Discover Solar Panel Cost China: Your Ultimate Sourcing Guide (2025)

Introduction: Navigating the Global Market for solar panel cost china

Navigating the global market for solar panel costs in China presents a significant challenge for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. With the increasing demand for renewable energy solutions, understanding the intricacies of sourcing solar panels from China becomes essential. This guide is designed to equip you with comprehensive insights into various solar panel types, their applications, and effective strategies for supplier vetting.

As buyers face the complexities of international trade, fluctuating prices, and diverse supplier capabilities, this guide empowers informed purchasing decisions. We delve into critical factors affecting solar panel costs, including manufacturing processes, import tariffs, and local regulations that may impact pricing in your region. Additionally, we provide actionable tips on negotiating favorable terms and ensuring product quality, which are vital for successful transactions.

By focusing on specific markets like Egypt and Colombia, this guide addresses region-specific challenges and opportunities, facilitating a more tailored approach to sourcing solar panels. Ultimately, you will gain the knowledge needed to navigate the complexities of the solar panel market in China, ensuring that your investments align with your business goals and sustainability targets.

Understanding solar panel cost china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Monocrystalline Panels | High efficiency (15-22%), space-efficient design | Commercial buildings, rooftops | Pros: High energy output, longer lifespan. Cons: Higher initial cost. |

| Polycrystalline Panels | Moderate efficiency (13-16%), cost-effective production | Large-scale solar farms | Pros: Lower cost per watt, good performance. Cons: Less efficient, requires more space. |

| Thin-Film Solar Panels | Lightweight, flexible, lower efficiency (10-12%) | Building-integrated photovoltaics | Pros: Versatile installation options, lower cost. Cons: Requires more space for the same output. |

| Bifacial Solar Panels | Dual-sided energy capture, high efficiency | Utility-scale solar projects | Pros: Increased energy yield, reduced land use. Cons: Higher upfront investment. |

| Building-Integrated PV | Integrated into building materials, aesthetically pleasing | Urban developments, architecture | Pros: Space-saving, enhances building design. Cons: Higher installation complexity. |

What Are the Characteristics of Monocrystalline Panels?

Monocrystalline panels are recognized for their high efficiency and sleek appearance, making them ideal for space-constrained installations. They typically feature a uniform dark color, which can enhance the aesthetic appeal of rooftops. B2B buyers should consider their higher initial cost against long-term energy savings and lifespan, as these panels often last longer than their counterparts.

How Do Polycrystalline Panels Compare in Cost and Performance?

Polycrystalline panels are made from multiple silicon crystals, resulting in a blue, speckled appearance. They offer a balance between cost and efficiency, making them a popular choice for large-scale solar farms where space is less of a concern. B2B buyers should weigh the lower upfront costs against the marginally lower efficiency and the larger footprint required for installations.

What Makes Thin-Film Solar Panels Unique for B2B Applications?

Thin-film solar panels are lightweight and flexible, making them suitable for unconventional applications, such as building-integrated photovoltaics (BIPV). Although they have lower efficiency, their versatility can be a significant advantage for businesses looking to incorporate solar solutions into existing structures. Buyers should consider the trade-off between space requirements and installation flexibility.

Why Are Bifacial Solar Panels Gaining Popularity?

Bifacial solar panels capture sunlight from both sides, increasing energy production, especially in reflective environments. This type is particularly advantageous for utility-scale projects where maximizing output is crucial. While the initial investment is higher, the potential for greater energy yield can lead to lower overall costs in the long run, making them an attractive option for B2B buyers focused on efficiency.

How Do Building-Integrated PV Systems Benefit Urban Developments?

Building-integrated photovoltaics (BIPV) seamlessly blend solar technology with building materials, offering an aesthetically pleasing solution for urban developments. These systems can save space and enhance the design of structures, appealing to businesses that prioritize sustainability and innovation. However, the complexity of installation and higher costs may require careful consideration from B2B buyers.

Related Video: My DIY Solar Panel System Total Cost VS Quoted Install

Key Industrial Applications of solar panel cost china

| Industry/Sector | Specific Application of solar panel cost china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Solar-powered irrigation systems | Reduces energy costs, enhances water management | Assess local solar incentives, durability of panels in harsh climates |

| Manufacturing | Solar energy for factory operations | Lowers operational costs, sustainable production | Evaluate compatibility with existing systems, local regulations |

| Mining | Off-grid solar solutions for remote sites | Ensures energy reliability, reduces diesel dependency | Consider logistics for panel transport, maintenance support options |

| Hospitality & Tourism | Solar installations for hotels and resorts | Enhances sustainability image, reduces utility bills | Examine installation costs vs. long-term savings, local energy tariffs |

| Telecommunications | Solar-powered cell towers | Improves network reliability, reduces operational costs | Look for scalability of solar systems, battery storage solutions |

How Are Solar Panels Used in Agriculture to Reduce Costs?

