedules |

| Construction Equipment | Manufacturing of heavy machinery components | Enhanced performance and longevity of parts | Quality assurance processes, after-sales support, warranty terms |

How is Carbide Inserts Used in Aerospace Manufacturing?

In the aerospace sector, carbide inserts are critical for the precision machining of turbine components, which require extreme accuracy and durability. These inserts help manufacturers achieve tight tolerances and high-quality surface finishes, reducing the need for rework and enhancing overall operational efficiency. International buyers should consider suppliers who meet rigorous certification standards, as compliance with aerospace regulations is paramount. Additionally, understanding material specifications and lead times can significantly impact project timelines.

What Role Do Carbide Inserts Play in Automotive Manufacturing?

Carbide inserts are extensively utilized in the automotive industry for machining engine blocks and cylinder heads. Their ability to maintain sharp cutting edges under high temperatures and pressures leads to improved surface finishes and reduced cycle times. For buyers from regions such as South America or Europe, it is crucial to ensure that suppliers provide compatibility with existing machinery and demonstrate reliability in delivery schedules. Cost-effectiveness without compromising quality is also a key consideration for automotive manufacturers.

How Do Carbide Inserts Improve Operations in Oil and Gas?

In the oil and gas industry, carbide inserts are employed in drilling and milling operations, offering increased tool life and reduced downtime. This is especially vital in regions like the Middle East, where operational efficiency directly correlates with profitability. Buyers should be aware of local regulations and environmental compliance requirements when sourcing these products. Additionally, having access to technical support can be a significant advantage in addressing any operational challenges that may arise.

Why are Carbide Inserts Important in Metal Fabrication?

Metal fabrication relies heavily on carbide inserts for tooling in stamping and cutting operations. The use of these inserts leads to higher productivity and reduced material waste, which is essential for maintaining competitive pricing in the global market. For international buyers, customization options from suppliers can provide tailored solutions that meet specific operational needs. It is also important to evaluate bulk purchasing agreements and delivery schedules to ensure consistent supply.

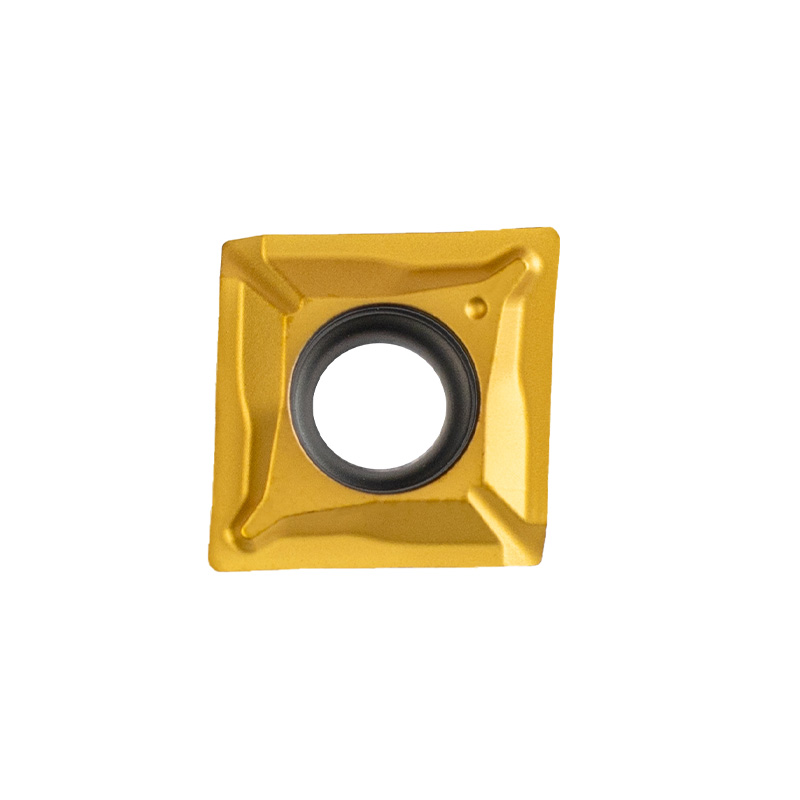

A stock image related to carbide inserts supplier.

How are Carbide Inserts Beneficial in Construction Equipment Manufacturing?

In the construction sector, carbide inserts play a vital role in manufacturing heavy machinery components. Their durability and ability to withstand harsh operating conditions enhance the performance and longevity of these parts, reducing maintenance costs. When sourcing carbide inserts, buyers should focus on suppliers that have robust quality assurance processes in place and offer comprehensive after-sales support. Warranty terms can also be a deciding factor in supplier selection, particularly for high-value components.

