Discover Custom Jackets: The Ultimate Sourcing Guide (2025)

Introduction: Navigating the Global Market for jacket custom

In the competitive landscape of global commerce, sourcing high-quality jacket custom solutions can pose significant challenges for international B2B buyers. With varying regional preferences and standards, particularly in Africa, South America, the Middle East, and Europe, understanding the intricacies of jacket customization becomes vital for successful procurement. This guide aims to equip you with essential insights into the diverse types of custom jackets available, their applications across industries, and the critical factors to consider when vetting suppliers.

Navigating this global market requires a keen understanding of material sourcing, design flexibility, production timelines, and cost structures. By exploring these dimensions, you will be better positioned to make informed purchasing decisions that align with your business needs. This comprehensive resource delves into the nuances of jacket customization, offering actionable strategies for evaluating suppliers, negotiating prices, and ensuring quality control.

As you embark on this journey, the guide will empower you to tackle common hurdles, such as language barriers and cultural differences, that may arise during international transactions. Whether your business operates in fashion, outdoor wear, or corporate branding, understanding the jacket custom landscape will enhance your ability to meet market demands efficiently. Prepare to unlock new opportunities and streamline your sourcing process with the insights provided in this guide, tailored specifically for B2B buyers across diverse regions.

Understanding jacket custom Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tailored Jackets | Custom-fit, personalized styles | Corporate uniforms, promotional events | Pros: Unique branding, tailored fit. Cons: Higher cost, longer production time. |

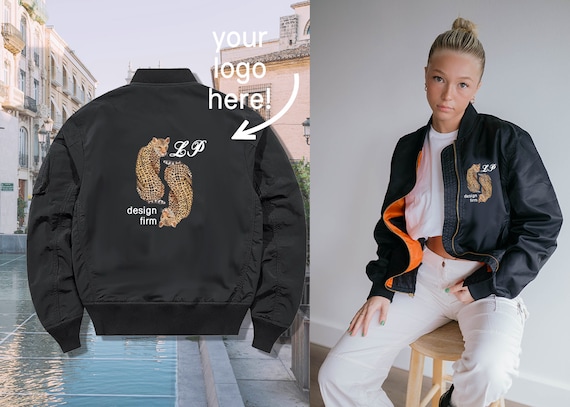

| Bomber Jackets | Short, fitted style, often with ribbed cuffs | Casual workwear, team apparel | Pros: Versatile design, popular among youth. Cons: Limited formal appeal. |

| Waterproof Jackets | Made with water-resistant materials | Outdoor events, travel industries | Pros: Functional in adverse weather, durable. Cons: Can be bulkier, higher price point. |

| Blazers | Structured, often semi-formal design | Business meetings, formal events | Pros: Professional appearance, versatile. Cons: Requires careful sizing, can be costly. |

| Softshell Jackets | Flexible, lightweight fabric | Activewear, outdoor activities | Pros: Comfortable and breathable. Cons: Less formal, limited insulation. |

What Are Tailored Jackets and Their B2B Advantages?

Tailored jackets are custom-fit garments designed to provide a unique style that reflects a company’s branding. They are particularly suitable for corporate uniforms and promotional events where a polished appearance is crucial. When purchasing tailored jackets, B2B buyers should consider the quality of fabric, the reputation of the manufacturer, and the potential for brand customization. While these jackets offer an exceptional fit and branding opportunity, they often come with a higher price point and longer production times.

How Do Bomber Jackets Fit into Business Apparel?

Bomber jackets are characterized by their short, fitted design and ribbed cuffs, making them a trendy choice for casual workwear and team apparel. They appeal to younger demographics and can be a great way to foster team spirit. B2B buyers should evaluate the style preferences of their target audience and the intended use of the jackets. While bomber jackets are versatile and generally well-received, they may not be suitable for formal business settings.

Why Choose Waterproof Jackets for Your Business Needs?

Waterproof jackets are crafted from materials designed to repel water, making them ideal for outdoor events and industries such as travel and adventure sports. They provide essential protection against the elements, which can be a significant selling point for businesses operating in regions with unpredictable weather. Buyers should assess the jacket’s breathability and durability, as these factors impact comfort and longevity. Despite their advantages, waterproof jackets can be bulkier and often come at a higher price point.

What Role Do Blazers Play in Professional Settings?

Blazers are structured garments often worn in semi-formal or professional contexts, making them suitable for business meetings and formal events. They can be paired with various outfits, enhancing versatility in a corporate wardrobe. B2B buyers should pay close attention to sizing and fabric quality, as these elements contribute significantly to the overall appearance and comfort. While blazers offer a professional look, they can be more expensive and require precise fitting.

How Do Softshell Jackets Cater to Active Businesses?

