Discover Reliable Sleeves Suppliers: Your Ultimate Guide (2025)

Introduction: Navigating the Global Market for sleeves supplier

In the ever-evolving landscape of international trade, sourcing high-quality sleeves from reliable suppliers can pose a significant challenge for B2B buyers. Whether you’re looking for protective sleeves for machinery, garment sleeves for fashion applications, or specialized medical sleeves, understanding the nuances of the global market is crucial. This guide provides a comprehensive overview of the sleeves supplier market, exploring various types, applications, and the critical factors involved in supplier vetting.

From assessing quality certifications to negotiating costs, we aim to equip international buyers, especially those from Africa, South America, the Middle East, and Europe (including Poland and Australia), with the knowledge necessary to make informed purchasing decisions. By addressing common concerns such as supply chain reliability, material specifications, and price competitiveness, this resource serves as a roadmap to navigate the complexities of sourcing sleeves.

Our goal is to empower businesses to not only find the right suppliers but also build lasting partnerships that can enhance their operational efficiency. With this guide in hand, you will be better positioned to tackle the challenges of sourcing, ensuring that your procurement strategy aligns with both your budget and quality expectations.

Understanding sleeves supplier Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Sleeve Suppliers | Tailor-made sleeves based on specific client needs | Fashion brands, Event organizers | Pros: Unique designs, personalized service. Cons: Higher costs, longer lead times. |

| Bulk Sleeve Suppliers | Mass-produced sleeves for large orders | Retailers, Wholesalers | Pros: Cost-effective, quick turnaround. Cons: Limited customization, potential quality variance. |

| Eco-Friendly Suppliers | Sleeves made from sustainable materials | Eco-conscious brands, Niche markets | Pros: Appeals to sustainability-focused customers. Cons: Often more expensive, limited availability. |

| Technology-Driven Suppliers | Use of advanced technology for production efficiency | Tech fashion brands, Innovation sectors | Pros: High precision, innovative designs. Cons: Initial investment costs, potential tech reliance issues. |

| Traditional Suppliers | Established suppliers using conventional production methods | Small businesses, Local designers | Pros: Familiarity, often lower costs. Cons: Slower production, less flexibility in design. |

What are Custom Sleeve Suppliers and When Should You Choose Them?

Custom sleeve suppliers focus on creating tailor-made products that meet the specific requirements of clients. These suppliers are particularly beneficial for fashion brands and event organizers that seek unique designs that stand out in the market. When purchasing from custom suppliers, consider the lead times and costs, as they tend to be higher compared to bulk options. However, the personalized service and exclusive designs often justify the investment, especially for brands looking to differentiate themselves.

How Do Bulk Sleeve Suppliers Operate and What Are Their Advantages?

Bulk sleeve suppliers are ideal for businesses that require mass-produced sleeves for large orders, such as retailers and wholesalers. They offer cost-effective solutions and quick turnaround times, making them suitable for high-volume needs. However, buyers should be mindful of the limitations in customization and the potential for quality variance due to mass production techniques. This option is best for businesses prioritizing cost savings over unique designs.

What Makes Eco-Friendly Suppliers Stand Out in the Market?

Eco-friendly sleeve suppliers produce products using sustainable materials, catering to eco-conscious brands and niche markets. These suppliers appeal to consumers who prioritize sustainability in their purchasing decisions. While the environmental benefits are significant, buyers should be prepared for potentially higher costs and limited availability of materials. This option is ideal for businesses looking to enhance their brand image through sustainable practices.

How Do Technology-Driven Suppliers Enhance Sleeve Production?

Technology-driven suppliers leverage advanced technology to improve production efficiency and precision. This is particularly beneficial for tech fashion brands and companies in innovative sectors that require high-quality, precise designs. While the initial investment in technology can be substantial, the benefits often include faster production times and the ability to create complex designs. Buyers should weigh the benefits of advanced technology against the potential for reliance on tech systems.

What are the Characteristics of Traditional Suppliers and Their Ideal Clients?

Traditional suppliers rely on established production methods, often appealing to small businesses and local designers. They typically offer familiarity and competitive pricing, making them accessible for startups or those with limited budgets. However, traditional suppliers may have slower production times and less flexibility in design options. This route is best for businesses that value cost-effectiveness and established relationships over rapid innovation.

Related Video: Silicone Sleeves Merefsa

Key Industrial Applications of sleeves supplier

| Industry/Sector | Specific Application of sleeves supplier | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Textile and Fashion | Protective sleeves for fabric handling | Reduces fabric damage during processing | Material durability, cost-effectiveness, and customization options. |

| Manufacturing | Insulation sleeves for machinery and equipment | Enhances safety and efficiency by preventing heat loss | Compliance with safety standards and heat resistance ratings. |

| Food and Beverage | Sleeves for food packaging and preservation | Extends shelf life and maintains product integrity | Food-grade materials and regulatory compliance. |

| Automotive | Protective sleeves for wiring and cables | Increases longevity of components, reduces maintenance costs | Resistance to chemicals and temperature fluctuations. |

| Construction | Sleeves for scaffolding and safety equipment | Enhances worker safety and equipment longevity | Compliance with industry safety regulations and material strength. |

How Are Sleeves Used in the Textile and Fashion Industry?

