Discover Quality and Cost-Savings in Medical Equipment China (2025)

Introduction: Navigating the Global Market for medical equipment china

In the ever-evolving landscape of global healthcare, sourcing high-quality medical equipment from China poses a significant challenge for B2B buyers. The complexities of navigating supplier networks, understanding regulatory standards, and ensuring product reliability can be daunting, particularly for international buyers from regions such as Africa, South America, the Middle East, and Europe. This guide aims to demystify the process of procuring medical equipment from China, offering insights into various types of equipment, their applications, and strategies for effective supplier vetting.

As you delve into this comprehensive resource, you will discover critical aspects of the purchasing journey, including cost considerations, quality assurance, and the importance of compliance with international health regulations. By equipping yourself with this knowledge, you will be empowered to make informed decisions that align with your organization’s needs and budget.

Whether you are seeking advanced diagnostic tools or essential surgical instruments, this guide provides actionable insights tailored to the unique challenges faced by B2B buyers. With a focus on fostering strong supplier relationships and ensuring product efficacy, you will be better positioned to navigate the global market for medical equipment from China, ultimately enhancing the quality of healthcare services in your region.

Understanding medical equipment china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Diagnostic Imaging Equipment | High-resolution imaging, various modalities (MRI, CT, X-ray) | Hospitals, clinics, research institutions | Pros: Essential for accurate diagnosis; Cons: High initial investment and maintenance costs. |

| Surgical Instruments | Precision-engineered tools for various surgical procedures | Operating rooms, surgical centers | Pros: High precision and reliability; Cons: Requires skilled handling and sterilization. |

| Patient Monitoring Systems | Real-time data collection, telemetry capabilities | Intensive care units, emergency rooms | Pros: Enhances patient safety; Cons: Potential for data overload if not managed properly. |

| Rehabilitation Equipment | Focus on recovery and mobility, includes physiotherapy tools | Rehabilitation centers, outpatient clinics | Pros: Improves patient recovery outcomes; Cons: Variability in quality and effectiveness. |

| Laboratory Equipment | Instruments for testing and analysis, e.g., blood analyzers | Diagnostic labs, research facilities | Pros: Critical for accurate lab results; Cons: Often requires specialized training to operate. |

What Are the Key Characteristics of Diagnostic Imaging Equipment?

Diagnostic imaging equipment, such as MRI and CT scanners, is crucial for non-invasive diagnostics. These devices produce high-resolution images that allow healthcare professionals to identify and monitor medical conditions effectively. When considering a purchase, B2B buyers should evaluate the technology’s compatibility with existing systems, service agreements, and the manufacturer’s reputation for reliability and support. Additionally, understanding the total cost of ownership, including installation and maintenance, is essential for financial planning.

How Do Surgical Instruments Differ in Their Applications?

Surgical instruments encompass a wide range of tools, including scalpels, forceps, and sutures, designed for various surgical procedures. Their precision-engineered nature ensures reliability and effectiveness during operations, making them indispensable in surgical settings. Buyers should consider factors such as sterilization processes, ergonomic design, and the availability of replacement parts when sourcing surgical instruments. Furthermore, understanding the regulatory requirements in their region is vital to ensure compliance and safety.

What Should Buyers Know About Patient Monitoring Systems?

Patient monitoring systems are designed to track vital signs and other health metrics in real-time, providing critical information for healthcare providers. These systems are widely used in intensive care units and emergency rooms, where timely data can be life-saving. B2B buyers should assess the system’s interoperability with existing technologies, user-friendliness, and data management capabilities. Additionally, ongoing training and support from the manufacturer can significantly enhance the effectiveness of these systems in clinical environments.

Why Is Rehabilitation Equipment Important in Healthcare?

Rehabilitation equipment, including devices for physiotherapy and mobility aids, plays a vital role in patient recovery post-injury or surgery. These tools help patients regain strength, balance, and coordination, which are essential for improving their quality of life. When purchasing rehabilitation equipment, buyers should evaluate the range of therapies supported, ease of use, and patient feedback. It’s also beneficial to consider the equipment’s adaptability to various patient needs and its compliance with health regulations.

What Are the Considerations for Laboratory Equipment Purchases?

Laboratory equipment, such as blood analyzers and centrifuges, is essential for conducting tests and analyses that inform patient care. The accuracy and reliability of lab results hinge on the quality of the equipment used. Buyers should focus on the equipment’s precision, ease of operation, and required maintenance. Additionally, understanding the manufacturer’s support for training and servicing can aid in maximizing the equipment’s utility and lifespan. Compliance with local and international standards is also a crucial factor for B2B buyers in the healthcare sector.

Related Video: List Lab Instruments and Their Use | medical laboratory equipment name and use

Key Industrial Applications of medical equipment china

| Industry/Sector | Specific Application of medical equipment china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Diagnostic Imaging Equipment (e.g., MRI, CT) | Enhanced patient diagnosis and treatment accuracy | Compliance with international standards, warranty, and after-sales support |

| Pharmaceuticals | Laboratory Equipment for Drug Testing | Improved drug development efficiency and safety | Quality certifications (ISO, CE), precision and reliability of equipment |

| Telemedicine | Remote Patient Monitoring Devices | Cost reduction in healthcare delivery and increased access | Connectivity features, data security, and ease of integration with existing systems |

| Rehabilitation Services | Physiotherapy Equipment (e.g., ultrasound, TENS) | Enhanced patient recovery and satisfaction | Training for staff, equipment durability, and maintenance services |

| Dental Care | Dental Imaging Systems (e.g., X-ray machines) | Improved diagnostic capabilities and patient care | Supplier reputation, technology updates, and customer support availability |

How is Medical Equipment from China Used in the Healthcare Sector?

