Discover Cost-Saving Tips from Top Fire Truck Manufacturers (2025)

Introduction: Navigating the Global Market for fire truck manufacturer

In an increasingly interconnected world, international B2B buyers face the critical challenge of sourcing reliable fire truck manufacturers that meet their specific operational needs and compliance standards. Navigating the global market for fire truck manufacturers requires a deep understanding of various types, applications, and innovative technologies available today. This comprehensive guide aims to demystify the complexities of sourcing fire trucks by providing actionable insights into supplier vetting processes, cost considerations, and industry best practices.

Buyers from regions such as Africa, South America, the Middle East, and Europe (including key markets like Colombia and Brazil) will benefit from tailored strategies that address regional challenges and opportunities. The guide covers essential topics, including the latest advancements in firefighting technology, the importance of selecting manufacturers with a proven track record, and effective negotiation tactics to secure favorable terms.

By equipping international B2B buyers with the knowledge necessary to make informed purchasing decisions, this resource empowers them to mitigate risks and maximize the value of their investments. Whether you are looking for specialized fire trucks for urban areas or rugged models for rural firefighting, understanding the global landscape of fire truck manufacturing is crucial for ensuring safety and operational efficiency in emergency response.

Understanding fire truck manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fire Engine | Equipped with water tanks, hoses, and pumps | Urban firefighting, rescue operations | Pros: Versatile, quick response. Cons: Higher maintenance costs. |

| Aerial Ladder Truck | Features extendable ladders for high-rise firefighting | High-rise buildings, industrial sites | Pros: Access to elevated areas. Cons: Limited maneuverability in tight spaces. |

| Wildland Fire Truck | Designed for rugged terrain, often smaller and more agile | Rural firefighting, forest areas | Pros: Excellent off-road capability. Cons: Limited water capacity. |

| Tanker Truck | Large water storage capacity, often with fire suppression systems | Remote areas, initial attack scenarios | Pros: High water supply, essential for large fires. Cons: Slower response time. |

| Rescue Truck | Focused on emergency medical services and rescue equipment | Emergency response, disaster relief | Pros: Equipped for various emergencies. Cons: May lack fire suppression features. |

What are the Key Characteristics of Fire Engines?

Fire engines are the backbone of firefighting operations, equipped with water tanks, hoses, and pumps. They are versatile and can respond quickly to urban fires, making them ideal for cities and densely populated areas. When purchasing, consider factors such as water capacity, pump efficiency, and maintenance requirements. Fire engines may incur higher maintenance costs due to their complex systems, but their ability to handle various emergencies makes them indispensable.

How Do Aerial Ladder Trucks Enhance Firefighting?

Aerial ladder trucks are specifically designed to tackle fires in high-rise buildings and industrial sites. These trucks feature extendable ladders that can reach significant heights, allowing firefighters to access upper floors safely. When evaluating aerial ladder trucks, buyers should consider the ladder’s reach, stability, and the truck’s maneuverability. While these trucks provide unparalleled access, their size can hinder movement in crowded urban environments.

Why Choose Wildland Fire Trucks for Rural Areas?

Wildland fire trucks are tailored for rugged terrain and are generally smaller and more agile than standard fire engines. They are essential for combating fires in rural and forested areas, where access can be challenging. Buyers should assess the truck’s off-road capabilities and water capacity, as these vehicles often carry less water than traditional fire engines. While they excel in navigating tough landscapes, their limited water supply can be a drawback in larger wildfires.

What Benefits Do Tanker Trucks Provide?

Tanker trucks are designed to transport large volumes of water, making them crucial for firefighting in remote or water-scarce areas. These trucks are equipped with fire suppression systems and can provide an immediate water supply during initial attack scenarios. When purchasing a tanker truck, consider its water capacity, pump performance, and overall speed. Although they are slower to respond due to their size, their ability to deliver substantial water supplies can be a game-changer in firefighting efforts.

How Do Rescue Trucks Support Emergency Services?

Rescue trucks focus on emergency medical services and are equipped with specialized rescue equipment. They play a vital role in emergency response and disaster relief situations, providing essential support beyond firefighting. Buyers should evaluate the equipment onboard, such as medical supplies and rescue tools, when considering a rescue truck. While they are highly effective for various emergencies, these trucks may lack the fire suppression capabilities of other fire truck types, necessitating a strategic approach to resource allocation during emergencies.

