Discover the Best Deals on 2005 Silverado 1500 Custom (2025)

Introduction: Navigating the Global Market for 2005 silverado 1500 custom

The 2005 Silverado 1500 Custom has emerged as a sought-after vehicle in the global market, especially for businesses looking to enhance their fleet capabilities. However, B2B buyers often face significant challenges in sourcing this model, including identifying reliable suppliers, understanding pricing structures, and assessing the vehicle’s suitability for specific applications. This guide aims to navigate these complexities by providing a comprehensive overview of the 2005 Silverado 1500 Custom, covering various types, applications, and key considerations for international sourcing.

In this guide, international buyers from Africa, South America, the Middle East, and Europe will find actionable insights on how to vet suppliers effectively and evaluate the total cost of ownership. We will delve into the nuances of the vehicle’s features, performance metrics, and customization options that can meet diverse business needs. Furthermore, we will address common concerns regarding compliance with local regulations and logistical considerations for importing vehicles across borders.

By equipping B2B buyers with the knowledge needed to make informed purchasing decisions, this guide empowers businesses to streamline their procurement processes and enhance operational efficiency. Whether you are looking to expand your fleet for logistics, construction, or other commercial applications, understanding the intricacies of the 2005 Silverado 1500 Custom will provide a competitive edge in today’s dynamic market.

Understanding 2005 silverado 1500 custom Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Silverado 1500 Work Truck | Heavy-duty frame, basic interior, robust engine options | Construction, logistics, fleet management | Pros: Cost-effective, durable. Cons: Limited features, basic comfort. |

| Silverado 1500 LT | Enhanced interior, chrome accents, additional tech features | Corporate fleets, transport services | Pros: Better comfort and tech, versatile. Cons: Higher cost than base models. |

| Silverado 1500 LTZ | Premium materials, advanced safety features, luxury options | Executive transport, high-end fleets | Pros: High comfort, advanced tech. Cons: Expensive maintenance, higher upfront cost. |

| Silverado 1500 Z71 | Off-road capabilities, unique styling, upgraded suspension | Adventure tourism, off-road services | Pros: Excellent off-road performance. Cons: Reduced fuel efficiency. |

| Silverado 1500 Hybrid | Fuel-efficient hybrid engine, eco-friendly features | Eco-conscious companies, urban transport | Pros: Lower operational costs, eco-friendly. Cons: Limited towing capacity. |

What are the Key Characteristics of the Silverado 1500 Work Truck?

The Silverado 1500 Work Truck is designed for heavy-duty tasks, featuring a rugged frame and powerful engine options. It’s ideal for businesses in construction and logistics, where durability and cost-effectiveness are paramount. When considering this model, buyers should weigh its basic interior against the potential need for additional features in a professional environment.

How Does the Silverado 1500 LT Enhance Business Operations?

The LT variant offers improved interior quality and additional technology features, making it suitable for corporate fleets and transport services. Its balance of comfort and utility allows businesses to cater to client needs without sacrificing performance. However, buyers should note that the increased features come with a higher price tag.

Why Choose the Silverado 1500 LTZ for Executive Transport?

The Silverado 1500 LTZ stands out with its premium materials and advanced safety features, making it an excellent choice for executive transport and high-end fleets. This model combines luxury with functionality, appealing to businesses that prioritize comfort and style. Buyers must consider the higher maintenance costs associated with luxury vehicles.

What Makes the Silverado 1500 Z71 Ideal for Off-Road Applications?

The Silverado 1500 Z71 is tailored for off-road capabilities, featuring enhanced suspension and distinctive styling. It’s perfect for companies in adventure tourism and off-road services. While it excels in rugged terrains, buyers should be aware of its reduced fuel efficiency, which may impact operational costs.

How Does the Silverado 1500 Hybrid Support Eco-Conscious Businesses?

The Silverado 1500 Hybrid offers a fuel-efficient hybrid engine, making it an attractive option for eco-conscious companies and urban transport. This model can significantly lower operational costs while minimizing environmental impact. However, potential buyers should consider its limited towing capacity, which may not suit all business needs.

Related Video: 2005 silverado 1500 5.3 Black widow race venom muffler

Key Industrial Applications of 2005 silverado 1500 custom

| Industry/Sector | Specific Application of 2005 Silverado 1500 Custom | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Farm Transportation | Efficient transport of goods and tools across farms | Durability, payload capacity, and off-road capability |

| Construction | Heavy Equipment Hauling | Reliable transport for construction materials and tools | Load capacity, towing capacity, and maintenance support |

| Logistics and Supply Chain | Freight Delivery | Cost-effective solution for local deliveries | Fuel efficiency, reliability, and service availability |

| Tourism and Recreation | Shuttle Services | Versatile transport for tourists and recreational use | Comfort, seating capacity, and customization options |

| Emergency Services | Rescue Operations | Quick response vehicle for emergency situations | Reliability, speed, and adaptability to various terrains |

How is the 2005 Silverado 1500 Custom Used in Agriculture?

In the agriculture sector, the 2005 Silverado 1500 Custom serves as an essential vehicle for transporting goods, equipment, and even livestock across expansive farm properties. Its robust design and off-road capabilities allow it to navigate rough terrains, ensuring that farmers can efficiently manage their operations. Buyers in this sector should consider the truck’s payload capacity and durability, as these features directly impact its ability to perform under demanding agricultural conditions.

