Discover Cost-Saving Tips from Top Fire Hydrant Suppliers (2025)

Introduction: Navigating the Global Market for fire hydrant supplier

In today’s global market, sourcing reliable fire hydrant suppliers poses a significant challenge for B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe. The need for high-quality fire hydrants is paramount for ensuring public safety and compliance with local regulations, yet navigating the complexities of supplier selection can be daunting. This comprehensive guide is designed to empower international B2B buyers by offering valuable insights into the various types of fire hydrants, their applications, and critical factors to consider when vetting suppliers.

From understanding the nuances of different fire hydrant designs to evaluating supplier credentials, this guide covers essential aspects that influence purchasing decisions. Buyers will learn about the importance of certifications, the implications of local regulations, and how to assess the total cost of ownership—including installation and maintenance. Additionally, we delve into sourcing strategies tailored for diverse markets, ensuring that buyers from Nigeria, Brazil, and beyond can make informed choices that align with their specific needs.

Ultimately, this guide serves as a roadmap for international B2B buyers seeking to streamline their procurement processes and secure the best fire hydrant solutions for their projects. By equipping decision-makers with actionable insights, we aim to facilitate smoother transactions and foster long-lasting supplier relationships in the global marketplace.

Understanding fire hydrant supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Hydrant | Standard design, often made of ductile iron | Urban infrastructure, fire safety | Pros: Widely available, reliable; Cons: Heavy, can be costly to install. |

| Dry Barrel Hydrant | Valve located below ground, prevents freezing | Cold climates, rural areas | Pros: Freeze protection; Cons: More complex installation. |

| Wet Barrel Hydrant | Valve located above ground, always filled with water | Warm climates, urban settings | Pros: Immediate water availability; Cons: Risk of freezing in cold weather. |

| High-Pressure Hydrant | Designed for high flow rates, often with larger outlets | Industrial zones, high-demand areas | Pros: Efficient for large fires; Cons: Higher initial cost. |

| Smart Hydrant | Equipped with sensors for monitoring and data collection | Smart cities, advanced fire safety | Pros: Real-time data, enhances safety; Cons: More expensive, requires tech support. |

What Are the Characteristics of Traditional Hydrants?

Traditional fire hydrants are commonly made of ductile iron and feature a standard design used in urban infrastructure. They are recognized for their reliability and ease of access for firefighters. These hydrants are suitable for various B2B applications, particularly in cities where fire safety regulations mandate their installation. When purchasing, buyers should consider factors such as installation costs, maintenance requirements, and the availability of replacement parts.

How Do Dry Barrel Hydrants Operate?

Dry barrel hydrants are designed with valves located below ground, preventing water from freezing in colder climates. This feature makes them ideal for rural areas and regions with harsh winters. Buyers should evaluate the installation complexity and potential costs associated with excavation and maintenance. While they offer significant advantages in frost-prone areas, their installation can be more complex compared to traditional hydrants.

What Are the Benefits of Wet Barrel Hydrants?

Wet barrel hydrants have their valves located above ground, keeping them constantly filled with water. This design provides immediate access to water, making them particularly suitable for warm climates and urban settings. B2B buyers should weigh the benefits of immediate water availability against the risks of freezing in colder regions. Understanding local climate conditions is crucial when deciding on this type.

What Are High-Pressure Hydrants and Their Applications?

High-pressure hydrants are engineered for high flow rates and feature larger outlets to accommodate greater water demands. These hydrants are essential in industrial zones and areas prone to large-scale fires. Buyers should consider the initial investment and ongoing maintenance costs, as these hydrants typically come with a higher price tag. Their efficiency in fighting large fires can justify the expense in high-demand applications.

What Makes Smart Hydrants Innovative?

Smart hydrants are equipped with sensors that monitor pressure, flow, and even environmental conditions. These advanced systems are becoming increasingly popular in smart cities and for enhancing fire safety measures. While they offer significant benefits in terms of real-time data collection and monitoring, buyers must be prepared for a higher upfront cost and the need for ongoing technical support. It’s essential to evaluate the long-term benefits against the initial investment when considering smart hydrants.

Related Video: Fire Hydrant System | Types of Fire Hydrants | Fire Hydrant Components | Fire Hydrant Colour Coding

Key Industrial Applications of fire hydrant supplier

| Industry/Sector | Specific Application of fire hydrant supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Fire hydrants for site safety | Ensures compliance with safety regulations | Quality certifications, local regulations |

| Oil & Gas | Fire hydrants in refineries | Rapid response to fire hazards | Durability in extreme conditions, maintenance support |

| Municipal Services | Urban fire protection systems | Protects public safety and property | Compatibility with local infrastructure, service agreements |

| Industrial Manufacturing | Fire hydrants in factories | Minimizes downtime and potential losses | Customization for specific industrial needs |

| Hospitality | Fire hydrants in hotels and resorts | Enhances guest safety and liability protection | Aesthetic integration, local fire codes compliance |

How Are Fire Hydrant Suppliers Used in the Construction Industry?

