Discover Quality: Sourcing from a Toyota Part Manufacturer (2025)

Introduction: Navigating the Global Market for toyota part manufacturer

Navigating the complex landscape of sourcing Toyota parts can be a daunting task for international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe. With the increasing demand for high-quality vehicle components, understanding the intricacies of the Toyota parts manufacturing market is crucial. This guide serves as a comprehensive resource, detailing various types of Toyota parts, their applications, and the critical considerations for supplier vetting. By exploring factors such as cost, quality assurance, and logistics, this guide empowers buyers to make informed purchasing decisions that align with their operational needs.

For businesses looking to enhance their supply chains, the challenge often lies in identifying reliable manufacturers who can deliver genuine parts while maintaining competitive pricing. This guide aims to address these challenges by providing actionable insights into the procurement process, ensuring that buyers can confidently navigate the global market. Whether you are sourcing parts for assembly lines, repair shops, or retail, understanding the nuances of the Toyota parts market will be essential for maximizing efficiency and profitability.

By leveraging this resource, international B2B buyers can streamline their procurement strategies and foster long-term partnerships with reputable suppliers, ultimately driving their business success in a competitive marketplace.

Understanding toyota part manufacturer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Original Equipment Manufacturer (OEM) | Produced by Toyota or authorized partners; guaranteed compatibility and quality. | Vehicle assembly, warranty replacements. | Pros: High quality, reliability. Cons: Higher cost. |

| Aftermarket Parts | Third-party manufacturers; often cheaper and varied options. | Vehicle repairs, custom modifications. | Pros: Cost-effective, diverse choices. Cons: Variable quality. |

| Remanufactured Parts | Used parts restored to working condition; environmentally friendly. | Cost-sensitive repairs, fleet maintenance. | Pros: Lower cost, eco-friendly. Cons: May have shorter lifespan. |

| Genuine Toyota Parts | Parts directly from Toyota; ensures brand integrity and performance. | Authorized service centers, repairs. | Pros: Brand assurance, high compatibility. Cons: More expensive than aftermarket. |

| Performance Parts | Designed for enhanced performance; often used in racing. | Motorsport applications, tuning. | Pros: Improved performance, specialized. Cons: May void warranties, higher costs. |

What Are the Key Characteristics of Original Equipment Manufacturer (OEM) Parts?

OEM parts are produced by Toyota or its authorized partners, ensuring they meet the same specifications and quality standards as the parts originally installed in the vehicle. These parts are crucial for maintaining the integrity of the vehicle, especially for warranty replacements. B2B buyers should consider OEM parts when seeking reliability and compatibility, particularly for new vehicle assembly or repairs where brand assurance is paramount.

How Do Aftermarket Parts Differ from OEM Parts?

Aftermarket parts are manufactured by third-party companies and are often priced lower than OEM parts. They offer a wide variety of options, catering to different needs from basic repairs to custom modifications. B2B buyers can benefit from the cost savings of aftermarket parts but should be cautious about the variability in quality. It’s essential to vet suppliers and possibly request samples to ensure that the parts meet required standards.

What Are the Advantages of Using Remanufactured Parts?

Remanufactured parts are used components that have been restored to their original specifications, making them a cost-effective and environmentally friendly option. These parts are particularly suitable for fleet maintenance or businesses looking to minimize repair costs without compromising quality. Buyers should weigh the potential for a shorter lifespan against the savings, as remanufactured parts can be a smart choice for budget-conscious operations.

Why Choose Genuine Toyota Parts?

Genuine Toyota parts are sourced directly from the manufacturer, ensuring that they maintain the brand’s integrity and performance standards. They are ideal for authorized service centers and repairs that require high compatibility. While these parts can be more expensive than alternatives, the assurance of quality and fit makes them a preferred choice for many B2B buyers focused on long-term vehicle performance.

What Are Performance Parts and Their Applications?

Performance parts are specifically designed to enhance a vehicle’s performance, often used in racing or high-performance applications. These parts cater to businesses involved in motorsport or tuning, offering specialized enhancements that can significantly improve vehicle capabilities. However, B2B buyers should consider the implications of using performance parts, such as potential warranty voiding and increased costs, to ensure they align with their operational goals.

Related Video: How to maintain your Toyota Part 1 : Engine oil and Filters

Key Industrial Applications of toyota part manufacturer

| Industry/Sector | Specific Application of Toyota Part Manufacturer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Supply of OEM parts for vehicle assembly | Ensures quality and compatibility with Toyota vehicles | Certification, lead time, and after-sales support |

| Heavy Equipment | Replacement parts for construction machinery | Enhances operational efficiency and reduces downtime | Quality standards, availability of parts, and warranty terms |

| Logistics and Transportation | Components for commercial vehicles | Improves reliability and safety of fleet operations | Cost-effectiveness, supplier reliability, and delivery timelines |

| Automotive Aftermarket | Aftermarket parts for vehicle repair and customization | Expands service offerings and increases customer satisfaction | Compatibility with various vehicle models and pricing strategy |

| Electric Vehicles | Battery and electrical system components | Supports the transition to sustainable technologies | Innovation in technology, compliance with regulations, and sourcing of eco-friendly materials |

How is Toyota Part Manufacturer Used in Automotive Manufacturing?

In the automotive manufacturing sector, Toyota part manufacturers supply Original Equipment Manufacturer (OEM) parts essential for the assembly of vehicles. These parts are designed to meet specific quality and compatibility standards, ensuring that the vehicles function optimally. For international B2B buyers, particularly those in Africa and South America, sourcing OEM parts can significantly enhance production quality and reduce warranty claims. Buyers must consider certification and lead times when selecting suppliers to ensure timely production schedules.

