Discover Cost-Saving Tips with Your Lighting Supplier (2025)

Introduction: Navigating the Global Market for lighting supplier

In today’s competitive landscape, sourcing reliable lighting suppliers can pose significant challenges for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. The complexities of navigating various supplier options, understanding local regulations, and ensuring quality compliance can be daunting. This guide aims to demystify the global market for lighting suppliers by providing actionable insights on diverse types of lighting solutions, their applications across different industries, and practical steps for effective supplier vetting.

Buyers will gain a thorough understanding of the cost structures associated with different lighting products, from energy-efficient LED systems to decorative fixtures, enabling them to make informed purchasing decisions. Additionally, this guide offers strategic approaches to overcoming common obstacles, such as logistical challenges and cultural nuances, that can affect procurement processes.

By equipping B2B buyers with comprehensive knowledge and expert advice, this resource empowers them to build strong partnerships with lighting suppliers that align with their business goals. Whether you are a buyer in Turkey looking for innovative lighting solutions or a purchasing manager in Nigeria aiming to enhance your project’s sustainability, this guide serves as your essential roadmap to successfully navigate the global lighting supplier market.

Understanding lighting supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manufacturers | Produce lighting fixtures and components directly. | Large-scale projects, OEM partnerships. | Pros: Customization options, direct sourcing. Cons: Minimum order quantities may apply. |

| Distributors | Act as intermediaries, sourcing from various manufacturers. | Retail, commercial installations. | Pros: Variety of products, faster delivery. Cons: Potential markup on prices. |

| Wholesalers | Bulk purchase and sell to retailers or contractors. | Resale to smaller businesses. | Pros: Competitive pricing, bulk purchase discounts. Cons: Limited product range compared to distributors. |

| Specialty Suppliers | Focus on niche markets (e.g., eco-friendly or smart lighting). | Specialized installations, unique projects. | Pros: Expertise in specific areas, innovative products. Cons: Higher prices for specialized items. |

| Online Marketplaces | Platforms connecting buyers with multiple suppliers. | Small to medium-sized projects. | Pros: Wide selection, easy price comparison. Cons: Quality assurance may vary. |

What Are the Characteristics of Lighting Manufacturers?

Lighting manufacturers are entities that design and produce lighting fixtures and components. They typically offer customization options, allowing B2B buyers to tailor products to specific project needs. Manufacturers are ideal for large-scale projects and original equipment manufacturer (OEM) partnerships, as they can provide direct sourcing and potentially lower costs on bulk orders. However, buyers should consider minimum order quantities and lead times, which may affect project timelines.

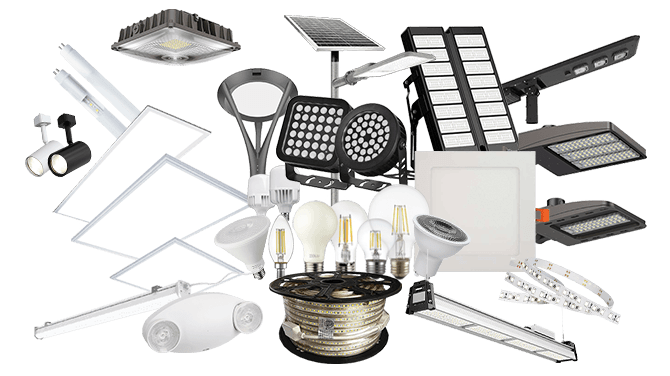

A stock image related to lighting supplier.

How Do Distributors Function in the Lighting Supply Chain?

A stock image related to lighting supplier.

Distributors play a crucial role in the lighting supply chain by sourcing products from multiple manufacturers and providing them to retailers or commercial clients. They offer a wide variety of products, making them suitable for businesses looking for a one-stop shop for lighting solutions. Distributors can facilitate quicker delivery times compared to manufacturers, but buyers should be aware of potential markups in pricing due to the added service layer.

What Are the Benefits of Working with Wholesalers?

Wholesalers focus on bulk purchasing and selling to retailers or contractors, making them a cost-effective option for businesses that need to buy in larger quantities. They typically provide competitive pricing and discounts for bulk orders, which can significantly reduce project costs. However, buyers may find that wholesalers have a more limited range of products compared to distributors, which can restrict options for specific projects.

Why Choose Specialty Suppliers for Niche Lighting Needs?

Specialty suppliers concentrate on niche markets, such as eco-friendly lighting or smart technology solutions. They provide a wealth of expertise and innovative products tailored to specific applications. These suppliers are ideal for unique projects that require specialized knowledge. However, buyers should be prepared for potentially higher prices, as specialty items often come with premium costs due to their unique features or advanced technology.

How Do Online Marketplaces Enhance B2B Lighting Purchases?