In the construction sector, fire hydrants are critical for ensuring site safety. They provide immediate access to water in the event of a fire, which is essential for compliance with local fire safety regulations. International buyers must consider local regulations and the specific needs of their construction sites, ensuring that the hydrants meet quality certifications and can withstand the environmental conditions of the region, especially in areas prone to extreme weather.

What Role Do Fire Hydrants Play in the Oil & Gas Industry?

Within the oil and gas industry, fire hydrants are vital for rapid fire response at refineries, where flammable materials are prevalent. Their presence minimizes the risk of catastrophic incidents and enhances overall safety protocols. Buyers in this sector should focus on sourcing hydrants that are durable and able to function effectively under extreme conditions, as well as ensuring they have access to maintenance support to keep systems operational.

How Do Municipal Services Utilize Fire Hydrant Suppliers?

Municipal services utilize fire hydrants as part of their urban fire protection systems. These systems are crucial for protecting public safety and minimizing property damage during emergencies. When sourcing hydrants, municipalities must ensure compatibility with existing infrastructure and consider service agreements for maintenance and repair. Additionally, they should evaluate the hydrants’ ease of access and visibility for firefighters during emergencies.

Why Are Fire Hydrants Important in Industrial Manufacturing?

In industrial manufacturing, fire hydrants play a significant role in minimizing downtime and potential losses due to fire hazards. They provide a reliable source of water for firefighting, which is essential in facilities that handle flammable materials. International buyers should seek out hydrants that can be customized to meet specific industrial needs, taking into account the unique risks associated with their operations and the regulatory requirements in their regions.

How Do Fire Hydrant Suppliers Contribute to Safety in the Hospitality Sector?

In the hospitality industry, fire hydrants contribute to guest safety and liability protection. Hotels and resorts must ensure that their fire safety measures are robust and compliant with local fire codes. When sourcing fire hydrants, buyers should consider not only the functional aspects but also how these systems can be aesthetically integrated into the property. Compliance with local regulations is essential to avoid legal liabilities while enhancing the overall safety of the establishment.

Related Video: Fire Hydrant Replacement

3 Common User Pain Points for ‘fire hydrant supplier’ & Their Solutions

Scenario 1: Navigating Quality and Compliance Standards in Fire Hydrants

The Problem: B2B buyers in regions like Africa and South America often face challenges in ensuring that fire hydrants meet local and international quality and compliance standards. This is particularly pressing in countries where regulations may vary widely or are under constant revision. Buyers may find it difficult to ascertain whether a supplier’s products comply with the necessary fire safety standards, which can lead to legal liabilities, safety risks, and increased costs for non-compliance.

The Solution: To effectively navigate this challenge, B2B buyers should prioritize suppliers who provide transparent documentation regarding compliance with local and international standards such as ISO or NFPA. It’s advisable to request certifications and test reports for each product before purchasing. Establishing a relationship with suppliers that offer on-site audits or third-party testing can further assure the quality and reliability of the fire hydrants. Additionally, engaging local industry experts or consultants familiar with the regulatory landscape can provide valuable insights and help to ensure that all products meet the required safety criteria.

Scenario 2: Managing Supply Chain Disruptions for Fire Hydrant Procurement

The Problem: International buyers frequently experience supply chain disruptions due to geopolitical factors, natural disasters, or global pandemics. Such disruptions can delay the delivery of critical fire safety equipment, leading to project delays and potential safety hazards. This is especially significant in developing regions where infrastructure may already be strained, and timely access to safety equipment is crucial.

The Solution: To mitigate supply chain risks, buyers should develop a diversified sourcing strategy by establishing relationships with multiple suppliers across different regions. This not only spreads risk but also allows for flexibility in case one supplier faces disruptions. Implementing a just-in-time (JIT) inventory system can help manage stock levels and reduce the impact of delays. Additionally, incorporating technology such as supply chain management software can provide real-time insights into shipment statuses and inventory levels, allowing buyers to make informed decisions quickly. Building strong communication channels with suppliers and logistics partners is essential for rapid response during disruptions.

Scenario 3: Understanding the Total Cost of Ownership for Fire Hydrants

The Problem: Many B2B buyers underestimate the total cost of ownership (TCO) associated with fire hydrants, leading to budget overruns and unexpected expenses over the product’s lifecycle. The initial purchase price is only one component; maintenance, installation, and potential operational inefficiencies can significantly increase overall costs. This is particularly true in regions where maintenance services might be limited or expensive.

The Solution: To address this issue, buyers should conduct a comprehensive cost analysis that includes not just the purchase price but also installation, maintenance, and operational costs over the expected lifespan of the hydrants. It is beneficial to engage with suppliers who offer maintenance services or warranties as part of the purchase agreement. Buyers should also consider investing in training for local staff on proper maintenance and operation of fire hydrants to minimize long-term costs. Utilizing tools like lifecycle cost analysis can help provide a clearer picture of TCO, allowing for more informed purchasing decisions that align with budget constraints and operational needs.

Strategic Material Selection Guide for fire hydrant supplier

When selecting materials for fire hydrants, international B2B buyers must consider various factors that influence performance, durability, and compliance with regional standards. The following analysis explores four common materials used in fire hydrant manufacturing: ductile iron, stainless steel, brass, and plastic composites. Each material’s properties, advantages, disadvantages, and applicability to specific markets are discussed to aid buyers in making informed decisions.

