Discover Cost-Saving Tips from Top Tarpaulin Manufacturers (2025)

Introduction: Navigating the Global Market for tarpaulin manufacturer

Navigating the global market for tarpaulin manufacturers presents a unique set of challenges for international B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. Sourcing high-quality tarpaulins that meet specific industry needs—be it for agriculture, construction, or logistics—requires a keen understanding of supplier capabilities, material specifications, and market dynamics. This guide aims to empower buyers by providing comprehensive insights into the various types of tarpaulins available, their applications across different sectors, and practical strategies for effective supplier vetting.

The scope of this guide encompasses critical areas such as identifying the most suitable materials for your needs, understanding pricing structures, and evaluating supplier reliability. By offering actionable insights on these topics, we aim to facilitate informed purchasing decisions that enhance operational efficiency and reduce risks associated with procurement.

Whether you are a business in South Africa looking for durable tarpaulins for outdoor events or a Brazilian company needing custom solutions for agricultural applications, this guide will equip you with the knowledge to navigate the complexities of the global tarpaulin market. With this information at your fingertips, you will be better positioned to establish successful partnerships and secure the right products to support your business objectives.

Understanding tarpaulin manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Canvas Tarpaulins | Made from heavy-duty cotton or polyester, durable, and breathable | Agriculture, construction, and outdoor events | Pros: Strong and long-lasting; Cons: Heavier and can be more expensive. |

| Polyethylene Tarpaulins | Lightweight, waterproof, and UV-resistant | Shipping, temporary shelters, and coverings | Pros: Cost-effective and versatile; Cons: Less durable compared to canvas. |

| Vinyl Tarpaulins | Made from PVC, highly resistant to tearing and punctures | Industrial applications, event tents | Pros: Excellent weather resistance; Cons: Can be less breathable, leading to condensation. |

| Mesh Tarpaulins | Made from woven polypropylene, allows airflow | Construction sites, debris containment | Pros: Lightweight and easy to handle; Cons: Not waterproof, limited protection. |

| Fire Retardant Tarpaulins | Treated with flame-resistant chemicals | Events, construction sites requiring safety compliance | Pros: Enhances safety; Cons: Generally more expensive due to treatment. |

What are the Key Characteristics of Canvas Tarpaulins for B2B Buyers?

Canvas tarpaulins are known for their durability and breathability, making them ideal for long-term outdoor use. Their heavy-duty fabric can withstand harsh weather conditions, making them a popular choice in agriculture and construction. Buyers should consider the weight and cost, as these tarps are heavier and may be more expensive than other options. Additionally, they are easy to repair, enhancing their long-term value.

How Do Polyethylene Tarpaulins Serve Various Industries?

Polyethylene tarpaulins are lightweight and waterproof, offering excellent UV resistance. They are widely used in shipping and temporary shelters, providing a versatile solution for many businesses. Their cost-effectiveness makes them appealing for budget-conscious buyers, but it’s important to note that they may not last as long as canvas tarps. When purchasing, consider the specific application and the expected lifespan of the tarpaulin.

What Makes Vinyl Tarpaulins Suitable for Industrial Applications?

Vinyl tarpaulins are constructed from PVC, providing exceptional resistance to tearing and punctures. This makes them ideal for industrial applications and event tents where durability is crucial. While they offer excellent weather resistance, buyers should be aware that vinyl tarps can trap moisture, leading to condensation issues. When selecting vinyl tarpaulins, assess the environmental conditions they will face to ensure optimal performance.

Why Choose Mesh Tarpaulins for Construction Sites?

Mesh tarpaulins are crafted from woven polypropylene, allowing for airflow while still providing some protection from debris. They are lightweight, making them easy to transport and install on construction sites. However, they are not waterproof, which limits their protective capabilities. Buyers should consider their specific needs for debris containment and airflow when opting for mesh tarpaulins.

How Do Fire Retardant Tarpaulins Enhance Safety Compliance?

Fire retardant tarpaulins are treated with flame-resistant chemicals, making them essential for environments requiring safety compliance, such as events and construction sites. While they provide an added layer of safety, the cost is generally higher due to the specialized treatment. Buyers should evaluate the necessity of fire resistance based on their operational risks and regulatory requirements when purchasing these tarps.

Related Video: Production of Tarpaulin

Key Industrial Applications of tarpaulin manufacturer

| Industry/Sector | Specific Application of tarpaulin manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Crop Protection Covers | Protects crops from adverse weather and pests | Durability, UV resistance, and size specifications |

| Construction | Site Protection and Temporary Structures | Ensures safety and compliance on job sites | Weight, tear resistance, and ease of installation |

| Transportation & Logistics | Cargo Covers | Safeguards goods during transit | Waterproofing, breathability, and custom sizes |

| Events & Hospitality | Event Tents and Canopies | Provides shelter and enhances guest experience | Aesthetic options, fire retardant properties |

| Military & Defense | Field Tarps and Shelters | Offers protection and versatility in the field | Military-grade materials, camouflage options, and durability |

How is Tarpaulin Used in Agriculture for Crop Protection?

In the agriculture sector, tarpaulin manufacturers provide crop protection covers that shield plants from harsh weather conditions, pests, and diseases. These covers are essential for maintaining crop health and ensuring yield stability, especially in regions prone to extreme weather events. For international buyers, particularly from Africa and South America, it is crucial to source tarpaulin that is durable, UV resistant, and tailored to specific crop sizes. This ensures that the materials used effectively mitigate environmental risks while enhancing agricultural productivity.