In the healthcare sector, diagnostic imaging equipment like MRI and CT scanners from China plays a critical role in patient diagnosis and treatment planning. These devices facilitate early detection of medical conditions, significantly enhancing patient outcomes. For international B2B buyers, particularly from regions like Africa and South America, it’s crucial to ensure that the equipment meets local regulatory standards and offers comprehensive after-sales support, including installation and training.

What Role Does Medical Equipment Play in Pharmaceuticals?

Laboratory equipment sourced from China is pivotal in the pharmaceutical industry for drug testing and development. This equipment increases the efficiency of research and testing phases, thereby accelerating the time-to-market for new drugs. Buyers should consider the quality certifications of the equipment, such as ISO and CE, which are essential for ensuring compliance with international safety standards and reliability in results.

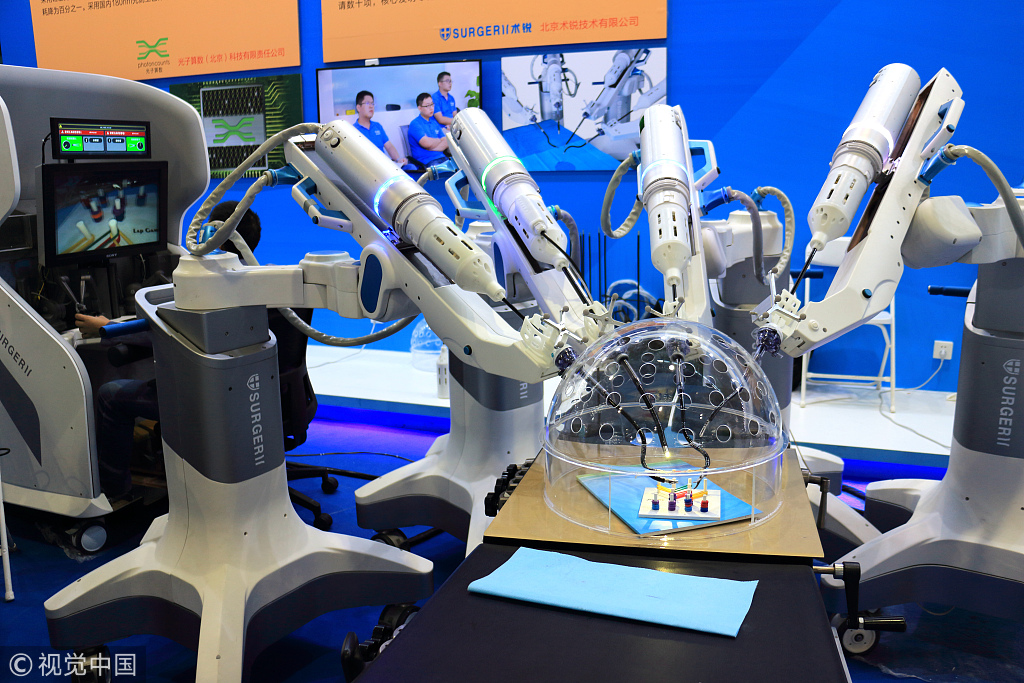

A stock image related to medical equipment china.

How Does Telemedicine Benefit from Chinese Medical Equipment?

Telemedicine has gained traction globally, and remote patient monitoring devices from China are instrumental in this field. These devices allow healthcare providers to monitor patients’ health data in real-time, leading to cost savings and improved access to care, especially in remote areas. International buyers must prioritize connectivity features and data security when sourcing these devices to ensure seamless integration into existing healthcare systems.

Why is Rehabilitation Equipment Important for Patient Care?

In rehabilitation services, physiotherapy equipment such as ultrasound machines and TENS units sourced from China enhances recovery processes for patients. These devices provide effective pain management and promote healing, resulting in higher patient satisfaction. Buyers should focus on the durability of the equipment and the availability of training for staff to maximize the benefits of their investment.

How Does Dental Care Utilize Medical Equipment from China?

A stock image related to medical equipment china.

In the dental sector, imaging systems like X-ray machines are essential for accurate diagnostics and treatment planning. Chinese manufacturers offer advanced dental imaging solutions that improve patient care and operational efficiency. B2B buyers should consider the supplier’s reputation and the availability of customer support, as these factors are critical for maintaining high standards of patient care and operational continuity.

Related Video: 37 Basic Medical Equipments With Names And Their Uses

3 Common User Pain Points for ‘medical equipment china’ & Their Solutions

Scenario 1: Navigating Quality Control Issues in Medical Equipment from China

The Problem:

International B2B buyers often face significant challenges with quality control when sourcing medical equipment from China. For instance, a hospital procurement officer in Africa might order diagnostic machines that fail to meet the necessary safety and efficacy standards. These discrepancies can lead to patient safety issues, potential legal liabilities, and significant financial losses. Furthermore, the lack of clear communication and understanding of regulatory standards between the buyer and the manufacturer can exacerbate these problems, resulting in equipment that is not fit for purpose.

