Discover How to Cut Costs with Piston Custom Solutions (2025)

Introduction: Navigating the Global Market for piston custom

Navigating the complexities of the global market for custom pistons can pose significant challenges for international B2B buyers. As industries evolve, the demand for tailored solutions that meet specific operational needs has surged. Buyers from regions like Africa, South America, the Middle East, and Europe often face hurdles in sourcing high-quality custom pistons that align with their unique requirements. This guide serves as a comprehensive resource, addressing key aspects such as types of custom pistons, their diverse applications, supplier vetting processes, and cost considerations.

By exploring the intricacies of the custom piston market, this guide empowers buyers to make informed purchasing decisions that can enhance operational efficiency and product performance. Whether you’re in Argentina seeking reliable suppliers or in Egypt looking for innovative designs, understanding the landscape of custom pistons will be crucial. We will delve into critical factors such as material selection, manufacturing techniques, and quality assurance standards, ensuring that you are equipped with the knowledge necessary to navigate this competitive marketplace.

Ultimately, this guide aims to demystify the process of sourcing custom pistons, offering actionable insights that cater specifically to the needs of international buyers. With the right information, you can confidently engage with suppliers and secure the best solutions for your business, driving growth and innovation in your industry.

Understanding piston custom Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Forged Pistons | Made from solid metal, offering high strength and durability. | High-performance engines, motorsports | Pros: Excellent strength-to-weight ratio. Cons: Higher initial cost. |

| Cast Pistons | Created by pouring molten metal into molds, more cost-effective. | Standard automotive applications | Pros: Lower cost, good for mass production. Cons: Less durable under extreme conditions. |

| Hypereutectic Pistons | Features a high silicon content for improved wear resistance. | Performance and heavy-duty engines | Pros: Better thermal stability, reduced expansion. Cons: More brittle than other types. |

| Aluminum Pistons | Lightweight and good thermal conductivity, often used in racing. | Racing, high-performance vehicles | Pros: Lightweight improves performance. Cons: Can warp under high heat. |

| Steel Pistons | Heavy and extremely durable, suitable for extreme conditions. | Heavy machinery, industrial engines | Pros: Exceptional durability and strength. Cons: Heavier, can affect overall engine performance. |

What Are the Key Characteristics of Forged Pistons?

Forged pistons are known for their exceptional strength and durability, making them ideal for high-performance applications such as motorsports and racing engines. These pistons are produced from solid metal, which enhances their structural integrity, allowing them to withstand extreme pressures and temperatures. When considering forged pistons, B2B buyers should evaluate their performance needs against the higher upfront costs, as these pistons typically demand a greater investment.

How Do Cast Pistons Compare in Terms of Cost and Application?

Cast pistons are manufactured by pouring molten metal into molds, making them a more economical choice for standard automotive applications. They are widely used in mass-produced vehicles due to their lower production costs. However, B2B buyers should be aware that while cast pistons are suitable for everyday use, they may not perform well under extreme conditions, which could lead to higher maintenance costs in the long run.

What Advantages Do Hypereutectic Pistons Offer?

Hypereutectic pistons are characterized by their high silicon content, which enhances wear resistance and thermal stability. These pistons are suitable for performance and heavy-duty engines, as they can handle higher temperatures and pressures without significant expansion. Buyers should consider hypereutectic pistons for applications requiring durability, but they should also note that their brittleness may pose a risk in some operational contexts.

Why Are Aluminum Pistons Preferred for Racing Applications?

Aluminum pistons are favored in racing and high-performance vehicles due to their lightweight nature and excellent thermal conductivity. This lightweight characteristic can significantly improve engine performance by reducing overall weight. However, B2B buyers must consider that aluminum pistons can warp under extreme heat, which could lead to performance issues. Therefore, careful monitoring and maintenance are essential when using aluminum pistons in demanding environments.

What Is the Role of Steel Pistons in Heavy Machinery?

Steel pistons are known for their unmatched durability, making them suitable for heavy machinery and industrial engines that operate under extreme conditions. Their robust construction allows them to withstand high levels of stress and wear. However, B2B buyers should be cautious of the added weight, which can affect overall engine performance. When purchasing steel pistons, businesses should assess their specific application needs to ensure compatibility with their operational requirements.

Related Video: How Piston ring works explained| what different piston rings mean

Key Industrial Applications of piston custom

| Industry/Sector | Specific Application of piston custom | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Custom pistons for high-performance engines | Enhanced engine efficiency and power output | Material quality, precision engineering, and compliance with standards |

| Oil and Gas Exploration | Custom pistons in drilling equipment | Increased durability and reduced maintenance costs | Supplier reliability, technical support, and customization options |

| Industrial Machinery | Custom pistons in hydraulic systems | Improved performance and energy efficiency | Compatibility with existing systems and availability of spare parts |

| Aerospace Engineering | Custom pistons for aircraft engines | Weight reduction and improved fuel efficiency | Certification for aerospace standards and material specifications |

| Agricultural Equipment | Custom pistons in tractors and harvesters | Enhanced operational efficiency and longevity | Adaptability to various agricultural conditions and local regulations |

How Are Custom Pistons Used in Automotive Manufacturing?

In the automotive sector, custom pistons are essential for high-performance engines. These pistons are designed to withstand higher pressures and temperatures, significantly improving engine efficiency and power output. B2B buyers in this industry need to focus on material quality and precision engineering to ensure the pistons meet stringent performance standards. Additionally, compliance with regional automotive regulations is crucial, particularly in markets like Europe and South America, where emissions standards are increasingly stringent.