What Role Do Toyota Parts Play in Heavy Equipment?

Heavy equipment manufacturers rely on Toyota part manufacturers for replacement parts that enhance the performance of construction machinery. These parts help maintain operational efficiency and minimize downtime, which is crucial in industries where time is money. For buyers from the Middle East and Europe, it’s essential to ensure that the sourced parts meet stringent quality standards. Additionally, understanding the availability of these parts and warranty terms can greatly influence purchasing decisions.

How Are Toyota Parts Utilized in Logistics and Transportation?

In the logistics and transportation sector, components from Toyota part manufacturers are vital for maintaining the reliability and safety of commercial vehicles. By using high-quality parts, businesses can improve fleet performance and reduce the risk of breakdowns. Buyers in regions like Spain and Indonesia should prioritize cost-effectiveness and supplier reliability when sourcing these components, as they directly affect operational costs and service levels.

What is the Importance of Toyota Parts in the Automotive Aftermarket?

The automotive aftermarket benefits significantly from Toyota part manufacturers, which provide a variety of aftermarket parts for vehicle repairs and customization. This allows service providers to expand their offerings and enhance customer satisfaction. For B2B buyers, particularly those in emerging markets, ensuring compatibility with different vehicle models is essential. Additionally, developing a competitive pricing strategy can help businesses attract more customers in a crowded marketplace.

How Do Toyota Parts Support Electric Vehicle Development?

As the automotive industry shifts towards electric vehicles (EVs), Toyota part manufacturers play a critical role by supplying battery and electrical system components. These components are essential for the development of sustainable technologies, enabling businesses to meet growing consumer demand for eco-friendly vehicles. For international buyers, especially in Europe, compliance with environmental regulations and the sourcing of innovative technologies are key considerations when selecting suppliers in this rapidly evolving sector.

Related Video: How to maintain your Toyota Part 4 Differential fluid, Wipers and AC service

3 Common User Pain Points for ‘toyota part manufacturer’ & Their Solutions

Scenario 1: Difficulty in Sourcing Genuine Toyota Parts for Repairs

The Problem: B2B buyers in the automotive repair industry often struggle to source genuine Toyota parts due to the overwhelming number of suppliers and the prevalence of counterfeit products. This not only increases the risk of using substandard components but also compromises the quality of repairs, leading to customer dissatisfaction and potential legal ramifications. Buyers may find themselves lost in a sea of options, unsure which suppliers can guarantee authenticity and reliability.

The Solution: To effectively source genuine Toyota parts, B2B buyers should start by establishing relationships with authorized Toyota dealerships and certified distributors. It’s crucial to verify their credentials and ensure they are recognized by Toyota as official suppliers. Additionally, leveraging online platforms that specialize in OEM (Original Equipment Manufacturer) parts can streamline the search process. Buyers should also consider joining industry forums and groups where they can gain insights and recommendations from peers. Implementing a robust vetting process, including requesting documentation of authenticity and checking for warranties, can further safeguard against counterfeit parts. Regularly updating supplier lists and maintaining open lines of communication with manufacturers can help in staying informed about new parts and recalls.

Scenario 2: Managing Inventory and Reducing Downtime with Toyota Parts

The Problem: For B2B buyers operating automotive service centers, managing inventory effectively is a constant challenge. Delays in receiving essential Toyota parts can lead to increased downtime for vehicles, which in turn affects service delivery and customer satisfaction. This situation is exacerbated when parts are either backordered or out of stock, leaving repair shops unable to meet customer needs promptly.

The Solution: Implementing an effective inventory management system tailored for automotive parts can significantly mitigate these issues. B2B buyers should consider using software that integrates with existing management systems to track parts usage and automate reordering processes. Establishing a safety stock for fast-moving parts, especially those commonly used in Toyota models, can prevent stockouts. Additionally, forming strategic partnerships with multiple suppliers can create a buffer against delays. Regularly analyzing sales data to identify trends in parts demand allows businesses to anticipate needs and adjust orders accordingly. Engaging in just-in-time inventory practices can also reduce holding costs while ensuring that essential parts are always available when needed.

Scenario 3: Understanding Technical Specifications and Compatibility Issues

The Problem: Another common pain point for B2B buyers is navigating the technical specifications and compatibility of Toyota parts. Many buyers may not have in-depth technical knowledge, leading to confusion over which parts are suitable for specific vehicle models. This can result in purchasing the wrong parts, leading to wasted time and financial loss, as well as damaging the reputation of the service provider.

The Solution: To overcome these technical challenges, B2B buyers should invest time in training and resources that enhance their understanding of Toyota parts and specifications. Utilizing detailed catalogs and databases that outline part numbers, compatibility, and specifications can be invaluable. Additionally, many manufacturers offer online tools or apps that allow buyers to input vehicle identification numbers (VIN) to verify part compatibility. Collaborating with experienced technicians during the purchasing process can provide insights into which parts are most reliable for certain repairs. Furthermore, maintaining an open dialogue with suppliers can help clarify any uncertainties regarding parts specifications. Regularly attending workshops or training sessions offered by Toyota or parts distributors can also keep buyers updated on new technologies and parts innovations.