Softshell jackets are made from flexible, lightweight materials that provide comfort and breathability, making them perfect for activewear and outdoor activities. They are particularly appealing to companies in the sports and leisure sectors. B2B buyers should consider the jacket’s insulation properties and intended usage when making a purchase. While softshell jackets are comfortable and versatile, they may lack the formal appeal of other jacket types, making them less suitable for traditional business environments.

Related Video: How a $5k Luxury Leather Jacket is Made

Key Industrial Applications of jacket custom

| Industry/Sector | Specific Application of jacket custom | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil and Gas | Thermal insulation jackets for pipelines | Reduces heat loss, improving energy efficiency and safety. | Ensure compliance with local regulations and material durability. |

| Food and Beverage | Custom jackets for temperature-sensitive products | Maintains product quality during transport and storage. | Look for suppliers with certifications for food safety standards. |

| Pharmaceuticals | Customizable jackets for cold chain logistics | Ensures temperature control, safeguarding product efficacy. | Verify suppliers’ experience with cold chain management solutions. |

| Manufacturing | Protective jackets for machinery and equipment | Enhances safety and prolongs equipment lifespan. | Assess the material specifications to match industry safety standards. |

| Textile and Apparel | Fashion-forward custom jackets for branding | Strengthens brand identity while meeting customer demands. | Evaluate the supplier’s design capabilities and customization options. |

How is ‘jacket custom’ utilized in the Oil and Gas industry?

In the oil and gas sector, custom jackets are primarily used for thermal insulation of pipelines. These jackets are designed to minimize heat loss, which is crucial for maintaining the efficiency of operations. By utilizing custom jackets, companies can enhance safety, as they help in preventing overheating and potential hazards. For international buyers, sourcing jackets that comply with local regulations and are made from durable materials is essential to ensure long-term performance and reliability.

What are the applications of custom jackets in the Food and Beverage industry?

Custom jackets play a pivotal role in the food and beverage industry, particularly for temperature-sensitive products. These jackets help maintain the integrity and quality of food items during transportation and storage, preventing spoilage. For B2B buyers, it is vital to partner with suppliers who have certifications for food safety standards to ensure compliance with health regulations. This guarantees that the jackets used do not compromise the quality of the products they are designed to protect.

Why are custom jackets important for Pharmaceuticals?

In the pharmaceutical sector, custom jackets are integral to cold chain logistics. They provide precise temperature control, which is crucial for safeguarding the efficacy of temperature-sensitive medications and vaccines. For international buyers, it is important to verify suppliers’ experience in managing cold chain solutions, as this ensures that the jackets will maintain the required temperatures throughout the supply chain. This attention to detail can significantly impact the success of pharmaceutical products in the market.

How do custom jackets enhance safety in Manufacturing?

Within manufacturing, protective custom jackets are utilized for machinery and equipment to enhance safety and prolong lifespan. These jackets shield equipment from environmental factors and wear, reducing maintenance costs and downtime. B2B buyers should assess the material specifications of these jackets to ensure they meet industry safety standards. This is particularly important for international buyers who may face varying regulations in different regions, such as Europe or the Middle East.

What role do custom jackets play in Textile and Apparel branding?

In the textile and apparel industry, custom jackets are often tailored to reflect brand identity while satisfying consumer demands for style and functionality. These jackets can be designed with unique branding elements, making them a powerful marketing tool. For B2B buyers, evaluating the supplier’s design capabilities and customization options is crucial to ensure that the final product aligns with their brand vision and resonates with target markets in regions like Africa and South America.

Related Video: Uses and Gratifications Theory – UGT

3 Common User Pain Points for ‘jacket custom’ & Their Solutions

Scenario 1: Navigating Sizing and Fit Issues with Custom Jackets

The Problem: One of the most prevalent challenges faced by B2B buyers when sourcing custom jackets is the inconsistency in sizing and fit. This is particularly true for businesses that operate in diverse markets like Africa and Europe, where body shapes and sizes can vary significantly. A buyer may order a batch of jackets based on standard measurements, only to discover upon delivery that they do not fit the intended recipients. This not only leads to wasted resources but also damages the company’s reputation among employees or clients expecting a professional appearance.

The Solution: To mitigate sizing and fit issues, it is crucial to establish a comprehensive size chart that reflects the specific demographics of your target market. Collaborate closely with the manufacturer to create a custom size guide that incorporates regional variations. For example, consider engaging a local tailor or fashion consultant who understands the body types prevalent in your region. Additionally, request samples in various sizes before placing a bulk order. This practice allows you to assess the fit firsthand and make any necessary adjustments before the final production run. Always prioritize clear communication regarding any unique sizing requirements during the initial discussions with your supplier.

Scenario 2: Overcoming Design Miscommunication in Custom Jacket Orders

The Problem: Miscommunication regarding design specifications can lead to frustration and unexpected costs for B2B buyers. This is especially common when dealing with international suppliers, where language barriers and cultural differences can distort the intended message. A company may envision a jacket with specific branding elements, only to receive a product that does not match their expectations, resulting in delays and additional expenses to rectify the issue.