Online marketplaces serve as platforms that connect buyers with a multitude of suppliers, offering a wide selection of lighting products. They enable small to medium-sized businesses to easily compare prices and access various options without the need for direct relationships with multiple suppliers. While online marketplaces provide convenience and accessibility, buyers should exercise caution regarding quality assurance, as the standards may vary across different suppliers listed on the platform.

Related Video: The Genius Behind Bach’s Goldberg Variations: CANONS

Key Industrial Applications of lighting supplier

| Industry/Sector | Specific Application of Lighting Supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Industrial LED Lighting for Production Facilities | Improved visibility leads to enhanced productivity and safety. | Energy efficiency, durability, and compliance with local regulations. |

| Retail | Decorative and Functional Lighting for Stores | Creates an inviting atmosphere, boosting customer engagement and sales. | Customization options and energy-saving solutions are crucial. |

| Hospitality | Ambient and Task Lighting for Hotels and Restaurants | Enhances guest experience, influencing satisfaction and return rates. | Consideration of design aesthetics and energy consumption. |

| Healthcare | Medical Lighting Solutions for Clinics and Hospitals | Ensures accurate diagnosis and patient safety through optimal lighting. | Compliance with health standards and flexibility in design. |

| Public Infrastructure | Street and Outdoor Lighting Solutions | Enhances safety and security, reducing crime rates in urban areas. | Weather resistance, energy efficiency, and maintenance support are vital. |

How is Lighting Used in Manufacturing Facilities?

In the manufacturing sector, industrial LED lighting is crucial for production facilities. These lighting solutions enhance visibility in large spaces, which is essential for safety and efficiency. By providing bright, even illumination, they reduce accidents and improve worker productivity. International buyers, especially from regions like Africa and South America, should consider energy efficiency and durability, as these factors significantly impact operational costs and maintenance schedules.

What Role Does Lighting Play in Retail Environments?

In retail, decorative and functional lighting is used to create an engaging shopping atmosphere. Effective lighting not only highlights products but also influences customer behavior, leading to increased sales. For international buyers, especially in Europe and the Middle East, it’s important to source lighting solutions that offer customization options to align with brand identity and aesthetic goals. Energy-saving features are also a key consideration, as they contribute to reducing operating costs.

How Does Lighting Enhance Guest Experience in Hospitality?

Lighting in the hospitality sector, including hotels and restaurants, is vital for creating ambiance. Ambient and task lighting work together to enhance guest experiences, making spaces feel welcoming and comfortable. International buyers should prioritize design aesthetics and energy efficiency when sourcing these solutions, as they impact both guest satisfaction and operational expenses. Additionally, compliance with local lighting regulations can affect sourcing decisions.

Why is Medical Lighting Important in Healthcare Settings?

In healthcare, medical lighting solutions are essential for clinics and hospitals. These specialized lighting systems ensure accurate diagnosis and enhance patient safety by providing optimal visibility during procedures. Buyers in this sector must consider compliance with health standards, as well as the flexibility of lighting designs to accommodate various medical needs. Sourcing from reputable suppliers with a track record in healthcare applications is crucial for ensuring quality and reliability.

How Can Outdoor Lighting Improve Public Safety?

Public infrastructure relies heavily on street and outdoor lighting solutions to enhance safety and security in urban areas. Well-lit streets deter crime and improve the overall quality of life for residents. For international buyers, particularly from regions with varying climates such as Africa and the Middle East, sourcing weather-resistant and energy-efficient lighting is vital. Additionally, ongoing maintenance support from suppliers can ensure the longevity and effectiveness of these lighting solutions.

Related Video: Industrial Control Panel Basics

3 Common User Pain Points for ‘lighting supplier’ & Their Solutions

Scenario 1: Navigating Complex Compliance and Regulations in Lighting Solutions

The Problem:

B2B buyers in regions like Africa and the Middle East often face the daunting challenge of navigating complex compliance and regulatory frameworks when sourcing lighting solutions. These regulations can vary significantly not only from country to country but also within regions. For instance, specific energy efficiency standards may be mandated by local governments, while others might require adherence to international safety certifications. The lack of clear information can lead to costly mistakes, such as sourcing products that do not meet local regulations, resulting in delays or even penalties.

The Solution:

To effectively navigate these compliance issues, B2B buyers should engage with lighting suppliers who demonstrate a clear understanding of local regulations. Start by researching suppliers that provide detailed documentation on their products’ compliance with regional standards. It’s advisable to request certifications and test reports before making a purchase. Additionally, consider leveraging local industry associations or trade groups that can provide insights into regulatory requirements. Establishing a direct line of communication with the supplier’s compliance team can also facilitate a smoother procurement process, ensuring that all products meet necessary regulations before they reach your facility.

Scenario 2: Managing Supply Chain Disruptions in Lighting Procurement

The Problem:

International B2B buyers, particularly in South America and Africa, are often affected by supply chain disruptions that can delay the procurement of lighting products. Factors such as political instability, natural disasters, or even global supply chain challenges (like those seen during the COVID-19 pandemic) can lead to significant delays. This unpredictability can hinder project timelines and result in financial losses, especially when deadlines are tight.