In the agriculture sector, solar panel installations are increasingly used for powering irrigation systems. By harnessing solar energy, farmers can significantly reduce their reliance on diesel generators or grid electricity, which is often expensive and unreliable in remote areas. This application is particularly beneficial for B2B buyers in regions like Africa and South America, where energy access can be limited. Buyers should consider the durability of solar panels in varying climates and investigate local solar incentives that can offset initial costs.

What Role Do Solar Panels Play in Manufacturing Efficiency?

Manufacturing facilities are adopting solar energy to power their operations, leading to substantial reductions in energy costs. By switching to solar power, businesses can not only lower their operational expenses but also enhance their sustainability credentials, which is increasingly important to consumers and regulatory bodies. International buyers should evaluate how solar systems can integrate with existing equipment and ensure compliance with local energy regulations to maximize benefits.

How Can Mining Operations Benefit from Off-Grid Solar Solutions?

Mining companies, often located in remote areas, benefit from off-grid solar solutions that provide a reliable energy source without the need for costly fuel deliveries. Solar panels can power essential operations, reducing dependence on diesel and minimizing environmental impact. B2B buyers in this sector must consider the logistics of transporting solar equipment to remote sites and the availability of maintenance support to ensure continuous operation.

Why Are Solar Installations Important for the Hospitality Sector?

Hotels and resorts are increasingly investing in solar installations to enhance their sustainability image and reduce utility bills. By incorporating solar energy, these businesses can appeal to eco-conscious travelers while significantly lowering energy costs. For B2B buyers in the hospitality industry, it’s crucial to examine the balance between installation costs and potential long-term savings, as well as the impact of local energy tariffs on overall profitability.

A stock image related to solar panel cost china.

How Do Solar-Powered Cell Towers Improve Telecommunications?

A stock image related to solar panel cost china.

In the telecommunications sector, solar-powered cell towers provide a reliable energy source that enhances network reliability, especially in regions with unstable grid power. This application is vital for ensuring consistent service in rural and underserved areas. B2B buyers should look for scalable solar solutions that can grow with their network demands and consider integrating battery storage to maintain operations during outages.

Related Video: Solar Panel Manufacturing Process in a Solar Plant

3 Common User Pain Points for ‘solar panel cost china’ & Their Solutions

Scenario 1: Understanding Fluctuating Solar Panel Costs from China

The Problem: B2B buyers in regions like Africa and South America often face uncertainty regarding the fluctuating costs of solar panels sourced from China. These price variations can stem from multiple factors, including changes in tariffs, shipping costs, and raw material prices. For example, a company in Egypt may budget for a specific solar panel project, only to find that the prices have increased significantly by the time the order is placed, impacting their overall project viability and profitability.

The Solution: To mitigate the impact of fluctuating costs, B2B buyers should establish long-term relationships with multiple suppliers in China. By negotiating fixed pricing agreements or bulk purchase discounts, companies can lock in prices for extended periods, providing predictability in budgeting. Additionally, utilizing cost tracking tools and market analysis reports can help buyers stay informed about market trends and anticipate price shifts. Engaging a local sourcing agent familiar with the Chinese solar panel market can also provide insights into the best times to purchase based on historical pricing data.

Scenario 2: Navigating Quality Assurance Concerns in Solar Panels from China

The Problem: Many international buyers are apprehensive about the quality of solar panels manufactured in China. Concerns about substandard products or inadequate warranties can lead to hesitation in making bulk purchases. For instance, a company in Colombia may hesitate to invest heavily in solar technology due to fears of receiving low-quality panels that could lead to high maintenance costs and decreased efficiency over time.

The Solution: To address quality assurance concerns, buyers should prioritize sourcing from reputable manufacturers who have established quality control processes and certifications such as ISO 9001. Conducting thorough research on suppliers, including reading reviews, requesting product samples, and verifying certifications, can help ensure that the panels meet international standards. Furthermore, establishing a clear quality assurance protocol that includes third-party inspections prior to shipment can provide additional peace of mind. Buyers may also consider investing in warranties that cover defects and performance guarantees, as this can protect their investment.

Scenario 3: Overcoming Payment and Financing Challenges for Solar Panel Purchases from China

The Problem: International B2B buyers frequently encounter challenges related to payment methods and financing options when purchasing solar panels from China. Different payment terms, currency exchange rates, and the potential for fraud can complicate transactions, especially for companies in the Middle East and Europe that may be unfamiliar with Chinese suppliers’ practices. A buyer in the Middle East might find that traditional payment methods like letters of credit can be cumbersome and slow, hindering project timelines.

