Discover Cost-Saving Tips from a Top Wire Harnes Manufacturer (2025)

Introduction: Navigating the Global Market for wire harnes manufacturer

In today’s interconnected world, sourcing reliable wire harness manufacturers poses a significant challenge for international B2B buyers. With the increasing demand for high-quality wiring solutions across various industries, including automotive, aerospace, and electronics, it becomes crucial to identify suppliers that not only meet quality standards but also align with your specific needs. This comprehensive guide is designed to navigate the complexities of the global wire harness market, offering insights into the diverse types and applications of wire harnesses, effective supplier vetting processes, and cost considerations.

By delving into the intricacies of sourcing wire harnesses, this guide empowers B2B buyers, particularly from Africa, South America, the Middle East, and Europe—including key markets like Spain and Australia—to make informed purchasing decisions. You’ll discover how to assess supplier capabilities, understand market trends, and leverage regional advantages, ensuring that your sourcing strategy is both effective and sustainable.

Moreover, we will address critical questions such as: What should I consider when evaluating wire harness manufacturers? How can I ensure compliance with international quality standards? By providing actionable insights and practical frameworks, this guide serves as a valuable resource for businesses looking to enhance their supply chain efficiency and secure competitive advantages in the global marketplace. Prepare to embark on a journey that transforms your approach to sourcing wire harness solutions, ultimately driving your business success.

Understanding wire harnes manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Wire Harness | Tailored designs, specific to client requirements | Automotive, Aerospace, Medical Devices | Pros: Perfect fit for unique needs; high flexibility. Cons: Longer lead times; potentially higher costs. |

| Standard Wire Harness | Pre-designed, mass-produced harnesses | Consumer Electronics, Appliances | Pros: Cost-effective; quick availability. Cons: Limited customization; may not fit all applications. |

| Industrial Wire Harness | Heavy-duty materials, built for harsh environments | Manufacturing, Robotics, Heavy Machinery | Pros: Durability; reliability in tough conditions. Cons: Heavier; may require specialized installation. |

| Automotive Wire Harness | Designed for vehicle systems, compliant with standards | Automotive Manufacturing | Pros: Meets industry regulations; optimized for performance. Cons: May have limited application outside automotive. |

| Military Wire Harness | Rugged design, resistant to extreme conditions | Defense, Aerospace, Telecommunications | Pros: High durability; designed for critical applications. Cons: Typically higher cost; longer development times. |

What are the Characteristics of Custom Wire Harnesses?

Custom wire harnesses are specifically engineered to meet the unique specifications of a client’s project. They are often used in industries like automotive, aerospace, and medical devices where precision and functionality are paramount. Buyers should consider their specific needs regarding design complexity and volume, as custom solutions may involve longer lead times and higher costs, but ultimately provide a perfect fit for specialized applications.

How Do Standard Wire Harnesses Benefit B2B Buyers?

Standard wire harnesses are pre-manufactured and widely available, making them a cost-effective option for businesses looking to streamline production processes. Commonly used in consumer electronics and appliances, they offer quick availability. However, businesses must weigh the benefits of lower costs against the potential drawbacks of limited customization, which may not suit all applications.

What Makes Industrial Wire Harnesses Suitable for Tough Environments?

Industrial wire harnesses are built with heavy-duty materials designed to withstand harsh conditions typically found in manufacturing and heavy machinery settings. Their durability and reliability make them ideal for environments that demand high performance. Buyers should consider the specific environmental factors they face, as these harnesses may be heavier and require specialized installation, impacting overall project timelines.

Why Are Automotive Wire Harnesses Essential for Vehicle Systems?

Automotive wire harnesses are tailored for vehicle systems and adhere to strict industry standards. They are crucial in automotive manufacturing, ensuring optimal performance and compliance with safety regulations. Buyers must assess their needs based on vehicle type and regulatory requirements, as these harnesses may not be suitable for applications outside the automotive sector.

What Are the Key Features of Military Wire Harnesses?

Military wire harnesses are designed to endure extreme conditions and are often used in defense and aerospace applications. Their rugged construction ensures reliability in critical situations. While they offer significant advantages in terms of durability and performance, buyers should be prepared for potentially higher costs and longer development times, making them more suitable for specific high-stakes projects.

Related Video: Wire harness assembly with projected work instructions

Key Industrial Applications of wire harnes manufacturer

| Industry/Sector | Specific Application of Wire Harness Manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Electrical Systems in Vehicles | Enhanced safety and reliability in vehicle operation | Compliance with automotive standards and certifications |

| Aerospace | Avionics and Control Systems | Improved performance and reduced weight for aircraft | Need for high-temperature resistance and lightweight materials |

| Industrial Automation | Robotics and Machinery Control | Increased efficiency and reduced downtime | Customization options for various machinery configurations |

| Renewable Energy | Solar and Wind Energy Systems | Maximized energy output and reliability | Understanding of environmental regulations and certifications |

| Consumer Electronics | Smart Home Devices | Enhanced user experience and connectivity | Scalability and adaptability to evolving technology trends |

How is Wire Harness Used in the Automotive Industry?