Related Video: How carbide inserts are made by Sandvik Coromant

3 Common User Pain Points for ‘carbide inserts supplier’ & Their Solutions

Scenario 1: Inconsistent Quality of Carbide Inserts

The Problem:

B2B buyers often face significant challenges with the quality of carbide inserts received from suppliers. Inconsistent quality can lead to premature tool wear, resulting in increased production costs and downtime. Buyers in industries such as automotive or aerospace may find that inserts don’t meet their specifications, causing defective products and customer dissatisfaction. This inconsistency can stem from various factors, including poor manufacturing processes or inadequate quality control measures implemented by suppliers.

The Solution:

To mitigate this issue, international B2B buyers should prioritize sourcing from suppliers who provide detailed certifications for their carbide inserts, such as ISO 9001 quality management standards. It is advisable to request sample products before committing to a large order, allowing buyers to evaluate the quality firsthand. Additionally, establishing a strong communication channel with suppliers can help in addressing quality concerns proactively. Buyers should also consider integrating a robust inspection process within their production lines, using precision measurement tools to ensure inserts meet specified tolerances. This combination of careful supplier selection and rigorous quality checks can significantly enhance the consistency of the carbide inserts used in production.

Scenario 2: Difficulty in Technical Support and Guidance

The Problem:

Many B2B buyers struggle with inadequate technical support when selecting and utilizing carbide inserts. This can lead to improper application, resulting in suboptimal machining performance and increased costs. For instance, buyers might not fully understand the specific grades of carbide inserts suitable for different materials or machining processes, leading to inefficiencies and wasted resources. This lack of guidance can be particularly frustrating for companies in developing regions like Africa or South America, where access to expert advice may be limited.

The Solution:

To overcome this challenge, buyers should seek suppliers who offer comprehensive technical support services. This includes access to experienced engineers who can provide insights into the best carbide insert selection for specific applications. Additionally, buyers can benefit from suppliers that offer training sessions, workshops, or online resources that detail the features and benefits of different insert types. Engaging with suppliers that utilize advanced software for tooling recommendations can also streamline the selection process. By fostering a collaborative relationship with suppliers that prioritize education and support, buyers can improve their machining processes and achieve better results.

Scenario 3: Supply Chain Disruptions and Lead Times

The Problem:

Supply chain disruptions are a common pain point for B2B buyers of carbide inserts, especially in the wake of global events that affect manufacturing and logistics. Buyers may experience long lead times, unexpected delays, or even stockouts, which can halt production and lead to significant financial losses. This issue is particularly acute for companies in Europe and the Middle East, where just-in-time manufacturing practices require reliable delivery schedules.

The Solution:

To counteract supply chain disruptions, B2B buyers should implement a diversified sourcing strategy. Instead of relying solely on one supplier, establishing relationships with multiple carbide inserts suppliers can provide backup options in case of delays. Additionally, buyers should consider negotiating longer-term contracts with suppliers to secure more favorable terms and prioritize their orders. Utilizing inventory management software can also help in forecasting needs and maintaining optimal stock levels. Finally, engaging with suppliers that offer transparent tracking systems can provide real-time updates on order status, enabling buyers to plan their production schedules more effectively. By adopting these proactive measures, buyers can enhance their supply chain resilience and reduce the impact of potential disruptions.

Strategic Material Selection Guide for carbide inserts supplier

What Are the Key Materials Used in Carbide Inserts?

When selecting carbide inserts, understanding the properties and applications of the materials used is crucial. Here, we analyze four common materials: tungsten carbide, ceramic, CBN (Cubic Boron Nitride), and PCD (Polycrystalline Diamond). Each material has unique characteristics that influence performance, durability, and suitability for various applications.

How Does Tungsten Carbide Perform in Industrial Applications?

Tungsten carbide is a widely used material for carbide inserts due to its exceptional hardness and wear resistance. It can withstand high temperatures and pressures, making it suitable for machining hard materials like steel and titanium. Tungsten carbide inserts typically have a temperature rating of up to 1000°C and exhibit good corrosion resistance.

Pros: Tungsten carbide is known for its durability and ability to maintain sharp edges, which enhances machining efficiency. It is relatively cost-effective compared to other advanced materials.

Cons: While tungsten carbide is strong, it is also brittle, which can lead to chipping under certain conditions. Additionally, it may not be suitable for applications involving highly abrasive materials.

Impact on Application: Tungsten carbide inserts are ideal for general machining applications, including turning, milling, and drilling. They perform well in environments where heat and pressure are significant factors.