In the textile and fashion industry, sleeves suppliers provide protective sleeves designed to minimize fabric damage during handling and processing. These sleeves are crucial for preserving the quality of delicate materials, reducing waste, and improving operational efficiency. International buyers, particularly from regions like Africa and South America, should prioritize sourcing options that offer durability and customization to meet specific design needs.

What Role Do Sleeves Play in Manufacturing?

Sleeves suppliers in the manufacturing sector supply insulation sleeves that are critical for machinery and equipment. These sleeves help in maintaining optimal operating temperatures, enhancing safety by preventing heat loss, and improving overall efficiency. For buyers in Europe and the Middle East, sourcing materials that comply with safety standards and offer high heat resistance is essential for ensuring workplace safety and compliance.

How Do Sleeves Impact the Food and Beverage Sector?

In the food and beverage industry, sleeves suppliers offer packaging solutions that extend the shelf life of products and maintain their integrity. These sleeves are often made from food-grade materials that comply with health regulations. International buyers should focus on sourcing sleeves that not only meet regulatory compliance but also offer effective preservation capabilities to enhance product appeal in competitive markets.

Why Are Protective Sleeves Important in the Automotive Industry?

Protective sleeves supplied for wiring and cables in the automotive sector serve to increase the longevity of components and reduce maintenance costs. These sleeves protect against wear, environmental factors, and chemical exposure. Buyers from Africa and Europe should consider sourcing options that offer chemical resistance and durability to ensure the reliability of automotive systems.

How Are Sleeves Utilized in Construction for Safety?

In the construction industry, sleeves suppliers provide protective solutions for scaffolding and safety equipment. These sleeves enhance worker safety by providing additional protection against environmental hazards and wear. Buyers in South America and the Middle East should ensure that sourced sleeves comply with safety regulations and are made from robust materials to withstand the rigors of construction work.

Related Video: Technical Process of Shrink Sleeves

3 Common User Pain Points for ‘sleeves supplier’ & Their Solutions

Scenario 1: Quality Control Challenges with Sleeve Suppliers

The Problem: Many B2B buyers face significant challenges when it comes to ensuring the quality of sleeves supplied for their products. For instance, a textile manufacturer in South America may order a batch of sleeves only to discover that the fabric quality does not meet their specifications. This can lead to production delays, increased costs, and potential damage to their brand reputation. Buyers often feel overwhelmed by the lack of clear quality assurance processes, resulting in uncertainty about the reliability of their suppliers.

The Solution: To mitigate these quality control challenges, buyers should implement a rigorous supplier evaluation process before placing large orders. Start by requesting samples of the sleeves to test their durability, texture, and overall quality. Additionally, establish clear quality standards in your purchase agreements. Consider utilizing third-party quality inspection services that can conduct on-site evaluations of the supplier’s manufacturing processes. This proactive approach ensures that the sleeves meet your specifications and minimizes the risk of receiving subpar products.

Scenario 2: Communication Barriers with International Suppliers

The Problem: International B2B buyers often encounter communication barriers that can hinder the procurement process. For example, a buyer in Africa may struggle to communicate specific design modifications to a sleeves supplier based in Europe due to language differences or time zone discrepancies. This miscommunication can result in incorrect orders, wasted materials, and frustration on both sides, ultimately impacting the buyer’s production timeline.

The Solution: To enhance communication with international suppliers, buyers should utilize technology-driven solutions. Implementing a collaborative platform that allows for real-time updates and discussions can bridge the gap. Use visual aids such as sketches or CAD drawings to convey design specifications clearly. Additionally, establish regular check-in meetings via video conferencing to address any questions or concerns promptly. By fostering open communication and leveraging technology, buyers can ensure that their needs are understood and met efficiently.

Scenario 3: Sourcing Sustainable Sleeve Materials

The Problem: As sustainability becomes increasingly important in the textile industry, B2B buyers are often challenged to source eco-friendly sleeve materials. A buyer from the Middle East may find it difficult to locate suppliers that offer sustainable options without compromising on quality or cost. This dilemma can result in hesitance to commit to a supplier, delaying production and complicating supply chain logistics.

The Solution: To effectively source sustainable materials, buyers should conduct thorough research on suppliers who specialize in eco-friendly fabrics. Look for certifications such as Global Organic Textile Standard (GOTS) or OEKO-TEX, which indicate compliance with environmental standards. Establish partnerships with suppliers who prioritize sustainability in their operations. Consider attending industry trade shows or webinars focused on sustainable textiles to network with suppliers who align with your values. By prioritizing sustainable sourcing, buyers not only meet consumer demand for eco-friendly products but also enhance their brand’s reputation in the marketplace.

Strategic Material Selection Guide for sleeves supplier

What Are the Key Properties of Common Materials Used by Sleeve Suppliers?

When selecting materials for sleeves, international B2B buyers must consider various factors that impact performance, durability, and application suitability. Here, we analyze four common materials used in sleeve production: rubber, silicone, PVC, and nylon.

How Does Rubber Perform in Sleeve Applications?

Rubber is a versatile material known for its elasticity and resilience. It can withstand a wide range of temperatures and pressures, making it suitable for various industrial applications. Rubber sleeves often exhibit excellent abrasion resistance and can handle exposure to various chemicals, which is crucial in sectors like automotive and manufacturing.