In the automotive sector, wire harnesses are critical for the integration of electrical systems within vehicles. They connect various components such as sensors, lights, and control units, ensuring seamless communication between parts. For international buyers, especially from Africa and South America, sourcing wire harnesses that comply with stringent automotive standards is vital. This not only enhances vehicle safety but also boosts reliability, thereby reducing the likelihood of costly recalls and repairs.

What Role Does Wire Harness Play in Aerospace Applications?

In aerospace, wire harnesses are essential for avionics and control systems, where reliability is paramount. They facilitate communication between critical systems such as navigation, communication, and flight control. Buyers from the Middle East and Europe must consider the need for high-temperature resistance and lightweight materials in their sourcing decisions. Effective wire harness solutions can lead to improved aircraft performance and fuel efficiency, which are crucial in a competitive aerospace market.

How is Wire Harness Essential for Industrial Automation?

Wire harnesses are pivotal in industrial automation, particularly in robotics and machinery control. They streamline the wiring process, reducing installation time and potential errors. For businesses in South America and Africa, sourcing customized wire harness solutions can lead to increased operational efficiency and reduced downtime. Buyers should prioritize suppliers that offer tailored solutions to meet specific machinery configurations, ensuring optimal performance in their automated systems.

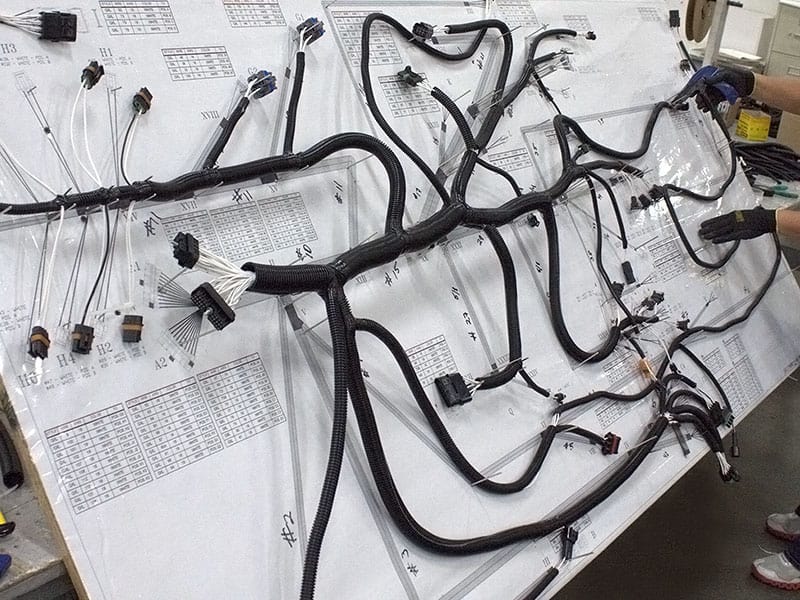

A stock image related to wire harnes manufacturer.

Why is Wire Harness Important in Renewable Energy Systems?

In renewable energy applications, such as solar and wind energy systems, wire harnesses are vital for connecting various components to maximize energy output. They ensure reliable power transmission from energy sources to inverters and storage systems. International buyers, particularly from Europe, should focus on sourcing wire harnesses that comply with environmental regulations and certifications. This approach not only enhances system reliability but also aligns with sustainability goals in the growing renewable energy sector.

How Do Wire Harnesses Enhance Consumer Electronics?

In the realm of consumer electronics, wire harnesses are crucial for smart home devices, facilitating connectivity between components for enhanced user experiences. They support functions like remote control, automation, and data transfer. For buyers in Africa and the Middle East, scalability and adaptability are key considerations when sourcing wire harnesses. Suppliers that can accommodate evolving technology trends can provide significant advantages, ensuring that businesses remain competitive in the fast-paced electronics market.

Related Video: How It’s Made – Industrial Wire Ropes

3 Common User Pain Points for ‘wire harnes manufacturer’ & Their Solutions

Scenario 1: Quality Assurance Challenges in Sourcing Wire Harnesses

The Problem: B2B buyers often face significant hurdles when sourcing wire harnesses, particularly regarding quality assurance. Many manufacturers may claim to meet industry standards, but inconsistencies in production processes can lead to defective products. This challenge is especially pronounced for companies in Africa and South America, where regulatory oversight may be less stringent, resulting in higher risks of receiving subpar components that can jeopardize the entire project or product reliability.

The Solution: To mitigate quality assurance issues, B2B buyers should conduct thorough due diligence when selecting a wire harness manufacturer. Start by requesting certifications such as ISO 9001, which indicates a commitment to quality management systems. Furthermore, establish a robust quality control protocol by incorporating pre-production samples into the procurement process. This allows for testing and validation of the harnesses before mass production. Engaging in regular audits or site visits can also provide insights into the manufacturer’s operational capabilities and adherence to quality standards. Leveraging third-party quality assurance services can further ensure that the products meet your specific requirements.

Scenario 2: Communication Gaps Leading to Misalignment

The Problem: Effective communication is crucial in the B2B landscape, yet it often becomes a pain point when dealing with wire harness manufacturers, especially those located overseas in regions such as the Middle East and Europe. Misunderstandings around technical specifications, timelines, and delivery schedules can lead to significant project delays and increased costs. Buyers may feel frustrated when their expectations are not met, leading to a breakdown in trust and collaboration.