The Solution:

To mitigate the risk of supply chain disruptions, it’s crucial to adopt a multi-supplier strategy. Rather than relying on a single supplier, B2B buyers should diversify their sources of lighting products across different regions. This can create a buffer against delays caused by localized issues. Additionally, investing in robust inventory management systems can help track stock levels and anticipate shortages before they impact operations. Establishing strong relationships with suppliers who offer transparent communication about lead times and potential disruptions can also be invaluable. By proactively managing the supply chain, buyers can better align their procurement strategies with their project timelines.

Scenario 3: Ensuring Energy Efficiency and Sustainability in Lighting Solutions

The Problem:

As global awareness of sustainability increases, B2B buyers are under pressure to source lighting solutions that are both energy-efficient and environmentally friendly. However, many suppliers may not provide clear information about the energy consumption or lifecycle impact of their products. This lack of transparency can complicate the decision-making process, making it difficult for buyers to justify their choices to stakeholders concerned about sustainability.

The Solution:

To address this challenge, buyers should prioritize suppliers that specialize in energy-efficient and sustainable lighting solutions. This involves looking for certifications such as ENERGY STAR or equivalent local certifications that guarantee a product’s energy efficiency. Requesting detailed product specifications, including energy consumption data and life expectancy, can help buyers make informed decisions. Furthermore, engaging with suppliers who have a proven track record of sustainability practices, such as using recyclable materials or eco-friendly manufacturing processes, can enhance the credibility of your procurement choices. Building partnerships with suppliers that can provide case studies or testimonials on their sustainability efforts can also support your organization’s environmental goals. By focusing on energy-efficient solutions, buyers not only comply with regulations but also contribute to broader sustainability initiatives.

Strategic Material Selection Guide for lighting supplier

When selecting materials for lighting products, international B2B buyers must consider various factors that influence product performance, manufacturing complexity, and compliance with regional standards. Here, we analyze four common materials used in lighting applications: aluminum, stainless steel, glass, and polycarbonate. Each material has unique properties, advantages, and limitations that can impact the final product’s suitability for specific applications.

What Are the Key Properties of Aluminum in Lighting Applications?

Aluminum is a lightweight and corrosion-resistant metal widely used in lighting fixtures. Its excellent thermal conductivity makes it ideal for heat dissipation in LED applications. Aluminum can withstand moderate temperatures and pressures, making it suitable for both indoor and outdoor lighting solutions.

Pros: Aluminum is durable, lightweight, and cost-effective. It is easy to machine and can be anodized for enhanced corrosion resistance.

Cons: While it performs well in most environments, aluminum can be susceptible to scratching and denting, which may affect aesthetic appeal.

Impact on Application: Aluminum’s thermal properties are beneficial for LED lighting, as they help maintain optimal operating temperatures.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local standards such as ASTM and DIN, particularly regarding corrosion resistance in humid environments.

How Does Stainless Steel Compare in Terms of Performance?

Stainless steel is known for its exceptional strength and corrosion resistance, making it a popular choice for outdoor and industrial lighting applications. It can withstand high temperatures and is less prone to rust compared to other metals.

Pros: Its durability and aesthetic appeal make stainless steel an attractive option for high-end lighting fixtures. It is also resistant to various chemicals, enhancing its longevity.

Cons: The primary drawback is its higher cost compared to aluminum. Additionally, stainless steel can be heavier, which may complicate installation.

Impact on Application: Stainless steel is ideal for environments exposed to harsh weather conditions, ensuring long-term performance.

Considerations for International Buyers: Compliance with JIS standards is crucial for buyers in Asia, while European buyers may prioritize DIN standards for quality assurance.

What Role Does Glass Play in Lighting Design?

Glass is often used in lighting fixtures for its aesthetic qualities and ability to diffuse light effectively. It comes in various types, including tempered and frosted glass, each offering different levels of durability and light transmission.

Pros: Glass provides a high-quality finish and can enhance the aesthetic appeal of lighting products. It is also resistant to UV radiation, making it suitable for outdoor applications.

Cons: Glass is fragile and can break easily, which may pose challenges during shipping and installation. It is also heavier than plastic alternatives.

Impact on Application: The choice of glass can significantly affect the light quality and distribution, making it essential for decorative and functional lighting.

Considerations for International Buyers: Buyers should be aware of packaging and shipping regulations, particularly in regions with high humidity, where glass may be more prone to damage.

Why Choose Polycarbonate for Lighting Solutions?

Polycarbonate is a durable plastic that offers excellent impact resistance and is much lighter than glass. It is often used in applications where safety and weight are concerns.

Pros: Polycarbonate is shatterproof and can withstand extreme temperatures, making it ideal for outdoor lighting. It is also cost-effective compared to glass.