The Solution: To streamline payment processes, buyers should explore alternative financing options such as trade finance solutions or letter of credit arrangements specifically designed for international trade. Using secure payment platforms that specialize in B2B transactions can also mitigate risks and enhance transaction security. Establishing clear payment terms with suppliers upfront and utilizing escrow services can protect both parties during the transaction. Additionally, buyers should consider engaging financial institutions that have experience in international trade to provide guidance and support in navigating these complexities. By improving their payment processes, buyers can ensure smoother transactions and maintain project momentum.

Strategic Material Selection Guide for solar panel cost china

When selecting materials for solar panels, international B2B buyers must consider various factors that influence performance, cost, and compliance with regional standards. Here, we analyze four common materials used in solar panel manufacturing, focusing on their properties, advantages and disadvantages, and implications for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Silicon in Solar Panels?

Silicon is the most widely used material in solar cells, primarily due to its excellent semiconductor properties. It operates effectively at a temperature range of -40°C to +85°C and exhibits good corrosion resistance.

Pros & Cons:

– Pros: Silicon is durable, has a long lifespan (typically over 25 years), and is relatively easy to manufacture. Its abundance makes it a cost-effective option.

– Cons: The manufacturing process can be energy-intensive, leading to higher initial costs. Additionally, silicon-based panels may have lower efficiency compared to some advanced materials.

Impact on Application: Silicon’s compatibility with various environmental conditions makes it suitable for diverse applications, from residential rooftops to large-scale solar farms.

Considerations for International Buyers: Buyers should ensure that the silicon panels comply with international standards such as ASTM and IEC. In regions like Egypt and Colombia, where sunlight is abundant, silicon panels can be a reliable choice.

How Does Thin-Film Technology Compare for Solar Panel Manufacturing?

Thin-film technology utilizes materials like cadmium telluride (CdTe) or amorphous silicon (a-Si). These materials are lightweight and flexible, making them suitable for a variety of applications.

Pros & Cons:

– Pros: Thin-film panels are less expensive to produce and can be integrated into building materials. They perform better in low-light conditions and high temperatures.

– Cons: They generally have lower efficiency and shorter lifespans compared to crystalline silicon panels.

Impact on Application: Thin-film technology is particularly effective in large-scale installations where weight and flexibility are critical, such as on rooftops or in urban environments.

Considerations for International Buyers: Compliance with environmental regulations is essential, especially regarding cadmium content. Buyers in Europe may face stricter regulations compared to those in Africa or South America.

What Are the Advantages of Using Bifacial Solar Panels?

Bifacial solar panels are designed to capture sunlight from both sides, utilizing materials like glass and transparent back sheets.

Pros & Cons:

– Pros: They can increase energy yield by up to 30% compared to traditional panels due to reflected light capture. Their durability is enhanced by the use of glass, which offers superior weather resistance.

– Cons: Higher manufacturing complexity can lead to increased costs. Installation may require specific mounting systems to maximize efficiency.

Impact on Application: Bifacial panels are ideal for installations with reflective surfaces, such as snow-covered areas or water bodies.

Considerations for International Buyers: Buyers should evaluate the additional costs against the potential energy savings. Compliance with local installation standards is crucial, especially in regions with varying climates.

Why Is Aluminum a Popular Choice for Solar Panel Frames?

Aluminum is commonly used for the framing of solar panels due to its lightweight nature and resistance to corrosion.

Pros & Cons:

– Pros: It is durable, lightweight, and provides excellent structural support. Aluminum frames can withstand harsh weather conditions, making them suitable for various climates.

– Cons: While generally cost-effective, the price of aluminum can fluctuate based on market demand, impacting overall project costs.

Impact on Application: The lightweight nature of aluminum allows for easier installation, particularly in remote or challenging locations.

Considerations for International Buyers: Buyers should consider the availability of aluminum in their region and ensure compliance with local manufacturing standards.

Summary Table of Material Selection for Solar Panels

| Material | Typical Use Case for solar panel cost china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon | Residential and commercial solar panels | Durable with a long lifespan | Energy-intensive manufacturing process | Medium |

| Thin-Film | Large-scale installations and flexible uses | Lower production cost | Lower efficiency and shorter lifespan | Low |

| Bifacial | Installations with reflective surfaces | Increased energy yield | Higher manufacturing complexity | High |

| Aluminum | Framing for solar panels | Lightweight and corrosion-resistant | Price fluctuations based on market demand | Medium |

This strategic material selection guide equips international B2B buyers with the necessary insights to make informed decisions regarding solar panel investments, ensuring compliance and suitability for their specific regional markets.

In-depth Look: Manufacturing Processes and Quality Assurance for solar panel cost china

What Are the Key Stages in Solar Panel Manufacturing Processes?