Pros: Rubber sleeves are durable and can provide a good seal, making them ideal for applications requiring tight fittings. They are generally cost-effective, which is attractive for bulk purchases.

Cons: While rubber is resilient, it may degrade over time when exposed to UV light or extreme temperatures. This can limit its use in outdoor applications or environments with high heat.

Impact on Application: Rubber sleeves are particularly effective in applications involving hydraulic systems or machinery where flexibility and durability are paramount.

Considerations for Buyers: Buyers from regions like Africa and South America should ensure that rubber products meet local standards for safety and performance, such as ASTM or ISO certifications.

What Advantages Does Silicone Offer for Sleeve Suppliers?

Silicone is another popular material for sleeves, known for its high-temperature resistance and flexibility. It can withstand extreme temperatures ranging from -60°C to 230°C (-76°F to 446°F), making it ideal for applications in automotive, aerospace, and food processing industries.

Pros: Silicone sleeves are non-reactive and can handle a variety of chemicals, making them suitable for food and pharmaceutical applications. They also have excellent weather resistance.

Cons: The primary drawback of silicone is its cost; it tends to be more expensive than rubber or PVC. Additionally, while silicone is durable, it may not provide the same level of mechanical strength as other materials.

Impact on Application: Silicone’s high-temperature resistance makes it suitable for applications involving steam or hot liquids, where other materials might fail.

Considerations for Buyers: International buyers, particularly from Europe, should verify that silicone materials comply with food safety standards (e.g., FDA regulations) when used in food-related applications.

Why Is PVC a Common Choice for Sleeve Suppliers?

Polyvinyl Chloride (PVC) is widely used in sleeve manufacturing due to its versatility and cost-effectiveness. It offers good chemical resistance and is suitable for various applications, including electrical insulation and fluid transfer.

Pros: PVC sleeves are lightweight, easy to manufacture, and can be produced in various colors and finishes. They are also relatively inexpensive compared to other materials.

Cons: PVC can become brittle over time, especially when exposed to UV light, which may limit its outdoor applications. Additionally, it has a lower temperature tolerance compared to rubber and silicone.

Impact on Application: PVC is commonly used in electrical and plumbing applications, where it provides reliable insulation and protection against moisture.

Considerations for Buyers: Buyers should ensure that PVC materials meet local environmental regulations, particularly in Europe, where there are strict guidelines regarding the use of PVC and its disposal.

What Role Does Nylon Play in Sleeve Applications?

Nylon is a synthetic polymer known for its strength and durability. It is often used in applications requiring high tensile strength and resistance to wear and tear, making it suitable for heavy-duty sleeves.