The Solution: To bridge communication gaps, B2B buyers should prioritize establishing a clear communication framework from the outset. This can include appointing a dedicated project manager who serves as the primary point of contact between your company and the manufacturer. Utilize collaborative tools like project management software that allows for real-time updates, tracking progress, and sharing documents. It’s also beneficial to create a detailed project timeline with key milestones, deliverables, and deadlines outlined. Regular virtual meetings can foster a more transparent dialogue and help preemptively address any concerns, ensuring that both parties remain aligned throughout the manufacturing process.

Scenario 3: Customization and Design Limitations

The Problem: Many B2B buyers encounter difficulties when seeking customized wire harness solutions that fit their unique project needs. Some manufacturers may offer limited design flexibility or lack the technical expertise to produce complex configurations. This challenge can be particularly acute for companies in Europe looking for specialized applications in sectors like automotive or aerospace, where precision and adaptability are paramount.

The Solution: To overcome customization challenges, buyers should engage with manufacturers that have a proven track record in producing bespoke wire harnesses. Start by clearly articulating your specific requirements, including the intended application, environmental factors, and performance specifications. It is advisable to request a portfolio of previous custom projects to gauge the manufacturer’s capability and innovation in design. Collaborating with the manufacturer’s engineering team during the design phase can also yield valuable insights and recommendations, ensuring that the final product aligns with your technical needs. Lastly, consider manufacturers that utilize advanced technology, such as CAD software, for design, as this can significantly enhance the precision and feasibility of custom wire harness solutions.

Strategic Material Selection Guide for wire harnes manufacturer

When selecting materials for wire harness manufacturing, international B2B buyers must consider various factors that influence performance, durability, and compliance with regional standards. Below, we analyze four common materials used in wire harnesses, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

What are the Key Properties of PVC in Wire Harness Manufacturing?

Polyvinyl Chloride (PVC) is one of the most widely used materials in wire harness manufacturing due to its excellent insulation properties. It can withstand temperatures ranging from -10°C to 70°C and offers good resistance to abrasion and chemicals. However, its performance can degrade under extreme temperatures and UV exposure.

Pros & Cons: PVC is cost-effective and easy to manufacture, making it a popular choice for many applications. However, it is less durable than other materials and may not be suitable for high-temperature or outdoor applications.

Impact on Application: PVC is compatible with various media, including oils and mild chemicals, making it suitable for automotive and industrial applications.

Considerations for International Buyers: Buyers should ensure compliance with local standards such as ASTM D3032 or DIN 5510. In regions with stringent environmental regulations, such as Europe, the use of PVC may be limited due to its chlorine content.

How Does Polyurethane Compare as a Material for Wire Harnesses?

Polyurethane (PU) is known for its flexibility and resilience, making it a preferred choice for applications requiring high durability. It can handle temperature ranges from -40°C to 90°C and offers excellent resistance to oils, fuels, and ozone.

Pros & Cons: The flexibility of PU allows for easier installation and routing in complex applications. However, it is generally more expensive than PVC and may require more complex manufacturing processes.

Impact on Application: PU is ideal for environments exposed to harsh chemicals or extreme weather conditions, making it suitable for automotive, aerospace, and outdoor applications.

Considerations for International Buyers: Buyers should verify that PU materials meet relevant standards such as ISO 9001 for quality management. In regions like South America, where chemical exposure can be significant, the use of PU can enhance the longevity of wire harnesses.

What Makes Teflon a Preferred Choice for High-Performance Wire Harnesses?

Teflon, or polytetrafluoroethylene (PTFE), is renowned for its exceptional thermal stability and chemical resistance. It can operate effectively in temperatures from -200°C to 260°C, making it suitable for high-performance applications.

Pros & Cons: Teflon’s high-performance characteristics come at a cost, as it is one of the more expensive materials. Its manufacturing process can also be complex, requiring specialized techniques.

Impact on Application: Teflon is particularly beneficial in applications involving aggressive chemicals or extreme temperatures, such as in the aerospace and medical industries.

Considerations for International Buyers: Compliance with standards like ASTM D3308 is crucial for Teflon applications. Buyers from the Middle East, where high temperatures can be prevalent, may find Teflon to be a reliable choice for wire harnesses.

Why is Nylon an Effective Material for Wire Harnesses?

A stock image related to wire harnes manufacturer.

Nylon is a synthetic polymer known for its strength, flexibility, and resistance to abrasion and chemicals. It can withstand temperatures from -40°C to 120°C, making it versatile for various applications.

Pros & Cons: Nylon’s durability and flexibility make it suitable for demanding environments. However, it can absorb moisture, which may affect its performance in humid conditions.

Impact on Application: Nylon is commonly used in automotive and industrial applications where strength and flexibility are paramount.

Considerations for International Buyers: Buyers should ensure that nylon materials comply with standards such as ISO 9001. In regions like Africa, where environmental conditions can vary, moisture absorption should be a consideration in material selection.