The manufacturing of solar panels involves several critical stages that ensure the final product meets the required performance and quality standards. Here’s a breakdown of the main stages involved:

-

Material Preparation

This initial phase involves sourcing and preparing raw materials such as silicon wafers, glass, and back sheets. High-purity silicon is crucial for achieving optimal efficiency in solar panels. The silicon is cut into thin wafers and treated to enhance its photovoltaic properties. Suppliers should prioritize materials that are compliant with international standards to ensure quality and sustainability. -

Forming

In this stage, the silicon wafers are treated and formed into photovoltaic cells. This typically involves processes like doping, where impurities are added to silicon to improve electrical conductivity. Advanced techniques such as passivation and texturing are employed to enhance light absorption and reduce reflection. Buyers should inquire about the technologies and methodologies used in this phase to understand how they impact the efficiency of the final product. -

Assembly

After forming the photovoltaic cells, the assembly process begins. This includes connecting the cells to form a module. The cells are arranged in a specific layout and interconnected using conductive ribbons. This stage may also involve the application of an encapsulant, which protects the cells from environmental damage. Understanding the assembly techniques can help buyers assess the durability and longevity of the solar panels. -

Finishing

The final stage involves the encapsulation of the solar cells within protective materials, typically glass on the front and a back sheet. This process is crucial for ensuring the panels can withstand various weather conditions. The panels are then framed, usually with aluminum, to provide structural integrity. Buyers should verify the finishing processes to ensure they align with their specific environmental conditions.

How Is Quality Assurance Implemented in Solar Panel Manufacturing?

Quality assurance (QA) is an integral part of the solar panel manufacturing process, ensuring that products meet both international and industry-specific standards. Here are key aspects of the QA process:

-

International Standards Compliance

Many manufacturers adhere to international standards like ISO 9001, which focuses on quality management systems. Compliance with these standards indicates that the manufacturer has a systematic approach to managing quality. Additionally, certifications such as CE mark in Europe and IEC standards for solar panels are critical indicators of product quality and safety. -

Quality Control Checkpoints

Various checkpoints throughout the manufacturing process help maintain quality. These include:

– Incoming Quality Control (IQC): Assessing raw materials upon arrival to ensure they meet specifications.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing stages to detect issues early.

– Final Quality Control (FQC): A thorough inspection of the finished products to verify they meet performance and safety standards. -

Testing Methods

Common testing methods include thermal cycling, humidity freeze testing, and mechanical load testing. These tests simulate real-world conditions to assess the durability and efficiency of solar panels. B2B buyers should inquire about the specific tests performed and the results, as this information is crucial for evaluating the reliability of the products.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying the quality control of suppliers is essential. Here are some actionable insights:

-

Conduct Supplier Audits

Regular audits of suppliers can help buyers assess the manufacturing processes and quality assurance protocols. These audits should evaluate compliance with international standards, the effectiveness of quality control measures, and the overall manufacturing environment. -

Request Quality Reports

Suppliers should be able to provide documentation regarding their quality control processes, including test results and compliance certifications. Buyers should specifically look for reports that detail the outcomes of various testing methods used during production. -

Engage Third-Party Inspection Services

Utilizing third-party inspection services can provide an unbiased evaluation of the supplier’s quality control processes. These services can conduct inspections at various stages of production and provide detailed reports that buyers can use to make informed decisions.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers must navigate various nuances related to quality control and certification when sourcing solar panels from China. Here are some key considerations:

-

Understanding Local Regulations

Each region may have different regulations regarding solar panel installations and certifications. Buyers must familiarize themselves with local standards in their respective countries, such as the Renewable Energy Directive in Europe or specific regulations in countries like Egypt and Colombia. -

Evaluating the Manufacturer’s Reputation

Researching the manufacturer’s history and reputation within the industry can provide insights into their reliability and adherence to quality standards. Engaging with other businesses that have sourced from the same manufacturer can yield valuable feedback. -

Assessing Warranty and Support

A robust warranty and post-sale support indicate a manufacturer’s confidence in their product quality. Buyers should ensure that the warranty covers defects in materials and workmanship for a reasonable period, which is a sign of a reputable supplier.

By understanding the manufacturing processes and quality assurance mechanisms in place, B2B buyers can make informed decisions when sourcing solar panels from China, ensuring they receive high-quality products that meet their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘solar panel cost china’

To successfully source solar panels from China, particularly for international B2B buyers from regions like Africa, South America, the Middle East, and Europe, a structured approach is essential. This checklist will guide you through the critical steps to ensure you procure quality products at competitive prices while mitigating risks.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications for the solar panels you require is the first step in the sourcing process. This includes determining the desired wattage, efficiency ratings, panel dimensions, and any certification requirements (like IEC or UL). Having a well-defined specification helps suppliers provide accurate quotes and ensures that the products meet your operational needs.

Step 2: Research the Market and Pricing Trends

Before reaching out to suppliers, conduct thorough market research to understand the current pricing trends of solar panels in China. Look for reports, industry publications, and pricing indexes to gauge the average costs. This knowledge will equip you to negotiate effectively and avoid overpaying.