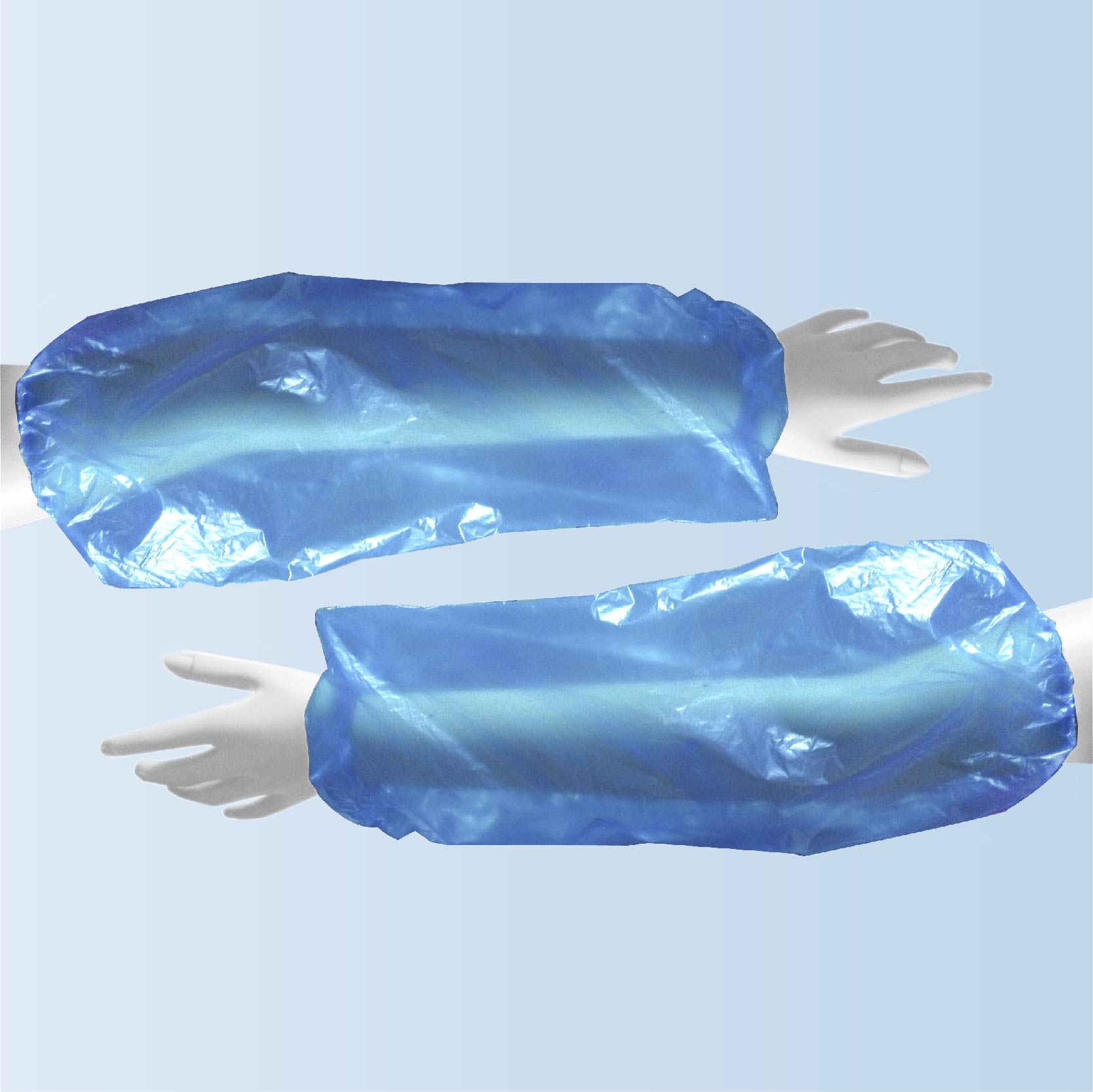

A stock image related to sleeves supplier.

Pros: Nylon sleeves are resistant to abrasion and chemicals, making them ideal for industrial applications. They also offer good flexibility and can withstand a range of temperatures.

Cons: Nylon can absorb moisture, which may impact its performance in certain environments. Additionally, it may require more complex manufacturing processes, increasing production costs.

Impact on Application: Nylon sleeves are often used in automotive and industrial applications where high strength and durability are critical.

Considerations for Buyers: Buyers from the Middle East and Africa should consider the climate and environmental conditions when selecting nylon, as moisture absorption could affect performance.

Summary Table of Material Properties for Sleeve Suppliers

| Material | Typical Use Case for sleeves supplier | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | Hydraulic systems, machinery | Durable and cost-effective | Degrades under UV light | Medium |

| Silicone | Food processing, automotive | High-temperature resistance | Higher cost than rubber | High |

| PVC | Electrical insulation, plumbing | Lightweight and versatile | Brittle over time | Low |

| Nylon | Heavy-duty industrial applications | High tensile strength | Absorbs moisture | Medium |

This guide provides essential insights into material selection for sleeves, helping international B2B buyers make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for sleeves supplier

What Are the Key Stages in the Manufacturing Process for Sleeve Suppliers?

A stock image related to sleeves supplier.

The manufacturing process for sleeves involves several critical stages that ensure the final product meets quality standards and customer specifications. Understanding these stages can help B2B buyers assess suppliers and their capabilities effectively.

Material Preparation

The first stage in manufacturing sleeves is material preparation. Suppliers typically use high-quality textiles, such as cotton, polyester, or blends, depending on the intended application of the sleeves. Material selection is essential, as it impacts durability, comfort, and functionality.

In this phase, raw materials are inspected for defects, and samples may be taken for testing. B2B buyers should inquire about the supplier’s sourcing practices to ensure that materials comply with international standards and are ethically sourced.

Forming Techniques: How Are Sleeves Shaped?

Once materials are prepared, the next step involves forming the sleeves. This can include several techniques, such as cutting, sewing, and bonding.

-

Cutting: The fabric is cut into specific shapes according to patterns. Automated cutting machines can enhance precision and reduce waste.

-

Sewing: This is a critical step where pieces are stitched together. Advanced sewing techniques, including double-stitched seams for strength, are often employed.

-

Bonding: For certain types of sleeves, especially those made from synthetic materials, bonding techniques may be used instead of traditional sewing. This can enhance water resistance and flexibility.

Buyers should evaluate whether suppliers utilize modern machinery and skilled labor in these processes, as this can significantly affect the final product’s quality.

Assembly and Finishing: What Are the Final Steps?

After the sleeves are formed, they undergo assembly and finishing.

-

Assembly: This involves attaching any additional components, such as cuffs, elastic bands, or decorative elements. The assembly process can also include quality checks to ensure all parts fit together correctly.

-

Finishing: This final stage includes processes such as washing, ironing, and applying any necessary treatments (e.g., anti-wrinkle or water-repellent finishes). Proper finishing enhances the sleeves’ appearance and performance.

B2B buyers should look for suppliers who maintain stringent quality control during assembly and finishing to ensure the product meets expectations.

How Is Quality Assurance Implemented in Sleeve Manufacturing?

Quality assurance (QA) is crucial in ensuring that sleeves meet the required standards and specifications. For international B2B buyers, understanding the QA process can help in selecting reliable suppliers.

What International Standards Should B2B Buyers Look For?

International standards play a significant role in the quality assurance of sleeve manufacturing. Suppliers often adhere to standards like ISO 9001, which focuses on quality management systems, ensuring consistent quality in production processes.

In addition to ISO certifications, industry-specific standards such as CE marking for products sold in Europe or API standards for industrial applications should also be considered. B2B buyers should confirm that their suppliers comply with these standards to mitigate risks associated with quality and safety.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically divided into several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet predefined specifications. This is crucial in preventing defects in the final product.

-

In-Process Quality Control (IPQC): During production, ongoing inspections are conducted to monitor quality at various stages. This includes checking stitching quality, seam integrity, and overall craftsmanship.