Summary Table of Material Selection for Wire Harness Manufacturers

| Material | Typical Use Case for wire harnes manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Automotive and industrial applications | Cost-effective and easy to manufacture | Less durable under extreme conditions | Low |

| Polyurethane | Aerospace and outdoor applications | High flexibility and resilience | More expensive and complex to manufacture | High |

| Teflon | High-performance applications in aerospace | Exceptional thermal and chemical resistance | High cost and complex manufacturing | High |

| Nylon | Automotive and industrial applications | Strong and flexible | Moisture absorption can affect performance | Medium |

This analysis provides B2B buyers with actionable insights into material selection, helping them make informed decisions that align with their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for wire harnes manufacturer

What Are the Key Stages in the Manufacturing Process for Wire Harnesses?

The manufacturing process of wire harnesses is intricate and consists of several critical stages, each requiring precision and expertise to ensure the final product meets industry standards. Understanding these stages helps B2B buyers identify reliable manufacturers and assess their capabilities.

1. Material Preparation: What Materials Are Used in Wire Harness Manufacturing?

The first stage of wire harness manufacturing involves the selection and preparation of materials. Common materials include:

- Conductors: Typically copper or aluminum, chosen for their electrical conductivity.

- Insulation: Materials like PVC, PTFE, or cross-linked polyethylene (XLPE) are used to prevent electrical shorts and enhance durability.

- Connectors and Terminals: These components are often made from brass, stainless steel, or other corrosion-resistant metals.

B2B buyers should inquire about the sourcing of these materials, as quality can significantly affect performance and longevity. Manufacturers should ideally provide certifications that guarantee the quality and origin of their materials.

2. How Is the Forming Process Conducted in Wire Harness Production?

Once materials are prepared, the forming stage begins. This involves cutting, stripping, and bending wires to specific lengths and shapes. Key techniques include:

- Cutting: Wires are cut to the required lengths using precision cutting machines to ensure accuracy.

- Stripping: This process removes insulation from wire ends to prepare them for connection. Automated stripping machines can enhance efficiency and consistency.

- Bending and Shaping: Wires may need to be bent or shaped to fit particular configurations. This is often done using specialized machinery that can handle complex designs.

B2B buyers should ensure that the manufacturer employs advanced machinery and skilled labor to achieve high precision in this stage.

3. What Does the Assembly Stage Entail in Wire Harness Manufacturing?

The assembly stage is where the real integration of components occurs. It typically involves:

- Connector Assembly: Wires are inserted into connectors, and terminals are crimped onto the wire ends. This step is crucial for ensuring a secure electrical connection.

- Bundling and Securing: Wires are bundled together using various methods such as tie wraps, adhesive tape, or heat shrink tubing to ensure organization and protection.

- Quality Checks: Throughout assembly, initial quality checks should be performed to catch any defects early.

B2B buyers should ask potential suppliers about their assembly techniques and whether they use automated systems to enhance accuracy and reduce human error.

4. How Is the Finishing Process Important in Wire Harness Manufacturing?

The finishing stage involves final touches that enhance the wire harness’s performance and appearance. This includes:

- Insulation Application: Additional insulation may be applied for enhanced protection against environmental factors.

- Marking and Labeling: Proper labeling is essential for identification during installation and maintenance.

- Final Inspection: A thorough inspection is performed to ensure all components are correctly assembled and functioning.

Buyers should ensure that manufacturers have a systematic approach to finishing, as it plays a vital role in the product’s reliability.

What Quality Assurance Standards Should B2B Buyers Be Aware Of?

Quality assurance is crucial in wire harness manufacturing, as it ensures that products meet the required safety and performance standards. Here are some key international and industry-specific standards:

1. What Are the Relevant International Quality Standards for Wire Harnesses?

- ISO 9001: This standard focuses on quality management systems and is critical for manufacturers to demonstrate their commitment to quality.

- ISO/TS 16949: Specifically for the automotive industry, this standard emphasizes continuous improvement and defect prevention.

B2B buyers from regions like Africa and South America should prioritize suppliers with these certifications, as they reflect a commitment to quality.

2. How Do Industry-Specific Certifications Impact Wire Harness Quality?

- CE Marking: This certification is necessary for products sold in the European Economic Area, indicating compliance with health and safety standards.

- API Standards: Relevant for manufacturers supplying the oil and gas sector, these standards ensure that products can withstand harsh conditions.

Understanding these certifications allows buyers to evaluate the suitability of a manufacturer for their specific industry needs.

What Quality Control Checkpoints Should Be Established in Wire Harness Manufacturing?

Quality control (QC) checkpoints are essential for ensuring that the manufacturing process yields high-quality products. Key checkpoints include:

1. Incoming Quality Control (IQC)

At this initial stage, raw materials are inspected before they enter the production process. This includes checking for material specifications, dimensions, and any visible defects. B2B buyers should request IQC reports to verify material quality.

2. In-Process Quality Control (IPQC)

During the manufacturing process, regular checks are performed to monitor compliance with specifications. This includes inspections at each stage of the manufacturing process, from material preparation to assembly. Buyers should inquire about the frequency and methods of these checks.

3. Final Quality Control (FQC)

The final inspection ensures that the completed wire harness meets all specifications and standards. Common testing methods include:

- Electrical Testing: To check for proper conductivity and insulation resistance.

- Mechanical Testing: To evaluate the durability and strength of connections.

- Environmental Testing: To ensure performance under various conditions (temperature, humidity, etc.).