The Solution:

To mitigate quality control issues, buyers should implement a multi-faceted approach. First, conducting thorough due diligence on suppliers is critical. This includes reviewing certifications (such as ISO 13485 for medical devices) and seeking out manufacturers with a proven track record in quality assurance. Engaging third-party quality inspection services before shipment can help ensure that the equipment meets required standards. Additionally, establishing clear specifications and performance metrics in contracts can prevent misunderstandings. Buyers should also consider developing a collaborative relationship with suppliers to facilitate ongoing quality improvements and feedback.

Scenario 2: Overcoming Language Barriers in Communication with Suppliers

The Problem:

Language barriers can significantly hinder effective communication between international buyers and Chinese manufacturers. For example, a procurement agent in South America may struggle to convey specific technical requirements for a new line of medical imaging equipment. Misunderstandings can lead to incorrect orders, delays in delivery, and increased costs due to the need for rework or replacements. The frustration of navigating these communication challenges can erode trust and result in lost business opportunities.

The Solution:

To overcome language barriers, buyers should prioritize working with suppliers who have dedicated multilingual support teams. Utilizing professional translation services for technical documents and specifications can also enhance clarity. Additionally, employing visual aids—such as diagrams and photographs—when discussing equipment specifications can bridge gaps in understanding. Regular video calls and face-to-face meetings, when feasible, can further strengthen relationships and foster clearer communication. Investing in cultural training for procurement teams can also improve interactions and ensure that both parties are on the same page.

Scenario 3: Managing Compliance with International Regulations

The Problem:

B2B buyers of medical equipment from China often grapple with the complexities of compliance with international regulations. For instance, a medical clinic in Europe might find that the equipment purchased does not comply with the EU’s Medical Device Regulation (MDR). This non-compliance can lead to hefty fines, product recalls, and damage to the clinic’s reputation. Additionally, the constantly evolving nature of regulatory requirements can make it challenging for buyers to stay informed.

The Solution:

To effectively manage compliance, buyers should develop a robust understanding of the regulatory landscape relevant to their region. This includes engaging with legal experts or consultants who specialize in medical device regulations. Buyers should also ensure that their suppliers are well-versed in international compliance standards and are willing to provide documentation that proves adherence to these regulations. Establishing a compliance checklist based on the specific requirements of the buyer’s country can streamline the procurement process. Regular training and updates on regulatory changes can empower procurement teams to make informed decisions and minimize risks associated with non-compliance.

Strategic Material Selection Guide for medical equipment china

What Are the Key Properties of Common Materials Used in Medical Equipment from China?

When selecting materials for medical equipment, international B2B buyers must consider various properties that directly affect product performance. Here are analyses of four common materials used in the manufacturing of medical equipment in China.

How Does Stainless Steel Perform in Medical Applications?

Stainless steel is renowned for its excellent corrosion resistance, high strength, and ability to withstand high temperatures and pressures. These properties make it a popular choice for surgical instruments, medical devices, and equipment that require sterilization.

Pros: Stainless steel is durable and can endure repeated sterilization cycles without degrading. It is also relatively easy to machine and fabricate, allowing for complex designs.

Cons: The primary drawback is its cost, which can be higher than other materials. Additionally, while it is resistant to corrosion, it can still be susceptible to certain chemicals, which may limit its use in specific applications.

Impact on Application: Stainless steel is compatible with a wide range of sterilization methods, including autoclaving. However, it’s essential to ensure that the specific grade of stainless steel is suitable for the intended application, particularly in environments with aggressive cleaning agents.

Considerations for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should ensure compliance with international standards such as ASTM and DIN for stainless steel grades. Understanding local regulations regarding medical equipment is crucial for successful procurement.

What Role Does Polycarbonate Play in Medical Equipment Manufacturing?

Polycarbonate is a versatile thermoplastic known for its high impact resistance and optical clarity. It is often used in medical devices such as housings, trays, and components that require transparency.

Pros: The lightweight nature of polycarbonate makes it easy to handle, and its high impact resistance ensures durability. It can also be sterilized using various methods, including ethylene oxide.

Cons: Polycarbonate is less resistant to certain chemicals and UV light, which can lead to degradation over time. Additionally, it may not withstand high temperatures as well as metals.

Impact on Application: Polycarbonate’s clarity allows for easy monitoring of contents in medical trays or containers. However, it is crucial to assess the chemical compatibility with disinfectants and cleaning agents used in medical settings.

Considerations for International Buyers: Buyers should look for polycarbonate that meets relevant standards, such as ISO 13485 for medical devices. Ensuring that the material is sourced from compliant manufacturers is vital for quality assurance.

How Does Silicone Enhance Medical Equipment Functionality?

Silicone is a flexible, biocompatible material often used in medical devices, particularly in applications requiring flexibility, such as tubing and seals.

Pros: Silicone is highly resistant to extreme temperatures and has excellent chemical stability. Its biocompatibility makes it suitable for applications in direct contact with the human body.

Cons: While silicone is durable, it can be more expensive than other elastomers. Additionally, its mechanical properties may not be suitable for high-stress applications.

Impact on Application: Silicone’s flexibility allows for easy maneuverability in medical devices, enhancing patient comfort. However, it is important to ensure that the silicone used is specifically designed for medical applications to avoid leaching harmful substances.

Considerations for International Buyers: Compliance with biocompatibility standards such as ISO 10993 is essential for silicone materials. Buyers should also consider the specific applications and ensure that the silicone meets the necessary regulatory requirements in their respective regions.

Why Is PVC Commonly Used in Medical Equipment?