What Role Does the 2005 Silverado 1500 Custom Play in Construction?

For the construction industry, the Silverado 1500 Custom is invaluable for hauling heavy equipment and materials to job sites. Its strong towing capacity and spacious bed make it suitable for transporting tools, lumber, and other essential construction supplies. International buyers, particularly in regions with diverse terrains, should prioritize sourcing vehicles that offer reliable maintenance support and parts availability to minimize downtime on construction projects.

How Can the 2005 Silverado 1500 Custom Enhance Logistics and Supply Chain Operations?

The 2005 Silverado 1500 Custom is a practical choice for logistics and supply chain operations, providing a cost-effective solution for local freight delivery. Its fuel efficiency and reliability make it an attractive option for businesses looking to optimize transportation costs while ensuring timely deliveries. B2B buyers should focus on the vehicle’s service availability and overall reliability, as these factors are critical in maintaining smooth supply chain operations.

In What Ways Does the 2005 Silverado 1500 Custom Support Tourism and Recreation?

In the tourism and recreation sector, the Silverado 1500 Custom can be adapted for shuttle services, offering comfortable transport for tourists exploring various attractions. Its spacious interior and ability to customize seating arrangements make it ideal for group travel. Buyers in this industry should consider factors like comfort and customization options, as these will directly influence customer satisfaction and experience.

How Is the 2005 Silverado 1500 Custom Utilized by Emergency Services?

The 2005 Silverado 1500 Custom is also employed in emergency services for rescue operations. Its reliability and speed enable quick responses to emergencies, making it a vital asset for first responders. When sourcing vehicles for this purpose, it is crucial to assess the truck’s adaptability to various terrains and its overall performance in urgent situations, as these elements can significantly impact response times and effectiveness.

Related Video: installing the ULTIMATE SILVERADO SUSPENSION in ONE DAY

3 Common User Pain Points for ‘2005 silverado 1500 custom’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Parts for 2005 Silverado 1500 Custom

The Problem: B2B buyers often struggle with finding high-quality replacement parts for the 2005 Silverado 1500 Custom. Many suppliers may offer subpar or counterfeit components that do not meet OEM standards, leading to potential vehicle performance issues and safety risks. This can be particularly challenging for businesses in Africa and South America, where access to reliable suppliers is limited. The lack of quality assurance can result in increased downtime and repair costs, negatively impacting profitability.

The Solution: To effectively source high-quality parts, B2B buyers should establish relationships with reputable suppliers who specialize in OEM and aftermarket components for the 2005 Silverado 1500 Custom. Conduct thorough research on suppliers, looking for those with positive reviews and a proven track record. Buyers can leverage industry-specific forums and networks to gather recommendations. It’s also advisable to request certifications and warranties for parts purchased, ensuring they meet the necessary quality standards. In addition, consider bulk purchasing to negotiate better pricing and ensure a consistent supply of reliable parts.

Scenario 2: Challenges in Customization and Upgrades

The Problem: Many businesses looking to customize their 2005 Silverado 1500 for specific applications face challenges in identifying compatible aftermarket parts. The customization process can be overwhelming, especially when trying to enhance performance, aesthetics, or utility features. This is particularly true for B2B buyers in the Middle East and Europe, where diverse demands for vehicle functionality may require specialized components that are not readily available.

The Solution: To navigate the customization landscape, B2B buyers should start by defining their specific needs and intended use for the vehicle. Consulting with customization specialists or automotive engineers can provide valuable insights into compatible parts and modifications. It’s crucial to explore suppliers that offer customization kits specifically designed for the 2005 Silverado 1500 Custom. Engaging with online communities or attending automotive trade shows can also expose buyers to innovative products and trends in customization. Additionally, buyers should consider working with local automotive shops that have experience with Silverado models to facilitate a smooth installation process.

Scenario 3: Understanding Maintenance and Repair Needs

The Problem: B2B buyers often encounter difficulties in understanding the ongoing maintenance and repair requirements of the 2005 Silverado 1500 Custom. Without a clear maintenance schedule and knowledge of common issues, businesses risk underperforming vehicles, which can lead to unexpected repairs and increased operational costs. This is particularly critical for fleet managers in Europe and South America, where vehicle reliability is paramount for business operations.

The Solution: To mitigate maintenance challenges, B2B buyers should invest in a comprehensive maintenance management system that tracks service intervals and repair history for each vehicle in their fleet. Utilizing the owner’s manual for the 2005 Silverado 1500 Custom can help establish a baseline for routine checks and services. Additionally, buyers should connect with certified mechanics who specialize in Silverado models to gain insights into common wear and tear issues. Regular training sessions for fleet maintenance staff can ensure they are aware of the latest best practices in vehicle upkeep. Establishing a proactive maintenance schedule based on manufacturer recommendations can significantly enhance vehicle reliability and reduce total cost of ownership over time.

Strategic Material Selection Guide for 2005 silverado 1500 custom

What Are the Key Materials Used in the 2005 Silverado 1500 Custom?

When considering the 2005 Silverado 1500 Custom, several materials are commonly used in its construction, each with unique properties and implications for performance and durability. Understanding these materials is crucial for international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, who may face specific compliance and operational challenges.

How Does Steel Contribute to the Performance of the 2005 Silverado 1500 Custom?

Key Properties: Steel is known for its high tensile strength and durability. It typically has a temperature rating of up to 600°F and excellent corrosion resistance when treated with coatings.