Step 3: Identify Potential Suppliers

Compile a list of potential suppliers by leveraging online platforms, trade shows, and industry referrals. Websites like Alibaba, Made-in-China, and Global Sources can be valuable resources. Ensure to prioritize suppliers with a proven track record in exporting solar products to your region.

Step 4: Verify Supplier Certifications

It’s crucial to verify that your potential suppliers hold the necessary certifications, such as ISO 9001 for quality management and relevant safety certifications for solar panels. This step is vital to ensure compliance with international standards and to mitigate risks associated with product quality and reliability.

Step 5: Request Samples for Evaluation

Before finalizing any orders, request samples of the solar panels to evaluate their quality. Conduct performance tests to assess efficiency and durability under conditions similar to those in your target market. This hands-on evaluation helps you make informed decisions and reduces the risk of costly mistakes later.

Step 6: Negotiate Terms and Pricing

Once you’ve identified a suitable supplier, it’s time to negotiate terms and pricing. Discuss payment options, delivery timelines, and warranty conditions. Be clear about your expectations regarding after-sales support and service, as this can significantly impact your long-term satisfaction with the supplier.

Step 7: Plan for Logistics and Import Regulations

Lastly, develop a logistics plan that includes shipping methods, customs clearance, and import regulations specific to your country. Understanding these logistics is crucial to ensure timely delivery and compliance with local laws, which can vary significantly between regions such as Africa, Europe, and South America.

By following these steps, B2B buyers can effectively navigate the complexities of sourcing solar panels from China, ensuring they obtain quality products that align with their project goals while maximizing cost-efficiency.

Comprehensive Cost and Pricing Analysis for solar panel cost china Sourcing

What Are the Key Cost Components for Sourcing Solar Panels from China?

When considering solar panel sourcing from China, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

-

Materials: The cost of raw materials, such as silicon, glass, and metals, significantly influences the final price. Prices fluctuate based on market demand and global supply chains.

-

Labor: Labor costs in China are generally lower compared to other regions. However, skilled labor for manufacturing high-quality solar panels may command higher wages.

-

Manufacturing Overhead: This encompasses expenses related to factory operations, including utilities, maintenance, and administrative costs. Efficient production processes can help minimize these overheads.

-

Tooling: Investment in molds and dies for panel production is a one-time cost that can be amortized over large production runs. Custom tooling can increase initial costs but may lead to greater efficiencies in high-volume orders.

-

Quality Control (QC): Implementing stringent QC measures ensures the reliability and efficiency of solar panels. Costs associated with QC can vary depending on the certifications required (e.g., ISO, CE).

-

Logistics: Shipping costs can vary widely based on the destination, volume, and mode of transport. Effective logistics planning can help mitigate these costs.

-

Margin: Suppliers typically include a profit margin that reflects their operating costs and market competition. Understanding the margin can help buyers negotiate better prices.

How Do Price Influencers Impact Solar Panel Costs?

Several factors can influence the pricing of solar panels sourced from China:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often offer better pricing for larger orders. Understanding the supplier’s MOQ can help buyers optimize their purchasing strategy.

-

Specifications and Customization: Customized panels with specific features or higher efficiency ratings may incur additional costs. Buyers should weigh the benefits of customization against their budget.

-

Materials and Quality Certifications: Higher-quality materials and certifications can increase upfront costs but may lead to lower maintenance and operational costs over the lifespan of the panels.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with a track record of quality may charge a premium.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial as they define the responsibilities of buyers and sellers during transportation. This can impact overall cost and risk exposure.

What Are the Best Practices for Negotiating Solar Panel Pricing?

International B2B buyers, especially those from Africa, South America, the Middle East, and Europe, can leverage several strategies to enhance cost efficiency:

-

Conduct Market Research: Familiarize yourself with current market trends and competitor pricing to establish a baseline for negotiations.

-

Emphasize Long-Term Relationships: Building a long-term relationship with suppliers can lead to better pricing and terms over time.

-

Negotiate Payment Terms: Flexible payment terms can improve cash flow. Consider negotiating partial payments tied to delivery milestones.

-

Evaluate Total Cost of Ownership (TCO): Focus on the long-term value rather than just the initial price. Assess how factors like efficiency, warranty, and maintenance affect the total cost.

-

Be Aware of Pricing Nuances: Understand that prices may vary significantly based on regional factors, including tariffs, taxes, and local market conditions.

What Should International Buyers Keep in Mind Regarding Prices?

It’s important for buyers to recognize that the prices listed for solar panels are often indicative and can vary based on the factors mentioned. Fluctuations in material costs, shipping rates, and global market dynamics can all influence final pricing. Always seek multiple quotes and conduct thorough due diligence before making purchasing decisions. This approach not only ensures competitive pricing but also helps in securing a reliable supply chain for solar projects.