-

Final Quality Control (FQC): Once production is complete, a final inspection occurs. This includes checking for defects, ensuring compliance with specifications, and verifying that all finishing processes have been correctly applied.

B2B buyers should ask suppliers about their QC protocols and the frequency of inspections to ensure product quality.

How Can B2B Buyers Verify Supplier Quality Control?

Verification of a supplier’s quality control processes is essential for international buyers looking to ensure that they receive high-quality products. Here are some actionable steps:

Conducting Supplier Audits: What Should Buyers Look For?

Regular audits of suppliers can provide invaluable insights into their manufacturing and QC practices. During an audit, buyers should assess:

- Compliance with international standards (ISO, CE, etc.).

- The effectiveness of IQC, IPQC, and FQC procedures.

- The equipment and technology used in the manufacturing process.

- Employee training and skill levels.

Buyers from regions such as Africa, South America, the Middle East, and Europe should consider engaging third-party auditing services to ensure objectivity and thoroughness.

Reviewing Quality Control Reports: What Information Is Valuable?

Suppliers should provide detailed QC reports that outline their inspection results, defect rates, and corrective actions taken. B2B buyers should look for:

- Consistency in QC results over time.

- Documentation of any non-conformances and how they were addressed.

- Trends in defect rates, which can indicate areas needing improvement.

These reports can provide a clearer picture of a supplier’s commitment to quality.

Utilizing Third-Party Inspections: How Can Buyers Ensure Objectivity?

Engaging third-party inspection services can offer an unbiased evaluation of a supplier’s manufacturing processes and quality control systems. This can be particularly beneficial for B2B buyers unfamiliar with local practices or standards.

Third-party inspectors can carry out:

- Random sampling of finished products.

- Verification of compliance with international standards.

- Detailed reporting on manufacturing practices and product quality.

By leveraging these inspections, buyers can mitigate risks and ensure they are sourcing from reputable suppliers.

Conclusion: What Should B2B Buyers Consider?

For international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance measures of sleeve suppliers is vital. By focusing on material preparation, forming techniques, assembly, finishing, and rigorous quality control, buyers can make informed decisions that lead to successful partnerships and high-quality products. Engaging with suppliers transparently about their processes and standards will further enhance trust and satisfaction in the procurement process.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘sleeves supplier’

In this guide, we provide a comprehensive checklist for B2B buyers seeking to source sleeves from suppliers globally. This step-by-step approach will help you navigate the complexities of international procurement, ensuring that you select the right supplier for your needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it is essential to outline your specific requirements for the sleeves. This includes the material, dimensions, and any particular features you need, such as waterproofing or breathability.

– What to consider: Think about the end use of the sleeves—are they for industrial applications, fashion, or sportswear? Each application may require different materials and designs.

Step 2: Research Potential Suppliers

Once your specifications are clear, begin researching suppliers. Look for those who specialize in the type of sleeves you require and have a proven track record in your industry.

– Where to look: Utilize B2B marketplaces, trade shows, and industry associations to identify reputable suppliers. Pay attention to reviews and testimonials from other buyers.

Step 3: Evaluate Supplier Capabilities

Assess the capabilities of potential suppliers to ensure they can meet your volume and quality requirements.

– Key factors to evaluate:

– Production capacity: Can they scale up if your demand increases?

– Quality assurance processes: Do they have certifications such as ISO or similar?

– Lead times: Understand their production and delivery timelines.

Step 4: Request Samples

Before making a bulk order, request samples of the sleeves you intend to purchase. This step is crucial for evaluating the quality and suitability of the product.

– What to look for in samples: Examine the fabric quality, stitching, and overall finish. Ensure that the samples meet your technical specifications and are fit for your intended use.

Step 5: Verify Supplier Certifications

Ensure that the suppliers hold relevant certifications that guarantee their compliance with international standards. This is particularly important when sourcing from regions like Africa or South America, where regulations may vary.

– Certifications to check: Look for ISO certifications, compliance with environmental standards, and any specific industry-related certifications that may apply.

Step 6: Negotiate Terms and Pricing

Once you’ve identified a potential supplier, discuss pricing, payment terms, and delivery schedules. Negotiation is key to ensuring that you get the best possible deal.

– What to consider: Be clear about your budget and any financial constraints. Discuss bulk order discounts or long-term partnership benefits.

Step 7: Establish Clear Communication Channels

Effective communication is vital for a successful supplier relationship. Establish clear channels for ongoing communication to address any concerns that may arise during the procurement process.

– Best practices: Utilize project management tools or communication platforms to keep all parties informed. Regular updates can help mitigate misunderstandings and ensure that deadlines are met.

By following this checklist, international B2B buyers can streamline the sourcing process for sleeves, minimize risks, and establish successful partnerships with suppliers.

Comprehensive Cost and Pricing Analysis for sleeves supplier Sourcing

What are the Key Cost Components in Sourcing Sleeves from Suppliers?

Understanding the cost structure of sourcing sleeves is crucial for international B2B buyers aiming for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of fabric and other materials significantly impacts pricing. High-quality, sustainable materials may incur higher costs but could enhance the final product’s value.

-

Labor: Labor costs vary by region and depend on the complexity of the sleeve design. Skilled labor in regions with higher wage standards can increase costs but may also ensure better craftsmanship.

-

Manufacturing Overhead: This encompasses the indirect costs related to production, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help minimize these costs.