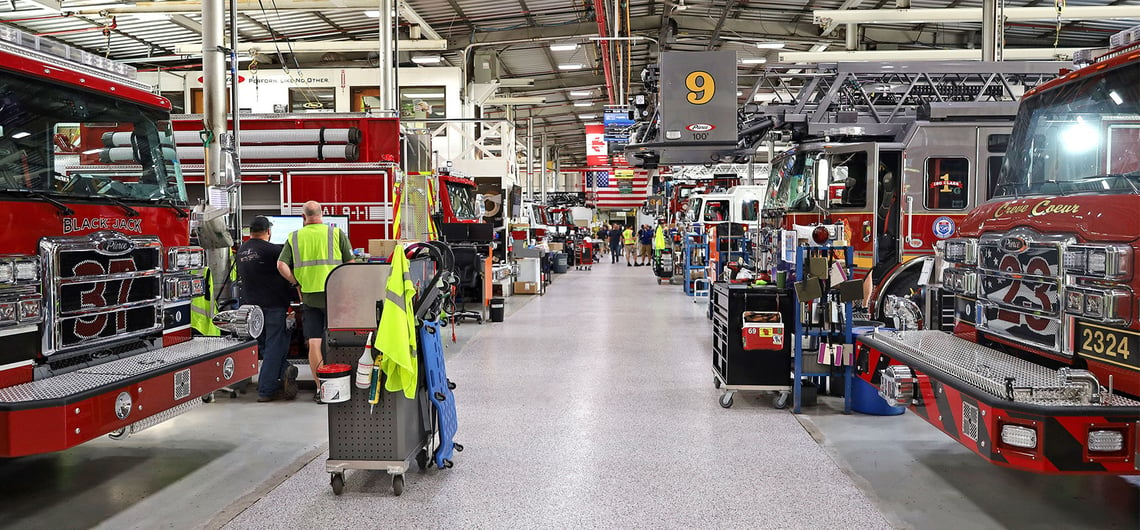

Related Video: Largest Fire Truck Manufacturer | Mega Manufacturing | Free Documentary

Key Industrial Applications of fire truck manufacturer

| Industry/Sector | Specific Application of Fire Truck Manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Municipal Fire Services | Custom-built fire trucks for urban firefighting | Enhanced response times and improved safety for citizens | Compliance with local regulations and standards |

| Oil and Gas Industry | Specialized firefighting units for oil rigs | Protection against fires and quick response to emergencies | Equipment durability in harsh environments |

| Forestry Management | Wildland fire suppression vehicles | Effective management of wildfires and environmental protection | Capability to operate in rugged terrains |

| Mining Operations | Fire trucks for mine site safety | Mitigation of fire hazards and protection of personnel | Adaptability to underground and surface conditions |

| Agriculture | Firefighting vehicles for crop protection | Prevention of agricultural losses due to fires | Versatility in various agricultural settings |

How Are Fire Trucks Used in Municipal Fire Services?

In municipal fire services, custom-built fire trucks are essential for urban firefighting. These vehicles are designed to navigate city streets efficiently while carrying the necessary equipment to combat fires. They solve the problem of delayed emergency responses by ensuring that firefighters have immediate access to water and firefighting tools. International buyers, particularly from developing regions in Africa and South America, should prioritize sourcing vehicles that comply with local firefighting standards and regulations to ensure operational effectiveness.

What Role Do Fire Trucks Play in the Oil and Gas Industry?

In the oil and gas sector, specialized firefighting units are critical for protecting oil rigs and refineries from fire hazards. These units are equipped with advanced firefighting systems tailored to handle flammable materials and high-risk environments. The primary benefit is the rapid response capability that these vehicles provide, significantly reducing the potential for catastrophic incidents. Buyers in the Middle East and Europe should consider the durability and adaptability of these units to extreme weather and operational conditions.

Why Are Fire Trucks Important for Forestry Management?

Forestry management relies heavily on wildland fire suppression vehicles to manage and control forest fires effectively. These vehicles are designed to operate in rugged terrains, making them ideal for remote areas where wildfires can spread rapidly. Their use minimizes environmental damage and protects wildlife. For international buyers, especially in regions prone to wildfires, it’s crucial to assess the vehicle’s capability to handle diverse landscapes and climates.

How Do Fire Trucks Enhance Safety in Mining Operations?

Fire trucks are vital in mining operations for ensuring site safety and mitigating fire hazards. These vehicles are equipped to respond quickly to fires that may occur due to equipment malfunction or other risks associated with mining activities. The key benefit is the protection of personnel and assets, which is critical in high-risk environments. Buyers from South America and Africa must focus on sourcing trucks that can adapt to both underground and surface mining conditions.

What Advantages Do Fire Trucks Offer in Agriculture?

In agriculture, firefighting vehicles are used to protect crops from wildfires and other fire-related incidents. These trucks can quickly deploy water and firefighting agents to safeguard valuable agricultural assets. The primary advantage is the prevention of significant economic losses due to fire damage. Buyers in Europe and South America should look for versatile firefighting solutions that can operate effectively in diverse agricultural settings, including fields and orchards.

3 Common User Pain Points for ‘fire truck manufacturer’ & Their Solutions

Scenario 1: Limited Access to Reliable Spare Parts

The Problem:

International B2B buyers often face significant challenges in sourcing reliable spare parts for fire trucks. In regions like Africa and South America, the availability of specific components can be inconsistent, leading to prolonged downtimes. This issue is exacerbated by the lack of established supply chains and logistical hurdles, which can delay repairs and maintenance. Fire departments may find themselves unable to respond effectively to emergencies, which can compromise public safety and operational readiness.

The Solution:

To mitigate this problem, buyers should prioritize manufacturers that offer comprehensive spare parts services as part of their sales agreements. Engage with fire truck manufacturers who have a solid international presence and established distribution networks. Before finalizing any purchase, inquire about the availability of spare parts, warranty terms, and turnaround times for orders. Additionally, consider negotiating service contracts that include regular maintenance checks and guaranteed parts availability. Leveraging local partnerships with authorized distributors can also facilitate quicker access to necessary components, ensuring that your fire trucks are always mission-ready.