Cons: While polycarbonate is durable, it can scratch more easily than glass, which may affect clarity over time.

Impact on Application: Its lightweight nature makes polycarbonate an excellent choice for portable lighting solutions and fixtures that require frequent handling.

Considerations for International Buyers: Compliance with local safety regulations is essential, especially in regions where safety standards are stringent.

Summary Table of Material Selection for Lighting Suppliers

| Material | Typical Use Case for lighting supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | LED fixtures, outdoor lighting | Lightweight and corrosion-resistant | Susceptible to scratching | Medium |

| Stainless Steel | Outdoor and industrial lighting | High strength and corrosion resistance | Higher cost and heavier | High |

| Glass | Decorative and functional fixtures | High aesthetic appeal | Fragile and heavy | Medium |

| Polycarbonate | Portable and safety lighting | Shatterproof and lightweight | Prone to scratching | Low |

This guide should assist international B2B buyers in making informed decisions regarding material selection, ensuring that their lighting products meet performance, aesthetic, and compliance requirements across diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for lighting supplier

What Are the Key Stages in the Manufacturing Process of Lighting Products?

The manufacturing process for lighting products is multifaceted and involves several critical stages that ensure high-quality output. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

-

Material Preparation

– The first step involves sourcing and preparing raw materials. Common materials for lighting fixtures include metals (like aluminum and steel), plastics, and glass. Suppliers often engage in rigorous supplier selection to ensure that raw materials meet specific standards. For B2B buyers, it’s crucial to inquire about the sourcing practices and certifications of materials used by potential suppliers. -

Forming

– This stage involves shaping the materials into desired components. Techniques such as CNC machining, stamping, and extrusion are prevalent. For example, CNC machining is often used for precision parts, while extrusion is applied for creating aluminum profiles. Buyers should look for suppliers that utilize advanced machinery and technology to enhance product accuracy and reduce waste. -

Assembly

– The assembly process integrates various components into finished products. This stage may involve manual labor or automated assembly lines, depending on the complexity of the lighting fixtures. Quality during assembly is paramount, as improper assembly can lead to product failure. B2B buyers should ask suppliers about their assembly techniques and workforce training programs. -

Finishing

– After assembly, products undergo finishing processes such as powder coating, anodizing, or painting. These processes not only enhance aesthetic appeal but also improve durability and resistance to corrosion. It’s beneficial for buyers to understand the finishing techniques used by suppliers, as these can affect the longevity and performance of the lighting products.

How Is Quality Assurance Implemented in Lighting Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process, ensuring that products meet both international standards and client expectations. Here’s a closer look at the QA process:

-

What Are the Relevant International Standards for Lighting Products?

– International standards such as ISO 9001 are essential for ensuring quality management systems. Additionally, industry-specific standards like CE marking in Europe or API standards for specific applications must be adhered to. Buyers should verify that suppliers possess the necessary certifications and understand how they maintain compliance with these standards. -

What Are the Key Quality Control Checkpoints?

– Effective quality control involves several checkpoints throughout the manufacturing process:- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during production to catch defects early.

- Final Quality Control (FQC): A comprehensive check of finished products before shipment to ensure they meet design specifications and quality standards.

-

What Common Testing Methods Are Used?

– Common testing methods include electrical safety tests, thermal performance evaluations, and photometric testing to measure light output. Buyers should inquire about the specific tests conducted and request test reports to assess product reliability.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those from diverse regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial. Here are actionable steps to undertake:

-

Conduct Supplier Audits

– Regular audits of potential suppliers can provide insights into their quality control processes. Buyers should develop a checklist based on industry standards and their specific needs. This can include reviewing documentation, interviewing staff, and inspecting production facilities. -

Request Quality Assurance Reports

– Suppliers should be able to provide detailed quality assurance reports, including results from IQC, IPQC, and FQC stages. These documents should outline any non-conformities found and corrective actions taken, which can help buyers assess the reliability of the supplier. -

Engage Third-Party Inspection Services

– Utilizing third-party inspection services can offer an unbiased evaluation of the supplier’s quality control measures. This can be particularly beneficial for international buyers who may not be able to visit suppliers in person.

What Are the Quality Control and Certification Nuances for International Buyers?

Navigating quality control and certification can be complex for international B2B buyers. Here are some essential considerations:

-

Understanding Regional Standards

– Different regions may have varying quality standards and regulations. For instance, lighting products sold in the European market must comply with CE marking requirements, while those in the Middle East may need to adhere to local safety standards. Buyers should familiarize themselves with the specific standards applicable to their target markets. -

Language and Cultural Barriers

– Communication can be a hurdle, especially when dealing with suppliers from different countries. Ensure that documentation is available in a language you understand and that the supplier can communicate effectively. Consider hiring a local consultant or partner who understands the regional market nuances. -

Building Long-term Relationships

– Establishing a long-term relationship with suppliers can lead to better collaboration on quality assurance practices. Regularly scheduled reviews and feedback sessions can enhance mutual understanding and improve product quality over time.