Polyvinyl chloride (PVC) is widely used in medical applications due to its versatility and cost-effectiveness. It is commonly found in tubing, bags, and other disposable medical products.

Pros: PVC is relatively inexpensive and can be easily molded into complex shapes. It also offers good chemical resistance and can be sterilized through various methods.

Cons: The primary limitation of PVC is its environmental impact, as it is less biodegradable than other materials. Additionally, certain additives used in PVC can raise concerns regarding safety and leaching.

Impact on Application: PVC’s flexibility and durability make it ideal for disposable applications, but it is crucial to assess the specific formulation to ensure safety and compliance with medical standards.

Considerations for International Buyers: Buyers should look for PVC that adheres to regulations such as REACH in Europe and ensure that the material is free from harmful additives. Understanding local disposal regulations for PVC products is also important.

Summary Table of Material Selection for Medical Equipment

| Material | Typical Use Case for medical equipment china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Surgical instruments and sterilizable devices | High strength and corrosion resistance | Higher cost and chemical susceptibility | High |

| Polycarbonate | Transparent housings and trays | Lightweight and impact-resistant | Chemical sensitivity and UV degradation | Medium |

| Silicone | Flexible tubing and seals | Excellent biocompatibility | Higher cost and limited mechanical strength | High |

| PVC | Disposable medical bags and tubing | Cost-effective and versatile | Environmental concerns and potential leaching | Low |

This strategic material selection guide provides essential insights for international B2B buyers looking to procure medical equipment from China, ensuring informed decisions that align with performance requirements and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for medical equipment china

What Are the Main Stages of Manufacturing Medical Equipment in China?

The manufacturing of medical equipment in China involves several key stages that ensure the production of high-quality products. These stages include:

-

Material Preparation

This initial phase involves selecting appropriate raw materials that meet specific regulatory standards. For medical equipment, materials such as stainless steel, plastics, and silicone are often used due to their durability and biocompatibility. Suppliers must ensure that materials are sourced from certified vendors who comply with international quality standards. -

Forming

The forming stage transforms raw materials into desired shapes through processes such as injection molding, machining, and 3D printing. Advanced techniques like CNC (Computer Numerical Control) machining are prevalent, allowing for precision and repeatability in component production. This is crucial for devices that require exact specifications, such as surgical instruments and diagnostic equipment. -

Assembly

In this phase, the various components manufactured in previous stages are assembled into final products. Automated assembly lines are commonly employed, enhancing efficiency and consistency. Skilled technicians often oversee the process to ensure that assembly meets stringent quality criteria, especially for devices like ventilators and infusion pumps. -

Finishing

The finishing stage includes surface treatment, sterilization, and packaging. Processes like anodizing, coating, and polishing enhance the durability and aesthetic of the products. Sterilization is critical for ensuring that the equipment is safe for medical use, and this is often validated through rigorous testing.

How Is Quality Assurance Implemented in Medical Equipment Manufacturing?

Quality assurance (QA) is integral to medical equipment manufacturing, ensuring that products meet both international and regional standards. Key components of QA include:

-

International Standards Compliance

Compliance with ISO 9001 is essential for all manufacturers, as it establishes a framework for quality management systems. In addition, medical devices often need to meet specific regulatory standards such as CE marking in Europe or FDA approval in the United States. Understanding these requirements is crucial for B2B buyers to ensure that the products they purchase are compliant with their local regulations. -

Industry-Specific Certifications

Certain medical devices may require additional certifications. For example, devices that come into contact with patients often need to comply with ISO 13485, which focuses on quality management systems specific to medical devices. B2B buyers should verify that suppliers possess these certifications, as they indicate adherence to stringent manufacturing practices. -

Quality Control Checkpoints

Implementing a robust quality control system is vital. Key checkpoints include:

– Incoming Quality Control (IQC): Ensures that raw materials meet predefined standards before production.

– In-Process Quality Control (IPQC): Monitors the manufacturing process to identify defects early on.

– Final Quality Control (FQC): Conducts comprehensive testing of finished products before shipment.

What Testing Methods Are Commonly Used in Medical Equipment Manufacturing?

Testing methods play a crucial role in validating the performance and safety of medical devices. Common methods include:

-

Functional Testing

This assesses whether the device operates as intended under specified conditions. Functional tests often simulate real-world scenarios to ensure reliability. -

Biocompatibility Testing

For devices that come into contact with the human body, biocompatibility testing is necessary to evaluate the material’s safety. This includes cytotoxicity and sensitization tests. -

Sterility Testing

Ensures that products are free from viable microorganisms. This is particularly important for surgical instruments and implants. -

Durability Testing

Devices are subjected to stress and fatigue tests to ensure they can withstand typical use over time. This is crucial for ensuring long-term reliability and safety.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is essential for ensuring product reliability. Here are actionable steps:

-

Supplier Audits

Conducting on-site audits of potential suppliers can provide insights into their manufacturing practices and quality control processes. Audits should focus on compliance with international standards and the presence of necessary certifications. -

Requesting Documentation

Buyers should request comprehensive documentation, including quality control reports, test results, and certifications. This information can help assess the supplier’s commitment to quality. -

Third-Party Inspections

Engaging third-party inspection agencies can provide an unbiased evaluation of the manufacturing process and quality assurance measures. These agencies can conduct random sampling and testing to ensure compliance with specified standards. -

Understanding Regional Nuances

Different regions may have varying regulatory requirements. Buyers from Europe, for example, should be familiar with the CE marking process, while those in Africa may need to navigate local compliance standards. Ensuring that suppliers are knowledgeable about these nuances can help mitigate risks.