Scenario 2: Compliance with Local Regulations and Standards

The Problem:

Fire truck specifications often need to comply with local regulations and standards, which can vary significantly across regions, particularly in the Middle East and Europe. Buyers may struggle to understand these requirements, leading to potential non-compliance that can result in fines, operational restrictions, or even the inability to deploy equipment in emergencies. Misunderstandings about local fire service requirements can result in purchasing unsuitable vehicles, wasting both time and financial resources.

The Solution:

To navigate this complexity, B2B buyers should conduct thorough research on local fire service regulations before engaging with manufacturers. Collaborate with local fire authorities to understand the specific requirements for fire trucks in your area. When selecting a manufacturer, choose one that demonstrates familiarity with local compliance issues and can provide documentation that proves their vehicles meet these standards. Request detailed specifications and certifications for the fire trucks you are considering. Additionally, establishing a dialogue with the manufacturer’s compliance team can help clarify any uncertainties, ensuring that your procurement process aligns with local regulations.

Scenario 3: High Initial Investment and Financing Options

The Problem:

The high initial cost of purchasing fire trucks can be a significant barrier for many organizations, particularly in developing regions such as parts of Africa and South America. Many municipalities and fire departments operate under tight budgets, making it difficult to allocate sufficient funds for such crucial investments. This financial strain can lead to delays in acquiring necessary equipment, ultimately affecting emergency response capabilities.

The Solution:

To address financial constraints, buyers should explore multiple financing options available through manufacturers or third-party financial institutions. Many fire truck manufacturers offer flexible payment plans or leasing options that can help spread the cost over time. Buyers should also investigate grant opportunities or government funding programs specifically aimed at supporting emergency services in their regions. Additionally, engaging in discussions with multiple manufacturers can provide insights into competitive financing offers, enabling you to make a more informed decision. Preparing a solid business case that outlines the operational benefits and cost savings of investing in modern fire trucks can also be instrumental in securing the necessary funds from stakeholders or financial partners.

Strategic Material Selection Guide for fire truck manufacturer

When selecting materials for fire truck manufacturing, it is essential to consider various factors that influence performance, durability, and compliance with international standards. Below, we analyze four common materials used in fire truck construction, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

A stock image related to fire truck manufacturer.

What are the Key Properties of Aluminum in Fire Truck Manufacturing?

Aluminum is a popular choice in fire truck manufacturing due to its excellent strength-to-weight ratio, corrosion resistance, and thermal conductivity. It typically withstands temperatures up to 600°F (315°C) and is resistant to rust, making it suitable for various environmental conditions.

Pros and Cons of Aluminum:

– Pros: Lightweight, which improves fuel efficiency and maneuverability; corrosion-resistant, reducing maintenance costs; and offers good thermal conductivity.

– Cons: Higher initial cost compared to steel; may require specialized welding techniques; and can be less durable under extreme impact conditions.

Impact on Application:

Aluminum is particularly effective for truck bodies and water tanks, enhancing the overall efficiency of fire suppression systems. However, it is crucial for buyers to ensure that the aluminum used complies with international standards like ASTM B209.

How Does Steel Compare as a Material for Fire Trucks?

Steel, particularly high-strength low-alloy (HSLA) steel, is another common material used in fire truck manufacturing. It has a high tensile strength and can withstand significant pressure and temperature variations, making it ideal for structural components.

Pros and Cons of Steel:

– Pros: High durability and strength, excellent impact resistance, and lower initial cost compared to aluminum.

– Cons: Heavier than aluminum, which can reduce fuel efficiency; susceptible to corrosion without proper treatment; and may require more extensive maintenance over time.

Impact on Application:

Steel is often used in the chassis and frame of fire trucks, where strength is paramount. Buyers should consider the need for corrosion-resistant coatings, especially in humid or coastal regions.

What are the Benefits of Composite Materials in Fire Truck Design?

A stock image related to fire truck manufacturer.

Composite materials, such as fiberglass and carbon fiber, are increasingly being used in fire truck manufacturing. These materials offer unique properties, including lightweight design and high resistance to corrosion and thermal degradation.

Pros and Cons of Composites:

– Pros: Lightweight, enhancing fuel efficiency; excellent corrosion resistance; and can be molded into complex shapes for aerodynamic designs.

– Cons: Higher manufacturing costs; potential for brittleness under extreme conditions; and may require specialized repair techniques.

Impact on Application:

Composites are particularly useful in body panels and interior components, providing aesthetic flexibility and weight savings. Buyers should ensure that the composites meet relevant standards, such as ASTM D638 for tensile properties.

What Role Does Stainless Steel Play in Fire Truck Manufacturing?

Stainless steel is known for its corrosion resistance and aesthetic appeal, making it suitable for various applications in fire trucks. It can withstand high temperatures and is often used in components exposed to harsh environments.

Pros and Cons of Stainless Steel:

– Pros: Excellent corrosion resistance; durable and strong; and requires minimal maintenance.

– Cons: Higher cost compared to regular steel; heavier than aluminum; and can be challenging to weld.

Impact on Application:

Stainless steel is commonly used in pump housings and fittings, where durability and resistance to corrosion are critical. Buyers should verify compliance with standards such as ASTM A240 for stainless steel sheets.