Pros & Cons: The primary advantage of steel is its strength, making it ideal for structural components like the frame and body panels. However, it can be heavier than alternatives, which might affect fuel efficiency. Manufacturing complexity is moderate, as steel can be easily welded and formed.

Impact on Application: Steel is compatible with various media, including oil and fuel, making it suitable for automotive applications. However, it may require additional treatments in humid or coastal environments to prevent rust.

Considerations for International Buyers: Buyers should ensure compliance with local standards such as ASTM or DIN for steel quality. In regions with high humidity, like parts of Africa and the Middle East, considerations for corrosion resistance treatments are essential.

What Role Does Aluminum Play in the Silverado 1500 Custom?

Key Properties: Aluminum is lightweight and has a good strength-to-weight ratio, with a melting point around 1,220°F. It also has decent corrosion resistance, especially when anodized.

Pros & Cons: The key advantage of aluminum is its lightweight nature, which can improve fuel efficiency and handling. However, it is generally more expensive than steel and can be more challenging to weld, requiring specialized techniques.

Impact on Application: Aluminum is often used in components like the engine block and transmission cases, where weight savings are critical. Its compatibility with various fluids is generally good, but care must be taken to avoid galvanic corrosion when in contact with dissimilar metals.

Considerations for International Buyers: Buyers should look for compliance with JIS standards, especially in markets like Japan and Australia. The higher cost of aluminum may be a limiting factor in regions with tighter budgets.

How Does Plastic Affect the 2005 Silverado 1500 Custom’s Design?

Key Properties: Plastics used in automotive applications often have good impact resistance and can withstand temperatures up to 200°F. They are lightweight and can be molded into complex shapes.

Pros & Cons: The main advantage of plastic is its versatility and low weight, which can enhance fuel efficiency. However, plastics may not be as durable as metals and can degrade over time when exposed to UV light.

Impact on Application: Plastics are commonly used for interior components and exterior trim. They are compatible with various automotive fluids, but their performance can be affected by extreme temperatures.

Considerations for International Buyers: Buyers should ensure that plastics meet relevant safety and environmental standards in their markets, such as REACH in Europe. Understanding the local preferences for materials can also influence purchasing decisions.

What is the Importance of Rubber in the Silverado 1500 Custom?

Key Properties: Rubber is flexible and can withstand a wide range of temperatures, typically from -40°F to 212°F. It also provides excellent vibration dampening and sealing properties.

Pros & Cons: The key advantage of rubber is its ability to absorb shocks and vibrations, making it ideal for components like bushings and seals. However, it can degrade over time due to exposure to heat, oil, and ozone.

Impact on Application: Rubber is critical for ensuring proper sealing in various systems, including the engine and transmission. Its compatibility with automotive fluids is generally good, but degradation can lead to leaks.

Considerations for International Buyers: Buyers should be aware of the different grades of rubber and their compliance with international standards. For example, certain regions may have specific requirements for rubber used in automotive applications.

Summary Table of Material Selection for 2005 Silverado 1500 Custom

| Material | Typical Use Case for 2005 Silverado 1500 Custom | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Frame and body panels | High strength and durability | Heavier than alternatives | Medium |

| Aluminum | Engine block and transmission cases | Lightweight, improves fuel efficiency | More expensive, welding complexity | High |

| Plastic | Interior components and trim | Versatile, low weight | Less durable, UV degradation | Low |

| Rubber | Seals and bushings | Excellent vibration dampening | Degrades over time | Medium |

This comprehensive analysis of materials used in the 2005 Silverado 1500 Custom provides valuable insights for international B2B buyers, enabling informed decisions based on performance, cost, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 2005 silverado 1500 custom

What Are the Key Manufacturing Processes for the 2005 Silverado 1500 Custom?

The manufacturing of the 2005 Silverado 1500 Custom involves several critical stages that ensure the truck meets both performance and quality standards. Understanding these processes is vital for international B2B buyers looking to source parts or the complete vehicle.

How Is Material Prepared for the 2005 Silverado 1500 Custom?

The first stage in the manufacturing process is material preparation. This involves sourcing high-quality raw materials, primarily steel and aluminum, which are essential for the vehicle’s body and frame. Suppliers must ensure that materials meet industry standards to enhance durability and performance.

- Material Inspection: Before any processing begins, materials undergo rigorous inspection to confirm their specifications, including thickness, tensile strength, and corrosion resistance.

- Cutting and Shaping: Materials are then cut and shaped using advanced machinery like laser cutters and CNC machines, ensuring precision in every part.

What Forming Techniques Are Used in the Silverado 1500 Custom Manufacturing?

The forming stage includes various techniques that shape the components of the Silverado 1500 Custom into their final forms.

- Stamping: This process is widely used for creating body panels. Stamping involves pressing sheets of metal into molds, which creates the desired shapes while maintaining structural integrity.

- Welding: After stamping, parts are joined using various welding techniques, such as MIG (Metal Inert Gas) welding, which is crucial for assembling the truck’s frame and body.

How Does Assembly Happen for the 2005 Silverado 1500 Custom?

The assembly stage is where all components come together to form the complete vehicle.

- Chassis Assembly: The chassis is the backbone of the vehicle, where the frame, suspension, and drivetrain are assembled. This stage often employs robotic arms for precision and speed.

- Interior Installation: Following the chassis assembly, the interior components, such as seats, dashboards, and electronic systems, are installed. This stage requires careful attention to detail to ensure functionality and comfort.