B2B buyers should ask manufacturers for detailed FQC reports and test results.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verifying a supplier’s quality control practices is crucial for ensuring product reliability. Here are actionable steps for B2B buyers:

- Conduct Audits: Regular audits of the manufacturing facility can provide insights into the supplier’s quality processes and compliance with standards.

- Request Quality Reports: Ask for documentation of quality control processes, including IQC, IPQC, and FQC reports.

- Utilize Third-Party Inspections: Engaging a third-party inspection service can provide an unbiased assessment of the manufacturer’s quality practices.

What Nuances Should International B2B Buyers Consider Regarding Quality Control?

International buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

- Cultural Differences: Understanding how quality is perceived and maintained in different cultures can impact communication and expectations.

- Regulatory Compliance: Different regions have varying regulatory requirements that can affect manufacturing processes and certifications.

- Language Barriers: Clear communication is vital for ensuring that quality standards are understood and met.

By considering these factors, B2B buyers can better navigate the complexities of international sourcing and ensure that they partner with manufacturers who prioritize quality.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘wire harnes manufacturer’

In the competitive landscape of sourcing wire harness manufacturers, having a structured approach is essential for international B2B buyers. This guide serves as a comprehensive checklist, designed to streamline your procurement process, minimize risks, and ensure that you partner with the right suppliers.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is the foundation of successful sourcing. Specify the materials, dimensions, and performance standards needed for your wire harnesses. This step is crucial because accurate specifications help suppliers understand your exact needs and reduce the likelihood of miscommunication.

- Material Requirements: Identify whether you need standard materials like copper or specialized options such as aluminum.

- Performance Standards: Consider environmental factors, such as temperature resistance and moisture exposure.

Step 2: Research Potential Suppliers

Conduct thorough market research to identify potential wire harness manufacturers. Utilize online platforms, industry directories, and trade shows to compile a list of candidates. Researching suppliers is vital to ensure that they have a solid reputation and relevant experience in your industry.

- Industry Experience: Look for manufacturers that have experience in your specific sector, whether automotive, aerospace, or consumer electronics.

- Geographical Considerations: Consider local suppliers for logistical advantages or international suppliers for cost benefits.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This step helps mitigate risks associated with quality and reliability.

- Quality Assurance: Inquire about their quality control processes and certifications, such as ISO 9001.

- Client Feedback: Seek testimonials or reviews from previous clients to gauge their satisfaction level.

Step 4: Verify Supplier Certifications

Ensuring that your chosen supplier meets industry standards is non-negotiable. Verify any certifications that demonstrate compliance with international quality and safety standards. This step is important as it assures you of the supplier’s commitment to quality.

- Common Certifications: Look for certifications like UL, RoHS, or IPC standards, which may be relevant to your wire harness applications.

- Regular Audits: Confirm whether the supplier undergoes regular audits to maintain their certifications.

Step 5: Request Samples and Prototypes

Once you have narrowed down your list of suppliers, request samples or prototypes of their wire harness products. This step is essential for assessing the quality and craftsmanship before placing a larger order.

- Testing for Fit: Ensure the samples meet your specifications and are compatible with your existing systems.

- Evaluate Durability: Conduct tests to assess the performance and longevity of the samples under expected operating conditions.

Step 6: Negotiate Terms and Conditions

Engage in negotiations to establish clear terms regarding pricing, payment methods, delivery schedules, and warranties. This step is crucial for preventing misunderstandings and ensuring a mutually beneficial relationship.

- Transparent Pricing: Ensure all costs, including shipping and customs, are clearly outlined.

- Delivery Commitments: Establish realistic timelines for delivery to avoid production delays.

Step 7: Establish Communication Channels

Finally, create effective communication channels with your chosen supplier. Establishing a reliable line of communication ensures that both parties can address issues or changes promptly.

- Regular Updates: Set up a schedule for regular updates on production progress.

- Crisis Management: Discuss procedures for addressing potential issues, such as delays or quality concerns.

By following this step-by-step checklist, international B2B buyers can effectively navigate the sourcing process for wire harness manufacturers, ensuring a partnership that meets their operational needs and standards.

Comprehensive Cost and Pricing Analysis for wire harnes manufacturer Sourcing

What Are the Key Cost Components in Wire Harness Manufacturing?

When sourcing wire harnesses, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials significantly impacts costs. Copper wiring, insulation, connectors, and other components must be carefully selected based on specifications. Premium materials may offer better performance but at a higher cost.

-

Labor: Labor costs vary by region and complexity of the manufacturing process. Skilled labor is essential for quality assembly, and regions with higher labor costs may reflect in the overall pricing.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and equipment depreciation. Efficient manufacturers often have lower overhead, enabling more competitive pricing.

-

Tooling: Initial tooling costs can be substantial, especially for custom harnesses. Buyers should inquire about these costs, as they can affect the overall price, particularly for low-volume orders.

-

Quality Control (QC): Robust QC processes ensure that products meet industry standards and specifications. While this may add to the upfront costs, it can prevent costly defects and recalls down the line.

-

Logistics: Shipping and handling costs must be factored into the total cost. International buyers should consider the implications of customs duties, taxes, and transportation modes.

-

Margin: Finally, the manufacturer’s margin will affect pricing. A higher margin may indicate a brand’s perceived value, but it’s essential to balance this with the quality and service provided.