What Are the Challenges Faced by International Buyers in Quality Assurance?

International buyers often face several challenges related to quality assurance when sourcing medical equipment from China:

-

Language Barriers

Communication issues can lead to misunderstandings about quality expectations and specifications. Engaging local representatives or translators can help bridge this gap. -

Cultural Differences

Different approaches to quality and business practices may exist between regions. Buyers should be aware of these differences and adapt their strategies accordingly. -

Logistical Issues

Delays in shipping or customs clearance can complicate quality assurance processes. Planning for contingencies and establishing clear communication with suppliers can help mitigate these risks.

By understanding these manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions when sourcing medical equipment from China, ensuring that they receive high-quality products that meet their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘medical equipment china’

In the rapidly evolving landscape of medical equipment sourcing from China, international B2B buyers must navigate various complexities to ensure they secure high-quality products at competitive prices. This practical sourcing guide provides a step-by-step checklist designed to facilitate the procurement process, particularly for buyers from Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Clearly outline the technical specifications and standards required for the medical equipment you intend to procure. This step is crucial as it sets the foundation for your sourcing process. Be specific about the equipment’s intended use, features, and compliance with local regulations, such as those stipulated by the WHO or regional health authorities.

- Consider user needs: Identify the primary users of the equipment and their requirements.

- Regulatory compliance: Ensure specifications meet both local and international standards.

Step 2: Conduct Market Research on Suppliers

Before approaching potential suppliers, conduct thorough market research to identify reputable manufacturers and distributors in China. This step helps you understand the landscape and available options.

- Use online platforms: Explore B2B marketplaces such as Alibaba, Made-in-China, or Global Sources.

- Evaluate industry reputation: Look for reviews, ratings, and case studies that demonstrate supplier reliability.

Step 3: Verify Supplier Certifications

It is essential to verify that suppliers possess the necessary certifications and licenses to manufacture medical equipment. This step protects your business from potential compliance issues and ensures product quality.

- Check for ISO certifications: Look for ISO 13485 certification, which indicates adherence to quality management systems in the medical device industry.

- Review product certifications: Ensure the equipment complies with relevant regulatory bodies, such as CE marking for European markets or FDA approval for the U.S.

Step 4: Request Samples for Evaluation

Before making a large purchase, request samples of the medical equipment for evaluation. This practical step allows you to assess the product’s quality, functionality, and suitability for your needs.

- Test for performance: Evaluate the equipment under real-world conditions to ensure it meets your specifications.

- Inspect for quality: Look for any signs of defects or quality issues that could affect performance.

Step 5: Negotiate Terms and Conditions

Once you have identified a suitable supplier and evaluated the samples, negotiate the terms and conditions of the contract. This step is critical to ensure that both parties have a clear understanding of expectations.

- Discuss pricing and payment terms: Ensure that the pricing structure is transparent and that payment terms align with your cash flow requirements.

- Establish delivery timelines: Set realistic timelines for production and delivery to avoid disruptions in your supply chain.

Step 6: Establish a Clear Communication Channel

Effective communication with your supplier is vital throughout the sourcing process. Establish a clear channel for ongoing dialogue to address any concerns or changes promptly.

- Use multiple channels: Consider using email, messaging apps, or video calls to maintain regular contact.

- Set expectations for response times: Agree on how quickly each party should respond to inquiries or issues.

Step 7: Plan for After-Sales Support

Finally, ensure that your supplier provides adequate after-sales support, including training, maintenance, and warranty services. This step is essential for maximizing the value of your investment.

- Review warranty terms: Understand the warranty coverage and claims process in case of defects or issues.

- Inquire about training: Ensure that the supplier offers training for your team on the proper use and maintenance of the equipment.

By following these steps, international B2B buyers can effectively navigate the complexities of sourcing medical equipment from China, ensuring a successful procurement process that aligns with their operational needs and regulatory requirements.

Comprehensive Cost and Pricing Analysis for medical equipment china Sourcing

Understanding the comprehensive cost and pricing structure for sourcing medical equipment from China is crucial for international B2B buyers, especially those operating in Africa, South America, the Middle East, and Europe. This analysis will break down the cost components, price influencers, and provide actionable tips for maximizing value.

What Are the Key Cost Components in Medical Equipment Sourcing?

When evaluating the costs associated with sourcing medical equipment from China, buyers should consider the following components:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality materials may increase the initial expenditure but can lead to better durability and compliance with international health standards.

-

Labor: Labor costs in China are generally lower than in many Western countries. However, skilled labor for specific medical equipment manufacturing can command higher wages. Understanding the workforce’s skill level and availability is essential.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and administrative expenses of the manufacturing facility. Overhead rates can vary significantly between suppliers, affecting the final pricing.

-

Tooling: Tooling costs refer to the initial investment required for molds and machinery specific to the production of medical equipment. These costs can be substantial, particularly for custom equipment.

-

Quality Control (QC): Implementing rigorous QC measures is vital in the medical industry. While it adds to costs, it ensures compliance with international safety standards, which can prevent costly recalls and reputational damage.

-

Logistics: Shipping costs can fluctuate based on the shipping method, distance, and current market conditions. Incoterms, which define responsibilities between buyers and sellers in shipping, can also affect overall logistics costs.