What Finishing Processes Are Involved in the Silverado 1500 Custom Manufacturing?

Finishing processes enhance the aesthetic appeal and protect the truck from environmental factors.

- Painting: The truck undergoes a multi-stage painting process, including primer application, base coat, and clear coat. This not only provides color but also adds layers of protection against rust and scratches.

- Quality Inspection: After painting, vehicles are subjected to thorough inspections to check for paint defects, ensuring a flawless finish before delivery.

How Is Quality Assurance Maintained in the Manufacturing of the 2005 Silverado 1500 Custom?

Quality assurance is paramount in the manufacturing process, especially for international B2B buyers who require compliance with various standards.

What Are the Relevant International Standards for Quality Assurance?

The manufacturing of the 2005 Silverado 1500 Custom adheres to several international standards that ensure quality and safety.

- ISO 9001: This standard is a quality management system that guarantees consistent product quality. Suppliers must demonstrate compliance to gain credibility in international markets.

- CE Marking: For vehicles sold within Europe, CE marking indicates conformity with health, safety, and environmental protection standards.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are critical for maintaining high standards throughout the manufacturing process.

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials before they enter the production line.

- In-Process Quality Control (IPQC): During manufacturing, ongoing inspections ensure that each stage meets quality benchmarks.

- Final Quality Control (FQC): After assembly, the vehicle undergoes a final inspection to verify that it meets all specifications and standards before shipping.

What Common Testing Methods Are Used for Quality Assurance?

To ensure quality, various testing methods are employed throughout the manufacturing process:

- Durability Testing: This includes stress tests to assess the vehicle’s performance under extreme conditions.

- Safety Testing: Crash tests and other safety evaluations ensure that the truck meets regulatory standards for occupant safety.

How Can B2B Buyers Verify Supplier Quality Assurance?

For international B2B buyers, verifying a supplier’s quality assurance processes is crucial.

What Audit Processes Should Buyers Consider?

Buyers should conduct thorough audits of potential suppliers to assess their manufacturing capabilities and quality control systems. This includes:

- Site Visits: Visiting the manufacturing facility allows buyers to observe processes firsthand and interact with quality assurance personnel.

- Review of Quality Documentation: Buyers should request detailed reports on quality control procedures, testing methods, and compliance with international standards.

How Do Third-Party Inspections Enhance Quality Assurance?

Utilizing third-party inspectors can provide an unbiased evaluation of a supplier’s quality assurance processes. These inspectors can conduct:

- Compliance Audits: Assessing whether the supplier meets necessary industry standards.

- Random Inspections: Conducting surprise checks to ensure ongoing compliance with quality protocols.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must navigate various quality control nuances.

- Understanding Local Regulations: Buyers should familiarize themselves with specific regulations and standards applicable in their regions, as these may differ significantly from international norms.

- Documentation Requirements: Ensuring that all quality assurance documentation is in order is critical for smooth customs clearance and compliance with local laws.

By understanding the intricate manufacturing processes and quality assurance measures involved in the production of the 2005 Silverado 1500 Custom, international B2B buyers can make informed decisions when sourcing vehicles or components, ensuring they meet their operational standards and customer expectations.

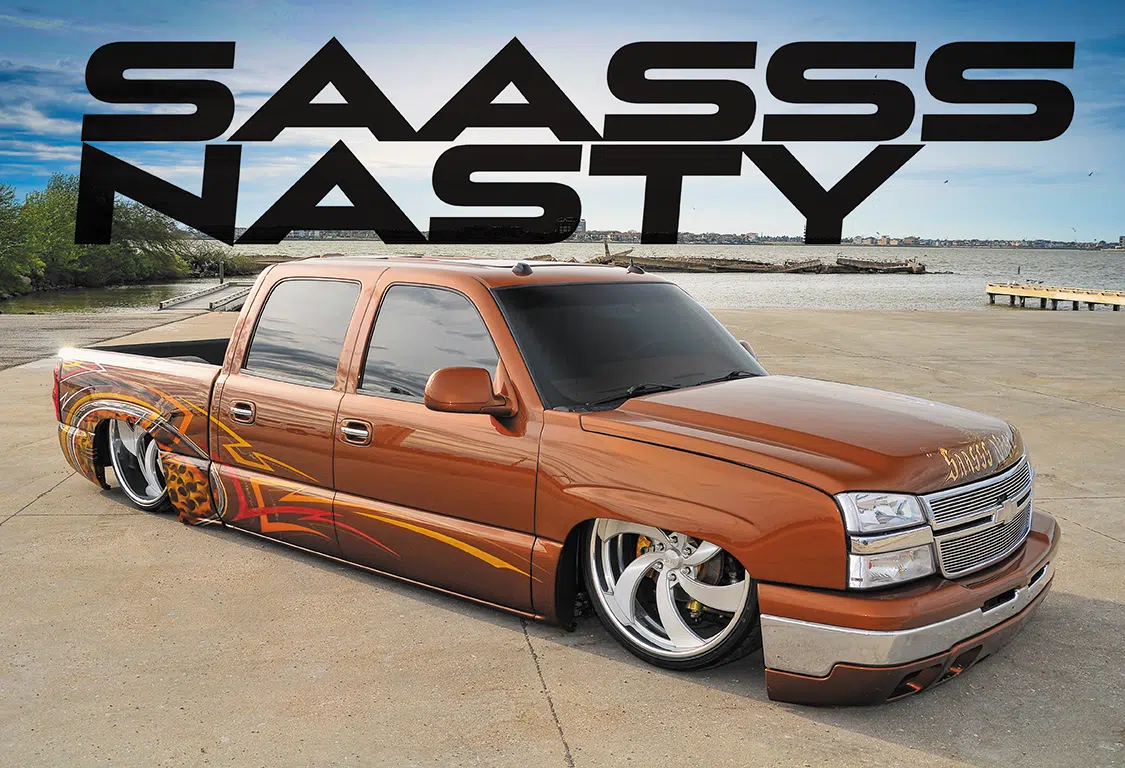

A stock image related to 2005 silverado 1500 custom.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘2005 silverado 1500 custom’