-

Tooling: Initial tooling costs for custom designs can be substantial. Buyers should consider whether the tooling costs are amortized over large orders to reduce the per-unit cost.

-

Quality Control (QC): Investing in robust QC processes can increase upfront costs but prevent expensive returns and reputational damage later.

-

Logistics: Shipping and handling costs can vary based on the supplier’s location and the buyer’s destination. Understanding Incoterms can help buyers manage these costs effectively.

-

Margin: Suppliers will factor in their desired profit margins, which can vary significantly based on market conditions and competition.

How Do Price Influencers Affect the Sourcing of Sleeves?

Several factors can influence the pricing of sleeves, impacting overall procurement costs:

-

Volume/MOQ (Minimum Order Quantity): Larger orders generally lead to lower per-unit costs. Buyers should assess their needs to negotiate favorable terms based on order size.

-

Specifications and Customization: Custom designs and specific fabric choices can increase costs. Buyers should weigh the benefits of customization against budget constraints.

-

Materials and Quality Certifications: Premium materials and certifications (such as organic or fair-trade) may command higher prices. However, these factors can enhance brand reputation and appeal to niche markets.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can affect pricing. Established suppliers with a track record of reliability may charge more due to perceived quality assurance.

-

Incoterms: Understanding shipping terms is essential for accurately calculating total costs. Different Incoterms can shift cost responsibilities between the buyer and supplier, impacting overall pricing.

What Are the Best Buyer Tips for Cost-Efficiency in Sourcing Sleeves?

To achieve cost-efficiency in sourcing sleeves, international buyers should consider the following strategies:

-

Negotiate Effectively: Building a strong relationship with suppliers can lead to better negotiation outcomes. Discussing long-term partnerships may encourage suppliers to offer discounts or favorable terms.

-

Focus on Total Cost of Ownership (TCO): TCO includes not just the purchase price but also logistics, storage, and potential returns. Buyers should evaluate the complete cost landscape to make informed decisions.

-

Understand Pricing Nuances: Regional market dynamics can influence pricing. Buyers from Africa, South America, the Middle East, and Europe should research local market conditions and trends to negotiate effectively.

-

Leverage Technology: Utilizing platforms that aggregate supplier options can help buyers compare prices and terms efficiently, ensuring they secure the best deal.

-

Consider Long-Term Partnerships: Establishing a long-term relationship with a supplier can lead to better pricing and more favorable terms over time, as suppliers often value consistent business.

Disclaimer on Indicative Prices

Prices for sleeves can vary significantly based on the aforementioned factors. It is essential for buyers to conduct thorough market research and obtain quotes from multiple suppliers to ensure competitive pricing. Always consider fluctuations in material costs, labor rates, and shipping fees when budgeting for sleeve sourcing.

Alternatives Analysis: Comparing sleeves supplier With Other Solutions

In the quest for optimal packaging solutions, businesses often explore various alternatives to traditional sleeves suppliers. Understanding the available options allows international B2B buyers to make informed decisions that align with their operational needs and budget constraints. Below, we compare the traditional sleeves supplier with two notable alternatives: flexible packaging solutions and rigid packaging systems.

| Comparison Aspect | Sleeves Supplier | Flexible Packaging Solutions | Rigid Packaging Systems |

|---|---|---|---|

| Performance | High durability and flexibility for various products. | Good durability, customizable sizes, but may have limitations on heavy items. | Excellent protection for fragile items, high structural integrity. |

| Cost | Moderate investment with potential for bulk discounts. | Generally lower cost, especially for large orders. | Higher upfront costs due to materials and manufacturing. |

| Ease of Implementation | Requires specific machinery for application. | Easier to implement with less specialized equipment needed. | More complex due to varied sizes and shapes, requires specialized handling. |

| Maintenance | Low maintenance once installed. | Minimal upkeep, but may require more careful handling. | Low maintenance, but storage space can be an issue. |

| Best Use Case | Ideal for products needing a snug fit and visual appeal. | Suitable for a wide range of products, especially snacks and non-perishables. | Best for heavy or fragile items that require maximum protection. |

What Are the Advantages and Disadvantages of Flexible Packaging Solutions?

Flexible packaging solutions offer a lightweight and versatile alternative to traditional sleeves. They are typically made from materials like plastic films that can be easily printed on and shaped to fit various products. The primary advantage of flexible packaging is its cost-effectiveness, particularly for large volumes. However, they may not provide the same level of protection for heavy or fragile items, which could lead to product damage during shipping.

How Do Rigid Packaging Systems Compare?

Rigid packaging systems, such as boxes or containers, are designed to offer superior protection for fragile items. They are especially useful for products that require structural integrity, like electronics or glassware. While they do provide excellent durability, the initial cost can be significantly higher than both sleeves and flexible packaging. Additionally, their implementation can be more complex, requiring specialized handling and storage solutions.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the right packaging solution, B2B buyers should evaluate their specific product requirements, budget constraints, and operational capabilities. If a product requires a high level of visibility and a snug fit, traditional sleeves may be the best option. Conversely, for businesses looking to reduce costs while maintaining a good level of protection, flexible packaging could be more suitable. Rigid packaging should be the go-to choice for items that are particularly fragile or need strong protection during transport.