What Role Does Tarpaulin Play in Construction Site Protection?

In construction, tarpaulins serve as protective barriers for sites and temporary structures, safeguarding equipment and materials from weather-related damage. They also help maintain safety standards by preventing debris from escaping the work area. Buyers in Europe and the Middle East should prioritize sourcing high-quality tarpaulins that are lightweight yet tear-resistant, facilitating easy installation and reusability. Ensuring compliance with local regulations regarding construction materials is also vital for international sourcing.

How Are Tarpaulins Utilized in Transportation and Logistics?

Tarpaulins are extensively used in the transportation and logistics sector as cargo covers to protect goods during transit. They prevent moisture, dirt, and other elements from damaging shipments, which is especially important for international trade. When sourcing tarpaulins for this purpose, buyers should consider features such as waterproofing, breathability, and the ability to customize sizes for various cargo types. This ensures that shipments arrive in optimal condition, thereby enhancing customer satisfaction and reducing losses.

A stock image related to tarpaulin manufacturer.

Why Are Tarpaulins Important for Events and Hospitality?

In the events and hospitality industry, tarpaulins are used to create event tents and canopies that provide shelter for guests. These structures enhance the overall experience by offering protection from the elements while allowing for aesthetic customization. For international buyers, particularly in Europe and Africa, sourcing fire-retardant tarpaulins is crucial for safety compliance. Additionally, selecting visually appealing options can help elevate the event’s ambiance and attract more attendees.

How Do Tarpaulins Support Military and Defense Operations?

In military and defense applications, tarpaulins are used for field shelters and protective covers. They provide essential protection against environmental elements, ensuring the safety and comfort of personnel in various terrains. Buyers in this sector must prioritize sourcing military-grade materials that offer durability, lightweight properties, and camouflage options. This is particularly important for international buyers from the Middle East, where operational conditions can be extreme and require robust solutions to maintain operational effectiveness.

Related Video: Tarpaulin Fabric Production Line, Tarpaulin Manufacturing Process

3 Common User Pain Points for ‘tarpaulin manufacturer’ & Their Solutions

Scenario 1: Sourcing Quality Tarpaulins That Withstand Harsh Conditions

The Problem: International B2B buyers, especially in regions like Africa and the Middle East, often face the challenge of sourcing tarpaulins that can endure extreme weather conditions such as intense heat, heavy rains, or strong winds. Many manufacturers provide products that may not be tested for such climates, leading to rapid degradation and potential losses in business operations. Buyers may find themselves stuck with subpar materials that cannot fulfill their intended purpose, causing frustration and increased costs.

The Solution: To overcome this challenge, buyers should prioritize sourcing from manufacturers who specialize in durable, high-quality tarpaulins specifically designed for their regional climates. Look for certifications or test results that demonstrate the product’s resilience to UV rays, water resistance, and tensile strength. When engaging with manufacturers, inquire about their testing processes and material specifications. It’s also beneficial to request samples before placing bulk orders. Establishing a relationship with a reputable supplier who understands your specific needs can ensure you receive tarpaulins tailored to withstand local environmental challenges, ultimately saving money and enhancing operational efficiency.

Scenario 2: Navigating Complex Import Regulations

The Problem: B2B buyers in regions such as South America and Europe frequently encounter bureaucratic hurdles when importing tarpaulins. Customs regulations can vary significantly between countries, leading to delays, additional costs, or even shipment rejections. This complexity can disrupt supply chains, causing businesses to miss deadlines and lose client trust.

The Solution: To effectively navigate import regulations, buyers should conduct thorough research into the specific requirements for importing tarpaulins into their respective countries. Engaging with a local customs broker can provide invaluable assistance in understanding import tariffs, documentation, and compliance requirements. Additionally, consider partnering with a tarpaulin manufacturer that has experience in international shipping and can help facilitate the import process. They may offer advice on necessary certifications or assist with documentation, ensuring that shipments are not only compliant but also arrive in a timely manner. Being proactive in understanding and managing these regulations can prevent costly delays and enhance your company’s reputation.

Scenario 3: Ensuring Customization and Flexibility in Orders

The Problem: Many B2B buyers require customized tarpaulin solutions to meet specific project needs, such as unique sizes or branding. However, not all manufacturers can accommodate these requests, leading to frustration and wasted time. Buyers may find themselves limited to standard sizes or colors that do not fit their operational requirements, resulting in additional expenses or project delays.

The Solution: When searching for a tarpaulin manufacturer, prioritize those that offer customization options. During initial discussions, clearly communicate your specific needs regarding size, material, and branding. Look for manufacturers with a reputation for flexibility and a history of successful custom orders. Request case studies or examples of past custom projects to gauge their capability. Additionally, establish open lines of communication throughout the order process to ensure that any adjustments can be made efficiently. By working with a manufacturer who values customization, buyers can achieve tailored solutions that align perfectly with their project requirements, enhancing satisfaction and operational effectiveness.

Strategic Material Selection Guide for tarpaulin manufacturer

What Are the Key Properties of PVC Tarpaulins?