The Solution: To prevent design miscommunication, utilize visual aids such as sketches or mock-ups during the negotiation process. Tools like digital design software or platforms that allow for collaborative editing can help ensure everyone is on the same page. Additionally, establish a detailed specification sheet that outlines materials, colors, logos, and placement. Regular check-ins during the production process can also help catch potential issues early. Finally, consider implementing a revision policy that allows for a certain number of design adjustments before final production, which can help manage expectations and reduce the risk of costly mistakes.

Scenario 3: Managing Lead Times and Delivery Delays for Custom Jackets

The Problem: Lead times can be a significant concern for B2B buyers, particularly when dealing with custom jackets that require specific materials and designs. Delays in delivery can disrupt supply chains and impact marketing campaigns or seasonal promotions. Buyers may find themselves in a bind if their orders arrive late, leading to missed opportunities and financial losses.

The Solution: To manage lead times effectively, it is essential to plan ahead and establish clear timelines with suppliers. Start by discussing production schedules and potential bottlenecks during the initial negotiation phase. Be proactive in providing suppliers with all necessary information about your order to avoid last-minute changes that could cause delays. Consider developing a buffer by ordering jackets well in advance of key events or seasons, especially in regions where logistics may be more challenging. Additionally, explore partnerships with multiple suppliers or manufacturers to diversify your sourcing options. This strategy can provide backup solutions in case of unexpected delays, ensuring that your business remains resilient and responsive to market demands.

Strategic Material Selection Guide for jacket custom

What Are the Key Properties of Common Materials for Custom Jackets?

When selecting materials for custom jackets, it is crucial to consider their properties in relation to the intended use. Here are some of the most common materials used in jacket production, along with their key properties, pros and cons, and specific considerations for international B2B buyers.

How Does Polyester Perform in Custom Jacket Applications?

Polyester is a synthetic fabric widely used in the apparel industry due to its versatility and durability. It has a high resistance to shrinking and stretching, making it ideal for jackets that require a snug fit. Polyester also exhibits excellent moisture-wicking properties, keeping the wearer dry in humid conditions.

Pros & Cons:

– Pros: Durable, lightweight, and resistant to wrinkles and mildew. It is also cost-effective, making it a popular choice for bulk orders.

– Cons: Polyester can be less breathable than natural fibers, which may affect comfort in warmer climates. Additionally, it is not biodegradable, raising environmental concerns.

Impact on Application: Polyester jackets are suitable for a variety of climates, but buyers in hotter regions should consider blends with more breathable materials.

Considerations for International Buyers: Compliance with environmental standards is crucial, particularly in Europe where regulations are stringent. Buyers should also be aware of ASTM and ISO standards for textile performance.

What Are the Advantages of Using Nylon for Custom Jackets?

Nylon is another synthetic fabric known for its strength and elasticity. It has a high resistance to abrasion and is often used in outdoor jackets that require durability against harsh conditions.

Pros & Cons:

– Pros: Extremely durable and resistant to tears, making it ideal for rugged outdoor use. It also dries quickly, which is advantageous in wet conditions.

– Cons: Nylon can be more expensive than polyester and may not provide as much insulation, which could be a drawback in colder climates.

Impact on Application: Nylon jackets are particularly well-suited for outdoor activities in varied climates, but buyers should consider insulation layers for colder regions.

Considerations for International Buyers: Buyers should ensure that nylon fabrics meet local compliance standards, especially in the Middle East and Africa, where UV resistance may be a priority.

Why Choose Cotton for Custom Jackets?

Cotton is a natural fiber known for its softness and breathability. It is often used in casual jackets and is favored for its comfort.

Pros & Cons:

– Pros: Highly breathable and comfortable against the skin, making it suitable for everyday wear. It is also biodegradable, appealing to environmentally conscious buyers.

– Cons: Cotton is less durable than synthetic options and can shrink or lose shape over time. It also tends to absorb moisture, which may not be ideal for wet conditions.

Impact on Application: Cotton jackets are best for mild climates and casual settings, but buyers in humid areas should consider blends to enhance moisture resistance.

Considerations for International Buyers: In Europe, buyers may prioritize organic cotton options to meet sustainability goals. Compliance with textile regulations is also essential.

What About Wool as a Material for Custom Jackets?

Wool is a natural fiber that offers excellent insulation and moisture-wicking properties. It is often used in jackets designed for colder climates.

Pros & Cons:

– Pros: Provides great warmth and is naturally water-resistant. Wool is also durable and can retain its shape over time.

– Cons: Wool can be more expensive and may require special care during washing. It may also not be suitable for warmer climates.

Impact on Application: Wool jackets are ideal for cold-weather applications, but buyers in warmer regions should be cautious about using wool.

Considerations for International Buyers: Buyers should verify compliance with animal welfare standards, especially in Europe, where ethical sourcing is increasingly important.