What Role Do Custom Pistons Play in Oil and Gas Exploration?

Custom pistons are vital components in drilling equipment used in the oil and gas industry. They enhance the durability of machinery, thereby reducing maintenance costs and downtime. For international buyers, especially in Africa and the Middle East, sourcing reliable suppliers who can provide technical support and customization options is essential. This ensures that the pistons can handle the extreme conditions often encountered in oil drilling operations, which can vary greatly by region.

How Are Custom Pistons Beneficial in Industrial Machinery?

In industrial machinery, custom pistons are used in hydraulic systems to improve performance and energy efficiency. These pistons must be compatible with existing systems to avoid costly modifications. B2B buyers should prioritize suppliers who offer extensive customization options and readily available spare parts. This is particularly important for companies in Europe and South America, where operational efficiency directly impacts profitability.

Why Are Custom Pistons Important in Aerospace Engineering?

In aerospace engineering, custom pistons are crucial for aircraft engines, as they contribute to weight reduction and improved fuel efficiency. Buyers in this sector need to ensure that their suppliers can provide certified components that meet aerospace standards. This includes adherence to specific material specifications and rigorous testing protocols. Given the high stakes of safety and performance in aviation, sourcing from reputable manufacturers is non-negotiable.

How Do Custom Pistons Enhance Agricultural Equipment Performance?

Custom pistons are increasingly used in agricultural equipment such as tractors and harvesters to enhance operational efficiency and longevity. These pistons are designed to adapt to various agricultural conditions, which is particularly relevant for buyers in regions like Argentina and Egypt, where farming practices can differ widely. Buyers should consider local regulations and the adaptability of the pistons to ensure they meet the specific needs of their agricultural machinery.

Related Video: Directional Control Valves (Hydraulic & Pneumatic): Types, Mechanism, Actuating Method, Applications

3 Common User Pain Points for ‘piston custom’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Custom Pistons

The Problem: For B2B buyers in industries such as automotive or heavy machinery, sourcing high-quality custom pistons can be a daunting task. Often, these buyers face challenges like inconsistent quality from suppliers, leading to mechanical failures and operational downtimes. This is particularly critical for businesses in Africa and South America, where local sourcing options may be limited, and importing can be fraught with regulatory hurdles and delays.

The Solution: To navigate this challenge, buyers should prioritize establishing relationships with reputable manufacturers who specialize in custom pistons. Conduct thorough background checks and request samples to assess quality before committing to bulk orders. Participating in industry trade shows or utilizing platforms like ThomasNet can help connect buyers with verified suppliers. Additionally, leveraging local resources, such as university engineering departments, can yield insights into potential manufacturers who adhere to high standards. Implementing a rigorous quality control process that includes pre-shipment inspections can further mitigate risks associated with sourcing.

Scenario 2: Miscommunication on Technical Specifications

The Problem: Misunderstandings around technical specifications can lead to costly errors in production. Buyers may find themselves receiving pistons that do not meet their exact requirements, resulting in wasted time and resources. This is especially prevalent in regions like the Middle East, where technical standards may vary significantly from those in Europe or North America.

The Solution: To ensure clear communication, B2B buyers should create detailed specification sheets that outline every requirement, including dimensions, material grades, and performance standards. Utilizing CAD models can also facilitate better understanding among all parties. When engaging with suppliers, it is beneficial to have bilingual staff or translation services to bridge any language gaps. Regular meetings via video calls can also help clarify expectations and foster a collaborative relationship. Additionally, utilizing project management tools to track specifications and changes can further reduce the chances of miscommunication.

Scenario 3: Long Lead Times and Delivery Delays

The Problem: A common pain point for international B2B buyers is the unpredictability of lead times and delivery schedules, which can severely disrupt production schedules. This issue is particularly pronounced for companies in Europe and Africa that rely on just-in-time manufacturing practices. Delays can occur due to various factors, including customs clearance, shipping logistics, and production bottlenecks.

The Solution: To combat long lead times, buyers should implement a proactive supply chain strategy. This includes identifying multiple suppliers to create a diversified sourcing strategy that mitigates risks associated with reliance on a single source. Additionally, setting clear expectations regarding delivery timelines in contracts and maintaining open lines of communication with suppliers can help anticipate and address potential delays. Utilizing logistics partners who specialize in international shipping can streamline the process and improve delivery times. Furthermore, forecasting demand accurately and placing orders well in advance can buffer against unforeseen delays, ensuring that production remains uninterrupted.

Strategic Material Selection Guide for piston custom

When selecting materials for custom pistons, international B2B buyers must consider various factors that influence performance, durability, and cost-effectiveness. This guide analyzes several common materials used in piston manufacturing, focusing on their properties, advantages, disadvantages, and specific considerations for buyers in Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Aluminum for Custom Pistons?

Aluminum is a popular choice for custom pistons due to its favorable weight-to-strength ratio. It typically has a temperature rating of up to 200°C and can withstand moderate pressures. Its inherent corrosion resistance makes it suitable for various environments, particularly in automotive applications.

Pros and Cons of Aluminum Pistons

Aluminum pistons are lightweight, which enhances engine efficiency and performance. They are relatively easy to manufacture, allowing for cost-effective production. However, they may not be suitable for high-temperature applications exceeding their thermal limits, and they can be prone to wear under extreme conditions.

Impact on Application

Aluminum pistons are compatible with a wide range of media, including gasoline and diesel fuels. However, they may not perform well in high-performance engines that generate excessive heat, necessitating careful application consideration.