Conclusion

Understanding the manufacturing processes and quality assurance mechanisms of lighting suppliers is vital for international B2B buyers. By being informed about the key stages of manufacturing, quality control checkpoints, and verification methods, buyers can make better decisions that align with their quality expectations and regional compliance needs. This strategic approach not only mitigates risks but also fosters successful supplier partnerships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘lighting supplier’

This guide provides a structured approach for international B2B buyers seeking to procure lighting supplies. Whether you are sourcing from Europe, Africa, South America, or the Middle East, following these steps will help ensure you select the right supplier for your needs.

-

Define Your Technical Specifications

Clearly outline the technical requirements for your lighting products. This includes aspects such as brightness, energy efficiency, color temperature, and design specifications. Having a precise specification helps streamline the sourcing process and ensures that suppliers understand your needs, reducing the risk of miscommunication. -

✅ Research Potential Suppliers

Conduct thorough research to identify potential lighting suppliers. Utilize platforms like Europages and industry-specific directories to find reputable manufacturers. Look for suppliers with a proven track record, positive reviews, and significant experience in your desired market, particularly those familiar with regulations in your region. -

Evaluate Supplier Certifications: What Should You Look For?

Verify that your shortlisted suppliers possess necessary certifications and compliance with international standards. Certifications such as ISO 9001 for quality management and relevant safety standards (e.g., CE marking in Europe) are essential indicators of a supplier’s reliability. This step helps mitigate risks related to product quality and safety, especially in regions with stringent regulations. -

✅ Request Samples Before Committing

Always request product samples before finalizing your order. This allows you to evaluate the quality, design, and functionality of the lighting products firsthand. Consider testing samples in real-world conditions to assess their performance and suitability for your specific applications. -

🔍 Analyze Pricing and Payment Terms

Compare pricing from different suppliers while considering the overall value rather than just the lowest price. Evaluate payment terms, including deposits, payment methods, and credit terms. Understanding the total cost of ownership—including shipping and duties—will help you make a well-informed decision.

-

✅ Verify Lead Times and Shipping Capabilities

Confirm lead times for production and delivery, as well as the shipping capabilities of your supplier. Factors such as shipping methods, customs clearance, and potential delays can significantly impact your project timelines. Ensure the supplier has a robust logistics plan to meet your delivery requirements. -

🔗 Establish Communication Channels

Establish clear communication channels with your chosen supplier. Regular updates and open lines of communication can help address any issues promptly. Consider language barriers and time zone differences, especially when dealing with suppliers from diverse regions.

By following this checklist, you can streamline your sourcing process for lighting supplies, ensuring that you select a supplier that meets your technical requirements, budget, and delivery expectations.

Comprehensive Cost and Pricing Analysis for lighting supplier Sourcing

What Are the Key Cost Components in Lighting Supplier Sourcing?

When sourcing lighting suppliers, understanding the cost structure is paramount for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly affects pricing. High-quality materials like aluminum or specialized glass can drive costs up, while standard plastics may lower them. Buyers should assess the durability and performance of materials to ensure they meet project requirements.

-

Labor: Labor costs vary by region. In countries like Turkey or Nigeria, labor may be less expensive than in Western Europe, but the skill level and expertise can also differ. It’s essential to consider the balance between cost and quality.

-

Manufacturing Overhead: This encompasses all indirect costs related to production, such as utilities and facility maintenance. It’s crucial to inquire about how these costs are accounted for in the pricing structure.

-

Tooling: Custom tooling for specific designs can add significant upfront costs. Buyers should consider whether they can standardize their requirements to reduce tooling expenses.

-

Quality Control (QC): Effective QC processes can prevent costly defects and returns, but they also add to the cost. Understanding a supplier’s QC procedures can provide insights into the long-term value of the partnership.

-

Logistics: Shipping costs can vary widely based on the supplier’s location and the chosen shipping method. Incoterms can also affect logistics costs, with options like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) impacting the final price.

-

Margin: Suppliers will apply a margin to cover their costs and ensure profitability. Knowing the industry standard margins can help buyers gauge whether pricing is competitive.

How Do Price Influencers Affect Lighting Supplier Quotes?

Several factors influence the final pricing of lighting products, including:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to reduced unit costs. Buyers should negotiate based on their projected needs to secure favorable pricing.

-

Specifications and Customization: Customized products typically incur higher costs due to additional design and production requirements. Buyers should evaluate the necessity of customization against budget constraints.

-

Material Choices: The quality and type of materials directly influence cost. Buyers should specify their material preferences clearly to avoid unexpected price changes.

-

Quality Certifications: Suppliers with recognized quality certifications (ISO, CE, etc.) may charge more, but this can ensure compliance with international standards and reduce risks.

-

Supplier Factors: The reputation and reliability of the supplier can also affect pricing. Established suppliers may charge a premium for their proven track record.