In the competitive landscape of B2B procurement, sourcing a specific vehicle model like the 2005 Silverado 1500 Custom requires a systematic approach. This guide provides a detailed checklist to ensure you make informed decisions and secure the best options available for your business needs.

Step 1: Define Your Technical Specifications

Begin by outlining the exact specifications you need for the 2005 Silverado 1500 Custom. This includes engine type, transmission, cab style, and any specific features or customizations required.

– Importance: Clear specifications help narrow down options and ensure that suppliers understand your exact needs, leading to more accurate quotes and faster delivery times.

Step 2: Research Market Availability

Conduct thorough research to identify the regions where the 2005 Silverado 1500 Custom is readily available. Utilize online platforms, dealer networks, and automotive marketplaces that specialize in used vehicles.

– Importance: Understanding market availability helps you gauge pricing trends and leads you to suppliers with the best inventory. This is crucial for timely procurement, especially if you require multiple units.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, vet potential suppliers meticulously. Request detailed company profiles, case studies, and references from other buyers, particularly those in your industry or region.

– Importance: Ensuring that suppliers have a solid reputation and experience with your required vehicle type minimizes risks associated with quality and service. Look for reviews and testimonials to validate their reliability.

Step 4: Verify Supplier Certifications

Check that your shortlisted suppliers have the necessary certifications and licenses to operate in your region. This may include automotive dealer licenses, ISO certifications, or compliance with local regulations.

– Importance: Valid certifications assure you of the supplier’s legitimacy and adherence to quality standards. This is particularly vital for international transactions, where regulations may vary.

Step 5: Request Detailed Quotes

Solicit detailed quotations from multiple suppliers, including pricing, delivery timelines, and warranty options. Ensure each quote reflects your defined specifications to make comparisons easier.

– Importance: Detailed quotes allow for straightforward comparisons, helping you identify the best value for your investment. Look beyond price; consider terms of service, after-sales support, and warranty conditions.

Step 6: Negotiate Terms and Conditions

Once you have selected a potential supplier, enter negotiations regarding the price, delivery schedule, and payment terms. Be prepared to discuss bulk order discounts if applicable.

– Importance: Negotiating favorable terms can lead to significant cost savings and better service agreements. Establishing clear terms upfront helps avoid misunderstandings later in the procurement process.

Step 7: Finalize Purchase and Arrange Logistics

After agreeing on terms, finalize the purchase and arrange logistics for shipping or pickup. Ensure that all documentation is complete, including invoices, shipping papers, and any required customs documentation for international shipments.

– Importance: Proper logistics management ensures that your vehicles arrive safely and on time. This step is crucial for maintaining operational continuity, especially if the vehicles are needed for business operations immediately.

By following this checklist, B2B buyers can navigate the complexities of sourcing a 2005 Silverado 1500 Custom effectively, ensuring a successful procurement process that meets their organizational needs.

Comprehensive Cost and Pricing Analysis for 2005 silverado 1500 custom Sourcing

What Are the Key Cost Components for Sourcing a 2005 Silverado 1500 Custom?

Understanding the cost structure of sourcing a 2005 Silverado 1500 custom is essential for B2B buyers aiming to optimize their purchasing decisions. The primary cost components include:

-

Materials: The type and quality of materials used in the manufacturing process significantly affect the overall cost. For instance, sourcing high-grade metals or specialized components can increase expenses but may enhance durability and performance.

-

Labor: Labor costs vary based on the region where the vehicle is manufactured. Countries with lower labor costs may offer more competitive pricing, but it’s crucial to assess the skill level and experience of the workforce, as these factors impact the quality of the finished product.

-

Manufacturing Overhead: This includes indirect costs such as utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help mitigate overhead costs, thus affecting the final pricing.

-

Tooling: Custom tooling can be a significant upfront cost for unique specifications. Buyers should consider whether the supplier has existing tooling that can accommodate their needs to reduce initial investment.

-

Quality Control (QC): Implementing stringent QC measures ensures product reliability and safety. While this may add to costs, it can prevent expensive recalls and enhance brand reputation.

-

Logistics: Shipping and handling costs can vary widely depending on the distance from the manufacturer to the buyer. Understanding the logistics involved, including potential tariffs and duties, is vital for accurate cost forecasting.

-

Margin: Suppliers will include their profit margins in the pricing structure. Understanding typical margins in the automotive industry can help buyers negotiate better deals.

How Do Price Influencers Affect the Sourcing of a 2005 Silverado 1500 Custom?

Several factors can influence the pricing of the 2005 Silverado 1500 custom, including:

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly impact pricing. Higher volume orders often lead to discounts, while smaller orders may incur additional fees.