-

Margin: Suppliers typically include a profit margin in their pricing. Buyers should be aware of the standard margins in the medical equipment sector to negotiate effectively.

How Do Price Influencers Affect Medical Equipment Costs?

Several factors influence pricing in the medical equipment sector:

-

Volume/MOQ: Minimum Order Quantities (MOQs) can affect pricing significantly. Larger orders often qualify for discounts, making it essential for buyers to assess their needs accurately.

-

Specifications and Customization: Custom features or specific technical requirements can lead to higher costs. Buyers should clearly define their specifications to avoid unexpected expenses.

-

Material Quality and Certifications: Equipment that meets international certifications (e.g., ISO, CE) may come at a premium but is often necessary for regulatory compliance in various markets.

-

Supplier Factors: The reputation, reliability, and experience of the supplier can influence pricing. Established suppliers may charge more but offer better quality assurance and support.

-

Incoterms: Understanding Incoterms is crucial for determining who is responsible for various shipping costs, which can affect total expenditure.

What Are Some Tips for Negotiating Costs Effectively?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, the following strategies can enhance cost-efficiency:

-

Conduct Thorough Research: Understand the market rates for the equipment you need. This knowledge equips you to negotiate better terms and pricing.

-

Leverage Total Cost of Ownership (TCO): Consider not only the purchase price but also ongoing costs such as maintenance, logistics, and potential downtime. A lower initial price may result in higher long-term costs.

-

Build Relationships: Establishing a good rapport with suppliers can lead to more favorable terms and conditions, including better pricing and priority service.

-

Be Clear on Requirements: Clearly communicate your needs and expectations to avoid misunderstandings that could lead to additional costs.

What Should Buyers Keep in Mind Regarding Pricing?

It is important to note that the prices for medical equipment can vary widely based on the factors discussed. Always request detailed quotations that break down all cost components. Additionally, consider potential currency fluctuations when dealing with international transactions, as these can significantly impact overall costs.

By understanding these dynamics, B2B buyers can make informed decisions, ensuring they achieve the best value while maintaining compliance with necessary regulations and standards.

Alternatives Analysis: Comparing medical equipment china With Other Solutions

Understanding the Importance of Evaluating Alternatives in Medical Equipment

In the ever-evolving landscape of healthcare, B2B buyers must assess various alternatives when considering medical equipment. This evaluation not only enhances decision-making but also ensures that healthcare providers can deliver quality care efficiently. This section compares ‘Medical Equipment China’ with two viable alternatives—European Medical Equipment and Locally Sourced Medical Solutions. Each option has distinct characteristics that can impact procurement strategies, operational efficiency, and overall care outcomes.

Comparison Table of Medical Equipment Solutions

| Comparison Aspect | Medical Equipment China | European Medical Equipment | Locally Sourced Medical Solutions |

|---|---|---|---|

| Performance | High, with rapid advancements in technology | High, often with rigorous standards | Varies widely based on local manufacturers |

| Cost | Generally lower costs due to economies of scale | Higher due to quality and regulatory compliance | Competitive, but may lack bulk purchasing power |

| Ease of Implementation | Moderate, may require adaptation to local standards | Easy, designed with European regulations in mind | Varies, may involve longer lead times |

| Maintenance | Requires understanding of local service networks | Well-supported with established service agreements | Limited, depending on local expertise |

| Best Use Case | Cost-sensitive projects needing rapid deployment | High-end facilities requiring top-tier equipment | Community health initiatives or startups |

What Are the Advantages and Disadvantages of European Medical Equipment?

European Medical Equipment is known for its stringent compliance with regulations and high-performance standards. This equipment is often designed with advanced technology and user-friendly interfaces, making it ideal for hospitals and clinics that prioritize quality and reliability. However, these advantages come at a higher cost, which may be prohibitive for budget-conscious buyers. Additionally, the implementation process can be straightforward due to established standards, but ongoing maintenance can be more costly compared to alternatives.

How Do Locally Sourced Medical Solutions Compare?

Locally Sourced Medical Solutions can be an appealing option for B2B buyers in developing markets. These solutions often support local economies and can be more adaptable to the specific needs of the community. The competitive pricing is a significant advantage, particularly for healthcare providers with limited budgets. However, the quality can vary significantly, and the lack of established service networks may lead to challenges in maintenance and support. This solution is best suited for community health initiatives or smaller facilities that are flexible and can manage variable quality.

Conclusion: How Can B2B Buyers Make the Right Choice?

Selecting the right medical equipment solution requires a thorough understanding of each option’s pros and cons. B2B buyers should consider factors such as budget constraints, performance requirements, and the specific healthcare needs of their communities. By carefully weighing these alternatives, buyers can make informed decisions that align with their organizational goals and enhance the quality of care they provide. Ultimately, the choice between Medical Equipment China, European Medical Equipment, or Locally Sourced Medical Solutions will depend on the unique context and operational priorities of the healthcare provider.

Essential Technical Properties and Trade Terminology for medical equipment china

What Are the Key Technical Properties of Medical Equipment from China?

When sourcing medical equipment from China, understanding critical technical properties is essential for ensuring product quality, compliance, and suitability for your market. Here are some key specifications to consider:

-

Material Grade

– Definition: This refers to the quality and type of materials used in the manufacturing of medical devices, such as stainless steel, plastic, or specialized alloys.