Summary Table of Material Selection for Fire Truck Manufacturing

| Material | Typical Use Case for Fire Truck Manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Truck bodies, water tanks | Lightweight and corrosion-resistant | Higher initial cost | Medium |

| Steel | Chassis, frame | High durability and lower cost | Heavier and requires maintenance | Low |

| Composite | Body panels, interior components | Lightweight and corrosion-resistant | Higher manufacturing costs | High |

| Stainless Steel | Pump housings, fittings | Excellent corrosion resistance | Higher cost and challenging to weld | Medium |

In conclusion, selecting the right material for fire truck manufacturing involves balancing performance, cost, and compliance with international standards. Buyers from regions such as Africa, South America, the Middle East, and Europe should consider local environmental conditions and regulatory requirements when making their choices.

In-depth Look: Manufacturing Processes and Quality Assurance for fire truck manufacturer

What Are the Main Stages of Manufacturing Fire Trucks?

The manufacturing process for fire trucks is a complex series of stages designed to produce high-quality, durable vehicles capable of withstanding the rigors of firefighting. Understanding these stages can help B2B buyers from regions such as Africa, South America, the Middle East, and Europe make informed purchasing decisions.

Material Preparation: How Is Raw Material Selected and Processed?

The first step in fire truck manufacturing involves the careful selection of materials. Manufacturers typically use high-strength steel, aluminum, and composite materials to ensure structural integrity and reduce weight. The material preparation phase includes cutting, machining, and treating these raw materials to enhance their properties. For instance, steel components may undergo galvanization to protect against corrosion, which is crucial in environments exposed to water and chemicals.

Forming: What Techniques Are Used to Shape Fire Truck Components?

Once materials are prepared, the forming stage begins. This involves various techniques such as stamping, bending, and welding. Advanced technologies like CNC (Computer Numerical Control) machining and laser cutting are often employed to achieve precise dimensions and complex shapes. These methods ensure that components fit together seamlessly, which is vital for both aesthetics and performance.

Assembly: How Are Fire Trucks Assembled?

The assembly process is where all the components come together to form the final product. This stage includes the integration of chassis, cab, pump systems, and storage compartments for hoses and equipment. Quality control is integral during assembly, with manufacturers often using jigs and fixtures to maintain alignment and consistency. The use of modular designs can also streamline assembly, allowing for easier customization based on buyer specifications.

Finishing: What Are the Final Touches in Fire Truck Manufacturing?

The finishing stage involves painting, applying protective coatings, and installing electronic systems. Fire trucks typically undergo a rigorous painting process to ensure durability and visibility; many opt for bright colors like red or yellow, which are standard for emergency vehicles. Additionally, manufacturers often implement quality checks at this stage to ensure that all systems, including lights and sirens, function correctly before the vehicle leaves the factory.

What Quality Assurance Practices Are Essential for Fire Truck Manufacturers?

Quality assurance (QA) is critical in ensuring that fire trucks meet safety standards and performance expectations. B2B buyers should look for manufacturers that adhere to international standards and have robust QA practices.

Which International Standards Should Fire Truck Manufacturers Comply With?

Manufacturers often comply with ISO 9001, a standard that outlines quality management systems to enhance customer satisfaction. Furthermore, fire trucks may need to meet region-specific certifications, such as the CE marking in Europe or API standards for certain components. These certifications indicate that the products have been rigorously tested and comply with safety and environmental regulations.

What Are the Key Quality Control Checkpoints in Fire Truck Manufacturing?

Quality control in fire truck manufacturing typically involves several checkpoints, including:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing inspections are conducted throughout the manufacturing process to identify defects early.

- Final Quality Control (FQC): The completed fire truck undergoes a thorough inspection and testing before delivery, ensuring all systems function correctly and meet regulatory standards.

Common testing methods include performance tests for pumps, structural integrity assessments, and safety feature evaluations. These methods help manufacturers identify any potential issues and ensure the vehicle is ready for service.

How Can B2B Buyers Verify the Quality Control of Fire Truck Suppliers?

For international B2B buyers, verifying a supplier’s quality control processes is essential. Here are some actionable steps to ensure you choose a reputable fire truck manufacturer:

What Audits and Reports Should Buyers Request?

Buyers should request copies of the supplier’s quality management certifications, such as ISO 9001, and any relevant audit reports. It’s also beneficial to inquire about the frequency of internal audits and any third-party inspections that may occur. This documentation provides insight into the manufacturer’s commitment to quality.

How Do Third-Party Inspections Enhance Supplier Reliability?

Engaging a third-party inspection agency can provide an unbiased assessment of the manufacturing process. These agencies typically conduct inspections at various stages, from raw material quality to final assembly. B2B buyers can request these third-party reports to gain further confidence in the supplier’s capabilities.

What Nuances Should International B2B Buyers Consider in Quality Assurance?

When dealing with international suppliers, it’s essential to understand regional nuances in quality assurance practices. For instance, compliance with local regulations in Africa, South America, the Middle East, and Europe may vary significantly. Buyers should conduct due diligence to ensure that the chosen manufacturer adheres to the relevant standards and practices in their target market.

Additionally, consider the manufacturer’s experience in exporting fire trucks to your region. Familiarity with local regulations can streamline the import process and reduce the risk of compliance issues.