Polyvinyl Chloride (PVC) is a widely used material in tarpaulin manufacturing due to its excellent durability and versatility. PVC tarpaulins are known for their high temperature and pressure ratings, making them suitable for various applications, including construction sites, outdoor events, and agricultural uses. They exhibit good resistance to corrosion, UV radiation, and water, which enhances their longevity in harsh environments.

Pros and Cons of PVC Tarpaulins

The primary advantage of PVC tarpaulins is their durability, which translates to a longer lifespan compared to other materials. They are relatively easy to clean and maintain, making them ideal for repeated use. However, the manufacturing complexity can lead to higher production costs. Additionally, PVC tarpaulins may not be environmentally friendly due to the release of harmful chemicals during production and disposal.

Impact on Application

PVC tarpaulins are particularly compatible with outdoor applications where exposure to the elements is a concern. Their water-resistant properties make them ideal for covering equipment and goods in transit, especially in regions with high rainfall, such as parts of South America and Africa.

Considerations for International B2B Buyers

When sourcing PVC tarpaulins, buyers should consider compliance with international standards such as ASTM and DIN. In Europe, there are strict regulations regarding the use of PVC, particularly concerning its environmental impact. Buyers from Africa and South America may prioritize cost-effectiveness while ensuring that the product meets local quality standards.

How Do Polyethylene Tarpaulins Compare in Performance?

Polyethylene (PE) tarpaulins are another popular choice, especially in regions where lightweight and cost-effective solutions are needed. PE is known for its excellent water resistance and is typically less expensive than PVC. It performs well in a variety of temperatures, making it suitable for both hot and cold climates.

Pros and Cons of Polyethylene Tarpaulins

The key advantage of PE tarpaulins is their lightweight nature, which simplifies transportation and handling. They are also resistant to mildew and mold, making them ideal for humid environments. However, they are generally less durable than PVC and may tear more easily, which can limit their lifespan. Additionally, they may not perform as well under extreme weather conditions.

Impact on Application

PE tarpaulins are commonly used for temporary covers, such as in agriculture for protecting crops or in construction for site protection. Their affordability makes them a preferred choice for short-term applications in diverse markets, including Africa and South America.

Considerations for International B2B Buyers

Buyers should evaluate the specific requirements of their applications and consider the trade-offs between cost and durability. Compliance with relevant standards is also crucial, especially in Europe, where regulations may dictate the types of materials that can be used.

What Are the Benefits of Canvas Tarpaulins?

Canvas tarpaulins are made from cotton or synthetic fibers and are known for their breathability and strength. They are often treated with water-resistant coatings, enhancing their performance in wet conditions.

Pros and Cons of Canvas Tarpaulins

The primary advantage of canvas tarpaulins is their robust nature, providing excellent durability and resistance to wear and tear. They are also environmentally friendly compared to synthetic materials. However, they can be heavier and more expensive, making them less suitable for applications requiring lightweight solutions.

Impact on Application

Canvas tarpaulins are ideal for long-term applications, such as outdoor events, camping, and agricultural uses. Their breathable nature makes them suitable for covering sensitive materials that require ventilation.

Considerations for International B2B Buyers

Buyers should consider the environmental impact of canvas tarpaulins and their compliance with sustainability standards, especially in Europe. The initial investment may be higher, but the long-term durability can justify the cost.

How Do Coated Fabrics Enhance Tarpaulin Performance?

Coated fabrics, often made from polyester or nylon with a PVC or PU coating, offer enhanced performance characteristics. They provide excellent resistance to water, UV rays, and chemicals, making them suitable for demanding applications.

Pros and Cons of Coated Fabrics

The main advantage of coated fabrics is their superior strength and durability, which allows them to withstand harsh environmental conditions. They are versatile and can be used in various industries, from transportation to agriculture. However, the manufacturing process can be complex, leading to higher costs.

Impact on Application

Coated fabrics are particularly beneficial in applications requiring high durability and resistance to extreme conditions, such as in the transportation of goods in the Middle East’s hot climate.

Considerations for International B2B Buyers

Buyers should assess the specific performance requirements for their applications and consider the associated costs. Compliance with international standards is essential, particularly in regions with stringent regulations.

Summary Table of Material Selection for Tarpaulin Manufacturing

| Material | Typical Use Case for Tarpaulin Manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Construction sites, outdoor events | Excellent durability | Environmental concerns | High |

| Polyethylene (PE) | Temporary covers, agriculture | Lightweight and cost-effective | Less durable under extreme conditions | Low |

| Canvas | Long-term outdoor events, camping | Robust and environmentally friendly | Heavier and more expensive | Medium |

| Coated Fabrics | Transportation, demanding applications | Superior strength and durability | Complex manufacturing process | High |

In-depth Look: Manufacturing Processes and Quality Assurance for tarpaulin manufacturer