What Are the Key Properties of Ductile Iron for Fire Hydrants?

Ductile iron is a popular choice for fire hydrants due to its excellent mechanical properties. It boasts high tensile strength, allowing it to withstand significant pressure and temperature variations. Additionally, ductile iron exhibits good corrosion resistance when properly coated, making it suitable for various environments, including urban and rural settings.

Pros and Cons of Ductile Iron

The primary advantage of ductile iron is its durability, which leads to a long service life and reduced maintenance costs. However, it can be heavier than other materials, which may complicate installation and transportation. The manufacturing complexity is moderate, as ductile iron requires casting and finishing processes.

Impact on Application

Ductile iron hydrants are compatible with water and other non-corrosive media, making them ideal for municipal water systems. Buyers in regions with strict compliance requirements, such as Europe, should ensure that the products meet standards like EN 14339.

How Does Stainless Steel Compare in Fire Hydrant Applications?

Stainless steel is renowned for its exceptional corrosion resistance and aesthetic appeal, making it suitable for environments where exposure to harsh chemicals or saline conditions is a concern. It can withstand high temperatures and pressures, which is crucial for fire hydrant applications.

Pros and Cons of Stainless Steel

The key advantage of stainless steel is its longevity and low maintenance requirements due to its resistance to rust and corrosion. However, it tends to be more expensive than ductile iron and may require specialized welding techniques during manufacturing, increasing complexity.

Impact on Application

Stainless steel hydrants are particularly beneficial in coastal regions or areas with high humidity, where corrosion is a significant risk. Buyers from South America and the Middle East should look for compliance with ASTM standards to ensure quality and performance.

What Are the Benefits of Using Brass in Fire Hydrant Manufacturing?

Brass is often used in smaller components of fire hydrants, such as valves and fittings, due to its excellent machinability and resistance to corrosion. It has a good pressure rating and can handle moderate temperature variations, making it suitable for various applications.

Pros and Cons of Brass

Brass hydrants are relatively lightweight and easy to install, which is a significant advantage for smaller systems. However, brass can be more susceptible to dezincification, especially in corrosive environments, which may limit its use in certain applications.

Impact on Application

Brass is compatible with water and other non-corrosive fluids, but its use in regions with aggressive water chemistry should be approached with caution. Compliance with JIS standards is essential for buyers in Asia and Africa to ensure product reliability.

What Role Do Plastic Composites Play in Fire Hydrant Design?

Plastic composites are emerging as a viable alternative in fire hydrant design, particularly for non-pressurized applications. They are lightweight, resistant to corrosion, and can be molded into various shapes, offering design flexibility.

Pros and Cons of Plastic Composites

The primary advantage of plastic composites is their low weight and ease of installation, which can significantly reduce labor costs. However, they may not withstand high pressures as effectively as metal options, limiting their use in certain scenarios.

Impact on Application

Plastic hydrants are suitable for temporary installations or areas where weight is a concern. Buyers should ensure that products meet local standards, as acceptance varies widely across regions like Africa and South America.

Summary Table of Material Selection for Fire Hydrant Suppliers

| Material | Typical Use Case for fire hydrant supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Ductile Iron | Municipal water systems | High durability and strength | Heavier, complicates installation | Medium |

| Stainless Steel | Coastal and high-humidity areas | Excellent corrosion resistance | Higher cost, complex manufacturing | High |

| Brass | Valves and fittings | Good machinability and lightweight | Susceptible to dezincification | Medium |

| Plastic Composites | Temporary installations or low-pressure systems | Lightweight and easy to install | Limited pressure resistance | Low |

This guide provides a comprehensive overview of material options for fire hydrants, enabling international B2B buyers to make informed decisions based on their specific regional needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for fire hydrant supplier

What Are the Typical Manufacturing Processes for Fire Hydrants?

Fire hydrant manufacturing involves a series of critical stages designed to ensure the product meets safety and reliability standards. Understanding these processes is essential for B2B buyers, especially when sourcing from diverse regions such as Africa, South America, the Middle East, and Europe.

What Are the Main Stages of Fire Hydrant Manufacturing?

-

Material Preparation

– Raw Materials: The primary materials used in fire hydrant production include ductile iron, aluminum, and various alloys. These materials are chosen for their strength, corrosion resistance, and durability.

– Material Treatment: Before forming, materials undergo treatments like heat treatment to enhance mechanical properties and surface coating processes to improve corrosion resistance. -

Forming Techniques

– Casting: The most common method for creating fire hydrant bodies. Molten metal is poured into molds to form the desired shape. This process allows for complex designs and ensures uniform thickness.

– Machining: Post-casting, components are machined to achieve precise dimensions. This includes drilling, milling, and threading, which are crucial for ensuring that parts fit together accurately. -

Assembly Process

– Component Integration: Hydrant components, such as the valve, bonnet, and nozzle, are assembled. Each component must be carefully inspected for defects before assembly to maintain quality.

– Sealing and Testing: Seals are installed to ensure water-tight integrity. Following assembly, the hydrant is tested for functionality and leaks under simulated pressure conditions. -

Finishing Techniques

– Surface Treatment: Final surface treatments, such as powder coating or painting, are applied to enhance aesthetics and provide additional protection against environmental factors.