Alternatives Analysis: Comparing solar panel cost china With Other Solutions

When considering energy solutions, particularly for international B2B buyers, it is crucial to evaluate various options that can meet specific needs and financial constraints. The market for renewable energy is expanding, and while solar panels from China are a popular choice due to their competitive pricing, other alternatives may offer benefits depending on the context and requirements of the buyer. Below, we will compare solar panel costs from China with two viable alternatives: wind energy systems and biomass energy solutions.

Comparison of Solar Panel Cost China With Alternative Energy Solutions

| Comparison Aspect | Solar Panel Cost China | Wind Energy Systems | Biomass Energy Solutions |

|---|---|---|---|

| Performance | High efficiency, varies by model | Variable efficiency, depends on wind conditions | Moderate efficiency, depends on biomass type |

| Cost | Generally low, $0.30-$0.60 per watt | Moderate to high, $1,200-$1,500 per installed kW | Variable, $4,000-$7,000 per kW |

| Ease of Implementation | Relatively simple; requires installation expertise | Requires site assessment, higher complexity | Complex; requires infrastructure for sourcing biomass |

| Maintenance | Low; occasional cleaning and inverter checks | Moderate; regular maintenance of mechanical parts | High; needs regular feedstock management and system upkeep |

| Best Use Case | Ideal for sunny regions, residential, commercial | Best in areas with consistent wind patterns | Suitable for agricultural areas with biomass availability |

In-Depth Analysis of Alternatives

What Are the Advantages and Disadvantages of Wind Energy Systems?

Wind energy systems convert kinetic energy from wind into electricity. They can be highly effective in regions with consistent wind patterns, making them suitable for countries in Europe and parts of South America. However, the initial capital investment can be substantial, and the efficiency is heavily reliant on local weather conditions. Maintenance can also be more involved due to the mechanical components of wind turbines, which require regular servicing to ensure optimal performance.

How Do Biomass Energy Solutions Compare?

Biomass energy solutions utilize organic materials, such as agricultural waste, to produce energy. This method is particularly advantageous in regions where waste materials are abundant, providing a dual benefit of waste management and energy production. However, the cost can be high, and the systems require significant infrastructure to collect and process biomass. Additionally, the efficiency can vary based on the type of biomass used, making it essential for buyers to assess local availability and logistics.

Conclusion: How to Choose the Right Energy Solution for Your Needs?

For B2B buyers, the choice between solar panel solutions from China, wind energy systems, and biomass energy solutions depends on several factors, including cost, available resources, regional climate conditions, and specific energy needs. Solar panels are a strong contender for their low initial costs and maintenance requirements, especially in sunny regions. However, wind and biomass alternatives might be more suitable for certain geographical areas or specific applications where their respective advantages can be maximized. Ultimately, conducting a thorough analysis of each option, considering both economic and operational factors, will guide buyers in making informed decisions tailored to their unique circumstances.

Essential Technical Properties and Trade Terminology for solar panel cost china

What Are the Key Technical Properties of Solar Panels from China?

When evaluating solar panels from China, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications:

-

Material Grade

– Solar panels are typically made from monocrystalline or polycrystalline silicon. Monocrystalline panels are known for their higher efficiency and longevity, making them suitable for commercial projects where space is limited. Polycrystalline panels, while slightly less efficient, are often more cost-effective and can be ideal for larger installations. Understanding the material grade helps buyers assess the long-term value and efficiency of the panels. -

Tolerance

– Tolerance refers to the permissible variation in the output power of solar panels. A common tolerance rating is ±3%, which indicates that a panel rated at 300W may produce between 291W and 309W. For B2B buyers, lower tolerance ratings can signify higher quality and reliability, ensuring that the installed systems perform as expected. -

Efficiency Rating

– The efficiency rating measures how well a solar panel converts sunlight into electricity. Higher efficiency ratings (above 20%) are preferred for commercial applications as they produce more power from a smaller area. This is especially important in regions with limited installation space. Buyers should prioritize panels with high efficiency ratings to maximize energy production. -

Temperature Coefficient

– This specification indicates how much a solar panel’s efficiency decreases as temperatures rise. A lower temperature coefficient (e.g., -0.35%/°C) means that the panel will perform better in hot climates. For buyers in warmer regions like Africa and South America, selecting panels with favorable temperature coefficients can enhance overall energy output and reliability. -

Warranty Period

– Warranties are critical for assessing the long-term reliability of solar panels. Most manufacturers offer a performance warranty of 25 years, which guarantees a certain level of efficiency over time. Buyers should evaluate warranty terms carefully, as they reflect the manufacturer’s confidence in their product and can significantly impact the total cost of ownership.

Which Trade Terms Should International Buyers Understand?