How Do Price Influencers Affect Wire Harness Sourcing?

Several factors influence the pricing of wire harnesses, making it essential for buyers to understand their implications:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically result in lower per-unit costs. Understanding MOQ requirements can help buyers negotiate better pricing structures.

-

Specifications and Customization: Customized wire harnesses often come with additional costs. Buyers should clearly define specifications to avoid unexpected expenses and delays.

-

Materials and Quality Certifications: Higher-quality materials and certifications (such as ISO or UL) can increase costs but also enhance product reliability. Buyers must evaluate whether the investment aligns with their application needs.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can influence pricing. Engaging with reputable manufacturers can lead to better quality assurance and support.

-

Incoterms: The chosen Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms is crucial for budgeting total costs accurately.

What Are Effective Buyer Tips for Negotiating Wire Harness Prices?

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should consider several strategies to optimize their sourcing process:

-

Negotiate Effectively: Establish clear communication with suppliers regarding pricing expectations and requirements. Leverage volume commitments to negotiate better rates.

-

Focus on Cost-Efficiency: Analyze the total cost of ownership rather than just the purchase price. This includes considering durability, maintenance, and potential downtime costs associated with low-quality harnesses.

-

Understand Pricing Nuances for International Markets: Pricing can vary significantly by region due to factors such as currency fluctuations, tariffs, and local economic conditions. Buyers should stay informed about these dynamics to make cost-effective decisions.

-

Request Detailed Quotes: Ensure that quotes include a breakdown of all cost components. This transparency allows for more informed negotiations and comparisons between suppliers.

-

Consider Long-Term Partnerships: Building strong relationships with manufacturers can lead to favorable pricing and terms in future transactions. Regular communication and feedback can foster a collaborative environment.

Conclusion

While sourcing wire harnesses can be complex, understanding the cost components, pricing influencers, and effective negotiation strategies can empower international B2B buyers to make informed decisions. By focusing on total cost of ownership and cultivating strong supplier relationships, buyers can achieve better pricing and quality outcomes in their sourcing efforts. Remember, indicative prices may vary, so it’s essential to conduct thorough market research and engage with multiple suppliers before finalizing agreements.

Alternatives Analysis: Comparing wire harnes manufacturer With Other Solutions

When evaluating the options available for wiring solutions, it is crucial to consider various alternatives to traditional wire harness manufacturing. Each solution comes with its own set of advantages and disadvantages, depending on the specific needs of the business. This analysis will help B2B buyers understand the strengths and weaknesses of wire harness manufacturers compared to other viable solutions.

Comparison Table of Wire Harness Manufacturer and Alternatives

| Comparison Aspect | Wire Harness Manufacturer | Custom Cable Assembly | PCB (Printed Circuit Board) Design |

|---|---|---|---|

| Performance | High durability and reliability | Moderate to high, depending on design | High density and miniaturization capabilities |

| Cost | Generally higher due to customization | Variable, often lower than harnesses | Cost-effective for high-volume production |

| Ease of Implementation | Moderate complexity; requires skilled labor | Relatively easy, depending on design | High complexity; requires specialized knowledge |

| Maintenance | Low maintenance; durable components | Moderate; depends on assembly quality | Low maintenance, but difficult to repair |

| Best Use Case | Complex machinery and automotive applications | Short runs or specialized applications | Consumer electronics and compact devices |

What Are the Advantages and Disadvantages of Custom Cable Assembly?

Custom cable assemblies provide a flexible alternative to wire harnesses, allowing businesses to tailor solutions to their specific needs. One of the main advantages is the cost-effectiveness for shorter production runs. Additionally, these assemblies can be designed for specific applications, making them ideal for specialized machinery. However, they may lack the durability and reliability of wire harnesses, particularly in harsh environments, and can require more frequent maintenance.

How Does PCB Design Compare to Wire Harness Manufacturing?

Printed Circuit Boards (PCBs) offer an innovative solution for electronic connectivity, especially in compact devices. The high density of components allows for a significant reduction in size and weight, which is a critical factor for consumer electronics. While PCBs can be cost-effective for mass production, they require a high level of expertise for design and implementation. Additionally, once a PCB is damaged, repairs can be complicated and costly, which may not suit all industries.

Conclusion: How Should B2B Buyers Choose the Right Wiring Solution?

Selecting the right wiring solution depends on a variety of factors, including the specific application, budget constraints, and operational requirements. For businesses involved in complex machinery or automotive applications, wire harness manufacturing may be the most reliable option despite higher costs. On the other hand, companies looking for flexibility and lower costs for specialized applications may find custom cable assemblies to be a better fit. For industries focused on compactness and high-density applications, PCB design could be the ideal solution. Ultimately, B2B buyers should assess their unique needs, weigh the pros and cons of each alternative, and consult with industry experts to make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for wire harnes manufacturer

What Are the Key Technical Properties for Wire Harness Manufacturing?

Understanding the essential technical properties of wire harnesses is crucial for B2B buyers to ensure product quality, safety, and compliance. Here are several critical specifications to consider:

1. Material Grade

The material grade refers to the type of metals and plastics used in the manufacturing of wire harnesses. Common materials include copper for conductors and various thermoplastics for insulation. The choice of material impacts conductivity, durability, and resistance to environmental factors. For buyers, selecting the appropriate material grade is vital for ensuring the wire harness performs effectively in its intended application, especially in industries like automotive and aerospace.