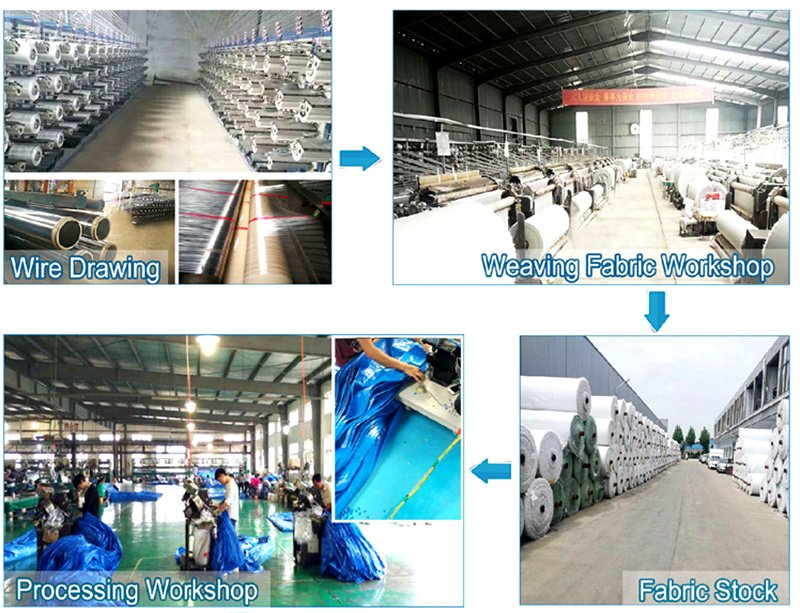

What Are the Key Stages in the Tarpaulin Manufacturing Process?

The manufacturing of tarpaulin involves several critical stages that ensure the final product meets the required specifications and quality standards. For international B2B buyers, understanding these stages is essential for making informed purchasing decisions.

Material Preparation: What Materials Are Used in Tarpaulin Production?

The first stage in tarpaulin manufacturing is material preparation, which typically involves selecting high-quality raw materials. The most common materials used include:

- Polyethylene (PE): Known for its durability and resistance to water and UV rays, PE is a popular choice for making tarpaulins.

- Polyvinyl Chloride (PVC): PVC tarpaulins offer excellent weather resistance and are often used for more demanding applications.

- Cotton or Canvas: For specialized applications, such as in agriculture, natural fibers like cotton may be used.

A stock image related to tarpaulin manufacturer.

During this phase, suppliers should provide certifications or test reports to verify the quality of the raw materials. Buyers should ask for Material Safety Data Sheets (MSDS) to understand any potential hazards associated with the materials.

How Are Tarpaulins Formed and Assembled?

Following material preparation, the next step is forming and assembling the tarpaulins. This stage often involves several key techniques:

- Weaving: For woven tarpaulins, threads are interlaced to create a strong fabric. This process can be done using various weaving patterns to enhance strength and flexibility.

- Coating: Many tarpaulins undergo a coating process to enhance water resistance and durability. This can involve applying a layer of PVC or PE to the fabric.

- Heat Sealing or Stitching: The edges of the tarpaulin are typically sealed using heat or stitched to prevent fraying. Heat sealing is preferred for waterproof applications, while stitching may be used for additional strength.

Understanding these techniques allows B2B buyers to assess the quality and functionality of the tarpaulin based on their specific needs.

What Finishing Touches Are Applied to Tarpaulins?

Finishing is the final stage of the manufacturing process, where several procedures are implemented to enhance the product’s usability:

- Trimming and Cutting: Tarpaulins are cut to the desired dimensions, ensuring they meet customer specifications.

- Eyeletting and Grommeting: Holes are reinforced with metal or plastic grommets, allowing for easy attachment and securing of the tarpaulin.

- Labeling: Final products are labeled with necessary information, including care instructions, material specifications, and compliance standards.

Buyers should inquire about the finishing processes to ensure that the tarpaulin meets their application requirements.

What International Standards Govern Tarpaulin Quality Assurance?

Quality assurance in tarpaulin manufacturing is crucial for ensuring product reliability and safety. Various international standards can guide B2B buyers in evaluating potential suppliers.

How Does ISO 9001 Impact Tarpaulin Manufacturers?

ISO 9001 is an internationally recognized quality management standard that ensures organizations consistently meet customer and regulatory requirements. Tarpaulin manufacturers adhering to ISO 9001 demonstrate a commitment to quality through:

- Continuous Improvement: Implementing processes for ongoing quality enhancements.

- Customer Focus: Engaging with clients to understand their needs and expectations.

Buyers should request ISO 9001 certification from suppliers to confirm their adherence to quality management practices.

What Other Certifications Should B2B Buyers Look For?

In addition to ISO 9001, buyers should consider other relevant certifications, such as:

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Certification: Relevant for tarpaulins used in oil and gas industries, ensuring compliance with industry-specific standards.

These certifications provide an additional layer of assurance regarding the quality and safety of tarpaulin products.

What Are the Key Quality Control Checkpoints in Tarpaulin Manufacturing?

Quality control (QC) checkpoints are critical for maintaining product integrity throughout the manufacturing process. Understanding these checkpoints can help B2B buyers evaluate suppliers effectively.

What Are the Common QC Checkpoints?

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival. It ensures that materials meet the specified standards before production begins.

- In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor processes and identify defects early. This can include checking the quality of seams, coatings, and overall fabric integrity.

- Final Quality Control (FQC): After production, the final product undergoes comprehensive testing. This may include water resistance tests, tensile strength tests, and durability assessments.

B2B buyers should inquire about the frequency and methods of these inspections to gauge the supplier’s commitment to quality.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verifying a supplier’s quality control practices is essential for mitigating risks associated with poor product quality. Here are effective strategies for B2B buyers:

What Steps Can Be Taken for Supplier Audits?

- Conduct On-Site Audits: Visiting the manufacturing facility allows buyers to assess QC practices firsthand. During the audit, buyers should examine production processes, QC documentation, and compliance with international standards.