What Advantages Do Ceramic Inserts Offer?

Ceramic inserts are known for their high hardness and thermal stability, making them suitable for high-speed machining. They can operate effectively at temperatures exceeding 1200°C and offer excellent wear resistance.

Pros: The primary advantage of ceramic inserts is their ability to maintain performance at high speeds, which can significantly increase productivity. They are also resistant to oxidation and chemical wear.

Cons: Ceramic materials are more brittle than tungsten carbide, making them prone to cracking under shock loads. They can also be more expensive, which may impact cost-sensitive projects.

Impact on Application: Ceramic inserts are particularly effective in machining hard materials and in applications where high-speed cutting is essential. They are often used in aerospace and automotive industries.

How Do CBN Inserts Compare in Terms of Performance?

Cubic Boron Nitride (CBN) is the second hardest material after diamond and is particularly effective for machining hardened steels. CBN inserts can operate at temperatures up to 1300°C and provide excellent wear resistance.

Pros: CBN inserts excel in maintaining cutting edge integrity, which leads to longer tool life and reduced downtime. They are also chemically stable, making them suitable for various industrial environments.

Cons: The primary limitation of CBN is its cost, as it is generally more expensive than tungsten carbide and ceramic options. Additionally, CBN inserts require specialized tooling and equipment.

Impact on Application: CBN inserts are ideal for precision machining of hardened steels and are commonly used in the automotive and manufacturing sectors.

What Are the Benefits of Using PCD Inserts?

Polycrystalline Diamond (PCD) inserts are known for their exceptional hardness and wear resistance, making them suitable for machining non-ferrous materials like aluminum and composites. PCD can withstand temperatures up to 800°C.

Pros: The main advantage of PCD inserts is their superior cutting performance and longevity, which can lead to significant cost savings over time. They also provide excellent surface finishes.

Cons: PCD inserts are relatively expensive and may not be suitable for machining ferrous materials. They are also sensitive to shock, which can lead to chipping.

Impact on Application: PCD inserts are highly effective for applications involving non-ferrous materials, such as in the aerospace and automotive industries, where lightweight materials are prevalent.

Summary Table of Material Selection for Carbide Inserts

| Material | Typical Use Case for carbide inserts supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Tungsten Carbide | General machining of steel and titanium | High durability and cost-effectiveness | Brittle, prone to chipping | Medium |

| Ceramic | High-speed machining of hard materials | Excellent wear resistance at high speeds | Brittle, higher cost | High |

| CBN | Precision machining of hardened steels | Long tool life and chemical stability | High cost, requires specialized tooling | High |

| PCD | Machining of non-ferrous materials | Superior cutting performance | Expensive, sensitive to shock | High |

This guide provides international B2B buyers with a comprehensive overview of material options for carbide inserts, emphasizing the importance of selecting the right material based on specific application needs and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for carbide inserts supplier

What Are the Key Stages in the Manufacturing Process of Carbide Inserts?

The manufacturing of carbide inserts involves several critical stages, each designed to enhance the quality and performance of the final product. These stages include material preparation, forming, assembly, and finishing.

1. Material Preparation

The primary raw material for carbide inserts is tungsten carbide, which is typically produced by sintering tungsten and carbon powders. This stage involves:

- Powder Sizing: The tungsten and carbon powders are carefully sized to achieve the desired particle distribution, which affects the final density and strength of the inserts.

- Mixing: Additives such as cobalt are incorporated to improve toughness. The mixing process must be uniform to ensure consistent properties across batches.

2. Forming

Once the material is prepared, the next step is forming, which can be done through various techniques:

- Cold Pressing: The mixed powder is compacted into a mold using high pressure. This process shapes the insert while maintaining its density.

- Isostatic Pressing: In this method, pressure is applied uniformly from all directions, leading to a more uniform density and improved mechanical properties.

These methods are crucial as they determine the initial geometry and physical characteristics of the carbide inserts.

3. Sintering

A stock image related to carbide inserts supplier.

After forming, the compacted inserts undergo sintering, a heat treatment process where the material is heated to a temperature below its melting point. This process solidifies the structure and enhances the hardness and wear resistance of the inserts.

4. Finishing

The final stage involves several finishing processes aimed at refining the inserts:

- Grinding: Inserts are ground to precise dimensions and surface finishes. This step is critical for ensuring that the inserts meet specific tolerances required by end users.

- Coating: Many manufacturers apply coatings (like TiN, TiAlN) to enhance performance characteristics such as wear resistance and thermal stability.