– Quality Control Checks: Each hydrant undergoes a final inspection to ensure it meets all specifications and safety standards before shipment.

How Is Quality Assurance Implemented in Fire Hydrant Production?

Quality assurance (QA) is integral to the manufacturing process of fire hydrants. It ensures that the products meet international standards and customer specifications, which is particularly important for international B2B buyers.

What International Standards Are Relevant to Fire Hydrant Manufacturing?

-

ISO 9001 Certification

– This standard focuses on quality management systems and is applicable across industries. Suppliers with ISO 9001 certification demonstrate their commitment to quality and customer satisfaction. -

Industry-Specific Standards

– CE Marking: Required for products sold in the European Economic Area (EEA), indicating compliance with safety standards.

– API Standards: The American Petroleum Institute offers guidelines that can be relevant for hydrants used in industrial settings.

What Are the Key Quality Control Checkpoints During Manufacturing?

To maintain high-quality output, several quality control checkpoints are established throughout the manufacturing process:

-

Incoming Quality Control (IQC)

– Raw materials are inspected upon arrival to ensure they meet specified standards. This step prevents defective materials from entering the production line. -

In-Process Quality Control (IPQC)

– Ongoing inspections are conducted during the manufacturing stages. This includes monitoring the casting process, machining tolerances, and assembly accuracy to catch any issues early. -

Final Quality Control (FQC)

– A thorough inspection is performed on the finished product. This includes testing for functional performance, pressure tests, and visual inspections for defects.

What Common Testing Methods Are Used for Fire Hydrants?

Testing is a critical aspect of quality assurance in fire hydrant manufacturing. Common methods include:

- Hydrostatic Testing: Ensures the hydrant can withstand high pressure without leaking.

- Functional Testing: Verifies that all moving parts operate correctly, including the opening and closing of valves.

- Corrosion Testing: Assesses the durability of surface coatings against environmental factors.

How Can B2B Buyers Verify Supplier Quality Control?

International B2B buyers must take proactive steps to verify a supplier’s quality control processes:

-

Conduct Supplier Audits

– Regular audits of the manufacturing facilities can provide insights into the quality systems in place and adherence to standards. -

Request Quality Assurance Reports

– Suppliers should provide detailed reports on quality control procedures, inspection results, and compliance with international standards. -

Utilize Third-Party Inspection Services

– Engaging third-party inspectors can offer an unbiased assessment of product quality before shipment, which is especially important for buyers in Africa, South America, the Middle East, and Europe.

What Are the Quality Control Nuances for International Buyers?

For international B2B buyers, particularly those in emerging markets, there are specific nuances to consider:

- Cultural and Regulatory Differences: Understanding the local regulations and cultural practices around quality assurance can help in assessing supplier capabilities.

- Language Barriers: Clear communication is essential. Ensure that documentation and quality reports are available in a language that is easily understood by all stakeholders.

- Logistical Considerations: Quality checks should also account for shipping and handling practices that may affect product integrity during transit.

Conclusion: Ensuring Quality in Fire Hydrant Procurement

Navigating the manufacturing processes and quality assurance landscape of fire hydrants is vital for B2B buyers. By understanding the stages of production, relevant international standards, and effective quality control measures, buyers can make informed decisions and ensure they are sourcing reliable and compliant products for their needs. This knowledge not only enhances procurement strategies but also contributes to overall safety and efficiency in fire protection systems across various regions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fire hydrant supplier’

This practical sourcing guide is designed to assist international B2B buyers in identifying and procuring fire hydrant suppliers effectively. Given the importance of fire safety in urban planning and infrastructure, having reliable suppliers is crucial for both compliance and safety. Follow these steps to ensure a successful sourcing process.

Step 1: Define Your Technical Specifications

Clearly outline the technical specifications for the fire hydrants you need. This includes size, material, pressure ratings, and any specific standards your project requires. By having detailed specifications, you can ensure that suppliers provide products that meet your operational needs and regulatory compliance.

- Industry Standards: Familiarize yourself with local and international standards such as NFPA (National Fire Protection Association) or ISO certifications that apply to fire hydrants.

- Customization Needs: Determine if you require customized solutions for unique environmental conditions or specific fire safety requirements.

Step 2: Research Potential Suppliers

Conduct comprehensive research to identify potential suppliers. Utilize online platforms, industry directories, and trade shows to compile a list of candidates. This step is crucial for building a network of suppliers that can meet your needs.

- Industry Reputation: Look for suppliers with a strong industry reputation, as this often correlates with quality and reliability.

- Geographical Considerations: Consider suppliers from regions known for their manufacturing excellence in fire safety equipment, such as Europe and North America.

Step 3: Evaluate Supplier Credentials

Before making any commitments, thoroughly evaluate each supplier’s credentials. This includes checking certifications, past projects, and customer reviews. A well-credentialed supplier is more likely to deliver quality products and services.

- Certifications: Verify that suppliers hold relevant certifications, such as ISO 9001 for quality management systems.

- References and Case Studies: Request references or case studies from similar projects to gauge the supplier’s capability and reliability.