- Request Quality Reports: Suppliers should provide detailed QC reports that outline inspection results and any corrective actions taken for non-conformities.

- Engage Third-Party Inspectors: Utilizing third-party inspection services can offer an unbiased assessment of the supplier’s quality assurance processes.

This proactive approach helps establish trust and ensures that suppliers meet the necessary quality standards.

What Are the Nuances of Quality Control for International B2B Buyers?

For international buyers, especially those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is vital.

How Do Regional Regulations Affect Quality Assurance?

Different regions may have specific regulations regarding product safety and quality. For instance, buyers in Europe need to be aware of CE marking requirements, while those in Africa might focus on local compliance standards. Understanding these nuances helps buyers select suppliers that align with their regulatory landscape.

What Challenges Do International Buyers Face?

- Language Barriers: Communication can sometimes hinder the verification of quality standards. Engaging local representatives or translators can help mitigate this issue.

- Logistics and Supply Chain Complexity: International shipping can introduce delays and potential damage. Buyers should work closely with suppliers to ensure proper packaging and handling.

By addressing these challenges, B2B buyers can navigate the international landscape more effectively and ensure that they procure high-quality tarpaulins that meet their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tarpaulin manufacturer’

Introduction

Navigating the procurement landscape for tarpaulin manufacturing can be complex, especially for international buyers from diverse regions such as Africa, South America, the Middle East, and Europe. This practical sourcing guide aims to streamline the process, ensuring you make informed decisions while minimizing risks. Follow these steps to effectively identify and engage with reliable tarpaulin manufacturers.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial before initiating supplier engagement. This includes determining the type of tarpaulin (e.g., PVC, polyethylene), thickness, weight, and any additional features such as UV resistance or flame retardancy. Documenting these specifications will help you communicate effectively with potential suppliers and ensure that the products meet your operational requirements.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential tarpaulin manufacturers. Utilize online platforms, industry directories, and trade fairs to compile a list of suppliers. Look for manufacturers with a solid reputation and extensive experience in the industry, as these factors often correlate with product quality and reliability.

Step 3: Evaluate Supplier Certifications

Before proceeding, verify the certifications of potential suppliers. Important certifications to look for include ISO 9001 for quality management systems and any specific industry-related certifications. This step is essential as it ensures the supplier adheres to international quality standards, which can significantly reduce the risk of subpar products.

Step 4: Request Samples for Assessment

Requesting samples from shortlisted suppliers is a vital step in the sourcing process. Evaluate the quality of the tarpaulin, including its durability, color fastness, and performance under different conditions. This firsthand assessment allows you to compare products and make an informed decision based on tangible evidence rather than marketing claims.

Step 5: Assess Supplier Production Capacity

Understanding a supplier’s production capacity is critical, especially if you anticipate large orders or require quick turnaround times. Inquire about their manufacturing processes, lead times, and ability to scale production based on your needs. A supplier with robust production capabilities can better accommodate your demands without compromising quality.

Step 6: Negotiate Terms and Pricing

Once you’ve selected a preferred supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Ensure that you discuss bulk order discounts, shipping costs, and any potential hidden fees. Clear and transparent negotiations will help establish a mutually beneficial relationship and avoid misunderstandings down the line.

Step 7: Establish a Communication Plan

Effective communication is key to a successful partnership with your tarpaulin manufacturer. Set up a communication plan that includes regular updates, feedback loops, and designated points of contact. This ensures that both parties are aligned throughout the production process and can quickly address any issues that may arise.

By following this step-by-step checklist, international B2B buyers can navigate the complexities of sourcing tarpaulin manufacturers with confidence, ensuring they make informed decisions that align with their operational needs and quality expectations.

Comprehensive Cost and Pricing Analysis for tarpaulin manufacturer Sourcing

Understanding the cost structure and pricing dynamics of tarpaulin manufacturing is crucial for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis delves into the key components of costs, pricing influences, and actionable tips for effective negotiations and sourcing strategies.

What Are the Key Cost Components in Tarpaulin Manufacturing?

-

Materials: The primary cost driver in tarpaulin production is the raw materials used, which typically include polyethylene, polypropylene, or canvas. The quality of the material directly affects durability and pricing, making it essential for buyers to choose materials that align with their specific application needs.

-

Labor: Labor costs can vary significantly based on geographical location and the skill level required for production. For instance, manufacturers in regions with lower labor costs may offer competitive pricing, but this can impact quality if not managed correctly.

-

Manufacturing Overhead: This includes indirect costs such as utilities, facility maintenance, and administrative expenses. Understanding these costs can help buyers assess the overall pricing strategy of a manufacturer.

-

Tooling: Initial setup costs for molds and production equipment can be substantial, especially for custom tarpaulin designs. Buyers should inquire about tooling costs when considering custom orders, as these can be amortized over larger production runs.

-

Quality Control (QC): Ensuring product quality often requires a dedicated QC process, which adds to the overall cost. Buyers should consider manufacturers with robust QC measures, as this can prevent future issues and costs associated with defective products.

-

Logistics: Shipping and handling costs are critical, particularly for international buyers. These costs can fluctuate based on distance, shipping method, and Incoterms. Understanding logistics can help buyers negotiate better terms and anticipate total expenditures.