– Importance: The material grade affects durability, biocompatibility, and overall performance. For instance, medical devices that come into contact with bodily fluids must use materials that are both safe and effective. -

Tolerance

– Definition: Tolerance specifies the allowable deviation from a standard dimension or measurement during the manufacturing process.

– Importance: In medical equipment, precise tolerances are critical for functionality and safety. For example, a slight deviation in the dimensions of a surgical instrument can compromise its effectiveness and may pose risks to patients. -

Sterilization Standards

– Definition: This refers to the methods and protocols used to ensure that medical equipment is free from viable microorganisms.

– Importance: Different regions have specific sterilization standards (e.g., ISO 11135 for ethylene oxide sterilization). Compliance with these standards is crucial for market acceptance and to ensure patient safety. -

Performance Specifications

– Definition: These are measurable criteria that define how the medical equipment should operate under specific conditions.

– Importance: Performance specifications ensure that the equipment meets the necessary clinical requirements. For example, a defibrillator must deliver a specific energy level to be effective in emergency situations. -

Regulatory Compliance

– Definition: This pertains to adherence to local and international regulations governing medical devices, such as CE marking in Europe or FDA approval in the United States.

– Importance: Understanding regulatory compliance is vital for market entry and to avoid legal issues. Non-compliance can lead to product recalls and significant financial losses.

What Trade Terms Should International Buyers Know When Sourcing Medical Equipment from China?

Familiarity with industry jargon can streamline negotiations and ensure clarity in transactions. Here are some common trade terms relevant to medical equipment sourcing:

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships can help buyers identify potential partners for custom products or private labeling, which can enhance brand presence in the market. -

MOQ (Minimum Order Quantity)

– Definition: MOQ is the smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ is crucial for budgeting and inventory management. Suppliers may set high MOQs, which can affect smaller businesses or those testing new markets. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document sent to suppliers to request pricing and availability for specific products.

– Importance: Crafting a detailed RFQ can lead to more accurate quotes and better understanding of supplier capabilities, facilitating comparison between different vendors. -

Incoterms (International Commercial Terms)

– Definition: These are internationally recognized terms that define the responsibilities of buyers and sellers in international trade.

– Importance: Familiarity with Incoterms (like FOB, CIF, and EXW) can help buyers understand shipping responsibilities and costs, mitigating risks related to logistics and delivery. -

Lead Time

– Definition: This refers to the time it takes from placing an order to receiving the product.

– Importance: Understanding lead times is essential for planning inventory and meeting market demands. Longer lead times may require buyers to manage stock levels more carefully. -

Quality Assurance (QA)

– Definition: QA encompasses the processes and procedures to ensure that products meet specified quality standards.

– Importance: Effective QA processes are critical for maintaining product quality and compliance with regulatory requirements, which is especially important in the medical field.

By grasping these technical properties and trade terms, international buyers can make informed decisions, ensuring that the medical equipment sourced from China meets their specific needs and regulatory standards.

Navigating Market Dynamics and Sourcing Trends in the medical equipment china Sector

What Are the Key Market Dynamics and Sourcing Trends in the Medical Equipment Sector from China?

The medical equipment sector in China is witnessing significant growth, driven by global health demands, technological advancements, and increased investments in healthcare infrastructure. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly looking to China for sourcing high-quality medical devices and equipment. This trend is propelled by the need for affordable healthcare solutions and the expansion of telemedicine and digital health technologies.

Key trends in sourcing include a rise in automation and AI integration in manufacturing processes, leading to enhanced efficiency and product quality. Additionally, the demand for customized medical solutions tailored to local markets is on the rise. Buyers should be aware of the increasing emphasis on regulatory compliance, including adherence to international standards such as ISO and CE markings, which ensure product safety and efficacy. As China continues to expand its global footprint, understanding regional dynamics, such as varying regulatory environments and market entry strategies, is crucial for successful sourcing.

Moreover, the COVID-19 pandemic has accelerated the shift towards e-commerce and digital platforms for procurement, making it easier for international buyers to access Chinese suppliers. Leveraging platforms that facilitate direct connections with manufacturers can streamline the sourcing process, reduce lead times, and enhance negotiation power.

How Can Sustainability and Ethical Sourcing Impact B2B Buyers in the Medical Equipment Sector?

Sustainability and ethical sourcing have become paramount in the medical equipment sector, as global awareness of environmental issues and corporate social responsibility continues to grow. International B2B buyers are increasingly prioritizing suppliers who demonstrate commitment to sustainable practices. This includes sourcing materials that are eco-friendly and employing manufacturing processes that minimize environmental impact.

The importance of ethical supply chains cannot be overstated; buyers must ensure that their suppliers adhere to ethical labor practices and comply with regulations regarding waste management and emissions. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are indicators of a supplier’s commitment to sustainability. Furthermore, demand for ‘green’ materials, such as biodegradable plastics and non-toxic substances, is rising as buyers seek to align their procurement strategies with environmental goals.

Incorporating sustainability into sourcing decisions not only helps mitigate risks associated with regulatory compliance but also enhances brand reputation and customer loyalty. Buyers should actively seek out suppliers who transparently communicate their sustainability efforts and provide documentation of their practices.

What Is the Evolution of the Medical Equipment Sector in China and Its Implications for B2B Buyers?

The evolution of the medical equipment sector in China dates back several decades, transitioning from a focus on domestic needs to becoming a global manufacturing powerhouse. Initially, the sector was characterized by low-cost production of basic medical devices; however, significant investments in research and development have transformed it into a hub for innovation.