Conclusion

Understanding the manufacturing processes and quality assurance practices of fire truck manufacturers is crucial for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, as well as scrutinizing quality assurance practices, buyers can make informed decisions that ensure they procure reliable and high-performance fire trucks. Engaging in thorough verification processes will further enhance the likelihood of selecting a manufacturer that meets the specific needs of your region.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fire truck manufacturer’

This guide aims to provide international B2B buyers with a practical checklist for sourcing fire truck manufacturers. With a focus on the unique needs of regions such as Africa, South America, the Middle East, and Europe, this checklist will help ensure that you make informed decisions in your procurement process.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the fire trucks you need. This includes specifications such as vehicle size, water capacity, pump type, and equipment features. Having a detailed specification document helps in obtaining accurate quotes from suppliers and ensures that the final product meets your operational needs.

- Consider regional needs: Different areas may require specialized features, such as off-road capabilities for rural regions or specific firefighting equipment for urban settings.

Step 2: Research Potential Manufacturers

Conduct thorough research to identify potential manufacturers with a strong reputation in the industry. Look for companies that have experience in producing fire trucks suitable for your specific market conditions.

- Check online resources: Utilize trade directories, industry publications, and forums to find manufacturers with positive reviews and case studies relevant to your region.

Step 3: Evaluate Supplier Certifications

Ensure that potential suppliers have the necessary certifications and comply with local and international standards. Certifications such as ISO 9001 for quality management systems or specific fire safety standards are critical indicators of a manufacturer’s reliability.

- Ask for documentation: Request copies of certifications and compliance documents to verify that the manufacturer meets industry regulations.

Step 4: Request Prototypes or Demonstrations

Before making a bulk purchase, it’s advisable to request prototypes or arrange for demonstrations of the fire trucks. This hands-on experience allows you to assess the quality, performance, and suitability of the vehicles for your needs.

- Engage with local representatives: If possible, have local fire department personnel test the vehicles to provide feedback on usability and functionality.

Step 5: Assess After-Sales Support and Warranty

Evaluate the after-sales support offered by manufacturers, including warranty terms, maintenance services, and spare parts availability. Strong after-sales support is essential for the long-term operational efficiency of your fire trucks.

- Consider local partnerships: Manufacturers that have local service centers or partnerships can provide faster response times for maintenance and repairs.

Step 6: Negotiate Pricing and Payment Terms

Once you’ve narrowed down your options, negotiate pricing, payment terms, and delivery schedules. Make sure to consider total cost of ownership, including maintenance and operational costs, rather than just the initial purchase price.

- Explore financing options: Some manufacturers may offer financing solutions that can help you manage cash flow while acquiring the necessary equipment.

Step 7: Finalize the Contract and Monitor Production

After agreeing on terms, finalize the contract, ensuring all specifications and warranties are documented. Maintain communication throughout the production process to address any potential issues or modifications promptly.

- Set clear milestones: Establish timelines for production phases and delivery to ensure that the project remains on track.

By following these steps, international B2B buyers can effectively navigate the sourcing process for fire truck manufacturers, ensuring they select the best suppliers to meet their operational needs.

Comprehensive Cost and Pricing Analysis for fire truck manufacturer Sourcing

What Are the Key Cost Components in Fire Truck Manufacturing?

When sourcing fire trucks, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The bulk of production costs arise from raw materials such as steel, aluminum, and specialized firefighting equipment. High-quality materials are essential for durability and performance, impacting both initial costs and long-term operational efficiency.

-

Labor: Skilled labor is necessary for assembly, welding, and quality control. Labor costs can vary significantly based on the region; for example, labor in Europe may be more expensive than in parts of Africa or South America.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and indirect labor. Efficient manufacturing processes can help reduce overhead and improve profit margins.

-

Tooling: Custom tooling for specialized trucks can represent a substantial upfront cost. However, investing in effective tooling can lead to greater efficiency and lower costs in the long run.

-

Quality Control (QC): Implementing rigorous QC processes ensures that fire trucks meet safety and operational standards. While this adds to costs, it can prevent costly recalls or repairs later.

-

Logistics: Shipping and handling costs can be significant, especially for international buyers. Understanding the logistics involved, including customs duties and tariffs, is essential for accurate cost estimation.

-

Margin: Manufacturers typically include a profit margin in their pricing. This can vary based on market demand, competition, and the value-added features of the fire trucks.

How Do Price Influencers Affect Fire Truck Sourcing?

Several factors can influence the pricing of fire trucks, making it vital for buyers to consider:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk can often lead to significant discounts. Understanding a supplier’s MOQ can help buyers negotiate better pricing.

-

Specifications and Customization: Custom features—such as specific pump types or hose configurations—can increase costs. Buyers should clearly communicate their needs to avoid unexpected expenses.

-

Materials and Quality Certifications: Trucks built with higher-grade materials or those that meet specific certifications (like NFPA standards) may cost more but can offer better performance and safety.

-

Supplier Factors: The reputation and reliability of the supplier can also affect pricing. Established manufacturers may charge a premium due to their proven track record.

-

Incoterms: These terms define the responsibilities of buyers and sellers in international shipping. Understanding Incoterms can help buyers manage costs related to shipping and insurance.

What Are the Best Practices for Negotiating Fire Truck Prices?