-

Margin: Manufacturers typically add a profit margin to their costs, which can vary based on market demand, competition, and brand positioning. Buyers should be aware of the typical margins in the industry to gauge whether a quote is competitive.

How Do Pricing Influencers Affect Tarpaulin Quotes?

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk can significantly lower the per-unit cost due to economies of scale. Buyers should negotiate for lower prices by increasing order sizes when feasible.

-

Specifications and Customization: Customized tarpaulins, whether in size, color, or material, often come at a premium. Buyers should carefully assess their needs to avoid unnecessary customization that inflates costs.

-

Material Quality and Certifications: Higher-quality materials and compliance with international certifications (e.g., ISO, CE) can increase costs but are essential for applications requiring durability and safety. Buyers should weigh the benefits of these materials against their budget.

-

Supplier Factors: The supplier’s reputation, reliability, and location can impact pricing. Established suppliers may charge more due to their brand value and assurance of quality, while newer entrants may offer competitive pricing to gain market share.

-

Incoterms: The choice of Incoterms affects how costs are allocated between buyer and seller, influencing the overall price. Buyers should understand terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) to make informed decisions about total costs.

What Tips Can Help Buyers Optimize Their Tarpaulin Sourcing?

-

Negotiate Effectively: Always be prepared to negotiate terms and pricing. Leverage competitive quotes from multiple manufacturers to secure better deals.

-

Focus on Total Cost of Ownership (TCO): Consider not just the upfront cost but also the long-term implications of sourcing decisions, including durability, maintenance, and potential replacement costs.

-

Understand Regional Pricing Nuances: Buyers from different regions may face unique challenges and pricing structures. For instance, tariffs or import duties can significantly affect the final cost in Africa and South America.

-

Conduct Market Research: Stay informed about market trends and shifts in pricing. This knowledge will empower buyers to make better purchasing decisions and anticipate cost fluctuations.

Disclaimer on Pricing

Please note that the prices and cost components discussed here are indicative and can vary widely based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough due diligence before finalizing any sourcing agreements.

Alternatives Analysis: Comparing tarpaulin manufacturer With Other Solutions

Introduction to Alternative Solutions for Tarpaulin Needs

When considering the procurement of tarpaulin solutions, international B2B buyers must evaluate various alternatives that may meet their operational requirements. The choice of materials and methods can significantly impact performance, cost-efficiency, and overall usability. This section provides a comparative analysis of tarpaulin manufacturing against alternative solutions, helping businesses make informed decisions based on their specific contexts, whether in Africa, South America, the Middle East, or Europe.

Comparison Table of Tarpaulin Manufacturer and Alternatives

| Comparison Aspect | Tarpaulin Manufacturer | Alternative 1: Polyethylene Sheeting | Alternative 2: Canvas Tarps |

|---|---|---|---|

| Performance | High durability, weather-resistant | Moderate durability; less resistant to harsh weather | High durability, excellent for heavy-duty use |

| Cost | Moderate to high | Low to moderate | Moderate to high |

| Ease of Implementation | Requires specialized setup | Easy to handle and install | Requires some setup; heavier material |

| Maintenance | Low maintenance required | Low maintenance; easy to clean | Moderate; may require waterproofing treatments |

| Best Use Case | Long-term, industrial applications | Temporary or short-term projects | Heavy-duty applications, outdoor events |

Pros and Cons of Each Alternative

What are the advantages and disadvantages of Polyethylene Sheeting?

Polyethylene sheeting is a versatile alternative that provides a cost-effective solution for various applications, including construction and agriculture. Its lightweight nature makes it easy to transport and install, which is a significant advantage for temporary projects. However, its moderate durability means it may not withstand extreme weather conditions or heavy loads as well as traditional tarpaulins. Buyers should consider this option for short-term uses where budget constraints are paramount, but they should be aware of its limitations in performance over time.

How does Canvas Tarps compare to tarpaulin manufacturing?

Canvas tarps are another viable alternative that offers excellent durability and strength, making them ideal for heavy-duty applications such as outdoor events and industrial uses. Their ability to withstand harsh conditions is a considerable advantage, especially in regions with extreme weather. However, they typically come at a higher cost compared to polyethylene options, and their weight can complicate transportation and installation. For businesses focused on long-term investments in quality and durability, canvas tarps may be the best choice, provided they are prepared for the associated costs and logistics.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right tarpaulin solution requires a careful assessment of your specific needs, including the intended use, budget, and environmental conditions. While tarpaulin manufacturers offer a robust and durable solution for long-term applications, alternatives like polyethylene sheeting and canvas tarps provide flexibility and cost-effectiveness for various scenarios. B2B buyers should weigh the performance attributes and overall costs of each option against their operational requirements to ensure they make a choice that aligns with their business objectives. By thoroughly analyzing these alternatives, companies can optimize their resource allocation and enhance their operational efficiency.

Essential Technical Properties and Trade Terminology for tarpaulin manufacturer

What Are the Key Technical Properties for Tarpaulin Manufacturing?

When considering the procurement of tarpaulin, it is essential to understand its technical properties. Here are some critical specifications that B2B buyers should consider:

1. Material Grade

Tarpaulins can be made from various materials, including polyethylene (PE), polypropylene (PP), and canvas. Each material grade offers distinct characteristics, such as weight, durability, and resistance to weather conditions. For example, high-density polyethylene (HDPE) is often preferred for its strength and UV resistance, making it ideal for outdoor applications. Understanding material grade is crucial for buyers as it affects both the longevity and performance of the tarpaulin in specific environments.