The government’s support for the healthcare industry, coupled with the rise of advanced technologies such as robotics and AI, has propelled China’s medical equipment sector into a competitive position on the global stage. For international B2B buyers, this evolution presents opportunities for accessing cutting-edge technologies and high-quality products at competitive prices.

Understanding this historical context is essential for navigating the current landscape. Buyers should consider not only the cost-effectiveness of sourcing from China but also the implications of technological advancements and regulatory changes that may influence product availability and quality in the future. By aligning their sourcing strategies with these dynamics, international buyers can position themselves for success in the rapidly evolving medical equipment market.

Frequently Asked Questions (FAQs) for B2B Buyers of medical equipment china

-

How do I ensure the quality of medical equipment sourced from China?

To ensure the quality of medical equipment from China, it’s crucial to conduct thorough supplier vetting. Start by checking certifications such as ISO 13485, CE marking, and FDA approval, which indicate compliance with international quality standards. Request product samples for testing and consider third-party inspections during production and before shipment. Establish clear quality assurance protocols and maintain open communication with your supplier throughout the process to address any concerns promptly. -

What are the common payment terms for importing medical equipment from China?

Payment terms for importing medical equipment from China typically include options like T/T (Telegraphic Transfer), L/C (Letter of Credit), or PayPal for smaller transactions. It’s common to pay a deposit (usually 30%) upfront, with the balance due before shipment or upon receiving documents. Ensure that payment terms are clearly outlined in the contract, and consider using escrow services for larger transactions to mitigate risks and protect your investment. -

What is the minimum order quantity (MOQ) for medical equipment from Chinese suppliers?

The minimum order quantity (MOQ) for medical equipment varies by supplier and product type. Generally, MOQs can range from as low as 10 units to several hundred units. It’s essential to communicate your needs upfront and negotiate MOQs that align with your purchasing capacity. Some suppliers may offer lower MOQs for first-time buyers or smaller businesses, so don’t hesitate to ask for flexibility. -

How can I customize medical equipment sourced from China to meet my specifications?

Customizing medical equipment from China requires clear communication of your specifications and requirements to the supplier. Many manufacturers offer customization options, including branding, design alterations, and specific features. Discuss your needs during the initial negotiations and request detailed prototypes or samples before full production. Ensure that customization agreements are documented in your contract to avoid misunderstandings later in the process. -

What should I know about logistics and shipping when importing medical equipment from China?

Understanding logistics and shipping is critical when importing medical equipment from China. Choose a reliable freight forwarder experienced in handling medical equipment, as they can assist with customs clearance, insurance, and compliance with local regulations. Discuss shipping options (air freight vs. sea freight) based on urgency and cost considerations. Be aware of potential delays and plan for them, especially if your equipment is time-sensitive. -

How can I assess the reliability of a Chinese medical equipment supplier?

To assess the reliability of a Chinese medical equipment supplier, start with background research, including checking online reviews and testimonials. Request references from previous clients and verify their credentials, such as business licenses and industry certifications. Conduct a factory visit or use a third-party inspection service to evaluate the production process and facility conditions. Building a long-term relationship based on trust and transparency is vital for successful collaboration. -

What are the key regulatory considerations when importing medical equipment into my country?

When importing medical equipment, it’s essential to understand the regulatory framework in your country. Each region has specific requirements, such as registration, quality standards, and import licenses. Consult with local health authorities or regulatory bodies to ensure compliance with safety and efficacy standards. Prepare necessary documentation, including import permits and product certifications, to facilitate a smooth customs clearance process. -

How can I handle disputes or issues with Chinese suppliers effectively?

Handling disputes with Chinese suppliers requires a proactive approach. Clearly outline terms and conditions in your contract, including dispute resolution mechanisms. If issues arise, communicate directly and professionally with the supplier to seek resolution. If informal discussions fail, consider mediation or arbitration as stipulated in your contract. Always keep records of communications and agreements to support your position in case of disputes.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for medical equipment china

What Are the Key Takeaways for International B2B Buyers in Medical Equipment Sourcing from China?

In conclusion, international B2B buyers must recognize the strategic advantages of sourcing medical equipment from China. The country not only offers a diverse range of high-quality products but also competitive pricing, which is vital for healthcare providers aiming to enhance their service delivery without compromising budget constraints. By leveraging China’s robust manufacturing capabilities and technological advancements, buyers can ensure they remain at the forefront of medical innovation.

How Can Strategic Sourcing Enhance Your Procurement Process?

Strategic sourcing allows businesses to optimize their procurement processes by fostering long-term relationships with reliable suppliers. This approach mitigates risks associated with supply chain disruptions, particularly in a rapidly changing global landscape. Establishing clear communication and collaboration with Chinese manufacturers can lead to better quality control, timely deliveries, and customized solutions tailored to specific regional needs.

What Does the Future Hold for Medical Equipment Sourcing from China?

Looking ahead, the medical equipment market is poised for significant growth, particularly in regions such as Africa, South America, the Middle East, and Europe. As healthcare demands evolve, buyers are encouraged to actively engage with Chinese suppliers to explore innovative solutions that meet emerging health challenges. By embracing a proactive sourcing strategy, international buyers can position themselves for success in a competitive marketplace. Now is the time to initiate or strengthen partnerships with Chinese manufacturers to ensure access to the latest medical technologies and solutions tailored to local needs.