International B2B buyers should consider the following tips when negotiating prices for fire trucks:

-

Conduct Market Research: Understand the average prices and features offered by various manufacturers. This knowledge can empower buyers during negotiations.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also maintenance, operational costs, and resale value. A higher upfront cost may be justified if the truck offers lower operating costs.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and more favorable terms. Frequent communication can foster trust and collaboration.

-

Be Transparent About Budgets: Communicating budget constraints can prompt suppliers to offer tailored solutions that fit within financial limits.

-

Request Detailed Quotes: Ensure that quotes break down all costs, including shipping, taxes, and any additional fees. This transparency can prevent surprises later on.

What Should Buyers Know About Pricing Nuances in Different Regions?

International buyers from regions like Africa, South America, the Middle East, and Europe should be aware of specific pricing nuances:

-

Regional Variations: Prices can vary widely based on local economic conditions, labor costs, and material availability. Buyers should account for these differences in their budgeting.

-

Currency Fluctuations: Exchange rates can impact pricing for international buyers. It’s advisable to lock in prices or negotiate terms that account for currency fluctuations.

-

Regulatory Differences: Compliance with local regulations can affect costs. Buyers should ensure that fire trucks meet all necessary standards in their respective countries.

Conclusion

Understanding the comprehensive cost and pricing analysis for fire truck manufacturing is essential for international B2B buyers. By considering the various cost components, price influencers, negotiation strategies, and regional nuances, buyers can make informed decisions that align with their budget and operational needs. Always remember that prices can fluctuate, so maintaining flexibility and open communication with suppliers is key to successful sourcing.

Alternatives Analysis: Comparing fire truck manufacturer With Other Solutions

When considering the procurement of fire suppression equipment, international B2B buyers often find themselves evaluating various solutions to meet their operational needs. While fire truck manufacturers provide specialized vehicles equipped for firefighting, there are alternative technologies and methods available that can also address fire safety and suppression effectively. This analysis compares traditional fire truck manufacturers with two alternative solutions: aerial firefighting drones and portable fire suppression systems.

| Comparison Aspect | Fire Truck Manufacturer | Aerial Firefighting Drones | Portable Fire Suppression Systems |

|---|---|---|---|

| Performance | High, with advanced features for various terrains and emergencies | Moderate, effective for targeted areas but limited by battery life | High for localized fires but limited range and capacity |

| Cost | High initial investment and operational costs | Moderate, lower than traditional trucks, but may require multiple units for coverage | Generally low; inexpensive and easy to deploy |

| Ease of Implementation | Requires extensive training and infrastructure | Simple to operate; training needed for effective use | Easy to implement; minimal training required |

| Maintenance | High, with regular servicing and parts replacement | Moderate, mainly software updates and battery maintenance | Low, typically requires only occasional checks |

| Best Use Case | Large-scale firefighting in urban and rural settings | Rapid response to wildfires or inaccessible areas | Urban settings, small fires, and emergency response |

What Are the Advantages and Disadvantages of Aerial Firefighting Drones?

Aerial firefighting drones are becoming increasingly popular due to their ability to quickly assess fire situations and deliver water or fire retardant in hard-to-reach areas. The advantages of drones include their lower operational costs compared to traditional fire trucks and their ability to provide real-time aerial surveillance. However, their effectiveness can be limited by battery life and payload capacity, making them less suitable for extensive firefighting operations that require sustained water delivery.

How Do Portable Fire Suppression Systems Compare?

Portable fire suppression systems are compact, easy-to-deploy solutions designed for quick response to small fires. These systems are cost-effective and can be operated by individuals with minimal training. They are particularly useful in urban environments or for first responders dealing with localized incidents. However, their limitation lies in the volume of water or retardant they can deliver, which may not suffice for larger fires or those that escalate rapidly.

How Can B2B Buyers Choose the Right Fire Suppression Solution?

When selecting the right fire suppression solution, B2B buyers must evaluate their specific operational needs, budget constraints, and the types of fire risks they face. For organizations in urban settings with a focus on rapid response and cost efficiency, portable fire suppression systems may be ideal. Conversely, for those needing comprehensive coverage and robust firefighting capabilities, investing in a fire truck manufacturer could be more appropriate. Aerial firefighting drones serve as a valuable adjunct, especially for remote or difficult-to-access areas, and could complement existing firefighting strategies. Ultimately, a thorough assessment of these alternatives will enable buyers to make informed decisions that align with their operational requirements and safety objectives.

Essential Technical Properties and Trade Terminology for fire truck manufacturer

What Are the Key Technical Properties of Fire Trucks?