2. Weight per Square Meter (GSM)

The weight of the tarpaulin is typically measured in grams per square meter (GSM). A higher GSM indicates a thicker and more durable tarpaulin. For instance, a GSM of 200 is suitable for light-duty applications, while a GSM of 600 or more is better suited for heavy-duty use. This specification is vital for B2B buyers to ensure that the tarpaulin meets the intended use and withstands the required environmental stresses.

3. Tolerance Levels

Tolerance refers to the acceptable variation in size and thickness of the tarpaulin. For B2B transactions, understanding tolerance levels ensures that the product meets precise specifications for fitting and application. For example, a tolerance of ±5% in dimensions allows for minor discrepancies during production, which can be critical for large-scale projects where accuracy is paramount.

4. UV Resistance

Tarpaulins often serve as protective covers exposed to sunlight. UV resistance is a measure of how well the material can withstand degradation from UV radiation. Buyers should seek products with high UV resistance ratings, especially in regions with intense sun exposure, as this prolongs the tarpaulin’s lifespan and maintains its functionality.

5. Water Resistance

The water resistance of a tarpaulin is determined by its material and construction quality. Buyers should look for tarpaulins with waterproof ratings, which indicate their ability to prevent water penetration. This is particularly important for applications such as covering goods during transport or protecting equipment from rain.

What Are Common Trade Terminologies in Tarpaulin Manufacturing?

Understanding industry-specific terminology is essential for effective communication and negotiation in B2B transactions. Here are some common terms you should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of tarpaulins, an OEM might produce tarpaulins for a brand that sells them under its label. Understanding OEM relationships can help buyers identify quality assurance and compatibility.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers, as it impacts inventory costs and supply chain management. Knowing the MOQ can assist in planning purchases effectively and avoiding excess inventory.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer submits to suppliers to request pricing for specific products. This process helps buyers compare prices and terms from different manufacturers, facilitating better decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are standardized terms that define the responsibilities of buyers and sellers in international trade. They cover aspects such as shipping costs, risk, and insurance. Familiarity with Incoterms is vital for B2B buyers engaging in international transactions, as they clarify obligations and reduce the risk of misunderstandings.

5. Lead Time

Lead time refers to the time taken from placing an order to the delivery of goods. Understanding lead times is essential for B2B buyers to plan their operations and manage inventory effectively.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions when sourcing tarpaulins, ensuring they select products that meet their specific needs and operational requirements.

Navigating Market Dynamics and Sourcing Trends in the tarpaulin manufacturer Sector

What Are the Current Market Dynamics and Sourcing Trends in the Tarpaulin Manufacturing Sector?

The global tarpaulin manufacturing sector is experiencing notable shifts influenced by various market dynamics. Key drivers include the increasing demand for durable and versatile materials across industries such as agriculture, construction, and transportation. In regions like Africa and South America, the agricultural sector’s growth is a significant contributor to the demand for tarpaulins used for crop protection and storage. Meanwhile, the Middle East and Europe are witnessing a rise in construction activities, boosting the need for protective coverings and temporary structures.

Emerging technologies are reshaping sourcing trends in the tarpaulin sector. The adoption of digital platforms for procurement is becoming prevalent, enabling international buyers to connect with manufacturers directly. This trend is particularly relevant for buyers in Africa and South America, where traditional sourcing channels may be less accessible. Furthermore, automation and advanced manufacturing techniques are enhancing production efficiency, leading to quicker turnaround times and improved product quality.

Sustainability is increasingly influencing purchasing decisions, with buyers prioritizing eco-friendly materials and ethical sourcing practices. As global awareness of environmental issues rises, manufacturers are adapting to these expectations by offering sustainable product lines. For B2B buyers, understanding these trends is crucial for making informed sourcing decisions that align with their operational needs and corporate social responsibility goals.

How Is Sustainability Reshaping the Tarpaulin Manufacturing Sector?

Sustainability in the tarpaulin manufacturing sector is becoming a critical factor for B2B buyers. The environmental impact of traditional tarpaulin materials, primarily made from non-biodegradable plastics, has led to increased scrutiny from consumers and regulatory bodies. As a result, manufacturers are innovating to develop eco-friendly alternatives, such as tarpaulins made from recycled materials or biodegradable polymers.

Ethical sourcing is also gaining traction, with buyers seeking transparency in their supply chains. This shift is prompting manufacturers to adopt sustainable practices, including responsible sourcing of raw materials and adherence to fair labor standards. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX serve as indicators of a manufacturer’s commitment to sustainability, providing assurance to buyers regarding the environmental and ethical integrity of their products.

For international B2B buyers, especially those from regions like Africa and Europe, aligning with manufacturers that prioritize sustainability can enhance brand reputation and meet the growing consumer demand for environmentally responsible products. By investing in sustainable tarpaulin solutions, businesses can not only mitigate their environmental footprint but also differentiate themselves in a competitive marketplace.

How Has the Tarpaulin Manufacturing Sector Evolved Over Time?