Strategic Material Selection Guide for toyota part manufacturer

When selecting materials for manufacturing Toyota parts, it is essential to consider various factors such as performance, cost, and suitability for specific applications. Below is an analysis of four common materials used in the automotive industry, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Aluminum in Toyota Parts Manufacturing?

Aluminum is widely used in automotive applications due to its lightweight nature and excellent corrosion resistance. Key properties include a temperature rating of up to 600°C and a pressure rating that varies based on alloy composition. Aluminum’s low density contributes to fuel efficiency, making it a popular choice for parts like engine components and structural elements.

Pros & Cons:

– Pros: Lightweight, good thermal conductivity, and excellent corrosion resistance.

– Cons: Higher manufacturing complexity and cost compared to some other materials, such as steel.

Impact on Application:

Aluminum is compatible with various media, including fuels and oils, but care must be taken with certain chemicals that can cause corrosion.

Considerations for International Buyers:

Buyers from regions like Africa and South America should be aware of local recycling practices and aluminum alloy standards, which may differ from those in Europe and the Middle East. Compliance with international standards such as ASTM and DIN is crucial.

How Does Steel Compare as a Material for Toyota Parts?

Steel is another common material used in the automotive sector, known for its strength and durability. It typically has a temperature rating up to 300°C and is resistant to various mechanical stresses.

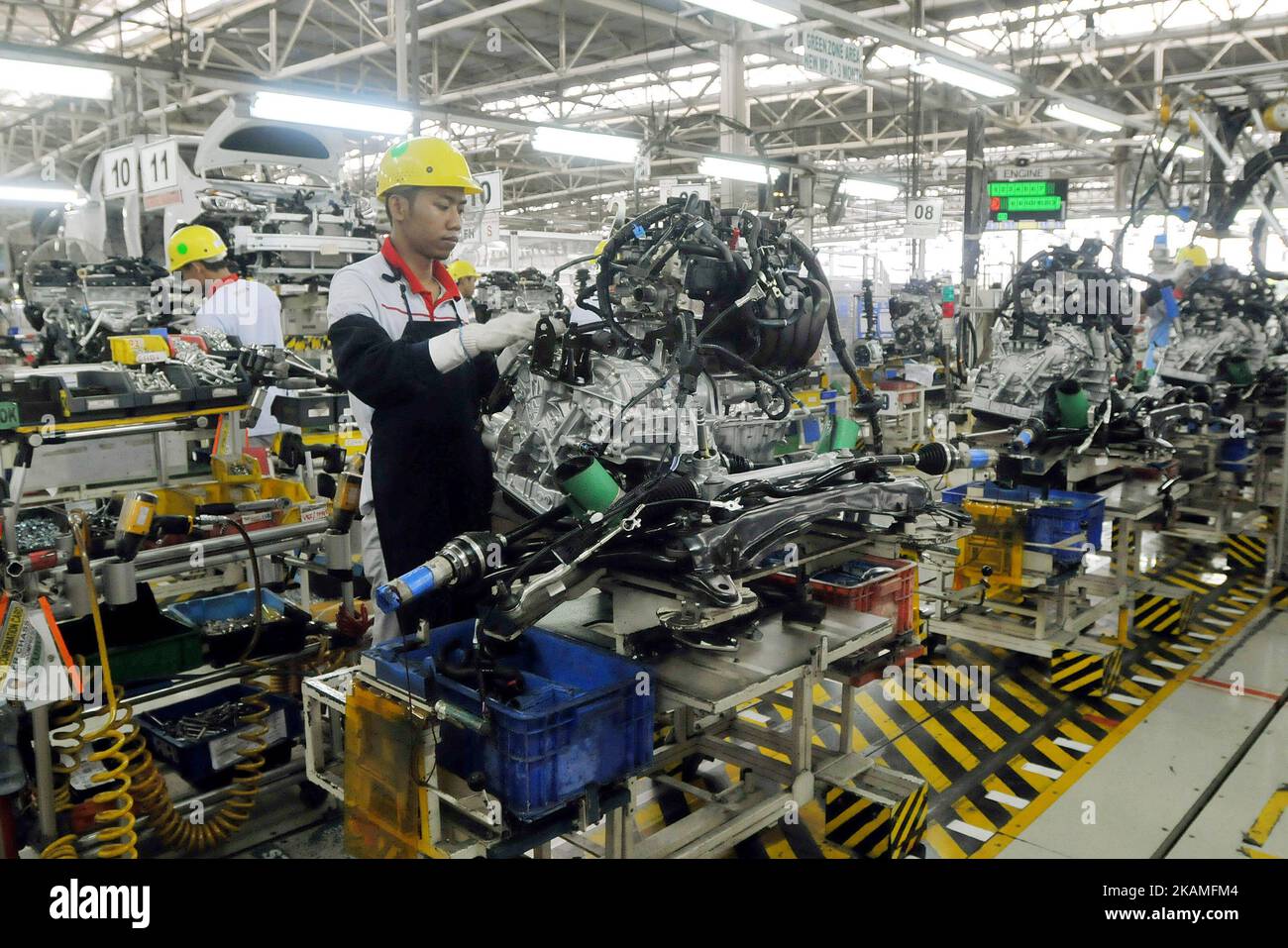

A stock image related to toyota part manufacturer.

Pros & Cons:

– Pros: High strength-to-weight ratio, cost-effective, and readily available.

– Cons: Heavier than aluminum, which can affect fuel efficiency, and may be prone to corrosion without proper treatment.

Impact on Application:

Steel is suitable for high-stress applications such as chassis and suspension components. However, it may require coatings or treatments to enhance corrosion resistance in humid or coastal environments.