How Do Quality Assurance Practices Ensure the Reliability of Carbide Inserts?

Quality assurance (QA) is vital in the manufacturing of carbide inserts, as it directly impacts product performance and customer satisfaction. International standards, such as ISO 9001, and industry-specific standards like CE and API, guide these practices.

Relevant International Standards for Quality Assurance

- ISO 9001: This standard focuses on quality management systems, ensuring that organizations consistently provide products that meet customer and regulatory requirements.

- CE Marking: For products sold in the European market, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: Particularly relevant for suppliers serving the oil and gas industry, these standards ensure that products meet stringent safety and performance criteria.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This phase involves inspecting raw materials upon arrival to ensure they meet specified standards. Materials that do not meet these criteria are rejected.

- In-Process Quality Control (IPQC): During the manufacturing stages, regular checks are performed to monitor the production process. This includes dimensional checks and mechanical property assessments to ensure adherence to specifications.

- Final Quality Control (FQC): Once manufacturing is complete, the finished products undergo rigorous testing to ensure they meet all quality standards. This includes visual inspections, hardness tests, and performance evaluations.

What Testing Methods Are Commonly Used for Carbide Inserts?

Several testing methods are employed to ensure the quality and reliability of carbide inserts:

- Hardness Testing: Techniques like Rockwell and Vickers hardness tests measure the material’s hardness, which is crucial for wear resistance.

- Microstructure Analysis: Using metallography, manufacturers examine the microstructure of the inserts to identify any defects and ensure uniformity.

- Wear Testing: Simulated operational conditions are used to assess the wear resistance of the inserts, providing insights into their performance in real-world applications.

How Can B2B Buyers Verify the Quality Control Processes of Suppliers?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for ensuring product reliability. Here are actionable steps:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures firsthand. This helps identify any potential risks in the supply chain.

- Requesting Quality Reports: Buyers should request detailed quality assurance reports from suppliers. These documents provide insights into the QC checkpoints and testing methods used.

- Third-Party Inspections: Engaging independent third-party inspectors can provide an unbiased evaluation of the supplier’s quality control practices. This is particularly important for buyers unfamiliar with local manufacturing standards.

What Are the Nuances of Quality Control for International B2B Buyers?

International buyers must consider several nuances when dealing with quality control in different regions:

- Regulatory Compliance: Different countries have varying regulations regarding product standards. Understanding these regulations is crucial for ensuring compliance and avoiding potential legal issues.

- Cultural Differences: The approach to quality assurance may vary between regions. Buyers should be aware of these differences to effectively communicate their quality requirements to suppliers.

- Language Barriers: Clear communication is vital in quality assurance. Buyers should ensure that all documentation and specifications are accurately translated to avoid misunderstandings.

By understanding the manufacturing processes and quality assurance practices in the carbide inserts industry, international B2B buyers can make informed decisions and select reliable suppliers that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘carbide inserts supplier’

Introduction

Sourcing carbide inserts requires careful consideration and a strategic approach, especially for international B2B buyers from diverse markets such as Africa, South America, the Middle East, and Europe. This checklist is designed to guide you through the essential steps for identifying and selecting the right carbide inserts supplier, ensuring you make informed decisions that align with your operational needs and quality standards.

Step 1: Define Your Technical Specifications

Before reaching out to potential suppliers, clearly outline your technical requirements for carbide inserts. This includes material type, size, coating, and application.

- Why It Matters: Accurate specifications help suppliers provide suitable products and prevent misunderstandings that could lead to delays or quality issues.

- What to Look For: Consider the specific machining processes you will be using and how the carbide inserts must perform under those conditions.

Step 2: Research Potential Suppliers Thoroughly

Conduct comprehensive research to identify suppliers specializing in carbide inserts. Utilize trade directories, industry publications, and online platforms.

- Why It Matters: A well-researched list of suppliers ensures you have options and can compare their offerings effectively.

- What to Look For: Focus on suppliers with a proven track record in your industry, as well as those who have positive reviews from previous clients.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications, such as ISO 9001 or other industry-specific standards.

- Why It Matters: Certifications indicate a commitment to quality and adherence to international standards, which is crucial for maintaining your product’s integrity.

- What to Look For: Request copies of certifications and check their validity. Ensure that the supplier’s production processes align with these standards.

Step 4: Request Samples for Testing

Before making a bulk purchase, ask for samples of the carbide inserts to evaluate their performance in your specific applications.

- Why It Matters: Testing samples allows you to assess quality, durability, and suitability for your machining needs.