Step 4: Request and Analyze Quotations

Once you have shortlisted potential suppliers, request detailed quotations. Analyze these quotes not just for price but also for terms of service, delivery timelines, and payment conditions. This will help you make an informed decision.

- Price Breakdown: Ensure that the quotation includes a detailed price breakdown to avoid hidden costs.

- Lead Times: Inquire about lead times for delivery, as this can significantly impact your project schedule.

Step 5: Conduct Site Visits

If possible, conduct site visits to the suppliers’ manufacturing facilities. This allows you to assess their production capabilities, quality control processes, and working conditions firsthand.

- Quality Assurance Processes: Observe the quality assurance measures they have in place to ensure product reliability.

- Operational Efficiency: Evaluate their operational efficiency and ability to scale production if your demand increases.

Step 6: Negotiate Terms and Conditions

Once you have selected a preferred supplier, engage in negotiations to finalize terms and conditions. This includes pricing, delivery schedules, payment terms, and warranty agreements. Effective negotiation can lead to better pricing and service terms.

- Flexibility: Assess the supplier’s flexibility in terms of adjusting orders or accommodating changes in your project.

- Long-term Relationship: Consider the potential for a long-term partnership and how that may influence negotiations.

Step 7: Finalize the Agreement

After successful negotiations, finalize the agreement with the chosen supplier. Ensure that all terms are clearly documented and understood by both parties. This contract will serve as a framework for your business relationship.

- Legal Review: Have a legal professional review the contract to ensure compliance with local laws and regulations.

- Performance Metrics: Include performance metrics and penalties for non-compliance to safeguard your interests.

By following these steps, B2B buyers can streamline their sourcing process for fire hydrant suppliers, ensuring quality, compliance, and reliability in their procurement decisions.

Comprehensive Cost and Pricing Analysis for fire hydrant supplier Sourcing

What Are the Key Cost Components for Sourcing Fire Hydrants?

When sourcing fire hydrants, understanding the cost structure is crucial for making informed decisions. The primary components of the cost include:

-

Materials: The choice of materials significantly impacts pricing. Common materials used in fire hydrants include ductile iron, bronze, and plastic components. The quality and source of these materials can lead to variations in cost.

-

Labor: Labor costs are affected by the region of production. Countries with lower labor costs may offer more competitive pricing, but this can also lead to concerns about quality and compliance with international standards.

-

Manufacturing Overhead: This encompasses indirect costs related to production, including utilities, rent, and equipment depreciation. Efficient manufacturing processes can help reduce these costs.

-

Tooling: Customization of fire hydrants may require specialized tooling, which adds to the initial investment but can lead to long-term savings through optimized production runs.

-

Quality Control (QC): Implementing rigorous QC measures ensures that the hydrants meet safety standards and specifications. This can increase costs but is essential for reliability and compliance.

-

Logistics: Shipping costs, import duties, and handling fees must be considered, especially when sourcing from international suppliers. The choice of transportation method can also affect overall costs.

-

Margin: Supplier profit margins can vary widely based on market conditions and competition. Understanding this can help buyers gauge the fairness of the quoted prices.

How Do Pricing Influencers Affect Fire Hydrant Costs?

Several factors can influence the pricing of fire hydrants:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes typically lead to lower per-unit costs due to economies of scale. Buyers should negotiate terms that align with their needs.

-

Specifications and Customization: Tailored hydrants designed to meet specific requirements may incur additional costs. Buyers should assess whether the benefits of customization outweigh the price increase.

-

Material Quality and Certifications: Hydrants that comply with international standards (e.g., UL, FM) often come at a premium. Ensuring that the supplier can provide necessary certifications is critical for safety and reliability.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a proven track record may charge more but offer better quality assurance.

-

Incoterms: Understanding Incoterms is essential for determining who bears the costs and risks at different stages of transportation. This knowledge helps buyers avoid unexpected expenses.

What Buyer Tips Can Help Negotiate Better Prices for Fire Hydrants?

When negotiating prices for fire hydrants, international B2B buyers can leverage several strategies to achieve cost efficiency:

-

Conduct a Total Cost of Ownership (TCO) Analysis: This goes beyond the purchase price to include installation, maintenance, and operational costs. A thorough TCO analysis can help justify higher initial costs if they lead to long-term savings.

-

Understand Pricing Nuances for International Transactions: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import tariffs, and local regulations that can affect pricing.

-

Establish Strong Relationships with Suppliers: Building rapport with suppliers can lead to better pricing and favorable terms. Long-term partnerships often yield discounts and priority during production.

-

Negotiate Payment Terms: Flexible payment options, such as deferred payments or financing, can alleviate cash flow issues and make purchasing more manageable.

-

Request Multiple Quotes: Obtaining quotes from several suppliers can provide insights into market pricing and help identify the best value for money.

Disclaimer on Indicative Prices

Pricing for fire hydrants can fluctuate based on market conditions, production costs, and other external factors. The figures mentioned in this analysis are indicative and should not be seen as fixed. Always consult with suppliers for current pricing tailored to your specific requirements.