2. Tolerance Levels

Tolerance levels indicate the acceptable limits of variation in the dimensions of the wire harness components. This specification is crucial for ensuring compatibility with other components in a system. High tolerance levels may be necessary for precision applications, while less stringent tolerances might suffice for simpler systems. Buyers should prioritize manufacturers that adhere to strict tolerance standards to minimize the risk of malfunction or failure in critical applications.

3. Temperature Rating

The temperature rating specifies the maximum and minimum temperatures at which the wire harness can operate effectively. This property is critical for applications exposed to extreme heat or cold. Understanding the temperature rating helps buyers select wire harnesses that maintain performance and safety standards under varying environmental conditions, particularly in industries such as oil and gas or renewable energy.

4. Electrical Rating

This specification defines the maximum voltage and current the wire harness can handle without risk of failure. Electrical ratings are essential for ensuring the wire harness can safely and efficiently transmit power. Buyers must consider the electrical rating to match the wire harness with the intended electrical load, preventing overheating and potential hazards.

5. Shielding Options

Shielding options refer to the additional protective layers that can be added to wire harnesses to reduce electromagnetic interference (EMI). This is particularly important in applications where signal integrity is paramount. Buyers should assess their specific needs for shielding to ensure optimal performance in sensitive electronic environments.

What Are Common Trade Terms in Wire Harness Manufacturing?

Familiarity with industry terminology can significantly enhance communication and negotiation with manufacturers. Here are some key trade terms every B2B buyer should know:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the wire harness industry, buyers often work with OEMs to ensure that components are specifically designed for their products. Understanding this term helps buyers identify reliable suppliers that can meet their unique specifications.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This is a critical consideration for B2B buyers, as it affects pricing and inventory management. Being aware of MOQs can help buyers negotiate better terms and optimize their purchasing strategies.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price proposals from suppliers for specific products or services. For wire harnesses, submitting an RFQ allows buyers to compare prices, lead times, and product specifications from multiple manufacturers, facilitating informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international trade terms that define the responsibilities of buyers and sellers in shipping and logistics. Understanding Incoterms is essential for buyers to clarify shipping costs, risk management, and delivery obligations. This knowledge ensures smoother transactions, especially in cross-border trade.

5. Lead Time

Lead time is the amount of time it takes from placing an order until the product is delivered. It is a crucial factor in supply chain management, impacting project timelines and inventory levels. Buyers should inquire about lead times during negotiations to ensure that their production schedules are not disrupted.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions that enhance the efficiency and reliability of their wire harness supply chain.

Navigating Market Dynamics and Sourcing Trends in the wire harnes manufacturer Sector

What Are the Current Market Dynamics and Key Trends in the Wire Harness Manufacturing Sector?

The wire harness manufacturing sector is experiencing dynamic growth, driven by several global factors. As industries increasingly shift towards automation and electrification, there is a growing demand for sophisticated wire harnesses that support advanced technologies in automotive, aerospace, and industrial applications. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding these market dynamics is crucial for effective sourcing.

Emerging technologies such as Industry 4.0, IoT, and AI are reshaping sourcing strategies. Buyers are now seeking manufacturers that leverage these technologies to enhance production efficiency and product quality. Additionally, the rise of digital platforms for B2B transactions is facilitating easier access to suppliers, enabling buyers to compare pricing and capabilities across different regions. This trend is particularly pronounced in Europe and the Middle East, where digital transformation is rapidly advancing.

Another key trend is the focus on customized solutions. As industries demand more specialized wire harnesses tailored to their unique requirements, buyers should look for manufacturers that offer flexible production capabilities. This adaptability can lead to shorter lead times and reduced costs, making it an attractive option for companies in fast-paced markets.

How Is Sustainability Influencing Sourcing Decisions in the Wire Harness Manufacturing Sector?

Sustainability is becoming a critical consideration for B2B buyers in the wire harness manufacturing sector. The environmental impact of production processes is under scrutiny, prompting companies to prioritize ethical sourcing and sustainable practices. Buyers must consider manufacturers that not only comply with local regulations but also adhere to international sustainability standards.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly aware of the implications of their sourcing decisions on communities and ecosystems. Therefore, selecting manufacturers that demonstrate a commitment to fair labor practices and environmentally responsible production methods is essential.

Moreover, the use of ‘green’ certifications and materials is gaining traction in the industry. Buyers should look for manufacturers that utilize recyclable materials or eco-friendly manufacturing processes. Certifications such as ISO 14001 can serve as indicators of a manufacturer’s commitment to sustainability. By prioritizing these factors, international buyers can not only contribute to environmental preservation but also enhance their brand reputation in an increasingly eco-conscious marketplace.

How Has the Wire Harness Manufacturing Sector Evolved Over Time?

The evolution of the wire harness manufacturing sector reflects broader technological advancements and changing market demands. Initially focused on basic electrical connections, the sector has transformed into a sophisticated field where manufacturers develop complex harnesses integrated with advanced electronics. This evolution has been fueled by the increasing complexity of modern vehicles and machinery, requiring more intricate wiring solutions.