In conclusion, understanding the pros and cons of each alternative is crucial for making an informed decision that enhances product safety, reduces costs, and meets consumer expectations. By carefully assessing their needs against the characteristics of each packaging option, international B2B buyers can strategically choose the solution that best aligns with their business goals.

Essential Technical Properties and Trade Terminology for sleeves supplier

What Are the Key Technical Properties Buyers Should Consider for Sleeves?

When sourcing sleeves from suppliers, understanding the technical properties is essential to ensure product quality and compatibility with your applications. Here are several critical specifications to consider:

1. Material Grade

The material grade of sleeves significantly affects their durability and performance. Common materials include polyester, cotton, and specialized synthetic blends. Each material offers different levels of resistance to wear, heat, and chemicals. For example, polyester sleeves are often preferred for their strength and moisture-wicking properties, making them suitable for industrial applications. Knowing the material grade helps buyers select sleeves that meet their operational requirements.

2. Tolerance

Tolerance refers to the permissible limits of variation in the dimensions of the sleeves. This specification is crucial for ensuring that sleeves fit accurately in their intended applications. For example, if a sleeve is designed to fit over a specific diameter, precise tolerances must be maintained to avoid operational issues. Understanding tolerance levels helps buyers prevent costly rework or replacement.

3. Thickness

The thickness of sleeves can influence both their protective qualities and flexibility. Thicker sleeves may offer better abrasion resistance, while thinner options can provide enhanced dexterity. Buyers should evaluate the thickness based on the intended use, whether for heavy-duty industrial tasks or more delicate operations.

4. Temperature Resistance

Temperature resistance is vital for sleeves used in environments subject to extreme heat or cold. Certain materials can maintain their integrity and performance under high temperatures, making them suitable for applications in manufacturing or automotive industries. Buyers should inquire about the temperature ratings of the sleeves to ensure they meet the specific conditions of their operations.

5. Moisture Wicking and Breathability

For applications where comfort is essential, especially in the garment industry, moisture-wicking and breathability properties are critical. Fabrics designed to draw moisture away from the skin can enhance user comfort and performance. Buyers should look for sleeves that specify these properties, particularly for uses in hot or humid environments.

What Are Common Trade Terms Used in the Sleeves Supply Industry?

Understanding industry jargon is equally important for effective communication with suppliers. Here are some common terms that buyers should familiarize themselves with:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are sold by another company under its brand name. In the context of sleeves, buyers may work with OEM suppliers to customize products according to specific requirements. This term is crucial for businesses looking to ensure product quality and brand consistency.

2. MOQ (Minimum Order Quantity)

MOQ indicates the minimum number of units that a supplier is willing to sell. This figure varies among suppliers and can significantly affect a buyer’s purchasing strategy. Understanding MOQ is essential for managing inventory and cost-effective procurement, especially for smaller businesses.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products. This process allows buyers to compare offers from multiple suppliers and negotiate better deals. It is a critical step in the procurement process, ensuring that buyers receive competitive pricing and terms.

4. Incoterms (International Commercial Terms)

Incoterms are standardized international shipping terms that clarify the responsibilities of buyers and sellers regarding the delivery of goods. Familiarity with Incoterms is vital for international buyers to understand shipping costs, risks, and obligations, particularly when sourcing sleeves from suppliers in different countries.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the products. Understanding lead times is crucial for supply chain management, as it affects inventory levels and project timelines. Buyers should always inquire about lead times to ensure they align with their operational needs.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing sleeves, ultimately improving their procurement efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the sleeves supplier Sector

What Are the Current Market Dynamics and Key Trends in the Sleeves Supplier Sector?

The sleeves supplier sector is experiencing significant shifts driven by various global factors. One of the primary drivers is the growing demand for customization and personalization in apparel, particularly in regions such as Africa and South America, where fashion trends are rapidly evolving. The rise of e-commerce has enabled suppliers to reach international markets, allowing them to cater to specific regional preferences. Additionally, advancements in B2B technology, such as digital supply chain management and automated inventory systems, are streamlining sourcing processes, enhancing efficiency, and reducing lead times for international buyers.

Emerging trends include the integration of artificial intelligence in forecasting demand and managing inventory, which helps suppliers respond more effectively to market changes. Furthermore, there is an increasing emphasis on data-driven decision-making, allowing suppliers to optimize their offerings based on consumer behavior analytics. For international buyers, especially those in Europe and the Middle East, understanding these trends is crucial for making informed sourcing decisions that align with market expectations and consumer preferences.

How Is Sustainability Influencing Sourcing Trends in the Sleeves Supplier Sector?

Sustainability is increasingly becoming a central theme in the sourcing strategies of B2B buyers in the sleeves supplier sector. The environmental impact of textile production is under scrutiny, prompting suppliers to adopt more sustainable practices. This includes using eco-friendly materials, reducing waste, and minimizing carbon footprints. Buyers are now prioritizing suppliers who demonstrate a commitment to ethical sourcing and sustainability.

Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® are becoming essential for suppliers looking to gain the trust of international buyers. These certifications assure buyers that the products meet high environmental and social standards. Furthermore, the trend towards circular fashion—where products are designed for longevity and recyclability—is influencing how sleeves are produced and marketed. For buyers in regions like Europe, where sustainability is a significant purchasing criterion, partnering with suppliers who align with these values can enhance brand reputation and customer loyalty.