-

Specifications and Customization: Custom specifications can drive up costs. Buyers should clearly define their requirements to avoid unexpected expenses later in the sourcing process.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications (e.g., ISO, IATF) can influence pricing. Buyers should verify that suppliers meet their quality standards to ensure product reliability.

-

Supplier Factors: The supplier’s reputation, reliability, and production capacity can affect pricing. Established suppliers with a proven track record may charge a premium, but they often deliver higher quality and reliability.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can affect pricing and risk management. For example, opting for EXW (Ex Works) may result in lower prices but shifts more logistical responsibility onto the buyer.

What Are the Best Buyer Tips for Sourcing a 2005 Silverado 1500 Custom?

To maximize cost-efficiency and minimize risks, B2B buyers should consider the following tips:

-

Negotiate Wisely: Engage suppliers in discussions about pricing and be prepared to negotiate terms. Leverage volume commitments or long-term contracts for better pricing.

-

Assess Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, parts availability, and resale value when evaluating the total cost of ownership.

-

Understand Pricing Nuances for International Buyers: Different regions may have varying pricing structures due to currency fluctuations, local regulations, and market demand. Buyers from Africa, South America, the Middle East, and Europe should conduct thorough market research to understand these nuances.

-

Request Detailed Quotes: Obtain detailed pricing quotes that break down the costs involved. This transparency can help identify areas for potential savings.

-

Stay Informed on Market Trends: Regularly monitor market trends and price changes in the automotive sector. Awareness of these trends can provide leverage during negotiations.

Disclaimer for Indicative Prices

Prices for the 2005 Silverado 1500 custom can fluctuate based on numerous factors, including market conditions, supplier pricing strategies, and geopolitical influences. It is advisable for buyers to conduct thorough research and obtain multiple quotes to ensure they are getting the best value for their investment.

Alternatives Analysis: Comparing 2005 silverado 1500 custom With Other Solutions

When considering the 2005 Silverado 1500 Custom for procurement, it’s essential to evaluate alternatives that may offer similar utility or performance. This comparison can assist B2B buyers, particularly in emerging markets such as Africa, South America, the Middle East, and Europe, in making informed purchasing decisions tailored to their specific operational needs.

Comparison Table of Alternatives

| Comparison Aspect | 2005 Silverado 1500 Custom | Ford F-150 (2005) | Toyota Tundra (2005) |

|---|---|---|---|

| Performance | 295 hp, 305 lb-ft torque | 292 hp, 320 lb-ft torque | 276 hp, 313 lb-ft torque |

| Cost | $15,000 – $20,000 | $16,000 – $22,000 | $18,000 – $24,000 |

| Ease of Implementation | Moderate | Moderate | Easy |

| Maintenance | Moderate | Low | Low |

| Best Use Case | General utility, towing | Off-road, heavy-duty | Reliability, work sites |

What Are the Pros and Cons of the Ford F-150 (2005)?

The Ford F-150 (2005) is a formidable competitor to the Silverado. With a slightly higher torque output, it excels in heavy-duty applications, making it suitable for businesses that require robust towing capabilities. Its maintenance costs are generally lower than the Silverado, partly due to a larger parts availability network. However, the initial cost may be higher, depending on the trim level. Additionally, the F-150’s off-road capabilities are superior, making it a prime choice for companies operating in rugged terrains.

How Does the Toyota Tundra (2005) Compare?

The Toyota Tundra (2005) is known for its reliability and strong build quality, which appeals to businesses seeking a durable workhorse. With a solid reputation for longevity, the Tundra can be an excellent investment for B2B buyers focused on minimizing downtime and repair costs. While it has lower horsepower compared to the Silverado and F-150, it compensates with a higher torque rating that enhances its towing capabilities. However, the higher price point can be a deterrent for budget-conscious buyers.

How Should B2B Buyers Choose the Right Solution?

Selecting the right vehicle involves more than just comparing specs; it requires a comprehensive understanding of the specific needs of your business. Consider factors such as the terrain in which the vehicle will operate, the type of loads it will carry, and the long-term maintenance costs associated with each option. For businesses in Africa or South America, where road conditions can be challenging, opting for a vehicle with superior off-road capabilities might be crucial. Conversely, companies focusing on urban logistics in Europe may prioritize fuel efficiency and ease of maintenance. Ultimately, the best choice will align with your operational goals, budget constraints, and geographical considerations.

Essential Technical Properties and Trade Terminology for 2005 silverado 1500 custom

What Are the Essential Technical Properties of the 2005 Silverado 1500 Custom?

When evaluating the 2005 Silverado 1500 Custom for international B2B procurement, understanding its technical specifications is critical. Here are some key properties that buyers should consider:

-

Engine Specifications

The 2005 Silverado 1500 Custom is equipped with a 4.3L V6 or a more powerful 5.3L V8 engine. The V8 variant delivers approximately 295 horsepower and 330 lb-ft of torque. For B2B buyers, this impacts vehicle performance, fuel efficiency, and overall operational costs, making it essential to choose the right engine type based on intended use. -

Payload Capacity

With a maximum payload capacity ranging from 1,600 to 2,200 pounds, the Silverado 1500 Custom is designed for both light-duty and moderate hauling tasks. This specification is crucial for businesses in logistics or construction, as it directly influences the vehicle’s utility and productivity. -

Towing Capacity

The towing capacity varies between 4,000 to 8,500 pounds, depending on the configuration and engine choice. This property is vital for businesses that require transporting trailers or heavy equipment. Understanding the towing limits ensures compliance with safety regulations and operational efficiency. -

Material Composition

The body is primarily constructed from high-strength steel, which enhances durability and resistance to wear. For international buyers, especially in regions with challenging road conditions, material strength is an essential consideration for long-term reliability and reduced maintenance costs. -

Fuel Economy

The Silverado 1500 Custom achieves an estimated 15-20 miles per gallon (mpg) in city and highway driving, respectively. Fuel efficiency is a significant factor for B2B buyers looking to minimize operating expenses and environmental impact, making it a key criterion during evaluation.