Considerations for International Buyers

Buyers from regions like Africa and South America should ensure compliance with local manufacturing standards, such as ASTM and ISO certifications. Understanding the regional climate and its impact on material performance is also crucial.

How Does Steel Perform as a Material for Custom Pistons?

Steel is another widely used material in piston manufacturing, known for its exceptional strength and durability. It can withstand high temperatures (up to 600°C) and pressures, making it ideal for heavy-duty applications.

Pros and Cons of Steel Pistons

The primary advantage of steel pistons is their durability and resistance to deformation. They are suitable for high-performance engines and applications requiring significant strength. However, steel pistons are heavier than aluminum counterparts, which can lead to reduced efficiency. Additionally, their manufacturing process is more complex, potentially increasing costs.

Impact on Application

Steel pistons are highly compatible with various media, including high-viscosity oils and fuels. Their robustness makes them suitable for industrial applications, but their weight may limit their use in lightweight automotive engines.

Considerations for International Buyers

For buyers in the Middle East and Europe, understanding the specific steel grades and standards, such as DIN and JIS, is essential. Compliance with local regulations regarding emissions and material sourcing can also impact procurement decisions.

What Are the Benefits of Using Composite Materials for Custom Pistons?

Composite materials, such as carbon fiber-reinforced plastics, are emerging as viable options for custom pistons. These materials offer excellent strength-to-weight ratios and can withstand temperatures up to 300°C.

Pros and Cons of Composite Pistons

Composite pistons are lightweight and can be engineered for specific applications, providing high performance while reducing overall weight. However, they can be more expensive to manufacture and may have limitations in terms of temperature and pressure resistance compared to metals.

Impact on Application

Composite materials are particularly suited for applications where weight reduction is critical, such as in motorsport or aerospace. Their chemical resistance makes them compatible with various fuels and lubricants.

Considerations for International Buyers

Buyers in regions like South America and Europe should be aware of the specific certifications required for composite materials. Understanding the lifecycle and recyclability of these materials can also influence purchasing decisions.

What Role Does Cast Iron Play in Custom Piston Manufacturing?

Cast iron is a traditional material used in piston manufacturing, known for its excellent wear resistance and ability to absorb vibrations. It typically performs well at temperatures up to 400°C and can handle significant pressure.

Pros and Cons of Cast Iron Pistons

Cast iron pistons are durable and have good thermal conductivity, making them suitable for various applications. However, they are heavier than aluminum and composite options, which can affect overall engine performance. Additionally, the manufacturing process can be more labor-intensive, leading to higher costs.

Impact on Application

Cast iron pistons are commonly used in heavy machinery and industrial applications where durability is paramount. They may not be suitable for high-speed applications due to their weight.

Considerations for International Buyers

For buyers in Africa and the Middle East, understanding local sourcing options and compliance with manufacturing standards is crucial. The availability of cast iron and its cost can vary significantly by region.

Summary Table of Material Selection for Custom Pistons

| Material | Typical Use Case for piston custom | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Automotive engines | Lightweight and efficient | Limited high-temperature use | Medium |

| Steel | Heavy-duty applications | High strength and durability | Heavier, complex manufacturing | High |

| Composite | Motorsports and aerospace | Excellent strength-to-weight | Higher manufacturing costs | High |

| Cast Iron | Industrial machinery | Excellent wear resistance | Heavier, labor-intensive | Medium |

This strategic material selection guide provides international B2B buyers with essential insights into the various materials available for custom pistons. By understanding the properties, advantages, and regional considerations, buyers can make informed decisions that align with their specific application needs.

In-depth Look: Manufacturing Processes and Quality Assurance for piston custom

What Are the Key Stages in Manufacturing Custom Pistons?

The manufacturing process for custom pistons is intricate, involving several key stages that ensure high performance and reliability. Understanding these stages is essential for B2B buyers looking to procure quality products.

Material Preparation: What Materials Are Commonly Used for Custom Pistons?

The first step in the manufacturing process is material preparation. Custom pistons are typically made from high-quality aluminum alloys or forged steel, chosen for their strength-to-weight ratio and thermal properties. Buyers should inquire about the specific grades of materials used, as this can greatly affect performance and longevity.

Once the material is selected, it undergoes processes such as cutting, heating, and chemical treatment to enhance its properties. It’s crucial for buyers to verify that suppliers source materials from reputable suppliers who comply with international standards, ensuring traceability and quality.

How Are Custom Pistons Formed and Shaped?

The forming stage involves several techniques, including casting, forging, and machining.

-

Casting: This method involves pouring molten metal into a mold to create the piston shape. It is cost-effective for large production runs but may not provide the precision that some applications require.

-

Forging: This technique uses compressive forces to shape the material, resulting in stronger and more durable pistons. Forging is often preferred for high-performance applications.

-

Machining: After forming, pistons typically undergo machining to achieve precise dimensions and surface finishes. CNC (Computer Numerical Control) machining is widely used for its accuracy and repeatability.

Buyers should ask suppliers about the specific techniques employed and their capabilities, as this can impact both the quality and cost of the pistons.

What Quality Assurance Measures Are Essential for Custom Pistons?

Quality assurance (QA) is paramount in the manufacturing of custom pistons. A robust QA process ensures that the final product meets or exceeds industry standards and customer specifications.

Which International Standards Should Buyers Look For?

B2B buyers should ensure that their suppliers adhere to recognized international quality standards, such as ISO 9001, which focuses on consistent quality management systems. In addition, industry-specific certifications like CE marking for European markets or API standards for oil and gas applications are critical indicators of quality.