Considerations for International Buyers:

For buyers in Europe, compliance with EN standards is essential. In contrast, buyers in the Middle East may need to consider the effects of high temperatures on material performance.

What Are the Benefits of Using Composite Materials in Toyota Parts?

Composite materials, such as carbon fiber and fiberglass, are increasingly popular in automotive manufacturing due to their high strength-to-weight ratio and design flexibility. These materials can withstand temperatures up to 200°C and are often used in high-performance applications.

Pros & Cons:

– Pros: Lightweight, excellent tensile strength, and design versatility.

– Cons: Higher costs and more complex manufacturing processes compared to metals.

Impact on Application:

Composites are suitable for applications requiring high performance and aesthetic appeal, such as body panels and interior components. However, they may not be compatible with all types of media.

Considerations for International Buyers:

B2B buyers should be mindful of the specific certifications required for composite materials, which can vary significantly by region. Compliance with standards like ISO and ASTM is essential for quality assurance.

Why Is Plastic a Viable Option for Toyota Parts?

Plastics are commonly used in automotive applications for their versatility and cost-effectiveness. They can handle temperatures up to 100°C and are resistant to many chemicals, making them suitable for various components, including dashboards and interior fittings.

Pros & Cons:

– Pros: Lightweight, low cost, and easy to mold into complex shapes.

– Cons: Lower strength compared to metals and may degrade under UV exposure.

Impact on Application:

Plastics are ideal for non-structural components but may not be suitable for high-stress applications. Their chemical resistance makes them suitable for fuel and oil tanks.

Considerations for International Buyers:

Buyers should ensure that the plastics used meet local regulations regarding recyclability and environmental impact, especially in Europe, where standards are stringent.

Summary Table of Material Selection for Toyota Parts

| Material | Typical Use Case for Toyota Part Manufacturer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Engine components, structural elements | Lightweight and corrosion-resistant | Higher manufacturing complexity | Medium |

| Steel | Chassis, suspension components | High strength and cost-effective | Heavier, prone to corrosion | Low |

| Composite | Body panels, high-performance parts | High strength-to-weight ratio | Expensive and complex to manufacture | High |

| Plastic | Dashboards, interior fittings | Versatile and low cost | Lower strength, UV degradation | Low |

This guide aims to provide international B2B buyers with the necessary insights to make informed decisions regarding material selection for Toyota parts manufacturing, ensuring compliance with regional standards and performance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for toyota part manufacturer

What Are the Main Stages of Manufacturing for Toyota Part Manufacturers?

Manufacturing processes for Toyota part manufacturers typically encompass several critical stages: material preparation, forming, assembly, and finishing. Each stage is designed to ensure high-quality output and adherence to Toyota’s stringent standards.

-

Material Preparation: This initial stage involves selecting high-quality raw materials that meet specific mechanical and chemical properties. Suppliers are often required to provide material certifications to demonstrate compliance with international standards. For instance, steel components may need to meet ASTM or JIS standards, which can be crucial for parts like chassis and engine components.

-

Forming: In this stage, raw materials undergo processes such as stamping, casting, or machining to create the desired shapes. Advanced techniques like precision stamping and die casting are commonly used to ensure that parts meet exact specifications. These processes often utilize Computer Numerical Control (CNC) machines for enhanced accuracy, which is vital for components that must fit seamlessly in the final assembly.

-

Assembly: Once formed, parts are assembled either manually or through automated systems. Toyota’s production system emphasizes Just-In-Time (JIT) manufacturing, where components are assembled as they are needed, reducing waste and increasing efficiency. This stage often involves multiple quality checks to ensure that each component fits correctly and functions as intended.

-

Finishing: The final stage includes processes such as coating, painting, and surface treatment to enhance durability and aesthetics. Techniques like powder coating or electroplating may be employed, depending on the part’s application. Final inspections are conducted to verify that the finish meets quality standards and specifications.

How Do Quality Assurance Processes Ensure Toyota’s Standards Are Met?

Quality assurance (QA) is integral to the manufacturing process, ensuring that every part meets Toyota’s high standards and relevant international regulations. Here are some key components of the QA process:

-

International Standards: Toyota part manufacturers typically adhere to ISO 9001, which outlines requirements for a quality management system. Compliance with ISO standards is crucial for international trade, as it assures buyers of consistent quality. Additionally, industry-specific certifications such as CE marking (for European markets) or API standards (for parts used in oil and gas applications) are often required.

-

Quality Control Checkpoints: Effective QA involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This phase involves inspecting raw materials and components upon arrival to ensure they meet specifications.

– In-Process Quality Control (IPQC): Inspections conducted during the manufacturing process help identify any deviations from quality standards early, allowing for corrective actions.

– Final Quality Control (FQC): This stage involves comprehensive testing and inspection of finished products before they are shipped. FQC ensures that all specifications and performance criteria are met. -

Common Testing Methods: Various testing methods are employed to evaluate product quality, including:

– Dimensional Inspection: Ensures that parts are manufactured to precise dimensions.

– Functional Testing: Verifies that parts operate correctly in real-world conditions.

– Non-Destructive Testing (NDT): Techniques like ultrasonic testing or X-ray inspection assess the integrity of materials without damaging them.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, must establish robust mechanisms to verify supplier quality control. Here are some actionable steps:

-

Conduct Audits: Regular audits of manufacturing facilities can provide insights into a supplier’s quality management practices. Buyers should consider conducting both pre-production and ongoing audits to ensure compliance with standards and identify potential issues early.