What Is the Historical Context of the Sleeves Supplier Sector That Influences Today’s Market?

The sleeves supplier sector has evolved significantly over the decades, shaped by technological advancements and changing consumer demands. Initially, sleeves were primarily produced as functional components of garments, with little emphasis on design or style. However, the late 20th century saw a shift towards fashion-forward thinking, where sleeves became an integral part of garment aesthetics.

The rise of fast fashion in the early 2000s further transformed the sector, leading to rapid production cycles and an increased focus on variety and trends. This evolution has led to today’s market dynamics, where international buyers seek suppliers who can provide not only quality and speed but also innovation in design. Understanding this historical context can help B2B buyers navigate current market offerings and identify suppliers that align with their strategic goals.

By leveraging these insights into market dynamics, sustainability practices, and the historical evolution of the sleeves supplier sector, international B2B buyers can make informed decisions that enhance their sourcing strategies and align with contemporary market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of sleeves supplier

-

How can I determine the quality of sleeves from a supplier?

To assess the quality of sleeves from a supplier, request samples to evaluate material durability, stitching, and overall craftsmanship. Additionally, check for certifications related to quality management standards such as ISO 9001. Engaging in a quality assurance audit can also provide insights into the supplier’s production processes and adherence to quality standards. Furthermore, read reviews and seek references from other buyers to gauge their experiences. -

What are the key factors to consider when choosing a sleeves supplier?

When selecting a sleeves supplier, consider factors such as their production capacity, lead times, and customization options. Evaluate their reputation in the market, focusing on customer service responsiveness and reliability. It’s also crucial to assess their adherence to international trade regulations and ethical sourcing practices. Lastly, review their pricing structure and payment terms to ensure alignment with your budget and cash flow needs. -

What is the minimum order quantity (MOQ) for sleeves?

The minimum order quantity (MOQ) for sleeves can vary significantly between suppliers. Typically, it ranges from 100 to 1,000 units, depending on the supplier’s production capabilities and the sleeve type. When negotiating, consider your own needs and how they align with the supplier’s requirements. Some suppliers may offer flexibility on MOQs for first-time orders or larger contracts, so it’s worth discussing your specific situation. -

How can I customize sleeves according to my specifications?

To customize sleeves, communicate your specific requirements to the supplier, including dimensions, materials, colors, and any design features. Most suppliers will have a design team that can help you create prototypes based on your specifications. Be sure to inquire about the costs and timelines associated with customization. It’s also beneficial to provide visual references or sketches to ensure clarity in your requests. -

What payment terms should I expect when dealing with sleeves suppliers?

Payment terms can vary widely among sleeves suppliers, but common practices include a 30% deposit upfront with the balance due upon delivery, or net 30/60 days post-delivery. Be sure to clarify payment methods accepted, such as wire transfers, letters of credit, or online payment platforms. Negotiating favorable terms can help manage cash flow, especially for larger orders, so don’t hesitate to discuss your financial preferences. -

What logistics considerations should I keep in mind when sourcing sleeves?

When sourcing sleeves internationally, consider shipping methods, transit times, and costs. Understand the customs regulations in your country and the supplier’s country to ensure smooth delivery. Additionally, factor in the lead time for production and shipping when planning your inventory needs. It’s also advisable to work with a logistics partner experienced in international trade to help navigate potential challenges. -

How can I ensure compliance with international trade regulations when importing sleeves?

To ensure compliance, familiarize yourself with the import regulations of your country, including tariffs, taxes, and documentation requirements. Work closely with your supplier to obtain necessary certifications and compliance documentation, such as certificates of origin and quality assurance reports. Engaging a customs broker can also simplify the process, ensuring all legal obligations are met and reducing the risk of delays. -

What quality assurance measures should I implement when sourcing sleeves?

Implementing quality assurance measures starts with conducting thorough supplier audits to evaluate their manufacturing processes and quality control systems. Request regular updates and inspections during production phases, and consider third-party inspections before shipment. Establish clear quality standards and communicate them to your supplier, ensuring they understand your expectations. This proactive approach will help mitigate risks and ensure that the sleeves meet your quality requirements upon arrival.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for sleeves supplier

As international B2B buyers navigate the complex landscape of sleeves suppliers, strategic sourcing emerges as a critical component for success. By focusing on quality, price competitiveness, and supply chain reliability, businesses can secure a sustainable advantage in their markets. The insights shared throughout this guide emphasize the importance of evaluating supplier capabilities, understanding regional dynamics, and fostering long-term partnerships that align with your business goals.

How Can Buyers Enhance Their Strategic Sourcing Efforts?

International buyers from Africa, South America, the Middle East, and Europe should prioritize building robust supplier relationships that transcend mere transactional exchanges. This involves leveraging technology for better communication, conducting regular performance assessments, and remaining flexible to adapt to market changes. Such proactive engagement not only mitigates risks but also opens pathways for innovation and collaboration.

What Does the Future Hold for Sleeve Supply Chains?

Looking ahead, the sleeves supply market is poised for growth, driven by evolving consumer preferences and increasing demand for customized solutions. By embracing sustainability and ethical sourcing practices, buyers can further enhance their brand reputation while catering to a conscientious customer base. Now is the time to invest in strategic sourcing initiatives that align with these trends, ensuring your business remains competitive in an ever-evolving landscape.