Summary Table of Material Selection for Custom Jackets

| Material | Typical Use Case for jacket custom | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Everyday wear, casual jackets | Durable and cost-effective | Less breathable than natural fibers | Low |

| Nylon | Outdoor jackets, rugged use | Highly durable and quick-drying | More expensive, less insulation | Med |

| Cotton | Casual jackets, mild climates | Soft and breathable | Less durable, moisture-absorbing | Low |

| Wool | Cold-weather jackets | Excellent insulation | Higher cost, special care needed | High |

This guide serves as a strategic resource for international B2B buyers looking to make informed decisions on material selection for custom jackets, ensuring compliance with local standards and preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for jacket custom

What Are the Main Stages of the Manufacturing Process for Custom Jackets?

The manufacturing process for custom jackets involves several critical stages that ensure the final product meets both aesthetic and functional requirements. Understanding these stages is essential for B2B buyers to make informed decisions when selecting suppliers.

Material Preparation

The first step in jacket manufacturing is material preparation. This stage involves selecting appropriate fabrics, linings, and insulation materials based on the jacket’s intended use—whether for fashion, outdoor activities, or industrial applications. Fabrics may include cotton, polyester, or specialized waterproof materials.

Once the materials are selected, they are pre-treated to enhance their properties, such as water resistance or durability. This may involve dyeing, coating, or applying treatments that improve the fabric’s performance.

What Techniques Are Used in Forming Custom Jackets?

After material preparation, the next step is forming the jacket. This stage typically employs various cutting and sewing techniques:

-

Pattern Making: Patterns are created based on design specifications. This process can be done manually or through CAD (Computer-Aided Design) software.

-

Cutting: The fabric is cut according to the patterns. Precision is crucial at this stage to minimize waste and ensure a proper fit.

-

Sewing: Different sewing techniques are used, including flatlock, overlock, and topstitching, depending on the design and intended use of the jacket. Advanced machinery, such as automatic sewing machines, may be utilized to enhance efficiency.

How Is the Assembly Process Managed?

The assembly stage involves bringing together all components of the jacket, including zippers, buttons, and linings. Quality control during assembly is critical to ensure that each piece fits together correctly.

B2B buyers should inquire about the assembly techniques used by their suppliers. For instance, some manufacturers may use robotic automation for consistency, while others may rely on skilled labor for intricate designs.

What Finishing Techniques Are Commonly Used in Custom Jacket Manufacturing?

Finishing processes enhance the jacket’s appearance and functionality. This includes:

- Quality Checks: Inspecting seams, zippers, and overall construction to ensure they meet quality standards.

- Ironing and Folding: Jackets are pressed and folded for presentation and packaging.

- Labeling and Packaging: Proper labeling is essential for brand recognition and compliance with international standards.

What Quality Assurance Measures Should B2B Buyers Consider?

Quality assurance (QA) is a pivotal aspect of the jacket manufacturing process. For international B2B buyers, understanding the QA measures in place can significantly impact their purchasing decisions.

Which International Standards Should Be Met?

Suppliers should adhere to relevant international standards, such as ISO 9001, which focuses on quality management systems. Compliance with these standards indicates that the manufacturer has established a robust QA framework.

Additionally, industry-specific certifications like CE marking for safety and API standards for performance can provide further assurance of product quality.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are integrated throughout the manufacturing process to ensure that each jacket meets specified standards. The key checkpoints include:

-

Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet predefined specifications.

-

In-Process Quality Control (IPQC): Continuous monitoring occurs during the manufacturing process to identify and rectify issues in real-time.

-

Final Quality Control (FQC): A thorough inspection is conducted before packaging to verify that the finished product meets all quality requirements.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain high standards of quality control, B2B buyers should consider several verification methods:

What Are Effective Audit and Inspection Practices?

-

Supplier Audits: Conducting regular audits of potential suppliers can provide insight into their manufacturing processes and quality control measures. Look for audits performed by recognized third-party organizations.

-

Requesting Quality Reports: Suppliers should provide detailed quality reports that outline their processes, compliance with standards, and any corrective actions taken in response to past quality issues.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. These inspections can occur at various stages of the manufacturing process.

What Are the Nuances of QC for International Buyers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, it’s essential to understand regional nuances in quality control standards. For instance, European buyers may emphasize compliance with stringent environmental and safety regulations, while buyers from other regions may prioritize cost-effectiveness and lead times.

Understanding these regional differences can help buyers negotiate better terms and ensure that their suppliers can meet both local and international standards.

Conclusion

By gaining a comprehensive understanding of the manufacturing processes and quality assurance measures for custom jackets, B2B buyers can make informed decisions when sourcing products. Engaging with suppliers who demonstrate a commitment to quality through robust manufacturing processes and adherence to international standards will not only enhance product satisfaction but also build long-term business relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘jacket custom’

The following is a practical sourcing guide designed specifically for B2B buyers looking to procure custom jackets. This checklist outlines key steps to ensure you find the right suppliers and achieve the desired quality and specifications.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements. This includes the type of material, design elements, sizes, and any specific features such as waterproofing or insulation.