The evolution of the tarpaulin manufacturing sector has been marked by significant technological advancements and changing consumer needs. Initially, tarpaulins were made from natural materials such as canvas or cotton, which offered durability but lacked water resistance. The introduction of synthetic materials like polyethylene and polypropylene revolutionized the industry, providing enhanced durability, weather resistance, and affordability.

In recent years, the focus has shifted toward innovation and sustainability. The development of lighter, more durable materials has expanded the applications of tarpaulins across various sectors. Additionally, the rise of e-commerce has transformed how manufacturers engage with international buyers, facilitating a more streamlined purchasing process.

Understanding this evolution is essential for B2B buyers as they navigate current market dynamics. The ongoing advancements in materials and manufacturing processes will continue to shape the tarpaulin landscape, offering new opportunities for businesses to leverage these innovations in their operations.

Frequently Asked Questions (FAQs) for B2B Buyers of tarpaulin manufacturer

-

How do I evaluate the quality of tarpaulin from manufacturers?

To assess the quality of tarpaulin from manufacturers, request samples to evaluate durability, tear resistance, and waterproofing. Look for industry certifications such as ISO or ASTM standards, which indicate adherence to quality norms. Engage in direct communication with the supplier to understand their manufacturing processes and materials used. Additionally, consider customer reviews and testimonials to gauge the experiences of other B2B buyers. Establishing a clear quality assurance protocol can further ensure that the products meet your specific requirements. -

What is the best type of tarpaulin for outdoor use?

For outdoor applications, PVC tarpaulin is often the best choice due to its excellent weather resistance and durability. It withstands UV rays, rain, and extreme temperatures, making it ideal for tents, covers, and protective sheeting. Canvas tarpaulin is another option, offering breathability and a natural look, but it may require additional treatment for water resistance. Evaluate your specific use case, environmental conditions, and budget to determine the most suitable tarpaulin type for your needs. -

What customization options can I request from tarpaulin manufacturers?

Most tarpaulin manufacturers offer a variety of customization options, including size, color, and printing. You can specify dimensions tailored to your project requirements, select from a palette of colors to align with branding, and request custom logos or designs printed on the tarpaulin. Discuss with the manufacturer about reinforced edges, grommets, or additional features like flame retardancy to enhance functionality. Ensure that all customization details are documented in the contract to avoid misunderstandings. -

What is the minimum order quantity (MOQ) for tarpaulin purchases?

The minimum order quantity (MOQ) for tarpaulin can vary significantly between manufacturers, often depending on the type and customization of the product. Generally, MOQs can range from as low as 100 meters for standard tarpaulin to several thousand meters for custom orders. When negotiating, inquire about bulk pricing discounts and the potential for smaller orders during initial trials. It’s crucial to discuss your specific needs with the supplier to find a mutually agreeable MOQ. -

What payment terms are typically offered by tarpaulin manufacturers?

Payment terms can vary widely among tarpaulin manufacturers, but common options include a 30% deposit upfront with the balance due upon delivery. Some suppliers may offer net 30 or net 60 terms for established relationships. Consider using escrow services for larger transactions to ensure security. Always clarify payment methods accepted, such as bank transfers or credit cards, and be aware of any additional fees for international transactions. -

How can I ensure timely delivery of tarpaulin orders?

To ensure timely delivery of your tarpaulin orders, establish clear timelines with the manufacturer, including production and shipping durations. Discuss logistics options, such as sea or air freight, depending on urgency and budget. Utilize tracking services to monitor the shipment’s progress. Building a buffer period into your project timeline can accommodate unexpected delays in production or customs clearance, especially when dealing with international suppliers. -

What quality assurance measures should I require from a tarpaulin supplier?

Request comprehensive quality assurance measures from your tarpaulin supplier, including pre-production samples and batch testing during manufacturing. Inquire about their quality control processes, such as inspections at various stages of production. Consider implementing a third-party inspection before shipment to ensure that the tarpaulin meets your specifications. Establishing a written agreement regarding quality standards and remedies for non-compliance can protect your interests. -

How do I vet potential tarpaulin manufacturers for reliability?

To vet potential tarpaulin manufacturers, conduct thorough research into their reputation and history in the industry. Check for certifications, reviews, and testimonials from other B2B buyers. Consider visiting their facilities if possible or utilizing third-party audits to assess their operations. Establish clear communication channels to gauge responsiveness and professionalism. Request references and follow up with them to understand their experiences regarding product quality and customer service.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for tarpaulin manufacturer

In today’s global marketplace, strategic sourcing is paramount for international B2B buyers seeking reliable tarpaulin manufacturers. By fostering strong relationships with suppliers, businesses can secure high-quality materials while optimizing costs. Buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize manufacturers that demonstrate sustainability and innovation in their production processes.

Understanding the diverse applications of tarpaulins—from agriculture to construction—enables buyers to tailor their sourcing strategies effectively. Engaging with manufacturers that offer customization options can lead to enhanced product performance, meeting specific regional needs and compliance standards.

As we look to the future, the demand for durable and eco-friendly tarpaulins is expected to rise. International buyers are encouraged to leverage technology and data analytics to streamline their sourcing processes, ensuring they remain competitive. By staying informed about market trends and establishing partnerships with forward-thinking manufacturers, businesses can navigate challenges and seize opportunities in the evolving landscape.

Take the next step towards strategic sourcing excellence—connect with reputable tarpaulin manufacturers today to enhance your supply chain resilience and achieve your business goals.