Navigating the solar panel market involves understanding specific trade terminology. Here are some key terms that B2B buyers should be familiar with:

-

OEM (Original Equipment Manufacturer)

– OEM refers to companies that manufacture products that are sold under another company’s brand name. In the solar panel industry, buyers may source panels from OEMs in China, ensuring they receive high-quality products tailored to their specifications. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest order quantity that a supplier is willing to accept. Understanding the MOQ is essential for buyers, as it can affect the overall cost and flexibility of procurement. Buyers should negotiate MOQs to align with their project needs and budget constraints. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to request pricing and terms for specific products. This process is crucial for B2B buyers to obtain competitive pricing and assess the capabilities of different manufacturers. A well-structured RFQ can streamline the procurement process and ensure clarity in communication. -

Incoterms

– International Commercial Terms (Incoterms) are standardized trade terms used in international contracts. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), helps buyers understand their liabilities and costs throughout the shipping process. -

Lead Time

– Lead time refers to the time it takes from placing an order to delivery. Understanding lead times is vital for project planning, especially for international shipments. Buyers should inquire about lead times upfront to ensure timely project execution and avoid delays.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions when sourcing solar panels from China, ultimately leading to successful project outcomes and optimized energy solutions.

Navigating Market Dynamics and Sourcing Trends in the solar panel cost china Sector

What Are the Current Market Dynamics and Key Trends in the Solar Panel Sector from China?

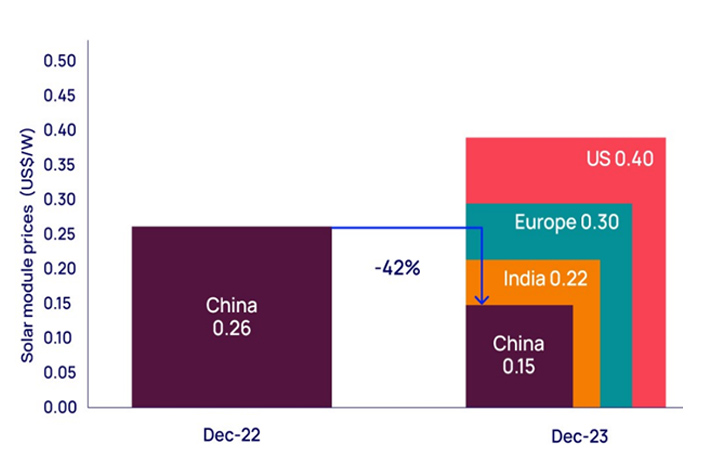

The global solar panel market is experiencing significant growth, driven by the increasing demand for renewable energy and the need for sustainable solutions. In regions like Africa, South America, the Middle East, and Europe, governments are implementing policies to encourage solar energy adoption, which is boosting the demand for solar panels sourced from China. Key trends include a shift towards higher efficiency panels, the integration of smart technologies, and the rise of energy storage solutions.

International B2B buyers are increasingly focusing on cost-effective sourcing strategies. The competitive pricing of Chinese solar panels is attracting buyers looking to maximize their return on investment. Additionally, advances in manufacturing technologies are leading to lower production costs, which can be passed on to buyers. The trend towards modular and scalable solar solutions is also gaining traction, allowing businesses to start small and expand as needed.

Another notable trend is the emphasis on local partnerships and logistics optimization. Buyers are seeking suppliers that can provide reliable shipping and local support to navigate import regulations effectively. Understanding these market dynamics is crucial for B2B buyers aiming to leverage the cost advantages offered by Chinese manufacturers while ensuring compliance with local standards.

How Important Is Sustainability and Ethical Sourcing in Solar Panel Procurement?

Sustainability and ethical sourcing are increasingly becoming critical factors in the procurement of solar panels. Environmental impacts associated with solar panel production, such as resource extraction and waste management, necessitate a focus on ethical supply chains. International B2B buyers are recognizing the importance of sourcing from manufacturers that adhere to sustainable practices.

Certifications like ISO 14001 (Environmental Management Systems) and initiatives like the Responsible Business Alliance (RBA) are essential for buyers looking to ensure that their suppliers are committed to minimizing environmental impacts. Moreover, the use of recyclable materials and the promotion of lifecycle assessments in product design can significantly enhance the sustainability profile of solar panels.

Buyers should prioritize suppliers who offer transparency in their supply chains and can demonstrate adherence to ethical sourcing practices. This not only helps mitigate risks related to regulatory compliance but also aligns with the growing consumer demand for environmentally responsible products. Ultimately, integrating sustainability into sourcing strategies can lead to long-term benefits, including enhanced brand reputation and customer loyalty.

What Is the Evolution of the Solar Panel Industry in China Relevant to B2B Buyers?

The solar panel industry in China has evolved significantly over the past two decades, transforming from a nascent market to a global powerhouse. Initially, the focus was primarily on manufacturing low-cost panels to meet domestic demand. However, as technology advanced, Chinese manufacturers began investing in research and development, leading to the production of higher efficiency and more reliable solar panels.