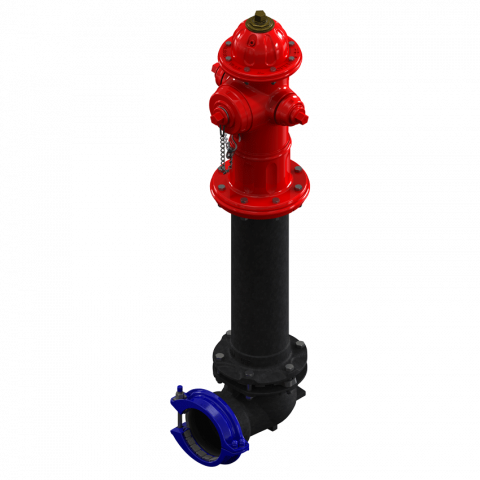

A stock image related to fire hydrant supplier.

Alternatives Analysis: Comparing fire hydrant supplier With Other Solutions

Understanding the Alternatives to Fire Hydrant Suppliers

In the search for effective fire protection solutions, international B2B buyers must consider various options beyond traditional fire hydrant suppliers. The right choice can significantly impact safety, compliance, and cost-efficiency. This section compares fire hydrants with alternative solutions, helping buyers make informed decisions tailored to their specific needs.

Comparison Table of Fire Protection Solutions

| Comparison Aspect | Fire Hydrant Supplier | Alternative 1: Fire Suppression Systems | Alternative 2: Water Mist Systems |

|---|---|---|---|

| Performance | High reliability for immediate access to water in emergencies. | Effective for rapid extinguishment; suitable for various fire types. | Efficient for cooling and extinguishing fires with less water usage. |

| Cost | Moderate initial investment; ongoing maintenance costs. | Higher upfront costs; potential savings in water and damage reduction. | Moderate costs; savings on water usage and reduced damage. |

| Ease of Implementation | Requires proper planning and installation; needs to meet local codes. | Complex installation; may require specialized contractors. | Easier to install in certain settings; can be retrofitted in existing structures. |

| Maintenance | Regular inspections and maintenance required; easy to service. | Requires specialized maintenance; may have higher service costs. | Low maintenance; system checks are straightforward. |

| Best Use Case | Ideal for urban areas with high water pressure; essential for firefighting. | Best for industrial settings and high-risk areas; effective in enclosed spaces. | Suitable for museums, data centers, and areas sensitive to water damage. |

Detailed Breakdown of Alternatives

What Are Fire Suppression Systems and Their Advantages?

Fire suppression systems, such as foam or gas-based systems, are designed to extinguish fires quickly. They are particularly effective in commercial and industrial environments where high-value assets are at risk. The primary advantage is their ability to suppress fires without causing extensive water damage. However, the initial installation costs can be significant, and they often require specialized contractors for setup and maintenance.

How Do Water Mist Systems Compare in Efficiency?

Water mist systems use fine water droplets to cool and extinguish fires while minimizing water usage. These systems are particularly advantageous in environments where water damage is a concern, such as historical buildings or data centers. They are easier to install than traditional systems, making them a practical alternative for retrofitting. However, they may not be as effective in all fire scenarios, particularly those involving flammable liquids.

How Can B2B Buyers Choose the Right Fire Protection Solution?

Selecting the right fire protection solution involves assessing the specific needs of your facility, considering factors such as fire risk, budget, and the physical environment. Buyers should weigh the pros and cons of each option, focusing on performance, cost, and maintenance requirements. Additionally, engaging with suppliers who offer comprehensive services, including installation and ongoing support, can enhance the decision-making process.

In conclusion, while traditional fire hydrant suppliers provide essential services for fire safety, exploring alternatives like fire suppression and water mist systems can offer tailored solutions for diverse environments. By understanding the strengths and weaknesses of each option, international B2B buyers can make more strategic investments in fire safety.

Essential Technical Properties and Trade Terminology for fire hydrant supplier

What Are the Essential Technical Properties of Fire Hydrants?

Understanding the technical properties of fire hydrants is crucial for B2B buyers to ensure they procure the right products for their specific needs. Here are some key specifications to consider:

1. Material Grade: Why Is It Important?

Fire hydrants are primarily made from materials such as ductile iron, bronze, or stainless steel. The material grade affects the hydrant’s durability, resistance to corrosion, and overall lifespan. For instance, ductile iron offers high tensile strength, making it suitable for areas with heavy traffic or harsh weather conditions. Buyers should assess local environmental factors to choose the appropriate material.

2. Hydraulic Performance: What Should Buyers Look For?

Hydraulic performance is measured in terms of flow rate and pressure. It is essential to ensure that the hydrant can deliver adequate water flow (typically measured in gallons per minute) to combat fires effectively. Buyers must consider the specific fire-fighting requirements in their region, as different locations may have varying standards.

3. Tolerance Levels: How Do They Affect Installation?

Tolerance levels refer to the permissible limits of variation in the dimensions of the hydrant components. Proper tolerances are critical for ensuring that hydrants fit seamlessly into existing water supply systems. Incorrect tolerances can lead to leaks or operational failures, which can be detrimental during emergencies. Buyers should verify that suppliers adhere to industry standards for manufacturing tolerances.