It is beneficial to request documentation proving compliance with these standards. Suppliers that have undergone third-party audits to certify their processes may provide added assurance regarding their commitment to quality.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This is the first line of defense, where raw materials are inspected for defects before production begins. Buyers should confirm that suppliers perform rigorous testing on incoming materials.

-

In-Process Quality Control (IPQC): During manufacturing, periodic checks are essential to ensure that the production process remains within specified tolerances. This may include dimensional checks and visual inspections.

-

Final Quality Control (FQC): After manufacturing, the finished pistons undergo comprehensive testing, including performance tests, dimensional verification, and surface quality assessments. Buyers should inquire about the testing methods used and the criteria for acceptance.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, verifying supplier quality control is critical to ensuring that purchased products meet expectations.

What Role Do Audits and Reports Play in Quality Assurance?

Conducting audits of potential suppliers can provide invaluable insights into their manufacturing processes and quality control measures. Buyers should request audit reports, which should include details on compliance with international standards and any corrective actions taken in response to past issues.

Additionally, establishing a relationship with suppliers that are open to regular audits fosters trust and transparency. Suppliers that maintain detailed documentation can demonstrate their commitment to quality.

How Important Are Third-Party Inspections?

Engaging third-party inspection services can further bolster confidence in the quality of custom pistons. These independent inspections can assess compliance with agreed specifications and standards at various stages of production. Buyers should consider incorporating third-party inspections as part of their procurement strategy, especially when dealing with new or unverified suppliers.

What Common Testing Methods Should Buyers Be Aware Of?

Understanding common testing methods can help buyers assess the quality of custom pistons. Key testing methods include:

- Dimensional Testing: Ensures that the pistons meet specified tolerances.

- Hardness Testing: Assesses the material hardness, which is crucial for durability.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and X-ray inspection can identify internal flaws without damaging the product.

- Performance Testing: Simulating operational conditions to evaluate the piston’s performance under stress.

Buyers should ensure that suppliers provide comprehensive testing reports that detail the methodologies used and the results obtained.

What Are the QC and Certification Nuances for International Buyers?

Navigating the nuances of quality control and certification can be complex for international buyers. Variations in standards and regulations across different regions can affect product acceptance.

How Do Regional Standards Impact Quality Assurance?

For example, buyers in Europe must comply with EU regulations, which may require additional certifications such as RoHS or REACH, while buyers in South America may face different regulatory environments. Understanding these regional requirements is crucial for compliance and market entry.

Furthermore, buyers should consider the implications of tariffs and trade agreements that may affect supply chain dynamics. Engaging with local experts or consultants familiar with these regulations can provide additional guidance.

Conclusion: How Can Buyers Ensure Quality in Custom Pistons?

In summary, international B2B buyers looking for custom pistons should thoroughly evaluate the manufacturing processes and quality assurance measures of potential suppliers. By understanding the key stages of production, verifying compliance with international standards, and utilizing robust QC practices, buyers can make informed decisions that enhance their procurement strategies and ensure the reliability of their piston products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘piston custom’

In the world of B2B procurement, especially for specialized products like custom pistons, a systematic approach is vital. This guide will help international buyers from regions such as Africa, South America, the Middle East, and Europe navigate the complexities of sourcing custom pistons. By following this checklist, you can ensure that your procurement process is efficient, cost-effective, and aligned with your technical requirements.

Step 1: Define Your Technical Specifications

Clearly outline the technical specifications of the custom pistons you require. This step is crucial as it sets the foundation for your sourcing process. Consider factors such as size, material, design requirements, and performance standards. Having a detailed specification will help suppliers understand your needs and provide accurate quotes.

- Material Requirements: Specify if you need aluminum, steel, or composite materials.

- Performance Standards: Define the operating conditions, such as temperature and pressure limits.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in custom pistons. This step is essential to ensure that you are engaging with reputable manufacturers who can meet your specifications. Utilize industry directories, trade shows, and online platforms to compile a list of candidates.

- Industry Connections: Leverage networks and trade associations to find trusted suppliers.

- Market Reputation: Read reviews and testimonials to gauge supplier reliability.

Step 3: Evaluate Supplier Capabilities

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; ask for evidence of their production capabilities and quality control measures.

- Production Capacity: Ensure the supplier can handle your order volume within your timeframe.

- Quality Assurance: Inquire about their quality control processes and certifications.

Step 4: Request Samples and Prototypes

Always request samples or prototypes before finalizing an order. This step allows you to assess the quality and compatibility of the custom pistons with your requirements. Reviewing samples can save you significant costs and time in the long run.

- Testing: Conduct performance tests to ensure they meet your specifications.

- Design Verification: Check that the samples align with your technical drawings.

Step 5: Negotiate Pricing and Terms

Engage in negotiations to establish clear pricing and payment terms. This step is vital to avoid unexpected costs and ensure that you understand the total cost of ownership. Discuss factors such as bulk discounts, payment schedules, and warranties.

- Transparent Pricing: Ask for a breakdown of costs, including shipping and handling.

- Payment Flexibility: Explore options for payment terms that suit your cash flow.

Step 6: Verify Compliance and Certifications

Ensure that your chosen supplier adheres to relevant industry standards and certifications. This verification is essential, particularly for international transactions, to avoid legal and compliance issues. Confirm that the supplier has certifications such as ISO, CE, or other relevant local regulations.

- Regulatory Compliance: Verify that the products meet the safety and environmental regulations of your country.

- Documentation: Request copies of certifications and compliance documents.