By the early 2010s, China had established itself as the largest producer of solar panels worldwide, driven by government incentives and export opportunities. This growth has allowed Chinese manufacturers to scale operations, reduce costs, and improve product quality, making them highly competitive in the international market.

Today, B2B buyers can benefit from this evolution by accessing a diverse range of products that cater to various energy needs and budgets. Understanding this historical context can help buyers appreciate the technological advancements and cost efficiencies that Chinese solar panels offer, enabling them to make informed procurement decisions in a rapidly changing energy landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of solar panel cost china

-

How do I determine the total cost of solar panels when sourcing from China?

To accurately assess the total cost of solar panels from China, consider not only the unit price but also additional expenses such as shipping, customs duties, and taxes. Request a detailed quotation from suppliers that includes these factors. It’s advisable to use Incoterms to clarify responsibility for shipping costs. Additionally, factor in potential costs for installation and maintenance, which can significantly impact the overall investment. -

What is the average price range for solar panels in China?

The average price for solar panels in China varies based on quality, type, and supplier. Typically, prices range from $0.25 to $0.60 per watt for standard photovoltaic panels. However, premium brands or specialized panels may command higher prices. For bulk purchases, negotiating pricing and exploring long-term contracts can lead to better rates. Always compare multiple suppliers to identify the best deals that align with your specifications. -

What are the key factors to consider when selecting a solar panel supplier in China?

When choosing a solar panel supplier, prioritize factors such as product quality, certifications (like ISO, CE), and manufacturing capacity. Evaluate their experience in international trade and check for references or case studies from previous clients, particularly in your region (Africa, South America, the Middle East, or Europe). It’s also beneficial to assess their customer service responsiveness and after-sales support to ensure a smooth procurement process. -

What are the minimum order quantities (MOQ) for solar panels from Chinese manufacturers?

Minimum order quantities can vary significantly among suppliers. Typically, MOQs range from 50 to 500 panels, depending on the manufacturer and the specific product. For larger orders, suppliers may offer more favorable terms or discounts. If your project requires fewer panels, consider discussing customization options or exploring group purchasing with other businesses to meet MOQ requirements. -

What payment terms should I expect when purchasing solar panels from China?

Payment terms can vary by supplier, but common practices include a 30% upfront deposit with the balance due before shipping or upon delivery. Some suppliers may offer letter of credit (LC) options for larger transactions. Always clarify payment methods accepted, such as bank transfers or payment platforms like PayPal. Establishing clear terms in your contract can help mitigate risks associated with international transactions. -

How can I ensure the quality of solar panels sourced from China?

To ensure quality, request certifications and compliance documents for the panels you intend to purchase. Conduct factory audits or engage third-party inspection services to assess manufacturing practices and product quality. Additionally, consider ordering samples before committing to a larger order. Establishing quality assurance protocols in your contract can help protect your investment. -

What logistics considerations should I be aware of when importing solar panels from China?

Logistics is crucial when importing solar panels. Consider factors like shipping methods (air vs. sea), estimated delivery times, and the reliability of freight forwarders. It’s important to understand customs regulations in your country, including any import duties and taxes. Collaborating with a logistics partner familiar with international shipping can streamline the process and help avoid potential delays. -

What customization options are available when sourcing solar panels from Chinese manufacturers?

Many Chinese manufacturers offer customization options, including panel size, wattage, and even branding. If you have specific technical requirements, communicate them clearly to potential suppliers. Customization may influence pricing and lead times, so discuss these details early in negotiations. Exploring different manufacturers can help you find one that aligns with your customization needs without compromising quality.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for solar panel cost china

What Are the Key Takeaways for International B2B Buyers on Solar Panel Costs in China?

As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the dynamics of solar panel costs in China is crucial for making informed purchasing decisions. Strategic sourcing allows businesses to leverage competitive pricing and high-quality products, ensuring cost-effective investments in renewable energy. Factors such as fluctuating raw material prices, shipping costs, and government incentives play a significant role in determining the overall expense of solar panels.

Additionally, building relationships with reliable suppliers can enhance negotiation power, leading to better pricing and terms. Emphasizing long-term partnerships can also facilitate access to the latest technological advancements and improved product offerings, which are essential in a rapidly evolving market.

How Can International Buyers Prepare for Future Trends in Solar Panel Costs?

Looking ahead, the global shift toward sustainable energy solutions will likely keep solar panel demand high. Buyers should stay attuned to market trends, including technological innovations and regulatory changes that could impact costs. Engaging with local distributors and manufacturers can provide insights into emerging opportunities and challenges.

In conclusion, by prioritizing strategic sourcing and fostering strong supplier relationships, international B2B buyers can not only optimize their solar panel investments but also contribute to a sustainable energy future. Now is the time to explore these opportunities and secure your place in the growing renewable energy market.