– Why it matters: Precise specifications help suppliers understand your needs, reducing the likelihood of miscommunication and ensuring that the final product meets your expectations.

Step 2: Research Market Trends and Pricing

Conduct thorough research on current market trends and pricing for custom jackets. This will provide insights into competitive pricing and popular styles within your target regions, such as Africa, South America, the Middle East, and Europe.

– What to look for: Check industry reports, trade publications, and competitor offerings to gauge what is trending and what price points are acceptable.

Step 3: Identify Potential Suppliers

Compile a list of potential suppliers who specialize in custom jackets. Use online directories, trade shows, and industry referrals to find manufacturers that align with your needs.

– Key considerations: Look for suppliers with a solid reputation, experience in your target market, and a portfolio that reflects similar projects.

Step 4: ✅ Verify Supplier Certifications

Ensure that the suppliers you are considering have the necessary certifications and comply with international quality standards.

– Why this is crucial: Certifications such as ISO, CE, or specific industry-related standards guarantee that the supplier adheres to quality management principles and can deliver products that meet regulatory requirements.

Step 5: Request Samples for Quality Assessment

Before making any commitments, request samples of the custom jackets. This will allow you to assess the quality of materials and craftsmanship firsthand.

– What to check: Evaluate the fabric, stitching, and overall finish. Pay attention to details that may impact durability and comfort, especially if the jackets will be used in demanding environments.

Step 6: Establish Clear Communication Channels

Effective communication is vital throughout the sourcing process. Ensure that you establish clear lines of communication with your chosen suppliers, including preferred methods and response times.

– Tips for success: Regular updates and feedback loops can prevent misunderstandings and ensure that both parties are aligned on expectations and timelines.

Step 7: Negotiate Terms and Conditions

Once you have selected a supplier, negotiate the terms of the contract. This includes pricing, payment terms, delivery schedules, and return policies.

– Important factors to consider: Ensure that all terms are documented clearly to avoid future disputes. Be aware of any import/export regulations that may affect your transaction based on your location.

By following this checklist, B2B buyers can streamline the sourcing process for custom jackets, ensuring they select the right suppliers and achieve high-quality results that meet their specific needs.

Comprehensive Cost and Pricing Analysis for jacket custom Sourcing

What Are the Key Cost Components in Jacket Custom Sourcing?

When sourcing custom jackets, understanding the cost structure is vital for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of fabric significantly influences the overall cost. Premium materials such as high-performance synthetics or organic fabrics can increase expenses, while bulk purchasing may yield discounts.

-

Labor: Labor costs vary widely depending on the region of production. For instance, manufacturing in countries with lower labor costs may offer savings, but potential quality issues could arise.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient production facilities can help minimize these expenses.

-

Tooling: Custom designs may require specialized tools or molds, which can be a one-time cost but should be factored into the total pricing.

-

Quality Control (QC): Ensuring that the jackets meet specified standards often necessitates additional QC measures, which can add to the overall cost.

-

Logistics: Transportation and warehousing costs are crucial, especially for international shipments. Understanding Incoterms can help clarify responsibilities and costs associated with logistics.

-

Margin: Suppliers will include a profit margin that varies based on their position in the market, the complexity of the order, and their operational efficiencies.

How Do Price Influencers Affect Custom Jacket Sourcing?

Several factors can influence pricing when sourcing custom jackets:

-

Volume/MOQ: Minimum order quantities (MOQs) often dictate pricing. Larger orders typically lower the per-unit cost, making it more economical for buyers willing to commit to higher quantities.

-

Specifications and Customization: Unique designs or additional features (e.g., waterproofing, insulation) can lead to increased costs. Buyers should clearly communicate their needs to avoid unexpected expenses.

-

Materials and Quality Certifications: High-quality materials and certifications (e.g., OEKO-TEX, GOTS) can increase production costs but may be necessary for certain markets, especially in Europe where sustainability is a growing concern.

-

Supplier Factors: The reputation, reliability, and location of the supplier can significantly affect pricing. Established suppliers may charge more due to their proven track record and quality assurance processes.

-

Incoterms: Understanding the terms of shipment and delivery can impact overall costs. Buyers should choose Incoterms that align with their logistical capabilities and risk tolerance.

What Are the Best Buyer Tips for Cost-Efficient Custom Jacket Sourcing?

To navigate the complexities of custom jacket sourcing effectively, consider these tips:

-

Negotiate Effectively: Engage suppliers in discussions about pricing, especially for larger orders. Highlighting long-term partnership potential may yield better rates.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes not just the purchase price but also shipping, customs duties, and potential returns. This holistic view can uncover hidden costs.

-

Understand Pricing Nuances: International buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of fluctuations in currency exchange rates and how they impact pricing.