Step 7: Establish a Communication Plan

Create a clear communication plan with your supplier to facilitate smooth interactions throughout the sourcing process. Regular updates and open lines of communication can help address any issues promptly and ensure project timelines are met.

- Contact Points: Define key contacts on both sides for specific issues.

- Regular Updates: Schedule regular check-ins to monitor progress and address concerns.

By following this sourcing checklist, B2B buyers can navigate the complexities of procuring custom pistons effectively, ensuring that they partner with reliable suppliers and achieve their operational goals.

Comprehensive Cost and Pricing Analysis for piston custom Sourcing

What Are the Key Cost Components in Piston Custom Sourcing?

Understanding the cost structure is crucial for international B2B buyers seeking to source custom pistons. The cost typically consists of several components:

-

Materials: The choice of materials significantly impacts the overall cost. Common materials include aluminum, steel, and specialty alloys. Prices can fluctuate based on global supply and demand, so keeping abreast of market trends is vital.

-

Labor: Labor costs vary widely by region. For instance, manufacturing in countries with lower labor costs may offer savings but could compromise quality. Assessing the skill level of the workforce is also essential, as it can affect production efficiency and product quality.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and administrative expenses. Understanding the overhead structure of your supplier can provide insights into their pricing strategies.

-

Tooling: Custom piston manufacturing often requires specialized tooling, which can be a significant upfront cost. Buyers should consider the tooling lifespan and how it may affect pricing over time.

-

Quality Control (QC): Implementing rigorous QC processes ensures that pistons meet specifications, but it also adds to costs. Buyers should evaluate the supplier’s QC practices to understand their impact on pricing.

-

Logistics: Shipping costs, tariffs, and handling fees can substantially increase the total cost. It’s crucial to consider the logistics strategy, including the choice of transport mode and delivery timelines.

-

Margin: Suppliers will include a margin in their pricing to cover risks and ensure profitability. Understanding typical margins in the custom piston market can help in negotiations.

How Do Price Influencers Impact Custom Piston Sourcing?

Several factors influence the pricing of custom pistons, which buyers must consider when negotiating:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically lower the cost per unit due to economies of scale. However, understanding the MOQ policies of suppliers is essential, as some may require substantial upfront commitments.

-

Specifications and Customization: Custom features can drive up costs. Clearly defining specifications early in the sourcing process can help avoid unexpected price increases later.

-

Materials: The choice of materials not only affects the cost but also the performance characteristics of the pistons. Buyers should evaluate the trade-offs between cost and performance when selecting materials.

-

Quality and Certifications: Suppliers that maintain high standards and possess relevant certifications (e.g., ISO, AS9100) may charge a premium. However, this can be justified by the reduced risk of defects and enhanced product reliability.

-

Supplier Factors: The reputation and experience of the supplier can influence pricing. Established suppliers may command higher prices due to their track record, while new entrants may offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is crucial for determining who bears the costs and risks during shipping. This can significantly affect the total landed cost of the pistons.

What Are Effective Buyer Tips for Cost-Efficient Sourcing of Custom Pistons?

To navigate the complexities of sourcing custom pistons, international B2B buyers should consider the following tips:

-

Negotiate Smartly: Leverage your understanding of the cost structure and market conditions when negotiating with suppliers. Be prepared to discuss specifics around volume and customization to achieve better pricing.

-

Evaluate Total Cost of Ownership (TCO): Beyond initial pricing, consider the TCO, which includes maintenance, warranty, and potential replacement costs. A lower upfront price may not always result in long-term savings.

-

Research Pricing Nuances in Different Regions: Each region has unique market dynamics that can affect pricing. For example, tariffs may apply differently in Africa compared to Europe, influencing your total costs.

-

Build Relationships with Suppliers: Establishing long-term relationships with suppliers can lead to more favorable pricing, better service, and priority during supply chain disruptions.

Disclaimer on Indicative Prices

Prices for custom pistons can vary widely based on the factors discussed above. The information provided in this section serves as a guide and should be validated with current market conditions and specific supplier quotes to ensure accurate budgeting and decision-making.

Alternatives Analysis: Comparing piston custom With Other Solutions

When evaluating solutions for industrial applications, it’s essential to consider various alternatives to ‘piston custom’ products. This section will explore comparable technologies and methodologies that can meet similar operational needs, providing B2B buyers with a comprehensive understanding of their options.

| Comparison Aspect | Piston Custom | Alternative 1: Hydraulic Cylinders | Alternative 2: Pneumatic Cylinders |

|---|---|---|---|

| Performance | High precision and efficiency | Good for heavy loads; less precision | Quick response; moderate precision |

| Cost | Generally higher initial cost | Moderate; depends on specifications | Lower initial cost; operational costs vary |

| Ease of Implementation | Requires specialized setup | More straightforward installation | Simple to install; less training needed |

| Maintenance | Moderate; requires skilled technicians | Low; regular inspections suffice | Low; minimal upkeep required |

| Best Use Case | Precision applications in manufacturing | Heavy-duty applications in construction | Assembly line tasks requiring speed |

What are the Advantages and Disadvantages of Hydraulic Cylinders Compared to Piston Custom?

Hydraulic cylinders are a viable alternative for applications requiring significant force. They excel in heavy-duty environments, providing robust performance for lifting and moving heavy loads. However, while they can handle larger weights, they often lack the precision offered by piston custom solutions. Moreover, hydraulic systems may require more complex plumbing and fluid management, which can complicate installation and maintenance.

How Do Pneumatic Cylinders Stack Up Against Piston Custom Products?