4. Operating Temperature Range: Why Is It Critical?

Fire hydrants must be capable of functioning under a wide range of temperatures, especially in regions experiencing extreme weather. The operating temperature range affects the hydrant’s ability to withstand freezing or overheating, which can impair its functionality. Buyers should ensure that the hydrants they purchase are rated for the specific climatic conditions of their region.

5. Coating and Finishing: What Are the Benefits?

The coating and finishing processes protect fire hydrants from corrosion and environmental damage. Common coatings include epoxy and polyurethane, which enhance durability and aesthetic appeal. Buyers should consider the longevity of the coating when evaluating products, as it directly impacts maintenance costs and the hydrant’s lifespan.

What Are Common Trade Terms Used in Fire Hydrant Procurement?

Familiarity with industry jargon is essential for smooth communication and negotiation. Here are some key terms that B2B buyers should understand:

1. OEM (Original Equipment Manufacturer): What Does It Mean?

OEM refers to companies that manufacture products that are sold under another company’s brand name. When sourcing fire hydrants, buyers may encounter OEM products, which can indicate a higher level of quality and reliability, as they often adhere to stringent manufacturing standards.

2. MOQ (Minimum Order Quantity): Why Is It Relevant?

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for buyers to manage inventory effectively and avoid overcommitting to large orders. It also impacts pricing, as larger orders may offer better per-unit costs.

3. RFQ (Request for Quotation): How Should It Be Used?

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products. For fire hydrants, a well-structured RFQ can ensure that buyers receive comprehensive quotes that include technical specifications, lead times, and shipping costs.

4. Incoterms (International Commercial Terms): Why Are They Important?

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce. They clarify the responsibilities of buyers and sellers in international trade, such as who is responsible for shipping costs and insurance. Understanding Incoterms is crucial for buyers to avoid unexpected expenses during procurement.

5. Lead Time: What Should Buyers Expect?

Lead time refers to the time it takes from placing an order to receiving the product. For fire hydrants, lead times can vary based on manufacturing processes and shipping logistics. Buyers should factor in lead times when planning for project timelines to ensure that hydrants are available when needed.

By grasping these essential technical properties and trade terminologies, international B2B buyers from Africa, South America, the Middle East, and Europe can make informed decisions when sourcing fire hydrants. This knowledge not only enhances procurement efficiency but also ensures compliance with local regulations and standards.

Navigating Market Dynamics and Sourcing Trends in the fire hydrant supplier Sector

What Are the Current Market Dynamics and Key Trends in the Fire Hydrant Supplier Sector?

The global fire hydrant supplier market is experiencing significant growth driven by urbanization, increasing safety regulations, and the need for robust fire protection systems. International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, must navigate a landscape shaped by technological advancements and evolving customer preferences. Key trends include the integration of IoT technologies, which enable real-time monitoring and maintenance of fire hydrants, thereby enhancing operational efficiency and safety.

Additionally, the shift towards smart cities is fueling demand for advanced fire safety solutions that align with urban planning initiatives. B2B buyers should be aware of the increasing importance of compliance with international standards and local regulations, which can vary significantly across regions. For instance, suppliers in Europe often adhere to stringent EU regulations, while those in Africa may face different compliance challenges. Understanding these dynamics is crucial for international buyers seeking reliable partnerships.

A stock image related to fire hydrant supplier.

Emerging sourcing trends highlight the significance of digital platforms for procurement processes. The rise of e-commerce in B2B transactions allows buyers to easily compare suppliers, assess product quality, and streamline purchasing decisions. Furthermore, strategic collaborations and partnerships are becoming essential for accessing innovative technologies and expanding market reach.

How Are Sustainability and Ethical Sourcing Influencing the Fire Hydrant Supplier Industry?

Sustainability has become a critical focus for B2B buyers in the fire hydrant sector. The environmental impact of manufacturing processes and materials used in fire hydrants is under scrutiny, prompting suppliers to adopt more sustainable practices. Buyers from Africa, South America, the Middle East, and Europe should prioritize suppliers who demonstrate a commitment to reducing their carbon footprint and utilizing eco-friendly materials.

Ethical sourcing is also gaining traction, with an emphasis on transparency throughout the supply chain. Buyers should seek suppliers who can provide certifications that verify sustainable practices, such as ISO 14001 for environmental management or the use of recycled materials in product manufacturing. These certifications not only reflect a supplier’s dedication to sustainability but can also enhance the buyer’s brand reputation.

Moreover, innovative materials such as ductile iron and corrosion-resistant coatings are becoming popular in fire hydrant production. These materials not only improve durability and performance but also contribute to lower lifecycle costs, aligning with the sustainability goals of many organizations. International buyers should assess the sustainability credentials of potential suppliers as part of their procurement strategy.

What Is the Historical Context of the Fire Hydrant Supplier Sector?

The fire hydrant supplier sector has evolved significantly since the introduction of the first hydrants in the early 19th century. Initially, hydrants were rudimentary, made from wood and iron, and primarily designed for basic firefighting needs. Over the decades, technological advancements have transformed hydrant design and functionality, leading to the development of more sophisticated, reliable systems.