-

Research Supplier Markets: Familiarize yourself with market trends and pricing variations in different regions. For instance, sourcing from Eastern Europe may offer a balance of quality and cost for European buyers.

-

Stay Informed About Regulations: Be aware of import regulations and tariffs that may apply to custom jackets, particularly when sourcing from regions with varying trade agreements.

Disclaimer on Indicative Prices

It is essential to note that the prices for custom jackets can fluctuate based on numerous factors, including market conditions, material availability, and production capacity. Always request quotes from multiple suppliers to ensure competitive pricing and to understand the full scope of costs involved in your sourcing strategy.

Alternatives Analysis: Comparing jacket custom With Other Solutions

Understanding the Importance of Alternatives in Jacket Customization

In the evolving landscape of B2B apparel solutions, the demand for customized jackets has surged. However, international buyers, particularly those from Africa, South America, the Middle East, and Europe, must consider alternative solutions that can meet their unique needs. Evaluating various options not only aids in cost-efficiency but also enhances the overall effectiveness of the end product. This analysis will explore the effectiveness of jacket customization in comparison to other viable alternatives, providing insights into how to make an informed decision.

A stock image related to jacket custom.

Comparison Table of Jacket Custom with Alternative Solutions

| Comparison Aspect | Jacket Custom | Mass Production Jackets | On-Demand Printing |

|---|---|---|---|

| Performance | High quality, tailored fit | Standardized sizing, variable quality | Variable quality, depends on printer technology |

| Cost | Higher initial investment | Lower per-unit cost | Moderate, varies based on order size |

| Ease of Implementation | Requires design input and sample approval | Streamlined production process | Requires design files and setup |

| Maintenance | Durable, depending on material choice | Varies, often less durable | May require more frequent replacement |

| Best Use Case | Corporate branding, unique promotional items | Bulk orders for events | Small runs, personal branding |

What Are the Advantages and Disadvantages of Mass Production Jackets?

Mass production jackets are a cost-effective solution for businesses looking to outfit large teams or distribute promotional apparel at scale. The primary advantage lies in the reduced per-unit cost, making it feasible for organizations with tight budgets. However, the trade-off is often in quality and fit, as these jackets typically come in standardized sizes that may not cater to all body types. Moreover, the lack of customization options can dilute branding efforts, making it less ideal for companies aiming for a unique image.

How Does On-Demand Printing Compare to Jacket Customization?

On-demand printing has emerged as a flexible alternative to jacket customization, allowing businesses to print designs on jackets as needed. This method is advantageous for small runs, making it suitable for startups or organizations testing new designs. However, the quality can vary significantly based on the technology used, and the setup may require specific design files, which can complicate the process. Additionally, while it offers some level of customization, it may not deliver the same durability and fit as fully customized jackets.

Conclusion: How to Choose the Right Jacket Solution for Your Business?

When selecting a jacket solution, international B2B buyers should carefully evaluate their specific needs, budget constraints, and branding goals. If personalization and quality are paramount, jacket customization is likely the best option, despite its higher costs. Conversely, for businesses focused on larger quantities with a tight budget, mass production jackets may be more appropriate. On-demand printing serves as a middle ground, ideal for those looking for flexibility without committing to large orders. Ultimately, understanding the strengths and weaknesses of each alternative will empower buyers to make informed decisions that align with their operational objectives.

Essential Technical Properties and Trade Terminology for jacket custom

What Are the Essential Technical Properties for Custom Jackets?

When engaging in the custom jacket market, understanding the technical properties is crucial for making informed purchasing decisions. Here are some key specifications that can significantly impact the quality and performance of custom jackets:

1. Material Grade: Why Is It Critical?

Material grade refers to the quality and type of fabric used in jacket production. Common materials include polyester, nylon, and cotton blends. Higher-grade materials tend to offer better durability, comfort, and weather resistance. For B2B buyers, selecting the right material grade ensures that the jackets meet the specific needs of their target market, such as outdoor use or fashion-forward designs.

2. Tolerance: How Does It Affect Fit and Functionality?

Tolerance in jacket manufacturing refers to the allowable variation in dimensions and specifications during production. A tighter tolerance means that the jacket will have a more precise fit, which is essential for brands focusing on tailored looks. Understanding tolerance levels helps buyers ensure that the final products will meet customer expectations and reduce returns due to sizing issues.

3. Weight: What Is Its Role in Jacket Performance?

The weight of the fabric impacts the jacket’s functionality, comfort, and intended use. Lightweight materials are ideal for layering and active wear, while heavier fabrics provide warmth and protection against the elements. Buyers must consider the weight of the fabric to align with the intended purpose of the jackets, ensuring they cater to their customers’ needs effectively.

4. Breathability: Why Is It Important for Comfort?

Breathability refers to a fabric’s ability to allow moisture and heat to escape, which is essential for comfort, especially in active or warmer climates. Fabrics with high breathability ratings are ideal for sports and outdoor jackets. For B2B buyers, selecting breathable materials can enhance customer satisfaction, as it contributes to the overall wearability of the jacket.