-

Request Quality Reports: Suppliers should be able to provide detailed quality control reports, including results from IQC, IPQC, and FQC. These reports should outline the methodologies used, findings, and any corrective actions taken.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These inspectors can conduct thorough evaluations and produce reports that highlight compliance with international standards.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers must navigate various quality control and certification nuances when sourcing from Toyota part manufacturers. Here are essential considerations:

-

Understanding Regional Standards: Different regions may have specific quality standards. For example, European buyers must be familiar with CE marking requirements, while buyers in the Middle East may need to comply with Gulf Cooperation Council (GCC) standards. Understanding these regional nuances can prevent compliance issues and ensure smoother transactions.

-

Language and Documentation: Ensure that all quality documentation, including certifications and reports, is available in a language that stakeholders can understand. This transparency helps build trust and facilitates smoother communication.

-

Cultural and Business Practices: Buyers should be aware of cultural differences that may impact business practices. Establishing strong relationships with suppliers and understanding their operational challenges can lead to better collaboration and quality assurance.

-

Logistics and Supply Chain Risks: Consider the logistics involved in shipping parts internationally. Delays or damage during transit can compromise quality. B2B buyers should work closely with suppliers to establish reliable shipping practices and consider insurance options to mitigate risks.

A stock image related to toyota part manufacturer.

By understanding these manufacturing processes and quality assurance measures, international B2B buyers can make informed decisions when sourcing from Toyota part manufacturers, ensuring that they receive high-quality products that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘toyota part manufacturer’

In the global landscape of automotive parts sourcing, particularly for Toyota parts, navigating the procurement process can be challenging. This guide provides international B2B buyers from regions like Africa, South America, the Middle East, and Europe with a practical checklist to streamline sourcing efforts. By following these steps, businesses can ensure they partner with reliable suppliers who meet their specific needs.

Step 1: Define Your Technical Specifications

Understanding your exact requirements is critical before reaching out to potential suppliers. Clearly outline the types of Toyota parts you need, including specifications, models, and quantities.

– Why it matters: This clarity helps in communicating effectively with suppliers and ensures you receive accurate quotes.

– What to include: Consider details such as material specifications, compliance with safety standards, and compatibility with existing vehicles.

Step 2: Research Reputable Suppliers

Conduct thorough research to identify suppliers with a strong reputation in the automotive parts industry. Use online platforms, trade directories, and industry forums to gather information about potential partners.

– Why it matters: A reputable supplier is more likely to provide quality products and services, reducing the risk of delays and defects.

– What to look for: Check for industry certifications, customer reviews, and case studies that demonstrate their expertise and reliability.

Step 3: Evaluate Supplier Certifications and Compliance

Before proceeding with any supplier, verify their certifications and compliance with industry standards such as ISO 9001 or TS16949. This step is crucial for ensuring quality management practices.

– Why it matters: Certification indicates that the supplier adheres to recognized quality standards, which can enhance your product’s reliability.

– What to check: Request copies of certifications and inquire about their quality control processes.

Step 4: Request Samples for Quality Assessment

Always request samples of the parts you intend to procure. This allows you to assess the quality and compatibility of the products with your requirements.

– Why it matters: Evaluating samples helps prevent costly errors and ensures that the parts meet your technical specifications.

– What to evaluate: Inspect samples for material quality, dimensions, and overall craftsmanship.

Step 5: Discuss Terms of Payment and Delivery

Clarify payment terms, pricing, and delivery schedules with potential suppliers. Establishing these details upfront can prevent misunderstandings later in the procurement process.

– Why it matters: Clear terms protect both parties and establish expectations for the transaction.

– What to confirm: Look for flexible payment options and realistic delivery timelines that align with your operational needs.

Step 6: Assess After-Sales Support and Warranty Policies

Inquire about the supplier’s after-sales support and warranty policies. Understanding these aspects is vital for long-term partnerships.

– Why it matters: Effective after-sales support can significantly enhance your operational efficiency, especially in case of defects or issues.

– What to request: Ensure that warranty terms are clear and that the supplier has a dedicated support team for addressing any concerns.

Step 7: Establish Communication Protocols

Set clear communication protocols with your chosen supplier to ensure a smooth procurement process. This includes defining points of contact and preferred communication methods.

– Why it matters: Effective communication can resolve issues quickly and enhance collaboration.

– What to implement: Agree on regular check-ins and updates to stay aligned throughout the procurement cycle.

By following this checklist, B2B buyers can confidently navigate the complexities of sourcing Toyota parts, ensuring they partner with suppliers that meet their operational standards and contribute to their business success.

Comprehensive Cost and Pricing Analysis for toyota part manufacturer Sourcing

What Are the Key Cost Components in Toyota Part Manufacturing?

When sourcing Toyota parts, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of raw materials significantly impacts the overall cost. High-quality materials typically increase durability and performance, but they also raise the price. For Toyota parts, sourcing from reputable suppliers ensures compliance with industry standards, which is vital for long-term reliability.

-

Labor: Labor costs vary by region and can be influenced by local wage standards and skill levels. Countries with higher labor costs may offer more skilled workers, which can enhance product quality but also increase expenses.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help minimize overhead costs, making it essential to evaluate suppliers’ operational efficiencies.

-

Tooling: The initial investment in tooling can be substantial, especially for custom parts. This cost is often amortized over the production run, so larger orders may yield a lower per-unit cost.