- What to Look For: Pay attention to the inserts’ wear resistance, chip formation, and overall performance during machining trials.

Step 5: Assess Supplier Communication and Support

Evaluate the responsiveness and professionalism of suppliers during your initial interactions.

- Why It Matters: Effective communication is key to a successful partnership. Suppliers should be willing to address your questions and provide necessary documentation.

- What to Look For: Assess their ability to provide timely information, technical support, and after-sales services.

Step 6: Review Pricing and Payment Terms

Compare pricing structures among shortlisted suppliers, taking into account the total cost of ownership rather than just the unit price.

- Why It Matters: Understanding the total cost helps you evaluate the long-term value of the inserts, including potential savings from durability and performance.

- What to Look For: Consider payment terms, shipping costs, and any additional fees that may apply to your order.

Step 7: Check References and Past Performance

Ask for references from other clients, particularly those in similar industries or regions.

- Why It Matters: Hearing from existing customers provides insights into the supplier’s reliability and product quality.

- What to Look For: Contact references to discuss their experiences, specifically focusing on delivery times, customer service, and product performance.

By following this checklist, B2B buyers can streamline the sourcing process for carbide inserts and establish fruitful partnerships with suppliers that meet their operational needs.

Comprehensive Cost and Pricing Analysis for carbide inserts supplier Sourcing

What Are the Key Cost Components in Sourcing Carbide Inserts?

When sourcing carbide inserts, understanding the cost structure is essential for international B2B buyers. The primary components that contribute to the overall cost include:

-

Materials: The cost of raw materials, particularly high-quality carbide, plays a significant role. Prices can fluctuate based on global supply and demand, impacting overall costs. Buyers should be aware of market trends and potential price increases.

-

Labor: Labor costs vary significantly by region. Countries with lower labor costs may offer competitive pricing, but it’s crucial to assess the quality of craftsmanship and expertise in the production process.

-

Manufacturing Overhead: This includes fixed and variable costs associated with production facilities, utilities, and equipment maintenance. Efficient manufacturing processes can lead to lower overhead, thus impacting the final price.

-

Tooling: Initial setup costs for tooling can be substantial, especially for custom inserts. Buyers should inquire about tooling costs and potential amortization over larger orders to understand the long-term price implications.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability and compliance with industry standards. While it adds to the cost, it can prevent expensive errors and rework in the long run.

-

Logistics: Shipping and handling costs are crucial, especially for international transactions. Factors such as distance, shipping method, and local tariffs can significantly influence logistics expenses.

-

Margin: Suppliers will typically include a profit margin in their pricing. This margin varies based on market conditions, competition, and the supplier’s business model.

How Do Price Influencers Affect Carbide Inserts Pricing?

Several factors can influence the pricing of carbide inserts, which international buyers must consider:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQ to optimize pricing based on their purchasing capabilities.

-

Specifications and Customization: Custom inserts tailored to specific applications may carry higher costs due to additional manufacturing processes. Buyers should clearly define specifications to avoid unexpected price hikes.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications (e.g., ISO) can impact pricing. High-grade materials and recognized certifications typically justify higher costs due to improved performance and durability.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge a premium for their products due to their proven track record and better customer service.

-

Incoterms: The chosen Incoterm (e.g., FOB, CIF) determines the responsibilities of buyers and sellers regarding shipping costs, insurance, and risk. Understanding these terms can help buyers manage total costs effectively.

What Are Effective Buyer Tips for Negotiating Carbide Inserts Prices?

For international B2B buyers, especially from Africa, South America, the Middle East, and Europe (e.g., Turkey, UK), effective negotiation strategies can lead to significant cost savings:

-

Conduct Market Research: Understanding current market prices for carbide inserts helps establish a baseline for negotiations. Knowledge of competitors and market trends can empower buyers during discussions.

-

Focus on Total Cost of Ownership (TCO): Instead of solely considering the purchase price, evaluate the TCO, which includes maintenance, operational efficiency, and lifespan. This broader perspective can justify higher initial costs if they lead to lower overall expenses.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Regular communication and demonstrating loyalty can encourage suppliers to offer discounts or more favorable conditions.

-

Be Open to Alternative Suppliers: Diversifying your supplier base can create competitive pressure, leading to better pricing. However, ensure that alternative suppliers maintain quality standards.

-

Negotiate Payment Terms: Flexible payment terms can improve cash flow and provide leverage in negotiations. Discussing options like extended payment periods or discounts for early payments can yield financial benefits.

Are There Any Pricing Nuances for International Buyers?