Pneumatic cylinders are known for their speed and efficiency, making them ideal for applications in assembly lines and other fast-paced environments. They typically have a lower initial cost compared to piston custom solutions, which can be appealing for budget-conscious buyers. However, pneumatic systems may not provide the same level of precision, which can be a drawback in applications where accuracy is crucial. Additionally, the performance of pneumatic cylinders can be affected by air quality and pressure variations, necessitating careful monitoring.

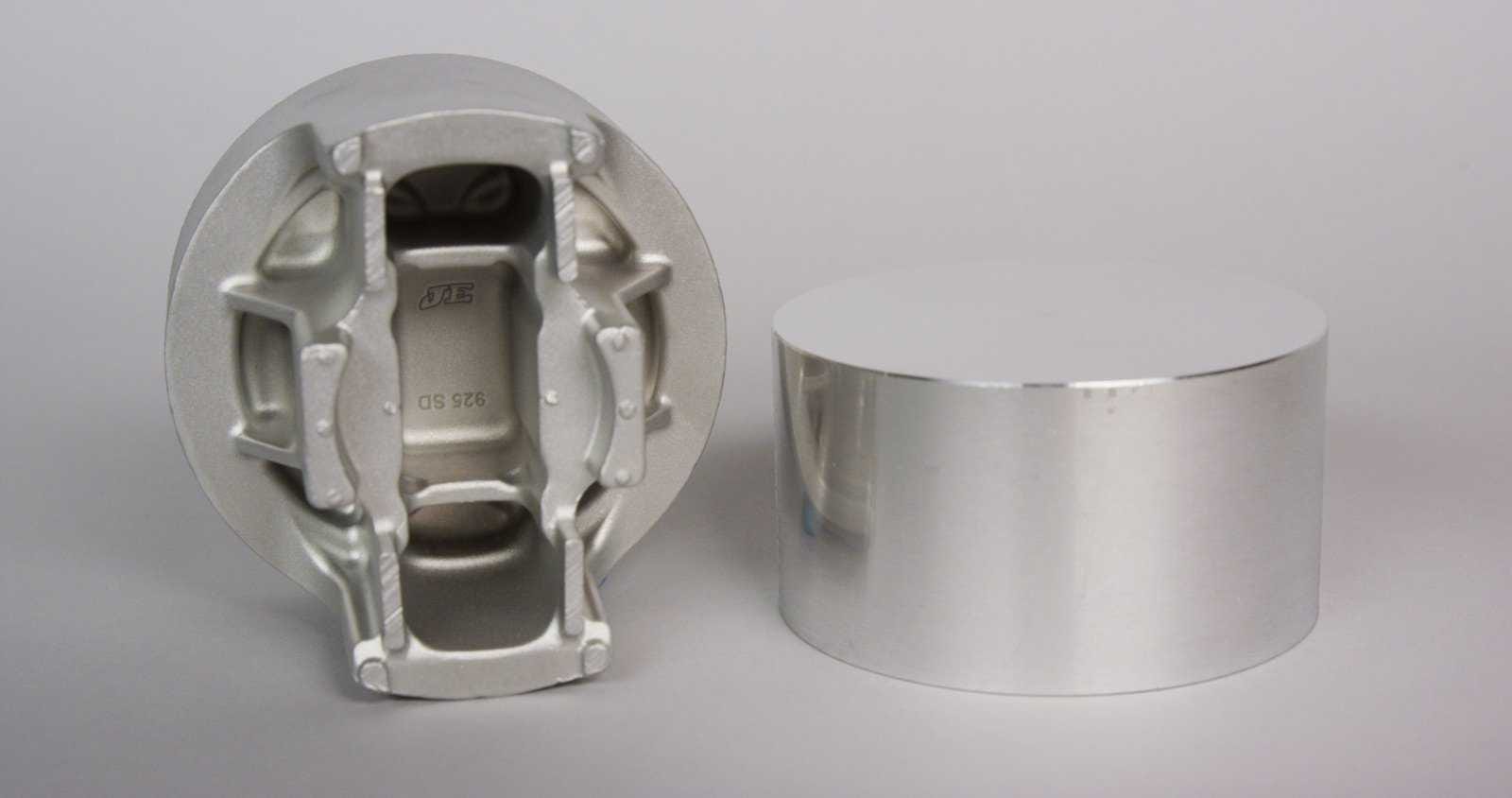

A stock image related to piston custom.

Which Solution is Right for Your Business Needs?

A stock image related to piston custom.

Choosing the appropriate solution depends on the specific requirements of your operations. If precision and efficiency are paramount, piston custom may be the best fit, particularly in sectors like automotive or aerospace manufacturing. For businesses focused on heavy-duty applications, hydraulic cylinders may be more appropriate. Conversely, if speed and cost-effectiveness are critical, pneumatic cylinders could be the most suitable choice.

In conclusion, B2B buyers should assess their unique operational needs, budget constraints, and the technical capabilities of their teams when comparing piston custom solutions with alternatives. By understanding the strengths and weaknesses of each option, buyers can make informed decisions that enhance productivity and efficiency in their respective industries.

Essential Technical Properties and Trade Terminology for piston custom

What Are the Key Technical Properties of Custom Pistons?

Understanding the essential technical properties of custom pistons is crucial for B2B buyers to make informed decisions. Here are some of the critical specifications that should be considered:

1. Material Grade: Why Is It Important for Custom Pistons?

The material grade of a piston is vital for its performance and durability. Common materials include aluminum alloys, cast iron, and forged steel. Each material has distinct properties, such as weight, thermal conductivity, and resistance to wear. For instance, aluminum is lightweight and offers excellent thermal efficiency, making it ideal for high-performance applications. Buyers must choose a material that aligns with their specific operational requirements, ensuring longevity and efficiency.