-

Quality Control (QC): Implementing robust QC processes ensures that parts meet Toyota’s high standards. While this adds to the cost, it helps avoid expensive recalls and enhances buyer confidence.

-

Logistics: Shipping and handling costs are critical, especially for international buyers. Factors such as distance, shipping method, and customs duties can significantly affect the total cost.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. Understanding the supplier’s margin expectations can aid in negotiations.

How Do Price Influencers Affect Toyota Part Sourcing?

Several factors can influence the pricing of Toyota parts:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to reduced per-unit costs. Buyers should consider their inventory needs and negotiate MOQs that balance cost savings with storage capabilities.

-

Specifications and Customization: Custom parts designed to meet specific requirements may incur additional costs. Buyers should be clear about their needs to avoid unexpected expenses.

-

Materials and Quality Certifications: Parts that meet specific quality certifications may cost more but are essential for compliance with safety and regulatory standards in various markets.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more for their proven track record, while newer entrants might offer lower prices to gain market share.

-

Incoterms: The choice of Incoterms affects the allocation of costs and risks between buyers and suppliers. Understanding these terms can help buyers manage their logistics expenses more effectively.

What Are the Best Practices for Negotiating Costs in Toyota Part Sourcing?

International B2B buyers can employ several strategies to optimize their sourcing costs:

-

Negotiate with Suppliers: Building a strong relationship with suppliers can lead to better pricing. Don’t hesitate to negotiate on volume discounts, payment terms, and delivery schedules.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the initial purchase price. Consider long-term factors such as maintenance, warranty, and potential downtime due to part failures.

-

Understand Pricing Nuances for Different Regions: Be aware of the economic conditions in the supplier’s country, as these can affect pricing. For example, suppliers in emerging markets may offer competitive pricing but could have different quality assurance practices.

-

Leverage Technological Tools: Utilize supply chain management software to analyze costs, compare suppliers, and track shipments. This can lead to more informed purchasing decisions.

-

Be Informed About Market Trends: Keeping abreast of industry trends and material costs can provide leverage during negotiations. Knowledge of market dynamics helps buyers anticipate price changes.

Conclusion

Navigating the cost structure and pricing landscape of Toyota part sourcing requires diligence and strategic planning. By understanding the key components, influencing factors, and best negotiation practices, international B2B buyers can make informed decisions that enhance their supply chain efficiency and overall profitability. Always approach negotiations with a clear understanding of both your needs and the market conditions to achieve the best possible outcomes.

Alternatives Analysis: Comparing toyota part manufacturer With Other Solutions

When considering the procurement of automotive parts, international B2B buyers must evaluate various manufacturing options. Toyota’s part manufacturing is renowned for its quality and reliability; however, there are alternative solutions available that may better suit specific operational needs or budget constraints. In this section, we will compare Toyota part manufacturing with two viable alternatives: Aftermarket Parts Manufacturers and OEM Part Suppliers.

Comparison Table: Evaluating Toyota Part Manufacturer and Alternatives

| Comparison Aspect | Toyota Part Manufacturer | Aftermarket Parts Manufacturers | OEM Part Suppliers |

|---|---|---|---|

| Performance | High | Variable, depends on the brand | High |

| Cost | Moderate to High | Generally lower | High |

| Ease of Implementation | Moderate | Easy, widely available | Moderate |

| Maintenance | Low | Variable, often requires more attention | Low |

| Best Use Case | Long-term reliability | Cost-sensitive repairs | Original specifications |

What Are the Advantages and Disadvantages of Aftermarket Parts Manufacturers?

Aftermarket parts manufacturers produce components that are not made by the original vehicle manufacturer. The primary advantage of aftermarket parts is their cost-effectiveness; they often come at a significantly lower price point compared to OEM parts. This makes them an attractive option for businesses operating on tight budgets or for those who need to perform repairs quickly without sacrificing too much on quality. However, the downside is that the performance and durability of aftermarket parts can vary widely, depending on the manufacturer. Some aftermarket components may not meet the same quality standards as OEM parts, which can lead to increased maintenance issues over time.

Why Consider OEM Part Suppliers?

OEM part suppliers provide components that are made by the same company that manufactured the original parts for the vehicle. This ensures that the parts will fit perfectly and meet the original specifications set by the manufacturer. The primary benefit of using OEM parts is the assurance of quality and reliability, making them ideal for businesses that prioritize long-term performance and safety. However, the cost of OEM parts is typically higher than that of aftermarket options, which may not be feasible for every buyer. Additionally, the availability of certain OEM parts may be limited, depending on the vehicle model and age.

How Can a B2B Buyer Choose the Right Solution for Their Needs?

When deciding between Toyota part manufacturing and its alternatives, B2B buyers should consider several factors, including their budget, the specific requirements of their operations, and the importance of part reliability. For businesses focused on cost savings and immediate repairs, aftermarket parts may be a suitable choice. Conversely, those prioritizing quality and long-term performance should lean toward OEM parts. Toyota’s part manufacturing remains a strong contender due to its reputation for durability and reliability. Ultimately, buyers should align their choice with their strategic goals and operational needs, ensuring they select the solution that best supports their business objectives.

Essential Technical Properties and Trade Terminology for toyota part manufacturer

What Are the Essential Technical Properties for Toyota Part Manufacturing?