In recent years, the proliferation of electric vehicles (EVs) has significantly impacted the sector, necessitating the development of specialized wire harnesses that can handle higher voltages and enhanced functionalities. This shift not only influences design and manufacturing processes but also drives innovation in materials and sustainability practices. As a result, international B2B buyers are presented with a wealth of opportunities to source high-quality, innovative wire harness solutions tailored to the demands of the modern marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of wire harnes manufacturer

-

How do I choose the right wire harness manufacturer for my needs?

Selecting the right wire harness manufacturer involves evaluating their industry experience, production capabilities, and quality certifications. Start by researching their portfolio and client testimonials. Consider their ability to customize products to meet your specific requirements, such as materials and design specifications. Additionally, assess their production capacity to ensure they can meet your order volume and timelines. Engaging in direct communication with potential suppliers can also help clarify their commitment to quality and customer service. -

What are the key factors to consider when vetting a wire harness supplier?

When vetting a wire harness supplier, focus on their experience in your industry, manufacturing standards, and quality assurance processes. Check for relevant certifications, such as ISO 9001, which indicate adherence to international quality management standards. It’s also crucial to inquire about their supply chain reliability, lead times, and customer support services. Requesting samples or prototypes can provide insights into their product quality and compatibility with your needs. -

What customization options should I look for in wire harness manufacturers?

Customization options can significantly impact the performance and integration of wire harnesses in your applications. Look for manufacturers that offer flexible design capabilities, including variations in wire gauge, insulation types, and connector options. It’s also beneficial if they can accommodate specific lengths, colors, and labeling requirements. Collaborating with manufacturers during the design phase can ensure that the wire harness meets your unique specifications and operational needs. -

What is the minimum order quantity (MOQ) for wire harnesses, and how does it vary by supplier?

Minimum order quantities (MOQs) for wire harnesses can vary widely among manufacturers, typically ranging from a few dozen to several thousand units. Factors influencing MOQ include the complexity of the harness, production costs, and the supplier’s capacity. For international buyers, it’s essential to clarify MOQs upfront to avoid potential supply chain disruptions. Some manufacturers may offer lower MOQs for custom designs, so negotiating terms based on your specific project requirements can be beneficial. -

What payment terms should I expect when sourcing wire harnesses internationally?

Payment terms can vary based on the manufacturer’s policies and the nature of the transaction. Common options include upfront payment, partial payment upon order confirmation, and payment upon delivery. International buyers should also consider using secure payment methods such as letters of credit or escrow services to mitigate risks. It’s advisable to discuss payment terms in detail during negotiations to ensure clarity and avoid future disputes. -

How do I ensure quality assurance when purchasing wire harnesses?

To ensure quality assurance, inquire about the manufacturer’s quality control processes and certifications. Request documentation of their testing methods, including electrical continuity and insulation resistance tests. Additionally, consider conducting factory visits or audits to observe their production practices firsthand. Establishing a clear agreement on quality standards in your purchase contract can also help safeguard against defects and ensure compliance with your specifications. -

What logistics considerations should I keep in mind when importing wire harnesses?

When importing wire harnesses, consider shipping methods, customs regulations, and potential tariffs or duties. Choose a reliable logistics partner experienced in international shipping to facilitate the process. Understanding the lead times for production and delivery is crucial for effective inventory management. Additionally, ensure that the manufacturer provides proper documentation, including invoices and certificates of origin, to streamline customs clearance. -

How can I build a long-term relationship with my wire harness supplier?

Building a long-term relationship with your wire harness supplier involves open communication, regular feedback, and mutual trust. Engage in regular discussions about performance, quality, and potential improvements. Establishing joint development projects can foster collaboration and innovation. Additionally, consider placing repeat orders or larger volumes over time, as this can lead to better pricing and priority service, benefiting both parties in the long run.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for wire harnes manufacturer

What Are the Key Takeaways for International B2B Buyers in Wire Harness Manufacturing?

Strategic sourcing in wire harness manufacturing is vital for optimizing supply chains and enhancing competitiveness. Buyers should prioritize suppliers that demonstrate flexibility, innovation, and robust quality control measures. Establishing long-term partnerships with manufacturers who understand regional market dynamics can lead to significant cost savings and improved product reliability.

How Can Strategic Sourcing Enhance Your Competitive Edge?

Investing in strategic sourcing not only streamlines procurement processes but also fosters collaboration, driving efficiencies across the board. Buyers from Africa, South America, the Middle East, and Europe can leverage regional advantages by sourcing locally where possible, reducing lead times and fostering sustainability. Additionally, engaging with manufacturers who embrace the latest technologies can offer cutting-edge solutions that cater to evolving industry needs.

What Should International B2B Buyers Consider Moving Forward?

As the wire harness industry continues to evolve, staying informed about market trends and technological advancements is crucial. Buyers are encouraged to take proactive steps in assessing their sourcing strategies, focusing on building resilient supply chains that can adapt to changing market conditions. By prioritizing strategic partnerships and innovative solutions, international B2B buyers can position themselves for success in the competitive landscape of wire harness manufacturing. Embrace these insights and initiate discussions with potential suppliers today to secure a prosperous future in your sourcing endeavors.