-

Incoterms: Understanding Incoterms is vital for managing costs associated with shipping and delivery. Buyers should clarify responsibilities for freight, insurance, and customs duties.

What Are the Best Negotiation Strategies for B2B Buyers in Lighting Supply?

To optimize sourcing costs, international B2B buyers should consider the following strategies:

-

Conduct Thorough Market Research: Understanding the market rates for similar products can provide leverage during negotiations.

-

Leverage Volume Discounts: If possible, consolidate orders to meet minimum order quantities that qualify for discounts.

-

Focus on Total Cost of Ownership (TCO): Assess not only the purchase price but also the long-term costs associated with maintenance, energy efficiency, and potential replacements.

-

Be Transparent About Your Needs: Clear communication about project specifications, timelines, and budget constraints can foster better supplier relationships and lead to more favorable terms.

-

Consider Long-Term Partnerships: Establishing long-term relationships with suppliers can lead to better pricing and improved service levels.

What Should B2B Buyers Keep in Mind Regarding Pricing Nuances?

International buyers should be aware of several pricing nuances:

-

Currency Fluctuations: Prices may vary based on currency exchange rates. Buyers should consider locking in prices or negotiating terms that protect against fluctuations.

-

Import Duties and Taxes: Additional costs such as tariffs can significantly impact the total expenditure. Understanding the import regulations in your region is essential for accurate budgeting.

-

Disclaimer on Indicative Prices: Pricing in the lighting industry can fluctuate based on market conditions, material availability, and economic factors. Buyers should treat quoted prices as indicative and confirm them before finalizing orders.

By understanding these cost components, price influencers, and effective negotiation strategies, international B2B buyers can make informed decisions that align with their budgetary and project needs.

Alternatives Analysis: Comparing lighting supplier With Other Solutions

When considering lighting solutions for industrial or commercial applications, it is essential to evaluate various alternatives to the traditional lighting supplier model. This analysis explores how different technologies and methods stack up against conventional suppliers, helping international B2B buyers make informed decisions.

| Comparison Aspect | Lighting Supplier | LED Lighting Technology | Solar-Powered Lighting |

|---|---|---|---|

| Performance | High-quality, consistent output | Excellent energy efficiency and longevity | Variable performance depending on sunlight availability |

| Cost | Initial investment can be high, but ROI through energy savings | Moderate upfront costs, lower long-term costs | Higher installation costs but minimal operational costs |

| Ease of Implementation | Requires professional installation and integration | Generally easy to install, especially in retrofits | Installation can be complex, requiring site assessment |

| Maintenance | Regular maintenance needed for optimal performance | Minimal maintenance required, long lifespan | Requires battery maintenance and potential replacement |

| Best Use Case | Ideal for large-scale commercial spaces needing uniform lighting | Excellent for both indoor and outdoor settings | Best for areas with high sunlight exposure and low energy access |

What Are the Pros and Cons of LED Lighting Technology?

LED lighting technology has gained traction due to its energy efficiency and durability. With an impressive lifespan of up to 25,000 hours, LED lights significantly reduce the frequency of replacements. They are also known for their low energy consumption, leading to substantial savings on electricity bills. However, the initial investment can be moderate, which may deter some businesses from transitioning immediately. LED lighting is highly versatile, making it suitable for various applications, from office spaces to outdoor areas.

How Does Solar-Powered Lighting Compare?

Solar-powered lighting presents a unique alternative, particularly for locations with limited access to traditional electrical infrastructure. Once installed, solar lights incur minimal operational costs, as they rely on renewable energy. This makes them environmentally friendly and cost-effective in the long run. However, the performance of solar-powered lighting is highly dependent on sunlight availability, which can be a significant drawback in regions with less consistent sunlight. Furthermore, the installation process can be complex, often requiring professional evaluation of the site to ensure optimal performance.

Conclusion: How Can B2B Buyers Choose the Right Lighting Solution?

Choosing the right lighting solution involves understanding the specific needs of your business, including the environment, budget constraints, and performance requirements. While traditional lighting suppliers offer a reliable option for extensive commercial spaces, alternatives like LED and solar-powered lighting can provide significant cost savings and sustainability benefits. Buyers should assess their operational environment and consider the long-term implications of each option, including maintenance and energy costs, to make the most informed decision for their lighting needs.

Essential Technical Properties and Trade Terminology for lighting supplier

What Are the Key Technical Properties of Lighting Products?

Understanding the technical properties of lighting products is essential for B2B buyers to make informed purchasing decisions. Here are some critical specifications to consider:

1. Material Grade

The material grade of lighting fixtures significantly affects their durability and performance. Common materials include aluminum, stainless steel, and various plastics. Higher-grade materials often provide better corrosion resistance and longevity, which is crucial for outdoor or industrial applications. Buyers should assess the material suitability based on the environment where the lighting will be installed.