5. Water Resistance: How Does It Impact Jacket Usability?

Water resistance is a critical property for jackets designed for outdoor use. Fabrics treated with water-repellent coatings or constructed with waterproof membranes can protect users from rain and moisture. For international buyers, especially from regions with variable climates, investing in water-resistant jackets can lead to greater market appeal and customer retention.

What Common Trade Terms Should B2B Buyers Know in the Custom Jacket Industry?

Navigating the custom jacket landscape requires familiarity with specific trade terminology. Here are some essential terms that B2B buyers should understand:

1. OEM (Original Equipment Manufacturer): What Does It Mean for Buyers?

OEM refers to a company that produces products that are then marketed and sold by another company under its brand name. For buyers, engaging with OEMs can offer cost-effective solutions while ensuring high-quality standards. Understanding OEM relationships can help buyers negotiate better terms and foster long-term partnerships.

2. MOQ (Minimum Order Quantity): Why Is It Significant?

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is vital for buyers as it affects inventory management and cash flow. A higher MOQ may require larger upfront investments, so understanding this term helps buyers plan their orders according to market demand.

3. RFQ (Request for Quotation): How Can It Streamline Purchasing?

An RFQ is a document sent to suppliers to request pricing for specific products or services. This process helps buyers compare offers and negotiate terms. For B2B buyers, effectively using RFQs can streamline the purchasing process and ensure they receive competitive pricing for custom jackets.

4. Incoterms: What Do They Mean for International Trade?

Incoterms (International Commercial Terms) are a set of predefined rules that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers to manage shipping costs, risk, and delivery timelines effectively. Familiarity with these terms helps mitigate disputes and enhances communication with suppliers.

5. Lead Time: Why Is It Essential in Custom Orders?

Lead time refers to the time it takes from placing an order to receiving the final product. For buyers, understanding lead times is critical for inventory planning and meeting customer demands. Shorter lead times can provide a competitive advantage in fast-paced markets, making it important for buyers to discuss and negotiate these timelines with suppliers upfront.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their procurement strategies and ultimately drive business success in the custom jacket market.

Navigating Market Dynamics and Sourcing Trends in the jacket custom Sector

What Are the Current Market Dynamics and Key Trends in the Custom Jacket Sector?

The custom jacket market is experiencing significant growth driven by several global factors. One of the primary drivers is the increasing demand for personalized products among consumers, which has trickled down to B2B buyers seeking unique offerings for their retail or corporate needs. Additionally, advancements in technology, such as 3D printing and digital fabric printing, are revolutionizing the production process, allowing for rapid prototyping and customization at scale.

A stock image related to jacket custom.

Emerging B2B sourcing trends highlight the shift towards online platforms that facilitate direct connections between buyers and manufacturers. This is particularly beneficial for international buyers from regions like Africa, South America, and the Middle East, where access to diverse suppliers can enhance product offerings. Moreover, the rise of e-commerce has made it easier for B2B buyers in Europe, such as those in France and Spain, to source custom jackets from global suppliers without the need for intermediary agents.

Another key trend is the focus on agility in supply chains. B2B buyers are increasingly looking for suppliers who can respond quickly to changing market demands, enabling them to adjust inventory and product lines rapidly. This agility is crucial in the custom jacket sector, where fashion trends can shift rapidly and consumer preferences can be highly dynamic.

How Is Sustainability and Ethical Sourcing Reshaping the Custom Jacket Industry?

Sustainability is becoming a cornerstone of the custom jacket sector, with B2B buyers increasingly prioritizing environmentally friendly practices. The environmental impact of textile production, particularly in terms of water usage and chemical waste, has led to a greater demand for sustainable sourcing options. Buyers are encouraged to seek suppliers who utilize eco-friendly materials, such as organic cotton or recycled polyester, which can significantly reduce the carbon footprint of their products.

In addition to materials, the importance of ethical supply chains cannot be overstated. Buyers are now more vigilant about the working conditions of those involved in the manufacturing process. Transparency in sourcing, fair labor practices, and adherence to international labor standards are becoming essential criteria for selecting suppliers. Certifications such as Global Organic Textile Standard (GOTS) and Fair Trade can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

By prioritizing sustainability and ethical sourcing, B2B buyers can not only enhance their brand reputation but also cater to an increasingly conscious consumer base that values eco-friendly and socially responsible products.

What Is the Brief Evolution of the Custom Jacket Sector?

The custom jacket sector has evolved significantly over the past few decades, transitioning from a niche market to a mainstream offering in the apparel industry. Initially, custom jackets were primarily associated with high-end fashion and bespoke tailoring, catering to a select clientele. However, with advancements in technology and changes in consumer behavior, the market has broadened.