What Trade Terminology Should B2B Buyers Understand?

Familiarity with industry jargon can significantly streamline the purchasing process. Here are several key terms relevant to the procurement of the 2005 Silverado 1500 Custom:

-

OEM (Original Equipment Manufacturer)

This term refers to the company that manufactures the vehicle or its components. For B2B buyers, sourcing from OEMs can ensure that parts are of high quality and compatible with the vehicle, reducing the risk of operational disruptions. -

MOQ (Minimum Order Quantity)

MOQ defines the minimum number of units a supplier is willing to sell. Understanding MOQ is critical for budgeting and inventory management, especially for businesses intending to purchase multiple vehicles or components at once. -

RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers. It allows buyers to compare costs and terms effectively. Using RFQs can lead to better negotiation outcomes and cost savings. -

Incoterms (International Commercial Terms)

These are standardized terms used in international trade to clarify the responsibilities of buyers and sellers. Understanding Incoterms is essential for B2B transactions, as they define shipping costs, risks, and delivery obligations. -

Aftermarket Parts

Aftermarket parts refer to components not made by the OEM. For B2B buyers, using aftermarket parts can provide cost-effective alternatives for repairs and upgrades, although they must ensure compatibility and quality. -

Warranty Terms

Warranty terms outline the coverage provided by the manufacturer for defects and repairs. Grasping the specifics of warranty terms can protect B2B buyers from unexpected costs and ensure the longevity of their investment.

By understanding these technical properties and trade terminologies, international B2B buyers can make informed decisions when sourcing the 2005 Silverado 1500 Custom, ensuring they select a vehicle that meets their operational needs effectively.

Navigating Market Dynamics and Sourcing Trends in the 2005 silverado 1500 custom Sector

What Are the Current Market Dynamics and Key Trends for the 2005 Silverado 1500 Custom?

The 2005 Silverado 1500 Custom segment is witnessing significant shifts driven by various global trends. As international B2B buyers, especially from Africa, South America, the Middle East, and Europe, navigate this landscape, understanding these dynamics is crucial. The demand for used vehicles, particularly those with custom modifications, is on the rise due to economic factors and changing consumer preferences. Buyers are increasingly seeking vehicles that offer both functionality and unique features, leading to a surge in customized options.

Technology is playing a vital role in shaping sourcing strategies. The rise of digital platforms allows buyers to access a broader range of suppliers and inventory options. E-commerce solutions and online marketplaces are transforming traditional sourcing processes, enabling buyers to compare prices, verify supplier credentials, and read reviews. This trend is particularly beneficial for international buyers, as it minimizes the barriers associated with cross-border transactions.

Moreover, sustainability is becoming a focal point in sourcing decisions. Buyers are increasingly considering the environmental impact of their purchases, leading to a preference for suppliers who prioritize eco-friendly practices. As a result, suppliers in the 2005 Silverado 1500 Custom sector are adapting to meet these demands, focusing on sustainable manufacturing processes and responsible sourcing of materials.

How Can Sustainability and Ethical Sourcing Influence B2B Decisions in the 2005 Silverado 1500 Custom Sector?

Sustainability and ethical sourcing are critical factors influencing B2B transactions in the automotive sector, including the 2005 Silverado 1500 Custom. The environmental impact of vehicle manufacturing and sourcing practices has led to increased scrutiny from consumers and businesses alike. For B2B buyers, particularly those in regions with strict environmental regulations, aligning with suppliers who adopt sustainable practices is not just a trend—it’s a necessity.

Buyers should look for suppliers that offer ‘green’ certifications, such as ISO 14001, which signifies a commitment to effective environmental management systems. Additionally, sourcing materials that are recycled or sustainably produced can significantly reduce the overall carbon footprint of the vehicles. This is particularly relevant for custom modifications, where the choice of aftermarket parts and accessories can either enhance or undermine sustainability goals.

A stock image related to 2005 silverado 1500 custom.

Furthermore, ethical supply chains are gaining traction. Buyers are increasingly interested in transparency regarding labor practices and sourcing origins. Suppliers that can demonstrate ethical practices not only foster trust but also appeal to a growing segment of environmentally and socially conscious consumers.

What Is the Brief Evolution of the 2005 Silverado 1500 Custom in the B2B Landscape?

The 2005 Silverado 1500 Custom has evolved significantly since its introduction, reflecting broader trends in the automotive industry. Initially launched as a robust and versatile pickup truck, its customization options quickly caught the attention of both individual consumers and B2B buyers. The demand for personalized vehicles has grown, leading to a thriving aftermarket industry that caters to specific needs—ranging from performance enhancements to aesthetic modifications.