International buyers should be aware of specific pricing nuances that can affect sourcing carbide inserts:

-

Currency Fluctuations: Exchange rates can significantly impact pricing, especially in long-term contracts. Buyers should consider locking in rates or using hedging strategies to mitigate risk.

-

Import Tariffs and Duties: Different countries have varying tariffs on imports, which can affect the final cost. Understanding local regulations and potential duties can aid in calculating total expenses.

-

Cultural Differences in Negotiation: Be mindful of cultural norms in negotiation styles, as they can vary significantly between regions. Tailoring your approach to fit the local context can facilitate smoother discussions.

Disclaimer for Indicative Prices

Prices for carbide inserts can fluctuate based on market conditions, material availability, and supplier pricing strategies. It is advisable for buyers to obtain multiple quotes and conduct thorough due diligence to ensure the best value for their investment.

Alternatives Analysis: Comparing carbide inserts supplier With Other Solutions

Understanding Alternatives for Carbide Inserts Suppliers

When evaluating options for machining and manufacturing processes, it is crucial for B2B buyers to consider various alternatives to carbide inserts suppliers. These alternatives can range from different types of cutting tools to advanced manufacturing techniques. Understanding the pros and cons of each option can help buyers make informed decisions that align with their operational goals and budget constraints.

Comparison Table of Alternatives

| Comparison Aspect | Carbide Inserts Supplier | CBN (Cubic Boron Nitride) Tools | Ceramic Cutting Tools |

|---|---|---|---|

| Performance | High durability and wear resistance, ideal for tough materials | Excellent for hard materials, maintains sharpness longer | Good for high-speed machining, less wear on the tool |

| Cost | Moderate to high cost, depending on grade and supplier | Generally higher initial investment but longer lifespan | Lower cost, but can be brittle and less versatile |

| Ease of Implementation | Easy to integrate into existing processes | Requires specific machines, may need adjustments | Can replace carbide inserts directly but requires careful handling |

| Maintenance | Low maintenance, but periodic inspection is recommended | Minimal maintenance; however, they can be fragile | Requires more frequent checks due to brittleness |

| Best Use Case | General machining, heavy-duty applications | Precision machining of hard steels and superalloys | High-speed machining of non-ferrous metals and certain ceramics |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of CBN Tools?

CBN tools are known for their exceptional performance when machining hard materials. They maintain sharpness over extended periods, reducing the frequency of tool changes and downtime. However, the initial investment can be significantly higher than carbide inserts, which may deter some buyers. Additionally, CBN tools may require specific machines or modifications to existing setups, adding to implementation complexity.

How Do Ceramic Cutting Tools Compare?

Ceramic cutting tools offer a cost-effective alternative to carbide inserts, especially in high-speed machining applications. They are less expensive and can provide good performance when working with non-ferrous metals. However, their brittleness is a significant drawback, as they can chip or break under high-stress conditions. Proper handling and careful process planning are essential to maximize their effectiveness and minimize waste.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right machining solution requires a comprehensive understanding of your specific operational requirements, including material types, production volumes, and budget constraints. While carbide inserts suppliers provide a well-rounded solution for various applications, alternatives like CBN and ceramic tools may offer advantages in specific scenarios. Evaluating the performance, cost, and ease of implementation of each option will empower international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, to make informed decisions that enhance productivity and reduce costs.

Essential Technical Properties and Trade Terminology for carbide inserts supplier

What Are the Key Technical Properties of Carbide Inserts?

When sourcing carbide inserts, understanding their technical properties is essential for international B2B buyers. Here are some critical specifications to consider:

-

Material Grade

Carbide inserts are primarily made from tungsten carbide, known for its hardness and wear resistance. The grade of carbide affects the insert’s performance in various applications, such as cutting speed and tool life. Different grades are suitable for different materials and machining conditions, making it vital to select the correct grade for your specific needs. -

Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension. In the context of carbide inserts, tighter tolerances ensure better fit and performance in machining operations. Understanding tolerance levels helps in reducing the risk of tool failure and enhancing production efficiency. -

Coating Type

Many carbide inserts come with coatings such as TiN (Titanium Nitride) or TiAlN (Titanium Aluminum Nitride), which enhance their wear resistance and thermal stability. Different coatings offer distinct advantages depending on the machining conditions and materials being processed. Buyers should consider the coating type to optimize tool performance and lifespan. -

Chipbreaker Design

Chipbreakers are geometrical features on the insert that help in controlling chip flow and improving surface finish. The design of the chipbreaker can influence the cutting process, particularly in terms of chip removal and heat dissipation. Selecting the right chipbreaker design is crucial for achieving desired machining results. -

Insert Geometry

The geometry of the carbide insert, including its shape and cutting edge design, plays a significant role in machining efficiency. Different geometries are suited for various applications, such as roughing or finishing. Understanding the geometry can help buyers choose inserts that match their specific operational requirements.