The introduction of digital printing and automated manufacturing processes has made customization more accessible and affordable for both suppliers and buyers. This shift has allowed businesses of all sizes to offer personalized jacket options, catering to diverse consumer preferences across different regions, including Africa, South America, the Middle East, and Europe. Today, the custom jacket market reflects a blend of tradition and innovation, providing B2B buyers with a plethora of options to meet the demands of their customers.

Frequently Asked Questions (FAQs) for B2B Buyers of jacket custom

-

How do I ensure the quality of custom jackets before placing a large order?

To ensure quality, start by requesting samples from potential suppliers. This allows you to assess the material, stitching, and overall craftsmanship. Additionally, verify the supplier’s certifications and quality assurance processes. Conduct a factory audit if possible, and inquire about their production capabilities and quality control measures. Engaging a third-party inspection service can further guarantee that your order meets specified standards before shipment. -

What are the key factors to consider when choosing a supplier for custom jackets?

Consider the supplier’s experience and reputation in the industry, particularly with businesses in your region. Evaluate their production capacity, lead times, and flexibility in customization options. It’s also crucial to assess their communication skills and responsiveness, as these factors can significantly impact your partnership. Lastly, check references or reviews from other clients to ensure reliability and quality. -

What minimum order quantities (MOQs) should I expect for custom jacket orders?

MOQs for custom jackets can vary significantly based on the supplier and the complexity of the design. Typically, you can expect MOQs to range from 100 to 500 pieces. However, some suppliers may accommodate smaller orders at a higher price per unit. Always discuss your needs upfront to negotiate suitable terms that align with your business goals and budget. -

How can I effectively manage payment terms with international suppliers?

Establish clear payment terms before finalizing any agreements. Common options include a deposit upfront with the balance due upon delivery or upon receipt of quality assurance documents. For larger orders, consider using a letter of credit to minimize risk. Ensure that the payment methods are secure and reliable, such as bank transfers or reputable payment platforms, to protect your financial interests. -

What logistics considerations should I keep in mind when importing custom jackets?

Logistics is crucial when importing custom jackets. First, understand the shipping methods available—air freight is faster but more expensive, while sea freight is cost-effective for larger orders but takes longer. Be aware of customs regulations and duties in your country to avoid unexpected costs. Collaborating with a logistics partner familiar with international trade can streamline the process and help navigate any potential challenges. -

How do I handle customs clearance for imported custom jackets?

Customs clearance involves submitting necessary documentation such as invoices, packing lists, and customs declarations. Ensure that your supplier provides accurate shipping documents to prevent delays. Familiarize yourself with the import regulations in your country, including tariffs and duties applicable to your jackets. Partnering with a customs broker can facilitate the process and ensure compliance with all legal requirements. -

What customization options should I consider for my jacket order?

Customization options can include fabric selection, color choices, logos, and unique design elements like zippers and pockets. Decide on the level of customization that aligns with your brand identity and market preferences. Also, consider functional aspects such as waterproofing, breathability, and lining materials, which can enhance the jacket’s appeal to specific customer segments. -

How do I evaluate the sustainability practices of my custom jacket supplier?

To evaluate sustainability practices, inquire about the supplier’s sourcing of materials, labor conditions, and waste management strategies. Look for certifications such as ISO 14001 for environmental management or Fair Trade for ethical labor practices. Request information on their production processes and whether they use eco-friendly materials. Engaging with suppliers who prioritize sustainability can enhance your brand’s reputation and appeal to environmentally-conscious consumers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for jacket custom

What Are the Key Takeaways for B2B Buyers in Custom Jackets?

In the evolving landscape of custom jackets, strategic sourcing emerges as a pivotal approach for international buyers. By prioritizing quality, sustainability, and supplier reliability, businesses can enhance their brand image and customer satisfaction. Engaging with suppliers who demonstrate a commitment to ethical manufacturing practices not only aligns with global trends but also builds long-term partnerships that are essential for growth in competitive markets.

How Can Buyers Leverage Market Trends for Better Sourcing Decisions?

Staying abreast of emerging trends—such as technological advancements in fabric production and the increasing demand for sustainable materials—enables buyers to make informed decisions. Exploring diverse markets, particularly in Africa, South America, the Middle East, and Europe, offers opportunities to tap into unique supplier capabilities and innovative designs that can set a brand apart.

What’s Next for International B2B Buyers in Custom Jackets?

As we look ahead, the importance of agility in supply chain management cannot be overstated. Buyers are encouraged to adopt a proactive sourcing strategy that incorporates flexibility and responsiveness to changing market demands. By fostering collaborative relationships with suppliers, businesses can navigate uncertainties more effectively and capitalize on new opportunities.

In conclusion, the landscape for custom jackets is ripe with potential. International B2B buyers should take decisive action now to refine their sourcing strategies, ensuring they remain competitive and responsive in an ever-changing marketplace. Embrace the future of custom jackets—start your strategic sourcing journey today.