Over the years, the Silverado’s reputation for reliability and durability has solidified its position in the market, making it a preferred choice for businesses looking for dependable fleet vehicles. As the market continues to evolve, the focus on customization, sustainability, and ethical sourcing is likely to shape the future of the 2005 Silverado 1500 Custom sector, presenting new opportunities for B2B buyers to align their purchasing strategies with contemporary values.

Frequently Asked Questions (FAQs) for B2B Buyers of 2005 silverado 1500 custom

-

How do I solve issues with sourcing a 2005 Silverado 1500 custom?

To effectively solve sourcing issues for a 2005 Silverado 1500 custom, begin by identifying reliable suppliers through trade platforms, industry directories, or local automotive trade shows. Verify their credibility by checking references, client testimonials, and certifications. Establish clear communication regarding your requirements, including customization options and shipping logistics. Additionally, consider reaching out to local representatives who can assist in navigating regional regulations and market conditions, particularly in Africa, South America, the Middle East, and Europe. -

What is the best approach for customizing a 2005 Silverado 1500 for international buyers?

The best approach to customizing a 2005 Silverado 1500 involves understanding the specific needs of your target market. Engage potential buyers in discussions to gather insights on preferred features, aesthetics, and performance upgrades. Collaborate with suppliers who offer a range of customization options and can provide samples or prototypes. Ensure that any modifications comply with local regulations, and consider logistics for shipping customized vehicles, as this can affect delivery timelines and costs. -

What are the minimum order quantities (MOQ) for purchasing a 2005 Silverado 1500 custom?

Minimum order quantities for a 2005 Silverado 1500 custom can vary significantly by supplier and region. Typically, MOQs may range from one vehicle for specialized suppliers to larger quantities for bulk purchases. It’s essential to negotiate with suppliers and clarify their MOQ policies. Understanding your own market demand will help you determine the most strategic order size, balancing inventory costs with the need to meet customer expectations. -

What payment terms should I expect when sourcing a 2005 Silverado 1500 custom?

When sourcing a 2005 Silverado 1500 custom, payment terms can vary widely based on the supplier’s policies and the buyer’s relationship with them. Common terms include full payment upfront, a deposit followed by final payment upon delivery, or installment payments for larger orders. Always negotiate favorable terms that accommodate your cash flow while ensuring supplier security. Additionally, consider using secure payment methods, such as letters of credit or escrow services, to protect both parties. -

How can I ensure quality assurance (QA) when purchasing a 2005 Silverado 1500 custom?

To ensure quality assurance when purchasing a 2005 Silverado 1500 custom, request detailed product specifications and quality certifications from suppliers. Implement a pre-shipment inspection process to evaluate the vehicle’s condition and compliance with your requirements. Establish a clear return policy and warranty terms to safeguard against defects. Building a strong relationship with your supplier can also facilitate open communication about quality concerns and improvements. -

What logistics considerations should I keep in mind when importing a 2005 Silverado 1500 custom?

When importing a 2005 Silverado 1500 custom, consider logistics factors such as shipping methods, customs clearance, and delivery timelines. Choose a shipping method that balances cost and speed, such as container shipping for bulk orders or roll-on/roll-off for individual vehicles. Understand the import regulations and tariffs in your target country to avoid unexpected costs. Working with a reliable freight forwarder can help streamline the logistics process and ensure compliance with all necessary documentation. -

What are the benefits of sourcing a 2005 Silverado 1500 custom from international suppliers?

Sourcing a 2005 Silverado 1500 custom from international suppliers can offer numerous benefits, including access to a broader range of customization options and potentially lower prices due to different manufacturing costs. It also allows for the opportunity to build partnerships with suppliers who have expertise in specific regional markets. Additionally, international sourcing can enhance your product offering and provide competitive advantages by meeting unique customer demands. -

How do I evaluate and vet suppliers for a 2005 Silverado 1500 custom?

To effectively evaluate and vet suppliers for a 2005 Silverado 1500 custom, start by researching their reputation in the industry. Look for reviews, case studies, and feedback from previous clients. Request product samples and inquire about their manufacturing processes and quality control measures. Establish communication to assess responsiveness and willingness to meet your specific needs. Conducting background checks and, if possible, visiting their facilities can provide further assurance of their reliability and capabilities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for 2005 silverado 1500 custom

What Are the Key Takeaways for Strategic Sourcing of the 2005 Silverado 1500 Custom?

In conclusion, the strategic sourcing of the 2005 Silverado 1500 Custom presents unique opportunities for international B2B buyers. The vehicle’s robust aftermarket support, combined with a variety of customization options, caters to diverse market needs, particularly in regions like Africa, South America, the Middle East, and Europe. By leveraging these attributes, buyers can enhance their operational efficiencies and meet specific customer demands.

How Can B2B Buyers Benefit from Strategic Sourcing?

Investing in strategic sourcing not only ensures cost-effectiveness but also fosters long-term relationships with suppliers who understand the nuances of your market. Buyers are encouraged to engage with reputable suppliers who offer transparency and quality assurance, thereby mitigating risks associated with procurement.

What Should International Buyers Consider Moving Forward?

Looking ahead, it is essential for B2B buyers to remain adaptable and informed about market trends and technological advancements. As the automotive landscape evolves, continuous evaluation of sourcing strategies will be crucial. Embrace this opportunity to explore the full potential of the 2005 Silverado 1500 Custom, ensuring that your business remains competitive and responsive to customer needs. Engage with trusted partners to navigate this journey effectively, and position your organization for sustainable growth in the years to come.