What Are Common Trade Terms Related to Carbide Inserts?

Familiarity with industry jargon is vital for effective communication in B2B transactions. Here are several important trade terms related to carbide inserts:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of carbide inserts, understanding whether you are dealing with an OEM or a distributor can affect pricing, availability, and support. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. For carbide inserts, MOQs can vary significantly between suppliers and can impact purchasing decisions, especially for smaller businesses or those testing new products. -

RFQ (Request for Quotation)

An RFQ is a document used to invite suppliers to submit price quotes for specific products or services. For buyers of carbide inserts, issuing an RFQ can help in obtaining competitive pricing and terms from multiple suppliers. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that define the responsibilities of buyers and sellers. Understanding Incoterms is crucial for international B2B transactions involving carbide inserts, as they clarify shipping responsibilities, insurance, and liability. -

Lead Time

Lead time is the period between placing an order and receiving the product. For carbide inserts, lead time can vary based on factors such as supplier location, order size, and product customization. Knowing the lead time helps buyers plan their operations and manage inventory effectively.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing carbide inserts, ensuring they select the right products for their specific machining needs.

Navigating Market Dynamics and Sourcing Trends in the carbide inserts supplier Sector

What Are the Key Market Dynamics and Trends Affecting Carbide Inserts Suppliers?

The global carbide inserts market is experiencing significant growth, driven by the increasing demand for precision machining across various industries, including automotive, aerospace, and manufacturing. Key trends include the adoption of advanced manufacturing technologies such as 3D printing and the integration of Industry 4.0 concepts, enabling suppliers to enhance production efficiency and reduce lead times. International B2B buyers, particularly in Africa, South America, the Middle East, and Europe, are increasingly looking for suppliers who can provide customized solutions and high-quality products at competitive prices.

Emerging technologies such as Artificial Intelligence (AI) and the Internet of Things (IoT) are transforming supply chain dynamics, allowing for better inventory management and predictive analytics. As a result, suppliers who invest in these technologies can offer greater transparency and responsiveness to buyers. Additionally, the trend toward digital marketplaces is reshaping sourcing strategies, enabling buyers to easily compare suppliers and products online. This shift emphasizes the importance of having a strong online presence and leveraging digital marketing strategies to attract international customers.

How Is Sustainability Influencing Sourcing Decisions for Carbide Inserts?

Sustainability has become a pivotal factor in the sourcing decisions of international B2B buyers. The environmental impact of production processes is under scrutiny, prompting companies to prioritize suppliers with sustainable practices. For carbide inserts suppliers, this includes using eco-friendly materials, reducing waste, and optimizing energy consumption during manufacturing. Buyers from regions such as Europe are especially inclined to choose suppliers who comply with stringent environmental regulations and demonstrate a commitment to sustainability.

Ethical sourcing is equally important, as buyers seek to ensure that their supply chains are free from human rights abuses and that labor practices are fair. Certifications such as ISO 14001 for environmental management and ethical sourcing certifications can serve as essential indicators of a supplier’s commitment to sustainable practices. By choosing suppliers with these certifications, buyers not only enhance their corporate social responsibility (CSR) profile but also meet the growing consumer demand for sustainable products.

What Is the Historical Context of the Carbide Inserts Supplier Sector?

The carbide inserts industry has evolved significantly since its inception in the mid-20th century. Initially developed to improve tool life and machining efficiency, carbide inserts have become a staple in various manufacturing processes. Over the decades, advancements in material science have led to the development of high-performance carbide grades that can withstand extreme conditions, further expanding their application across industries.

The globalization of trade has also played a crucial role in shaping the market dynamics of carbide inserts. International trade agreements and improvements in logistics have enabled suppliers to access new markets and create competitive pricing strategies. As a result, buyers today have a broader range of options when sourcing carbide inserts, making it essential for suppliers to differentiate themselves through quality, innovation, and customer service.

Conclusion

Understanding the market dynamics, sourcing trends, and sustainability considerations is crucial for international B2B buyers in the carbide inserts sector. By staying informed about these aspects, businesses can make strategic sourcing decisions that align with their operational needs and corporate values.

Frequently Asked Questions (FAQs) for B2B Buyers of carbide inserts supplier

-

How do I choose the right carbide inserts supplier for my business needs?