2. Tolerance: How Does It Affect Performance?

Tolerance refers to the permissible limit of variation in a physical dimension of the piston. It is crucial for ensuring proper fit and function within the engine. Tight tolerances can lead to improved performance and reduced wear, while loose tolerances may result in operational inefficiencies and increased friction. B2B buyers should specify tolerance levels during the procurement process to ensure that the pistons meet their performance criteria.

3. Surface Finish: What Role Does It Play?

The surface finish of a piston affects its ability to resist wear and friction. A smoother surface finish can lead to better lubrication and lower operating temperatures, thereby enhancing engine efficiency. Different processes, such as anodizing or polishing, can be employed to achieve the desired finish. Buyers should consider the intended application of the piston to select the appropriate surface treatment.

4. Weight: Why Is It a Critical Factor?

The weight of a piston is another essential property, especially in performance applications. Lighter pistons can reduce the overall engine weight, leading to better fuel efficiency and responsiveness. However, buyers must balance weight with strength and durability to avoid compromising performance. Understanding weight specifications can help in selecting the right piston for specific applications.

5. Heat Resistance: How Does It Impact Longevity?

Heat resistance is a critical property for pistons, particularly in high-performance or high-temperature applications. Materials must be able to withstand extreme temperatures without deforming or losing integrity. B2B buyers should assess the heat resistance requirements based on the operational environment to ensure that the custom pistons will perform effectively throughout their intended lifespan.

What Are Common Trade Terms Used in the Custom Piston Industry?

Familiarizing oneself with industry-specific terminology can significantly enhance communication and understanding in B2B transactions. Here are some common terms you should know:

1. OEM (Original Equipment Manufacturer): What Does It Mean?

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of custom pistons, understanding whether a supplier is an OEM can indicate the quality and reliability of the parts being offered. OEM parts typically meet stringent quality standards and are designed to fit specific applications.

2. MOQ (Minimum Order Quantity): Why Is It Relevant?

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers, as it affects inventory management and cost. Understanding the MOQ can help businesses plan their purchases more effectively, ensuring they meet their operational needs without overcommitting resources.

3. RFQ (Request for Quotation): How to Use It Effectively?

An RFQ is a document that a buyer submits to suppliers to obtain price quotes for specific products or services. When dealing with custom pistons, issuing an RFQ allows buyers to gather competitive pricing and terms, facilitating better decision-making. Clearly outlining specifications and requirements in the RFQ can lead to more accurate and favorable quotes.

4. Incoterms: What Are They and Why Do They Matter?

Incoterms (International Commercial Terms) are a set of rules that define the responsibilities of buyers and sellers in international transactions. They clarify aspects such as shipping costs, insurance, and risk transfer. Understanding Incoterms is crucial for B2B buyers, as they impact the total cost of procurement and the delivery process.

In conclusion, a solid grasp of the essential technical properties and trade terminology for custom pistons is vital for international B2B buyers. By focusing on these aspects, businesses can enhance their purchasing strategies and ensure they select the right components for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the piston custom Sector

What Are the Current Market Dynamics Affecting the Piston Custom Sector?

The piston custom sector is witnessing significant shifts driven by global demand for high-performance, customized components in various industries, including automotive, aerospace, and manufacturing. One of the primary drivers is the increasing emphasis on efficiency and performance, pushing manufacturers to innovate and offer tailored solutions. In regions like Africa and South America, the burgeoning automotive markets are fostering a greater need for customized pistons that cater to local manufacturing standards and consumer preferences.

Emerging technologies such as 3D printing and advanced materials are reshaping sourcing trends. These innovations allow for rapid prototyping and the creation of complex designs that were previously unattainable. Additionally, digital platforms are facilitating easier access to suppliers, enabling B2B buyers to compare options, negotiate pricing, and streamline procurement processes. For international buyers, particularly from Europe and the Middle East, understanding these dynamics is crucial for leveraging competitive advantages and ensuring timely delivery of high-quality products.

Moreover, the ongoing shift towards automation and Industry 4.0 is influencing production practices. Manufacturers are integrating smart technologies to enhance supply chain visibility and operational efficiency, leading to reduced lead times and improved product quality. For B2B buyers, this translates into a need for strategic partnerships with suppliers who are at the forefront of these technological advancements.

How Is Sustainability Shaping Sourcing Decisions in the Piston Custom Sector?

Sustainability is becoming a cornerstone of sourcing strategies within the piston custom sector. As global awareness of environmental issues rises, businesses are increasingly held accountable for their supply chain practices. The environmental impact of manufacturing processes, including carbon emissions and waste generation, is under scrutiny. Consequently, B2B buyers from Africa, South America, the Middle East, and Europe must prioritize suppliers who adopt sustainable practices.

Ethical sourcing is not only about environmental stewardship; it also encompasses social responsibility. Buyers should seek suppliers that comply with international labor standards and promote fair working conditions. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s commitment to sustainability. By choosing partners who prioritize ethical sourcing, B2B buyers can enhance their brand reputation and meet the growing consumer demand for responsible products.

Additionally, the trend towards using ‘green’ materials in manufacturing is gaining traction. For instance, suppliers that utilize recyclable materials or offer bio-based alternatives for piston manufacturing are increasingly attractive to buyers focused on reducing their environmental footprint. Understanding these trends will enable international buyers to make informed sourcing decisions that align with their sustainability goals.