2. Lumen Output

Lumen output measures the total amount of visible light emitted by a fixture. It is a critical specification for determining the brightness of lighting products. For B2B buyers, understanding lumen output is essential for ensuring adequate illumination in commercial spaces. Consider the application, as different environments (e.g., retail vs. manufacturing) may require varying levels of brightness.

3. Color Temperature

Color temperature, measured in Kelvin (K), indicates the hue of the light emitted. Options typically range from warm white (2700K) to cool white (6500K). The choice of color temperature can influence the ambiance and functionality of a space. For example, cooler temperatures are often preferred in workspaces for increased alertness, while warmer tones create a relaxed atmosphere suitable for hospitality settings.

4. Energy Efficiency Rating

Energy efficiency ratings, such as those defined by the Energy Star program, indicate how much light is produced per watt of electricity consumed. Higher ratings represent more efficient products, which can lead to substantial cost savings over time. B2B buyers should prioritize energy-efficient lighting solutions not only for cost-effectiveness but also for sustainability and regulatory compliance.

5. Tolerance Levels

Tolerance levels refer to the permissible variation in dimensions and performance specifications of lighting fixtures. These levels are vital for ensuring compatibility with existing installations and meeting safety standards. Inaccurate tolerances can lead to installation issues or performance failures, impacting operational efficiency.

What Are Common Trade Terms Used in the Lighting Industry?

Familiarity with industry jargon is crucial for effective communication between buyers and suppliers. Here are some common trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the lighting industry, this often involves manufacturers creating custom lighting solutions for larger brands. Understanding OEM relationships can help buyers identify potential partnerships for customized products.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers as it impacts inventory management and overall costs. Buyers should negotiate MOQs to align with their business needs while ensuring they can meet supplier requirements.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. It typically includes detailed specifications and quantities required. For B2B buyers, issuing an RFQ helps compare suppliers effectively and ensures they receive competitive pricing aligned with their project requirements.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs. Understanding these terms is essential for B2B buyers engaged in cross-border transactions, as they help mitigate risks and ensure clarity in the purchasing process.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. This term is crucial for project planning and inventory management. B2B buyers should inquire about lead times upfront to avoid delays that could impact operational timelines.

By understanding these technical properties and trade terms, B2B buyers in regions like Africa, South America, the Middle East, and Europe can navigate the lighting supply market more effectively, ensuring they make informed decisions that align with their business needs.

Navigating Market Dynamics and Sourcing Trends in the lighting supplier Sector

What Are the Current Market Dynamics and Key Trends in the Lighting Supplier Sector?

The global lighting supplier sector is experiencing significant growth driven by several factors, including technological advancements, urbanization, and an increasing focus on energy efficiency. In particular, the rise of smart lighting solutions—integrated with IoT (Internet of Things)—is reshaping how businesses source lighting products. These smart systems not only enhance energy efficiency but also provide data analytics that can lead to improved operational efficiencies.

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial. The demand for LED lighting continues to surge, fueled by its long lifespan and lower energy consumption compared to traditional lighting. Additionally, sustainable lighting solutions are becoming more prevalent as companies seek to reduce their carbon footprints. Buyers should also be aware of emerging sourcing trends, such as direct procurement from manufacturers, which can lead to cost savings and greater supply chain transparency.

Furthermore, as regional markets evolve, the importance of local regulations and standards cannot be overstated. For instance, the European Union’s EcoDesign Directive influences product development and sourcing decisions. Buyers must stay informed about these regulations to ensure compliance and to leverage potential market opportunities.

How Important Is Sustainability and Ethical Sourcing in the Lighting Supplier Industry?

Sustainability and ethical sourcing are increasingly vital considerations for B2B buyers in the lighting sector. The environmental impact of lighting products—especially concerning energy consumption and waste—has become a focal point for many organizations. Buyers are now prioritizing suppliers who demonstrate a commitment to sustainable practices, such as using recyclable materials and minimizing carbon emissions during production.

Moreover, ethical supply chains are crucial for fostering trust and reliability. Buyers should look for suppliers that hold certifications such as ISO 14001 (Environmental Management) and those that utilize ‘green’ materials, such as recyclable metals and eco-friendly plastics. These certifications not only validate a supplier’s commitment to sustainability but also provide buyers with assurance that they are making responsible sourcing decisions.

As the demand for environmentally friendly products grows, companies that can offer sustainable lighting solutions will be better positioned in the market. This shift is not just a trend; it reflects a broader societal move toward sustainability that can enhance brand reputation and customer loyalty.

What Is the Historical Context of the Lighting Supplier Sector and Its Impact on Today’s Market?

The lighting supplier sector has undergone a remarkable transformation over the past few decades. Initially dominated by incandescent bulbs, the industry began shifting toward energy-efficient options in response to rising energy costs and environmental concerns. The introduction of compact fluorescent lamps (CFLs) marked a significant turning point, followed by the widespread adoption of LED technology, which now accounts for a substantial share of the market.