Choosing the right carbide inserts supplier involves evaluating several key factors. First, assess the supplier’s product range to ensure they offer the specific types of inserts you require for your operations. Look for suppliers with a solid reputation for quality and reliability, supported by customer reviews and testimonials. Additionally, consider their capacity to meet your order volume, lead times, and whether they provide customization options. Finally, engage in discussions to gauge their customer service responsiveness, as this can significantly impact your procurement process. -

What are the common customization options available for carbide inserts?

Many carbide inserts suppliers offer customization options to meet specific machining requirements. These can include variations in geometry, size, coating types, and grades of carbide material. Suppliers may also provide the ability to produce inserts tailored to unique applications or machining conditions. When discussing customization, it’s essential to communicate your specific needs clearly and inquire about the supplier’s capabilities, lead times, and any additional costs associated with custom orders. -

What are the minimum order quantities (MOQs) for carbide inserts?

Minimum order quantities (MOQs) for carbide inserts can vary widely among suppliers. Some may have a low MOQ to accommodate smaller businesses, while others might require larger orders to justify production costs. It’s crucial to clarify the MOQ during your initial discussions with potential suppliers. If your needs are below their MOQ, inquire whether they can offer flexibility or suggest alternative solutions, such as partnering with other buyers to meet the required quantity. -

How can I ensure quality assurance when sourcing carbide inserts internationally?

To ensure quality assurance when sourcing carbide inserts internationally, start by requesting certifications such as ISO 9001, which indicates adherence to quality management systems. Conduct thorough supplier evaluations, including on-site visits if possible, or utilize third-party inspection services to assess product quality before shipment. Establish clear quality standards and specifications in your purchase agreement, and consider implementing a trial order to evaluate the inserts’ performance before committing to larger purchases. -

What payment terms should I expect when working with international carbide insert suppliers?

Payment terms can vary significantly among international suppliers. Common options include advance payments, letters of credit, or net terms (e.g., 30, 60, or 90 days). It is advisable to negotiate terms that are mutually beneficial and consider factors such as your cash flow and the supplier’s trustworthiness. Always ensure that the payment method you choose is secure and provides some level of buyer protection against fraud or non-delivery. -

How does logistics impact the procurement of carbide inserts from international suppliers?

Logistics plays a critical role in the procurement of carbide inserts, as it affects delivery times, costs, and overall supply chain efficiency. When sourcing internationally, consider the shipping methods (air, sea, or land), transit times, and any customs regulations that may apply. Collaborate with your supplier to understand their logistics capabilities and explore options for expedited shipping if needed. Additionally, factor in potential delays and plan your inventory accordingly to avoid production disruptions. -

What are the key factors to consider when vetting a carbide inserts supplier?

When vetting a carbide inserts supplier, consider their experience and specialization in the industry. Evaluate their production capacity, delivery reliability, and quality control processes. Reviewing customer feedback and case studies can provide insights into their performance. Additionally, assess their ability to provide technical support and after-sales service. Engaging with their sales team can also give you a sense of their responsiveness and willingness to meet your specific needs. -

What should I do if I encounter issues with the quality of carbide inserts received?

If you encounter quality issues with the carbide inserts received, promptly document the problem, including photographs and detailed descriptions. Contact the supplier immediately to report the issue and initiate a discussion about potential resolutions, such as refunds, replacements, or adjustments. Ensure you refer to the quality standards specified in your purchase agreement. Building a good relationship with the supplier can facilitate a smoother resolution process, so communicate openly and professionally to address the concerns.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for carbide inserts supplier

Why Is Strategic Sourcing Essential for B2B Buyers of Carbide Inserts?

In conclusion, strategic sourcing plays a pivotal role in optimizing the procurement process for carbide inserts, enhancing both cost-effectiveness and supply chain efficiency. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize building strong relationships with reliable suppliers. This not only ensures consistent quality but also provides access to innovative solutions that can elevate manufacturing capabilities.

Understanding market dynamics, including regional trends and supplier capabilities, allows buyers to make informed decisions that align with their operational goals. Moreover, leveraging technological advancements in procurement can facilitate real-time data analysis, enabling buyers to anticipate shifts in demand and adjust their sourcing strategies accordingly.

What Should B2B Buyers Do Next?

As you move forward, consider conducting thorough supplier evaluations and fostering partnerships that prioritize transparency and collaboration. This proactive approach will empower you to navigate challenges in the global market more effectively. Embrace the future of procurement by integrating strategic sourcing practices that are responsive to the evolving needs of your business. Engage with suppliers who not only meet your requirements but also contribute to your long-term success.