What Is the Historical Context of the Piston Custom Sector?

The piston custom sector has evolved significantly over the past few decades, adapting to technological advancements and changing market demands. Initially dominated by traditional manufacturing processes, the industry has transitioned towards more sophisticated methods, including CNC machining and additive manufacturing. This evolution has allowed for greater precision and customization, catering to the unique requirements of diverse industries.

Historically, the shift towards customization emerged as manufacturers recognized the need to differentiate their products in an increasingly competitive marketplace. As global trade expanded, the demand for specialized components grew, leading to the establishment of a more interconnected and responsive supply chain. For B2B buyers, understanding this historical context is essential for navigating the complexities of the current market and anticipating future trends.

Frequently Asked Questions (FAQs) for B2B Buyers of piston custom

-

How do I choose the right supplier for custom pistons?

Selecting the right supplier for custom pistons involves several critical steps. First, research potential suppliers by evaluating their track record and reputation in the industry. Look for certifications like ISO to ensure quality standards. Engage with suppliers from regions you are familiar with, such as Africa or Europe, to mitigate communication barriers. Request samples to assess product quality and inquire about their production capabilities and lead times. Finally, consider their customer service responsiveness, as a reliable supplier should be easily accessible for ongoing support. -

What are the typical minimum order quantities (MOQs) for custom pistons?

Minimum order quantities (MOQs) for custom pistons can vary significantly based on the supplier and the complexity of the design. Generally, MOQs can range from 100 to 1,000 units. Suppliers may be more flexible with established relationships or bulk orders. When negotiating, clarify the MOQ upfront, and consider discussing options for smaller initial orders if you’re testing a new product line. This approach can help you manage inventory costs while assessing market demand. -

What are the best payment terms for international B2B transactions?

In international B2B transactions, the best payment terms typically balance risk and cash flow needs. Common methods include letters of credit, which provide security for both parties, and advance payments, which can be negotiated for initial orders. Consider using escrow services for large transactions to ensure that funds are only released upon satisfactory delivery. Always clarify payment timelines and methods upfront, and be aware of currency exchange rates that may affect the final cost. -

How can I ensure quality assurance (QA) in custom piston manufacturing?

Ensuring quality assurance (QA) in custom piston manufacturing involves setting clear expectations and standards with your supplier. Request detailed specifications and quality control processes during the initial negotiation phase. It’s advisable to conduct factory audits or hire third-party inspection services to assess production practices. Additionally, implement a testing phase for the pistons before full-scale production to identify potential issues early. Establishing an ongoing QA communication channel with your supplier can also foster transparency and accountability. -

What logistics considerations should I keep in mind when sourcing custom pistons?

When sourcing custom pistons, logistics play a crucial role in the efficiency of your supply chain. Consider factors such as shipping methods, lead times, and customs regulations in your country. Collaborate with suppliers who have experience exporting to your region to navigate potential challenges. Evaluate transportation costs and delivery timelines to ensure they align with your production schedule. Additionally, consider warehousing options in your region to reduce transit times and costs. -

What customization options are available for pistons?

Customization options for pistons can vary widely based on application requirements. Common customizations include material selection, size adjustments, and specific design features like coatings for enhanced durability. Discuss your application needs with the supplier to explore available options. Some suppliers may also offer design assistance to optimize performance based on your specifications. Be clear about your requirements and any industry standards that must be met to ensure compliance. -

How do I manage communication with international suppliers effectively?

Effective communication with international suppliers is essential for successful transactions. Leverage technology by using video conferencing tools and project management platforms to facilitate clear discussions. Be aware of time zone differences and schedule meetings accordingly. Utilize a common language, typically English, and confirm understanding by summarizing key points after discussions. Regular updates on production status and prompt responses to inquiries will help build a strong working relationship. -

What are the key considerations when negotiating prices for custom pistons?

Negotiating prices for custom pistons requires a strategic approach. Start by researching market prices and understanding your supplier’s cost structure, including material and labor costs. Clearly communicate your budget and volume requirements, as larger orders can often lead to discounts. Be prepared to discuss trade-offs, such as longer lead times for lower costs. Lastly, don’t hesitate to explore alternative suppliers if negotiations do not meet your expectations, as this can provide leverage in discussions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for piston custom

In navigating the complexities of the global market for custom pistons, international B2B buyers must prioritize strategic sourcing to enhance their competitive edge. Key takeaways from this guide highlight the importance of understanding supplier capabilities, assessing quality control measures, and fostering strong relationships with manufacturers. By leveraging strategic sourcing practices, buyers can not only secure high-quality products but also optimize costs and streamline their supply chain processes.

How Can Strategic Sourcing Transform Your Piston Procurement?

Strategic sourcing offers a roadmap for buyers to identify and collaborate with suppliers who align with their business objectives. This proactive approach minimizes risks and ensures a steady supply of custom pistons tailored to specific applications. Moreover, the growing emphasis on sustainability and innovation in manufacturing processes can lead to enhanced product performance and environmental responsibility.

What’s Next for International B2B Buyers in the Custom Piston Market?

Looking ahead, buyers in Africa, South America, the Middle East, and Europe should remain agile and adaptable to shifts in market dynamics and technological advancements. Engaging in continuous market research and supplier evaluation will be crucial. By taking these steps, businesses can position themselves for future growth and success in the evolving landscape of custom piston procurement. Embrace strategic sourcing today to unlock new opportunities and drive your business forward.