Understanding the critical technical properties of Toyota parts is essential for B2B buyers, especially when sourcing components that meet stringent quality and performance standards. Here are some key specifications that should be considered:

1. Material Grade

Material grade refers to the classification of materials used in manufacturing parts, which impacts durability, performance, and cost. For Toyota parts, common materials include high-strength steel, aluminum alloys, and plastics. Buyers must ensure that the material grade aligns with the intended application to prevent early failures and ensure compliance with safety regulations.

2. Tolerance Levels

Tolerance levels indicate the permissible limits of variation in a part’s dimensions, which is critical in ensuring proper fit and function. For instance, a tolerance of ±0.01 mm may be required for precision components like engine parts. Understanding tolerance specifications helps buyers assess the manufacturing capabilities of suppliers and ensure that parts will integrate seamlessly into existing systems.

3. Surface Finish

The surface finish refers to the texture and smoothness of a part’s exterior, which can affect both aesthetics and functionality. Different finishes, such as anodizing or plating, can enhance corrosion resistance or reduce friction. B2B buyers should specify surface finish requirements to ensure that parts will perform optimally in their intended environment.

4. Weight Specifications

Weight specifications are particularly important in the automotive industry, as they can impact fuel efficiency and vehicle performance. Buyers should consider the weight of parts to ensure that they meet regulatory standards and enhance the overall efficiency of the vehicle. Lightweight materials can lead to better performance and lower emissions, which is increasingly important in today’s market.

5. Heat Treatment Processes

Heat treatment processes, such as quenching or tempering, are used to alter the mechanical properties of materials, enhancing strength and durability. For Toyota parts that experience high stress, understanding the heat treatment processes used by manufacturers can help buyers ensure that the components will withstand operational demands.

What Are Common Trade Terms Used in the Toyota Parts Industry?

Familiarity with industry jargon is vital for effective communication and negotiation between buyers and suppliers. Here are several common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture parts that are used in the original assembly of vehicles. For B2B buyers, sourcing OEM parts ensures compatibility and quality assurance since these components are designed to meet the specifications set by the vehicle manufacturer.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers, as it impacts inventory management and cost efficiency. Buyers should negotiate MOQs to align with their purchasing needs and storage capabilities.

3. RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers for specific products or services. This process helps buyers compare pricing and terms across multiple vendors, ensuring competitive sourcing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers to avoid misunderstandings in international trade.

5. Lead Time

Lead time refers to the period between placing an order and receiving the goods. Understanding lead times helps buyers plan their inventory and production schedules effectively, ensuring that they maintain adequate stock levels without incurring excess costs.

By grasping these essential technical properties and trade terms, international B2B buyers can make informed decisions when sourcing Toyota parts, ultimately enhancing their operational efficiency and competitiveness in the marketplace.

Navigating Market Dynamics and Sourcing Trends in the toyota part manufacturer Sector

What Are the Key Market Dynamics and Sourcing Trends in the Toyota Part Manufacturer Sector?

The Toyota part manufacturer sector is currently experiencing significant transformations driven by technological advancements, consumer demands, and global economic shifts. A primary global driver is the increasing demand for electric and hybrid vehicles, which necessitates a reevaluation of sourcing strategies for components such as batteries and electric drivetrains. International B2B buyers, especially those from Africa, South America, the Middle East, and Europe, must stay informed about these shifts to effectively navigate the market landscape.

Emerging technologies such as automation and artificial intelligence are playing a crucial role in optimizing manufacturing processes. These innovations not only enhance production efficiency but also improve the accuracy of supply chain management. B2B buyers should consider suppliers who leverage such technologies, as this can lead to cost savings and faster turnaround times. Additionally, the rise of digital platforms for procurement is reshaping sourcing strategies, enabling buyers to access a broader range of suppliers and negotiate better terms.

Another key trend is the emphasis on local sourcing. As geopolitical tensions and trade barriers increase, many manufacturers are looking to establish more localized supply chains. This shift is particularly relevant for buyers in regions like Europe and Africa, where local partnerships can mitigate risks associated with global logistics and supply chain disruptions. Understanding these dynamics will empower B2B buyers to make informed decisions and develop resilient supply chains.

How Is Sustainability Influencing B2B Sourcing for Toyota Parts?

Sustainability has become a critical factor in the sourcing strategies of international B2B buyers in the Toyota part manufacturer sector. The environmental impact of manufacturing processes and the importance of ethical supply chains are at the forefront of buyer considerations. Companies are increasingly held accountable for their carbon footprints, prompting a shift towards sourcing parts that are produced sustainably.

Buyers should prioritize suppliers who demonstrate a commitment to sustainability through certifications such as ISO 14001 or adherence to the UN Sustainable Development Goals. These certifications indicate that a supplier is taking steps to minimize environmental impacts, which can enhance the buyer’s brand reputation and align with consumer preferences for eco-friendly products. Moreover, utilizing recycled materials in manufacturing can significantly reduce waste and lower resource consumption.

The integration of sustainability into procurement not only addresses environmental concerns but also opens up new market opportunities. Many consumers are increasingly inclined to support brands that prioritize ethical sourcing practices, making it essential for B2B buyers to partner with manufacturers who align with these values. By emphasizing sustainability, buyers can foster stronger relationships with suppliers and contribute positively to the industry’s environmental performance.

What Is the Historical Context of the Toyota Part Manufacturer Sector?

The evolution of the Toyota part manufacturer sector is rooted in the company’s long-standing commitment to quality and innovation. Founded in 1937, Toyota quickly became a leader in the automotive industry, introducing the Toyota Production System (TPS), which emphasized efficiency and waste reduction. This framework not only revolutionized manufacturing processes within Toyota but also set new standards across the global automotive sector.