The introduction of standardized testing and regulatory frameworks in the late 20th century marked a turning point, ensuring that fire hydrants met safety and performance criteria essential for urban infrastructure. This evolution continues today, with a focus on integrating smart technologies and sustainable materials to meet the demands of modern urban environments. For international B2B buyers, understanding this historical context is vital for recognizing the advancements and innovations that have shaped the current market landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of fire hydrant supplier

-

How do I choose the right fire hydrant supplier for my business needs?

Selecting the right fire hydrant supplier requires careful evaluation of several factors. Begin by assessing the supplier’s reputation and experience in the industry. Look for certifications and compliance with international safety standards. Additionally, consider their ability to provide customized solutions that meet your specific requirements, such as hydrant specifications and regional standards. Request references from other clients and conduct due diligence to ensure they have a reliable supply chain and good customer service support. -

What are the common payment terms offered by fire hydrant suppliers?

Payment terms can vary significantly among fire hydrant suppliers, but typical options include advance payment, net 30, or net 60 days. Some suppliers may offer discounts for early payment, while others may require a letter of credit for international transactions. It’s crucial to discuss and negotiate these terms upfront to ensure they align with your cash flow and budget. Be aware of any additional fees related to currency conversion or international transactions that may affect your overall costs. -

What is the minimum order quantity (MOQ) for fire hydrants?

Minimum order quantities (MOQ) for fire hydrants can differ based on the supplier and the specific products. Generally, MOQs can range from a few units to several hundred, depending on the supplier’s production capabilities and inventory. When sourcing, inquire about MOQs and assess whether they fit your project needs and budget. If your requirements are lower than the MOQ, some suppliers may be willing to negotiate or offer a solution, such as joining a collective order with other buyers. -

What should I know about the quality assurance process for fire hydrants?

Quality assurance (QA) is critical when sourcing fire hydrants, as these products play a vital role in public safety. Ensure that the supplier has a robust QA process in place, which includes regular inspections and testing of materials and finished products. Ask for documentation of compliance with local and international standards, such as ISO certifications or ASTM specifications. Additionally, consider conducting a factory audit to verify their manufacturing practices and quality control measures firsthand. -

How can I ensure timely delivery of fire hydrants from international suppliers?

To ensure timely delivery of fire hydrants, start by discussing lead times with your supplier upfront. Establish clear communication regarding production schedules, shipping methods, and potential delays due to customs or logistics issues. Utilize a freight forwarder who specializes in international shipments to navigate complexities. Implement tracking systems to monitor shipment progress and establish contingency plans for unexpected delays, ensuring you remain informed throughout the process. -

What customization options are available for fire hydrants?

Many fire hydrant suppliers offer customization options to meet specific regional or project requirements. Customizations may include color, size, material specifications, and additional features like anti-vandalism locks or unique threading standards. When approaching suppliers, clearly communicate your needs and preferences. Request samples or prototypes to evaluate before committing to a larger order, ensuring that the final product meets your exact specifications. -

How do I vet fire hydrant suppliers for reliability and performance?

Vetting fire hydrant suppliers involves a multi-faceted approach. Start by reviewing their track record, including years in business and client testimonials. Seek out suppliers with industry certifications and compliance records. Conduct site visits or audits if possible, and ask for references from previous clients who have similar needs. Additionally, assess their customer service responsiveness and willingness to support you post-purchase, which is essential for a long-term partnership. -

What are the key regulations governing fire hydrant installations in different regions?

Fire hydrant installation regulations can vary significantly by region, influenced by local building codes and safety standards. In Africa, South America, the Middle East, and Europe, it’s crucial to familiarize yourself with specific national and municipal codes. These may dictate installation locations, hydrant types, and maintenance protocols. Consulting with local fire safety authorities or hiring a compliance expert can help ensure that your installations meet all necessary legal requirements and safety standards.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for fire hydrant supplier

In the evolving landscape of fire hydrant supply, strategic sourcing emerges as a pivotal approach for international B2B buyers. By prioritizing quality, reliability, and compliance with local regulations, organizations can ensure the safety and efficiency of their fire protection systems. Buyers from regions like Africa, South America, the Middle East, and Europe must focus on building strong supplier relationships that facilitate transparent communication and foster collaboration.

What Are the Key Takeaways for B2B Buyers in Fire Hydrant Sourcing?

-

Prioritize Local Compliance: Understanding regional safety standards is crucial. Ensure that suppliers meet the specific requirements of your locality, enhancing safety and operational efficiency.

-

Evaluate Supplier Capabilities: Assess the production capacity, technology, and innovation of potential suppliers. This evaluation helps mitigate risks associated with supply chain disruptions.

-

Invest in Long-Term Partnerships: Building relationships with suppliers can yield long-term benefits, including better pricing, priority service, and access to new technologies.

How Can International Buyers Prepare for Future Trends?

As the demand for advanced fire safety solutions grows, buyers should remain proactive in identifying suppliers who are investing in innovative technologies. Embrace sustainability by considering suppliers who prioritize eco-friendly materials and processes.

In conclusion, adopting a strategic sourcing approach not only enhances procurement efficiency but also positions businesses for future growth. International buyers are encouraged to leverage these insights and take action towards securing reliable and compliant fire hydrant solutions. The time to invest in your fire safety infrastructure is now.