When sourcing fire trucks, international B2B buyers need to consider several essential technical properties to ensure they meet operational requirements and safety standards. Here are critical specifications to evaluate:

-

Chassis Material Grade

Fire trucks are typically constructed from high-strength steel or aluminum alloys. The material grade affects durability, weight, and resistance to corrosion. Buyers should prioritize materials that provide a balance between structural integrity and weight to optimize maneuverability and fuel efficiency. -

Pump Capacity

The pump capacity, measured in gallons per minute (GPM), is crucial for a fire truck’s firefighting effectiveness. A higher GPM allows for faster water delivery to extinguish fires more efficiently. Buyers should assess the required pump capacity based on the typical emergency scenarios they expect to encounter. -

Water Tank Volume

Water tank volume impacts the fire truck’s ability to operate independently during emergencies. Tanks typically range from 500 to 3,000 gallons. Buyers should consider local fire regulations and the average distance to water sources when selecting the appropriate tank size for their needs. -

Tolerance Levels

Tolerance levels refer to the acceptable limits of variation in dimensions during manufacturing. High tolerance levels ensure that components fit together correctly, which is vital for the vehicle’s operational reliability. Buyers should inquire about the manufacturer’s tolerance standards to avoid potential issues in assembly and functionality. -

Gross Vehicle Weight Rating (GVWR)

GVWR is the maximum weight a fire truck can safely carry, including its own weight and that of the crew and equipment. This specification is critical for compliance with local road regulations and for ensuring safe operation under various load conditions. Buyers should ensure the selected fire truck meets the GVWR requirements relevant to their regions. -

Pump and Roll Capability

This feature allows the fire truck to pump water while in motion, which is essential for wildland firefighting. Buyers in regions prone to wildfires should look for trucks equipped with this capability to enhance operational flexibility and responsiveness.

Which Trade Terminology Should International Buyers Understand?

Understanding industry-specific terminology can significantly streamline the purchasing process for fire trucks. Here are some key terms that buyers should familiarize themselves with:

-

OEM (Original Equipment Manufacturer)

An OEM produces parts or vehicles that are sold under another company’s brand. In the context of fire trucks, sourcing from OEMs ensures high-quality components that meet industry standards. Buyers should prioritize OEMs to guarantee reliability and performance. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. For fire trucks, this can affect pricing and inventory management. Buyers should negotiate MOQs to align with their budget and operational needs, especially if they require multiple units. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. It is crucial for buyers to provide detailed specifications in their RFQ to receive accurate quotations that reflect their requirements. This process helps in comparing offers and making informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs. Buyers must understand these terms to mitigate risks and avoid unexpected costs during shipping. -

Lead Time

Lead time is the duration from placing an order to receiving the product. For fire trucks, understanding lead times is critical, especially in emergency-prone areas where timely delivery can save lives. Buyers should communicate their urgency clearly to suppliers to ensure timely fulfillment. -

Warranty Period

The warranty period indicates how long the manufacturer guarantees the vehicle against defects. A robust warranty can provide peace of mind and financial protection for buyers. Understanding the warranty terms helps buyers assess the long-term value of their investment in fire trucks.

By grasping these technical properties and trade terms, international buyers can make informed decisions that enhance their procurement strategy for fire trucks, ensuring they acquire vehicles that meet their operational needs effectively.

Navigating Market Dynamics and Sourcing Trends in the fire truck manufacturer Sector

What Are the Key Trends Driving the Fire Truck Manufacturing Market?

The fire truck manufacturing sector is witnessing a paradigm shift driven by several global factors. Increasing urbanization, especially in developing regions such as Africa and South America, is leading to a higher demand for advanced fire protection services. As cities expand, the need for reliable firefighting solutions becomes paramount. Additionally, technological advancements are reshaping the market landscape. Innovations such as telematics, IoT integration, and enhanced firefighting equipment are being embraced by manufacturers to improve operational efficiency and response times.

Emerging markets are also becoming key players in the fire truck sector. Countries like Brazil and Colombia are investing in modernizing their emergency response systems, leading to a rise in procurement activities for advanced fire trucks. Furthermore, the impact of climate change has heightened awareness of fire risks, particularly in regions prone to wildfires. This trend is prompting governments and organizations to invest in firefighting capabilities, thus expanding the market opportunities for international B2B buyers.

How Is Sustainability Impacting the Sourcing Decisions in Fire Truck Manufacturing?

Sustainability is no longer just a buzzword; it has become a critical factor in the sourcing and manufacturing processes of fire trucks. B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to reducing their environmental impact. This encompasses everything from the use of sustainable materials to energy-efficient manufacturing processes. Certifications such as ISO 14001 for environmental management systems are becoming essential for manufacturers seeking to attract international buyers.

Moreover, ethical sourcing practices are gaining traction, with buyers looking for transparency in their supply chains. Manufacturers are expected to provide clear documentation regarding the sourcing of materials and the environmental impact of their production processes. This shift towards sustainability not only meets regulatory requirements but also aligns with the growing consumer demand for environmentally responsible products. As a result, B2B buyers should actively seek partnerships with manufacturers that prioritize sustainability in their operations.

How Has the Fire Truck Manufacturing Sector Evolved Over Time?

The fire truck manufacturing sector has undergone significant transformations over the decades. Initially, fire trucks were rudimentary, primarily functioning as simple transportation vehicles for firefighting crews. However, advancements in technology have led to the incorporation of sophisticated equipment such as aerial ladders, water pumps, and emergency medical services (EMS) capabilities.

In recent years, the focus has shifted towards creating multifunctional fire trucks that can adapt to various emergencies, including wildfires and urban firefighting scenarios. This evolution is largely driven by increased awareness of safety standards and the necessity for more effective emergency response solutions. As international B2B buyers navigate this evolving landscape, understanding the historical context will be vital in making informed procurement decisions.