As the automotive landscape shifted towards globalization, Toyota adapted by establishing manufacturing plants worldwide, facilitating local sourcing and production. This strategic move enabled the company to respond swiftly to regional market demands while maintaining high-quality standards. For international B2B buyers, understanding this historical context is essential, as it highlights Toyota’s emphasis on quality and innovation, which continues to influence sourcing decisions today.

In conclusion, international B2B buyers engaging with the Toyota part manufacturer sector must navigate a complex landscape characterized by technological advancements, sustainability pressures, and historical precedence. By leveraging these insights, buyers can position themselves strategically in the market, ensuring they select the right partners and products to meet their needs.

Frequently Asked Questions (FAQs) for B2B Buyers of toyota part manufacturer

-

How do I ensure the quality of Toyota parts when sourcing from manufacturers?

To ensure quality when sourcing Toyota parts, conduct thorough supplier vetting. Look for manufacturers with ISO certifications and positive industry reviews. Request samples to assess the quality firsthand and inquire about their quality assurance processes. Additionally, consider suppliers who offer warranties or guarantees on their products, as this demonstrates confidence in their quality standards. Regular audits and inspections can also help maintain quality throughout the production process. -

What are the best practices for vetting a Toyota parts supplier?

When vetting a Toyota parts supplier, start by checking their credentials, including business licenses, certifications, and industry affiliations. Look for suppliers with a proven track record in manufacturing specific Toyota parts. Request references from previous clients to gauge their reliability and service quality. Evaluate their production capabilities, technology, and compliance with international standards. Lastly, assess their communication skills and responsiveness, as these are crucial for a successful partnership. -

What is the typical minimum order quantity (MOQ) for Toyota parts?

The minimum order quantity (MOQ) for Toyota parts can vary significantly among manufacturers. Typically, MOQs range from 100 to 1,000 units, depending on the part’s complexity and the supplier’s production capabilities. For customized or specialized parts, MOQs may be higher. It’s advisable to negotiate MOQs based on your specific needs and explore suppliers willing to accommodate smaller orders, especially for initial trials or testing phases. -

What payment terms should I expect when sourcing from Toyota parts manufacturers?

Payment terms for sourcing Toyota parts often include options like upfront payments, partial payments upon order confirmation, and balance payments before shipment. Common practices involve a 30% deposit with the order and the remaining 70% due prior to shipping. However, terms can vary by supplier and your negotiation leverage. Always clarify payment methods accepted (e.g., bank transfer, letters of credit) and ensure terms are documented in your purchase agreement to prevent disputes. -

How can I customize Toyota parts to meet specific requirements?

To customize Toyota parts, communicate your specific requirements clearly to potential manufacturers. Many suppliers offer customization options, including modifications in design, materials, and features. Discuss your needs during the initial discussions and request prototypes to evaluate the customization process. Ensure that the manufacturer has the necessary technology and expertise to deliver the desired modifications. Additionally, factor in lead times for custom orders, as they may differ from standard parts. -

What logistics considerations should I keep in mind when importing Toyota parts?

When importing Toyota parts, consider logistics aspects such as shipping methods, customs clearance, and delivery timelines. Choose reliable freight forwarders experienced in handling automotive parts to ensure smooth transportation. Understand the import regulations of your country, including tariffs and duties. It’s also essential to plan for potential delays in shipping and customs processing, so factor in buffer time in your supply chain management to avoid disruptions. -

How do I manage potential risks in international trade when sourcing Toyota parts?

Managing risks in international trade involves thorough research and strategic planning. Start by diversifying your supplier base to mitigate dependency on a single source. Conduct regular risk assessments to identify potential disruptions, such as political instability or natural disasters. Consider using trade finance options like letters of credit to protect your transactions. Establish clear contractual agreements outlining terms, responsibilities, and dispute resolution mechanisms to safeguard your interests. -

What quality assurance processes should I expect from a reputable Toyota parts manufacturer?

A reputable Toyota parts manufacturer should have robust quality assurance processes in place. These typically include incoming material inspections, in-process quality checks, and final product testing. Look for manufacturers that implement statistical process control (SPC) techniques to monitor production quality. They should also provide documentation of their quality management system, including certifications and audit reports. Regular communication regarding quality metrics and improvements is also a sign of a committed supplier.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for toyota part manufacturer

What Are the Key Takeaways for International B2B Buyers in Sourcing Toyota Parts?

Strategic sourcing of Toyota parts presents a multitude of opportunities for international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe. Establishing robust relationships with reliable suppliers can enhance supply chain efficiency and reduce costs. Buyers should prioritize suppliers that offer high-quality components, consistent availability, and competitive pricing to ensure they meet the demands of their markets.

The value of strategic sourcing lies not only in cost savings but also in risk management and quality assurance. By diversifying their supplier base and leveraging technology for better supply chain visibility, companies can mitigate disruptions and enhance operational resilience. Engaging with manufacturers that adhere to international standards can further assure product quality and compliance.

How Can International Buyers Prepare for Future Sourcing Trends?

Looking ahead, B2B buyers should remain agile and responsive to market changes, such as shifts towards sustainability and digital transformation within the automotive industry. Embracing these trends will position companies favorably in the competitive landscape.

We encourage buyers to actively seek partnerships with innovative Toyota part manufacturers who are committed to quality and sustainability. By doing so, they can not only enhance their operational capabilities but also contribute to a more sustainable future in the automotive sector.