This evolution has paved the way for innovative lighting solutions, such as smart lighting systems that integrate with home and building automation. As technology continues to advance, the sector is expected to further evolve, providing new opportunities for international B2B buyers. Understanding this historical context is essential for making informed sourcing decisions that align with current market trends and consumer expectations.

In summary, staying abreast of market dynamics, prioritizing sustainability, and understanding the sector’s evolution are critical for international B2B buyers looking to thrive in the competitive lighting supplier landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of lighting supplier

-

How do I choose the right lighting supplier for my business needs?

Selecting the right lighting supplier involves several key factors. First, assess your specific requirements, such as the type of lighting (e.g., LED, decorative, industrial) and the scale of your project. Research suppliers’ reputations through customer reviews and industry ratings. Look for suppliers that offer customization options to meet your unique needs. Additionally, consider their experience in your region, as local suppliers may have better insights into regulatory compliance and market trends. -

What are the common payment terms offered by lighting suppliers?

Payment terms can vary widely among lighting suppliers. Common arrangements include upfront payments, 30/60/90-day payment terms, and letters of credit. International buyers should inquire about options that provide security, such as escrow services, especially for large orders. It’s also advisable to clarify currency options and any potential fees associated with international transactions. Establishing clear payment terms can help prevent misunderstandings and ensure smooth transactions. -

How can I ensure the quality of lighting products from international suppliers?

To ensure product quality, request samples before placing large orders. Check for certifications that demonstrate compliance with international standards (e.g., ISO, CE, UL). Conduct factory audits or third-party inspections to verify manufacturing processes. Establish a quality assurance (QA) protocol that includes specifications for materials, performance, and safety. Building a strong communication channel with suppliers can also facilitate feedback and resolve quality concerns promptly. -

What are the typical minimum order quantities (MOQs) for lighting products?

Minimum order quantities (MOQs) can vary significantly based on the supplier and product type. Some suppliers may have MOQs as low as 100 units, while others may require thousands. It’s crucial to clarify MOQs during your initial discussions with potential suppliers to avoid unexpected costs. If your needs are below the MOQ, consider negotiating with the supplier or exploring alternatives such as group purchasing with other businesses. -

What logistics considerations should I keep in mind when importing lighting products?

When importing lighting products, consider shipping methods, customs duties, and import regulations in your country. Air freight is faster but more expensive than sea freight, which is cost-effective for larger shipments. Be aware of packaging requirements to prevent damage during transit. Additionally, ensure that you have a reliable logistics partner familiar with international trade to help navigate customs clearance and delivery processes. -

How do I vet a lighting supplier before making a purchase?

Vetting a lighting supplier involves thorough research and due diligence. Start by checking their business credentials, such as registration and certifications. Look for industry experience and customer testimonials to gauge reliability. Request references from previous clients and follow up on their experiences. Additionally, assess the supplier’s responsiveness and willingness to communicate, as this can be indicative of their customer service and support. -

What customization options are available for lighting products?

Many lighting suppliers offer customization options to tailor products to your specifications. Common customizations include adjustments in size, color, wattage, and design features. Discuss your requirements upfront and request prototypes if necessary. Understand the implications of custom orders on lead times and costs, as these can differ from standard products. Having a clear design brief can help suppliers deliver the desired outcomes efficiently. -

What are the trends in lighting technology that B2B buyers should be aware of?

B2B buyers should stay informed about several trends in lighting technology, such as energy-efficient LED solutions, smart lighting systems, and human-centric lighting designs. Sustainable lighting options, including solar-powered fixtures, are gaining traction, particularly in regions with limited access to electricity. Additionally, the integration of IoT technology allows for remote control and monitoring of lighting systems, enhancing operational efficiency. Understanding these trends can help buyers make informed purchasing decisions that align with current market demands.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for lighting supplier

In today’s global marketplace, effective strategic sourcing is essential for B2B buyers in the lighting industry. By leveraging international suppliers, particularly from regions like Africa, South America, the Middle East, and Europe, businesses can access innovative lighting solutions that enhance operational efficiency and aesthetic appeal. Key takeaways include the importance of establishing strong supplier relationships, understanding regional regulations, and utilizing platforms like Europages to streamline sourcing processes.

Investing in strategic sourcing not only reduces costs but also improves supply chain resilience. As international buyers seek to meet growing demands for sustainable and energy-efficient lighting solutions, they should prioritize suppliers who demonstrate a commitment to innovation and quality. Engaging with manufacturers that offer customized solutions can also provide a competitive edge in local markets.

Looking ahead, the lighting industry is poised for significant growth, driven by technological advancements and increasing sustainability requirements. B2B buyers are encouraged to proactively explore partnerships with reputable suppliers and stay informed about emerging trends. By doing so, they can position themselves for success in an evolving landscape and meet the diverse needs of their customers.