Conclusion

International B2B buyers, especially those from Africa, South America, the Middle East, and Europe, are navigating a complex landscape in the fire truck manufacturing sector. By staying informed about key trends, prioritizing sustainability, and understanding the historical evolution of the market, buyers can make strategic decisions that align with their operational needs and values.

Frequently Asked Questions (FAQs) for B2B Buyers of fire truck manufacturer

-

How do I choose the right fire truck manufacturer for my needs?

Selecting the right fire truck manufacturer involves evaluating several key factors. Begin by assessing the manufacturer’s experience and reputation in the industry, particularly in your region. Look for a company that understands local regulations and specific fire challenges faced in your area, whether in Africa, South America, the Middle East, or Europe. Request case studies or references from previous clients to gauge their customer satisfaction. Additionally, consider the customization options available to ensure the fire truck meets your operational requirements. -

What types of fire trucks are available for international buyers?

International buyers can access a diverse range of fire trucks, including pumper trucks, aerial ladder trucks, water tankers, and specialized units for wildland firefighting. Each type serves distinct purposes based on the specific needs of fire departments. Assess your local fire service requirements, such as the type of terrain, population density, and potential hazards, to determine which vehicle suits your operational needs best. Manufacturers often provide tailored solutions to meet these diverse requirements. -

What is the typical minimum order quantity (MOQ) for fire trucks?

Minimum order quantities (MOQ) for fire trucks can vary significantly based on the manufacturer and the complexity of the vehicle. Typically, MOQs may range from one to several units, especially for specialized or custom-designed trucks. For international buyers, it’s essential to discuss MOQs directly with the manufacturer, as they may offer flexibility based on your specific needs or the potential for future orders. Consider discussing bulk purchase discounts if you plan to acquire multiple vehicles. -

How can I ensure the quality of fire trucks from international suppliers?

To ensure quality, conduct thorough due diligence on potential suppliers. Look for manufacturers with ISO certifications or those who comply with international safety and quality standards. Request detailed specifications and quality assurance processes they follow during production. Consider visiting the manufacturing facility if feasible, or ask for third-party quality inspection reports. Establishing a clear communication channel for ongoing support and service post-purchase is also crucial for maintaining quality assurance.

-

What payment terms should I expect when purchasing fire trucks internationally?

Payment terms for international fire truck purchases typically include options such as letters of credit, advance payments, or staggered payments tied to production milestones. It’s essential to discuss and negotiate these terms upfront to ensure mutual understanding. Be aware of any additional costs such as shipping, tariffs, and customs duties that may impact the total price. Always engage legal advice for contracts to ensure all terms are clearly outlined and protect your investment. -

How do I vet suppliers for fire trucks in different regions?

Vetting suppliers requires a multi-step approach. Start by researching the manufacturer’s background, including years in business, client testimonials, and industry certifications. Utilize platforms like LinkedIn to connect with industry professionals and gather insights. Attend trade shows or industry conferences to meet manufacturers face-to-face and evaluate their offerings. Additionally, consider using third-party services for background checks and financial assessments to mitigate risks associated with international transactions. -

What customization options are available for fire trucks?

Many fire truck manufacturers offer extensive customization options to meet specific operational needs. Customization can include features like specialized firefighting equipment, enhanced vehicle dimensions, or unique paint schemes. Discuss your department’s requirements with the manufacturer to explore available options. They may also provide modular designs allowing for future upgrades as technology evolves or as your needs change, ensuring longevity and adaptability of the vehicles. -

What are the logistics considerations when importing fire trucks?

Importing fire trucks involves several logistical considerations, including shipping methods, customs clearance, and delivery timelines. Work with experienced logistics providers familiar with heavy equipment transport to ensure safe and timely delivery. Understand the import regulations in your country, including any certifications required for firefighting equipment. Additionally, factor in the costs associated with shipping, insurance, and potential taxes. Planning these logistics in advance can help prevent delays and unexpected expenses.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for fire truck manufacturer

As the demand for fire safety solutions escalates globally, particularly in regions prone to wildfires and urban fires, strategic sourcing emerges as a critical component for international B2B buyers in the fire truck manufacturing sector. By leveraging a thorough understanding of local regulations, supplier capabilities, and technological advancements, buyers can enhance their procurement processes. This not only ensures compliance with international safety standards but also optimizes cost-effectiveness and operational efficiency.

How Can Strategic Sourcing Enhance Your Fire Truck Procurement?

The strategic sourcing approach allows buyers from Africa, South America, the Middle East, and Europe to build robust partnerships with reputable manufacturers, ensuring access to high-quality fire trucks equipped with the latest firefighting technologies. By investing in long-term supplier relationships, organizations can benefit from tailored solutions that meet their unique operational needs while also fostering innovation in product development.

What Is the Future Outlook for Fire Truck Manufacturers?

Looking ahead, the fire truck manufacturing industry is poised for growth, driven by increasing investments in emergency response capabilities and infrastructure development. International buyers are encouraged to stay informed about emerging trends, such as electric fire trucks and advanced firefighting technologies, which will shape the future of firefighting.

In conclusion, as you navigate your sourcing decisions, prioritize strategic partnerships that align with your mission to enhance public safety and emergency response readiness. Engage with manufacturers who share your commitment to innovation and quality, and position your organization at the forefront of fire safety solutions.